Abstract

Fertilizers are commonly used to improve the soil quality in both conventional and organic agriculture. One such fertilizer is dolomite for which soil application in granulated form is advantageous. These granules are commonly produced from ground dolomite powder in continuous pan transfer granulators. During production, the granulator’s operation parameters affect the granules’ properties and thereby also the overall performance of the fertilizer. To ensure product granules of certain specifications and an efficient overall production, process control and intensification approaches based on mathematical models can be applied. However, the latter require high-quality quantitative experimental data describing the effects of process operation parameters on the granule properties. Therefore, in this article, such data is presented for a lab-scale experimental setup. Investigations were carried out into how variations in binder spray rate, binder composition, feed powder flow rate, pan inclination angle, and angular velocity affect particle size distribution, mechanical stability, and humidity. Furthermore, in contrast to existing work samples from both, pan granules and product granules are analyzed. The influence of operation parameter variations on the differences between both, also known as trajectory separation, is described quantitatively. The results obtained indicate an increase in the average particle size with increasing binder flow rate to feed rate and increasing binder concentration and the inclination angle of the pan. Compressive strength varied significantly depending on the operating parameters. Significant differences in properties were observed for the product and the intermediate (pan) samples. In fact, for some operation parameters, e.g., binder feed rate, the magnitude of the separation effect strongly depends on the specific value of the operation parameter. The presented concise data will enable future mathematical modeling of the pan granulation process, e.g., using the framework of population balance equations.

1. Introduction

Fertilizers, plant protection products, and soil conditioners of natural origin are increasingly used in both conventional and organic agriculture. The widespread and often excessive use of fertilizers results in progressive soil acidification and consequently reduces the yield and quality of crop production. Acid rains additionally contribute to soil degradation [1,2,3]. Under these circumstances, the use of commercially available magnesium-calcium fertilizers for deacidification purposes is no longer sufficient, and enrichment with suitable trace elements is required. One such fertilizer is dolomite, which in powder form, after grinding, acts as a fertilizer providing magnesium and calcium to the soil [4,5,6]. It improves the quality of soil, especially acidic soil, and has good plant availability. The disadvantage of dolomite in powder form is the difficulty of its application. The unavoidable presence of a certain amount of dust in the mass (bed) of ground dolomite results in unintentional dispersion into the surrounding area during spreading, or any other form of soil application, which may in some cases cause specific environmental damage. An effective remedy to prevent unanticipated dusting of dolomite is granulation [4,5,7].

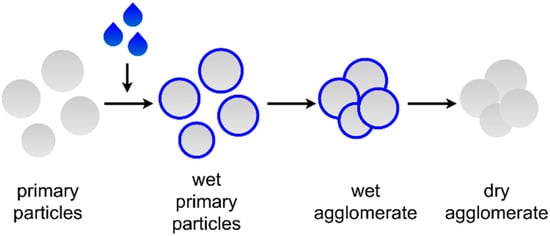

The most common focus of that process is size enlargement (see Figure 1), i.e., fusion of fine powder particles to larger agglomerates [8,9]. The main properties determined are the average granule size and the granule size distribution [10,11]. Furthermore, other properties like particle shape [12,13] and mechanical strength [14], which have direct impact on product properties [15] are of interest.

Figure 1.

Schematic representation of the formation of agglomerates.

A wide range of granulation devices are commonly found in industrial applications, including fluidized-beds, drums, extruders, and discs [9,16]. For fertilizer manufacturing, the granulation of dusty raw materials is commonly carried out by hopper mixing in pan granulators because of the technical simplicity and economic advantages of the process [12,13,17,18,19]. Here, granulated forms provide uniform composition allowing uniform supply of macro and microelements to the soil and reduction of the tendency for fertilizer aging, e.g., the tendency for phosphorus to volatilize into forms not available to plants. The biggest disadvantage of the fertilizer granulation process is increase in the cost of their manufacture, which can reach 30%. The continuous operation mode is especially promising with that respect as it enables constant throughput and product quality in terms of desired granule properties compared to batch operation [20].

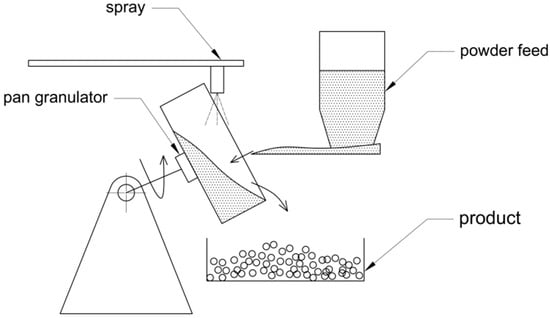

In the continuous pan transfer granulator, depicted schematically in Figure 2, the particles of powder material are set in circular motion on the rotating pan of the device. During the granulation process, a binding liquid (binder) is distributed, e.g., by spraying, onto the material. As a result of wetting and continually repeated contact and separation, the granulated material builds up. Initially, agglomerates of small size and loose structure are formed. These agglomerates form the nucleus of the granules themselves. In the course of time, the seed particles are repeatedly covered by successive layers of moistened material particles during the pan circular motion. This leads to a gradual increase in the size of the granules until they reach the desired size and mechanical properties [21,22].

Figure 2.

Schematic representation of the pan granulation process.

An efficient and economical operation of granulation requires the use of suitable binders, i.e., agents that bind solid phase particles into agglomerates. They are usually solid substances with a strongly developed surface which gives a high surface energy [23]. Lignin binders, containing sodium and calcium lignosulfonates are widely applied to make full utilization of the properties of dolomite in soil. Calcium lignosulfonate was proved to provide the best granulation conditions for dolomite granulation while sodium lignosulfonate provided the best conditions for limestone meal [24,25,26].

In general, the mechanical strength of the wet granulation product, which is a crucial parameter for the fertilizer in practice, depends on at least three types of force—intergrain friction, surface tension, and capillary forces associated with the presence of liquids, which are predominant in static systems, and viscous forces associated with the presence of liquids, mainly active in dynamic systems [27]. In a number of experimental studies, attempts have been made to determine the influence of individual physicochemical parameters and process conditions on the granulate properties [14,16,28,29,30,31,32], including angle of repose, bulk density, compressive strength, and humidity. Angle of repose determines material flowability, which is an important property influencing processing, storage, and conveying of particular materials [33]. Materials with low angle of repose are highly flowable and can be transported using gravitational force or little energy [34]. Physically, the angle of repose can be defined as the angle that differentiates the transitions between phases of the granular material [35]. It is the steepest slope of the unconfined material and is measured from the horizontal plane on which the material can be heaped without collapsing [36]. Bulk density is of importance for economical and functional reasons. High bulk density is desirable for reducing shipping and packaging costs. On the other hand, low bulk density, influences other properties, such as flowability [37]. Another important parameter of granules is their compressive strength [15,38,39,40]. It is an indicator of the ability to resist the external forces acting on the granules and one of the most important criteria for evaluating fertilizer quality. A generally accepted measure of the compressive strength is the force required to crush the granule. Humidity is a particularly important property for the formation of new and durable agglomerates. Humidity of the granules affects their dynamic mechanical strength and product durability [28].

An additional advantageous and representative feature of pan granulation is the simultaneous classification of the granular material in terms of size, i.e., separation of its components caused by the difference in their size and density [41,42]. In the case of pan granulators, it is called trajectory segregation, where larger particles (with higher kinetic energy) travel further than smaller ones. As a result of this type of segregation, granules with smaller mass, and therefore smaller dimensions, move along tracks with smaller radius (closer to the axis of the machine), while larger granules, which are affected by a higher centrifugal force, are thrown towards the circumference of the granulator. Due to the occurrence of the so-called trajectory segregation, an intermediate product, termed a pan sample, is formed which can be acquired directly from the granulator pan. Larger granules, which are subjected to greater centrifugal force, are thrown outside, and form the granulation product.

As mentioned above, continuous operation is favored over batch as it enables constant product yield and quality. However, in practice variations in the raw materials’ properties and environmental conditions may affect the granulation and thereby the granules’ properties in an unfavorable manner. To prevent resulting deviations from the desired product granule properties, e.g., a specific characteristic size range of the particles, automatic feedback control can be applied. Here, depending on the current state of the product granules, process operation parameters are automatically adjusted to fulfill the desired specifications. Such approaches can also guarantee efficient change of the operation point, i.e., a change of product specifications, in the running process. Mostly, those methods are based on mathematical models of the underlying granulation process which can also be used to design process intensification schemes for more efficient and sustainable plant operation. In general, model development is challenging, particularly in view of the complex interaction mechanisms between granules. Besides lumped modeling approaches which only account for average product properties and complex DEM approaches, population balance modeling has been established as a meso-scale modelling method for this type of particle formation process. Here, dynamics are described in terms of the number density distribution function of particles with respect to particle properties which is affected by particle formation processes like growth, agglomeration, breakage, and nucleation which depend on the process operation parameters. The specific mechanisms of those are not known beforehand and as their first-principle modeling is generally too complex, they are commonly identified based on experimental data for varying process operation parameters. While many references discuss the properties of the product granules and how they are affected by operation conditions, there is a lack of references with respect to their effects on the trajectory separation. However, for the future design of a meaningful and predictive model, both effects must be analyzed from quantitative data.

Therefore, the aim of this manuscript is to present and analyze a consistent and sound data set for the development of advanced models, e.g., population balance models [8,9,43,44,45], for continuous hopper transfer pan granulation of dolomite powder analogous to investigations presented in Strenzke et al. [10] and Otto et al. [43] for fluidized bed agglomeration. Focus is on description of effects of variation of inclination angle, angular velocity, binder spray rate and composition, and feed powder flow rate on particle size distribution (PSD), angle of repose, bulk density, humidity, and compressive strength. Furthermore, these data are presented for both, intermediate and final products. Thereby, the effects of the operation parameters on the trajectory separation can be inferred. Furthermore, the corresponding separation function, characterizing the differences between both, which also depends on the operation parameters and is crucial for future model development, can be determined.

The manuscript is structured as follows: In the next section, the experimental plant, raw materials, and analytical methods are described along with the experimental plan. The subsequent section contains presentation of the obtained results as well as their discussion and interpretation. In the last section, the results are summarized, and an outlook is given for possible future research.

2. Materials and Methods

2.1. Raw Materials

The particle material was powdered dolomite. Dolomite was selected because of its wide industrial application (mainly as construction material and fertilizers) and cheap acquisition costs. The material studied came from the Devonian dolomites quarry for aggregate production, located in the Świętokrzyskie region. The binder solution contained 2.5–10 wt% sodium lignosulfonate and 97.5–90 wt% of water. Sodium lignosulfonate is a water-soluble anionic polyelectrolyte polymer produced from waste compounds from paper manufacturing. Lignosulfonates are characterized by a wide range of applications utilizing their binding, lubricating, dispersing, and emulsifying properties.

2.2. Lab-Scale Pan Granulation System

The experiment was realized in a pilot-scale pan granulator shown in Figure 2. The pan has an inner diameter of 400 mm, and depth of 100 mm, schematically shown in Figure 3. The particles were placed in a tank and then, using vibratory conveyor, transported into the pan. The primary particles were sprayed by a nozzle which was installed in a top-spray configuration at a distance of 350 mm above the pan of the granulator. An external pump and air compressor supplied the feeding of the sprayed binder solution. The pan was set into rotary motion by a motor (Model AR304, ERWEKA GmbH), with the rotational velocity and pan inclination angle being adjustable in ranges of 2–80 rpm and 0–70 deg, respectively. The device is designed for continuous operation. It has a hopper for powder material with a vibrating motor for removing overhangs and blockages. The powder material is fed by a vibrating conveyor. The flow rate is adjustable in the range 0–250 g/min. The machine is equipped with replaceable binder hoppers. The binder flow, the powder flow, and the air flow were controlled with a main control panel (Model CE255, G.U.N.T. Gerätebau GmbH). All components of experimental setup were made of stainless steel and assembled on a metal table.

Figure 3.

Pilot-scale pan granulator used for the experiments.

2.3. Analytical Methods

The pan samples (intermediate product) and product samples were analyzed offline. The PSD of each sample was measured offline with a Mastersizer (Malvern Instruments, Malvern, Worcestershire, UK), which infers particle size via dynamic light scattering [11]. The output data from the analyzer is PSDs, normalized with respect to the volume of the particle collective for each sample. For granules larger than 2 mm, the sieve analysis method was additionally applied and compiled with the results from Mastersizer. Additionally the median diameter D(0.5) and the Sauter diameter D(3.2) were determined.

Angle of repose and bulk density were measured used Powder Tester PT-S (Hosokawa Micron B.V., Doetinchem, The Netherlands) as described in detail in [33,34,35,36]. The bulk density was determined by measuring the mass of bulk solid that occupied a unit volume of a bed, including the volume of all interparticle voids [37].

The compressive strength [15,38,39,40] was measured using a C9B load cell force tester from HBM (Hottinger Baldwin Messtechnik GmbH, Darmstadt, Germany), with a range up to 200 N. The sensor was coupled to a SPIDER 8 amplifier (HBM) interfacing with a computer. The measurement results were recorded by Catman Easy 2.1 software, which reads the force values indicated by the sensor at a frequency of 50 Hz.

The humidity was determined using a RADWAG MA.R laboratory moisture analyzer (Radom, Poland) in 110 °C. Humidity measurements were carried out until a constant weight of the material was obtained at a given temperature [28].

2.4. Experimental Plan and Sample Collection

In this work, the investigated parameters were powder flow rate, binder flow rate, inclination angle of the pan (IA), rotation speed of the pan (RS), and binder concentration in water solution, which resulted in a total of eleven experiments. Each experiment was carried out with the same initial bed mass and the same PSD of primary particles. Dolomite was used as nuclei particles and feeding material. The injected binder solution was a mixture of water and sodium lignosulfonate as binder.

The work started with some preliminary granulation tests and parameter selection for a reference sample. The used binder solution contained 2.5–10 wt% sodium lignosulfonate and 90–97.5 wt% of water. The feed flow was varied from 40 to 80 g/min, and binder flow from 10 to 20 g/min. The IA varied from 20 to 40 deg and the RS from 25 to 35 rpm. The initial bed mass for the experiment was 200 g. The nozzle air flow pressure was 2 bar. An overview of the operation parameters is shown in Table 1 (see nomenclature for further details). It is seen that the parameters were varied “one-at-a-time”, i.e., for investigation of each parameter, two additional experiments were conducted, one with a higher and one with lower value compared to the REF experiment, while the other parameters remained unchanged in the reference configuration. The REF was chosen as a central experiment for the five parameter variations.

Table 1.

Experimental plan for the variation of the operation parameters (varied parameters indicated bold).

The first experiment was conducted in continuous mode using the parameters shown in Table 1 for the REF sample. Once a steady state was established, operation parameters were changed to the next setting as reported in Table 1 and the process was continued until the subsequent steady state was attained. Thereby, a total number of eleven experiments were conducted in a row. Steady states were determined by measuring the mass flow rate of the product and comparing it to the constant raw material flow rate in each experiment. When the raw material flow rate was equal to the product flow rate, a sample was taken and the granule size distribution was examined. The tests were repeated for subsequent samples taken and it was assumed that steady state was reached when two consecutive samples showed the same granule size distribution. The corresponding steady state sampling times are reported in Table 1. However, it must be emphasized that those sample times can hardly be compared to each other as the experiments for different operation parameter settings were run subsequently in the same order as provided in the table. To be comparable, each experiment would have to be started from the same initial condition, e.g., the reference experiment REF, with sampling after the corresponding steady-states were reached.

All abbreviations used are reported in the nomenclature.

In each experiment, the pan and product samples were taken systematically. The pan samples were taken manually, directly from the pan. The first parameter measured was the humidity of the product and pan samples. The samples had to be analyzed as soon as possible to avoid moisture loss, which might affect the accuracy of the measurements. The granules were then dried at 40 °C for 48 h to obtain the moisture content of 1–2%. The properties of the dried granules were then studied. The PSD of the granules was determined first, followed by the measurements of angle of repose and bulk density. The last parameter determined was the compressive strength of the granules.

3. Results and Discussion

First, the reference experiment (REF) is discussed in detail. Then, each investigated process operation parameter is discussed individually and results are compared to the reference experiment. For the comparison, the focus is on the following granule properties: PSD, D(0.5) diameter, D(3.2) diameter, angle of repose, aerated bulk density, humidity, and mechanical strength.

Qualitative results for the particle properties were not surprising, as the general effects of parameter changes have already been described more generally in the literature (see [7,9]). However, in this manuscript, to the best of the authors’ knowledge, the differences between intermediate and final product have been analyzed quantitatively for the first time.

3.1. Reference Experiment

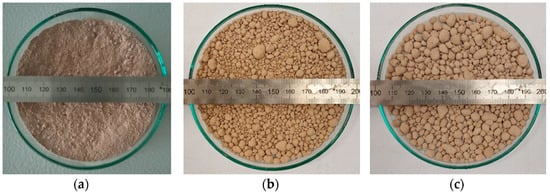

As mentioned above, the reference experiment (REF) was chosen as a central experiment for the seven parameter variations of the two series (see Table 1). It was conducted at temperature of 90 °C with a nuclei feed rate of 60 g/min and an average binder rate of 15 g/min. This reference ratio between binder and nuclei feed ensured appropriate humidity of the primary particles and agglomerates. At the beginning of the experiment, the initial mass of the loaded material was 200 g. The IA was 30 deg, the RS 30 rpm, and the used binder solution contained 5 wt% sodium lignosulfonate and 95 wt% of water. The nozzle air flow pressure was 2 bar. The obtained granulation product is shown in Figure 4. The selection of the parameters for the reference sample was based on several preliminary granulation tests.

Figure 4.

Raw material (a) pan (b) and product (c) samples of the granulation.

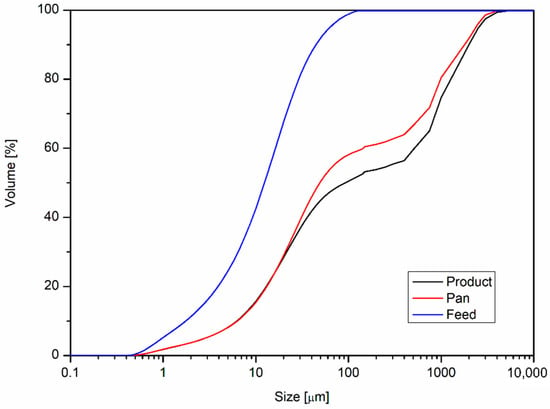

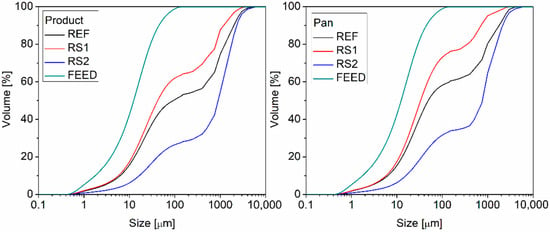

Figure 5 shows PSD for the product and pan samples used in REF. It can be seen that the product samples have a higher contribution of larger particle sizes, especially for sizes above 20 µm. Under the centrifugal force of the granulator pan, the heavier particles with larger sizes were pushed outside the plate, while the lighter smaller particles still remained inside the pan.

Figure 5.

PSD for product, feed, and pan samples of the reference experiment.

For all experimental cases, differences were observed between the product and pan samples indicating the simultaneous segregation and classification in the course of the process. Considering the nature of running a disc granulation process using rotary motion, this is a situation that was to be expected—larger granules with higher weight under the influence of centrifugal force get out of the granulator faster, whereas smaller granules remain inside the granulator longer. Since the process was carried out continuously, raw material was continuously fed into the granulator plate, which resulted in an excess of un-granulated material in the pan samples in each case. The results obtained may be useful in selecting process conditions suitable for formation of specific grain sizes.

3.2. Effects of Process Operation Parameters on Characteristic PSDs

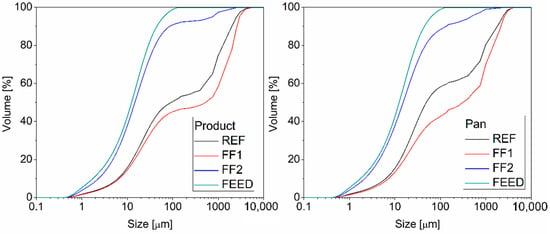

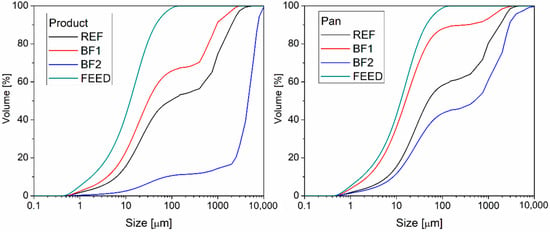

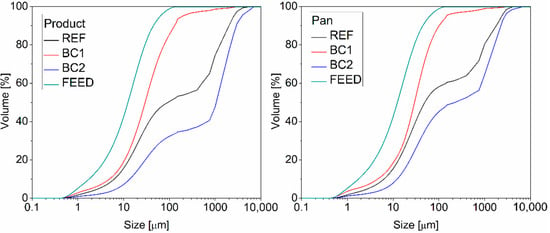

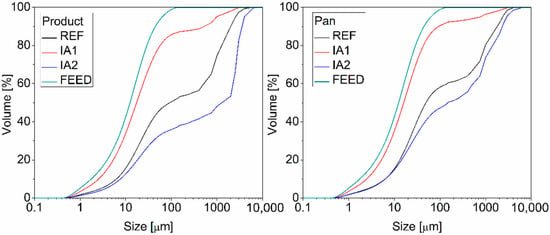

In the first step, the effect of the process parameters on PSD was analyzed for each of the product and pan samples. The results are presented as cumulative size distribution curves with respect to mass (Figure 6, Figure 7, Figure 8, Figure 9 and Figure 10). A curve for the powder material was included on each graph to facilitate interpretation. The effect of each process parameter on PSD was analyzed for three cases including a reference case with averaged parameters with respect to other samples.

Figure 6.

Influence of the feed flow on PSD of product and pan samples of the granulation.

Figure 7.

Influence of the binder flow on PSD of product and pan samples of the granulation.

Figure 8.

Influence of the binder content on PSD of product and pan samples of the granulation.

Figure 9.

Influence of IA on PSD of product and pan samples of the granulation.

Figure 10.

Influence of the RS of the pan on PSD of product samples of pan granulation.

The each of the changed process parameters affected the PSD. The greatest effect was observed by changing the binder flow rate (Figure 7). The higher the binder flow rate, the larger the granules obtained for both product and pan samples. The higher the powder flow rate, the smaller the granules obtained. The granule size can therefore be determined by the mass flow ratio of binder liquid to raw material feed. The larger this ratio, the larger the granules. In the case of samples with lower ratios, a higher proportion of un-granulated material was observed, higher for the pan samples than the product samples.

The granule size distribution changed regularly with the change in the binder concentration. The higher the binder concentration, the larger the size of granules. The changes were particularly noticeable for the product samples. Increasing the binder concentration can be an alternative to increase in the binder flow rate or decrease in the raw material feed rate.

Regular changes in PSD were also observed when the IA was changed. The greater the IA of the granulator pan, the larger the granules obtained. The change in IA affected the residence time of the granules in the pan—a larger IA with respect to vertical axis induced a longer residence time. The nuclei formed by a combination of capillary adhesion forces and viscous forces due to the presence of a binder can attach a higher number of powder particles by staying longer in the granulator, resulting in larger granule sizes. Increase in IA also extends the distance that the granules cover inside the granulator, which also enhances attachment of powder particles and results in increase the size.

Significant changes in PSD were also observed for the samples for which the RS was changed. The higher RS, the larger the granules obtained. This may have been due to the elongation of the distance to be covered by the granules in the pan. Increase in RS causes the granules under the influence of inertia forces to move higher inside the granulator, and thus they are in contact with a larger number of raw material particles and can form permanent bonds with them.

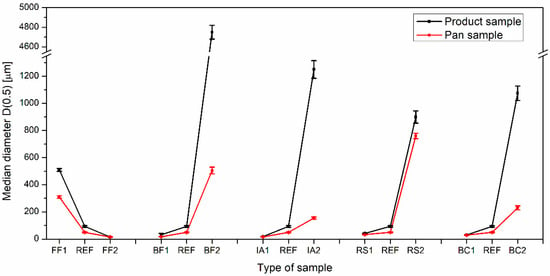

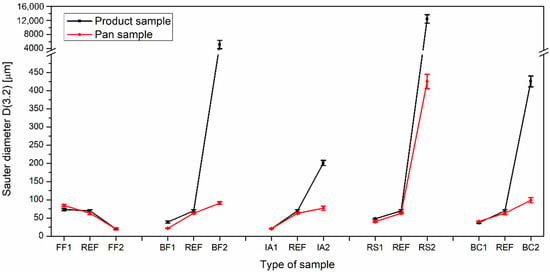

Figure 11 and Figure 12 illustrate the effect of process conditions on D(0.5) of the products. Significant changes were observed for each of the analyzed parameters. For all cases, D(0.5) of the product samples were larger compared with the pan samples. The most pronounced differences were observed when binder flow rate was changed. The higher the binder flow rate, the larger the granules obtained. For the sample BF2, the largest differences were observed between the product and pan samples, which indicated that higher binder flow rates have a beneficial effect on D(0.5). The changes in raw material flow rate had the smallest impact D(0.5).

Figure 11.

Influence of the operating parameters on the D(0.5) diameter.

Figure 12.

Influence of the operating parameters on the D(3.2) diameter.

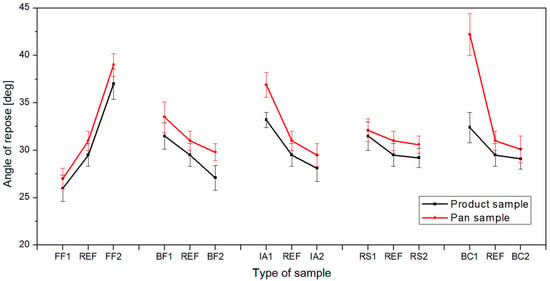

3.3. Effects of the Operation Parameters on Angle of Repose

For all cases, larger values of angle of repose were observed for the pan samples than for the product samples (Figure 13). The product samples contained higher amounts of granules with a regular shape. When the grains are smooth and rounded, the angle of repose is low. The highest values of angle of repose, and thus the worst flowability, were exhibited by the pan samples of BC1 with the lowest binder concentration and FF2 with the highest raw material flow rate. Both samples contained significant amounts of un-granulated material. The FF1 sample with the lowest raw material flow rate showed the lowest angle of repose value. It can be concluded that the higher number of granules with larger diameters, the smaller angle of repose, and thus the better flowability of the material. The lower the raw material flow rate, the higher the binder flow rate, the higher inclination angle of the granulator plate, the higher the binder concentration, and the lower the angle of repose value. In the case of rotational speed, the changes were the least significant for the investigated parameter variations.

Figure 13.

Influence of the operating parameters on angle of repose.

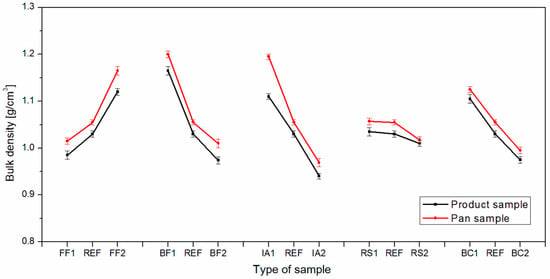

3.4. Effects of the Process Operation Parameters on Bulk Density

As in case of angle of repose, higher bulk density values were observed for the pan samples than for the product, as pan samples contained more ungranulated raw material. The samples with the lowest ratio of binder flow rate to raw material flow rate, i.e., FF2 and BF1, had the highest bulk density. They contained the most powder material with a small size. Small raw material particles can fill free space between the granules, and thus increase bulk density and impair flowability of the material. The higher the value of the bulk density, the higher the raw material flow rate, the lower the binder flow rate, the smaller AI of the granulator plate, and the lower the binder concentration. As in case of angle of repose, changes in RS were the least significant for the investigated samples.

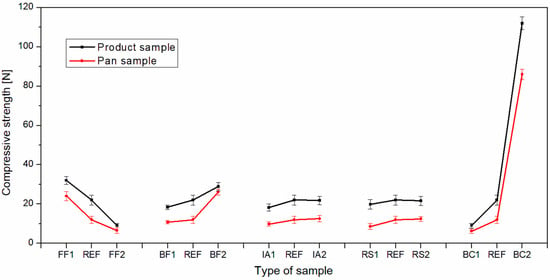

3.5. Effects of the Operation Parameters on Compressive Strength

The compressive strength varied significantly depending on the operating parameters. A correlation between particle size and compressive strength was observed. Larger granules had higher compressive strength. This trend was observed for all cases; higher compressive strength was observed for the product samples than for the pan samples. The BC2 sample with the highest binder concentration had the highest compressive strength. In this case, the viscous forces from the binder were so high that the compressive strength was over 110 N. In addition, the samples with higher binder to raw material flow ratio (FF1, BF2) were characterized by higher compressive strengths. Changes in the AI of the granulator plate and the RS do not significantly affect the compressive strength. Samples FF2 and BF1 showed the lowest strength values, unacceptable for use as granular fertilizer.

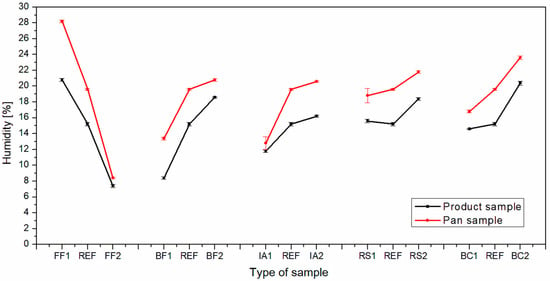

3.6. Effects of Process Operation Parameters on Humidity

The results obtained revealed an increase in D(0.5) with increasing moisture content. The samples with the highest moisture content also showed the highest value of compressive strength. Samples with the highest moisture content had a lower bulk density value, which seems to be the opposite to the expected result. However, it should be considered that the bulk density value was also affected by the presence of a large amount of un-granulated raw material, and in the case of samples with a high moisture content a predominance of granules with a size larger than the powdered raw material was observed. The higher the moisture content, the lower angle of repose; that conclusion may also contradict the general trend of increasing the value of angle of repose with increasing moisture content, and thus the cohesion of the powder materials.

An increase in moisture content resulted in more durable granules with regular shapes. The process of granule growth prevailed over granule disintegration. The obtained granules were characterized by a regular spherical shape, which facilitated the movement of granules in relation to each other and thus reduced the value of angle of repose (improved flowability). The higher the ratio of binder flow rate to raw material, the higher the IA of the granulator (higher residence time in the granulator), the higher the RS and the higher the binder concentration, the higher the material moisture content. A higher moisture content was observed for the pan samples, which can be related to the higher residence time of the particles in the granulator. Another reason may be the fact that in the pan, smaller and wetter particles had a higher density and segregated to the bottom of the pan. Those particles were not observed in such quantities in the product.

3.7. Effects of Process Operation Parameters on Trajectory Separation

It was shown that trajectory separation did not only affect the mean value of the corresponding product particle size distribution but also its shape in comparison to the pan particles (e.g., influence of binder flow, Figure 7, BF2). Furthermore, for some parameters, differences between intermediate and final product strongly depended on the parameter values. For D(0.5) and D(3.2) and higher values for the binder feed (Figure 11 and Figure 12, BF2) and the binder content (Figure 11 and Figure 12, BC2), a significant difference between pan and product samples was observed, while this feature only weakly manifested for lower parameter values (Figure 11 and Figure 12, BF1/REF/BC1). In contrast, changes in feed-flow did not have a strong effect on the trajectory separation.

For angle of repose, significant differences between pan and product samples were observed for low binder content (Figure 13, BC1). In contrast, for higher binder content (Figure 13, BC2/REF) differences were small. A similar observation was also made for changes in the other operation parameters, for which changes between pan and product were about the same for all experimental settings. Thus, it can be stated that those parameters did not have a significant effect on the trajectory separation.

From the results displayed in Figure 14, a similar behavior was observed for bulk density. The effects of the operation parameter levels were not as pronounced as for particle size. Only for lower values of the inclination angle (IA1) was there a stronger difference between pan and product samples. In contrast, other parameters did not have significant effects on the trajectory separation.

Figure 14.

Influence of the operating parameters on bulk density.

For compressive strength (Figure 15), feed flow rate, binder feed rate, and binder content showed mild effects on the separation, while inclination angle and rotational speed had no significant effects.

Figure 15.

Influence of the operating parameters on compressive strength.

For particle humidity (Figure 16), binder feed, rotational speed, and binder content levels do not significantly affect the trajectory separation. In contrast, different feed flow rates and angles of inclination had mild effects on the trajectory separation.

Figure 16.

Influence of the operating parameters on the humidity.

4. Discussion

As expected, a significant effect of the process parameters on the measured granule properties was observed. The results indicate an increase in the average particle size with increasing binder flow rate to feed rate ratio, increasing binder concentration, and inclination angle of the pan. Compressive strength varied significantly depending on the operating parameters. A relationship between particle size and compressive strength was observed—larger granules were characterized by higher compressive strength. Based on the research, several conditions must be met to produce large particles with lower shear strength. One should strive to reduce the mass accumulated in the pan (e.g., by changing the inclination angle of the pan) causing less mass pressure on the newly formed granules, which increases their porosity and consequently reduces their compressive strength. At the same time, one should aim to increase the amount of binder or its concentration so that the tendency of the granules to grow is maintained. Thus, production of large particles with smaller compressive strength is possible via smaller amounts of binder liquid. The samples with the lowest ratio of binder flow rate to raw material flow rate had the highest bulk density.

Furthermore, significant effects of the operation parameters on the trajectory separation were observed—larger values of angle of repose were observed for the pan samples than for product samples. The product samples contained a higher number of larger granules with a regular shape. When the granules were smooth and rounded, the angle of repose was low. The highest values of angle of repose, and thus the worst flowability, were exhibited by the pan samples with the lowest binder concentration and with the highest raw material flow rate. As in case of angle of repose, higher bulk density values were observed for the pan samples than for the product samples, since the pan samples contained higher amount of un-granulated raw material.

It was shown that some operation parameters had stronger effects on the trajectory separation, i.e., the difference between intermediate and final product granules, than other ones. In particular, for average particle size and variations of the binder feed or rotational velocity, higher values resulted in a much more distinct separation than lower values. In contrast, for bulk density, parameter variations did not significantly affect the degree of separation.

From the points discussed above, it can be deducted that during continuous operation, measurement of pan granules in addition to product granules may be advantageous as it allows direct monitoring and control of the actual manufacturing process. In contrast, measurement of product granules alone may, on the one hand, give information on the properties of the product granule, but, on the other, only limited information on the manufacturing process as the operation parameters affect the granule properties not only directly but also indirectly via the trajectory separation.

5. Conclusions and Outlook

In this study the influence of different operation conditions on the process behavior and properties of the produced granules for hopper pan transfer granulation was investigated. The specific aim was to provide a concise set of experimental data for subsequent formulation of mathematical models, e.g., population balance models. Here, focus was on the analysis of effects not only on granule size distribution, but also on humidity, angle of repose, bulk density, and compressive strength. Moreover, the influence of the operation parameters on the trajectory separation were investigated.

It was observed that during continuous process operation the operation parameters affected the properties of the product granules not only directly but also indirectly via the trajectory separation. Therefore, it can be concluded that simultaneous measurement of intermediate and product granules may be advantageous for improved control of the process.

So far, only the effects of single parameter variations have been researched. It is commonly assumed that variations of multiple parameters result in a simple overlay or superposition of one-parameter-variation effects. However, in general, when more than one parameter is changed, additional combined effects may be observed. Such effects need to be analyzed quantitatively in future experimental studies.

Furthermore, currently focus is on steady-state operation, as it simplifies analysis of the effects of operation parameter variations. In the case of transient non-steady-state operation, additional effects, e.g., changing total number of particles or total particle surface area, may affect the process which makes analysis of separate parameter changes difficult. In fact, for a full mathematical model, also those dynamic effects need to be taken into account, requiring additional experimental work in the future. However, in practice, focus is on steady-state continuous operation with constant product particle properties and rarely on transient operation. Thus, mathematical models for the steady-state process are valuable tools for model-based process intensification and control.

Therefore, the experimental data presented in this manuscript represents a sound basis for subsequent mathematical modeling approaches, e.g., using population balance equations [41,42]. Those will be topic of future investigations. Such models can be used to predict and optimize the process dynamics and temporal evolution of the product granule properties. Moreover, as shown recently for fluidized bed granulation [46,47], mathematical models facilitate the application of sophisticated process intensification and automatic control approaches to ensure reliable and sustainable plant operation as well as constant product quality and throughput for continuous operation mode, e.g., in face of unforeseen variations in the raw materials’ properties.

Author Contributions

M.P.: investigation, writing—original draft preparation, data curation, visualization, conceptualization, and methodology; R.D.: methodology, conceptualization, validation, writing—review and editing, and formal analysis; E.O.: writing—review and editing and validation; A.K.: supervision, project administration, funding acquisition and writing—review and editing; D.A.: resources, supervision, project administration, funding acquisition, and writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This work is partly funded by the European Regional Development Fund (ERDF) project “Center of Dynamics Systems”. The financial support is hereby gratefully acknowledged.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data presented in this article is available on request.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Symbol | Description | Unit |

| d | Diameter | μm |

| Feed mass flow rate | ||

| Binder mass flow rate | ||

| t | Time | s |

| T | Temperature | °C |

| Cb | Mass binder content | % |

| Greek letters | ||

| ρ | Density | k·gm−3 |

| Subscripts | ||

| b | Binder | |

| pan | Pan sample | |

| feed | Nuclei feed | |

| in | Inlet | |

| out | Outlet | |

| pro | Product | |

| sep | Separation | |

| Abbreviations | ||

| AOR | Angle of repose | [deg] |

| BC | Binder mass content | [%] |

| BF | Binder mass flow | [g/min] |

| FF | Feed mass flow | [g/min] |

| IA | Inclination angle of the pan | [deg] |

| PSD | Particle size distribution | |

| REF | Reference experiment | |

| RS | Rotation speed of the pan | [rpm] |

| D(3.2) | Sauter mean diameter | [µm] |

| D(0.5) | Median diameter | [µm] |

References

- Yang, Y.; He, Z.; Yang, X.; Stoffella, P.J. Dolomite phosphate rock (DPR) application in acidic sandy soil in reducing leaching of phosphorus and heavy metals-a column leaching study. Environ. Sci. Pollut. Res. 2013, 20, 3843–3851. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.C.; He, Z.L.; Stoffella, P.J.; Yang, X.E.; Yu, S.; Yang, J.Y.; Calvert, D.V. Leaching potential of heavy metals (Cd, Ni, Pb, Cu and Zn) from acidic sandy soil amended with dolomite phosphate rock (DPR) fertilizers. J. Trace Elem. Med. Biol. 2006, 20, 127–133. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Xiong, J.; He, Z. Activated dolomite phosphate rock fertilizers to reduce leaching of phosphorus and trace metals as compared to superphosphate. J. Environ. Manag. 2020, 255, 109872. [Google Scholar] [CrossRef]

- Chen, G.C.; He, Z.L.; Stoffella, P.J.; Yang, X.E.; Yu, S.; Calvert, D. Use of dolomite phosphate rock (DPR) fertilizers to reduce phosphorus leaching from sandy soil. Environ. Pollut. 2006, 139, 176–182. [Google Scholar] [CrossRef] [PubMed]

- Baltrusaitis, J.; Sviklas, A.M.; Galeckiene, J. Liquid and solid compound granulated Diurea sulfate-based fertilizers for sustainable sulfur source. ACS Sustain. Chem. Eng. 2014, 2, 2477–2487. [Google Scholar] [CrossRef]

- Malinowski, P.; Borowik, M.; Wantuch, W.; Urbańczyk, L.; Dawidowicz, M.; Biskupski, A. Utilization of waste gypsum in fertilizer production. Pol. J. Chem. Technol. 2014, 16, 45–47. [Google Scholar] [CrossRef] [Green Version]

- Dittmar, H. Fertilizers, 4. Granulation. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley–VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2009. [Google Scholar]

- Iveson, S.M.; Litster, J.D.; Hapgood, K.; Ennis, B.J. Nucleation, growth and breakage phenomena in agitated wet granulation processes: A review. Powder Technol. 2001, 117, 3–39. [Google Scholar] [CrossRef]

- Litster, J.D.; Ennis, B.J. The Science and Engineering of Granulation Process; Particle Technology Series; Springer Science & Business Media: New York, NY, USA, 2004; Volume 15. [Google Scholar]

- Strenzke, G.; Dürr, R.; Bück, A.; Tsotsas, E. Influence of operating parameters on process behavior and product quality in continuous spray fluidized bed agglomeration. Powder Technol. 2020, 375, 210–220. [Google Scholar] [CrossRef]

- Merkus, H.G. Particle Size Measurements: Fundamentals, Practice, Quality; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Azrar, H.; Zentar, R.; Abriak, N.E. The Effect of Granulation Time of the Pan Granulation on the Characteristics of the Aggregates Containing Dunkirk Sediments. Procedia Eng. 2016, 143, 10–17. [Google Scholar] [CrossRef] [Green Version]

- García, L.; Rodríguez, G.; Orjuela, A. Study of the pilot-scale pan granulation of zeolite-based molecular sieves. Braz. J. Chem. Eng. 2021, 38, 165–175. [Google Scholar] [CrossRef]

- Gluba, T. The effect of wetting conditions on the strength of granules. Physicochem. Probl. Miner. Process. 2002, 36, 233–242. [Google Scholar]

- Kwiatek, J.; Siuda, R.; Gluba, T.; Olejnik, T.P.; Obraniak, A.; Marszałek-Gubiec, A.; Pietrasik, T. Granulation of limestone powder with selected binding liquids. Przem. Chem. 2018, 97, 1542–1548. [Google Scholar] [CrossRef]

- Gluba, T. Granulacja Bębnowa Surowców Drobnoziarnistych o Różnych Skłądach Ziarnowych. Zesz. Naukowe. Rozpr. Nauk. Politech. Łódzka 2012, 423, 1–206. [Google Scholar]

- Pamungkas, R.B.; Jos, B.; Djaeni, M.; Saputri, K.A.D. Granulation processing variables on the physical properties of granule slow release urea fertilizer. AIP Conf. Proc. 2020, 2197, 100001. [Google Scholar]

- Ouchlyama, N.; Tanaka, T. Kinetic Analysis of Continuous Pan Granulation. Possible Explanations for Conflicting Experiments and Several Indications for Practice. Ind. Eng. Chem. Process Des. Dev. 1981, 20, 340–348. [Google Scholar] [CrossRef]

- Olbrycht, M.; Kołodziej, M.; Bochenek, R.; Przywara, M.; Balawejder, M.; Matłok, N.; Antos, P.; Piątkowski, W.; Antos, D. Mechanism of nutrition activity of a microgranule fertilizer fortified with proteins. BMC Plant Biol. 2020, 20, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Meline, R.S.; McCamy, I.W.; Graham, J.L.; Sloan, T.S. Plant-Scale Production of Fertilizers in a Pan Granulator. J. Agric. Food Chem. 1968, 16, 235–240. [Google Scholar] [CrossRef]

- Parrott, E.L. Handbook of powder science and technology. By M. E. Fayed and L. Otten, Van Nostrand Reinhold Company, Inc., 135 West 50th Street, New York, NY 10020. 1984. 650pp. 18 × 26cm. Price: $79.50. J. Pharm. Sci. 1984, 73, 1676. [Google Scholar] [CrossRef]

- Schubert, H. Capillary forces—Modeling and application in particulate technology. Powder Technol. 1984, 37, 105–116. [Google Scholar] [CrossRef]

- Yohe, G.R. Binding materials used in making pellets and briquets. Ind. Miner. Notes No. 19 1964. Available online: https://www.ideals.illinois.edu/bitstream/handle/2142/43127/bindingmaterials19yohe.pdf?sequence=2 (accessed on 14 July 2021).

- Veverka, J.; Hinkle, R. A Comparison of Liquid Binders for Limestone Pelletizing. In Institute for Briquetting and Agglomeration 27th Biennial Conference; Institute for Briquetting and Agglomeration: Portersville, PA, USA, 2002; Volume 27, pp. 141–152. [Google Scholar]

- Siuda, R.; Kwiatek, J.; Szufa, S.; Obraniak, A.; Piersa, P.; Adrian, Ł.; Modrzewski, R.; Ławińska, K.; Siczek, K.; Olejnik, T.P. Industrial verification and research development of lime-gypsum fertilizer granulation method. Minerals 2021, 11, 119. [Google Scholar] [CrossRef]

- Schwaeble, C.F.; Pott, R.W.M.; Goosen, N.J. The effect of sodium alginate, lignosulfonate and bentonite binders on agglomeration performance and mechanical strength of micro-fine agricultural lime pellets. Part. Sci. Technol. 2020, 1–12. [Google Scholar] [CrossRef]

- Iveson, S.M.; Page, N.W. Dynamic strength of liquid-bound granular materials: The effect of particle size and shape. Powder Technol. 2005, 152, 79–89. [Google Scholar] [CrossRef]

- Verkoeijen, D.; Meesters, G.M.H.; Vercoulen, P.H.W.; Scarlett, B. Determining granule strength as a function of moisture content. Powder Technol. 2002, 124, 195–200. [Google Scholar] [CrossRef]

- Leszczuk, T. Evaluation of the fertilizer granules strength obtained from plate granulation with different angle of granulation blade. Acta Mech. Autom. 2014, 8, 141–145. [Google Scholar] [CrossRef] [Green Version]

- Chitu, T.M.; Oulahna, D.; Hemati, M. Wet granulation in laboratory scale high shear mixers: Effect of binder properties. Powder Technol. 2011, 206, 25–33. [Google Scholar] [CrossRef]

- Saleh, K.; Vialatte, L.; Guigon, P. Wet granulation in a batch high shear mixer. Chem. Eng. Sci. 2005, 60, 3763–3775. [Google Scholar] [CrossRef]

- Hibare, S.; Sivanathan, R.; Nadakatti, S. Behaviour of soft granules under compression: Effect of reactive and non-reactive nature of the binder on granule properties. Powder Technol. 2011, 210, 241–247. [Google Scholar] [CrossRef]

- Kutz, M. Handbook of Farm, Dairy and Food Machinery Engineering; Academic Press: Waltham, MA, USA, 2019. [Google Scholar]

- López-Córdoba, A.; Goyanes, S. Food Powder Properties. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–7. [Google Scholar]

- Liu, Z. Measuring the Angle of Repose of Granular Systems. Ph.D. Thesis, University of Pittsburgh, Pittsburgh, PA, USA, 2011. [Google Scholar]

- Mehta, A.; Barker, G.C. The dynamics of sand. Rep. Prog. Phys. 1994, 57, 383. [Google Scholar] [CrossRef]

- Kalyankar, S.D.; Deshmukh, M.A.; Chopde, S.S.; Khedkar, C.D.; Lule, V.K.; Deosarkar, S.S. Milk Powder. In Encyclopedia of Food and Health; Academic Press: Waltham, MA, USA, 2015. [Google Scholar]

- Tyc, A.; Penkala, S.; Biegun, M.; Nieweoe, D.; Huculak-MĄczka, M.; Hoffmann, K. The effectiveness of commercial anticaking agents for ammonium nitrate fertilizers. Ecol. Chem. Eng. A 2020, 26, 127–135. [Google Scholar] [CrossRef]

- Pesonen, J.; Kuokkanen, V.; Kuokkanen, T.; Illikainen, M. Co-granulation of bio-ash with sewage sludge and lime for fertilizer use. J. Environ. Chem. Eng. 2016, 4, 4817–4821. [Google Scholar] [CrossRef]

- Siuda, R.; Kwiatek, J.; Obraniak, A.; Gluba, T.; Olejnik, T.P.; Marszałek-Gubiec, A.; Pietrasik, T. Comparison of granulation methods of lime-gypsum fertilizer. Przem. Chem. 2018, 97, 1549–1553. [Google Scholar] [CrossRef]

- Chadwick, P.C.; Bridgwater, J. Solids flow in dish granulators. Chem. Eng. Sci. 1997, 52, 2497–2509. [Google Scholar] [CrossRef]

- Chadwick, P.C.; Rough, S.L.; Bridgwater, J. Holdup and residence time distributions in inclined dishes. Ind. Eng. Chem. Res. 2005, 44, 7529–7539. [Google Scholar] [CrossRef]

- Otto, E.; Dürr, R.; Strenzke, G.; Palis, S.; Bück, A.; Tsotsas, E.; Kienle, A. Kernel identification in continuous fluidized bed spray agglomeration from steady state data. Adv. Powder Technol. 2021, 32, 2517–2529. [Google Scholar] [CrossRef]

- Ramkrishna, D. Inverse Problems in Population Balances. In Population Balances; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Dürr, R.; Bück, A. Approximate moment methods for population balance equations in particulate and bioengineering processes. Processes 2020, 8, 414. [Google Scholar] [CrossRef] [Green Version]

- Bück, A.; Dürr, R.; Schmidt, M.; Tsotsas, E. Model predictive control of continuous layering granulation in fluidised beds with internal product classification. J. Process Control 2016, 45, 65–75. [Google Scholar] [CrossRef]

- Neugebauer, C.; Diez, E.; Bück, A.; Palis, S.; Heinrich, S.; Kienle, A. On the dynamics and control of continuous fluidized bed layering granulation with screen-mill-cycle. Powder Technol. 2019, 354, 765–778. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).