Effects of Parent Coal Properties on the Pyrolytic Char Chemical Structure: Insights from Micro-Raman Spectroscopy Based on 32 Kinds of Chinese Coals

Abstract

:1. Introduction

2. Experiments and Methods

3. Results and Discussion

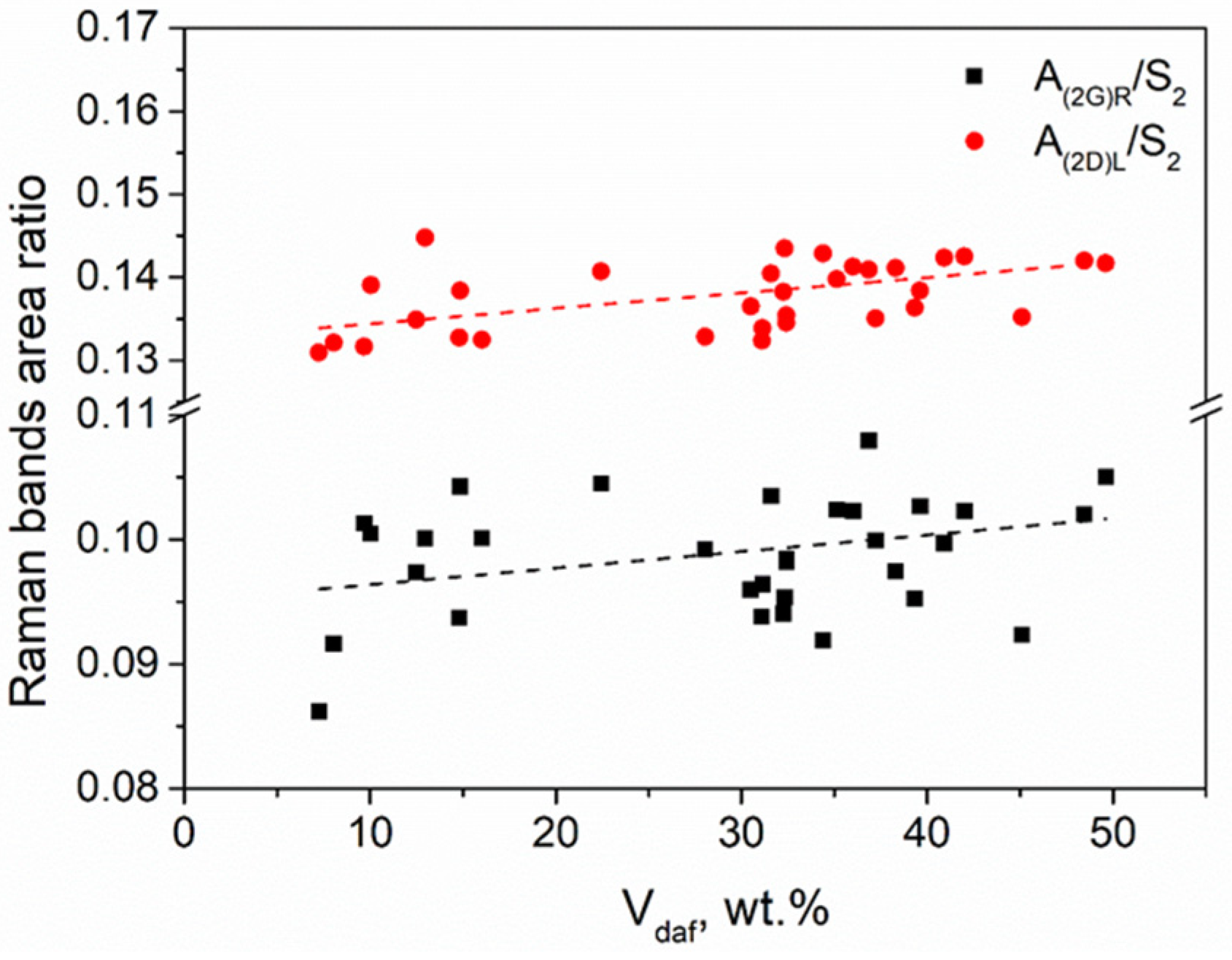

3.1. The C-H Structures in Pyrolytic Chars

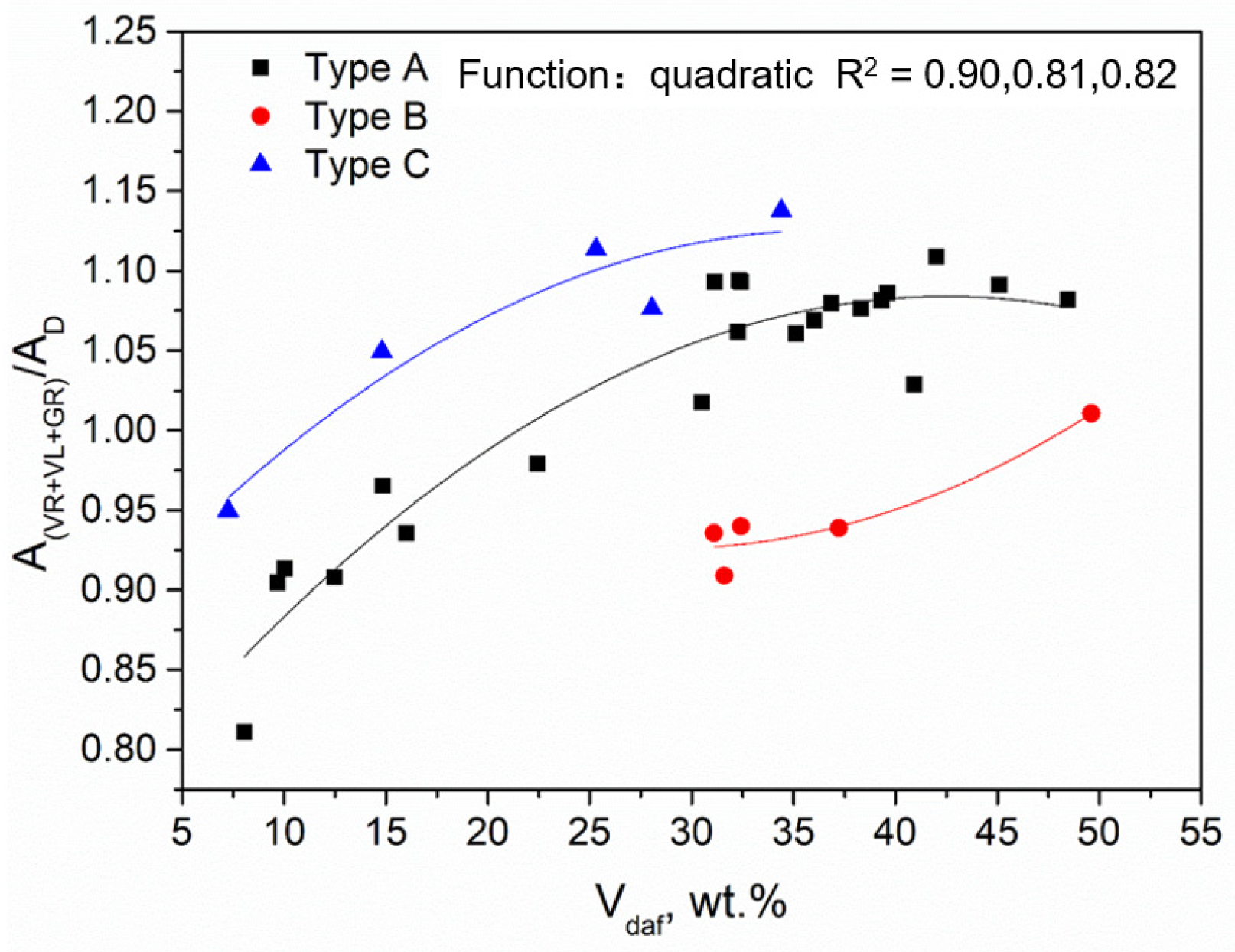

3.2. The Aromatic Rings in Pyrolytic Chars

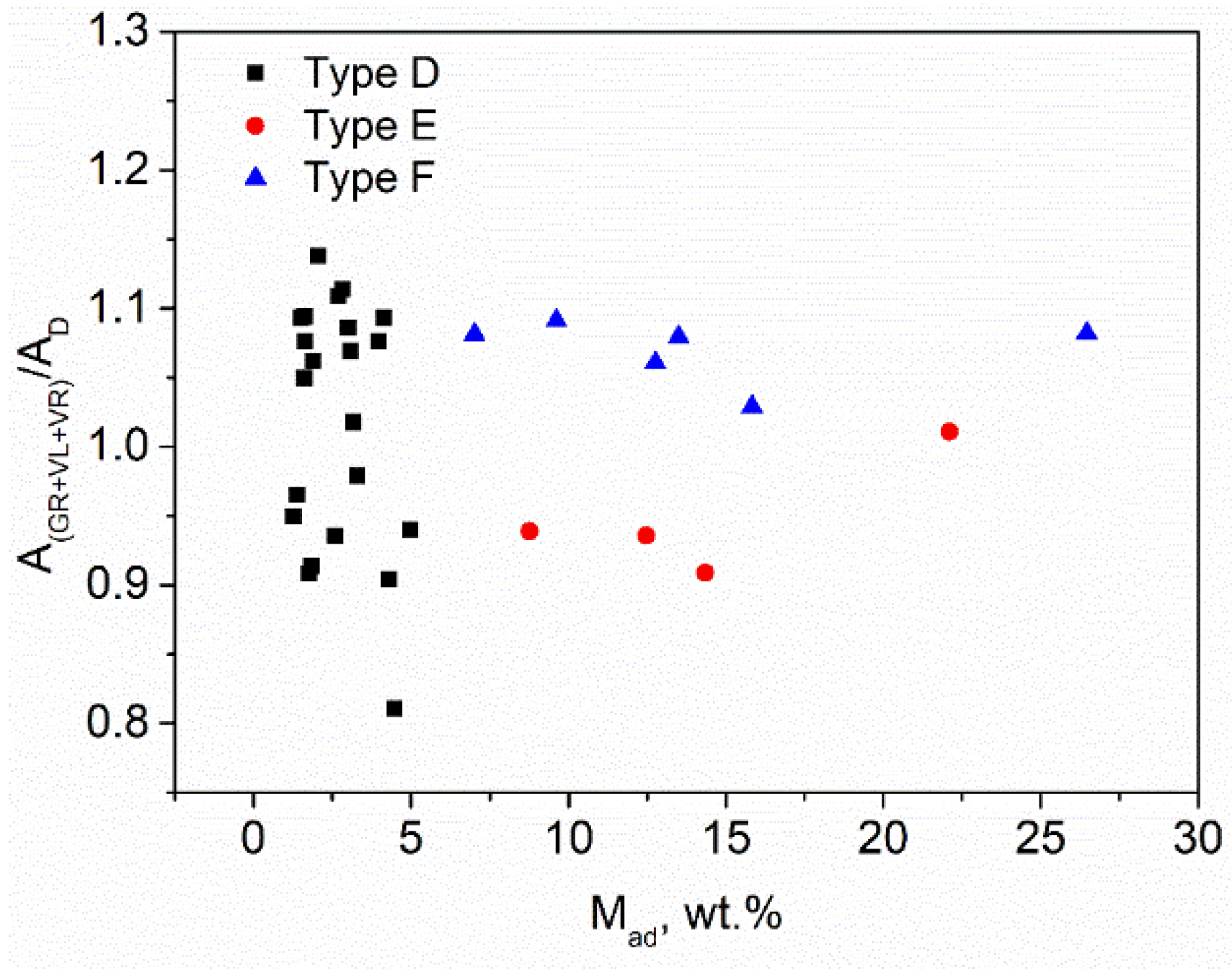

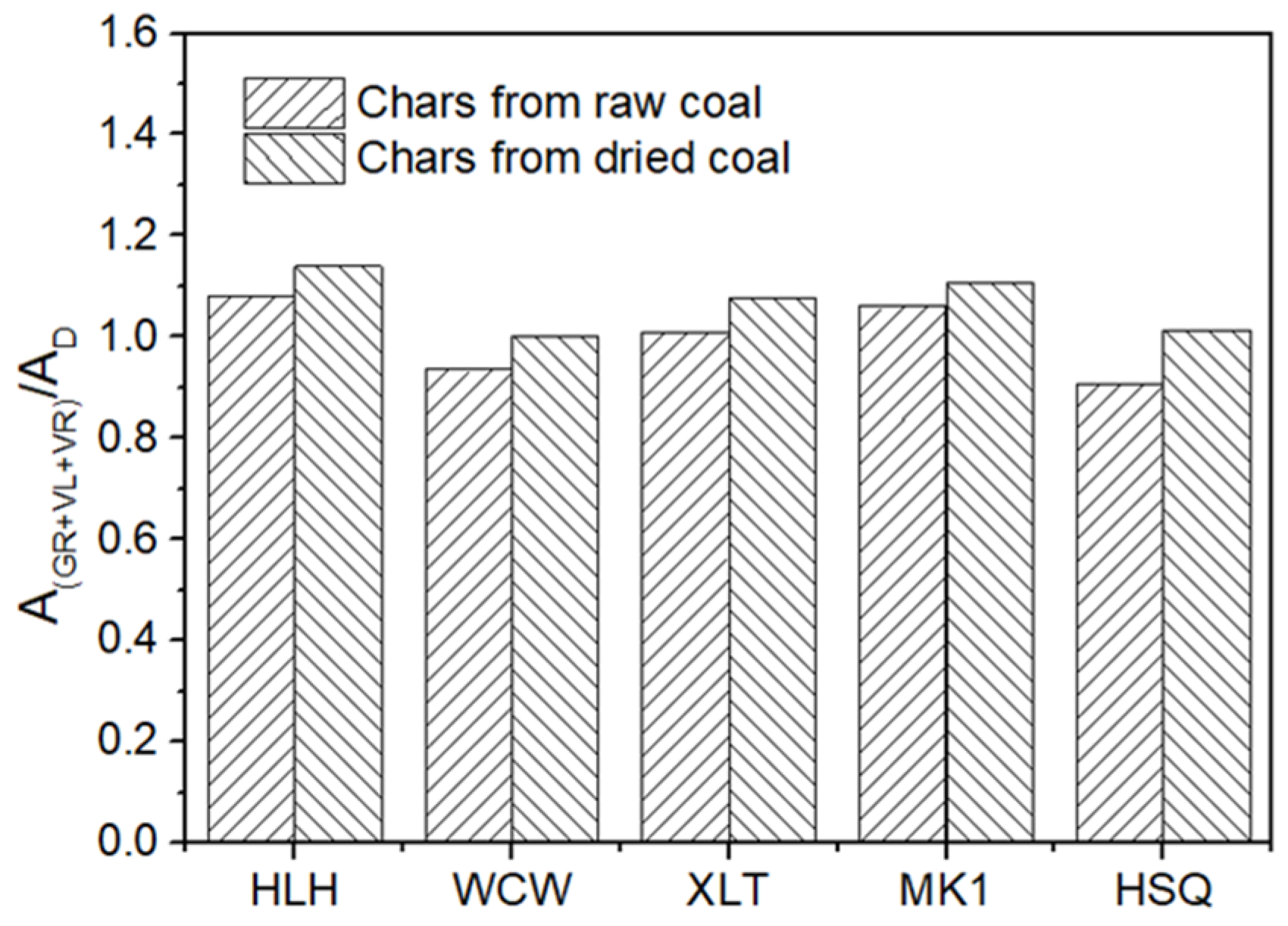

3.2.1. Effects of Moisture in Parent Coal on the Aromatic Rings’ Structure

3.2.2. Effects of Ash in Parent Coal on the Aromatic Rings’ Structure

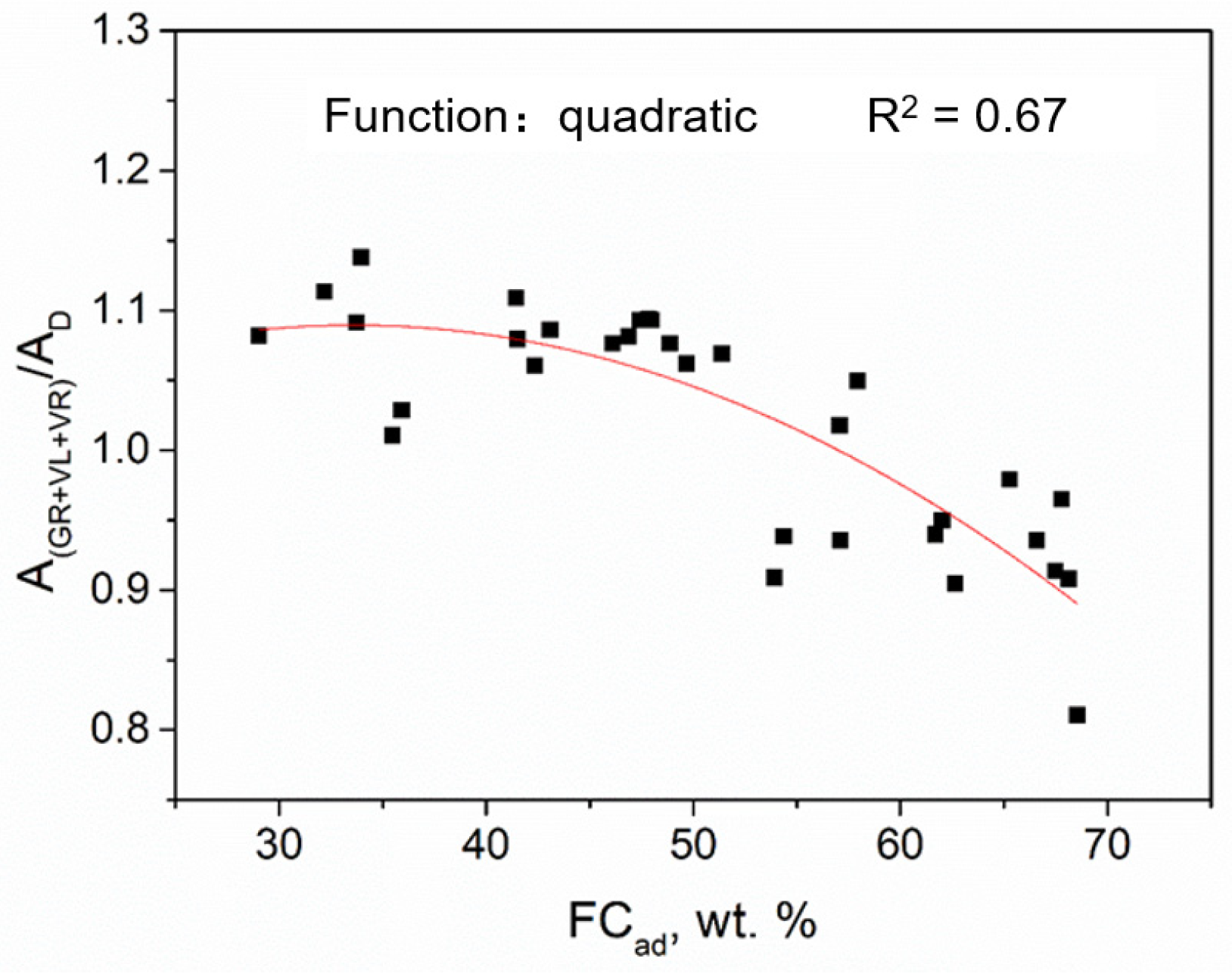

3.2.3. Effects of the Fixed Carbon Content in Parent Coal on the Aromatic Rings’ Structure

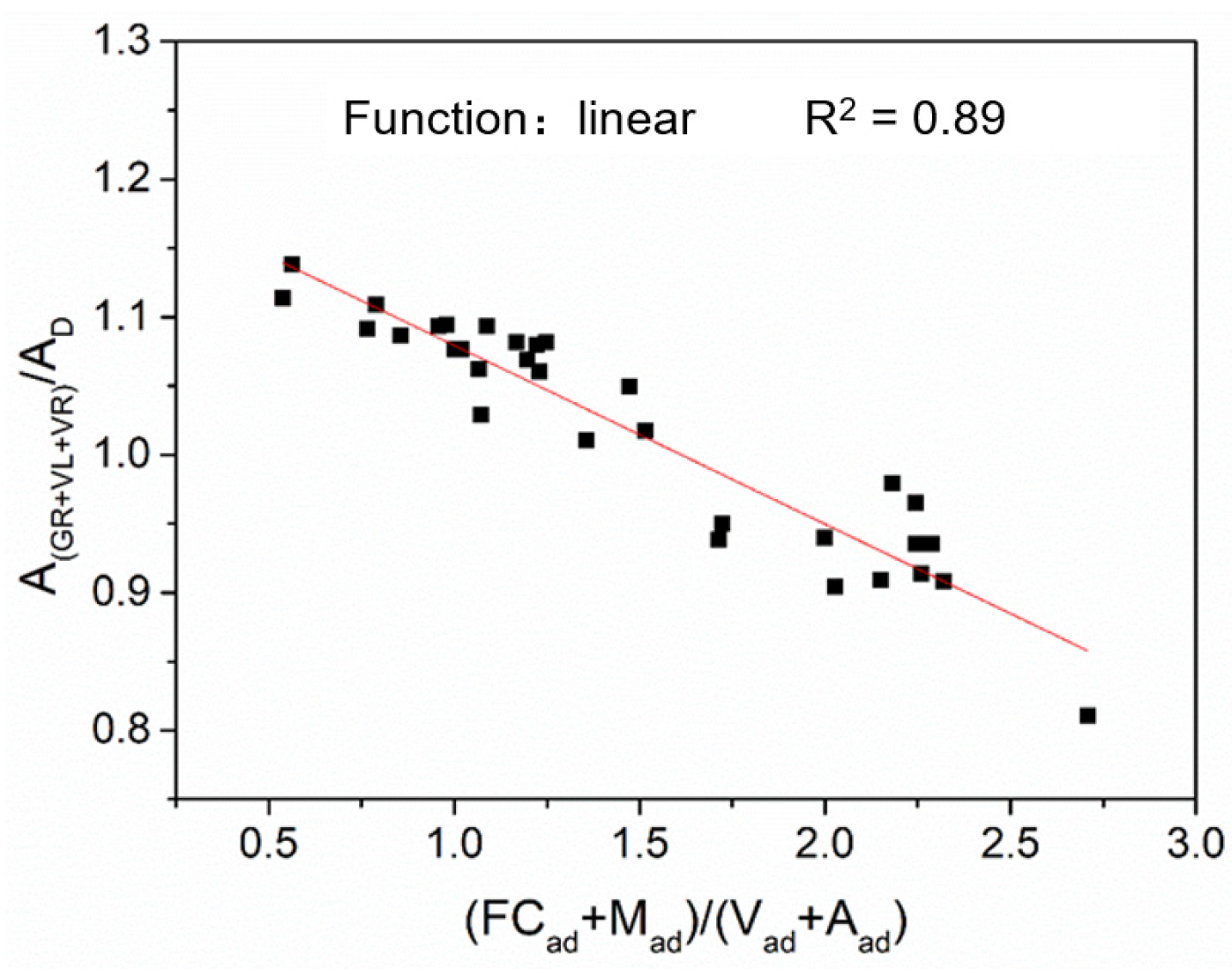

3.3. Relationship between the Comprehensive Coal Property Index and Pyrolytic Char Structures

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tomaszewicz, M.; Mianowski, A. Char structure dependence on formation enthalpy of parent coal. Fuel 2017, 199, 380–393. [Google Scholar] [CrossRef]

- Xu, J.; Tang, H.; Su, S.; Liu, J.; Xu, K.; Qian, K.; Wang, Y.; Zhou, Y.; Hu, S.; Zhang, A.; et al. A study of the relation-ships between coal structures and combustion characteristics: The insights from micro-Raman spectroscopy based on 32 kinds of Chinese coals. Appl. Energy 2018, 212, 46–56. [Google Scholar] [CrossRef]

- Yu, J.; Lucas, J.A.; Wall, T.F. Formation of the structure of chars during devolatilization of pulverized coal and its thermoproperties: A review. Prog. Energy Combust. Sci. 2007, 33, 135–170. [Google Scholar] [CrossRef]

- Morga, R.; Jelonek, I.; Kruszewska, K.; Szulikc, W. Relationships between quality of coals, resulting cokes, and micro-Raman spectral characteristics of these cokes. Int. J. Coal Geol. 2015, 144, 130–137. [Google Scholar] [CrossRef]

- Sheng, C. Char structure characterised by Raman spectroscopy and its correlations with combustion reactivity. Fuel 2007, 86, 2316–2324. [Google Scholar] [CrossRef]

- Xu, J.; Su, S.; Sun, Z.; Qing, M.; Xiong, Z.; Wang, Y.; Jiang, L.; Hu, S.; Xiang, J. Effects of steam and CO2 on the characteristics of chars during devolatilization in oxy-steam combustion process. Appl. Energy 2016, 182, 20–28. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, R.; Bi, J. Effect of catalyst on coal char structure and its role in catalytic coal gasification. Catal. Commun. 2016, 79, 1–5. [Google Scholar] [CrossRef]

- Borah, R.C.; Ghosh, P.; Rao, P.G. A review on devolatilization of coal in fluidized bed. Int. J. Energy Res. 2011, 35, 929–963. [Google Scholar] [CrossRef]

- Xu, J.; He, Q.; Xiong, Z.; Yu, Y.; Zhang, S.; Hu, X.; Jiang, L.; Su, S.; Hu, S.; Wang, Y.; et al. Raman Spectroscopy as a Versatile Tool for Investigating Thermochemical Processing of Coal, Biomass, and Wastes: Recent Advances and Future Perspectives. Energy Fuels 2021, 35, 2870–2913. [Google Scholar] [CrossRef]

- Xu, J.; Xiang, X.; Xu, K.; He, L.; Han, H.; Su, S.; Wang, Y.; Hu, S.; Xiang, J. Developing micro-Raman spectroscopy for char structure characterization in the scale of micro- and bulk: A case study of Zhundong coal pyrolysis. Fuel 2021, 291, 120–168. [Google Scholar] [CrossRef]

- Yi, B.; Zhang, L.; Yuan, Q.; Yan, S.; Zheng, C. The evolution of coal char structure under the oxy-fuel combustion containing high H2O. Fuel Process. Technol. 2016, 152, 294–302. [Google Scholar] [CrossRef]

- Wang, B.; Sun, L.; Su, S.; Xiang, J.; Hu, S.; Fei, H. Char Structural Evolution during Pyrolysis and Its Influence on Combustion Reactivity in Air and Oxy-Fuel Conditions. Energy Fuels 2012, 26, 1565–1574. [Google Scholar] [CrossRef]

- Lu, L.; Sahajwalla, V.; Harris, D. Characteristics of Chars Prepared from Various Pulverized Coals at Different Temperatures Using Drop-Tube Furnace. Energy Fuels 2000, 14, 869–876. [Google Scholar] [CrossRef]

- Yu, J.; Tahmasebi, A.; Han, Y.; Yin, F.; Li, X. A review on water in low rank coals: The existence, interaction with coal structure and effects on coal utilization. Fuel Process. Technol. 2013, 106, 9–20. [Google Scholar] [CrossRef]

- Nyathi, M.S.; Clifford, C.B.; Schobert, H.H. Characterization of graphitic materials prepared from different rank Pennsylvania anthracites. Fuel 2013, 114, 244–250. [Google Scholar] [CrossRef]

- Qi, X.; Guo, X.; Xue, L.; Zheng, C. Effect of iron on Shenfu coal char structure and its influence on gasification reactivity. J. Anal. Appl. Pyrolysis 2014, 110, 401–407. [Google Scholar] [CrossRef]

- Tang, H.; Xu, J.; Dai, Z.J.; Zhang, L.P.; Sun, Y.; Liu, W.; Mostafa, M.E.; Su, S.; Hu, S.; Wang, Y.; et al. Functional Mechanism of Inorganic Sodium on the Structure and Reactivity of Zhundong Chars during Pyrolysis. Energy Fuels 2017, 31, 10812–10821. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, Z.; Xiong, J.; Yu, G.; Wang, F. Effects of alkaline metal on coal gasification at pyrolysis and gasification phases. Fuel 2011, 90, 1723–1730. [Google Scholar]

- Wang, C.; Wu, S.; Lv, Q.; Liu, X.; Chen, W.; Che, D. Study on correlations of coal chemical properties based on database of real-time data. Appl. Energy 2017, 204, 1115–1123. [Google Scholar] [CrossRef]

- Li, X.; Hayashi, J.I.; Li, C.Z. FT-Raman spectroscopic study of the evolution of char structure during the pyrolysis of a Victorian brown coal. Fuel 2006, 85, 1700–1707. [Google Scholar] [CrossRef]

- Perry, S.T.; Hambly, E.; Fletcher, T.; Solum, M.; Pugmire, R. Solid-state 13 C NMR characterization of matched tars and chars from rapid coal devolatilization. Proc. Combust. Inst. 2000, 28, 2313–2319. [Google Scholar] [CrossRef]

- Li, X.; Hayashi, J.I.; Li, C.Z. Volatilisation and catalytic effects of alkali and alkaline earth metallic species during the pyrolysis and gasification of Victorian brown coal. Part VII. Raman spectroscopic study on the changes in char structure during the catalytic gasification in air. Fuel 2006, 85, 1509–1517. [Google Scholar] [CrossRef]

- Xu, J.; Tang, H.; Su, S.; Liu, J.; Han, H.; Zhang, L.; Xu, K.; Wang, Y.; Hu, S.; Zhou, Y.; et al. Micro-Raman Spectroscopy Study of 32 Kinds of Chinese Coals: Second-Order Raman Spectrum and Its Correlations with Coal Properties. Energy Fuels 2017, 31, 7884–7893. [Google Scholar] [CrossRef]

- Xu, J.; Liu, J.; Zhang, X.; Ling, P.; Xu, K.; He, L.; Su, S.; Wang, Y.; Hu, S.; Xiang, J. Chemical imaging of coal in micro-scale with Raman mapping technology. Fuel 2020, 264, 116826. [Google Scholar] [CrossRef]

- Colangeli, L.; Mennella, V.; Baratta, G.A.; Bussoletti, E.; Strazzulla, G. Raman and infrared spectra of polycyclic aromatic hydrocarbon molecules of possible astrophysical interest. Astrophys. J. 1992, 396, 369–377. [Google Scholar] [CrossRef]

- Péron, O.; Rinnert, E.; Lehaitre, M.; Crassous, P.; Compère, C. Detection of polycyclic aromatic hydrocarbon (PAH) compounds in artificial sea-water using surface-enhanced Raman scattering (SERS). Talanta 2009, 79, 199–204. [Google Scholar] [CrossRef] [PubMed]

- Antunes, E.F.; Lobo, A.O.; Corat, E.J.; Trava-Airoldi, V.; Martin, A.; Veríssimo, C. Comparative study of first- and second-order Raman spectra of MWCNT at visible and infrared laser excitation. Carbon 2006, 44, 2202–2211. [Google Scholar] [CrossRef]

- Zaida, A.; Bar-Ziv, E.; Radovic, L.R.; Lee, Y.-J. Further development of Raman Microprobe spectroscopy for characterization of char reactivity. Proc. Combust. Inst. 2007, 31, 1881–1887. [Google Scholar] [CrossRef]

- Sharma, R.K.; Wooten, J.B.; Baliga, V.L.; Lin, X.; Chan, W.G.; Hajaligol, M.R. Characterization of chars from pyrolysis of lignin. Fuel 2004, 83, 1469–1482. [Google Scholar] [CrossRef]

- Tay, H.L.; Kajitani, S.; Zhang, S.; Li, C.-Z. Inhibiting and other effects of hydrogen during gasification: Further insights from FT-Raman spectroscopy. Fuel 2014, 116, 1–6. [Google Scholar] [CrossRef]

- Zhang, S.; Min, Z.; Tay, H.; Asadullah, M.; Li, C.-Z. Effects of volatile-char interactions on the evolution of char structure during the gasification of Victorian brown coal in steam. Fuel 2011, 90, 1529–1535. [Google Scholar] [CrossRef]

- Xiang, J.; Liu, J.; Xu, J.; Su, S.; Tang, H.; Hu, Y.; Mostafa, M.E.; Xu, K.; Wang, Y.; Hu, S. The fluorescence interference in Raman spectrum of raw coals and its application for evaluating coal property and combustion characteristics. Proc. Combust. Inst. 2019, 37, 3053–3060. [Google Scholar] [CrossRef]

- Akyildiz, M.; Ural, S. Studies of the relationship between mineral matter and grinding properties for low-rank coals. Int. J. Coal Geol. 2004, 60, 81–84. [Google Scholar]

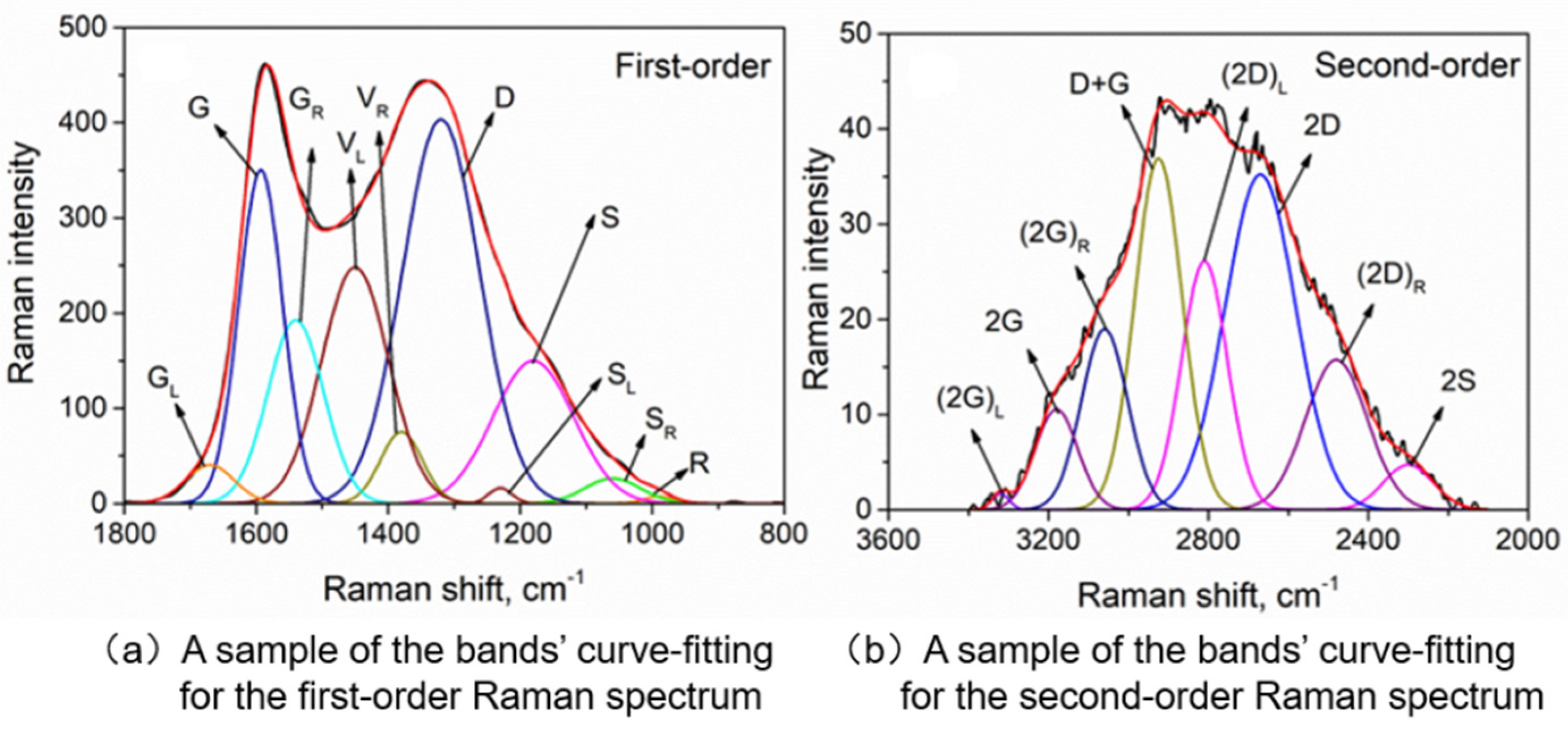

| Band Name | Band Position, cm−1 | Description |

|---|---|---|

| R | 960-800 | C-C on alkanes and cyclic alkanes; C-H on aromatic rings |

| SR | 1060 | C-H on aromatic rings; benzene (ortho-di-substituted) ring |

| S | 1185 | Caromatic-Calkyl; aromatic (aliphatic) ethers; C-C on hydro-aromatic rings; hexagonal diamond carbon sp3; C-H on aromatic rings |

| SL | 1230 | Aryl-alkyl ether; para-aromatics |

| D | 1320 | D band on highly ordered carbonaceous materials; C-C between aromatic rings and aromatics with not less than 6 rings |

| VR | 1380 | Methyl group; semi-circle breathing of aromatic rings; amorphous carbon structures |

| VL | 1465 | Methylene or methyl; semi-circle breathing of aromatic rings; amorphous carbon structures |

| GR | 1540 | Aromatics with 3–5 rings; amorphous carbon structures |

| G | 1590 | Graphite ; aromatic ring quadrant breathing; alkene C = C |

| GL | 1680 | Carbonyl group C = O |

| 2S | 2300 | Overtone of the band at 1150cm−1, Caromatic-Calkyl, C = O structures |

| (2D)R | 2480 | Large aromatic rings system |

| 2D | 2670 | Overtone of the D band, C-C between aromatic rings, large aromatic rings system |

| (2D)L | 2810 | C-H stretch of methyl and methylene, amorphous carbon structures |

| D+G | 2925 | Combination of D band and G band, large aromatic rings system |

| (2G)R | 3060 | Aryl C-H stretch vibration |

| 2G | 3180 | Overtone of the G band at 1590 cm−1, aromatic rings |

| (2G)L | 3320 | Overtone of the peaks at 1670 cm−1, Carbonyl group C = O |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; Ning, X.; Tang, W.; Xu, J.; Xu, K.; He, L.; Han, H.; Su, S.; Jiang, L.; Wang, Y.; et al. Effects of Parent Coal Properties on the Pyrolytic Char Chemical Structure: Insights from Micro-Raman Spectroscopy Based on 32 Kinds of Chinese Coals. Processes 2021, 9, 1575. https://doi.org/10.3390/pr9091575

Chen D, Ning X, Tang W, Xu J, Xu K, He L, Han H, Su S, Jiang L, Wang Y, et al. Effects of Parent Coal Properties on the Pyrolytic Char Chemical Structure: Insights from Micro-Raman Spectroscopy Based on 32 Kinds of Chinese Coals. Processes. 2021; 9(9):1575. https://doi.org/10.3390/pr9091575

Chicago/Turabian StyleChen, Dezhi, Xinyu Ning, Wen Tang, Jun Xu, Kai Xu, Limo He, Hengda Han, Sheng Su, Long Jiang, Yi Wang, and et al. 2021. "Effects of Parent Coal Properties on the Pyrolytic Char Chemical Structure: Insights from Micro-Raman Spectroscopy Based on 32 Kinds of Chinese Coals" Processes 9, no. 9: 1575. https://doi.org/10.3390/pr9091575

APA StyleChen, D., Ning, X., Tang, W., Xu, J., Xu, K., He, L., Han, H., Su, S., Jiang, L., Wang, Y., Hu, S., & Xiang, J. (2021). Effects of Parent Coal Properties on the Pyrolytic Char Chemical Structure: Insights from Micro-Raman Spectroscopy Based on 32 Kinds of Chinese Coals. Processes, 9(9), 1575. https://doi.org/10.3390/pr9091575