Optimization Study on Increasing Yield and Capacity of Fluid Catalytic Cracking (FCC) Units

Abstract

:1. Introduction

2. Materials and Methods

2.1. Case Study

2.1.1. Reaction Regeneration System

2.1.2. Fractionation System

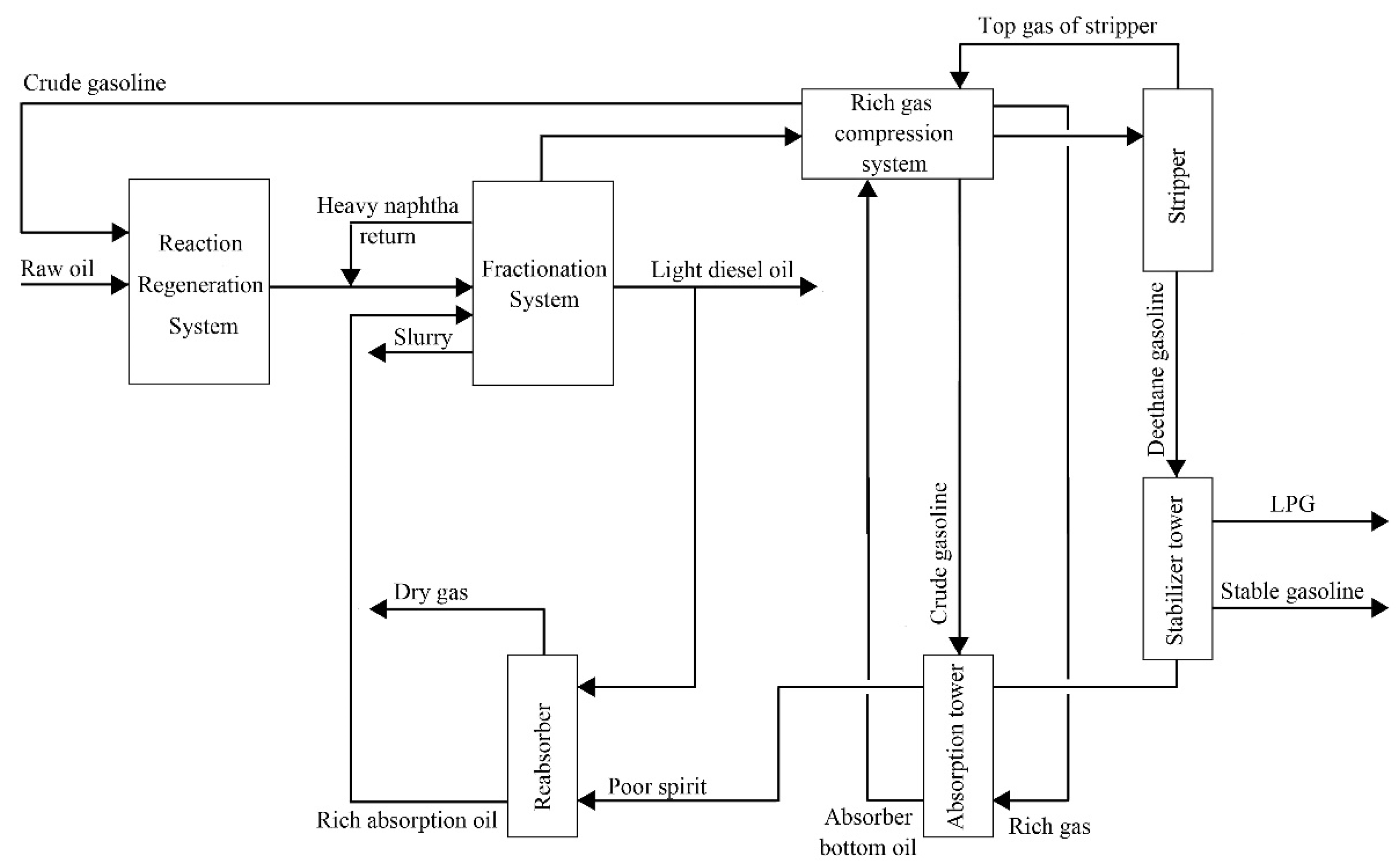

2.1.3. Absorption Stabilization System

2.2. Simulation Methods

3. Results and Discussion

3.1. Yield Analysis on the Model

3.2. Comparative Analysis of the Main Operating Parameters of the Model

3.3. Comparative Analysis of the Distillation Curves of the Main Products of the Model

3.4. Optimization of Improving Gasoline Yield

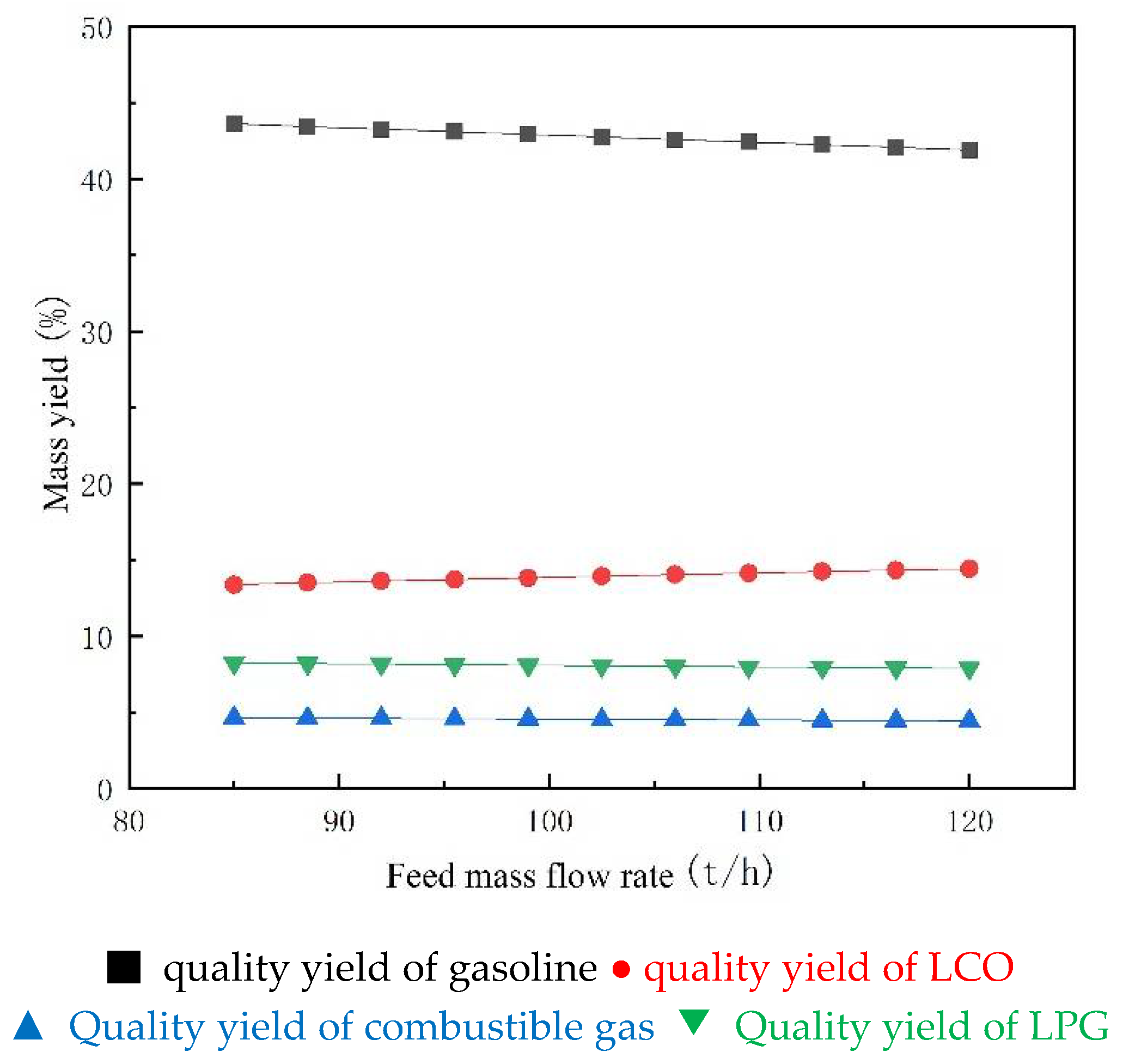

3.5. Optimization of Increasing the Capacity of the Unit

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sadeghbeigi, R. Fluid Catalytic Cracking Handbook: An Expert Guide to the Practical Operation, Design, and Optimization of FCC Units, 4th ed.; Gulf Publishing Company: Houston, TX, USA, 2020. [Google Scholar] [CrossRef]

- Marafi, A.; Albazzaz, H.; Rana, M.S. Hydroprocessing of heavy residual oil: Opportunities and challenges. Catal. Today 2019, 329, 125–134. [Google Scholar] [CrossRef]

- Survey: Global Refining Industry Competes to Supply Growing Asian Market. Oil Energy Trends 2017, 42, 10–17. [CrossRef]

- Speight, J.G. Catalytic cracking. In The Refinery of the Future, 2nd ed.; Gulf Professional Publishing: Houston, TX, USA, 2020; pp. 197–226. [Google Scholar] [CrossRef]

- Gao, J.; Xu, C.; Lu, C.; Yang, C.; Wang, G.; Lan, X.; Zhang, Y. Novel Fluid Catalytic Cracking Processes; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Fahim, M.A.; Alsahhaf, T.A.; Elkilani, A. Fluidised Catalytic Cracking. In Fundamentals of Petroleum Refining; Elsevier: Amsterdam, The Netherlands, 2010; Chapter 8; pp. 199–235. [Google Scholar] [CrossRef]

- Santos, P.; Van Gerven, T. Aspen Hysys—Unity Interconnection. An Approach for Rigorous Computer- Based Chemical Engineering Training. Comput. Aided Chem. Eng. 2020, 48, 2053–2058. [Google Scholar] [CrossRef]

- Arbel, A.; Huang, Z.; Rinard, I.H.; Shinnar, R.; Sapre, A.V. Dynamic and Control of Fluidized Catalytic Crackers. 1. Modeling of the Current Generation of FCC’s. Ind. Eng. Chem. Res. 1995, 34, 1228–1243. [Google Scholar] [CrossRef]

- McFarlane, R.; Reineman, R.; Bartee, J.; Georgakis, C. Dynamic simulator for a Model IV fluid catalytic cracking unit. Comput. Chem. Eng. 1993, 17, 275–300. [Google Scholar] [CrossRef]

- Alshamsi, A.H. Modeling and optimization of fluid catalytic cracking riser. In Proceedings of the 2013 International Conference on Industrial Engineering and Systems Management (IESM), Rabat, Morocco, 28–30 October 2013; pp. 1–5. [Google Scholar]

- Stratiev, D.; Argirov, G.; Jelyaskova, M. Effect of Lukoil Neftochim Bourgas FCC Unit Revamp to Vortex Separation System Riser on the Unit Performance. Oil Gas Eur. Mag. 2005, 121, 7–10. [Google Scholar]

- Yong, L.; Zhimin, W.; Zhipeng, Q.; Huan, W.; Huaxing, D. Study on getting high gas energy yield by biomass catalytic cracking. In Proceedings of the 2011 International Conference on Electric Information and Control Engineering, Wuhan, China, 15–17 April 2011; pp. 2675–2678. [Google Scholar] [CrossRef]

- Wallin, G.; Gilbert, L.; Zhukau, Y.; Diabat, A. A mathematical programming approach to maximizing profit in residual catalytic cracking through altering the use of the catalyst. In Proceedings of the 2013 International Conference on Industrial Engineering and Systems Management (IESM), Rabat, Morocco, 28–30 October 2013; pp. 1–5. [Google Scholar]

- Chen, J.W.; Xu, Y.H. Catalytic Cracking Process and Engineering; China Petrochemical Press: Beijing, China, 2005. [Google Scholar]

- Hamid, M.K.A. HYSYS: An Introduction to Chemical Engineering Simulation for UTM Degree++ Program. Simulation. 2007. Available online: http://eprints.utm.my/id/eprint/3030/2/HYSYS_for_UTM_Degree++_Program.pdf (accessed on 4 August 2015).

- Pashikanti, K.; Liu, Y.A. Predictive Modeling of Large-Scale Integrated Refinery Reaction and Fractionation Systems from Plant Data. Part 2: Fluid Catalytic Cracking (FCC) Process. Energy Fuels 2011, 25, 5298–5319. [Google Scholar] [CrossRef]

- AspenTech. Aspen RefSYS Option Guide; AspenTech: Cambridge, MA, USA, 2006. [Google Scholar]

- AspenTech. Aspen Plus FCC User’s Guide; AspenTech: Cambridge, MA, USA, 2006. [Google Scholar]

- Hanyak, M.E., Jr. Chemical Process Simulation and Aspen HYSYS Software; Department of Chemical Engineering, Bucknell University: Cranbury, NJ, USA, 2012. [Google Scholar]

- Iancu, M.; Agachi, P. Optimal Process Control and Operation of an Industrial Heat Integrated Fluid Catalytic Cracking Plant Using Model Predictive Control. Comput. Aided Chem. Eng. 2010, 28, 505–510. [Google Scholar] [CrossRef]

- Ahmmed, S.I.; Aref, W. HYSYS Software for Chemical and Petroleum Engineering; LAP LAMBERT Academic Publishing: Saarbrucken, Germany, 2014. [Google Scholar]

- Al-Malah, K.I. Aspen Plus: Chemical Engineering Applications; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Raseev, S. Thermal and Catalytic Processes in Petroleum Refining; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar] [CrossRef]

- Habib, E.T.; Zhao, X.; Yaluris, G.; Cheng, W.C.; Boock, L.T.; Gilson, J.P. Advances in Fluid Catalytic Cracking. In Zeolites for Cleaner Technologies; Michel, G., Jean-Pierre, G., Eds.; Imperial College Press: London, UK, 2002; Volume 3, pp. 105–130. [Google Scholar] [CrossRef]

- Chang, A.-F.; Pashikanti, K.; Liu, Y.A. Refinery Engineering: Integrated Process Modeling and Optimization. In Refinery Engineering: Integrated Process Modeling and Optimization; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Coker, A.K. Petroleum Refining Design and Applications Handbook Volume 1; Scrivener-Wiley: Beverly, MA, USA, 2018. [Google Scholar]

- Zhang, K.W.; Wang, J.J.; Yi, Y.H. Analysis of 100 Typical Faults in Catalytic Cracking; China Petrochemical Press: Beijing, China, 2020. [Google Scholar]

- John, Y.M.; Patel, R.; Mujtaba, I.M. Maximization of Gasoline in an Industrial FCC Unit. Energy Fuels 2017, 31, 5645–5661. [Google Scholar] [CrossRef]

| Product Name | Calibration Yield (%) | Simulation Yield (%) | Deviance |

|---|---|---|---|

| LPG | 22.3 | 18 | 0.19 |

| gasoline | 37.4 | 40.6 | 0.09 |

| light diesel oil | 21.3 | 23 | 0.08 |

| dry gas | 3.5 | 5.5 | 0.57 |

| slurry | 8.5 | 4.6 | 0.46 |

| Project | Unit | Design Control Scope | Simulation Value |

|---|---|---|---|

| Settler pressure | Mpa | 0.218~0.318 | 0.300 |

| Riser outlet temperature | °C | 475~535 | 518 |

| Preheating temperature of feed oil | °C | 170~240 | 175 |

| Regenerator top pressure | Mpa | 0.248~0.348 | 0.348 |

| Regeneration dense phase temperature | °C | 660~720 | 680 |

| Regenerator dense reservoir | t | 45~150 | 80 |

| Fractionator bottom temperature | °C | 320~350 | 349.8 |

| Fractionator top temperature | °C | 105~130 | 119.7 |

| Top pressure of stabilizer | Mpa | ≯1.05 | 1.17 |

| Analysis of tower top pressure | Mpa | 1.2~1.5 | 1.266 |

| Reabsorber top pressure | Mpa | 1.1~1.4 | 1.200 |

| Stabilizer bottom temperature | °C | 150~190 | 157.5 |

| Bottom temperature of analytical tower | °C | 95~135 | 115 |

| Absorber top pressure | Mpa | 1.1~1.4 | 1.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, Z.; Wang, Z.; Jin, Q. Optimization Study on Increasing Yield and Capacity of Fluid Catalytic Cracking (FCC) Units. Processes 2021, 9, 1497. https://doi.org/10.3390/pr9091497

Zhang Y, Li Z, Wang Z, Jin Q. Optimization Study on Increasing Yield and Capacity of Fluid Catalytic Cracking (FCC) Units. Processes. 2021; 9(9):1497. https://doi.org/10.3390/pr9091497

Chicago/Turabian StyleZhang, Yuming, Ziming Li, Zeyu Wang, and Qibing Jin. 2021. "Optimization Study on Increasing Yield and Capacity of Fluid Catalytic Cracking (FCC) Units" Processes 9, no. 9: 1497. https://doi.org/10.3390/pr9091497

APA StyleZhang, Y., Li, Z., Wang, Z., & Jin, Q. (2021). Optimization Study on Increasing Yield and Capacity of Fluid Catalytic Cracking (FCC) Units. Processes, 9(9), 1497. https://doi.org/10.3390/pr9091497