Effects of Spray-Drying Inlet Temperature on the Production of High-Quality Native Rice Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Protein Extraction

2.3. Spray Drying

2.4. Physicochemical Properties of Waxy Rice Starch

2.4.1. Moisture Content Analysis

2.4.2. Kjeldahl Method

2.4.3. Process Yield

2.4.4. Particle Size Analysis

2.4.5. Density and Flowability Analyses

2.5. Pasting Profiles

2.6. Raman Spectroscopy

2.7. Starch Crystallinity Analysis

2.7.1. Polarized Light Microscopy

2.7.2. Differential Scanning Calorimetry (DSC)

2.7.3. X-ray Diffraction (XRD) Analysis

2.8. Statistical Analysis

3. Results and Discussion

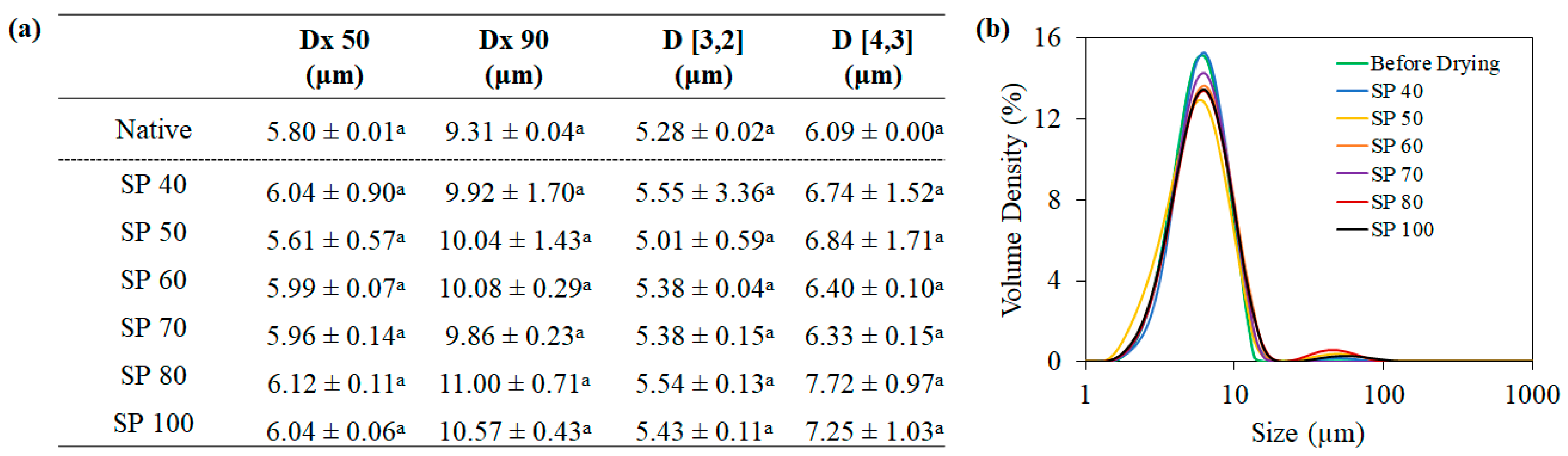

3.1. Physical Properties of Spray-Dried Waxy Rice Starch

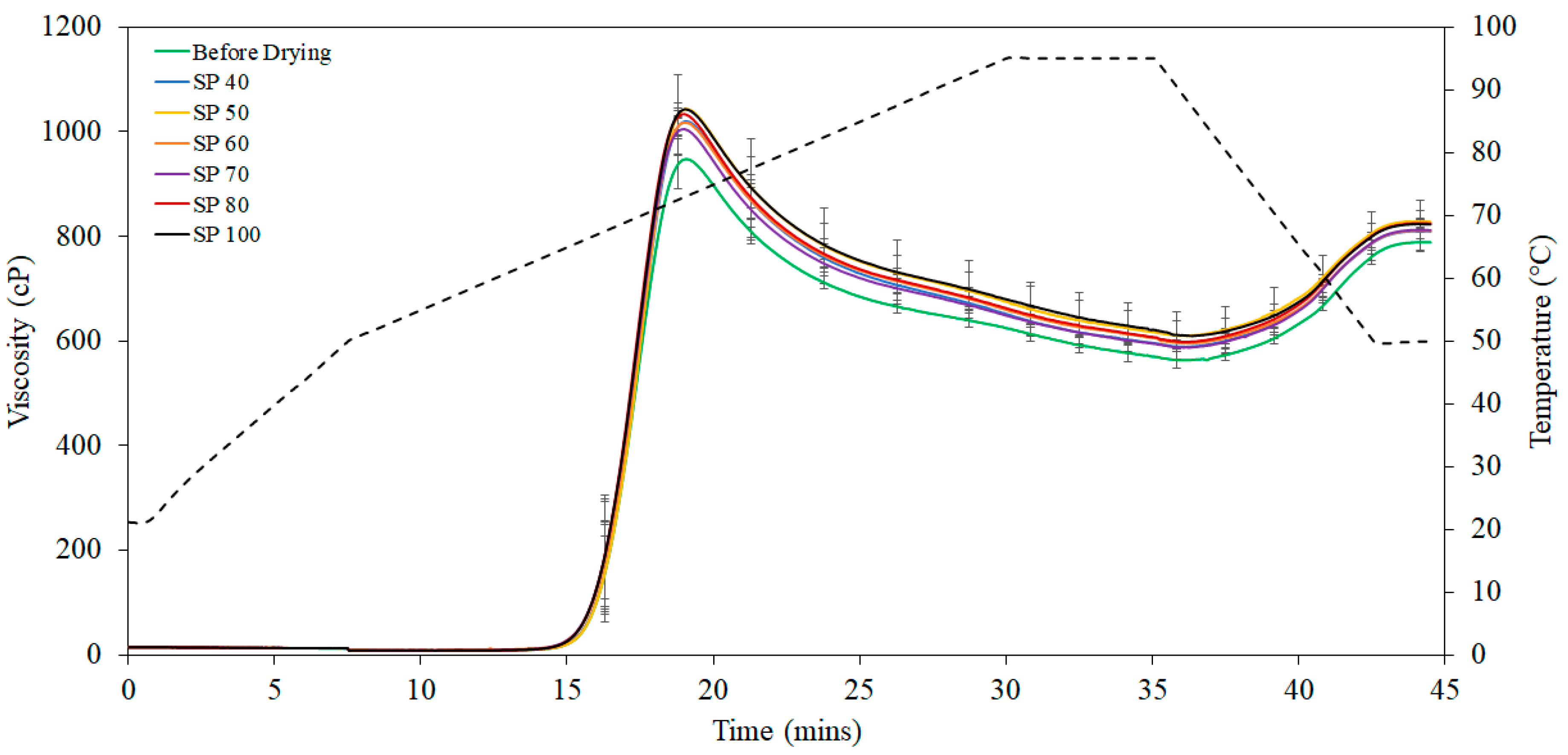

3.2. Pasting Behaviour

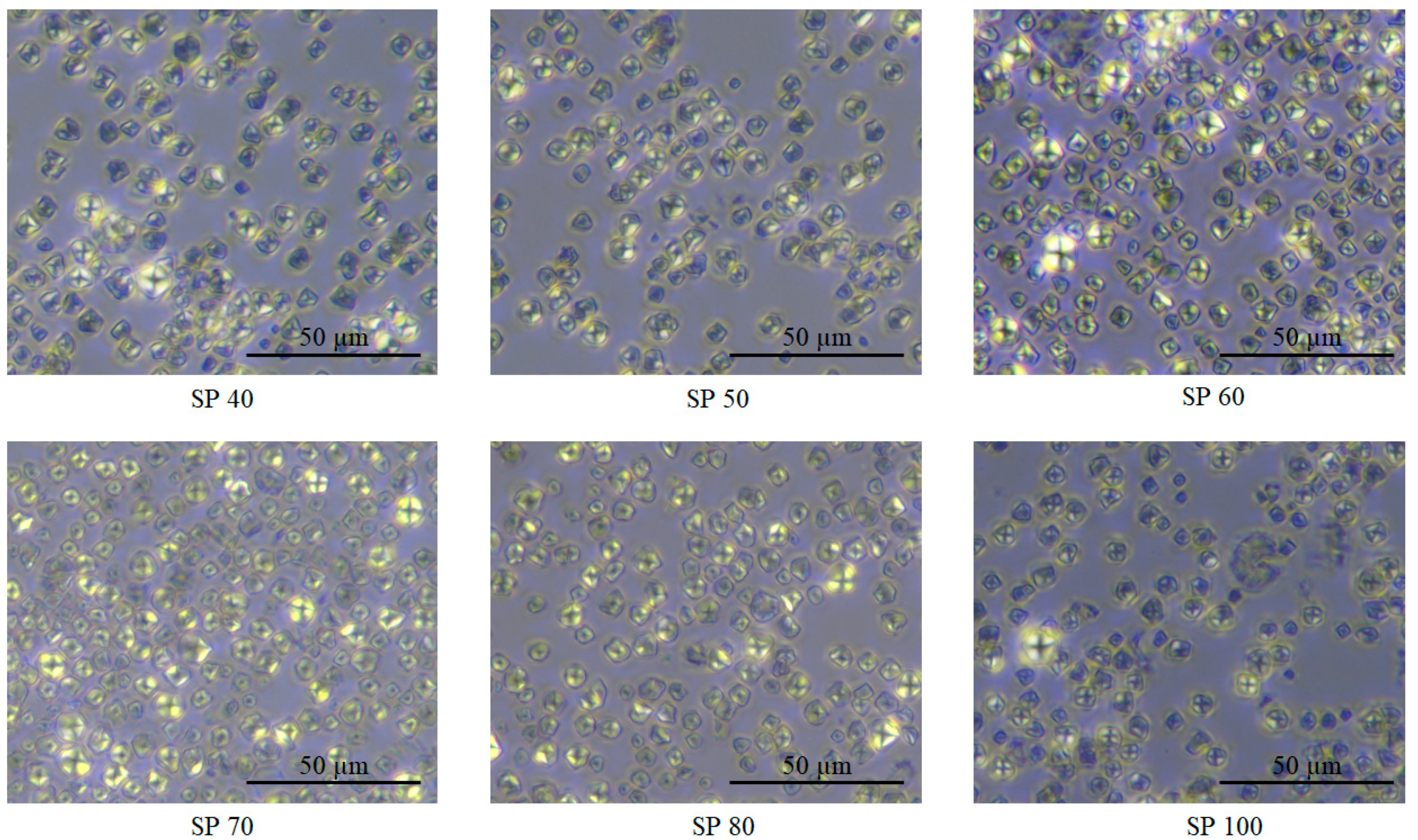

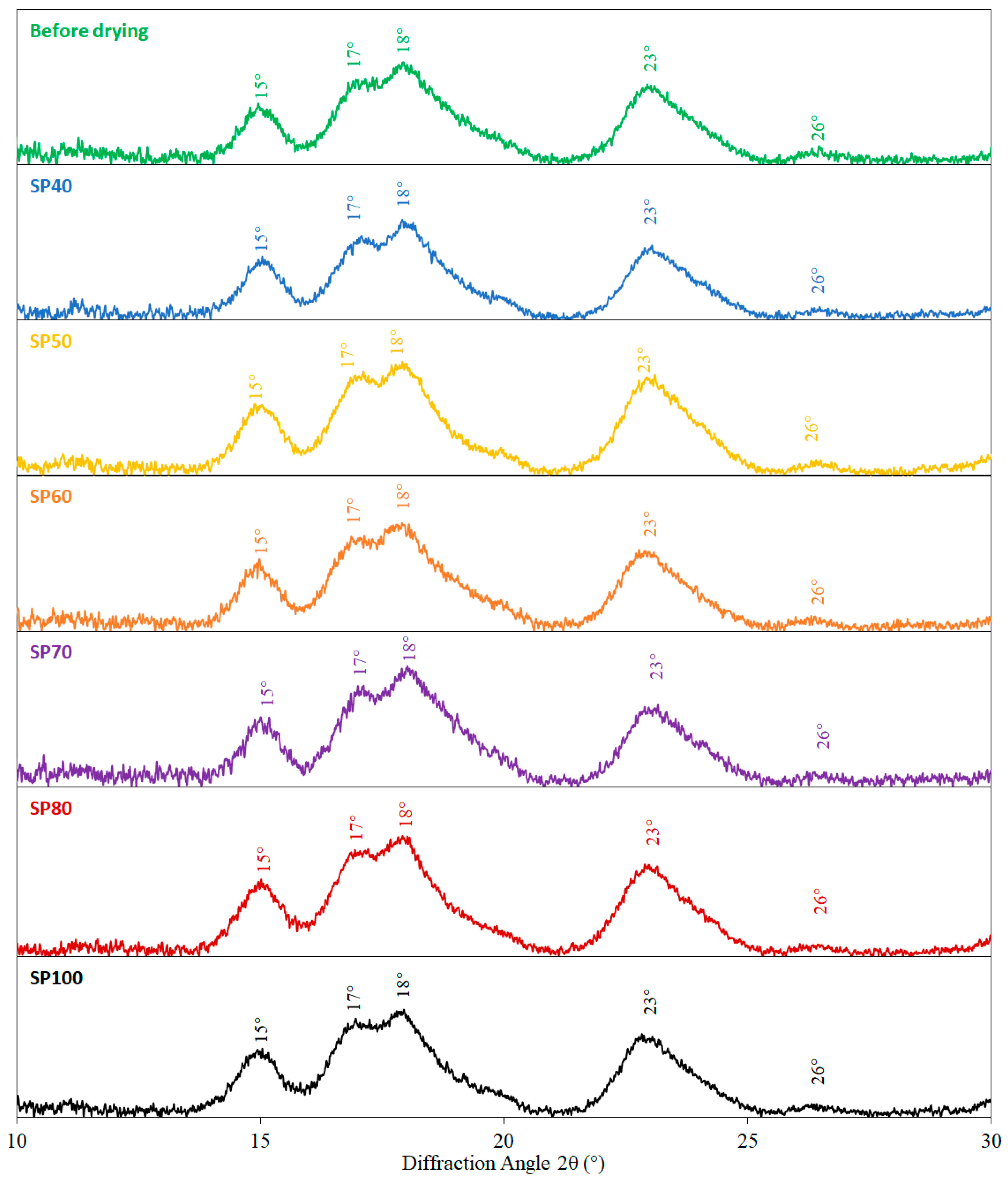

3.3. Crystalline Structure

3.4. Molecular Changes

3.5. Optimized Spray Drying Temperature for Production

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Palacios-Fonseca, A.J.; Castro-Rosas, J.; Gómez-Aldapa, C.A.; Tovar-Benítez, T.; Millán-Malo, B.M.; Del Real, A.; Rodríguez-García, M.E. Effect of the alkaline and acid treatments on the physicochemical properties of corn starch. CyTA-J. Food 2013, 11, 67–74. [Google Scholar] [CrossRef] [Green Version]

- Šárka, E.; Dvořáček, V. New processing and applications of waxy starch (a review). J. Food Eng. 2017, 206, 77–87. [Google Scholar] [CrossRef]

- Oh, S.M.; Shin, M. Physicochemical properties and molecular structures of Korean waxy rice starches. Food Sci. Biotechnol. 2015, 24, 791–798. [Google Scholar] [CrossRef]

- Luh, B.S. Rice: Volume I. Production; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; ISBN 1489937544. [Google Scholar]

- Miano, A.C.; Rojas, M.L.; Augusto, P.E.D. Other Mass Transfer Unit Operations Enhanced by Ultrasound. In Ultrasound: Advances for Food Processing and Preservation; Elsevier: Amsterdam, The Netherlands, 2017; pp. 369–389. [Google Scholar]

- Chapuis, A.; Precoppe, M.; Méot, J.-M.; Sriroth, K.; Tran, T. Pneumatic drying of cassava starch: Numerical analysis and guidelines for the design of efficient small-scale dryers. Dry. Technol. 2017, 35, 393–408. [Google Scholar] [CrossRef]

- Supprung, P.; Noomhorm, A. Optimization of drum drying parameters for low amylose rice (KDML105) starch and flour. Dry. Technol. 2003, 21, 1781–1795. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Shoemaker, C.F.; Xu, Z.; Zhu, S.; Zhong, F. Effect of dry heat treatment with xanthan on waxy rice starch. Carbohydr. Polym. 2013, 92, 1647–1652. [Google Scholar] [CrossRef]

- Santos, D.; Franco, C.M.L.; Mischan, M.M.; Leonel, M. Improvement in spray-drying technology for preparation of pregelatinized cassava starch. Food Sci. Technol. 2019, 39, 939–946. [Google Scholar] [CrossRef] [Green Version]

- Keshani, S.; Daud, W.R.W.; Nourouzi, M.M.; Namvar, F.; Ghasemi, M. Spray drying: An overview on wall deposition, process and modeling. J. Food Eng. 2015, 146, 152–162. [Google Scholar] [CrossRef]

- Tay, J.B.J.; Chua, X.; Ang, C.; Goh, K.K.T.; Subramanian, G.S.; Tan, S.Y.; Lin, E.M.J.; Wu, W.-Y.; Lim, K. Continuous low-temperature spray drying approach for efficient production of high quality native rice starch. Dry. Technol. 2021, 1–16. [Google Scholar] [CrossRef]

- Zambrano, M.V.; Dutta, B.; Mercer, D.G.; MacLean, H.L.; Touchie, M.F. Assessment of moisture content measurement methods of dried food products in small-scale operations in developing countries: A review. Trends Food Sci. Technol. 2019, 88, 484–496. [Google Scholar] [CrossRef]

- Opaliński, I.; Chutkowski, M.; Hassanpour, A. Rheology of moist food powders as affected by moisture content. Powder Technol. 2016, 294, 315–322. [Google Scholar] [CrossRef]

- Kamal, M.M.; Baini, R.; Mohamaddan, S.; Selaman, O.S.; Zauzi, N.A.; Rahman, M.R.; Rahman, N.A.; Chong, K.H.; Atan, M.F.; Samat, N.A.S.A. Effect of temperature to the properties of sago starch. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Miri, Malaysia, 1–3 December 2016; IOP Publishing: Bristol, UK, 2017; Volume 206, p. 12039. [Google Scholar]

- Dos Santos, T.P.R.; Franco, C.M.L.; Demiate, I.M.; Li, X.-H.; Garcia, E.L.; Jane, J.; Leonel, M. Spray-drying and extrusion processes: Effects on morphology and physicochemical characteristics of starches isolated from Peruvian carrot and cassava. Int. J. Biol. Macromol. 2018, 118, 1346–1353. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, A.; Li, D.; Wang, L.; Zhou, Y.; Adhikari, B. Spray drying of starch submicron particles prepared by high pressure homogenization and mini-emulsion cross-linking. J. Food Eng. 2012, 113, 399–407. [Google Scholar] [CrossRef]

- Wani, A.A.; Singh, P.; Shah, M.A.; Schweiggert-Weisz, U.; Gul, K.; Wani, I.A. Rice starch diversity: Effects on structural, morphological, thermal, and physicochemical properties—A review. Compr. Rev. Food Sci. Food Saf. 2012, 11, 417–436. [Google Scholar] [CrossRef]

- Magee, J.S.; Mitchell, M.M. Fluid Catalytic Cracking: Science and Technology; Elsevier: Amsterdam, The Netherlands, 1993; ISBN 0080887686. [Google Scholar]

- Reddy, R.S.; Ramachandra, C.T.; Hiregoudar, S.; Nidoni, U.; Ram, J.; Kammar, M. Influence of processing conditions on functional and reconstitution properties of milk powder made from Osmanabadi goat milk by spray drying. Small Rumin. Res. 2014, 119, 130–137. [Google Scholar] [CrossRef]

- Xu, G.; Lu, P.; Li, M.; Liang, C.; Xu, P.; Liu, D.; Chen, X. Investigation on characterization of powder flowability using different testing methods. Exp. Therm. Fluid Sci. 2018, 92, 390–401. [Google Scholar] [CrossRef]

- Yang, J.; Sliva, A.; Banerjee, A.; Dave, R.N.; Pfeffer, R. Dry particle coating for improving the flowability of cohesive powders. Powder Technol. 2005, 158, 21–33. [Google Scholar] [CrossRef]

- Arollado, E.C.; Pellazar, J.M.M.; Manalo, R.A.M.; Siocson, M.P.F.; Ramirez, R.-L.F. Comparison of the Physicochemical and Pharmacopeial Properties of starches Obtained from Artocarpus odoratissimus Blanco, Nephelium lappaceum l., and Mangifera indica l. seeds with Corn starch. Acta Med. Philipp. 2018, 52, 360. [Google Scholar] [CrossRef]

- Odeniyi, M.A.; Adepoju, A.O.; Jaiyeoba, K.T. Native and modified Digitaria exilis starch nanoparticles as a carrier system for the controlled release of naproxen. Starch-Stärke 2019, 71, 1900067. [Google Scholar] [CrossRef]

- Jain, G.; Khar, R.K.; Ahmad, F.J. Theory and Practice of Physical Pharmacy-E-Book; Elsevier Health Sciences: Amsterdam, The Netherlands, 2013; ISBN 8131232654. [Google Scholar]

- Ie, P.S. Gelatinization and Molecular Properties of Organic and Conventional Rice and Spelt Starches; Ohio State University: Columbus, OH, USA, 2011. [Google Scholar]

- Todaro, C.M.; Vogel, H.C. Fermentation and Biochemical Engineering Handbook; William Andrew: Norwish, NY, USA, 2014; ISBN 1455730467. [Google Scholar]

- Santos, D.; Maurício, A.C.; Sencadas, V.; Santos, J.D.; Fernandes, M.H.; Gomes, P.S. Spray drying: An overview. In Pignatello, R. (Comp.). Biomaterials-Physics and Chemistry-New Edition; InTechOpen Limited: London, UK, 2018; pp. 9–35. [Google Scholar]

- Wang, Y.; Wang, L. Structures of four waxy rice starches in relation to thermal, pasting, and textural properties. Cereal Chem. 2002, 79, 252–256. [Google Scholar] [CrossRef] [Green Version]

- Dome, K.; Podgorbunskikh, E.; Bychkov, A.; Lomovsky, O. Changes in the Crystallinity Degree of Starch Having Different Types of Crystal Structure after Mechanical Pretreatment. Polymers 2020, 12, 641. [Google Scholar] [CrossRef] [Green Version]

- Martens, B.M.J.; Gerrits, W.J.J.; Bruininx, E.M.A.M.; Schols, H.A. Amylopectin structure and crystallinity explains variation in digestion kinetics of starches across botanic sources in an in vitro pig model. J. Anim. Sci. Biotechnol. 2018, 9, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Cai, C.; Wei, C. In situ observation of crystallinity disruption patterns during starch gelatinization. Carbohydr. Polym. 2013, 92, 469–478. [Google Scholar] [CrossRef] [PubMed]

- Pan, T.; Lin, L.; Wang, J.; Liu, Q.; Wei, C. Long branch-chains of amylopectin with B-type crystallinity in rice seed with inhibition of starch branching enzyme I and IIb resist in situ degradation and inhibit plant growth during seedling development. BMC Plant Biol. 2018, 18, 9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lian, X.; Cheng, K.; Wang, D.; Zhu, W.; Wang, X. Analysis of crystals of retrograded starch with sharp X-ray diffraction peaks made by recrystallization of amylose and amylopectin. Int. J. Food Prop. 2017, 20, S3224–S3236. [Google Scholar] [CrossRef]

- Liu, K.; Hao, Y.; Chen, Y.; Gao, Q. Effects of dry heat treatment on the structure and physicochemical properties of waxy potato starch. Int. J. Biol. Macromol. 2019, 132, 1044–1050. [Google Scholar] [CrossRef] [PubMed]

- Kadam, S.U.; Tiwari, B.K.; O’Donnell, C.P. Improved thermal processing for food texture modification. Modifying Food Texture 2015, 115–131. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, C.; Jiang, S.; Cao, J.; Xiong, L.; Sun, Q. Functional properties of glutinous rice flour by dry-heat treatment. PLoS ONE 2016, 11, e0160371. [Google Scholar] [CrossRef]

- Cornejo-Ramírez, Y.I.; Martínez-Cruz, O.; Del Toro-Sánchez, C.L.; Wong-Corral, F.J.; Borboa-Flores, J.; Cinco-Moroyoqui, F.J. The structural characteristics of starches and their functional properties. CyTA-J. Food 2018, 16, 1003–1017. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, Y.; Yan, Y.; Hu, D.; Yang, L.; Shen, R. Application of Raman spectroscopy in structure analysis and crystallinity calculation of corn starch. Starch-Stärke 2015, 67, 612–619. [Google Scholar] [CrossRef]

- Qin, J.; Kim, M.S.; Chao, K.; Bellato, L.; Schmidt, W.F.; Cho, B.-K.; Huang, M. Inspection of maleic anhydride in starch powder using line-scan hyperspectral Raman chemical imaging technique. Int. J. Agric. Biol. Eng. 2018, 11, 120–125. [Google Scholar] [CrossRef] [Green Version]

- Volant, C.; Gilet, A.; Beddiaf, F.; Collinet-Fressancourt, M.; Falourd, X.; Descamps, N.; Wiatz, V.; Bricout, H.; Tilloy, S.; Monflier, E. Multiscale structure of starches grafted with hydrophobic groups: A new analytical strategy. Molecules 2020, 25, 2827. [Google Scholar] [CrossRef] [PubMed]

| Protein Content (%) | Moisture Content (%) | Process Yield (%) | |

|---|---|---|---|

| SP 40 | 0.64 ± 0.22 a | 13.92 ± 0.32 a | 74.83 ± 4.34 a |

| SP 50 | 0.79 ± 0.24 a | 12.42 ± 1.67 ab | 82.42 ± 5.73 a |

| SP 60 | 0.66 ± 0.19 a | 10.74 ± 1.08 bcd | 84.55 ± 1.77 a |

| SP 70 | 0.73 ± 0.14 a | 9.67 ± 0.53 cef | 85.16 ± 0.82 a |

| SP 80 | 0.66 ± 0.15 a | 9.26 ± 0.40 deg | 88.66 ± 6.19 b |

| SP 100 | 0.66 ± 0.13 a | 7.99 ± 0.30 fg | 85.66 ± 1.18 a |

| Bulk Density (g/cm3) | Tapped Density (g/cm3) | Hausner Ratio (HR) | Carr’s Index (%) | |

|---|---|---|---|---|

| SP 40 | 0.33 ± 0.01 h | 0.47 ± 0.02 a | 1.41 ± 0.02 a | 28.96 ± 1.00 a |

| SP 50 | 0.36 ± 0.01 abc | 0.51 ± 0.02 abcd | 1.40 ± 0.04 a | 28.31 ± 2.06 a |

| SP 60 | 0.37 ± 0.00 ade | 0.51 ± 0.00 bef | 1.39 ± 0.00 a | 28.00 ± 0.00 a |

| SP 70 | 0.37 ± 0.01 bdf | 0.52 ± 0.02 ceg | 1.40 ± 0.02 a | 28.69 ± 1.15 a |

| SP 80 | 0.38 ± 0.00 cefg | 0.53 ± 0.01 dfg | 1.38 ± 0.02 a | 27.35 ± 1.15 a |

| SP 100 | 0.40 ± 0.00 g | 0.57 ± 0.01 h | 1.42 ± 0.02 a | 29.34 ± 1.15 a |

| TO (°C) | TP (°C) | TC (°C) | TC-TO (°C) | △H (J/g) | |

|---|---|---|---|---|---|

| Native | 59.00 ± 0.00 a | 68.50 ± 0.57 a | 76.70 ± 0.57 a | 17.70 ± 0.57 a | 2.12 ± 0.10 a |

| SP 40 | 57.90 ± 2.72 a | 66.03 ± 1.42 a | 75.97 ± 0.84 a | 18.07 ± 3.16 a | 1.42 ± 0.69 a |

| SP 50 | 57.87 ± 1.27 a | 65.33 ± 0.45 a | 74.90 ± 0.85 a | 17.03 ± 1.88 a | 0.99 ± 1.07 a |

| SP 60 | 58.23 ± 1.36 a | 67.07 ± 2.29 a | 75.90 ± 0.78 a | 17.67 ± 1.16 a | 1.47 ± 0.84 a |

| SP 70 | 58.07 ± 1.60 a | 66.20 ± 1.23 a | 75.10 ± 1.10 a | 17.03 ± 2.70 a | 1.53 ± 0.53 a |

| SP 80 | 58.50 ± 1.32 a | 65.97 ± 0.81 a | 76.13 ± 0.65 a | 17.63 ± 1.88 a | 1.80 ± 0.45 a |

| SP 100 | 57.97 ± 2.12 a | 66.07 ± 1.17 a | 75.67 ± 1.04 a | 17.70 ± 2.21 a | 1.45 ± 0.12 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tay, J.B.J.; Chua, X.; Ang, C.; Subramanian, G.S.; Tan, S.Y.; Lin, E.M.J.; Wu, W.-Y.; Goh, K.K.T.; Lim, K. Effects of Spray-Drying Inlet Temperature on the Production of High-Quality Native Rice Starch. Processes 2021, 9, 1557. https://doi.org/10.3390/pr9091557

Tay JBJ, Chua X, Ang C, Subramanian GS, Tan SY, Lin EMJ, Wu W-Y, Goh KKT, Lim K. Effects of Spray-Drying Inlet Temperature on the Production of High-Quality Native Rice Starch. Processes. 2021; 9(9):1557. https://doi.org/10.3390/pr9091557

Chicago/Turabian StyleTay, Jamie Boon Jun, Xinying Chua, Cailing Ang, Gomathy Sandhya Subramanian, Sze Yu Tan, Esther Marie Jierong Lin, Wen-Ya Wu, Kelvin Kim Tha Goh, and Kaiyang Lim. 2021. "Effects of Spray-Drying Inlet Temperature on the Production of High-Quality Native Rice Starch" Processes 9, no. 9: 1557. https://doi.org/10.3390/pr9091557

APA StyleTay, J. B. J., Chua, X., Ang, C., Subramanian, G. S., Tan, S. Y., Lin, E. M. J., Wu, W.-Y., Goh, K. K. T., & Lim, K. (2021). Effects of Spray-Drying Inlet Temperature on the Production of High-Quality Native Rice Starch. Processes, 9(9), 1557. https://doi.org/10.3390/pr9091557