Fractionating of Lemongrass (Cymbopogon citratus) Essential Oil by Vacuum Fractional Distillation

Abstract

1. Introduction

2. Materials and Methods

2.1. Obtainment of Essential Oil

2.2. Description of the Vacuum Fractionation Distillation System

2.3. Fractionating Tests

2.4. Chromatographic Analysis

3. Results and Discussion

3.1. Chemical Composition of Raw Lemongrass Essential Oil

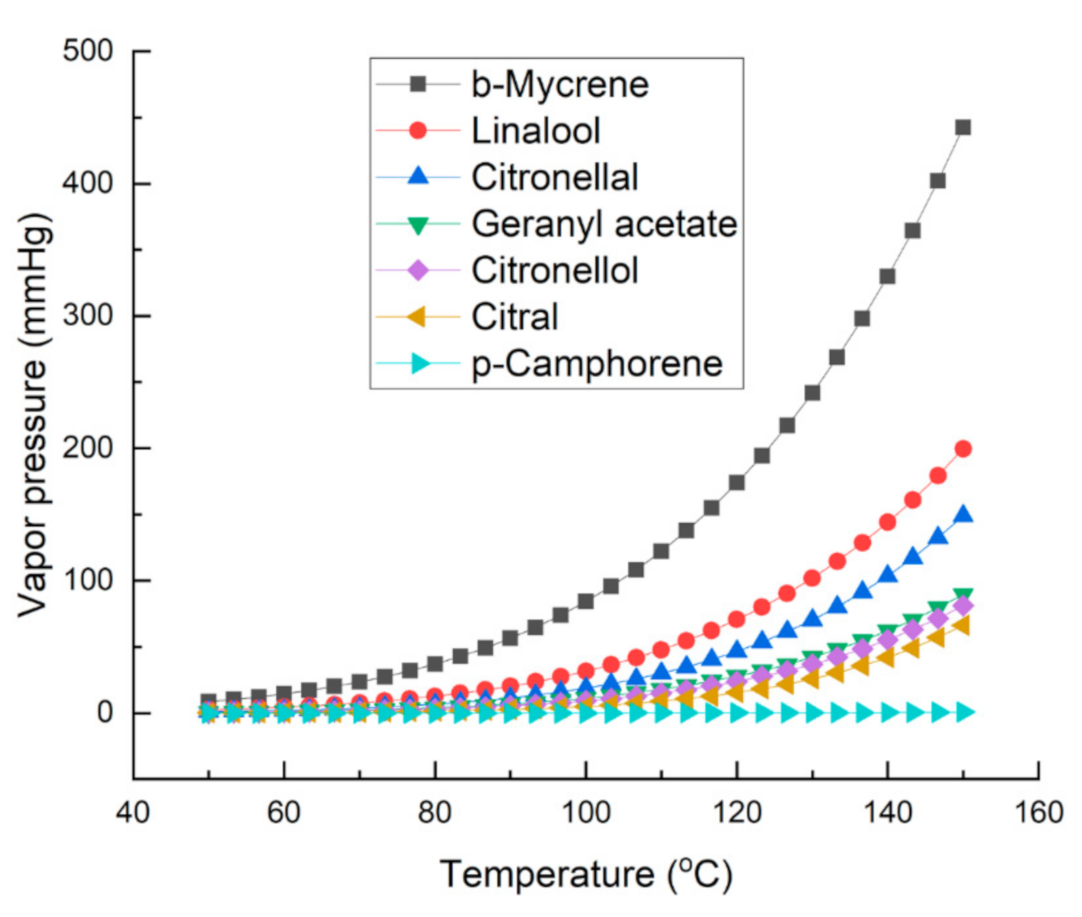

3.2. Influence of Vapor Pressure on Boiling Temperature of Lemongrass Essential Oil (Simulation by Aspen Plus V11)

3.3. Fractionating by Temperature (GC-MS Analysis)

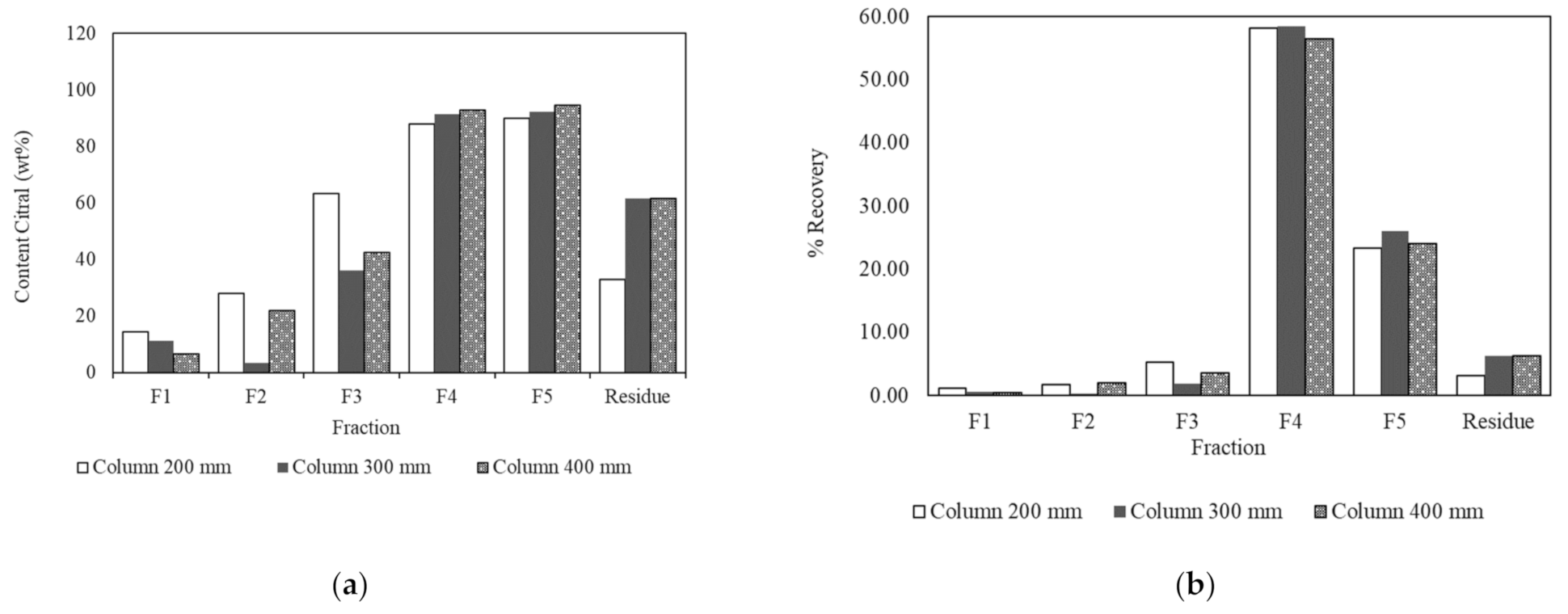

3.4. Effect of Distillation Column on the Fractionation Time, Content, and Recovery of Citral in the Fractions

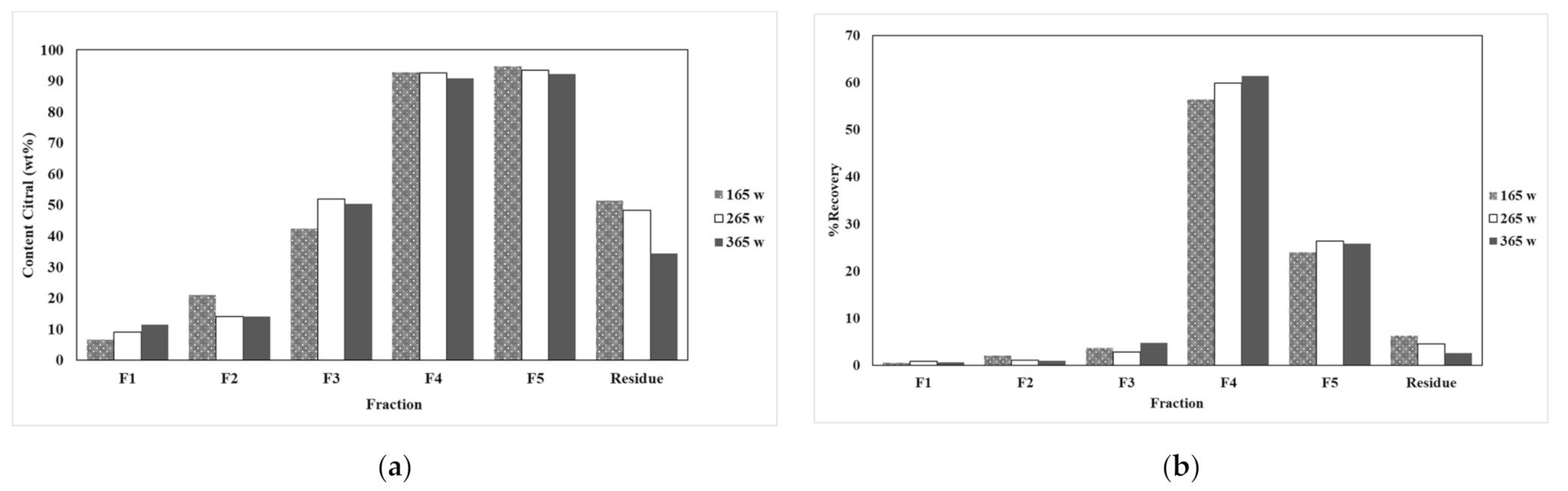

3.5. The Effect of The Rate of Distillation Process on the Fractionation Time, Content, and Recovery of Citral in the Fractions

3.6. The Effect of Vacuum Pressure on the Fractionation Time, Content, and Recovery of Citral in the Fractions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haque, A.N.M.A.; Remadevi, R.; Naebe, M. Lemongrass (Cymbopogon): A review on its structure, properties, applications and recent developments. Cellulose 2018, 25, 5455–5477. [Google Scholar] [CrossRef]

- Hanaa, A.M.; Sallam, Y.I.; El-Leithy, A.S.; Aly, S.E. Lemongrass (Cymbopogon citratus) essential oil as affected by drying methods. Ann. Agric. Sci. 2012, 57, 113–116. [Google Scholar] [CrossRef]

- Abdulazeez, M.A.; Abdullahi, A.S.; James, B.D. Chapter 58—Lemongrass (Cymbopogon spp.) Oils. In Essential Oils in Food Preservation, Flavor and Safety; Preedy, V.R., Ed.; Academic Press: San Diego, CA, USA, 2016; pp. 509–516. [Google Scholar]

- Ekpenyong, C.E.; Akpan, E.E. Use of Cymbopogon citratus essential oil in food preservation: Recent advances and future perspectives. Crit. Rev. Food Sci. Nutr. 2017, 57, 2541–2559. [Google Scholar] [CrossRef] [PubMed]

- Avoseh, O.; Oyedeji, O.; Rungqu, P.; Nkeh-Chungag, B.; Oyedeji, A. Cymbopogon Species; Ethnopharmacology, Phytochemistry and the Pharmacological Importance. Molecules 2015, 20, 7438–7453. [Google Scholar] [CrossRef] [PubMed]

- Fokom, R.; Adamou, S.; Essono, D.; Ngwasiri, D.P.; Eke, P.; Mofor, C.T.; Tchoumbougnang, F.; Fekam, B.F.; Zollo, P.A.; Nwaga, D.; et al. Growth, essential oil content, chemical composition and antioxidant properties of lemongrass as affected by harvest period and arbuscular mycorrhizal fungi in field conditions. Ind. Crop. Prod. 2019, 138, 111477. [Google Scholar] [CrossRef]

- Guimarães, L.G.L.; dasGraças Cardoso, M.; Souza, P.E.; de Andrade, J.; Vieira, S.S. Antioxidant and fungitoxic activities of the lemongrass essential oil and citral. Rev. Ciênc. Agron. 2011, 42, 464–472. [Google Scholar] [CrossRef]

- Adukwu, E.C.; Bowles, M.; Edwards-Jones, V.; Bone, H. Antimicrobial activity, cytotoxicity and chemical analysis of lemongrass essential oil (Cymbopogon flexuosus) and pure citral. Appl. Microbiol. Biotechnol. 2016, 100, 9619–9627. [Google Scholar] [CrossRef]

- Tzortzakis, N.G.; Economakis, C.D. Economakis. Antifungal activity of lemongrass (Cympopogon citratus L.) essential oil against key postharvest pathogens. Innov. Food Sci. Emerg. Technol. 2007, 8, 253–258. [Google Scholar] [CrossRef]

- Han, X.; Parker, T.L. Lemongrass (Cymbopogon flexuosus) essential oil demonstrated anti-inflammatory effect in pre-inflamed human dermal fibroblasts. Biochim. Open 2017, 4, 107–111. [Google Scholar] [CrossRef]

- Sharma, P.R.; Mondhe, D.M.; Muthiah, S.; Pal, H.C.; Shahi, A.K.; Saxena, A.K.; Qazi, G.N. Anticancer activity of an essential oil from Cymbopogon flexuosus. Chem.-Biol. Interact. 2009, 179, 160–168. [Google Scholar] [CrossRef]

- Tyagi, B.K.; Shahi, A.K.; Kaul, B.L. Evaluation of repellent activities of Cymbopogon essential oils against mosquito vectors of Malaria, Filariasis and Dengue Fever in India. Phytomedicine 1998, 5, 324–329. [Google Scholar] [CrossRef]

- Kumar, V.; Tewari, R.; Singh, K. Comparative Studies of Drying Methods on Yield and Composition of the Essential Oil of Cymbopogon citratus. J. Essent. Oil Bear. Plants 2015, 18, 744–750. [Google Scholar] [CrossRef]

- Verma, R.K.; Verma, R.S.; Chauhan, A.; Bisht, A. Evaluation of essential oil yield and chemical composition of eight lemongrass (Cymbopogon spp.) cultivars under Himalayan region. J. Essent. Oil Res. 2015, 27, 197–203. [Google Scholar] [CrossRef]

- Mbili, N.C.; Opara, U.L.; Lennox, C.L.; Vries, F.A. Citrus and lemongrass essential oils inhibit Botrytis cinerea on ‘Golden Delicious’, ‘Pink Lady’ and ‘Granny Smith’ apples. J. Plant. Dis. Prot. 2017, 124, 499–511. [Google Scholar] [CrossRef]

- Shaikh, M.N.; Suryawanshi, Y.C.; Mokat, D.N. Volatile Profiling and Essential Oil Yield of Cymbopogon citratus (DC.) Stapf Treated with Rhizosphere Fungi and Some Important Fertilizers. J. Essent. Oil Bear. Plants 2019, 22, 477–483. [Google Scholar] [CrossRef]

- Tajidin, N.E.; Ahmad, S.H.; Rosenani, A.B.; Azimah, H.; Munirah, M. Chemical composition and citral content in lemongrass (Cymbopogon citratus) essential oil at three maturity stages. Afr. J. Biotechnol. 2012, 11, 2685–2693. [Google Scholar] [CrossRef]

- Barbosa, L.C.A.; Pereira, U.A.; Martinazzo, A.P.; Maltha, C.R.Á.; Teixeira, R.R.; Melo, E.D.C. Evaluation of the Chemical Composition of Brazilian Commercial Cymbopogon citratus (D.C.) Stapf Samples. Molecules 2008, 13, 1864–1874. [Google Scholar] [CrossRef]

- Kpoviessi, S.; Bero, J.; Agbani, P.; Gbaguidi, F.; Kpadonou-Kpoviessi, B.; Sinsin, B.; Accrombessi, G.; Frédérich, M.; Moudachirou, M.; Quetin-Leclercq, J. Chemical composition, cytotoxicity and in vitro antitrypanosomal and antiplasmodial activity of the essential oils of four Cymbopogon species from Benin. J. Ethnopharm. 2014, 151, 652–659. [Google Scholar] [CrossRef]

- Schaneberg, B.T.; Khan, I.A. Comparison of Extraction Methods for Marker Compounds in the Essential Oil of Lemon Grass by GC. J. Agric. Food Chem. 2002, 50, 1345–1349. [Google Scholar] [CrossRef]

- Reverchon, E.; Porta, G.D.; Senatore, F. Supercritical CO2 Extraction and Fractionation of Lavender Essential Oil and Waxes. J. Agric. Food Chem. 1995, 43, 1654–1658. [Google Scholar] [CrossRef]

- Reverchon, E. Supercritical fluid extraction and fractionation of essential oils and related products. J. Supercrit. Fluids 1997, 10, 1–37. [Google Scholar] [CrossRef]

- Sato, M.; Goto, M.; Hirose, T. Fractional extraction with supercritical carbon dioxide for the removal of terpenes from citrus oil. Ind. Eng. Chem. Res. 1995, 34, 3941–3946. [Google Scholar] [CrossRef]

- Shukla, A.; Naik, S.N.; Goud, V.V.; Das, C. Supercritical CO2 extraction and online fractionation of dry ginger for production of high-quality volatile oil and gingerols enriched oleoresin. Ind. Crops Prod. 2019, 130, 352–362. [Google Scholar] [CrossRef]

- Wrona, O.; Rafińska, K.; Możeński, C.; Buszewski, B. Supercritical carbon dioxide extraction of Solidago gigantea Ait.: Optimization at quarter-technical scale and scale up the process to half-technical plant. Ind. Crops Prod. 2019, 130, 316–324. [Google Scholar] [CrossRef]

- Dąbrowski, G.; Czaplicki, S.; Konopka, I. Fractionation of sterols, tocols and squalene in flaxseed oils under the impact of variable conditions of supercritical CO2 extraction. J. Food Compos. Anal. 2019, 83, 103261. [Google Scholar] [CrossRef]

- Kaltenbrunner, O.; Lu, Y.; Sharma, A.; Lawson, K.; Tressel, T. Risk–benefit evaluation of on-line high-performance liquid chromatography analysis for pooling decisions in large-scale chromatography. J. Chromatogr. A 2012, 1241, 37–45. [Google Scholar] [CrossRef]

- Beneti, S.C.; Rosset, E.; Corazza, M.L.; Frizzo, C.D.; Di Luccio, M.; Oliveira, J.V. Fractionation of citronella (Cymbopogon winterianus) essential oil and concentrated orange oil phase by batch vacuum distillation. J. Food Eng. 2011, 102, 348–354. [Google Scholar] [CrossRef]

- Wankat, P.C. Separation Process Engineering; Prentice Hall: Upper Saddle River, NJ, USA, 2017. [Google Scholar]

- Silvestre, W.P.; Agostini, F.; Muniz, L.A.; Pauletti, G.F. Fractionating of green mandarin (Citrus deliciosa Tenore) essential oil by vacuum fractional distillation. J. Food Eng. 2016, 178, 90–94. [Google Scholar] [CrossRef]

- Farah, A.; Afifi, A.; Fechtal, M.; Chhen, A.; Satrani, B.; Talbi, M.; Chaouch, A. Fractional distillation effect on the chemical composition of Moroccan myrtle (Myrtus communis L.) essential oils. Flavour Fragr. J. 2006, 21, 351–354. [Google Scholar] [CrossRef]

- Perini, J.F.; Silvestre, W.P.; Agostini, F.; Toss, D.; Pauletti, G.F. Fractioning of orange (Citrus sinensis L.) essential oil using vacuum fractional distillation. Sep. Sci. Technol. 2017, 52, 1397–1403. [Google Scholar] [CrossRef]

- Amanzadeh, Y.; Ashrafi, M.; Mohammadi, F. New Elaborated Technique for Isolation and Purification of Limonene from Orange Oil. Iran. J. Pharm. Sci. 2006, 2, 87–90. [Google Scholar]

- Silvestre, W.P.; Medeiros, F.R.; Agostini, F.; Toss, D.; Pauletti, G.F. Fractionation of rosemary (Rosmarinus officinalis L.) essential oil using vacuum fractional distillation. J. Food Sci. Technol. 2019, 56, 5422–5434. [Google Scholar] [CrossRef]

- Falcao, M.A.; Fianco, A.L.; Lucas, A.M.; Pereira, M.A.; Torres, F.C.; Vargas, R.M.; Cassel, E. Determination of antibacterial activity of vacuum distillation fractions of lemongrass essential oil. Phytochem. Rev. 2012, 11, 405–412. [Google Scholar] [CrossRef]

- Kasali, A.A.; Oyedeji, A.O.; Ashilokun, A.O. Volatile leaf oil constituents of Cymbopogon citratus (DC) Stapf. Flavour Fragr. J. 2001, 16, 377–378. [Google Scholar] [CrossRef]

- Bonamin, F.; Moraes, T.M.; Dos Santos, R.C.; Kushima, H.; Faria, F.M.; Silva, M.A.; Junior, I.V.; Nogueira, L.; Bauab, T.M.; Brito, A.R.S.; et al. The effect of a minor constituent of essential oil from Citrus aurantium: The role of β-myrcene in preventing peptic ulcer disease. Chem. Biol. Interact. 2014, 212, 11–19. [Google Scholar] [CrossRef]

- Cahyani, C.; Cahayo, M. Effect of Column Length in Batch Vacuum Fractionation on The Distribution of Major Components of Citronella Oil (Cymbopogon winterianus). IOP Conf. Ser. Mater. Sci. Eng. 2019, 546, 022033. [Google Scholar]

| RT (min) | Identified Compound | Area % |

|---|---|---|

| 5.1 | 6-Methyl-5-heptene-2-one | 2.72 |

| 5.19 | β-Myrcene | 7.68 |

| 6.12 | trans-β-Ocimene | 0.48 |

| 6.34 | β-cis-Ocimene | 0.21 |

| 7.44 | β-Linalool | 1.07 |

| 8.62 | Citronellal | 0.41 |

| 8.88 | Isoneral | 0.4 |

| 9.28 | Isogeranial | 1.04 |

| 9.88 | cis-Carveol | 0.18 |

| 10.33 | cis-Geraniol | 0.11 |

| 10.61 | β-Citral | 33.06 |

| 10.9 | Geraniol | 1.98 |

| 11.27 | α-Citral | 44.97 |

| 12.58 | cis-α-Bergamotene | 0.36 |

| 13.73 | Geranyl acetate | 1.09 |

| 14.63 | Caryophyllene | 0.1 |

| 14.91 | trans-α-Bergamotene | 0.14 |

| 16.07 | γ-Cadinene | 0.17 |

| 17.99 | Selin-6-en-4α-ol | 0.28 |

| 23.16 | m-Camphorene | 0.38 |

| 23.51 | p-Camphorene | 0.18 |

| Aldehydes and ketones | 82.69 | |

| Alcohols | 3.64 | |

| Esters | 1.09 | |

| Hydrocarbon terpenes | 9.9 |

| Compound | Raw Oil (wt%) | F1 | F2 | F3 | F4 | F5 | Overall Recovery (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60–64 | 65–70 | 71–95 | 98–107 | 108–110 | ||||||||

| Average(wt%) | Recovery(wt%) | Average(wt%) | Recovery(wt%) | Average(wt%) | Recovery(wt%) | Average(wt%) | Recovery(wt%) | Average(wt%) | Recovery(wt%) | |||

| Sulcatone | 2.72 | 10.75 | 23.71 | 18.61 | 22.66 | 16.24 | 40.00 | 0.15 | 2.62 | - | - | 89.00 |

| β-Myrcene | 7.68 | 73.30 | 57.27 | 48.30 | 22.01 | 20.69 | 18.05 | 0.08 | 0.49 | 0.02 | 0.05 | 97.87 |

| β-Linalool | 1.07 | - | - | 2.00 | 6.54 | 2.50 | 15.65 | 1.60 | 71.03 | 0.01 | 0.19 | 93.41 |

| Isogeranial | 1.04 | 0.19 | 1.10 | 0.18 | 0.61 | 3.47 | 22.35 | 1.41 | 64.40 | 0.32 | 6.09 | 94.55 |

| β-Citral | 33.06 | 2.45 | 0.44 | 12.13 | 1.28 | 23.19 | 4.70 | 41.18 | 59.17 | 33.11 | 19.83 | 91.29 |

| Geraniol | 1.98 | - | - | - | - | 0.96 | 3.25 | 2.52 | 60.45 | 2.86 | 28.60 | 92.30 |

| α-Citral | 44.97 | 4.22 | 0.56 | 11.79 | 0.92 | 19.30 | 2.88 | 51.59 | 54.49 | 61.50 | 27.08 | 95.00 |

| Geranyl acetate | 1.09 | 0.09 | 0.50 | 0.07 | - | 0.01 | 0.06 | 0.86 | 37.48 | 1.92 | 34.88 | 87.88 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Do, D.N.; Nguyen, D.P.; Phung, V.-D.; Le, X.-T.; Le, T.M.; Do, V.M.; Minh, B.Q.; Luu, X.C. Fractionating of Lemongrass (Cymbopogon citratus) Essential Oil by Vacuum Fractional Distillation. Processes 2021, 9, 593. https://doi.org/10.3390/pr9040593

Do DN, Nguyen DP, Phung V-D, Le X-T, Le TM, Do VM, Minh BQ, Luu XC. Fractionating of Lemongrass (Cymbopogon citratus) Essential Oil by Vacuum Fractional Distillation. Processes. 2021; 9(4):593. https://doi.org/10.3390/pr9040593

Chicago/Turabian StyleDo, Dinh Nhat, Dinh Phuc Nguyen, Viet-Duc Phung, Xuan-Tien Le, Tuan Minh Le, Van Manh Do, Bui Quang Minh, and Xuan Cuong Luu. 2021. "Fractionating of Lemongrass (Cymbopogon citratus) Essential Oil by Vacuum Fractional Distillation" Processes 9, no. 4: 593. https://doi.org/10.3390/pr9040593

APA StyleDo, D. N., Nguyen, D. P., Phung, V.-D., Le, X.-T., Le, T. M., Do, V. M., Minh, B. Q., & Luu, X. C. (2021). Fractionating of Lemongrass (Cymbopogon citratus) Essential Oil by Vacuum Fractional Distillation. Processes, 9(4), 593. https://doi.org/10.3390/pr9040593