A Doubly Green Separation Process: Merging Aqueous Two-Phase Extraction and Supercritical Fluid Extraction

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

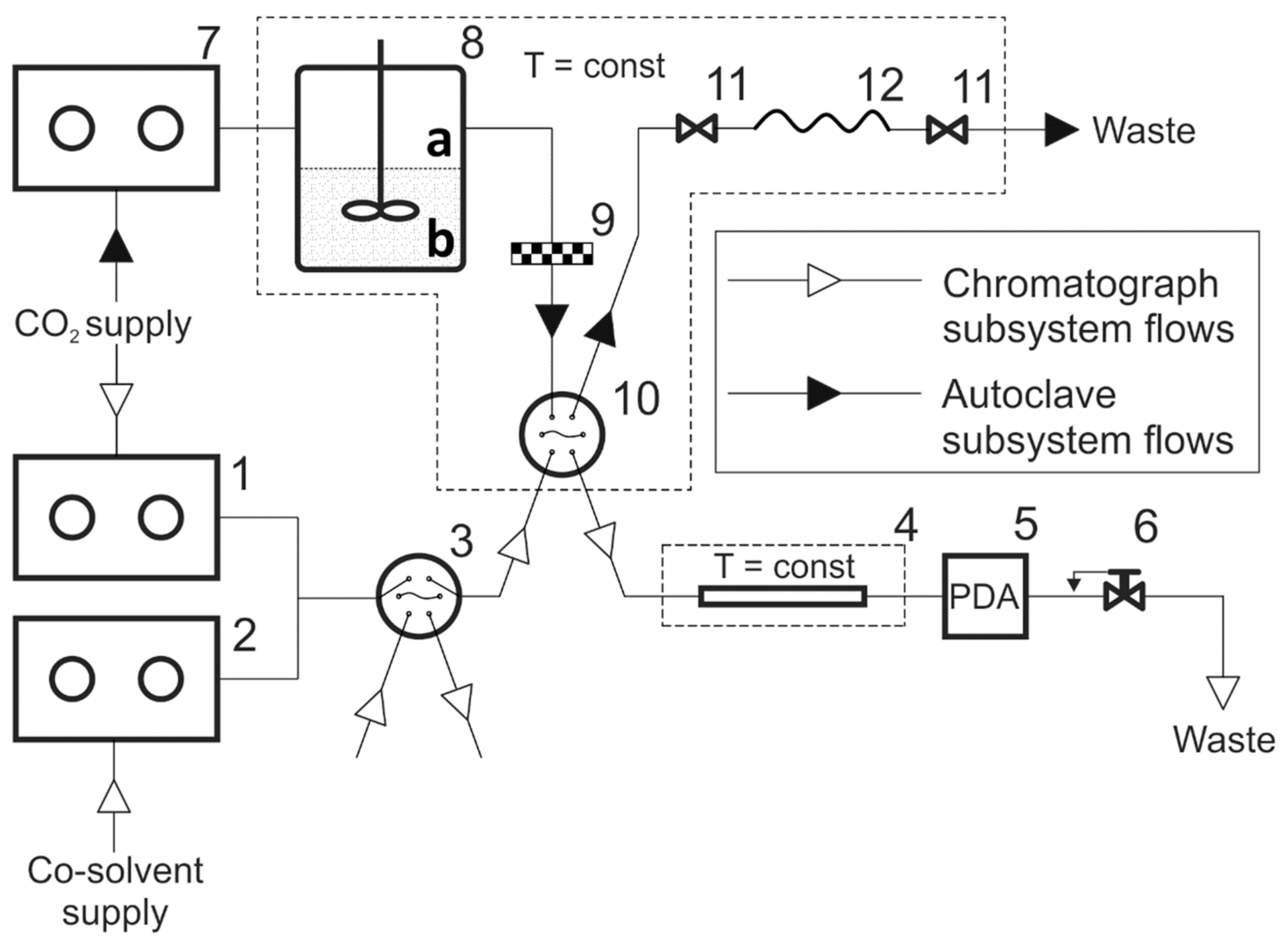

2.2. Supercritical Extraction Procedure

2.3. Concentration Measurement via At-Line Autoclave-Supercritical Fluid Chromatograph Hyphenation

2.4. Water-Polymer Phase Analysis via Offline UV Spectroscopy

2.5. Calculations

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

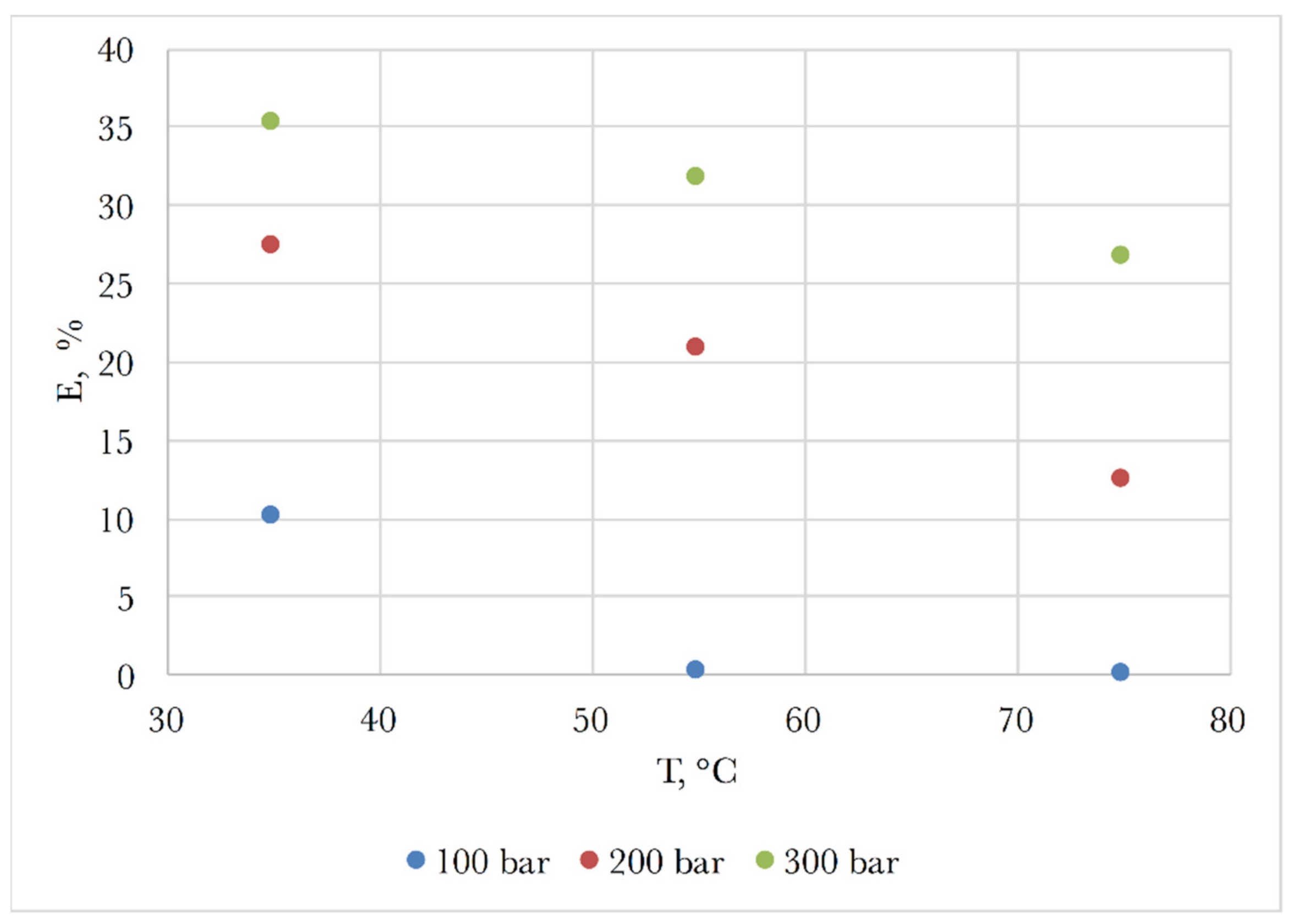

| C = 1.942 g/L | C = 2.427 g/L | ||

|---|---|---|---|

| E1, % | E2, % | E1, % | E2, % |

| 10.12 | 10.31 | 9.42 | 9.44 |

| 0.19 | 0.19 | 0.21 | 0.21 |

| 0.07 | 0.07 | 0.13 | 0.12 |

| 27.37 | 27.20 | 26.39 | 25.84 |

| 20.84 | 20.29 | 20.47 | 19.93 |

| 12.43 | 11.91 | 11.69 | 11.28 |

| 35.19 | 35.99 | 35.86 | 35.52 |

| 31.67 | 31.52 | 29.93 | 29.86 |

| 26.76 | 25.77 | 26.60 | 25.32 |

| T, °C | P, bar | C (CO2), g/L | C1 (Water), g/L | D1 | E1, % | C2 (Water), g/L | D2 | E2, % |

|---|---|---|---|---|---|---|---|---|

| 35 | 100 | 0.039 | 2.199 | 0.018 | 9.42 | 2.194 | 0.018 | 9.44 |

| 55 | 100 | 0.0009 | 2.422 | 0.00036 | 0.21 | 2.489 | 0.00035 | 0.21 |

| 75 | 100 | 0.0005 | 2.424 | 0.00021 | 0.13 | 2.553 | 0.00020 | 0.12 |

| 35 | 200 | 0.108 | 1.787 | 0.060 | 26.39 | 1.839 | 0.059 | 25.84 |

| 55 | 200 | 0.084 | 1.931 | 0.043 | 20.47 | 1.996 | 0.042 | 19.93 |

| 75 | 200 | 0.048 | 2.144 | 0.022 | 11.69 | 2.231 | 0.021 | 11.28 |

| 35 | 300 | 0.147 | 1.557 | 0.094 | 35.86 | 1.580 | 0.093 | 35.52 |

| 55 | 300 | 0.122 | 1.701 | 0.072 | 29.93 | 1.706 | 0.072 | 29.86 |

| 75 | 300 | 0.109 | 1.782 | 0.061 | 26.60 | 1.905 | 0.057 | 25.32 |

References

- Iqbal, M.; Tao, Y.; Xie, S.; Zhu, Y.; Chen, D.; Wang, X.; Huang, L.; Peng, D.; Sattar, A.; Shabbir, M.A.B.; et al. Aqueous two-phase system (ATPS): An overview and advances in its applications. Biol. Proc. Online 2016, 18, 1–18. [Google Scholar] [CrossRef]

- Rito-Palomares, M. Practical application of aqueous two-phase partition to process development for the recovery of biological products. J. Chromatogr. B 2004, 807, 3–11. [Google Scholar] [CrossRef]

- Fedorova, M.I.; Levina, A.V.; Zakhodyaeva, Y.A.; Voshkin, A.A. Interphase Distribution of V (IV) in the Polyethylene Glycol 1500–Sodium Nitrate–Water System. Theor. Found. Chem. Eng. 2020, 54, 604–609. [Google Scholar]

- Zinov’eva, I.V.; Zakhodyaeva, Y.A.; Voshkin, A.A. Interphase distribution of caffeine and coumarin in extraction systems with polyethylene glycol and sodium sulfate. Theor. Found. Chem. Eng. 2019, 53, 996–1000. [Google Scholar] [CrossRef]

- Zinov’eva, I.V.; Zakhodyaeva, Y.A.; Voshkin, A.A. Extraction of monocarboxylic acids from diluted solutions with polyethylene glycol. Theor. Found. Chem. Eng. 2019, 53, 871–874. [Google Scholar] [CrossRef]

- Zinov’eva, I.V.; Zakhodyaeva, Y.A.; Voshkin, A.A. Data on the extraction of benzoic, salicylic and sulfosalicylic acids from dilute solutions using PEG-based aqueous two-phase systems. Data Brief 2020, 28, 105033. [Google Scholar] [CrossRef] [PubMed]

- Chong, K.Y.; Brooks, M.S.L. Effects of recycling on the aqueous two-phase extraction of bioactives from haskap leaves. Sep. Purif. Technol. 2021, 255, 117755. [Google Scholar] [CrossRef]

- Zakhodyaeva, Y.A.; Zinov’eva, I.V.; Tokar, E.S.; Voshkin, A.A. Complex Extraction of Metals in an Aqueous Two-Phase System Based on Poly(Ethylene Oxide) 1500 and Sodium Nitrate. Molecules 2019, 24, 4078. [Google Scholar] [CrossRef]

- Zakhodyaeva, Y.A.; Izyumova, K.V.; Solov’eva, M.S.; Voshkin, A.A. Extraction separation of the components of leach liquors of batteries. Theor. Found. Chem. Eng. 2017, 51, 883–887. [Google Scholar] [CrossRef]

- Gismonti, P.R.; Paulino, J.F.; Afonso, J. Recovery of metals from electroactive components of spent ni-mh batteries after leaching with formic acid. Detritus 2021, 14, 68. [Google Scholar]

- Vargas, S.J.; Schaeffer, N.; Souza, J.C.; da Silva, L.H.; Hespanhol, M.C. Green separation of lanthanum, cerium and nickel from waste nickel metal hydride battery. J. Waste Manag. 2021, 125, 154–162. [Google Scholar] [CrossRef]

- Voshkin, A.A.; Zakhodyaeva, Y.A.; Zinov’eva, I.V.; Shkinev, V.M. Interphase Distribution of Aromatic Acids in the Polyethylene Glycol–Sodium Sulfate–Water System. Theor. Found. Chem. Eng. 2018, 52, 890–893. [Google Scholar] [CrossRef]

- Zakrzewska, M.E.; Nunes, A.V.; Barot, A.R.; Fernández-Castané, A.; Visak, Z.P.; Kiatkittipong, W.; Najdanovic-Visak, V. Extraction of antibiotics using aqueous two-phase systems based on ethyl lactate and thiosulphate salts. Fluid Phase Equilibria 2021, 539, 113022. [Google Scholar] [CrossRef]

- Torres-Acosta, M.A.; Mayolo-Deloisa, K.; González-Valdez, J.; Rito-Palomares, M. Aqueous Two-Phase Systems at Large Scale: Challenges and Opportunities. Biotechnol. J. 2019, 14, 1800117. [Google Scholar] [CrossRef]

- Kitamura, K.; Takazawa, Y.; Hashimoto, S.; Choi, J.W.; Ito, H.; Morita, M. Effective extraction method for dioxin analysis from lipid-rich biological matrices using a combination of pressurized liquid extraction and dimethyl sulfoxide/acetonitrile/hexane partitioning. Anal. Chim. Acta 2004, 512, 27–37. [Google Scholar] [CrossRef]

- Gupta, R.B.; Shim, J.J. Solubility in Supercritical Carbon Dioxide; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Kostenko, M.O.; Ustinovich, K.B.; Pokrovskiy, O.I. Online monitoring of adsorption onto silica xerogels and aerogels from supercritical solutions using supercritical fluid chromatography. Russ. J. Inorg. Chem. 2020, 65, 1577–1584. [Google Scholar] [CrossRef]

- Brunner, G. Counter-current separations. J. Supercrit. Fluids 2009, 47, 574–582. [Google Scholar] [CrossRef]

- Peper, S.; Dohrn, R. Sampling from fluid mixtures under high pressure: Review, case study and evaluation. J. Supercrit. Fluids 2012, 66, 2–15. [Google Scholar] [CrossRef]

- Johannsen, M.; Brunner, G. Solubilities of the xanthines caffeine, theophylline and theobromine in supercritical carbon dioxide. Fluid Phase Equilibria 1994, 95, 215–226. [Google Scholar] [CrossRef]

- Li, B.; Guo, W.; Song, W.; Ramsey, E.D. Interfacing supercritical fluid solubility apparatus with supercritical fluid chromatography operated with and without on-line post-column derivatization: Determining the solubility of caffeine and monensin in supercritical carbon dioxide. J. Supercrit. Fluids 2016, 115, 17–25. [Google Scholar] [CrossRef]

- Li, B.; Guo, W.; Ramsey, E.D. Determining phenol partition coefficient values in water- and industrial process water-supercritical CO2 systems using direct aqueous SFE apparatus simultaneously interfaced with on-line SFC and on-line HPLC. J. Supercrit. Fluids 2019, 152, 104558. [Google Scholar] [CrossRef]

- Vorobei, A.M.; Pokrovskiy, O.I.; Ustinovich, K.B.; Parenago, O.O.; Lunin, V.V. A method for measuring solubility in multi-component sub- and supercritical fluids using an online hyphenation of supercritical antisolvent precipitation and supercritical fluid chromatography. J. Mol. Liq. 2019, 280, 212–217. [Google Scholar] [CrossRef]

- Pokrovskiy, O.; Vorobei, A.; Zuev, Y.; Kostenko, M.; Lunin, V. Investigation of precipitation selectivity and particle size concentration dependences in supercritical antisolvent method via online supercritical fluid chromatography. Adv. Powder Technol. 2020, 31, 2257–2266. [Google Scholar] [CrossRef]

- Kostenko, M.O.; Pokrovskiy, O.I.; Zakhodyaeva, Y.A.; Voshkin, A.A.; Lunin, V.V. Unusual effect of flow rate on retention in analytical supercritical fluid chromatography exemplified by polyethylene glycol separation. J. Chromatogr. A 2020, 1610, 460513. [Google Scholar] [CrossRef]

| Component | Chemical Formula | Chemical Structure | M.W., g/mol | Solubility in CO2, y × 106 * [16] |

|---|---|---|---|---|

| caffeine | C8H10N4O2 |  | 194.19 | 63 (313.15 K and 100 bar) |

| benzoic acid | C7H6O2 |  | 122.12 | 800 (308.25 K and 101 bar) |

| T, °C | P, bar | C (CO2), g/L | C1 (Water) *, g/L | D1 | C2 (Water) *, g/L | D2 |

|---|---|---|---|---|---|---|

| 35 | 100 | 0.033 | 1.745 | 0.019 | 1.710 | 0.019 |

| 55 | 100 | 0.0006 | 1.938 | 0.0003 | 1.953 | 0.0003 |

| 75 | 100 | 0.0002 | 1.941 | 0.0001 | 2.019 | 0.0001 |

| 35 | 200 | 0.090 | 1.410 | 0.064 | 1.423 | 0.063 |

| 55 | 200 | 0.068 | 1.537 | 0.044 | 1.590 | 0.043 |

| 75 | 200 | 0.041 | 1.700 | 0.024 | 1.786 | 0.023 |

| 35 | 300 | 0.115 | 1.259 | 0.092 | 1.215 | 0.095 |

| 55 | 300 | 0.104 | 1.327 | 0.078 | 1.336 | 0.078 |

| 75 | 300 | 0.088 | 1.422 | 0.062 | 1.497 | 0.059 |

| T, °C | P, bar | C (CO2), g/L | C (Water), g/L | D * |

|---|---|---|---|---|

| 35 | 100 | 0.053 | 0.906 | 0.059 |

| 55 | 100 | 0.005 | 1.191 | 0.004 |

| 75 | 100 | 0.002 | 1.211 | 0.001 |

| 35 | 200 | 0.079 | 0.751 | 0.105 |

| 55 | 200 | 0.069 | 0.815 | 0.084 |

| 75 | 200 | 0.051 | 0.918 | 0.056 |

| 35 | 300 | 0.087 | 0.708 | 0.122 |

| 55 | 300 | 0.084 | 0.721 | 0.117 |

| 75 | 300 | 0.078 | 0.759 | 0.103 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voshkin, A.; Solov’ev, V.; Kostenko, M.; Zakhodyaeva, Y.; Pokrovskiy, O. A Doubly Green Separation Process: Merging Aqueous Two-Phase Extraction and Supercritical Fluid Extraction. Processes 2021, 9, 727. https://doi.org/10.3390/pr9040727

Voshkin A, Solov’ev V, Kostenko M, Zakhodyaeva Y, Pokrovskiy O. A Doubly Green Separation Process: Merging Aqueous Two-Phase Extraction and Supercritical Fluid Extraction. Processes. 2021; 9(4):727. https://doi.org/10.3390/pr9040727

Chicago/Turabian StyleVoshkin, Andrey, Vitaliy Solov’ev, Mikhail Kostenko, Yulia Zakhodyaeva, and Oleg Pokrovskiy. 2021. "A Doubly Green Separation Process: Merging Aqueous Two-Phase Extraction and Supercritical Fluid Extraction" Processes 9, no. 4: 727. https://doi.org/10.3390/pr9040727

APA StyleVoshkin, A., Solov’ev, V., Kostenko, M., Zakhodyaeva, Y., & Pokrovskiy, O. (2021). A Doubly Green Separation Process: Merging Aqueous Two-Phase Extraction and Supercritical Fluid Extraction. Processes, 9(4), 727. https://doi.org/10.3390/pr9040727