Proton Exchange Membrane Fuel Cell Parameter Extraction Using a Supply–Demand-Based Optimization Algorithm

Abstract

:1. Introduction

2. PEMFC Modeling

2.1. Basic Operation of PEMFC

2.2. Theoretical Modeling

2.3. Objective Function and Constraints

3. Optimization Method and Implementation

3.1. Preliminary Concepts

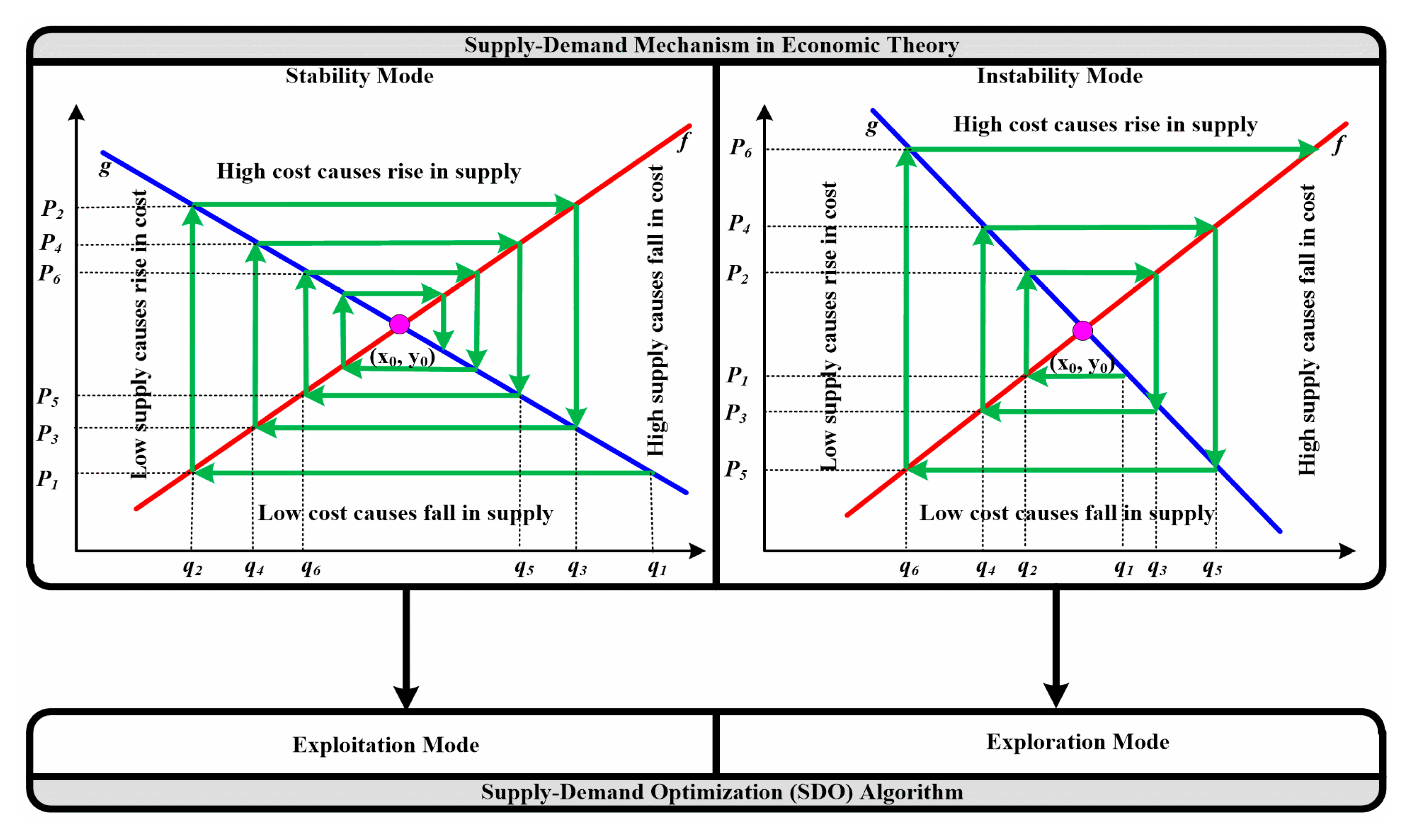

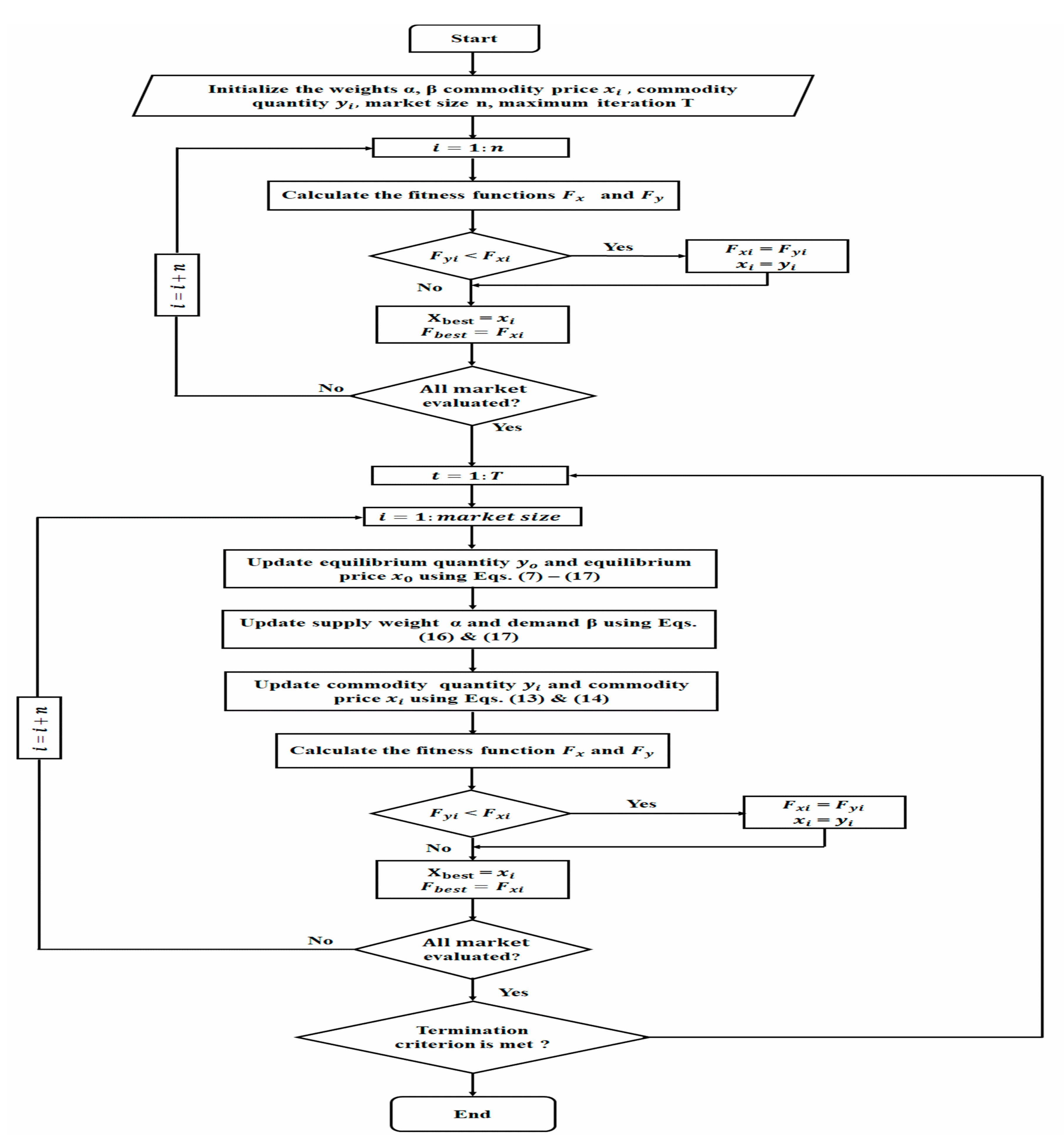

3.2. Supply–Demand-Based Optimization (SDO) Algorithm

4. Experimental Results and Discussion

4.1. Case Study 1 (Different Operational Conditions)

4.2. Case Study 2 (Different Types of PEMFC Stacks)

4.2.1. BCS-500W

4.2.2. Horizon-500W

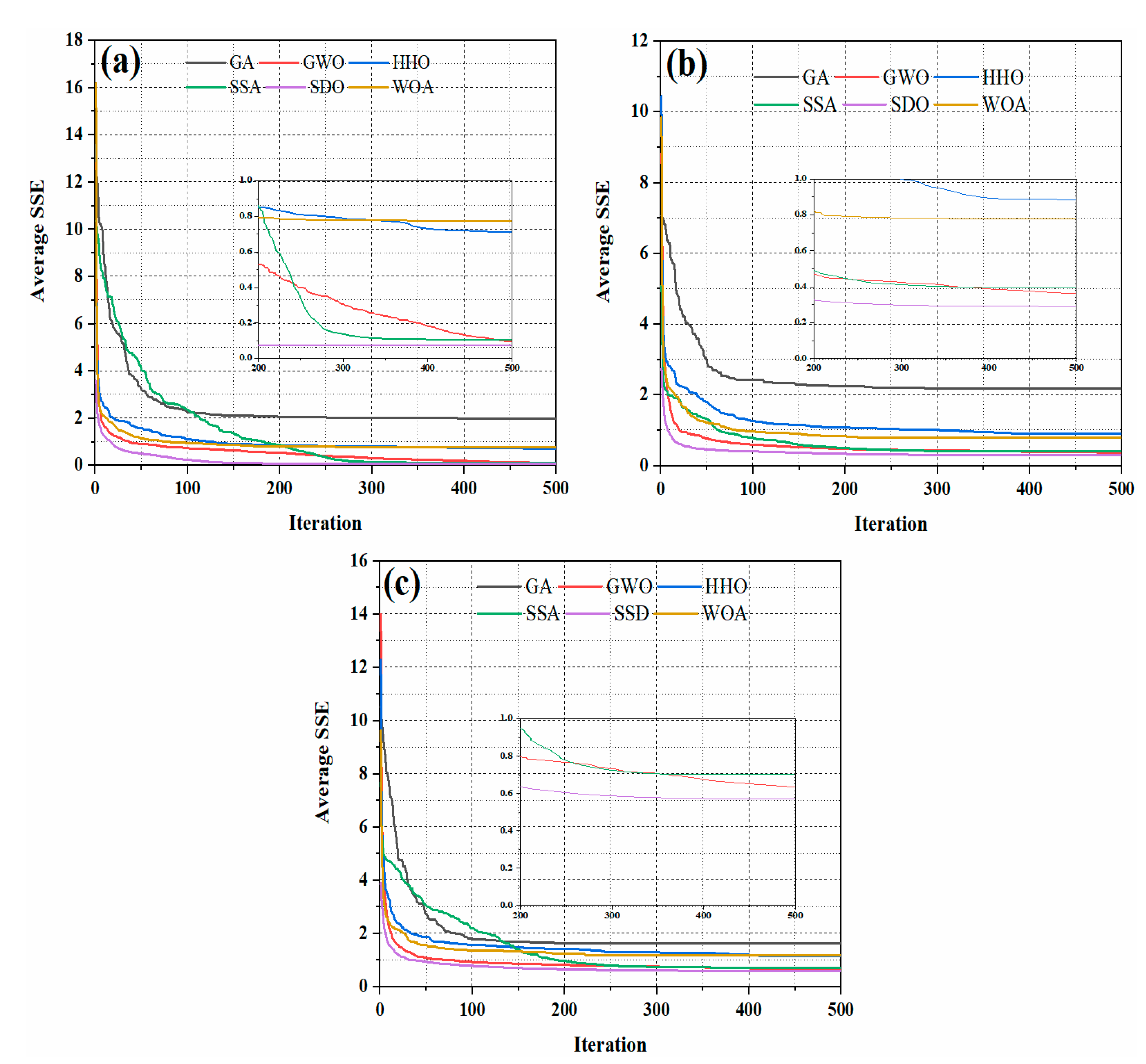

4.3. Average Convergence Rate

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | SBO | satin bowerbird optimizer | |

| ABS | artificial bee swarm algorithm | TGA | tree growth algorithm |

| ABC | artificial bee colony algorithm | TS | tabu search |

| ALO | ant lion optimizer | TLBO | teaching learning-based optimizer |

| ASO | atom search optimizer | VSA | vortex search algorithm |

| AIS | artificial immune system | WOA | whale optimization algorithm |

| BBBC | big bang–big crunch algorithm | ||

| BSA | backtracking search algorithm | Variables | |

| BBO | biogeography-based optimization | A | active area of membrane |

| BMO | bird mating optimizer | concentration of dissolved oxygen | |

| BA | bat algorithm | nernst theoretical voltage | |

| CSA | crow search algorithm | PEMFC current | |

| CS | cuckoo search algorithm | , | current density and maximum current density |

| DEA | differential evolution algorithm | membrane thickness | |

| DA | dragonfly algorithm | number of fuel cells | |

| FC | fuel cell | partial gas pressures of hydrogen and oxygen | |

| FFA | fruit fly algorithm | pressure at anode side and cathode side | |

| FPA | flower pollination algorithm | saturation pressure of water | |

| FFO | firefly optimization | lower and higher cell connections resistance | |

| GWO | grey wolf optimizer | relative humidity at cathode node and anode node | |

| GOA | grasshopper optimization algorithm | membrane resistance against transfer of protons | |

| GA | genetic algorithm | equivalent resistance of membrane | |

| HHO | harris hawks optimization | temperature of cell | |

| HS | harmony search | output voltage of PEMFC stack | |

| ICA | imperialist competitive algorithm | experimental and simulation output voltage of PEMFC | |

| MVO | multi-verse optimizer | activation voltage losses | |

| OSA | owl search algorithm | ohmic voltage losses | |

| PSO | particle swarm optimization | concentration voltage losses | |

| PEMFC | proton exchange membrane fuel cell | output voltage of one fc | |

| SDO | supply–demand-based optimization | semi-empirical coefficients | |

| SA | simulated annealing | specific resistivity of membrane | |

| SSA | salp swarm algorithm | empirical parameter of membrane preparation | |

| SSE | sum of the squared error | parametric coefficient | |

| SSO | shark smell optimizer | , | lowest and highest values of parametric coefficient |

| SFLA | shuffled frog-leaping algorithm | lowest and highest values of empirical coefficients | |

| SOA | seagull optimization algorithm | lowest and highest values of preparation parameter | |

Appendix A

| No. | 3/5 bar 353.15 K | 1/1 bar 343.15 K | 2.5/3 bar 343.15 K | 1.5/1.5 bar 343.15 K | ||||

|---|---|---|---|---|---|---|---|---|

| Current (A) | Voltage (V) | Current (A) | Voltage (V) | Current (A) | Voltage (V) | Current (A) | Voltage (V) | |

| 1 | 0.2729 | 23.5410 | 0.2046 | 21.5139 | 0.2582 | 23.2710 | 0.2417 | 22.6916 |

| 2 | 1.2790 | 21.4756 | 1.2619 | 19.6737 | 1.3340 | 21.0280 | 1.3177 | 20.1869 |

| 3 | 2.6603 | 20.3484 | 2.6433 | 18.7154 | 2.6471 | 20.0748 | 2.6819 | 19.2897 |

| 4 | 3.9734 | 19.8969 | 3.9734 | 17.9449 | 4.0281 | 19.4019 | 4.0118 | 18.5607 |

| 5 | 5.3547 | 19.4642 | 5.3206 | 17.5497 | 5.3919 | 18.8972 | 5.3755 | 18.1682 |

| 6 | 6.7190 | 19.0127 | 6.7019 | 17.1545 | 6.7726 | 18.5047 | 6.7563 | 17.7196 |

| 7 | 8.0321 | 18.5049 | 8.0491 | 16.6843 | 8.0852 | 18.0561 | 8.0689 | 17.2710 |

| 8 | 10.7265 | 17.8835 | 10.7265 | 15.8752 | 10.8297 | 17.2897 | 10.8134 | 16.4299 |

| 9 | 13.4720 | 17.2808 | 13.4720 | 15.1411 | 13.5230 | 16.5047 | 13.4556 | 15.7009 |

| 10 | 16.1664 | 16.2089 | 16.1494 | 14.4634 | 16.1652 | 15.7196 | 16.1488 | 14.9907 |

| 11 | 17.4966 | 15.8701 | 17.4795 | 14.0870 | 17.5459 | 15.3271 | 17.5295 | 14.6542 |

| 12 | 18.8608 | 15.5312 | 18.8438 | 13.5792 | 18.8584 | 14.9907 | 18.8423 | 14.0374 |

| 13 | 20.1910 | 15.1923 | 20.1739 | 12.6772 | 20.2733 | 14.5421 | 20.2234 | 13.1963 |

| 14 | 21.5553 | 14.6282 | 21.5382 | 10.8743 | 21.5523 | 13.5888 | 21.6049 | 12.0187 |

| 15 | 22.9195 | 13.7450 | 22.9025 | 8.92130 | 22.9337 | 12.5234 | 22.9189 | 10.1308 |

| No. | Current (A) | Voltage (V) | No. | Current (A) | Voltage(V) |

|---|---|---|---|---|---|

| 1 | 0.60 | 29 | 10 | 15.73 | 21.09 |

| 2 | 2.10 | 26.31 | 11 | 17.02 | 20.68 |

| 3 | 3.58 | 25.09 | 12 | 19.11 | 20.22 |

| 4 | 5.08 | 24.25 | 13 | 21.20 | 19.76 |

| 5 | 7.17 | 23.37 | 14 | 23.00 | 19.36 |

| 6 | 9.55 | 22.57 | 15 | 25.08 | 18.86 |

| 7 | 11.35 | 22.06 | 16 | 27.17 | 18.27 |

| 8 | 12.54 | 21.75 | 17 | 28.06 | 17.95 |

| 9 | 13.73 | 21.45 | 18 | 29.26 | 17.30 |

| No. | Current (A) | Voltage (V) |

|---|---|---|

| 1 | 0.6 | 29.370000 |

| 2 | 2.5 | 26.777390 |

| 3 | 5 | 25.290250 |

| 4 | 7.5 | 24.281859 |

| 5 | 10 | 23.418000 |

| 6 | 12 | 22.739103 |

| 7 | 14 | 22.058523 |

| 8 | 16 | 21.386148 |

| 9 | 18 | 20.721728 |

| 10 | 20 | 20.026000 |

| 11 | 21 | 19.636350 |

| 12 | 22 | 19.191807 |

| 13 | 23 | 18.663630 |

| 14 | 24 | 18.015227 |

| 15 | 25 | 17.201250 |

References

- Al-Shamma’a, A.A.; Addoweesh, K.E. Techno-economic optimization of hybrid power system using genetic algorithm. Int. J. Energy Res. 2014, 38, 1608–1623. [Google Scholar] [CrossRef]

- Uzunoglu, M.; Alam, M.S. Fuel-Cell Systems for Transportations; Elsevier BV: Amsterdam, The Netherlands, 2018; pp. 1091–1112. [Google Scholar]

- Ghasemi, M.; Shahgaldi, S.; Ismail, M.; Yaakob, Z.; Daud, W.R.W. New generation of carbon nanocomposite proton exchange membranes in microbial fuel cell systems. Chem. Eng. J. 2012, 184, 82–89. [Google Scholar] [CrossRef]

- Jia, J.; Wang, Y.; Li, Q.; Cham, Y.T.; Han, M. Modeling and Dynamic Characteristic Simulation of a Proton Exchange Membrane Fuel Cell. IEEE Trans. Energy Convers. 2009, 24, 283–291. [Google Scholar] [CrossRef]

- Massonnat, P.; Gao, F.; Roche, R.; Paire, D.; Bouquain, D.; Miraoui, A. Multiphysical, multidimensional real-time PEM fuel cell modeling for embedded applications. Energy Convers. Manag. 2014, 88, 554–564. [Google Scholar] [CrossRef]

- Soltani, M.; Bathaee, S.M.T. Development of an empirical dynamic model for a Nexa PEM fuel cell power module. Energy Convers. Manag. 2010, 51, 2492–2500. [Google Scholar] [CrossRef]

- Gao, F.; Blunier, B.; Miraoui, A. (Eds.) Proton Exchange Membrane Fuel Cells Modeling; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2012. [Google Scholar]

- Secanell, M.; Wishart, J.; Dobson, P. Computational design and optimization of fuel cells and fuel cell systems: A review. J. Power Sources 2011, 196, 3690–3704. [Google Scholar] [CrossRef]

- Secanell, M.; Carnes, B.; Suleman, A.; Djilali, N. Numerical optimization of proton exchange membrane fuel cell cathodes. Electrochim. Acta 2007, 52, 2668–2682. [Google Scholar] [CrossRef]

- Mohammadi, A.; Cirrincione, G.; Djerdir, A.; Khaburi, D.A. A novel approach for modeling the internal behavior of a PEMFC by using electrical circuits. Int. J. Hydrogen Energy 2018, 43, 11539–11549. [Google Scholar] [CrossRef]

- Lin, H.-H.; Cheng, C.-H.; Soong, C.-Y.; Chen, F.; Yan, W.-M. Optimization of key parameters in the proton exchange membrane fuel cell. J. Power Sources 2006, 162, 246–254. [Google Scholar] [CrossRef]

- Youssef, M.; Elsal-Nadi, K.E.; Khalil, M.H. Lumped model for proton exchange membrane fuel cell (PEMFC). Int. J. Electrochem. Sci. 2010, 5, 267–277. [Google Scholar]

- Jiang, Y.; Yang, Z.; Jiao, K.; Du, Q. Sensitivity analysis of uncertain parameters based on an improved proton exchange membrane fuel cell analytical model. Energy Convers. Manag. 2018, 164, 639–654. [Google Scholar] [CrossRef]

- Amirinejad, M.; Rowshanzamir, S.; Eikani, M.H. Effects of operating parameters on performance of a proton exchange membrane fuel cell. J. Power Sources 2006, 161, 872–875. [Google Scholar] [CrossRef]

- Yang, X.-S. Review of meta-heuristics and generalised evolutionary walk algorithm. Int. J. Bio-Inspired Comput. 2011, 3, 77. [Google Scholar] [CrossRef]

- Mohamed, I.; Jenkins, N. Proton exchange membrane (PEM) fuel cell stack configuration using genetic algorithms. J. Power Sources 2004, 131, 142–146. [Google Scholar] [CrossRef]

- Askarzadeh, A.; Rezazadeh, A. Optimization of PEMFC model parameters with a modified particle swarm optimization. Int. J. Energy Res. 2010, 35, 1258–1265. [Google Scholar] [CrossRef]

- Zhang, G.; Xiao, C.; Razmjooy, N. Optimal parameter extraction of PEM fuel cells by meta-heuristics. Int. J. Ambient. Energy 2020, 2020, 1–10. [Google Scholar] [CrossRef]

- Ali, M.; El-Hameed, M.; Farahat, M. Effective parameters’ identification for polymer electrolyte membrane fuel cell models using grey wolf optimizer. Renew. Energy 2017, 111, 455–462. [Google Scholar] [CrossRef]

- Outeiro, M.; Chibante, R.; Carvalho, A.; de Almeida, A. A parameter optimized model of a Proton Exchange Membrane fuel cell including temperature effects. J. Power Sources 2008, 185, 952–960. [Google Scholar] [CrossRef]

- Askarzadeh, A.; Rezazadeh, A. An Innovative Global Harmony Search Algorithm for Parameter Iden-tification of a PEM Fuel Cell Model. IEEE Trans. Ind. Electron. 2012, 59, 3473–3480. [Google Scholar] [CrossRef]

- Askarzadeh, A.; Rezazadeh, A. A new artificial bee swarm algorithm for optimization of proton ex-change membrane fuel cell model parameters. J. Zhejiang Univ. Sci. C 2011, 12, 638–646. [Google Scholar] [CrossRef]

- Priya, K.; Rajasekar, N. Application of flower pollination algorithm for enhanced proton exchange membrane fuel cell modelling. Int. J. Hydrogen Energy 2019, 44, 18438–18449. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, N.; Yang, S. Hybrid artificial bee colony algorithm for parameter estimation of proton exchange membrane fuel cell. Int. J. Hydrogen Energy 2013, 38, 5796–5806. [Google Scholar] [CrossRef]

- Sedighizadeh, M.; Mahmoodi, M.M.; Soltanian, M. Parameter identification of proton exchange membrane fuel cell using a Hybrid Big Bang-Big Crunch optimization. In Proceedings of the 2014 5th Conference on Thermal Power Plants (lPGC2014), Tehran, Iran, 10–11 June 2014; pp. 35–39. [Google Scholar]

- El-Fergany, A.A. Extracting optimal parameters of PEM fuel cells using Salp Swarm Optimizer. Renew. Energy 2018, 119, 641–648. [Google Scholar] [CrossRef]

- Han, W.; Li, D.; Yu, D.; Ebrahimian, H. Optimal parameters of PEM fuel cells using chaotic binary shark smell optimizer. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 2019, 1–15. [Google Scholar] [CrossRef]

- Fathy, A.; Rezk, H. Multi-verse optimizer for identifying the optimal parameters of PEMFC model. Energy 2018, 143, 634–644. [Google Scholar] [CrossRef]

- Guo, C.; Lu, J.; Tian, Z.; Guo, W.; Darvishan, A. Optimization of critical parameters of PEM fuel cell using TLBO-DE based on Elman neural network. Energy Convers. Manag. 2019, 183, 149–158. [Google Scholar] [CrossRef]

- Khan, S.S.; Rafiq, M.A.; Shareef, H.; Sultan, M.K. Parameter optimization of PEMFC model using back-tracking search algo-rithm. In Proceedings of the 2018 5th International Conference on Renewable Energy: Generation and Applications (ICREGA), Al Ain, United Arab Emirates, 25–28 February 2018; pp. 323–326. [Google Scholar]

- Sun, Z.; Wang, N.; Bi, Y.; Srinivasan, D. Parameter identification of PEMFC model based on hybrid adaptive differential evolution algorithm. Energy 2015, 90, 1334–1341. [Google Scholar] [CrossRef]

- Niu, Q.; Zhang, L.; Li, K. A biogeography-based optimization algorithm with mutation strategies for model parameter es-timation of solar and fuel cells. Energy Convers. Manag. 2014, 86, 1173–1185. [Google Scholar] [CrossRef]

- Kandidayeni, M.; Macias, A.; Khalatbarisoltani, A.; Boulon, L.; Kelouwani, S. Benchmark of proton ex-change membrane fuel cell parameters extraction with metaheuristic optimization algorithms. Energy 2019, 183, 912–925. [Google Scholar] [CrossRef]

- El-Fergany, A.A. Electrical characterisation of proton exchange membrane fuel cells stack using grasshopper optimiser. IET Renew. Power Gener. 2018, 12, 9–17. [Google Scholar] [CrossRef]

- Askarzadeh, A.; Rezazadeh, A. A new heuristic optimization algorithm for modeling of proton ex-change membrane fuel cell: Bird mating optimizer. Int. J. Energy Res. 2013, 37, 1196–1204. [Google Scholar] [CrossRef]

- El-Fergany, A.A.; Hasanien, H.M.; Agwa, A.M. Semi-empirical PEM fuel cells model using whale optimization algorithm. Energy Convers. Manag. 2019, 201, 112197. [Google Scholar] [CrossRef]

- Duan, B.; Cao, Q.; Afshar, N. Optimal parameter identification for the proton exchange membrane fuel cell using Satin Bowerbird optimizer. Int. J. Energy Res. 2019. [Google Scholar] [CrossRef]

- Cao, Y.; Li, Y.; Zhang, G.; Jermsittiparsert, K.; Razmjooy, N. Experimental modeling of PEM fuel cells using a new improved seagull optimization algorithm. Energy Rep. 2019, 5, 1616–1625. [Google Scholar] [CrossRef]

- Fathy, A.; Elaziz, M.A.; Alharbi, A.G. A novel approach based on hybrid vortex search algorithm and differential evolution for identifying the optimal parameters of PEM fuel cell. Renew. Energy 2020, 146, 1833–1845. [Google Scholar] [CrossRef]

- Turgut, O.E.; Coban, M.T. Optimal proton exchange membrane fuel cell modelling based on hybrid Teaching Learning Based Optimization—Differential Evolution algorithm. Ain Shams Eng. J. 2016, 7, 347–360. [Google Scholar] [CrossRef]

- Kamel, S.; Jurado, F.; Sultan, H.M.; Menesy, A.S. Tree Growth Algorithm for Parameter Identification of Proton Exchange Membrane Fuel Cell Models. Int. J. Interact. Multimed. Artif. Intell. 2020, 6, 11. [Google Scholar] [CrossRef] [Green Version]

- Menesy, A.S.; Sultan, H.M.; Selim, A.; GAshmawy, M.; Kamel, S. Developing and Applying Chaotic Harris Hawks Optimization Technique for Extracting Parameters of Several Proton Exchange Membrane Fuel Cell Stacks. IEEE Access 2020, 8, 1146–1159. [Google Scholar] [CrossRef]

- Agwa, A.M.; El-Fergany, A.A.; Sarhan, G.M. Steady-State Modeling of Fuel Cells Based on Atom Search Optimizer. Energies 2019, 12, 1884. [Google Scholar] [CrossRef] [Green Version]

- Isa, Z.M.; Nayan, N.M.; Arshad, M.H.; Kajaan, N.A.M. Optimizing PEMFC model parameters using ant li-on optimizer and dragonfly algorithm: A comparative study. Int. J. Electr. Comput. Eng. 2019, 9, 5295. [Google Scholar]

- Chen, Y.; Wang, N. Cuckoo search algorithm with explosion operator for modeling proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2019, 44, 3075–3087. [Google Scholar] [CrossRef]

- Askarzadeh, A.; Rezazadeh, A. Artificial immune system-based parameter extraction of proton exchange membrane fuel cell. Int. J. Electr. Power Energy Syst. 2011, 33, 933–938. [Google Scholar] [CrossRef]

- Xu, S.; Wang, Y.; Wang, Z. Parameter estimation of proton exchange membrane fuel cells using eagle strategy based on JAYA algorithm and Nelder-Mead simplex method. Energy 2019, 173, 457–467. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, L.; Zhang, Z. Supply-Demand-Based Optimization: A Novel Economics-Inspired Algorithm for Global Optimization. IEEE Access 2019, 7, 73182–73206. [Google Scholar] [CrossRef]

- Mo, Z.-J.; Zhu, X.-J.; Wei, L.-Y.; Cao, G.-Y. Parameter optimization for a PEMFC model with a hybrid genetic algorithm. Int. J. Energy Res. 2006, 30, 585–597. [Google Scholar] [CrossRef]

- Mann, R.F.; Amphlett, J.C.; Hooper, M.A.I.; Jensen, H.M.; Peppley, B.A.; Roberge, P.R. Development and application of a generalised steady-state electrochemical model for a PEM fuel cell. J. Power Sources 2000, 86, 173–180. [Google Scholar] [CrossRef]

- Dedigama, I.; Ayers, K.; Shearing, P.R.; Brett, D.J.L. An experimentally validated steady state polymer electrolyte membrane water electrolyser model. Int. J. Electrochem. Sci. 2014, 9, 2662–2681. [Google Scholar]

- Nguyen, T.V.; White, R.E. A Water and Heat Management Model for Proton-Exchange-Membrane Fuel Cells. J. Electrochem. Soc. 1993, 140, 2178–2186. [Google Scholar] [CrossRef]

- Amphlett, J.C.; Baumert, R.M.; Mann, R.F.; Peppley, B.A.; Roberge, P.R.; Harris, T.J. Performance Modeling of the Ballard Mark IV Solid Polymer Electrolyte Fuel Cell: II. Empirical Model Development. J. Electrochem. Soc. 1995, 142, 9–15. [Google Scholar] [CrossRef]

- Saleh, I.M.M.; Ali, R.; Zhang, H. Simplified mathematical model of proton exchange membrane fuel cell based on horizon fuel cell stack. J. Mod. Power Syst. Clean Energy 2016, 4, 668–679. [Google Scholar] [CrossRef] [Green Version]

- Ohenoja, M.; Leiviskä, K. Validation of genetic algorithm results in a fuel cell model. Int. J. Hydrogen Energy 2010, 35, 12618–12625. [Google Scholar] [CrossRef]

| Parameter | Constraints | |

|---|---|---|

| Upper | Lower | |

| −0.8532 | −1.19969 | |

| 5.00 × 10−3 | 1.00 × 10−3 | |

| 9.8 × 10−5 | 3.6 × 10−5 | |

| −9.54 × 10−5 | −260 × 10−4 | |

| (Ω) | 8.00 × 10−4 | 1.00 × 10−4 |

| (V) | 0.5 | 0.0136 |

| 24 | 10 | |

| 178 | 51 | |

| 1500 | 850 | |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| n | 24 | Pa (bar) | 1.0–3.0 |

| A (cm2) | 27 | Pb (bar) | 1.0–5.0 |

| Power (w) | 250 | RHa | 1.0 |

| T(K) | 343.15–353.15 | RHb | 1.0 |

| SSE | Optimization Algorithms | |||||

|---|---|---|---|---|---|---|

| WOA | GWO | SSA | HHO | GA | SDO | |

| Minimum | 0.154639186 | 0.146884822 | 0.152883434 | 0.167631296 | 0.350360131 | 0.145167469 |

| Mean | 0.419153062 | 0.170258026 | 0.178072981 | 0.491306301 | 1.561131011 | 0.148407841 |

| Median | 0.397898527 | 0.157920235 | 0.155409751 | 0.424590144 | 1.360612054 | 0.147780145 |

| Maximum | 1.073495308 | 0.346056858 | 0.419199433 | 1.288663305 | 7.448856801 | 0.154441127 |

| STD | 0.196771275 | 0.033980005 | 0.062370696 | 0.262778766 | 1.266038132 | 0.002718387 |

| Variable | Algorithm | |||||

|---|---|---|---|---|---|---|

| WOA | GWO | SSA | HHO | GA | SDO | |

| −0.884007645 | −0.944234024 | −1.07199885 | −1.156237962 | −0.90822 | −0.964599939 | |

| 0.002484898 | 0.002893255 | 0.002880452 | 0.002958249 | 0.00295 | 0.002440458 | |

| 6.06253 × 10−5 | 7.86346 × 10−5 | 4.99592 × 10−5 | 3.73411 × 10−5 | 0.00009 | 3.96338 × 10−5 | |

| −0.000139704 | −0.000137972 | −0.000137754 | −0.000144177 | −0.00013 | −0.000138061 | |

| 0.000178974 | 0.000172751 | 0.000158811 | 0.000559279 | 0.00045 | 0.000100003 | |

| 0.051607571 | 0.019026091 | 0.026518418 | 0.016646806 | 0.089330 | 0.015471 | |

| 16.02236023 | 10.46643873 | 15.5096387 | 10.00002765 | 12.14717 | 10.00039 | |

| 0.008914346 | 0.010066463 | 0.014396789 | 0.008537823 | 0.00815 | 0.010209 | |

| 0.939531061 | 0.873824589 | 0.886530415 | 0.864155406 | 1.27485 | 0.86617 | |

| 0.154639186 | 0.146884822 | 0.152883434 | 0.167631296 | 0.350360131 | 0.145167 | |

| SSE | Algorithms | |||||

|---|---|---|---|---|---|---|

| WOA | GWO | SSA | HHO | GA | SDO | |

| Minimum | 0.300165193 | 0.295994285 | 0.309587261 | 0.29652213 | 0.699327274 | 0.287824529 |

| Mean | 0.577755836 | 0.377546219 | 0.399386254 | 0.936986404 | 2.553703279 | 0.291280092 |

| Median | 0.463634598 | 0.371127461 | 0.40787451 | 0.544159818 | 2.515251534 | 0.290517966 |

| Maximum | 2.037256664 | 0.458303674 | 0.456663355 | 2.774235022 | 6.340709893 | 0.300122801 |

| STD | 0.305965318 | 0.04832738 | 0.040168552 | 0.736897544 | 1.213128222 | 0.003306558 |

| Variable | Algorithms | |||||

|---|---|---|---|---|---|---|

| WOA | GWO | SSA | HHO | GA | SDO | |

| −0.9715 | −0.890402371 | −0.935709319 | −1.188920972 | −0.971500 | −1.108875289 | |

| 0.00251 | 0.002491237 | 0.003094492 | 0.003832179 | 0.002510 | 0.00344834 | |

| 0.000036 | 4.91 × 10−5 | 7.92 × 10−5 | 7.78 × 10−5 | 0.000036 | 6.85 × 10−5 | |

| −0.00015 | −0.000178916 | −0.000178501 | −0.000177945 | −0.000150 | −0.00018002 | |

| 0.00047 | 0.000185305 | 0.000125487 | 0.000100056 | 0.000470 | 0.000100079 | |

| 0.24611 | 0.128317025 | 0.116173722 | 0.132384143 | 0.246110 | 0.133014223 | |

| 15.32527 | 21.56036185 | 19.20514021 | 19.76775546 | 15.32527 | 23.99819531 | |

| 0.00807 | 0.005306549 | 0.008197421 | 0.005272008 | 0.008070 | 0.005101562 | |

| 1.40447 | 0.85 | 0.85 | 0.850476147 | 1.404470 | 0.850000467 | |

| 0.699327274 | 0.295994285 | 0.309587261 | 0.29652213 | 0.699327274 | 0.287824529 | |

| SSE | Algorithm | |||||

|---|---|---|---|---|---|---|

| WOA | GWO | SSA | HHO | GA | SDO | |

| Minimum | 0.625844193 | 0.573184966 | 0.57403609 | 0.615881844 | 0.819730928 | 0.56426671 |

| Mean | 1.061565396 | 0.636443826 | 0.736015304 | 1.896482889 | 1.628325244 | 0.567576781 |

| Median | 1.011063049 | 0.619793268 | 0.697756101 | 0.788884976 | 1.395475534 | 0.565250928 |

| Maximum | 4.841737291 | 0.887128302 | 0.952794404 | 10.23959957 | 4.949883945 | 0.58254602 |

| STD | 0.559655929 | 0.065968875 | 0.108664932 | 2.287173428 | 0.810383099 | 0.004466494 |

| Variable | Algorithm | |||||

|---|---|---|---|---|---|---|

| WOA | GWO | SSA | HHO | GA | SDO | |

| −1.199166641 | −0.887481442 | −1.155052815 | −0.854760973 | −0.975720 | −0.902401475 | |

| 0.003060175 | 0.002252875 | 0.003202954 | 0.001875009 | 0.003110 | 0.002101847 | |

| 4.64 × 10−5 | 5.56 × 10−5 | 6.62 × 10−5 | 3.60 × 10−5 | 0.000098 | 4.16 × 10−5 | |

| −0.000109916 | −0.000112573 | −0.00011186 | −0.000106249 | −0.000100 | −0.000112065 | |

| 0.000100072 | 0.000119116 | 0.000101536 | 0.000100031 | 0.000550 | 0.000100019 | |

| 0.160910761 | 0.195372815 | 0.194323477 | 0.177260104 | 0.220680 | 0.199832662 | |

| 10.01525068 | 21.55450995 | 18.31630737 | 10.003083 | 18.90174 | 23.995893 | |

| 0.006712446 | 0.00554807 | 0.0051 | 0.005101572 | 0.011480 | 0.005100055 | |

| 0.85106307 | 0.85 | 0.85 | 0.850262055 | 1.017500 | 0.850000594 | |

| 0.625844193 | 0.573184966 | 0.57403609 | 0.615881844 | 0.819730928 | 0.56426671 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Shamma’a, A.A.; Ali, F.A.A.; Alhoshan, M.S.; Alturki, F.A.; Farh, H.M.H.; Alam, J.; AlSharabi, K. Proton Exchange Membrane Fuel Cell Parameter Extraction Using a Supply–Demand-Based Optimization Algorithm. Processes 2021, 9, 1416. https://doi.org/10.3390/pr9081416

Al-Shamma’a AA, Ali FAA, Alhoshan MS, Alturki FA, Farh HMH, Alam J, AlSharabi K. Proton Exchange Membrane Fuel Cell Parameter Extraction Using a Supply–Demand-Based Optimization Algorithm. Processes. 2021; 9(8):1416. https://doi.org/10.3390/pr9081416

Chicago/Turabian StyleAl-Shamma’a, Abdullrahman A., Fekri Abdulraqeb Ahmed Ali, Mansour S. Alhoshan, Fahd A. Alturki, Hassan M. H. Farh, Javed Alam, and Khalil AlSharabi. 2021. "Proton Exchange Membrane Fuel Cell Parameter Extraction Using a Supply–Demand-Based Optimization Algorithm" Processes 9, no. 8: 1416. https://doi.org/10.3390/pr9081416

APA StyleAl-Shamma’a, A. A., Ali, F. A. A., Alhoshan, M. S., Alturki, F. A., Farh, H. M. H., Alam, J., & AlSharabi, K. (2021). Proton Exchange Membrane Fuel Cell Parameter Extraction Using a Supply–Demand-Based Optimization Algorithm. Processes, 9(8), 1416. https://doi.org/10.3390/pr9081416