The Tip Clearance Cavitation Mechanism of a High-Speed Centrifugal Pump with a Splitter-Bladed Inducer

Abstract

:1. Introduction

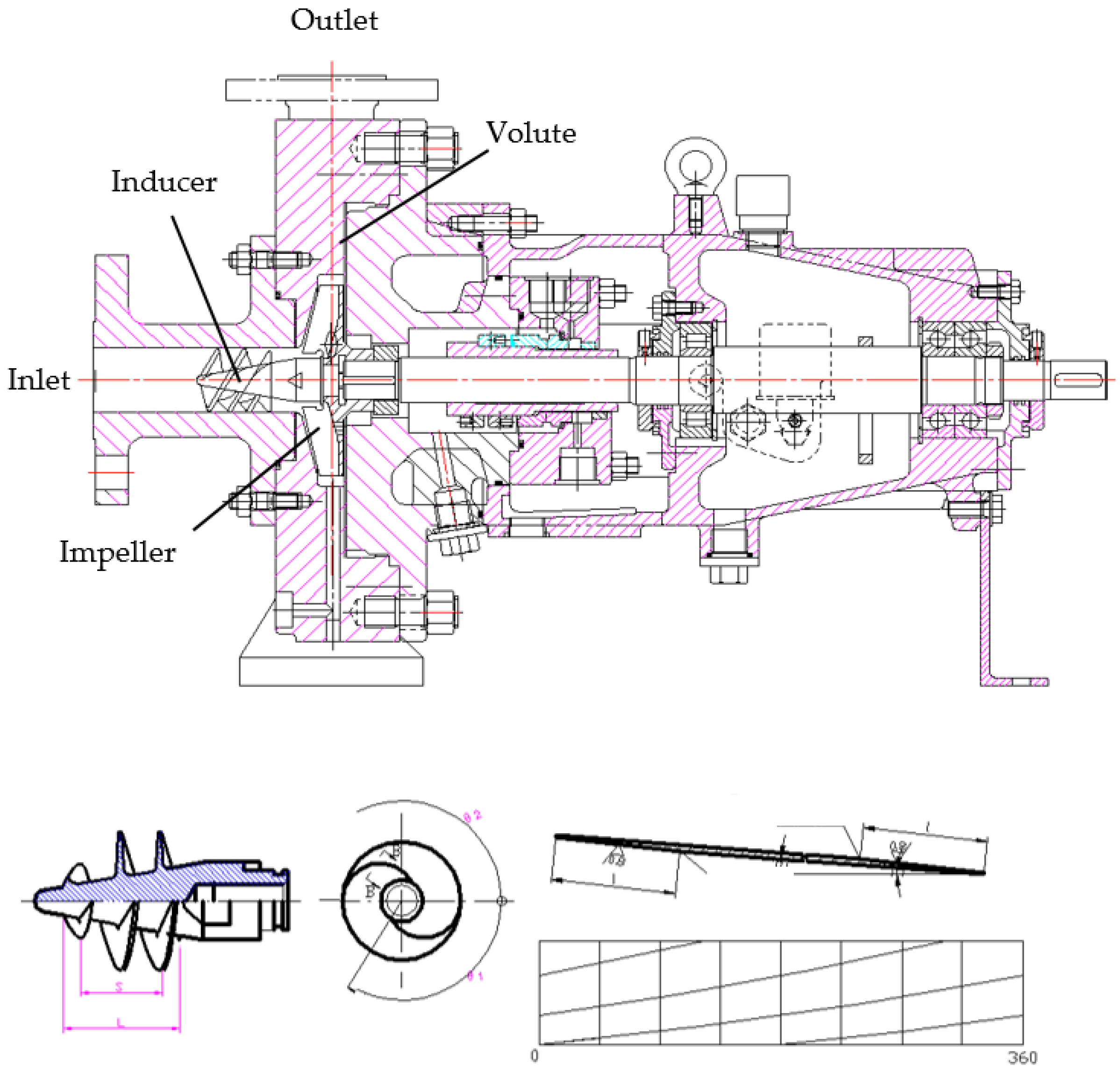

2. Main Parameters and Experimental System of the High-Speed Centrifugal Pump

2.1. Main Parameters

2.2. Experimental System

3. Numerical Calculation Method

3.1. Calculation Area and Grid Layout

3.2. Validation of Grid Independence

3.3. Numerical Calculation Model

4. Numerical Calculation and Analysis of Test Results

4.1. Reliability Analysis of Numerical Calculation Results

4.2. Analysis of Calculation Results under Different Tip Clearance

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shuai, L. Influence of Tip Clearance on the Flow and Cavitation Characteristics of Inducer; Zhejiang University of Technology: Hangzhou, China, 2017. [Google Scholar]

- Kaibin, N. Numerical Analysis of Backflow Catitation in Inlet of Centrifugal Pump with Inducer; Xi’an University of Technology: Xi’an, China, 2010. [Google Scholar]

- Guo, X.; Zhu, Z.; Cui, B.; Huang, Y. Anti-cavitation performance of a splitter-bladed inducer under different flow rates and different inlet pressures. Sci. China-Technol. Sci. 2015, 58, 2131–2138. [Google Scholar] [CrossRef]

- Guo, X.; Zhu, Z.; Cui, B.; Li, Y. The Rotating Cavitation Performance of a Centrifugal Pump with a Splitter-Bladed Inducer under Different Rotational Speed. Int. J. Turbo Jet-Engines 2015, 32, 275–283. [Google Scholar] [CrossRef]

- Guo, X.; Zhu, Z.; Cui, B.; Li, Y. Effects of the short blade locations on the anti-cavitation performance of the splitter-bladed inducer and the pump. Chin. J. Chem. Eng. 2015, 23, 1095–1101. [Google Scholar] [CrossRef]

- Guo, X.; Zhu, L.; Zhu, Z.; Cui, B.; Li, Y. Numerical and experimental investigations on the cavitation characteristics of a high-speed centrifugal pump with a splitter-blade inducer. J. Mech. Sci. Technol. 2015, 29, 259–267. [Google Scholar] [CrossRef]

- Guo, X.; Zhu, Z.; Cui, B.; Shi, G. Effects of the number of inducer blades on the anti-cavitation characteristics and external performance of a centrifugal pump. J. Mech. Sci. Technol. 2016, 30, 3173–3181. [Google Scholar] [CrossRef]

- Guo, X.; Zhu, Z.; Shi, G.; Huang, Y. Effects of rotational speeds on the performance of a centrifugal pump with a variable-pitch inducer. J. Hydrodyn. 2017, 29, 854–862. [Google Scholar] [CrossRef]

- Song, M.; Xie, H.; Yang, B.; Zhang, S. Influence of Tip Clearance on Flow Characteristics of Axial Compressor. Processes 2020, 8, 1445. [Google Scholar] [CrossRef]

- Shen, S.; Qian, Z.; Ji, B.; Agarwal, R.K. Numerical investigation of tip flow dynamics and main flow characteristics with varying tip clearance widths for an axial-flow pump. Proc. Inst. Mech. Eng. Part A J. Power Energy 2019, 233, 476–488. [Google Scholar] [CrossRef]

- Xu, B.; Shen, X.; Zhang, D.; Zhang, W. Experimental and numerical investigation on the tip leakage vortex cavitation in an axial flow pump with different tip clearances. Processes 2019, 7, 935. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Tan, L.; Liu, Y.; Cao, S. Pressure fluctuation and flow pattern of a mixed-flow pump with different blade tip clearances under cavitation condition. Adv. Mech. Eng. 2017, 9, 1687814017696227. [Google Scholar] [CrossRef]

- Dreyer, M.; Decaix, J.; Muench-Alligne, C.; Farhat, M. Mind the gap: A new insight into the tip leakage vortex using stereo-PIV. Exp. Fluids 2014, 55, 1849. [Google Scholar] [CrossRef]

- Li, W.; Yang, Y.; Shi, W.; Zhao, X.; Li, W. The Correction and Evaluation of Cavitation Model considering the Thermodynamic Effect. Math. Probl. Eng. 2018, 2018, 7217513. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Yuan, S.; Lai, H. Numerical Study of Unsteady Flows with Cavitation in a High-Speed Micro Centrifugal Pump. J. Therm. Sci. 2017, 26, 18–24. [Google Scholar] [CrossRef]

- Yang, X.; Qin, Y.; Qu, Z. Leakage Loss Study of a Synchronal Rotary Multiphase Pump With a Full Range of Inlet Gas Volume Fractions. J. Fluids Eng. Trans. ASME 2016, 138, 071301. [Google Scholar] [CrossRef]

- Campos-Amezcua, R.; Khelladi, S.; Mazur-Czerwiec, Z.; Bakir, F.; Campos-Amezcua, A.; Rey, R. Numerical and experimental study of cavitating flow through an axial inducer considering tip clearance. Proc. Inst. Mech. Eng. Part A J. Power Energy 2013, 227, 858–868. [Google Scholar] [CrossRef]

- Hong, S.; Kim, D.; Kim, J.; Choi, C.; Kim, J. Study on inducer and impeller of a centrifugal pump for a rocket engine turbopump. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2013, 227, 311–319. [Google Scholar] [CrossRef] [Green Version]

- Okita, K.; Ugajin, H.; Matsumoto, Y. Numerical Analysis of the Influence of the Tip Clearance Flows on the Unsteady Cavitating Flows in a Three-Dimensional Inducer. J. Hydrodyn. 2009, 21, 34–40. [Google Scholar] [CrossRef]

- Kim, S.; Choi, C.; Kim, J.; Park, J.; Baek, J. Tip Clearance Effects on Cavitation Evolution and Head Breakdown in Turbopump Inducer. J. Propuls. Power 2013, 29, 1357–1366. [Google Scholar] [CrossRef]

- Kim, C.; Kim, S.; Choi, C.; Baek, J. Effects of inducer tip clearance on the performance and flow characteristics of a pump in a turbopump. Proc. Inst. Mech. Eng. Part A J. Power Energy 2017, 231, 398–414. [Google Scholar] [CrossRef]

- Yanxia, F.; Jianping, Y.; Shouqi, Y.; Pace, G.; D’Agostino, L. Effect of Tip Clearance on the Internal Flow and Hydraulic Performance of a Three-Bladed Inducer. Int. J. Rotating Mach. 2017, 2017, 2329591. [Google Scholar]

- Torre, L.; Pasini, A.; Cervone, A.; Pace, G.; Miloro, P.; D’Agostino, L. Effect of Tip Clearance on the Performance of a Three-Bladed Axial Inducer. J. Propuls. Power 2011, 27, 890–898. [Google Scholar] [CrossRef]

- Ji, B.; Luo, X.; Wu, Y.; Peng, X.; Duan, Y. Numerical analysis of unsteady cavitating turbulent flow and shedding horse-shoe vortex structure around a twisted hydrofoil. Int. J. Multiph. Flow 2013, 51, 33–43. [Google Scholar] [CrossRef] [Green Version]

- Ji, B.; Luo, X.; Arndt, R.E.A.; Wu, Y. Numerical simulation of three dimensional cavitation shedding dynamics with special emphasis on cavitation-vortex interaction. Ocean. Eng. 2014, 87, 64–77. [Google Scholar] [CrossRef]

| Rotation Speed n (r/min) | Flow Rate Q (m3/h) | Head H (m) | Specific Speed ns | Inducer Blades |

|---|---|---|---|---|

| 6000 | 4 | 100 | 23.08 | 4 |

| TC (mm) | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.8 | 1.5 | 2.0 |

| Maximum vapor volume fraction | 0.553 | 0.842 | 0.889 | 0.885 | 0.888 | 0.854 | 0.854 | 0.663 |

| Cavitation area (mm2) | 50.76 | 63.01 | 47.23 | 51.64 | 52.36 | 16.39 | 20.48 | 27.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Yang, S.; Li, X.; Shi, L.; Hua, E.; Zhu, Z. The Tip Clearance Cavitation Mechanism of a High-Speed Centrifugal Pump with a Splitter-Bladed Inducer. Processes 2021, 9, 1576. https://doi.org/10.3390/pr9091576

Guo X, Yang S, Li X, Shi L, Hua E, Zhu Z. The Tip Clearance Cavitation Mechanism of a High-Speed Centrifugal Pump with a Splitter-Bladed Inducer. Processes. 2021; 9(9):1576. https://doi.org/10.3390/pr9091576

Chicago/Turabian StyleGuo, Xiaomei, Shidong Yang, Xiaojun Li, Liang Shi, Ertian Hua, and Zuchao Zhu. 2021. "The Tip Clearance Cavitation Mechanism of a High-Speed Centrifugal Pump with a Splitter-Bladed Inducer" Processes 9, no. 9: 1576. https://doi.org/10.3390/pr9091576

APA StyleGuo, X., Yang, S., Li, X., Shi, L., Hua, E., & Zhu, Z. (2021). The Tip Clearance Cavitation Mechanism of a High-Speed Centrifugal Pump with a Splitter-Bladed Inducer. Processes, 9(9), 1576. https://doi.org/10.3390/pr9091576