Determining the Effect of Pre-Treatment in Rice Noodle Quality Subjected to Dehydration through Hierarchical Scoring

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pre-Treatment

2.3. Hot Air Drying

2.4. Heat Pump Drying

2.5. Freeze Drying

2.6. Texture Analysis

2.7. Colour Analysis

2.8. Fat Content Analysis

2.9. Starch Gelatinization

2.10. Hierarchical Scoring

2.11. Statistical Analysis

3. Results

4. Discussion

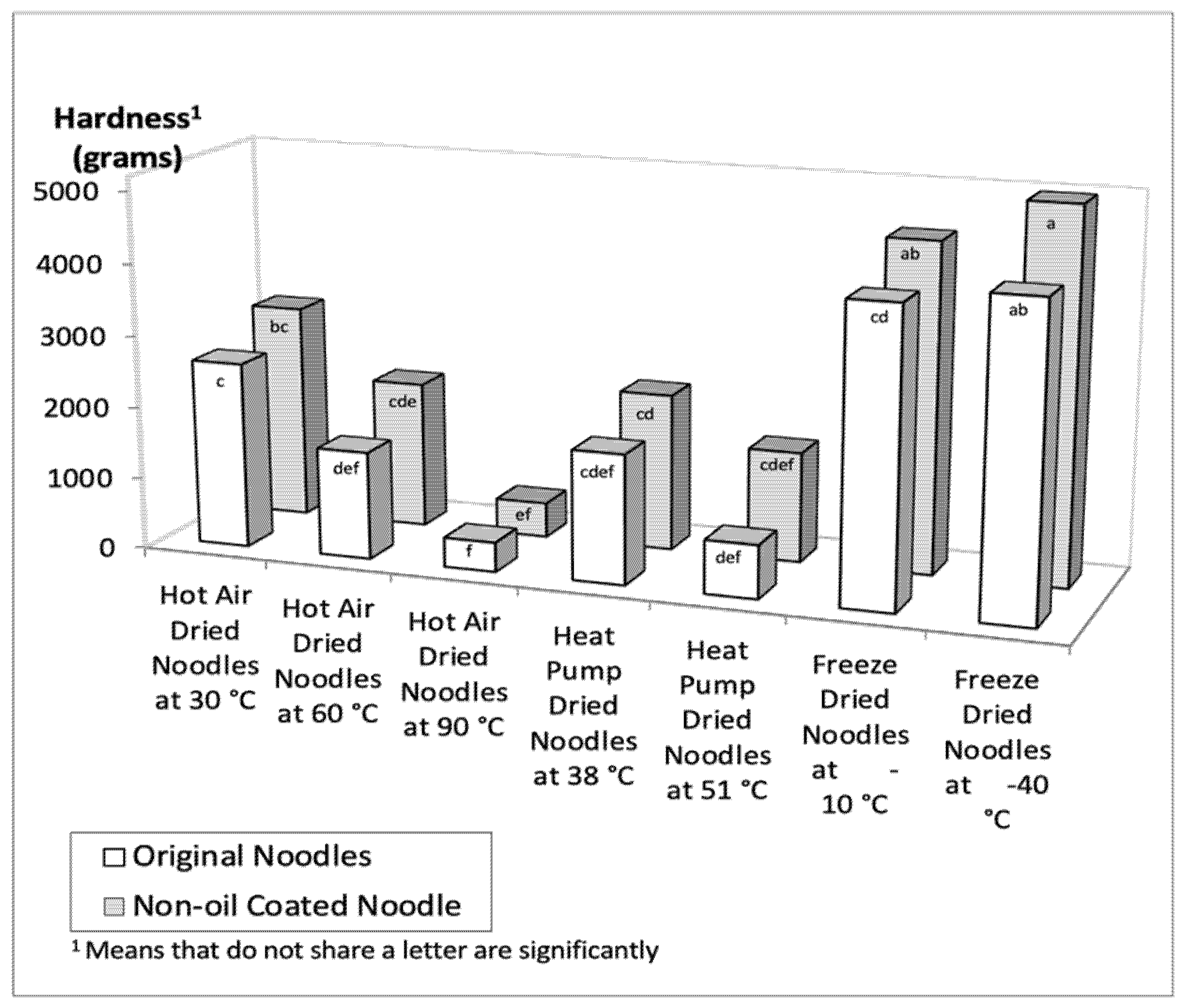

4.1. Effect of Pretreatment, Temperature, and Drying Procedures on Texture

4.2. Effect of Pretreatment, Temperature, and Drying Methods on Colour

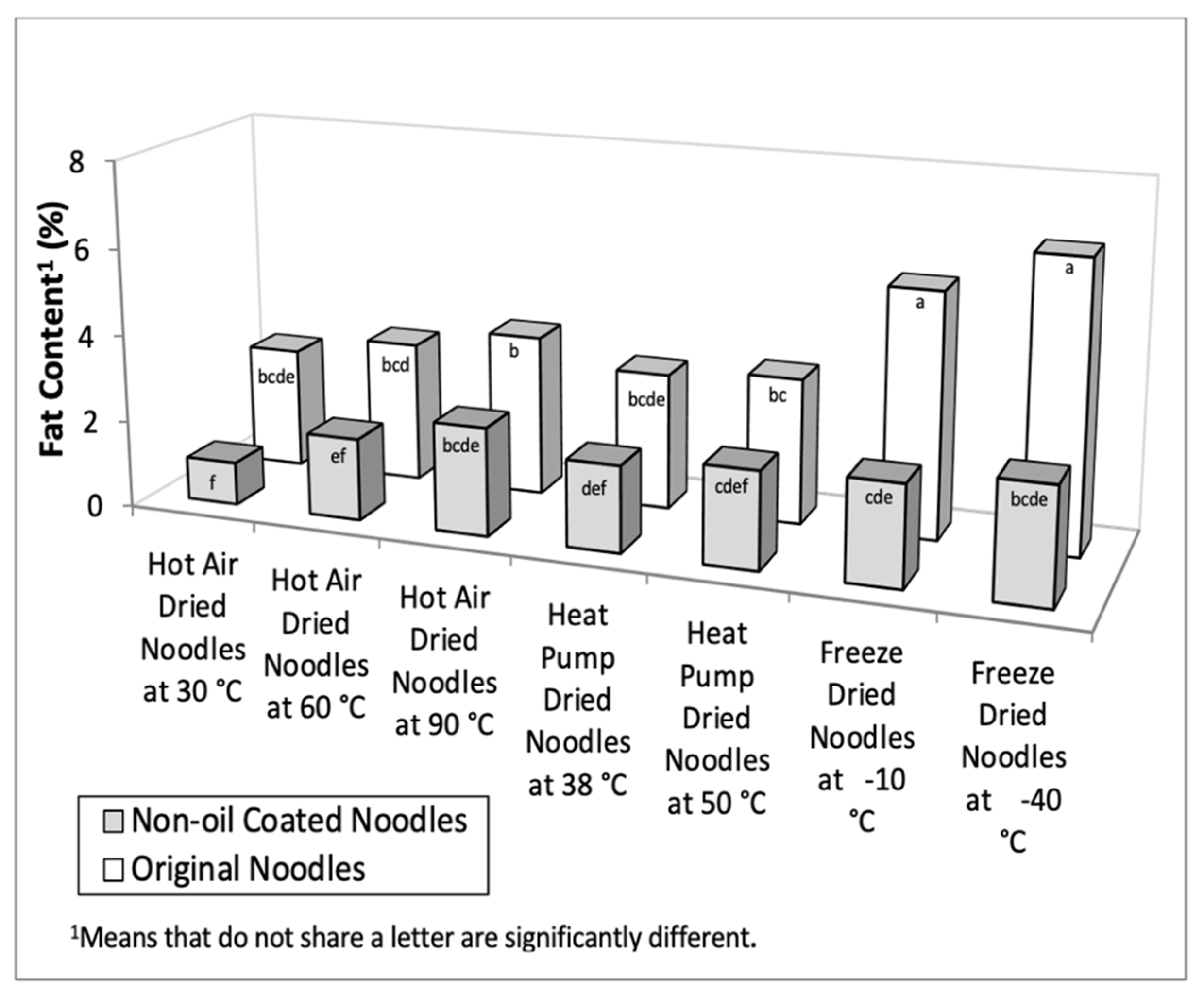

4.3. Effect of Pretreatment, Temperature, and Drying Methods on Fat Content

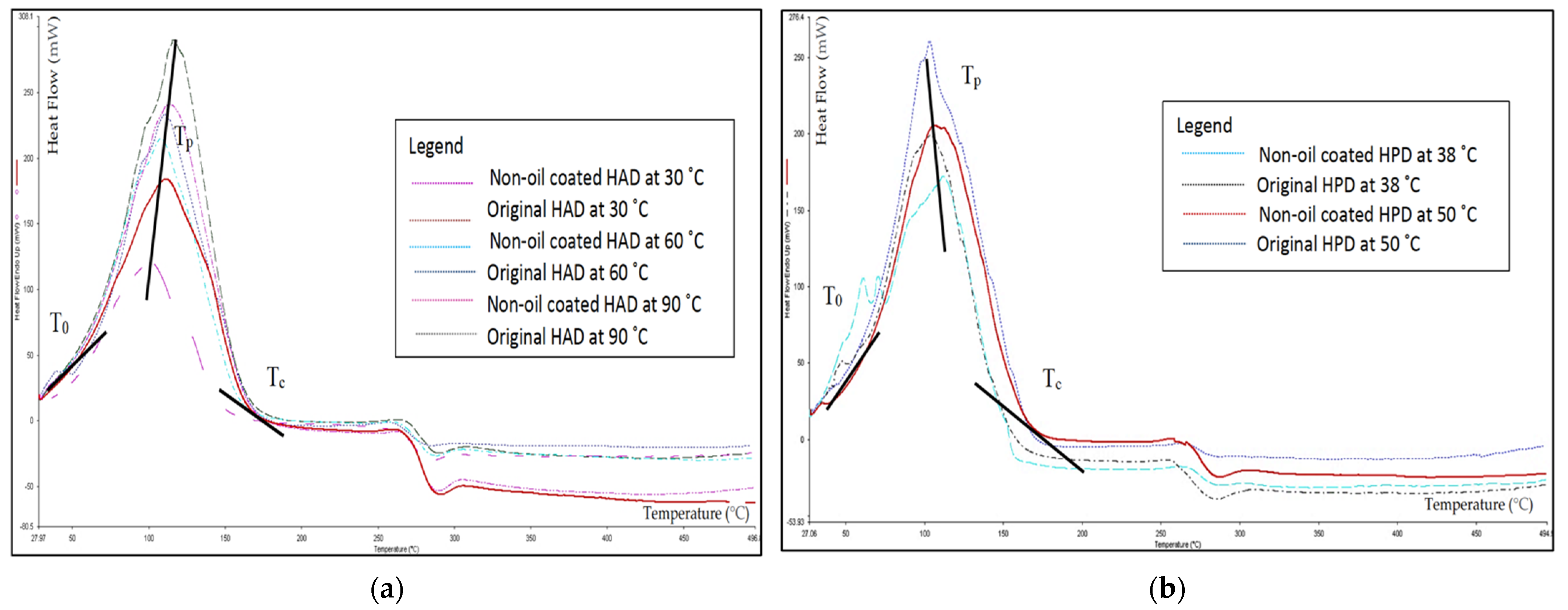

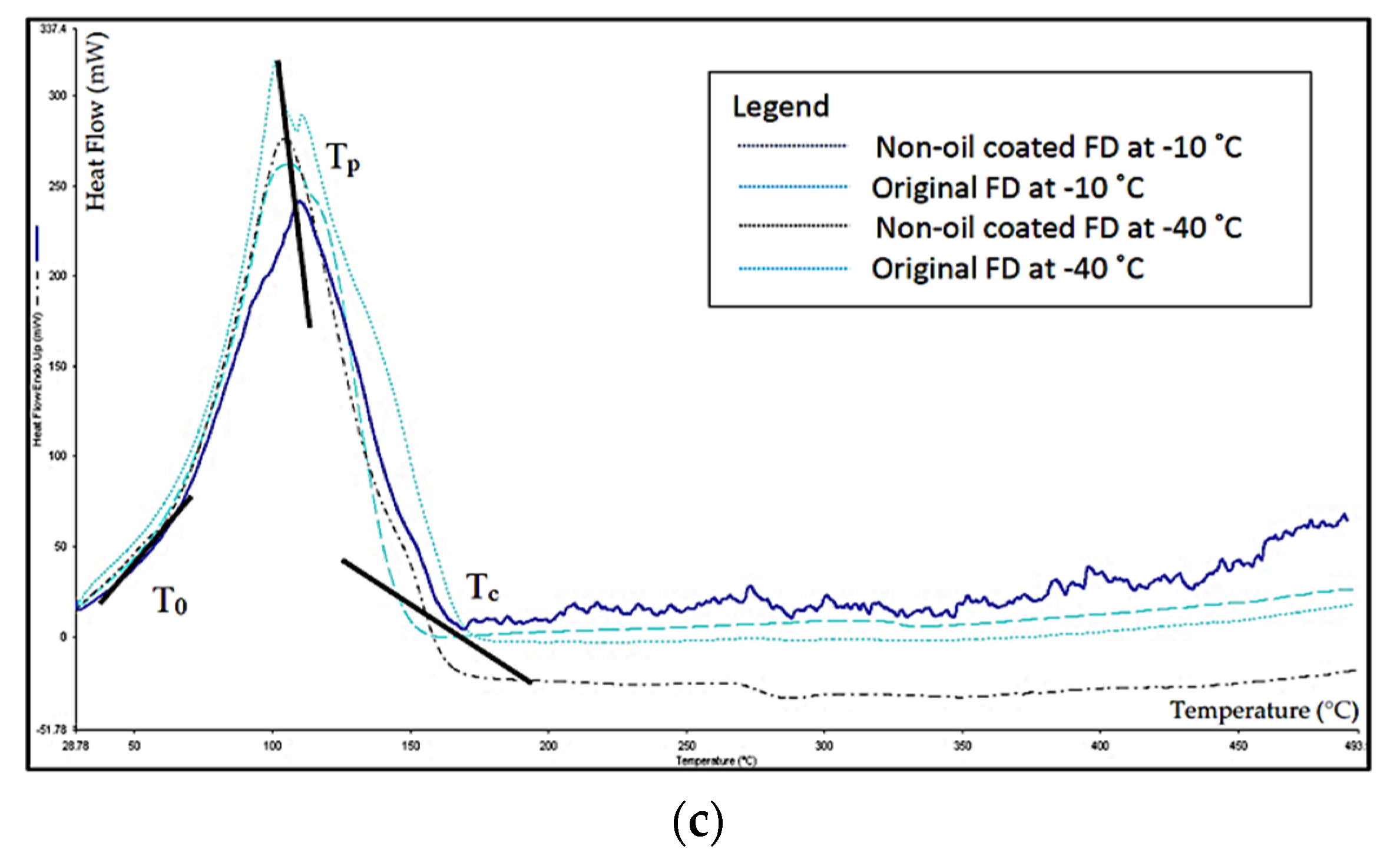

4.4. Effect of Pretreatment, Temperature, and Drying Methods on Starch Gelatinization

4.5. Hierarchical Method

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fu, B.X. Asian noodles: History, classification, raw materials, and processing. Food Res. Int. 2008, 41, 888–902. [Google Scholar] [CrossRef]

- Ahmed, I.; Qazi, I.M.; Li, Z.; Ullah, J. Rice Noodles: Materials, Processing and Quality Evaluation. Proc. Pakistan Acad. Sci. Pakistan Acad. Sci. B Life Environ. Sci. 2016, 53, 215–238. [Google Scholar]

- Li, Y.; Liang, J.F.; Yang, M.Y.; Chen, J.Y.; Han, B.Z. Traditional Chinese rice noodles: History, classification, and processing methods. Cereal Foods World 2015, 60, 123–127. [Google Scholar] [CrossRef] [Green Version]

- Singh, A. Edible Oil Coatings Prolong Shelf Life and Improve Quality of Guava (Psidium guajava L.). Int. J. Pure Appl. Biosci. 2017, 5, 837–843. [Google Scholar] [CrossRef]

- Arévalo-Pinedo, A.; Murr, X.F.E. Influence of pre-treatments on the drying kinetics during vacuum drying of carrot and pumpkin. J. Food Eng. 2007, 80, 152–156. [Google Scholar] [CrossRef]

- Kraithong, S.; Rawdkuen, S. Quality attributes and cooking properties of commercial Thai rice noodles. Peer J. 2021, 9, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Zhu, K.-X.; Sun, Q.-J.; Amza, T.; Guo, X.-N.; Zhou, H.-M. Quality characteristics, structural changes, and storage stability of semi-dried noodles induced by moderate dehydration: Understanding the quality changes in semi-dried noodles. Food Chem. 2016, 194, 797–804. [Google Scholar] [CrossRef] [PubMed]

- Hasegawa, A.; Ogawa, T.; Adachi, S. Estimation of the Gelatinization Temperature of Noodles from Water Sorption Curves under Temperature-Programmed Heating Conditions. Biosci. Biotechnol. Biochem. 2012, 76, 2156–2158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rachtanapun, P.; Tangnonthaphat, T. Effects of Packaging Types and Storage Temperatures on the Shelf Life of Fresh Rice Noodles under Vacuum Conditions. Chiang Mai J. Sci. 2011, 38, 579–589. [Google Scholar]

- Morgan, C.A.; Herman, N.; White, P.A.; Vesey, G. Preservation of micro-organisms by drying; A review. J. Microbiol. Methods 2006, 66, 183–193. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Lipan, L.; Cano-Lamadrid, M.; Kharaghani, A.; Masztalerz, K.; Carbonell-Barrachina, Á.A.; Figiel, A. Comparison of traditional and novel drying techniques and its effect on quality of fruits, vegetables and aromatic herbs. Foods 2020, 9, 1261. [Google Scholar] [CrossRef]

- Kongkiattisak, P.; Songsermpong, S. Effect of temperature and velocity of drying air on kinetics, quality and energy consumption in drying process of rice noodles. Kasetsart J. Nat. Sci. 2012, 46, 603–619. [Google Scholar]

- Fayose, F.; Huan, Z. Heat pump drying of fruits and vegetables: Principles and potentials for Sub-Saharan Africa. Int. J. Food Sci. 2016, 2016, 9673029. [Google Scholar] [CrossRef] [Green Version]

- Orak, H.H.; Aktas, T.; Yagar, H.; Selen, S.; Ekinci, N. Effects of hot air and freeze drying methods on antioxidant activity, colour and some nutritional characteristics of strawberry tree (Arbutus unedo L.) fruit. Food Sci. Technol. Int. 2011, 18, 391–402. [Google Scholar] [CrossRef] [PubMed]

- Purwandari, U.; Khoiri, A.; Muchlis, M.; Noriandita, B.; Zeni, N.F.; Lisdayana, N.; Fauziyah, E. Textural, cooking quality, and sensory evaluation of gluten-free noodle made from breadfruit, konjac, or pumpkin flour. Int. Food Res. J. 2014, 21, 1623–1627. [Google Scholar]

- Hii, C.L.; Law, C.L.; Suzannah, S. Drying kinetics of the individual layer of cocoa beans during heat pump drying. J. Food Eng. 2012, 108, 276–282. [Google Scholar] [CrossRef]

- Hii, C.L.; Ogugo, J.F. Effect of pre-treatment on the drying kinetics and product quality of star fruit slices. J. Eng. Sci. Technol. 2014, 9, 122–134. [Google Scholar]

- Nasir, S.; Allai, F.M.; Gani, M.; Ganaie, S.; Gul, K.; Jabeen, A.; Majeed, D. Physical, Textural, Rheological, and Sensory Characteristics of Amaranth-Based Wheat Flour Bread. Int. J. Food Sci. 2020, 2020, 8874872. [Google Scholar] [CrossRef]

- Ritthiruangdej, P.; Parnbankled, S.; Donchedee, S.; Wongsagonsup, R. Physical, chemical, textural and sensory properties of dried wheat noodles supplemented with unripe banana flour. Kasetsart J. Nat. Sci. 2011, 45, 500–509. [Google Scholar]

- Wootton, M.; Bamunuarachchi, A. Application of Differential Scanning Calorimetry to Starch Gelatinization. I. Commercial Native and Modified Starches. Starch-Stärke 1979, 31, 201–204. [Google Scholar] [CrossRef]

- Barrett, D.M.; Beaulieu, J.C.; Shewfelt, R. Color, flavor, texture, and nutritional quality of fresh-cut fruits and vegetables: Desirable levels, instrumental and sensory measurement, and the effects of processing. Crit. Rev. Food Sci. Nutr. 2010, 50, 369–389. [Google Scholar] [CrossRef]

- Astuti, R.D.; David, W. Ardiansyah Sensory evaluation of noodles substituted by sweet potato flour and rice bran. Curr. Res. Nutr. Food Sci. 2020, 8, 144–154. [Google Scholar] [CrossRef]

- Tun, M.M.; Juchelková, D. Drying methods for municipal solid waste quality improvement in the developed and developing countries: A review. Environ. Eng. Res. 2019, 24, 529–542. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.; Li, M.; Wei, Y.; Guo, B.; Brennan, M.; Brennan, C.S. Quality differences between fresh and dried buckwheat noodles associated with water status and inner structure. Foods 2021, 10, 187. [Google Scholar] [CrossRef]

- Kuen, N.H.; Hamid, M.A.; Mamat, H.; Akanda, J.H.; Ahmad, F. Effect of Chickpea and Okara Composite Flours on the Quality of Instant Noodles. In Proceedings of the First International Conference on Social, Applied Science, and Technology in Home Economics, Surabaya, Indonesia, 12 September 2017. [Google Scholar]

- Al-Baarri, A.N.; Widayat Aulia, R.; Prahasiwi, E.K.; Mawarid, A.A.; Pangestika, W.; Lestari, F.P. The hardness analysis of noodles made from modified cassava flour, spirulina (Spirulina platensis) and basil leaves extract (Ocimum sanctum L.). IOP Conf. Ser. Earth Environ. Sci. 2021, 653, 012051. [Google Scholar] [CrossRef]

- El-Sohaimy, S.A.; Brennan, M.; Darwish, A.M.G.; Brennan, C. Physicochemical, texture and sensorial evaluation of pasta enriched with chickpea flour and protein isolate. Ann. Agric. Sci. 2020, 65, 28–34. [Google Scholar] [CrossRef]

- Agusman, M.; Wahyuni, T. The nutritional quality and preference of wheat noodles incorporated with Caulerpa sp. seaweed. Int. Food Res. J. 2020, 27, 445–453. [Google Scholar]

- Victoriano, L.G.; Güemes Vera, N.; Soto Simental, S.; Hernández, J.P.; Quintero Lira, A.; Piloni Martini, J. Quality properties of doughs and noodles using chayotextle (Sechiem edule) flours. Food Sci. Technol. 2021, 41, 158–166. [Google Scholar] [CrossRef]

- Huang, L.L.; Zhang, M.; Mujumdar, A.S.; Lim, R.X. Comparison of four drying methods for re-structured mixed potato with apple chips. J. Food Eng. 2011, 103, 279–284. [Google Scholar] [CrossRef]

- Tiony, M.C.; Irene, O. Quality and sensory properties of instant fried noodles made with soybean and carrot pomace flour. Afr. J. Food Sci. 2021, 15, 92–99. [Google Scholar] [CrossRef]

- Xu, J.; Bock, J.E.; Stone, D. Quality and textural analysis of noodles enriched with apple pomace. J. Food Process. Preserv. 2020, 44, 1–8. [Google Scholar] [CrossRef]

- Zhang, L.; Nishizu, T.; Hayakawa, S.; Goto, K. Effects of Different Drying Conditions on Pasta Quality. In Proceedings of the 11th International Congress on Engineering and Food, Athens, Greece, 22–26 May 2011. [Google Scholar]

- Zhang, Y.Q.; Hui, Y.; Wang, Y.; Zhang, B.; Guo, B.L.; Zhang, G.Q.; Wei, Y.M. Effects of Drying Temperature and Relative Humidity on Quality Properties of Chinese Dried Noodles. J. Food Qual. 2020, 2020, 8843974. [Google Scholar] [CrossRef]

- Nour, V.; Trandafir, I.; Ionica, M.E. Effects of Pre-Treatments and Drying Tempera- Tures on the Quality of Dried Button Mushrooms. J. Hortic. Biol. Environ. 2011, 2, 15–24. [Google Scholar]

- Al-Baarri, A.N.; Widayat Cahyono, B.; Baety Nirbaya, A.; Khairunnisa, U.; Pangestika, W. The Color Analysis of Noodle Made from Modified Cassava Flour. IOP Conf. Ser. Earth Environ. Sci. 2020, 518, 012041. [Google Scholar] [CrossRef]

- Martins, S.; Jongen, W.; Boekel, V.; Martinus, A. A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci. Technol. 2001, 11, 364–373. [Google Scholar] [CrossRef]

- Pei, F.; Yang, W.J.; Shi, Y.; Sun, Y.; Mariga, A.M.; Zhao, L.Y.; Fang, Y.; Ma, N.; An, X.X.; Hu, Q.H. Comparison of Freeze-Drying with Three Different Combinations of Drying Methods and Their Influence on Colour, Texture, Microstructure and Nutrient Retention of Button Mushroom (Agaricus bisporus) Slices. Food Bioprocess Technol. 2014, 7, 702–710. [Google Scholar] [CrossRef]

- Henriques, F.; Guiné, R.P.F.; Barroca, M.J. Infl uence of Drying Treatment on Physical Properties of Pumpkin. Croat. J. Food Technol. Biotechnol. Nutr. 2012, 7, 53–58. [Google Scholar]

- Fan, K.; Zhang, M.; Mujumdar, A.S. Recent developments in high efficient freeze-drying of fruits and vegetables assisted by microwave: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1357–1366. [Google Scholar] [CrossRef]

- Bao, H.; Zhou, J.; Yu, J.; Wang, S. Effect of Drying Methods on Properties of Potato Flour and Noodles Made with Potato Flour. Foods 2021, 10, 1115. [Google Scholar] [CrossRef]

- Dewi, E.N. Quality Evaluation of Dried Noodle With Seaweeds Puree Subsitution. J. Coast. Dev. 2011, 14, 151–158. [Google Scholar]

- Kajihausa, O.E.; Fasasi, R.A.; Atolagbe, Y.M. Effect of Different Soaking Time and Boiling on the Proximate Composition and Functional Properties of Sprouted Sesame Seed Flour. Niger. Food J. 2014, 32, 8–15. [Google Scholar] [CrossRef] [Green Version]

- Gary, G. Hou Asian Noodles Science, Technology, and Processing, 1st ed.; John Wiley & Sons: Oregon, OR, USA, 2010. [Google Scholar]

- Yang, Z.; Zhu, E.; Zhu, Z.; Wang, J.; Li, S. A comparative study on intermittent heat pump drying process of Chinese cabbage (Brassica campestris L.ssp.) seeds. Food Bioprod. Process. 2013, 91, 381–388. [Google Scholar] [CrossRef]

- Gatade, A.A.; Sahoo, A.K. Effect of additives and steaming on quality of air dried noodles. J. Food Sci. Technol. 2015, 52, 8395–8402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ross, A.; Crosbie, G.B. Asian wheat flour noodles. In The Encyclopedia of Grain Science; Wrigley, C.W., Corke, H., Walker, C.E., Eds.; Elsevier Academic Press: Oxford, UK, 2004; pp. 304–312. [Google Scholar]

- Khatkar, A.B.; Kaur, A. Effect of Different Methods of Instantization, Drying and Gum Addition on Quality Characteristics of Instant Noodles. Food Nutr. 2018, 1.1, 1–8. [Google Scholar]

- Tangthanantorn, J.; Wichienchot, S.; Sirivongpaisal, P. Development of fresh and dried noodle products with high resistant starch content from banana flour. Food Sci. Technol. 2021, 2061. [Google Scholar] [CrossRef]

- Obadi, M.; Chen, Y.; Qi, Y.; Liu, S.; Xu, B. Effects of different pre-gelatinized starch on the processing quality of high value-added Tartary buckwheat noodles. J. Food Meas. Charact. 2020, 14, 3462–3472. [Google Scholar] [CrossRef]

- Liu, J.; Yang, R.; Yang, F. Study on basic properties of freeze-drying gelatinized glutinous rice starch. Adv. Mater. Res. 2014, 1010–1012, 1793–1796. [Google Scholar] [CrossRef]

- Afifah, N.; Ratnawati, L. Quality assessment of dry noodles made from blend of mocaf flour, rice flour and corn flour. IOP Conf. Ser. Earth Environ. Sci. 2017, 101, 012021. [Google Scholar] [CrossRef]

- Sakiyan, O.; Sumnu, G.; Sahin, S.; Meda, V.; Koksel, H.; Chang, P. A Study on Degree of Starch Gelatinization in Cakes Baked in Three Different Ovens. Food Bioprocess Technol. 2011, 4, 1237–1244. [Google Scholar] [CrossRef]

- Champathi Gunathilake, D.M.C. Application of two temperature hot water soaking for improving of paddy parboiling process. Agric. Eng. Int. CIGR J. 2018, 20, 164–168. [Google Scholar]

- Tao, C.; Wang, K.; Liu, X.; Gou, E. Effects of potato starch on the properties of wheat dough and the quality of fresh noodles. CYTA J. Food 2020, 18, 427–434. [Google Scholar] [CrossRef]

- Ma, Y.J.; Guo, X.D.; Liu, H.; Xu, B.N.; Wang, M. Cooking, Textural, Sensorial, and Antioxidant Properties of Common and Tartary Buckwheat Noodles. Food Sci. Biotechnol. 2013, 22, 153–159. [Google Scholar] [CrossRef]

- Antal, T. Comparative study of three drying methods: Freeze, hot airassisted freeze and infrared-assisted freeze modes. Agron. Res. 2015, 13, 863–878. [Google Scholar]

| Quality Analysis | Scale Values 14  1 1 |

|---|---|

| Texture | Low  High High |

| Colour | High  Low Low |

| Fat Content | High  Low Low |

| Starch Gelatinization | High  Low Low |

| Treatment | Total Colour Change, ΔE | ||

|---|---|---|---|

| Hot Air Drying | 30 °C | Non-oil Coated | 28.367 ± 3.092 cd |

| Original | 35.100 ± 2.307 bc | ||

| 60 °C | Non-oil Coated | 35.900 ± 5.242 abc | |

| Original | 36.767 ± 5.918 abc | ||

| 90 °C | Non-oil Coated | 43.033 ± 2.307 ab | |

| Original | 43.867 ± 1.498 ab | ||

| HPD | 38 °C | Non-oil Coated | 41.233 ± 4.302 ab |

| Original | 42.267 ± 4.912 ab | ||

| 50 °C | Non-oil Coated | 43.000 ± 2.821 ab | |

| Original | 45.667 ± 3.500 a | ||

| Freeze Drying | −10 °C | Non-oil Coated | 23.033 ± 1.290 de |

| Original | 18.033 ± 3.099 e | ||

| −40 °C | Non-oil Coated | 19.333 ± 1.124 de | |

| Original | 18.400 ± 1.473 de | ||

| Drying Procedures | Texture Analysis | Colour Analysis | Oil Content | Starch Gelatinization | Average | Ranking | ||

|---|---|---|---|---|---|---|---|---|

| Hot Air Drying | 30 °C | Non-oil Coated | 1 | 5 | 1 | 5 | 4 | 3 |

| Original | 8 | 6 | 8 | 6 | 6.5 | 8 | ||

| 60 °C | Non-oil Coated | 2 | 8 | 2 | 8 | 6.25 | 6 | |

| Original | 10 | 10 | 10 | 10 | 9.5 | 11 | ||

| 90 °C | Non-oil Coated | 6 | 12 | 6 | 12 | 10.75 | 12 | |

| Original | 12 | 14 | 12 | 14 | 13.25 | 14 | ||

| Heat Pump Drying | 38 °C | Non-oil Coated | 3 | 7 | 3 | 7 | 6.5 | 7 |

| Original | 9 | 9 | 9 | 9 | 9.25 | 9 | ||

| 50 °C | Non-oil Coated | 4 | 11 | 4 | 11 | 9.25 | 10 | |

| Original | 11 | 13 | 11 | 13 | 12.5 | 13 | ||

| Freeze Drying | −10 °C | Non-oil Coated | 5 | 2 | 5 | 2 | 3.25 | 2 |

| Original | 13 | 4 | 13 | 4 | 5.5 | 4 | ||

| −40 °C | Non-oil Coated | 7 | 1 | 7 | 1 | 3 | 1 | |

| Original | 14 | 3 | 14 | 3 | 5.5 | 5 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ismail, M.H.; Lik, H.C.; Routray, W.; Woo, M.W. Determining the Effect of Pre-Treatment in Rice Noodle Quality Subjected to Dehydration through Hierarchical Scoring. Processes 2021, 9, 1309. https://doi.org/10.3390/pr9081309

Ismail MH, Lik HC, Routray W, Woo MW. Determining the Effect of Pre-Treatment in Rice Noodle Quality Subjected to Dehydration through Hierarchical Scoring. Processes. 2021; 9(8):1309. https://doi.org/10.3390/pr9081309

Chicago/Turabian StyleIsmail, Muhammad Heikal, Hii Ching Lik, Winny Routray, and Meng Wai Woo. 2021. "Determining the Effect of Pre-Treatment in Rice Noodle Quality Subjected to Dehydration through Hierarchical Scoring" Processes 9, no. 8: 1309. https://doi.org/10.3390/pr9081309

APA StyleIsmail, M. H., Lik, H. C., Routray, W., & Woo, M. W. (2021). Determining the Effect of Pre-Treatment in Rice Noodle Quality Subjected to Dehydration through Hierarchical Scoring. Processes, 9(8), 1309. https://doi.org/10.3390/pr9081309