A 3D Food Printing Process for the New Normal Era: A Review

Abstract

:1. Introduction

2. 3D Food Printer Technology and the Trends

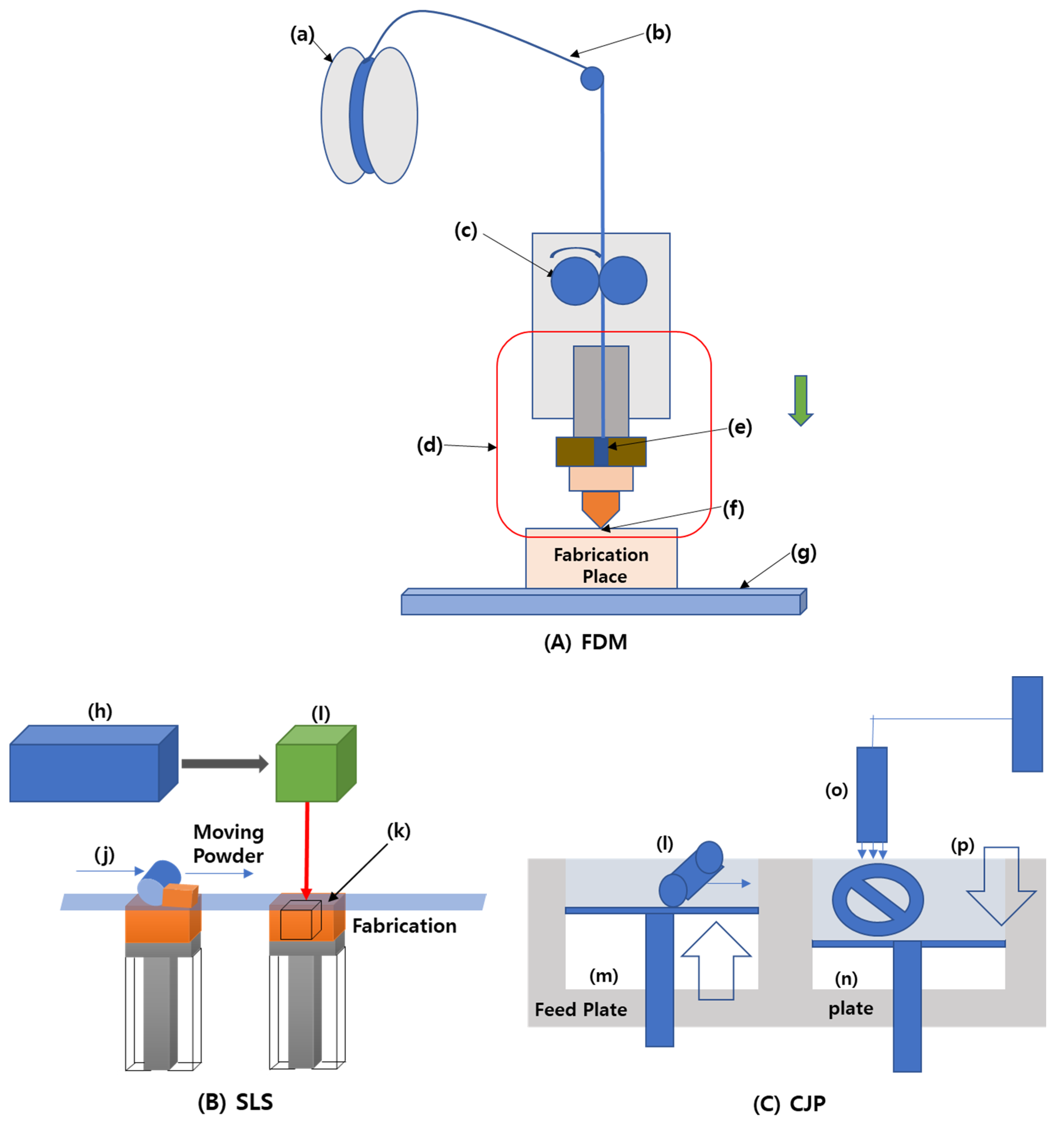

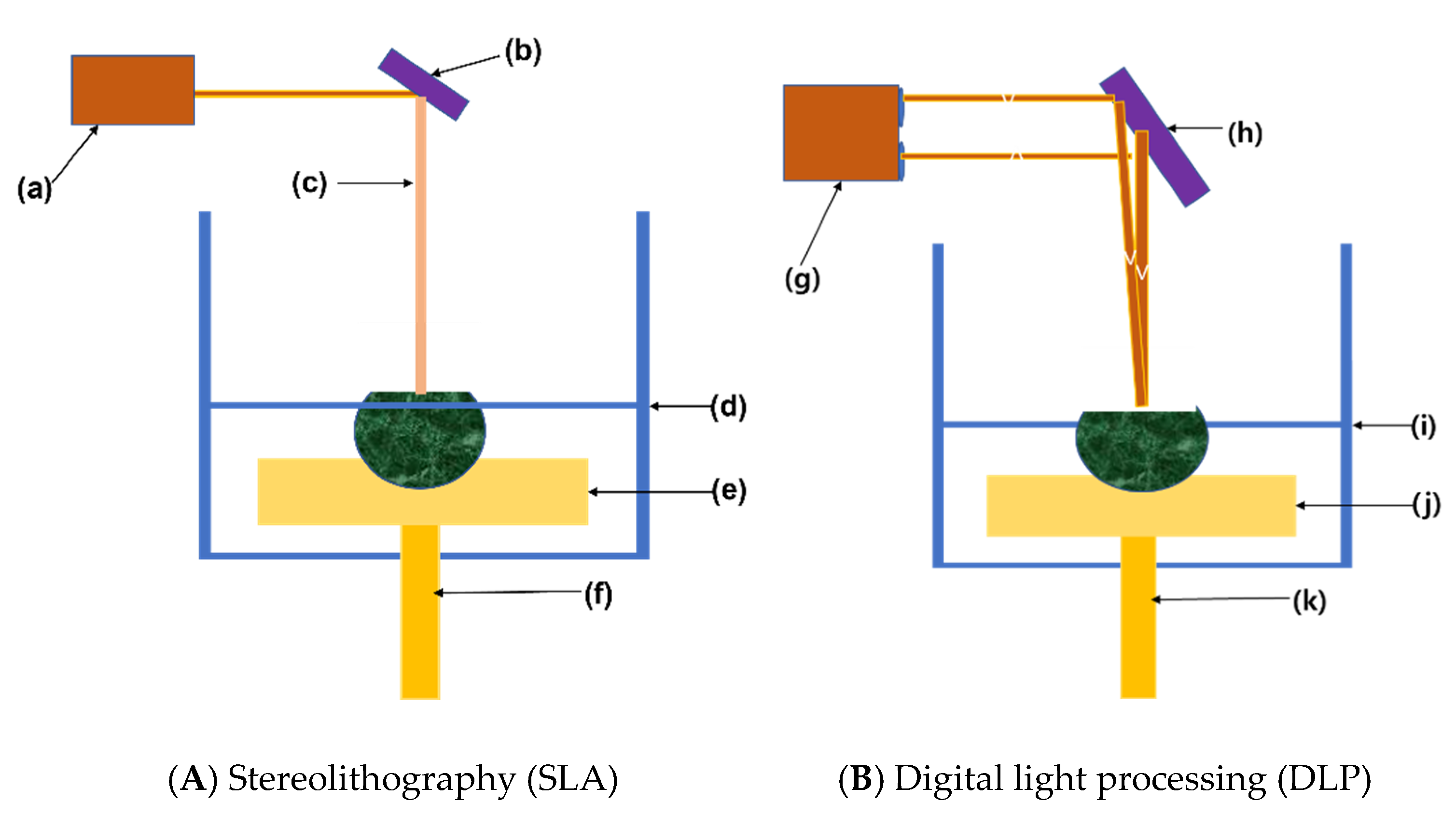

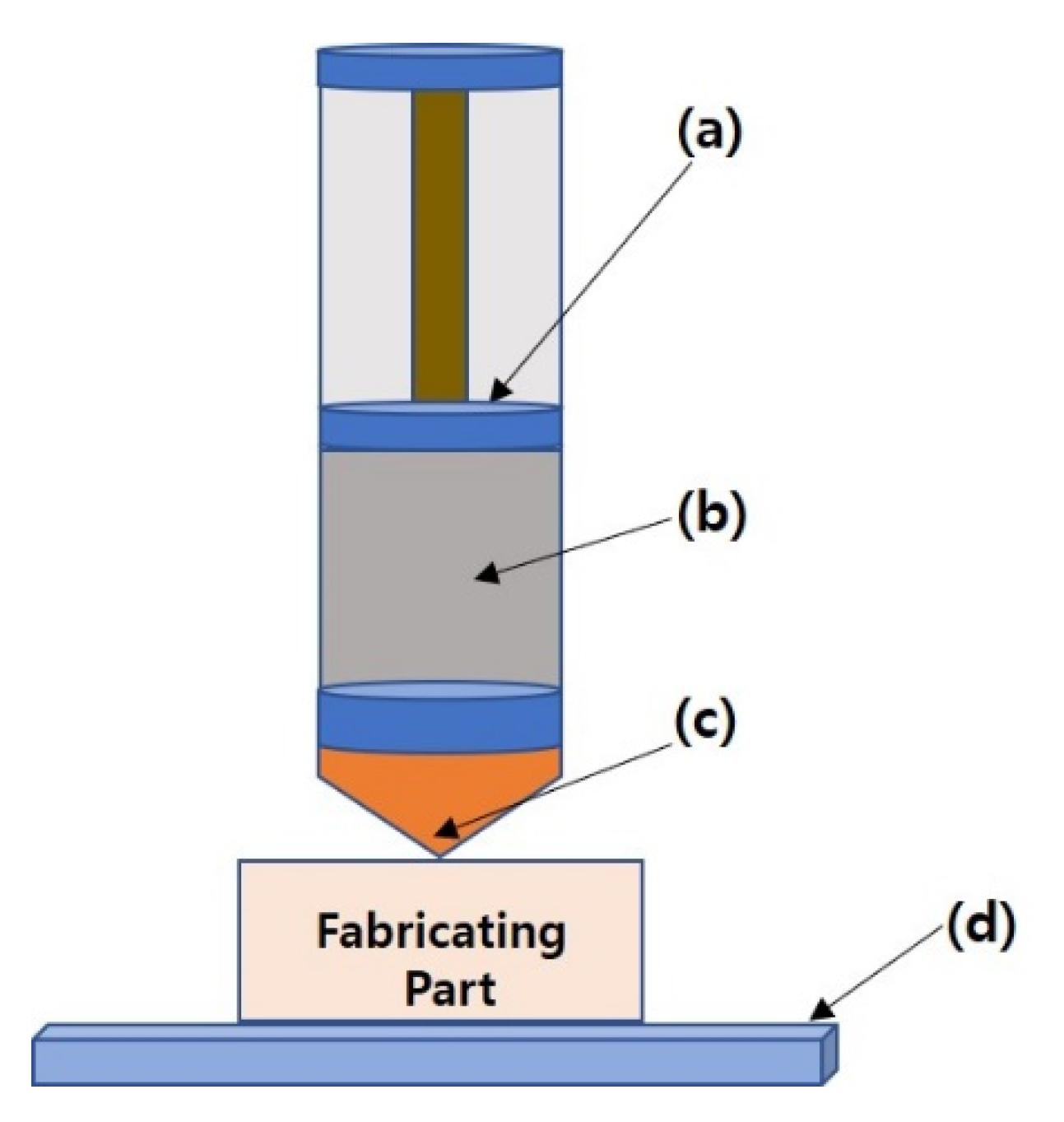

2.1. FDM, SLS, and CJP for 3D Food Printing

2.2. Selection of Edible Ingredients for 3D Food Printing

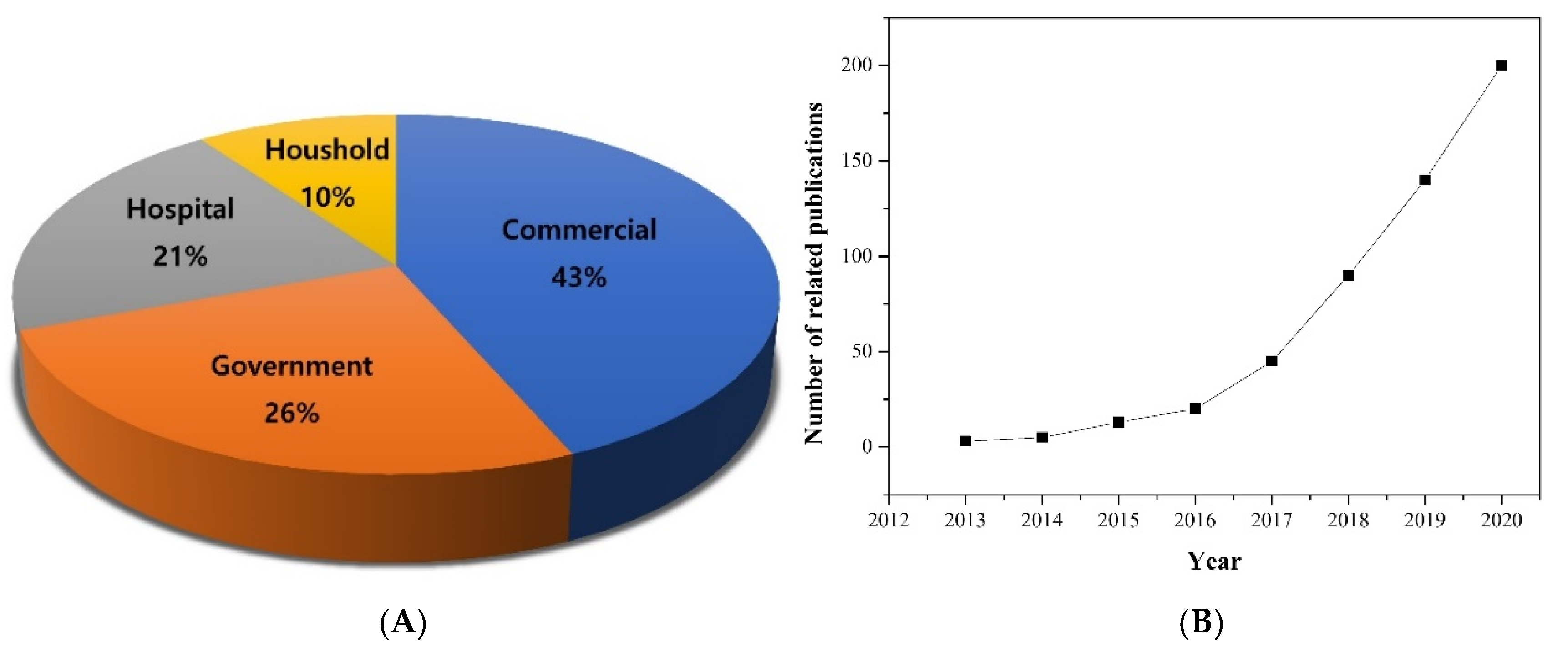

2.3. Trends in 3D Food Printers

2.4. 3D Food Printing Technology for New Normal Era

2.5. Limitations and Future Perspectives for Food 3D Printing

3. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, C.T.; Meang, J.S.; Shin, W.S.; Shim, I.C.; Oh, S.I.; Jo, Y.H.; Kim, J.H.; Kim, C.J. Food 3D-printing technology and its application in the food industry. Food Eng. Prog 2017, 21, 12–21. [Google Scholar] [CrossRef]

- Gu, Z.; Fu, J.; Lin, H.; He, Y. Development of 3D bioprinting: From printing methods to biomedical applications. Asian J. Pharm. Sci. 2020, 15, 529–557. [Google Scholar] [CrossRef]

- Kim, S.H. Technology opportunities in 3D printing. Korean Ind. Chem. News 2015, 18, 11–26. [Google Scholar]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Macko, M. AI-Optimized Technological Aspects of the Material Used in 3D Printing Processes for Selected Medical Applications. Materials 2020, 13, 5437. [Google Scholar] [CrossRef] [PubMed]

- Molteni, F.; Gasperini, G.; Cannaviello, G.; Guanziroli, E. Exoskeleton and nd-Effector Robots for Upper and Lower Limbs Rehabilitation: Narrative Review. Phys. Med. Rehabil. 2018, 10 (Suppl. S2), S174–S188. [Google Scholar]

- Palermo, A.E.; Maher, J.L.; Baunsgaard, C.B.; Nash, M.S. Clinician-Focused Overview of Bionic Exoskeleton Use After Spinal Cord Injury. Top. Spinal Cord Inj. Rehabil. 2017, 23, 234–244. [Google Scholar] [CrossRef] [PubMed]

- Torres, F.; Puente, S.; Úbeda, A. Assistance Robotics and Biosensors. Sensors 2018, 18, 3502. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, M.; Zhou, Z.; Gravish, N. Flexoskeleton Printing Enables Versatile Fabrication of Hybrid Soft and Rigid Robots. Soft Robot. 2020, 7, 770–778. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, A.; Lavranos, J.; Choong, P.; Oetomo, D. Flexo-glove: A 3D printed soft exoskeleton robotic glove for impaired hand rehabilitation and sssistance. In Proceedings of the 40th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Honolulu, HI, USA, 18–21 July 2018; pp. 2120–2123. [Google Scholar]

- Yoo, H.J.; Lee, S.; Kim, J.; Park, C.; Lee, B. Development of 3D-printed myoelectric hand orthosis for patients with spinal cord injury. J. Neuroeng. Rehabil. 2019, 16, 162. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heung, K.H.L.; Tang, Z.Q.; Ho, L.; Tung, M.; Li, Z.; Tong, R.K.Y. Design of a 3D printed soft robotic hand for stroke rehabilitation and daily activities assistance. In Proceedings of the 16th International Conference of the IEEE Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; pp. 65–70. [Google Scholar]

- Xing, F.; Xiang, Z.; Rommens, P.M.; Ritz, U. 3D Bioprinting for Vascularized Tissue-Engineered Bone Fabrication. Materials 2020, 13, 2278. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Leu, M.C.; Nakagawa, T. Progress in Additive Manufacturing and Rapid Prototyping. Ann. ClRP 1998, 47, 525–540. [Google Scholar] [CrossRef]

- Campbell, I.; Bourell, D.; Gibson, I. Additive manufacturing: Rapid prototyping comes of age. Rapid Prototyp. J. 2012, 18, 255–258. [Google Scholar] [CrossRef] [Green Version]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D printing of building a: Construction of the sustainable houses of the future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D printing of building components as the future of sustainable construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef] [Green Version]

- Park, H.J.; Kim, H.W. Global Food 3D Printing Technology and Industry Trends and Future Prospect. World Agr. 2017, 2020, 147–168. [Google Scholar]

- Lili, L.; Yuanyuan, M.; Ke, C.; Yang, Z. 3D Printing Complex Egg White Protein Objects: Properties and Optimization. Food Bioprocess Technol. 2018, 1, 1–11. [Google Scholar]

- Singh, P.; Raghav, A. 3D Food Printing: A Revolution in Food Technology. Act. Sci. Nutr. Health 2018, 2, 1–2. [Google Scholar]

- Dankar, I.; Pujola, M.; Omar, F.E.; Sepulcre, F.; Haddarah, A. Impact of Mechanical and Microstructural Properties of Potato Puree-Food Additive Complexes on Extrusion-Based 3D Printing. Food Bioprocess Technol. 2018, 1, 1–11. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Wang, Y. 3D printing: Printing precision and application in food sector. Trends Food Sci. Technol. 2017, 69, 83–94. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.J.; Kim, M.K.; You, Y.S. Food 3D Printing Technology and Food Materials of 3D Printing. Clean Technol. 2020, 26, 109–115. [Google Scholar]

- Jiménez, M.; Romero, L.; Dom-nguez, I.; del Mar Espinosa, M.; Dom-nguez, M. Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 1–30. [Google Scholar] [CrossRef] [Green Version]

- Jin, Y.A.; Li, H.; He, Y.; Fu, J.Z. Quantitative analysis of surface profile in fused deposition modelling. Addit. Manuf. 2015, 8, 142–148. [Google Scholar] [CrossRef]

- Turunen, S.M.; Melchels, F.P.W.; Kellomaki, M. A review of rapid prototyping techniques for tissue engineering purposes. Ann. Med. 2008, 40, 268–280. [Google Scholar]

- Kim, G.B.; Lee, S.; Kim, H.; Yang, D.H.; Kim, Y.H.; Kyung, Y.S.; Kim, C.S.; Choi, S.H.; Kim, J.B.; Ha, H.; et al. Three-Dimensional Printing: Basic Principles and Applications in Medicine and Radiology. Korean J. Radiol. 2016, 17, 182–197. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3d printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef] [Green Version]

- Lanaro, M.; Forrestal, D.P.; Scheurer, S.; Slinger, D.J.; Liao, S.; Powell, S.K.; Woodruff, M.A. 3D printing complex chocolate objects: Platform design, optimization, and evaluation. J. Food Eng. 2017, 215, 13–22. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Yang, C. Impact of rheological properties of mashed potatoes on 3D printing. J. Food Eng. 2018, 220, 76–82. [Google Scholar] [CrossRef] [Green Version]

- Silva, D.N.; Gerhardt de Oliveira, M.; Meurer, E.; Meurer, M.I.; Lopes da Silva, J.V.; Santa-Bárbara, A. Dimensional error in selective laser sintering and 3D-printing of models for craniomaxillary anatomy reconstruction. J. Craniomaxillofac. Surg. 2008, 36, 443–449. [Google Scholar] [CrossRef]

- Raphael, O.; Hervé, R. Clinical applications of rapid prototyping models in cranio-maxillofacial surgery. In Advanced Applications of Rapid Prototyping Technology in Modern Engineering; Hoque, M., Ed.; InTech: Rijeka, Croatia, 2011; pp. 173–206. [Google Scholar]

- Krkobabi’c, M.; Medarevi’c, D.; Peši’c, N.; Vasiljevi’c, D.; Ivkovi’c, B.; Ibri’c, S. Digital Light Processing (DLP) 3D Printing of Atomoxetine Hydrochloride Tablets Using Photoreactive Suspensions. Pharmaceutics 2020, 12, 833. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, D. Additive Manufacturing Technologies, 2nd ed.; Springer: New York, NY, USA, 2015; pp. 63–103. [Google Scholar]

- Schmidt, J.; Colombo, P. Digital light processing of ceramic components from polysiloxanes. J. Eur. Ceram. Soc. 2018, 38, 57–66. [Google Scholar] [CrossRef]

- Patel, D.K.; Sakhaei, A.H.; Layani, M.; Zhang, B.; Ge, Q.; Magdassi, S. Highly Stretchable and UV Curable Elastomers for Digital Light Processing Based 3D Printing. Adv. Mater. 2017, 29, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Choong, Y.Y.C.; Maleksaeedi, S.; Eng, H.; Su, P.C.; Wei, J. Curing characteristics of shape memory polymers in 3D projection and laser stereolithography. Virtual Phys. Prototyp. 2017, 12, 77–84. [Google Scholar] [CrossRef]

- Varghese, G.; Moral, M.; Castro-García, M.; López-López, J.J.; Marín-Rueda, J.R.; Yagüe-Alcaraz, V.; Hernández-Afonso, L.; Ruiz-Morales, J.C.; Canales-Vázquez, J. Fabrication and characterisation of ceramics via low-cost DLP 3D printing. Bol. La Soc. Esp. Ceram. Y Vidr. 2018, 57, 9–18. [Google Scholar] [CrossRef]

- Schirmeister, C.G.; Hees, T.; Licht, E.H.; Mülhaupt, R. 3D printing of high density polyethylene by fused filament fabrication. Addit. Manuf. 2019, 28, 152–159. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Bhandari, B. Recent development in 3D food printing. Crit. Rev. Food Sci. Nutr. 2017, 57, 3145–3153. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Zhou, W.; Yan, L.; Huang, D.; Lin, L. Extrusion-based food printing for digitalized food design and nutrition control. J. Food Eng. 2018, 220, 1–11. [Google Scholar] [CrossRef]

- Noort, M.W.J.; Diaz, J.V.; Van Bommel, K.J.C.; Renzetti, S.; Henket, J.; Hoppenbrouwers, M.B. Method for the Production of an EDIBLE object Using SLS. WO Patent 2016085344, 2 June 2016. [Google Scholar]

- Singhal, S.; Rasane, P.; Kaur, S.; Garba, U.; Bankar, A.; Singh, J.; Gupta, N. 3D food printing: Paving way towards novel foods. An. Acad. Bras. Cienc. 2020, 92, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Jandyal, M.; Malav, O.P.; Nitin, M.; Chatli, M.K.; Kumar, P.; Wagh, R.V.; Kour, S.; Tanwar, T. 3D Printing of Meat: A New Frontier of Food from Download to Delicious: A Review. Int. J. Curr. Microbiol. App. Sci. 2021, 10, 2095–2111. [Google Scholar]

- Sachs, E.; Cima, M.; Cornie, J. Three-dimensional printing: Rapid tooling and prototypes directly from a CAD model. CIRP Ann. Manuf. Technol. 1990, 39, 201–204. [Google Scholar] [CrossRef]

- Southerland, D.; Walters, P.; Huson, D. Edible 3D printing. In Proceedings of the 27th International Conference on Digital Printing Technologies, Minneapolis, MN, USA, 1 January 2011; pp. 819–822. [Google Scholar]

- Yang, J.; Wu, L.; Liu, J. Rapid Prototyping and Fabrication Method for 3-D Food Objects. U.S. Patent No. 6280785, 28 March 2000. [Google Scholar]

- Sun, J.; Peng, Z.; Zhou, W.; Fuh, J.Y.H.; Hong, G.S.; Chiu, A. A Review on 3D Printing for Customized Food Fabrication. Procedia Manuf. 2015, 1, 308–319. [Google Scholar] [CrossRef] [Green Version]

- Yoon, H.S.; Lee, M.; Jin, X.; Lee, S.; You, Y.S.; Rhee, J.K. 3D printing technology and its applications in the future food industry: A review. Food Sci. Ind. 2016, 12, 64–69. [Google Scholar]

- Bhandari, B.R.; Howes, T. Implication of Glass Transition for the Drying and Stability of Dried foods. J. Food Eng. 1999, 40, 71–79. [Google Scholar] [CrossRef]

- Bhandari, B.R.; Roos, Y.H. Dissolution of Sucrose crystal in the Anhydrous Sorbitol Melt. Carbohyd. Res. 2003, 338, 361–367. [Google Scholar] [CrossRef]

- Haque, M.K.; Roos, Y.H. Differences in the Physical state and Thermal Behavior of Spray-Dried and Freeze-Dried Lactose and lactose/Protein Mixtures. Innov. Food Sci. Emerg. Technol. 2006, 7, 63–73. [Google Scholar] [CrossRef]

- Roos, Y.H. Glass Transition Temperature and its Relevance in Food Processing. Annu. Rev. Food Sci. Technol. 2010, 1, 469–496. [Google Scholar] [CrossRef]

- Slade, L.; Levine, H. Water and the Glass Transition-Dependence of the Glass Transition on Composition and Chemical Structure: Special Implications for Flour Functionality in Cookie Baking. J. Food Eng. 1995, 22, 431–509. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Pandya, J.K.; McClements, D.J.; Lu, J.; Kinchla, A.J. Advancements in 3D food printing: A comprehensive overview of properties and opportunities. Crit. Rev. Food Sci. Nutr. 2021, 3, 1–18. [Google Scholar]

- Gholamipour-Shirazi, A.; Norton, I.; Mills, T. Designing hydrocolloid based food-ink formulations for extrusion 3D printing. Food Hydrocoll. 2019, 95, 161–167. [Google Scholar] [CrossRef]

- Liu, L.; Meng, Y.; Dai, X.; Chen, K.; Zhu, Y. 3D printing complex egg white protein objects: Properties and optimization. Food Bioprocess Technol. 2019, 12, 267–279. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Prakash, S.; Liu, Y. Physical properties of 3D printed baking dough as affected by different compositions. Innov. Food Sci. Emerg. Technol. 2018, 49, 202–210. [Google Scholar] [CrossRef]

- Theagarajan, R.; Moses, J.A.; Anandharamakrishnan, C. 3D extrusion printability of rice starch and optimization of process variables. Food Bioprocess Technol. 2020, 13, 1048–1062. [Google Scholar] [CrossRef]

- Xiao, J.Y.; Zhan, M.Q.; Cong, R.H.; Hua, M.H.; Ma, F.L.; Wan, Y. Study on the 3D printing formability of chocolate with Chinese medicine functional factor. Sci. Technol. Food Ind. 2019, 40, 77–82. [Google Scholar]

- Teng, X.; Zhang, M.; Bhandri, B. 3D printing of Cordyceps flower powder. J. Food Process Eng. 2019, 42, e13179. [Google Scholar] [CrossRef]

- Ramachandraiah, K. Potential Development of Sustainable 3D-Printed Meat Analogues: A Review. Sustainability 2021, 13, 938. [Google Scholar] [CrossRef]

- Dong, X.; Pan, Y.; Zhao, W.; Huang, Y.; Qu, W.; Pan, J.; Qi, H.; Prakash, S. Impact of microbial transglutaminase on 3D printing quality of Scomberomorus niphonius surimi. LWT-Food Sci. Technol. 2020, 124, 109123. [Google Scholar] [CrossRef]

- Severini, C.; Derossi, A.; Ricci, I.; Caporizzi, R.; Fiore, A. Printing a blend of fruit and vegetables. New advances on critical variables and shelf life of 3D edible objects. J. Food Eng. 2018, 220, 89–100. [Google Scholar] [CrossRef]

- Severini, C.; Azzollini, D.; Albenzio, M.; Derossi, A. On printability, quality and nutritional properties of 3D printed cereal based snacks enriched with edible insects. Food Res. Int. 2018, 106, 666–676. [Google Scholar] [CrossRef] [PubMed]

- Vakevainen, K.; Ludena-Urquizo, F.; Korkala, E.; Lapvetelainen, A.; Peraniemi, S.; von Wright, A.; Plumed-Ferrer, C. Potential of quinoa in the development of fermented spoonable vegan products. LWT-Food Sci. Technol. 2020, 120, 108912. [Google Scholar] [CrossRef]

- Vancauwenberghe, V.; Delele, M.A.; Vanbiervliet, J.; Aregawi, W.; Verboven, P.; Lammertyn, J.; Nicolaï, B. Model-based design and validation of food texture of 3D printed pectin-based food simulants. J. Food Eng. 2018, 231, 72–82. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, M.; Bhandari, B. Materials properties of printable edible inks and printing parameters optimization during 3D printing: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 3074–3081. [Google Scholar] [CrossRef]

- Liu, C.; Ho, C.; Wang, J. The development of 3D food printer for printing fibrous meat materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kuala Lumpur, Malaysia, 13–14 August 2018; Volume 284, pp. 12–19. [Google Scholar]

- Liu, Y.; Zhang, W.; Wang, K.; Bao, Y.; Mac Regenstein, J.; Zhou, P. Fabrication of gel-like emulsions with whey protein isolates using micro fluidization: Rheological properties and 3D printing performance. Food Bioprocess Technol. 2019, 12, 1967–1979. [Google Scholar] [CrossRef]

- Liu, L.; Yang, X.; Bhandari, B.; Meng, Y.; Prakash, S. Optimization of the formulation and properties of 3D-printed complex egg white protein objects. Foods 2020, 9, 164. [Google Scholar] [CrossRef] [Green Version]

- Lipton, J.I.; Cutler, M.; Nigl, F.; Cohen, D.; Lipson, H. Additive manufacturing for the food industry. Trends Food Sci. Technol. 2015, 43, 114–123. [Google Scholar] [CrossRef]

- Andrianaivo, M.R.; Graciela, W.P. Effects of Lamination and Coating with Drying Oils on Tensile and Barrier Properties of Zein Films. J. Agric. Food Chem. 2001, 49, 2860–2863. [Google Scholar]

- Pant, A.; Lee, A.; Karyappa, R.; Lee, C.; An, J.; Hashimoto, M.; Tan, U.; Wong, G.; Chua, C.; Zhang, Y. 3D food printing of fresh vegetables using food hydrocolloids for dysphagic patients. Food Hydrocoll. 2021, 114, 106546. [Google Scholar] [CrossRef]

- Puttalingamma, V. Edible Coatings of Carnauba Wax—A Novel Method for Preservation and Extending Longevity of Fruits and Vegetables A Review. Int. J. Food Saf. 2014, 16, 1–5. [Google Scholar]

- Derry, J. A Study on the Processing Methods of Shellac, and the Analysis of Selected Physical and Chemical Characteristics. Master’s Thesis, University of Oslo, Oslo, Norway, 2012. [Google Scholar]

- Shahbazi, M.; Jäger, H. Current Status in the Utilization of Biobased Polymers for 3D Printing Process: A Systematic Review of the Materials, Processes, and Challenges. ACS Appl. Bio Mater. 2021, 4, 325–369. [Google Scholar] [CrossRef]

- Péreza, B.; Nykvist, H.; Brøgger, A.F.; Larsen, M.B.; Falkeborg, M.F. Impact of macronutrients printability and 3D-printer parameters on 3D-food printing: A review. Food Chem. 2019, 287, 249–257. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Zhang, M.; Bhandari, B.; Liu, Y. Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT-Food Sci. Technol. 2018, 87, 67–76. [Google Scholar] [CrossRef] [Green Version]

- He, C.; Zhang, M.; Guo, C. 4D printing of mashed potato/purple sweet potato puree with spontaneous color change. Innov. Food. Sci. Emerg. Technol. 2020, 59, 11020. [Google Scholar] [CrossRef]

- Dankar, I.; Haddarah, A.; El Omar, F.; Sepulcre, F.; Pujolà, M. Assessing the microstructural and rheological changes induced by food additives on potato puree. Food Chem. 2018, 240, 304–313. [Google Scholar] [CrossRef] [Green Version]

- Chuanxing, F.; Qi, W.; Hui, L.; Quancheng, Z.; Wang, M. Effects of pea protein on the properties of potato starch-based 3D printing materials. Int. J. Food Eng. 2018, 14, 20170297. [Google Scholar] [CrossRef]

- Vancauwenberghe, V.; Katalagarianakis, L.; Wang, Z.; Meerts, M.; Hertog, M.; Verboven, P.; Moldenaers, P.; Hendrickx, M.E.; Lammertyn, J.; Nicolai, B. Pectin based food-ink formulations for 3-D printing of customizable porous food simulants. Innov. Food Sci. Emerg. Technol. 2017, 42, 138–150. [Google Scholar] [CrossRef]

- Derossi, A.; Caporizzi, R.; Azzollini, D.; Severini, C. Application of 3D printing for customized food. A case on the development of a fruit-based snack for children. J. Food Eng. 2017, 220, 65–75. [Google Scholar] [CrossRef]

- Lipton, J.; Arnold, D.; Nigl, F. Multi-Material Food Printing with Complex Internal Structure Suitable for Conventional Post-Processing; Solid Freeform Fabrication Symposium: Austin, TX, USA, 2010; pp. 809–815. [Google Scholar]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Kim, H.W.; Bae, H.; Park, H.J. Reprint of: Classification of the printability of selected food for 3D printing: Development of an assessment method using hydrocolloids as reference material. J. Food Eng. 2018, 220, 28–37. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.; Yang, C. Investigation on fish surimi gel as promising food material for 3D printing. J. Food Eng. 2017, 220, 101–108. [Google Scholar] [CrossRef]

- Le Tohic, C.; O’Sullivan, J.J.; Drapala, K.P.; Chartrin, V.; Chan, T.; Morrison, A.P.; Kerry, J.P.; Kelly, A.L. Effect of 3D printing on the structure and textural properties of processed cheese. J. Food Eng. 2018, 220, 56–64. [Google Scholar] [CrossRef]

- Lee, H. 3D printing technology and food industry in future. Food Preserv. Process. Ind. 2017, 16, 24–28. [Google Scholar]

- Sun, J.; Peng, Z.; Yan, L.; Fuh, J.; Hong, G.S. 3D food printing-An innovative way of mass customization in food fabrication. Int. J. Bioprint. 2015, 1, 27–38. [Google Scholar] [CrossRef]

- Li, N.; Qiao, D.; Zhao, S.; Lin, Q.; Zhang, B.; Xie, F. 3D printing to innovate biopolymer materials for demanding applications: A review. Mater. Today Chem. 2021, 20, 100459. [Google Scholar] [CrossRef]

- Weller, C.; Kleer, R.; Piller, F.T. Economic implications of 3D printing: Market structure models in light of additive manufacturing revisited. Int. J. Product. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- Van Bommel, K.; Spicer, A. Hail the snail: Hegemonic struggles in the slow food movement. Organ. Stud. 2011, 32, 1717–1744. [Google Scholar] [CrossRef] [Green Version]

- Park, M.; Lee, Y.; Kim, K.; Park, S.; Han, J. Actual Conditions of the Food industry’s Application of Food Tech and Its Tasks: Focusing on Alterative Livestock Products and 3D Food Printing; RI-879; Science Report from Korea Rural Economic Institute (KREI): Naju, Korea, 2019; pp. 61–72. [Google Scholar]

- 3D Food Printing-Golbal Market Trajectory & Analytics. Available online: https://www.researchandmarkets.com/reports/5301799 (accessed on 24 July 2021).

- Food Ink Ltd. Available online: http://foodink.io/ (accessed on 24 July 2021).

- Global Fermented Food and Ingredients Market, Emergen Research. Available online: https://www.emergenresearch.com/industry-report/fermented-food-and-ingredients-market (accessed on 24 July 2021).

- Adebiyi, J.; Obadina, A.; Adebo, O.; Kayitesi, E. Comparison of nutritional quality and sensory acceptability of biscuits obtained from native, fermented, and malted pearl millet (Pennisetum glaucum) flour. Food Chem. 2017, 232, 210–217. [Google Scholar] [CrossRef]

- Torrico, D.; Fuentes, S.; Viejo, C.; Ashman, H.; Dunshea, F. Cross-cultural effects of food product familiarity on sensory acceptability and non-invasive physiological responses of consumers. Food Res. Int. (Ottawa Ont.) 2019, 115, 439–450. [Google Scholar] [CrossRef] [PubMed]

- Tuorila, H.; Hartmann, C. Consumer responses to novel and unfamiliar foods. Curr. Opin. Food Sci. 2020, 33, 1–8. [Google Scholar] [CrossRef]

- Krishnaraj, P.; Anukiruthika, T.; Choudhary, P.; Moses, J.; Anandharamakrishnan, C. 3D extrusion printing and post-processing of fibre-rich snack from indigenous composite flour. Food Bioprocess Technol. 2019, 12, 1776–1786. [Google Scholar] [CrossRef]

- Lin, C. 3D Food Printing: A Taste of the Future. J. Food Sci. Edu. 2015, 14, 86–87. [Google Scholar] [CrossRef] [Green Version]

- Malone, E.; Lipson, H. Fab@Home: The personal desktop fabricator kit. In Proceedings of the 17th Solid Freeform Fabrication Symposium, Austin, TX, USA, 14–16 August 2006; pp. 1–14. [Google Scholar]

| Class FDA | Class IEC | Laser Product Hazard |

|---|---|---|

| I | 1, 1M |

|

| IIa, II | 2, 2M |

|

| IIIa | 3R |

|

| IIIb | 4B |

|

| IV | 4 |

|

| Printing Method | Food Material Conditions | Applied Process to 3D Printer |

|---|---|---|

| FDM | Materials that melt when heated and may come out through the nozzle and harden at room temperature. | Add thermoplastic in the form of filament by dissolving it in the nozzle. |

| CJP | Food ingredients in powder condition and food adhesives in liquid conditions that are adhesive when combined with powder. | Use inkjet method to mix the adhesive onto the plaster powder material and add it after curing it. |

| Stereolithography (SLA) | Materials in liquid conditions that can be coagulated in response to UV. | Apply ultraviolet (UV) laser to the surface of the liquid UV light-hardening resin in the shape of the layer to cure and stacking. |

| SLS | Powder-shaped materials that can be sintered or mixed with laser. | Sinter the layer of the laser into the powder material and layer it. |

| Digital Light Processing (DLP) | Materials in the resin state that can be coagulated in response to UV. | Use UV DLP to project layer image onto resin material, hardening, stacking. |

| Multi Jet Modeling (MJM) | Materials that can be sprayed with the printer head in resin state and cured by UV. | Spray resin or wax in layer shape using piezo printhead, harden with UV, and stack. |

| Nutrients | Types | Utilization | Ref. |

|---|---|---|---|

| Carbohydrates | Agar |

| [56] |

| Gelatin |

| [57] | |

| Flour |

| [58] | |

| Potato starch |

| [58] | |

| Rich starch |

| [59] | |

| Maltitol/Xylitol |

| [60] | |

| Isomaltose |

| [61] | |

| Proteins | Patty |

| [62] |

| Surimi |

| [63] | |

| Edible insects |

| [64] | |

| [65] | ||

| Bean Protein |

| [66] | |

| Pectin |

| [67] | |

| Pea protein |

| [68] | |

| Whey protein |

| [69] | |

| [70] | ||

| Egg protein |

| [71] | |

| Fat | Butter |

| [72] |

| Margarine |

| [23] | |

| Cooking oil |

| [73] | |

| Food viscosity agents | Xanthan/Arabic gum, Kappa carrageenan |

| [74] |

| Carnauba wax |

| [75] | |

| Shellac |

| [76] | |

| CMC |

| [77] |

| Nutrients | Food Materials | References |

|---|---|---|

| Carbohydrates | Lemon juice gel | [79] |

| Mashed potato | [30,80,81,82] | |

| Pectin | [83] | |

| Fruit snack | [84] | |

| Fruit and vegetable blend | [64] | |

| Smoothie | [64] | |

| Dough varying | [58] | |

| Baking cookies | [85] | |

| Skim milk powder | [86] | |

| Hydrocolloids | [87] | |

| Proteins | Turkey meat and scallop | [88] |

| Cereal dough snack with yellow mealworm powder | [65] | |

| Fish surimi gel | [89] | |

| Lipids | Bacon fat | [90] |

| Chocolate | [28] | |

| Cheese | [91] |

| Contents | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | AGR (%) (2018~2023) | |

|---|---|---|---|---|---|---|---|---|---|

| Products | Confectionary | 20.1 | 30.8 | 47.1 | 71.6 | 106.0 | 153.6 | 219.5 | 48.1 |

| Dough | 11.7 | 17.7 | 27.0 | 40.3 | 58.9 | 84.4 | 119.1 | 46.1 | |

| Dairy product | 8.8 | 13.0 | 19.4 | 28.2 | 40.3 | 56.4 | 77.8 | 43.0 | |

| Fruits and Vegetables | 5.6 | 8.3 | 12.3 | 17.8 | 25.4 | 35.3 | 48.5 | 42.5 | |

| Meat | 3.6 | 5.6 | 8.6 | 13.2 | 19.7 | 28.8 | 41.4 | 49.5 | |

| Other (Sauce, Supplements, Snacks, etc.) | 2.4 | 3.5 | 5.1 | 7.4 | 10.4 | 14.3 | 19.4 | 40.8 | |

| Total | 52.2 | 78.9 | 119.0 | 178.5 | 260.7 | 372.8 | 525.6 | 46.1 | |

| Technologies | Fused Deposition Manufacturing (FDM) | 33.4 | 50.7 | 77.5 | 116.1 | 170.4 | 245.0 | 347.4 | 47.0 |

| Selective Sintering | 10.0 | 15.0 | 22.8 | 33.9 | 49.4 | 70.6 | 99.3 | 45.9 | |

| Inkjet Printing | 6.1 | 9.1 | 13.6 | 20.0 | 28.8 | 40.5 | 56.2 | 44.0 | |

| Powder Bed Binder Jetting | 2.8 | 4.0 | 6.0 | 8.6 | 12.1 | 16.7 | 22.6 | 41.1 | |

| Total | 52.2 | 78.8 | 119.8 | 178.6 | 260.7 | 372.8 | 525.6 | 46.1 | |

| Global area | North America | 18.6 | 28.2 | 43.0 | 64.3 | 94.1 | 134.9 | 190.8 | 46.6 |

| EU | 16.7 | 24.8 | 37.1 | 54.4 | 78.1 | 109.9 | 152.4 | 43.8 | |

| Asia–Pacific | 11.0 | 17.0 | 26.3 | 40.0 | 59.5 | 86.7 | 124.6 | 49.0 | |

| Middle East, Africa, South America | 5.9 | 8.9 | 13.4 | 19.9 | 28.9 | 41.2 | 57.8 | 45.5 | |

| Total | 52.2 | 78.9 | 119.8 | 178.6 | 260.7 | 372.8 | 525.6 | 46.1 | |

| Advantages/Disadvantages | Contents | Applications |

|---|---|---|

| Advantages | Curiosity stimulation | A pancake with 3D scan of my face |

| Satisfaction of individual tastes | A healthy taste that controls a consumer’s diet | |

| Self-creation of the shape required by consumers | Chocolate made by oneself | |

| Production without food specialists | Library utilization | |

| Ease of replication | 3D pancake | |

| Growth into food for the food | Pizza for the space station | |

| Novel food to increase value | Coffee with personal bubble design | |

| New foods with increased added value | Roosevelt’s ‘Edible Grow’ | |

| Special food development | Food satisfying personal condition | |

| Disadvantages or Improvements | Contents | |

| Ensuring stability of food from the machine | ||

| Slow printing time | ||

| Energy efficiency | ||

| Intellectual property rights of modeling data | ||

| Productivity and affordability | ||

| Need for 3D modeling training | ||

| Company | Model | Food Materials | Type | The Linked Website | Product Pictures |

|---|---|---|---|---|---|

| CandyFab | CandyFab-4000 | Sugar | SLS | https://candyfab.org/ |  |

| 3D Systems | ChefJet | Chocolate, sugar, starch, protein | Binder Jetting | https://uncrate.com/chefjet-3d-printer/ |  |

| Choc Edge | Choc Creator V2.0 Plus | Chocolate | FDM | https://www.3dsystems.com/ |  |

| 3DCloud | QiaoKe | Chocolate | Extrusion | http://chocedge.com/ |  |

| Blue Rhapsody | Barilla-developed 3D pasta printer | Starch for pasta or letters | Extrusion | https://blurhapsody.com/ |  |

| Fouche Chocolates | Fouche Chocolate printer | Chocolate | Extrusion | https://www.fouche3dprinting.com/ |  |

| Nourished | Printrbot | Sugar, starch for vitamin | Extrusion | https://get-nourished.com/ |  |

| Natural machine | Foodini | Chocolate, cake | Extrusion | https://www.naturalmachines.com/ |  |

| Hershey | CocoJet 3D Printer | Hershey Chocolate | Extrusion | https://www.thehersheycompany.com/ |  |

| Katjes Magic Candy Factory | 3D Gummy Candy Printer | Candy | Extrusion | http://magiccandyfact-ory.com/ |  |

| BeeHex | Chef 3D | Pizza | Extrusion | https://www.beehex.com/ |  |

| ByFlow | Focus 3D Food Printer | Chocolate | Extrusion | https://www.3dbyflo-w.com/ |  |

| Print3Taste | Procusini 3.0 | Chocolate, jelly | Extrusion | https://www.procusin-i.com/ |  |

| WASP | Power WASP EVO | Chocolate | Extrusion | https://www.3dwasp.com/ |  |

| Zmorph | Zmorph VX | Chocolate, cake | Extrusion | https://zmorph3d.com/ |  |

| XYZ Printing | 3D Food Printer | Cookie, cake | Extrusion | https://www.xyzprinting.com/ |  |

| Open Meals | Pixel 3D Food Printer | Sushi | Extrusion | https://www.open-meals.com/ |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J. A 3D Food Printing Process for the New Normal Era: A Review. Processes 2021, 9, 1495. https://doi.org/10.3390/pr9091495

Lee J. A 3D Food Printing Process for the New Normal Era: A Review. Processes. 2021; 9(9):1495. https://doi.org/10.3390/pr9091495

Chicago/Turabian StyleLee, Jinyoung. 2021. "A 3D Food Printing Process for the New Normal Era: A Review" Processes 9, no. 9: 1495. https://doi.org/10.3390/pr9091495

APA StyleLee, J. (2021). A 3D Food Printing Process for the New Normal Era: A Review. Processes, 9(9), 1495. https://doi.org/10.3390/pr9091495