Design and Optimization of a Curved-Crease-Folding Process Applied to a Light Metallic Structure

Abstract

:1. Introduction

- -

- The realization of an algorithm based on generative methods that are able to describe the curved-crease-folding process;

- -

- Describing the material’s behaviour in the algorithm;

- -

- The selection of suitable production methods for spatial structures realization.

2. Materials and Methods

- -

- The development of an algorithm for the curved crease folding design;

- -

- The analysis of the material behavior after folding at different length scales from micro/mesoscale to macroscale level in the proximity and at a distance from the folding paths;

- -

- The development of a production method for the experimental model realization and specific testing of the spatial structure to validate the design.

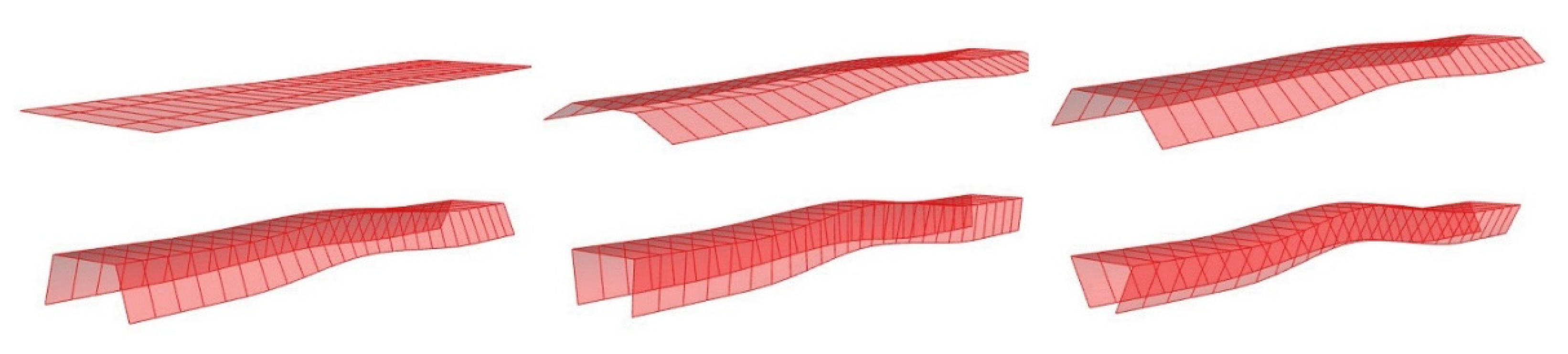

2.1. The Development of the Curved-Crease-Folded Surfaces Using Digital Design

- -

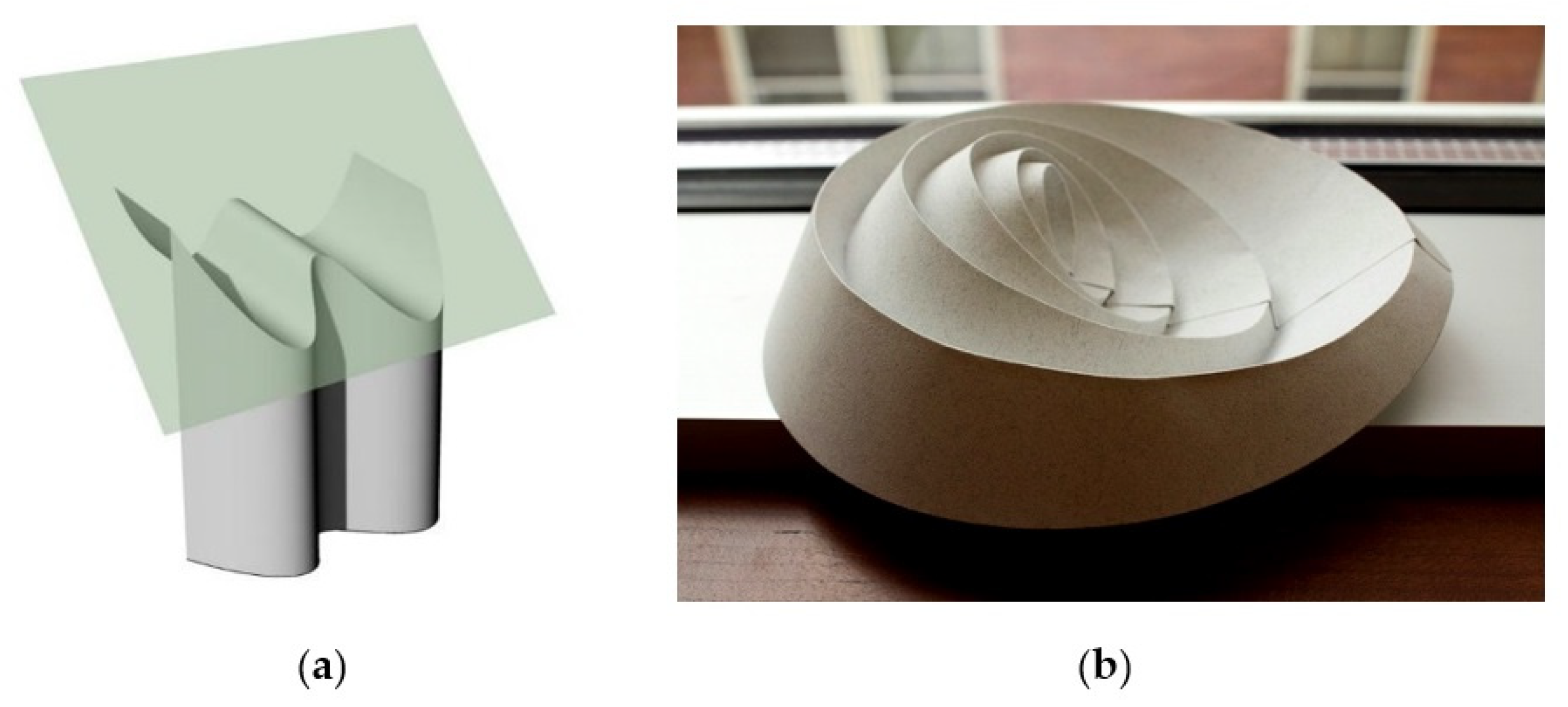

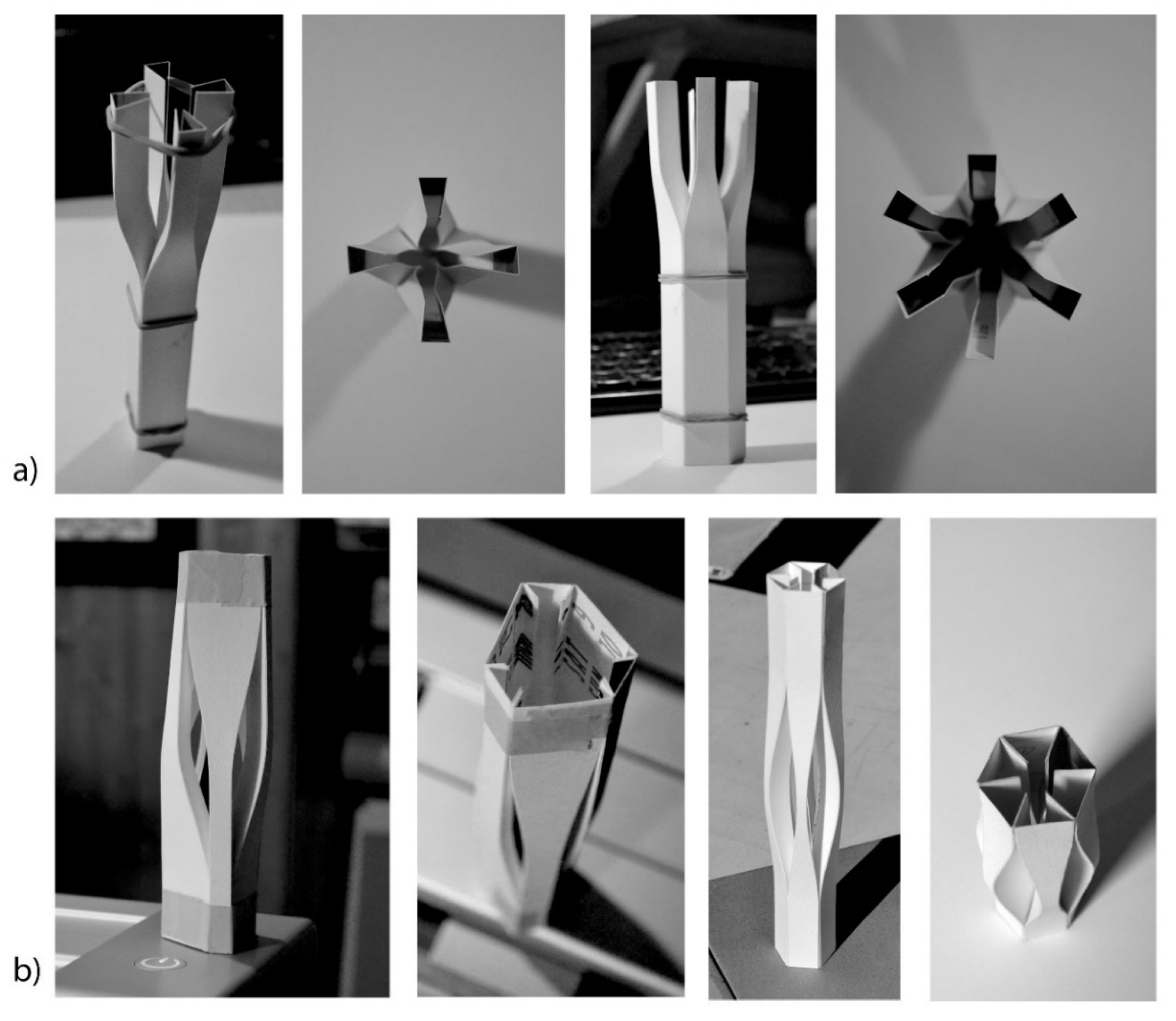

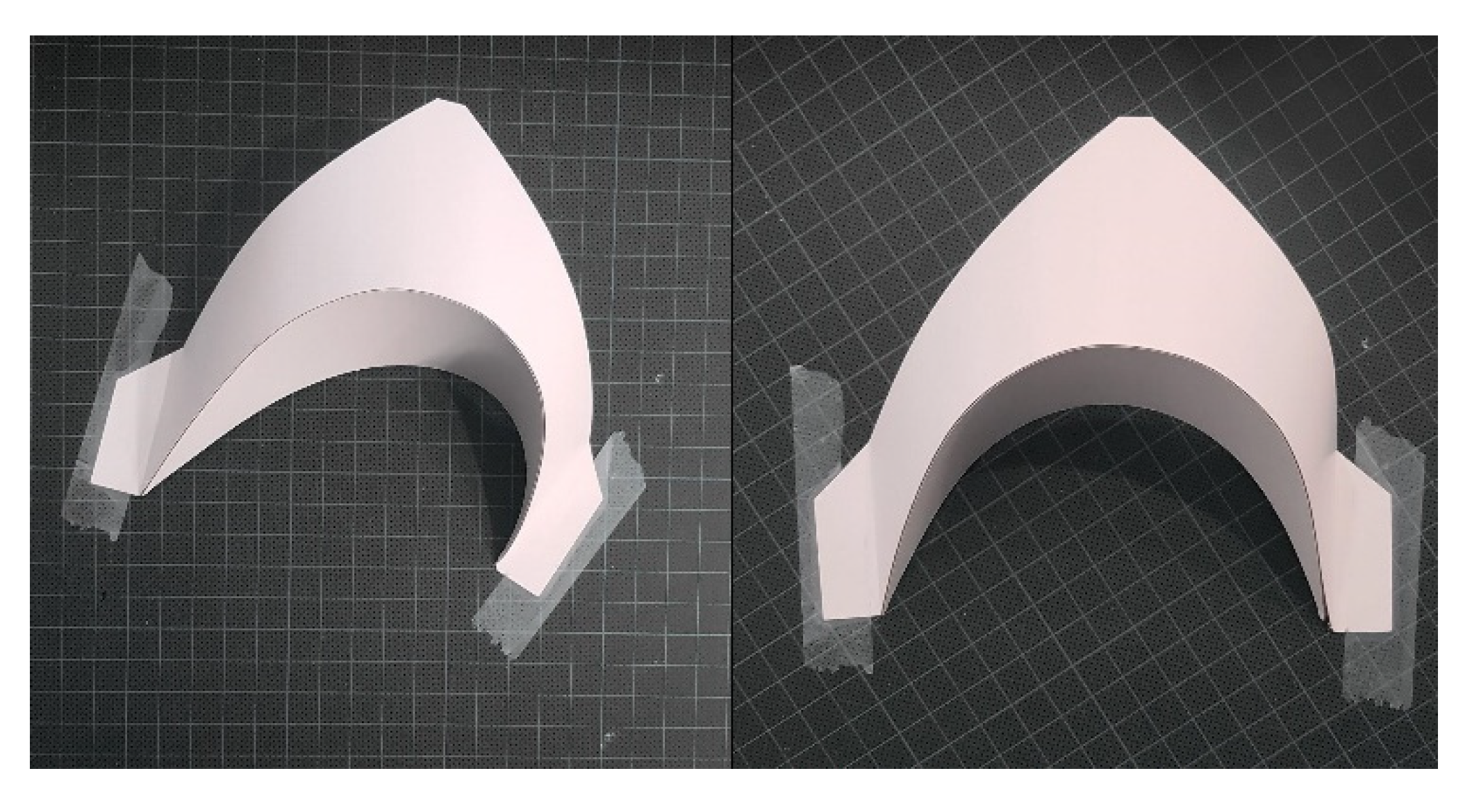

- Initially, a design solution was sought using physical models (usually cardboard models).

- -

- Once a plausible idea arose, the planar development was digitally generated (understood as a two-dimensional shape that could be folded into a three-dimensional shape, also called the “net” of the crease-folded element), preferably in an algorithmic manner; this approach allowed for easily changing many parameters. The planar development/the net with the folding trajectories that were already marked was a key object in the design process. Depending on the design accuracy and the material’s intrinsic mechanical properties, the result may or may not the expected one.

- -

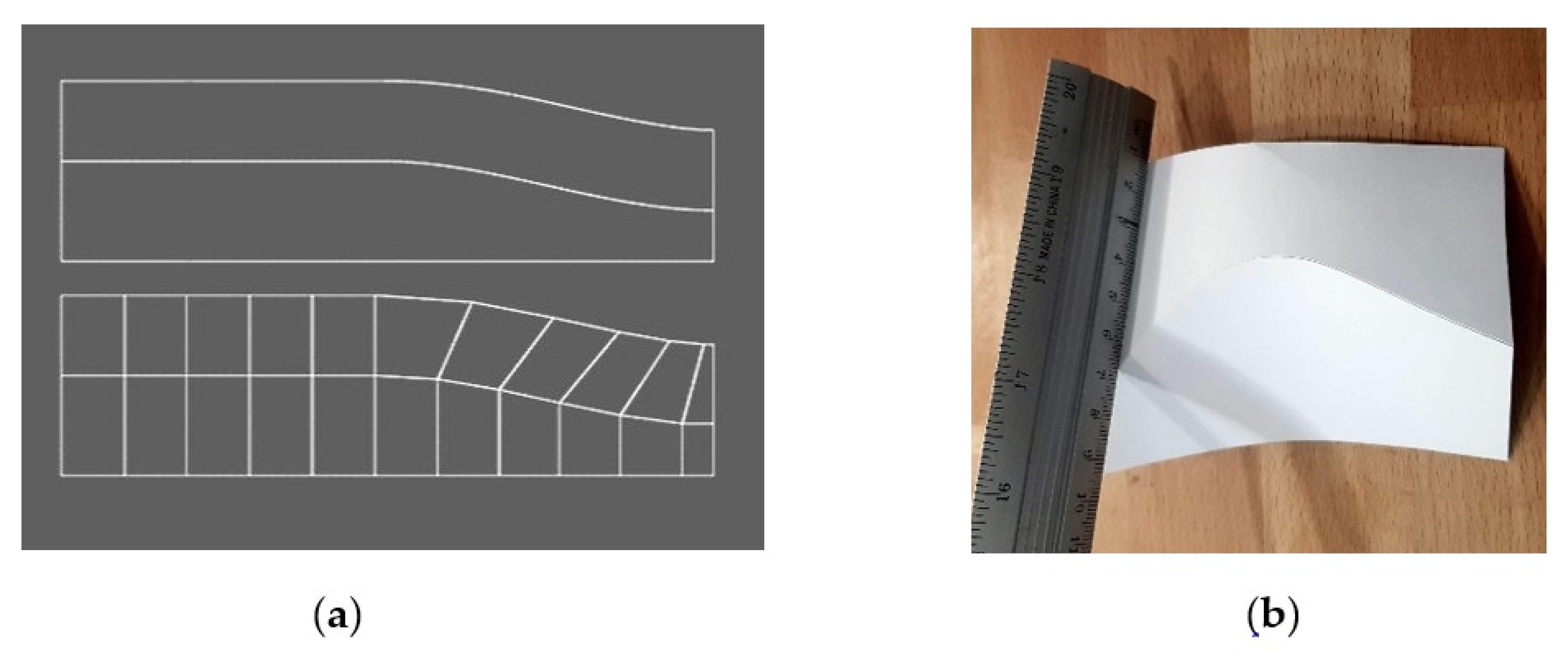

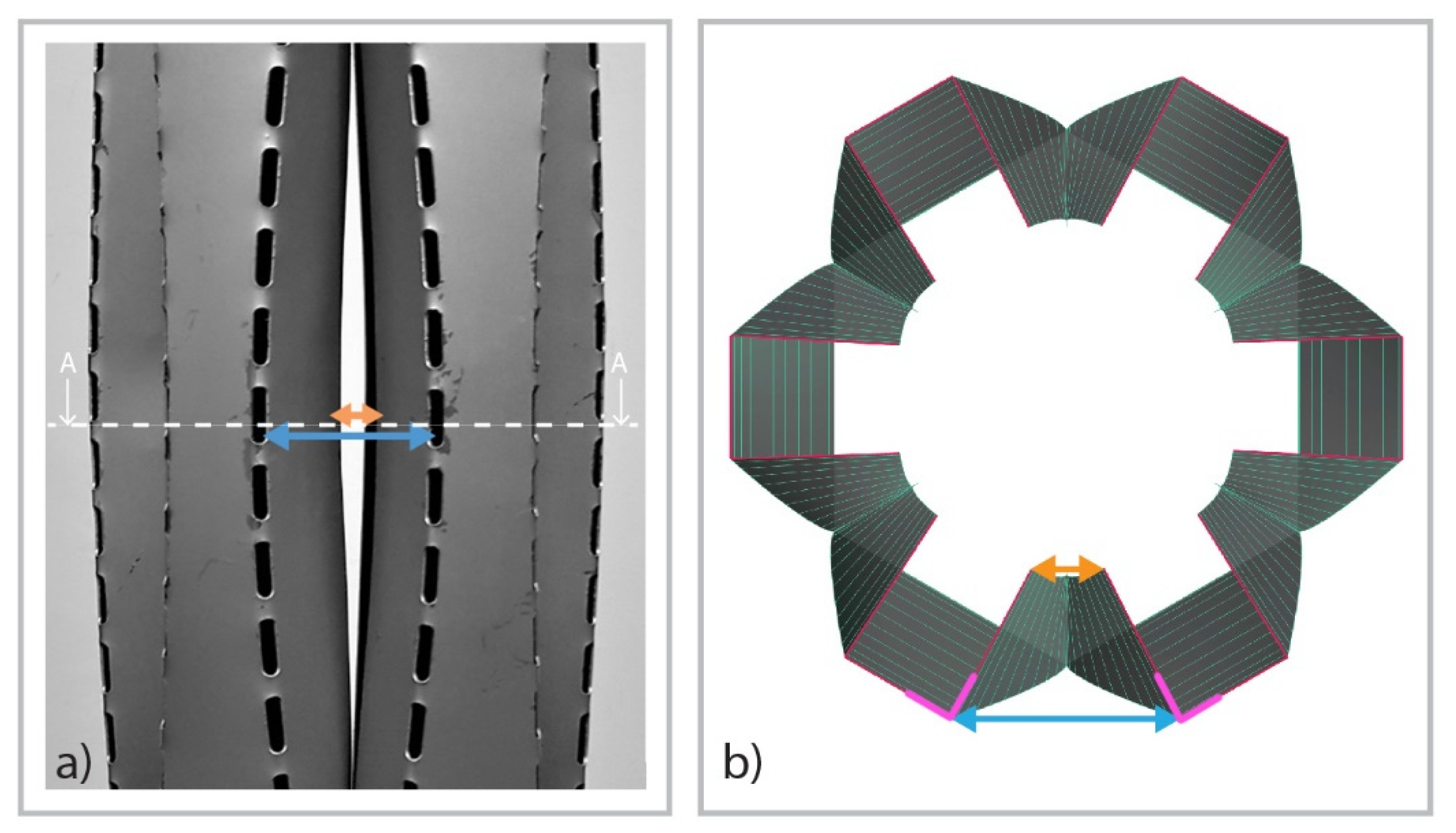

- The simulation of the curved-crease-folding process took place using an interpretation/conversion of the planar development (that would be used for fabrication) as a rigid origami pattern (Figure 3a (bottom)). No analogies with the numerical simulations (FEM, for example) could be done. Rigid origami uses polyhedral planar plates that are joined by rectilinear hinges [43]; just for the rigid origami pattern, everything was based on straight lines.

- -

- The above conversion required the so-called “ruling lines” of the curved folded spatial shape (Figure 3b). A particular curved crease planar development did not describe a single possible folding outcome (Figure 4); it depended on the way the first strip/surface was bent. This, in turn, determined the shape/curvature of the adjacent piece, and so on. In any case, the outcome was a ruled surface, which was therefore developable and integrated the ruling lines.

- -

- Different folding variations of the same planar development exhibited differently oriented ruling lines, which changed their orientation depending on the curvature of the strips that formed the overall shape. This means that the “rulings pattern” determined the way in which the planar development was digitally folded; more specifically, it determined the way the separate strips/parts of the planar development were folded/bent during the folding process.

- -

- The orientation of the ruling lines on the planar development could be transferred in the digital representation.

- -

- Digital analysis: at this stage, the planar development (converted initially into polyhedral planar plates joined by rectilinear hinges, i.e., a rigid origami) was folded digitally/virtually; after the virtual folding, the folded element could be subjected to different analyses, either structural or otherwise.

2.2. Algorithmic Design of the CCF Thin-Walled Metallic Structure

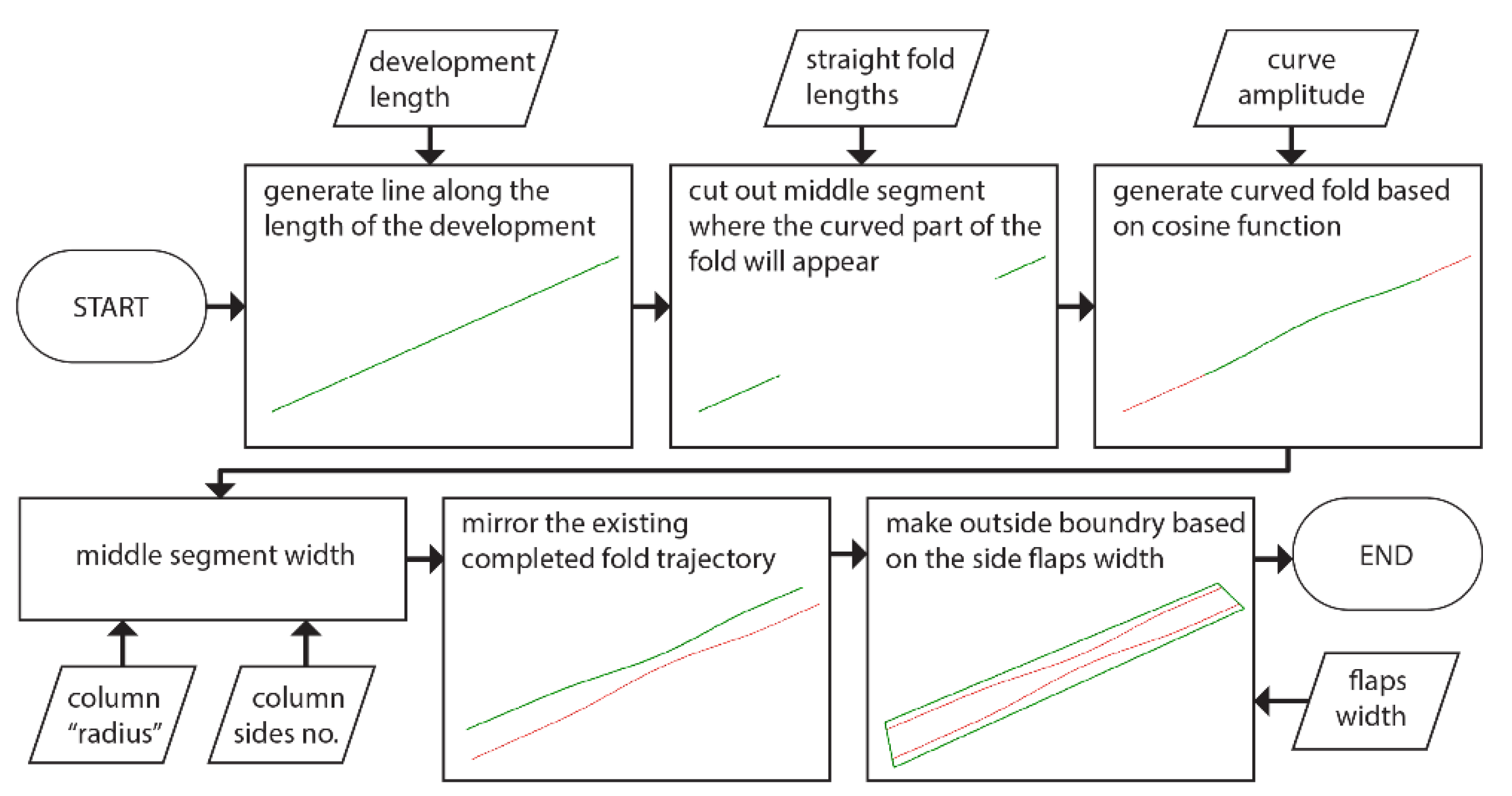

2.2.1. The Algorithm for Rationalized Planar Development

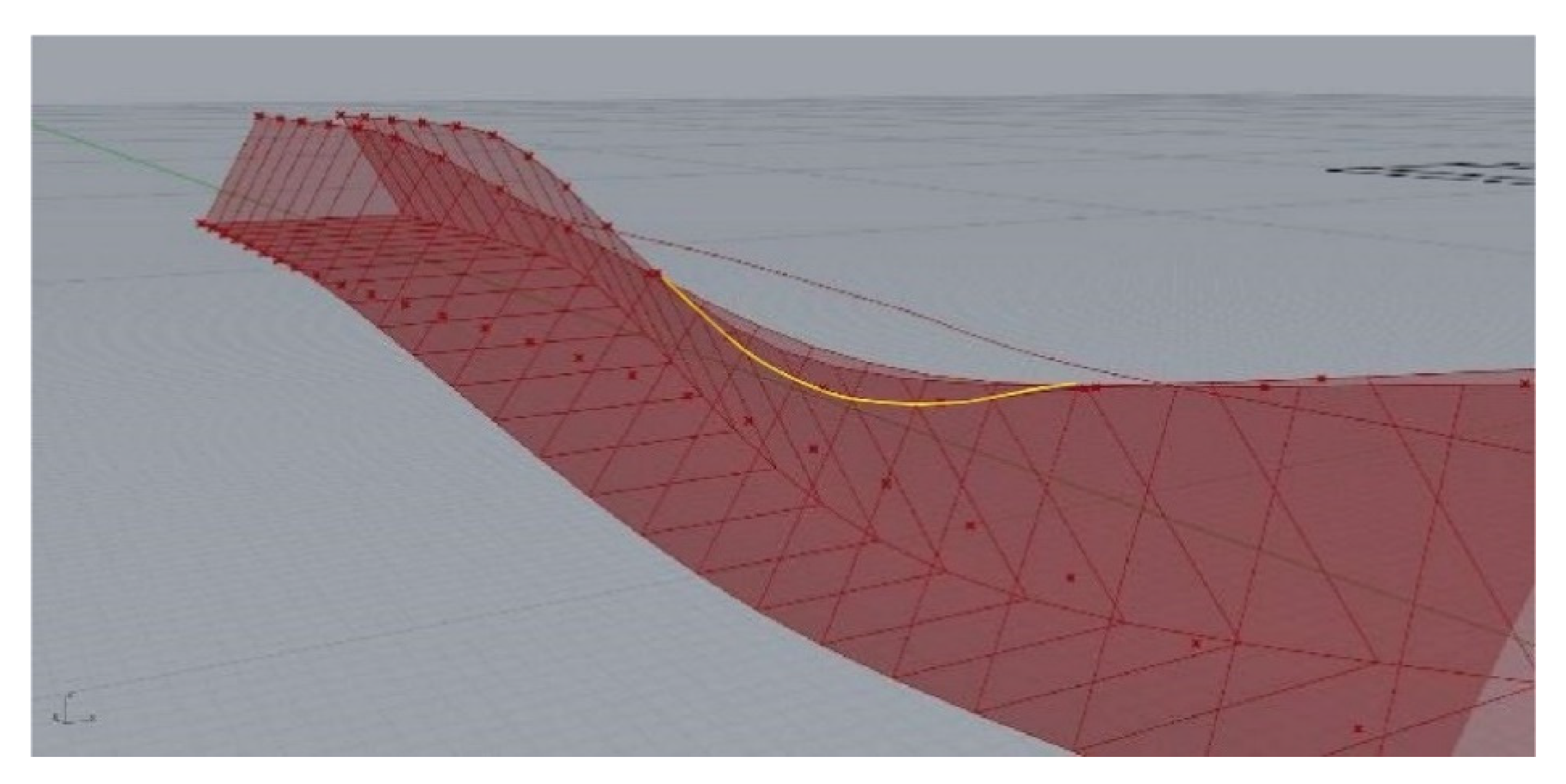

2.2.2. Concept of the Digital/Virtual Simulation of Curved Crease Folding for the Constitutive Element of the Column

2.2.3. The Development of the Algorithm for Digital Curved-Crease-Folding Simulation

- -

- A set of points on the lower straight segments of the folding lines are used as anchors, meaning they keep the mesh in place when it gets folded.

- -

- Their counterparts on the upper straight segments are able to slide toward the middle as the mesh folds and therefore compress longitudinally, but they are not allowed to migrate away from the area where they are originally located.

- -

- Kangaroo works on assembles made of “springs,” which are straight-line segments that can be rigid or flexible; the mesh is interpreted as a network of rigid springs along the edges of the quads, but rigid springs are also generated on the diagonals to ensure they do not skew during the process.

- -

- A “planarize” component is also used to ensure the quad faces remain planar when the folding occurs so that they reproduce the mechanics of real-world rigid plate origami (which can estimate a curved folding process).

- -

- A “plastic hinge” goal is used that implements a limited resistance to the folding of the model.

- -

- A solid point collide goal is used so that the points on the lateral flaps of the development/mesh are pushed by two virtual “banks.” These banks are a pair of boxes/parallelepipeds that will gradually rotate (via user input) to fold the mesh into place. The folding process should be gradual, from the initial flat net to folded one, allowing for providing a relevant shape of the mesh with Kangaroo. The final folding angle cannot be used directly.

- -

- After the conditions for folding are defined and Kangaroo (compiler) is running, the angle is gradually increased until it reaches its end value, which is based on the number of sides of the column.

- -

- After the mesh is folded, it is reproduced in a circular array to display the column as a whole.

2.3. Post-Folding Analysis

- -

- The gradient of properties in different areas of the folded element.

- -

- The additional tension gained after folding; this was partially implemented by some authors just for certain particular designs [48].

- -

- The influence of the solid–void ratio for the case in which the folding lines are marked on the physical planar cut-out using perforations.

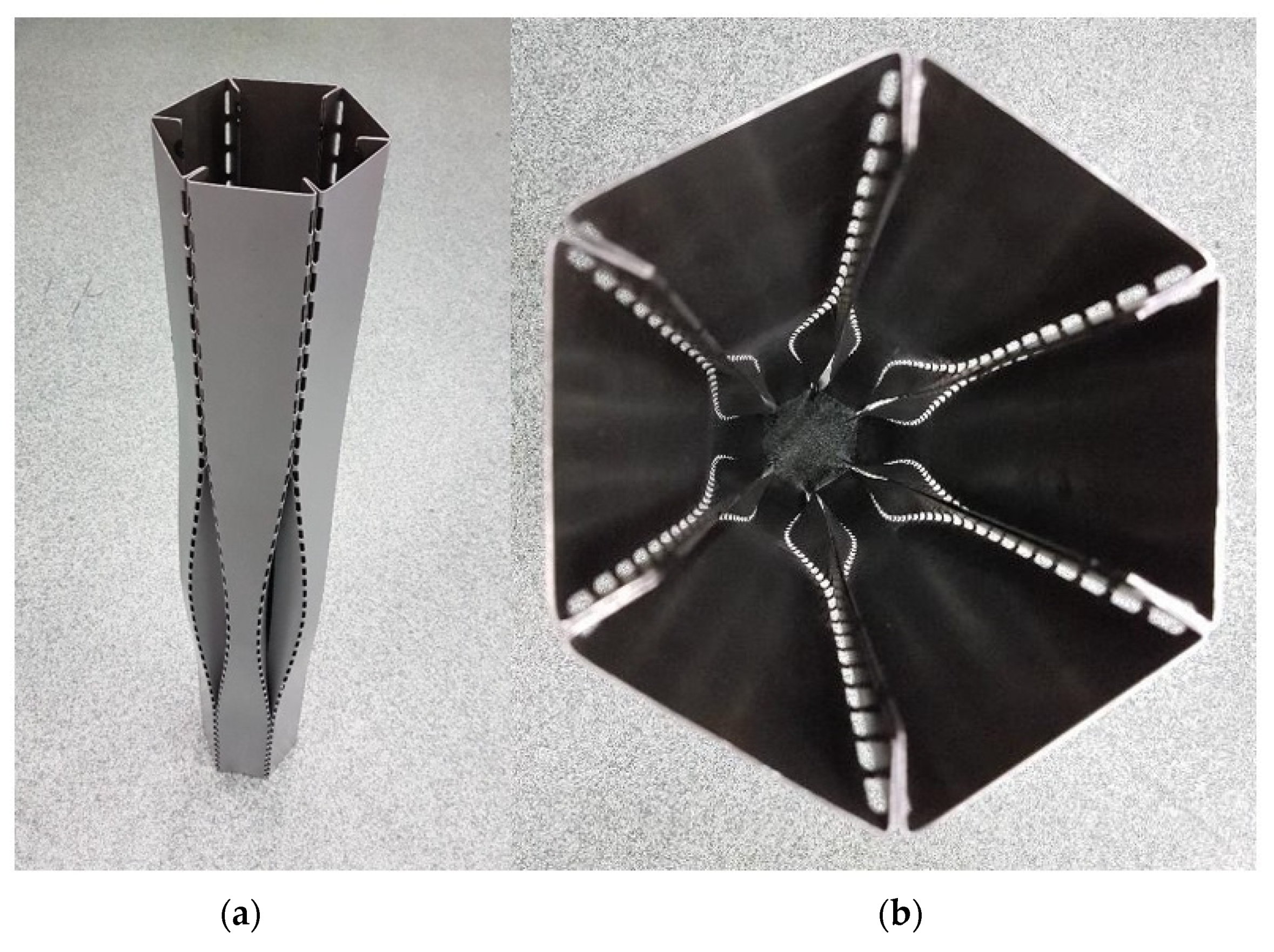

2.4. The Thin-Walled Metallic Spatial Structure Fabrication

2.5. Evaluation and Validation of the Design Results

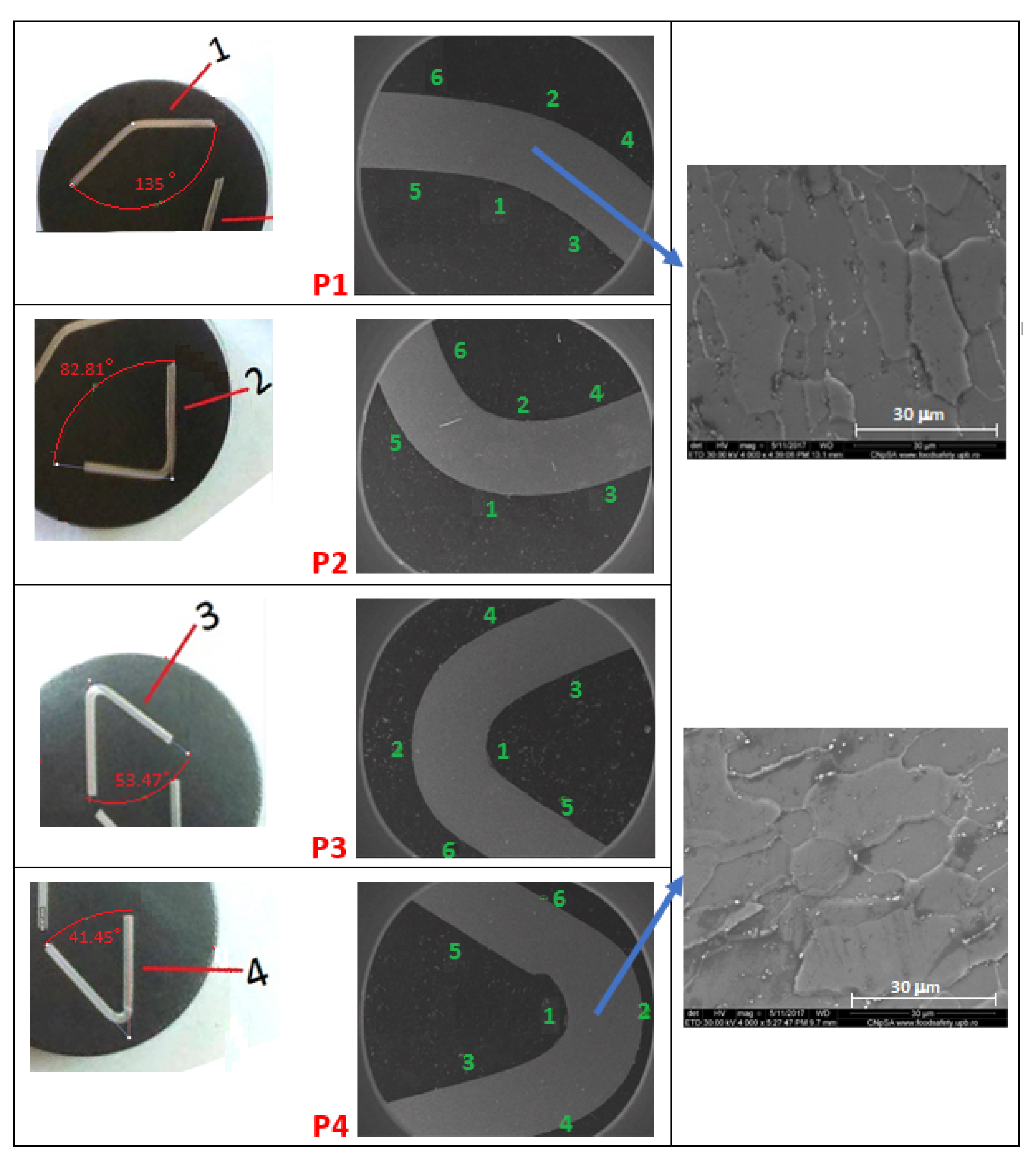

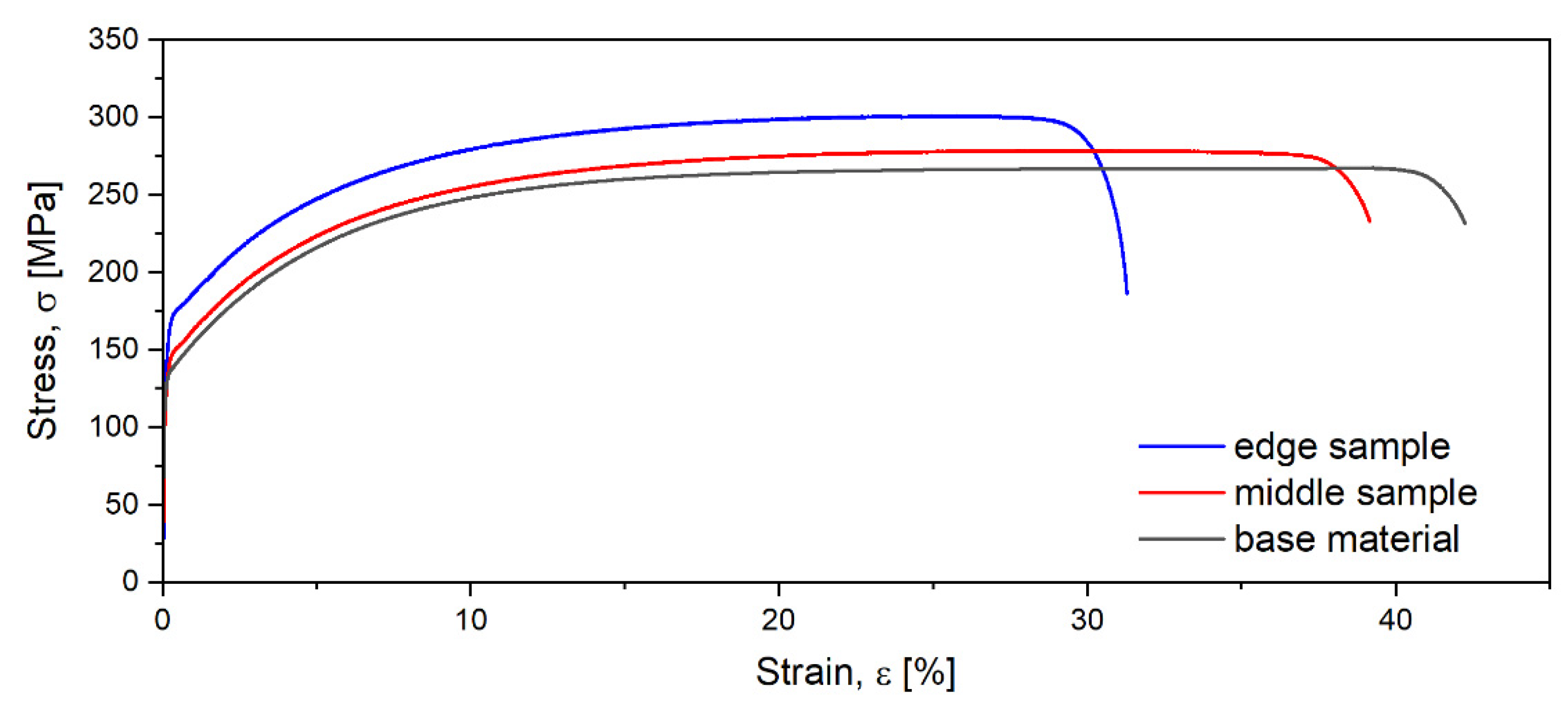

2.5.1. Analysis of the Metallic Material’s Behaviour after the CCF Process

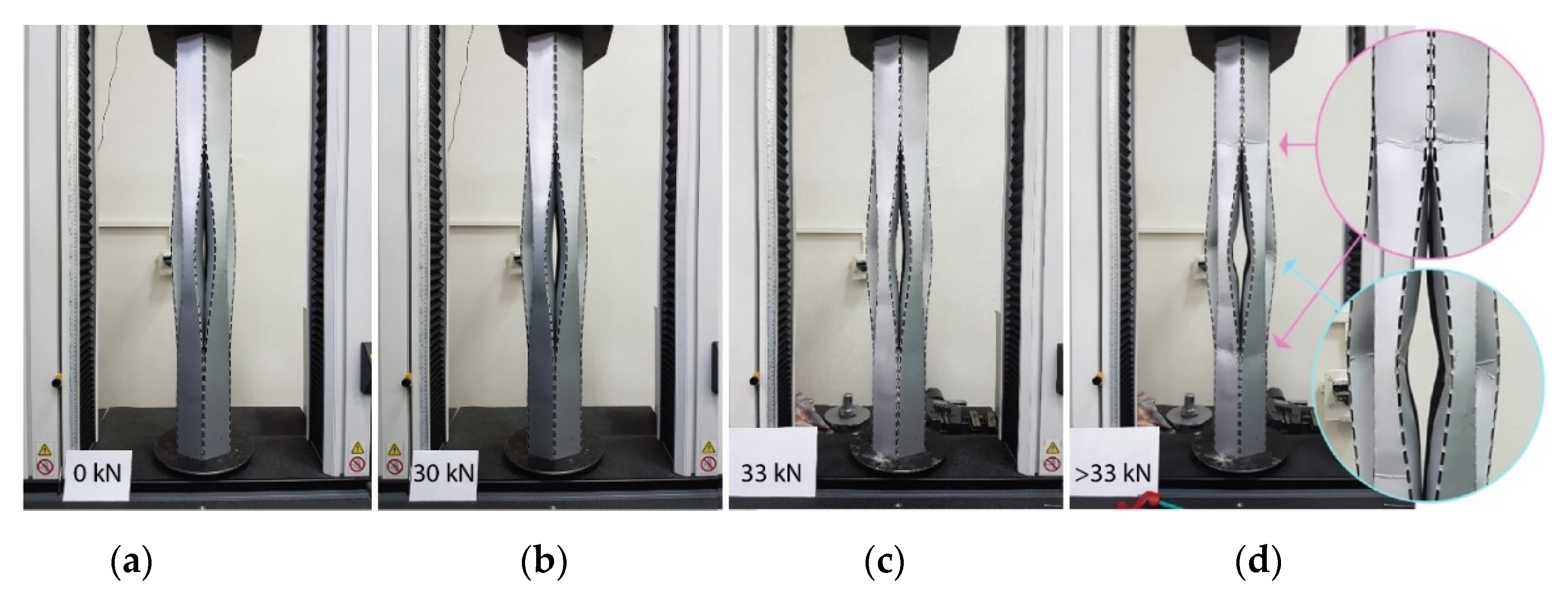

2.5.2. Mechanical and Structural Testing of the Metallic Column

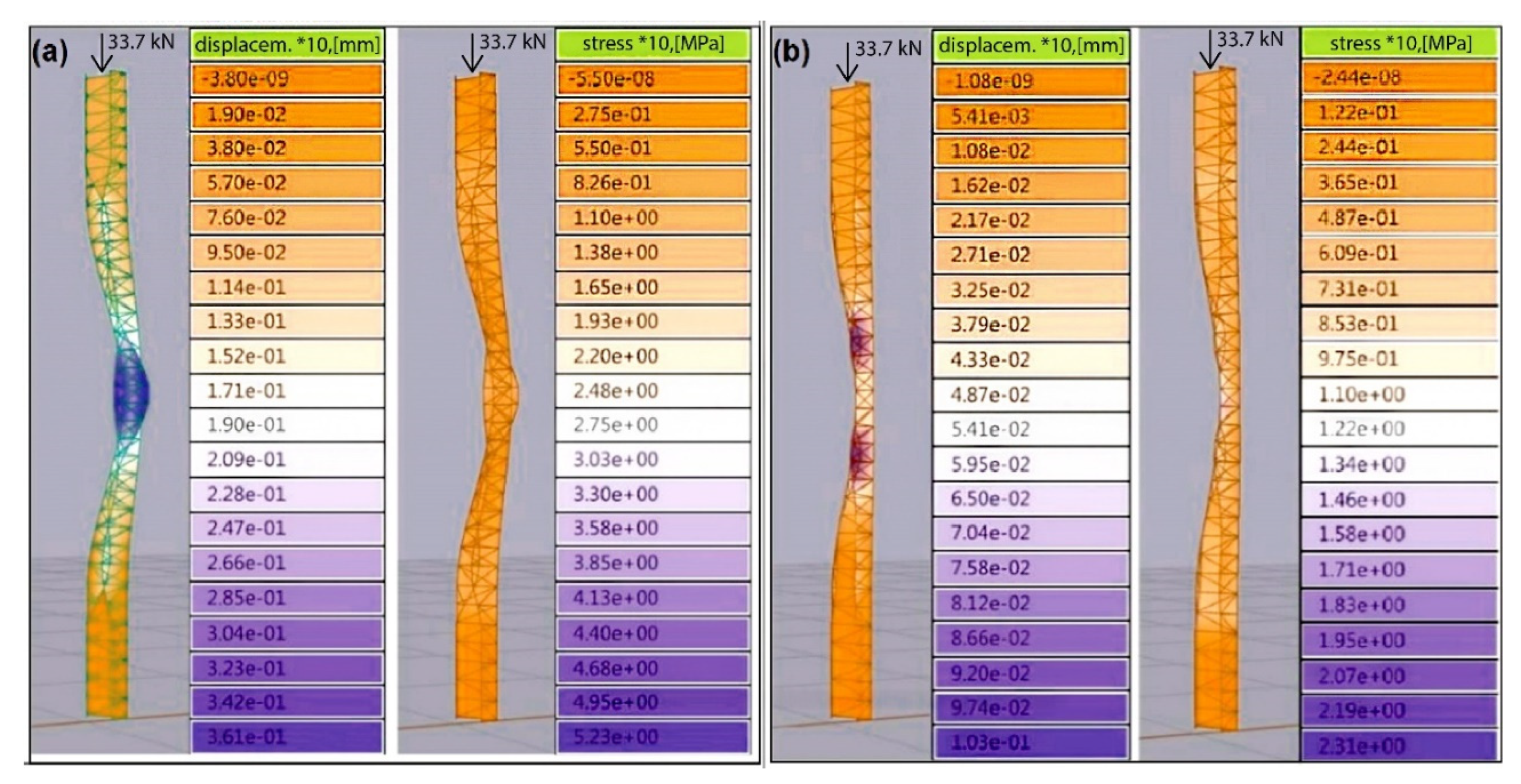

3. Results

3.1. Analysis of the Metallic Material’s Behavior after the CCF Process

3.2. Mechanical Testing of the Metallic Column

4. Discussion

4.1. Metallic Material’s Behavior after the CCF Process

4.2. The Mechanical Behavior of the Metallic Column during Loading

4.3. Design Modifications and Prospects

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Flory, S.; Nagai, Y.; Isvoranu, F.; Pottmann, H.; Wallner, J. Ruled free forms. In Advances in Architectural Geometry 2012; Hanssen, L.M., Ed.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 57–66. [Google Scholar]

- Wong, J.F. The text of free-form architecture: Qualitative study of the discourse of four architects. Des. Stud. 2010, 31, 237–267. [Google Scholar] [CrossRef]

- Liu, J.; Fan, X.; Wen, G.; Qing, Q.; Wang, H.; Zhao, G. A Novel Design Framework for Structures/Materials with Enhanced Mechanical Performance. Materials 2018, 11, 567. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luck, R. Kinds of seeing and spatial reasoning: Examining user participation at an architectural design event. Design Studies 2012, 33, 557–588. [Google Scholar] [CrossRef]

- Bullock, G.N.; Denham, M.J.; Parmee, I.C.; Wade, J.G. Developments in the use of the genetic algorithm in engineering design. Des. Stud. 1995, 16, 507–524. [Google Scholar] [CrossRef]

- Bates-Brkljac, N. Assessing perceived credibility of traditional and computer generated architectural representations. Des. Stud. 2009, 30, 415–437. [Google Scholar] [CrossRef]

- Kaveh, A.; Ghazaan, M.I. Meta-Heuristic Algorithms for Optimal Design of Real-Size Structures; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Wang, X.; Zhang, Q.; Qin, X.; Sun, Y. An efficient discrete optimization algorithm for performance-based design optimization of steel frames. Adv. Struct. Eng. 2020, 23, 411–423. [Google Scholar] [CrossRef]

- Hybs, I.; Gero, J.S. An evolutionary process model of design. Des. Stud. 1992, 13, 273–290. [Google Scholar] [CrossRef]

- Singh, V.; Gu, N. Towards an integrated generative design framework. Des. Stud. 2012, 33, 185–207. [Google Scholar] [CrossRef]

- Vaissier, B.; Pernot, J.P.; Chougrani, L.; Veron, P. Parametric design of graded truss lattice structures for enhanced thermal dissipation. Comput. Aided Des. 2019, 115, 1–12. [Google Scholar] [CrossRef]

- Chahardoli, S.; Alavi Nia, A.; Asadi, M. Parametric investigation of the mechanical behavior of expanding-folding absorbers and their implementation in sandwich panels core. Thin-Walled Struct. 2019, 137, 53–66. [Google Scholar] [CrossRef]

- Talaslioglu, T. Optimal design of steel skeletal structures using the enhanced genetic algorithm methodology. Front. Struct. Civ. Eng. 2019, 13, 863–889. [Google Scholar] [CrossRef]

- Bello-Garcia, A.; Coz Diaz, J.J.; Suarez, F.; Prendes Gero, M.B. Optimization of steel structures with one genetic algorithm according to three international building codes. Rev. Constr. 2018, 17, 47–59. [Google Scholar] [CrossRef] [Green Version]

- Ahlquist, S.; Kampowski, T.; Torghabehi, O.O.; Menges, A.; Speck, T. Development of a digital framework for the computation of complex material and morphological behavior of biological and technological systems. Comput. Aided Des. 2015, 60, 84–104. [Google Scholar] [CrossRef]

- Rezazadeh, F.; Mirghaderi, R.; Hosseini, A.; Talatahari, S. Optimum energy-based design of BRB frames using nonlinear response history analysis. Struct. Multidiscip. Optim. 2017, 57, 1005–1019. [Google Scholar] [CrossRef]

- Mansouri, I.; Soori, S.; Amraie, H.; Hu, J.; Shahbazi, S. Performance based design optimum of CBFs using bee colony algorithm. Steel Compos. Struct. 2018, 27, 613–622. [Google Scholar]

- Mundilova, K. On mathematical folding of curved crease origami: Sliding developables and parametrizations of folds into cylinders and cones. Comput. Aided Des. 2019, 115, 34–41. [Google Scholar] [CrossRef]

- Zhu, L.; Igarashi, T.; Mitani, J. Soft folding. Comput. Graph. Forum 2013, 32, 167–176. [Google Scholar] [CrossRef]

- Lebee, A. From Folds to Structures-a Review. Int. J. Space Struct. 2015, 30, 55–74. [Google Scholar] [CrossRef] [Green Version]

- Kilian, M.; Flory, S.; Chen, Z.; Mitra, N.J.; Sheffer, A.; Pottmann, H. Curved folding. ACM Trans. Graph. 2008, 27, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Gong, H.; Chen, X.; Chen, C.Q. Folding to Curved Surfaces: A Generalized Design Method and Mechanics of Origami-based Cylindrical Structures, September 2016, Scientific Reports 6:33312. Available online: https://www.nature.com/articles/srep33312 (accessed on 13 January 2021).

- Rabinovich, M.; Hoffmann, T.; Sorkine-Hornung, O. Modeling Curved Folding with Freeform Deformations, ACM SIGGRAPH ASIA 2019. In Proceedings of the 12th SIGGRAPH Conference and Exhibition on Computer Graphics and Interactive Techniques in Asia, BCEC Brisbane, Australia, 17–20 November 2019; Available online: https://igl.ethz.ch/publications/igl-bibtex.php#Rabinovich:Curvedfolds:2019 (accessed on 24 January 2020).

- Bhooshan, S.; Bhooshan, V.; ElSayed, M.; Shepherd, P. Applying dynamic relaxation techniques to form-find and manufacture curve-crease folded panels. Simul. Trans. Soc. Modeling Simul. Int. 2015, 91, 773–786. [Google Scholar] [CrossRef] [Green Version]

- Gattas, M.J.; You, Z. Miura-base rigid origami: Parametrizations of curved-crease geometries. J. Mech. Des. 2014, 136, 121404. [Google Scholar] [CrossRef]

- Mitani, J.; Igarashi, T. Interactive Design of Planar Curved Folding by Reflection. Pac. Graph. 2011, 77–81. [Google Scholar] [CrossRef]

- Huffman, D.A. Curvature and Creases: A Primer on Paper. IEEE Trans. Comput. 1976, 10, 1010–1019. [Google Scholar] [CrossRef]

- Photo. Available online: www.flickr.com/photos/53416300@N00/15153304523 (accessed on 10 May 2020).

- Demaine, E.D.; Demaine, M.L.; Koschitz, D.; Tachi, T. Curved Crease Folding a Review on Art, Design and Mathematics, Personal Communication. Available online: http://martindemaine.org/papers/CurvedCrease_IASS2011/paper.pdf (accessed on 10 July 2020).

- Wang, S.; Xia, Y.; Wang, R.; You, L.; Zhang, J. Optimal NURBS conversion of PDE surface-represented high-speed train heads. Optim. Eng. 2019, 20, 907–928. [Google Scholar] [CrossRef] [Green Version]

- Miyashita, S.; DiDio, I.; Ananthabothla, I.; An, B.; Sung, C.; Arabagi, S.; Rus, D. Folding Angle Regulation by Curved Crease Design for Self-Assembling Origami Propellers. J. Mech. Robot. 2015, 7, 2. [Google Scholar] [CrossRef] [Green Version]

- Lee, T.U.; You, Z.; Gattas, J.M. Elastica surface generation of curved-crease origami. Int. J. Sol. Str. 2018, 136, 13–27. [Google Scholar] [CrossRef]

- Vergauwen, L.A.; De Laet, N. De Temmerman, Computational modelling methods for pliable structures based on curved-line folding. Comput. Aided Des. 2017, 83, 51–63. [Google Scholar] [CrossRef]

- Available online: https://www.robofold.com/make/process/process-4/ (accessed on 17 December 2019).

- Gholizadeh, S.; Fattahi, F. Damage-controlled performance-based design optimization of steel moment frames. Struct. Des. Tall Spec. Build. 2018, 27, e1498. [Google Scholar] [CrossRef]

- Eversmann, P.; Ihde, A.; Ehret, A. Curved-folding of thin aluminium plates: Towards structural multi-panel shells. In Proceedings of the IASS Annual Symposia, Hamburg, Germany, 25–27 September 2017. [Google Scholar]

- Garrett, D.; You, Z.; Gattas, J.M. Curved crease tube structures as an energy absorbing crash box. In Proceedings of the ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016; American Society of Mechanical Engineers: New York, NY, USA, 2016. [Google Scholar]

- Raducanu, V.A.; Cojocaru, V.D.; Raducanu, D. Structural architectural elements made of curved folded sheet metal. In Proceedings of the 34th Annual eCAADe Conference, Oulu, Finland, 22–26 August 2016; Volume 2, pp. 409–416. [Google Scholar]

- Nocivin, A.; Raducanu, D.; Raducanu, V.A.; Trisca-Rusu, C.; Moager Poladian, V.; Moldovan, L.; Simionescu, V.; Cinca, I.; Cojocaru, V.D. An Experimental Study for Applying Generative Design to fabricate a light Metallic Structural Element. U.P.B. Sci. Bull. Ser. B 2016, 78, 155–168. [Google Scholar]

- Raducanu, V.A.; Moldovan, L.; Raducanu, D.; MAngelescu, L.; Cinca, I.; Cojocaru, V.D.; Nocivin, A.; Șerban, N. Parametric Design and Structural Performances of a Light Metallic Structure. U.P.B. Sci. Bull. Ser. B 2017, 79, 97–102. [Google Scholar]

- Raducanu, V.A.; Cojocaru, V.D.; Raducanu, D.; Moldovan, L. Curved folded sheet metal structural columns (Poster presentation). In Proceedings of the Advances in Architectural Geometry-AAG2016 Conference, Zurich, Switzerland, 9–13 September 2016. [Google Scholar]

- Tachi, T.; Epps, G. Designing One-DOF Mechanisms for Architecture by Rationalizing Curved Folding. In Proceedings of the International Symposium on Algorithmic Design for Architecture and Urban Design, Tokyo, Japan, 14–16 March 2011. [Google Scholar]

- Miura, K. Proposition of Pseudo-Cylindrical Concave Polyhedral Shells; Institute of Space and Aeronautical Science, University of Tokyo: Tokyo, Japan, 1969. [Google Scholar]

- Khan, S.; Awan, M.J. A generative design technique for exploring shape variations. Adv. Eng. Inform. 2018, 38, 712–724. [Google Scholar] [CrossRef] [Green Version]

- Kergosien, Y.; Gotoda, H.; Kunii, T. Bending and Creasing Virtual Paper. IEEE Comput. Graph. Appl. 1994, 14, 40–48. [Google Scholar] [CrossRef]

- Available online: www.tsg.ne.jp/TT/software (accessed on 7 November 2019).

- Narain, R.; Pfaff James, T.; O’Brien, F. Folding and Crumpling Adaptive Sheets. ACM Trans. Graph. 2013, 32, 51. [Google Scholar] [CrossRef]

- Available online: https://simonschleicher.wordpress.com/2016/09/14/paper-at-aag2016 (accessed on 21 October 2016).

- Available online: www.karamba3d.com (accessed on 22 November 2019).

- Available online: https://www.architonic.com/en/project/oskar-zieta-fidu-bridge/5101416 (accessed on 12 February 2021).

- Cojocaru, V.D.; Raducanu, D.; Gloriant, T.; Gordin, D.M.; Cinca, I. Effects of cold-rolling deformation on texture evolution and mechanical properties of Ti-29Nb-9Ta-10Zr alloy. Mater. Sci. Eng. A 2013, 586, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Mahamood, R.M.; Akinlabi, E.T. Functionally Graded Material: An Overview. In Proceedings of the World Congress on Engineering, London, UK, 4–6 July 2012; Volume III. [Google Scholar]

- Chahardoli, S.; Alavi Nia, A. Investigation of mechanical behavior of energy absorbers in expansion and folding modes under axial quasi-static loading in both experimental and numerical methods. Thin-Walled Struct. 2017, 120, 319–332. [Google Scholar] [CrossRef]

- Cojocaru, V.D.; Raducanu, D.; Gordin, D.M.; Cinca, I. Texture in ultra-strength Ti-25Ta-25Nb alloy strips. J. Alloy. Comp. 2013, 576, 170–176. [Google Scholar] [CrossRef]

- Oxman, R. Informed tectonics in material-based design. Des. Stud. 2012, 33, 427–455. [Google Scholar] [CrossRef]

- Yu, W.W.; LaBoube, R.A. Cold-Formed Steel Design, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 978-0-470-91976-7. [Google Scholar]

| Mechanical Characteristic | Base Material | Edge Sample | Middle Sample |

|---|---|---|---|

| Yield strength—σ0.2 (MPa) | 165.3 | 177.5 | 146.5 |

| Ultimate tensile strength—σUTS (MPa) | 267.5 | 300.9 | 278.8 |

| Elongation to fracture—εf (%) | 42 | 40 | 32 |

| Elastic modulus—E (GPa) | 141.3 | 143.5 | 138.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raducanu, D.; Cojocaru, V.D.; Raducanu, V.A.; Nocivin, A.; Serban, N.; Cinca, I.; Cojocaru, E.M.; Moldovan, L.; Trisca-Rusu, C.; Balkan, I.V. Design and Optimization of a Curved-Crease-Folding Process Applied to a Light Metallic Structure. Processes 2021, 9, 1110. https://doi.org/10.3390/pr9071110

Raducanu D, Cojocaru VD, Raducanu VA, Nocivin A, Serban N, Cinca I, Cojocaru EM, Moldovan L, Trisca-Rusu C, Balkan IV. Design and Optimization of a Curved-Crease-Folding Process Applied to a Light Metallic Structure. Processes. 2021; 9(7):1110. https://doi.org/10.3390/pr9071110

Chicago/Turabian StyleRaducanu, Doina, Vasile Danut Cojocaru, Vlad Andrei Raducanu, Anna Nocivin, Nicolae Serban, Ion Cinca, Elisabeta Mirela Cojocaru, Laurentiu Moldovan, Corneliu Trisca-Rusu, and Irina Varvara Balkan. 2021. "Design and Optimization of a Curved-Crease-Folding Process Applied to a Light Metallic Structure" Processes 9, no. 7: 1110. https://doi.org/10.3390/pr9071110

APA StyleRaducanu, D., Cojocaru, V. D., Raducanu, V. A., Nocivin, A., Serban, N., Cinca, I., Cojocaru, E. M., Moldovan, L., Trisca-Rusu, C., & Balkan, I. V. (2021). Design and Optimization of a Curved-Crease-Folding Process Applied to a Light Metallic Structure. Processes, 9(7), 1110. https://doi.org/10.3390/pr9071110