Multiscale Characterization of Isotropic Pyrolytic Carbon Used for Mechanical Heart Valve Production

Abstract

1. Introduction

2. Materials and Methods

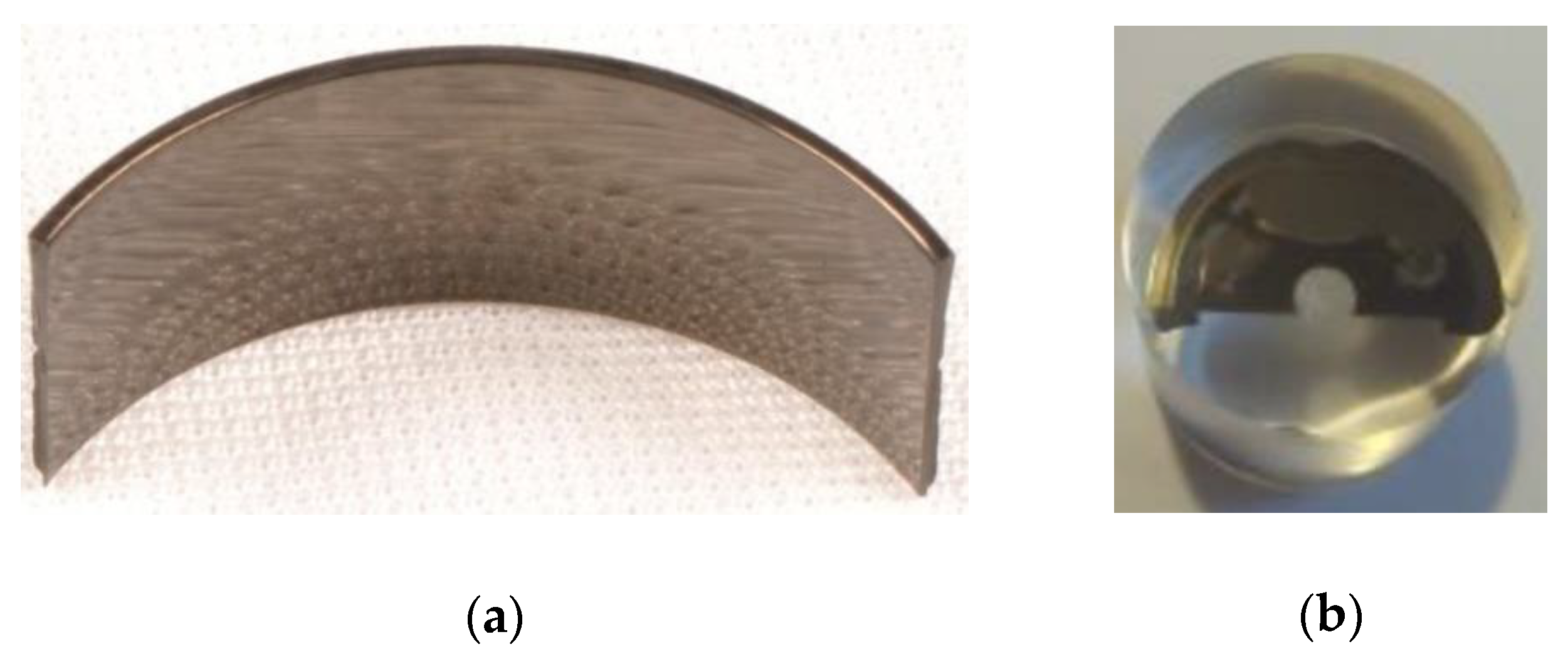

2.1. Sample Preparation

2.2. Three-Point Bending Test

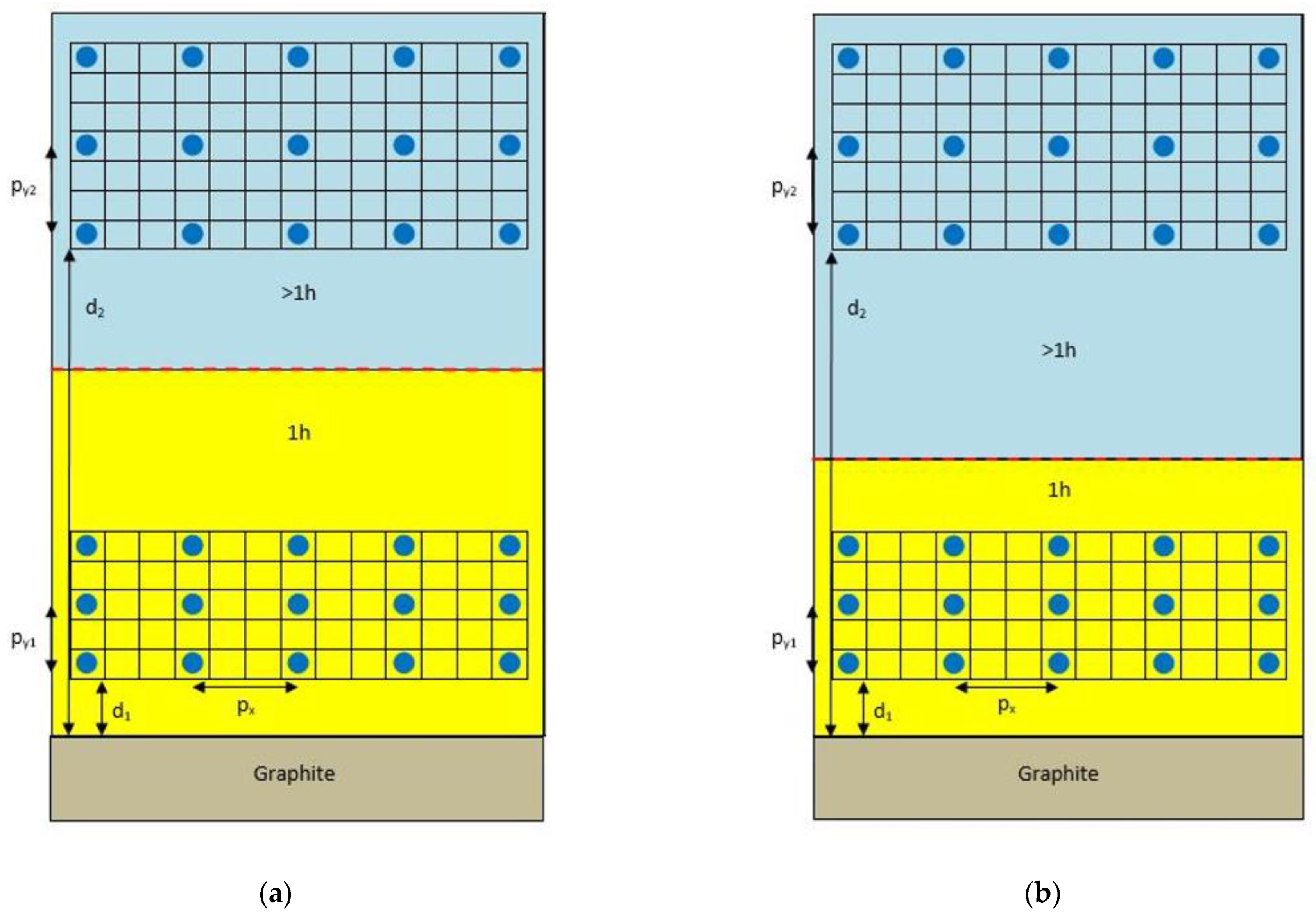

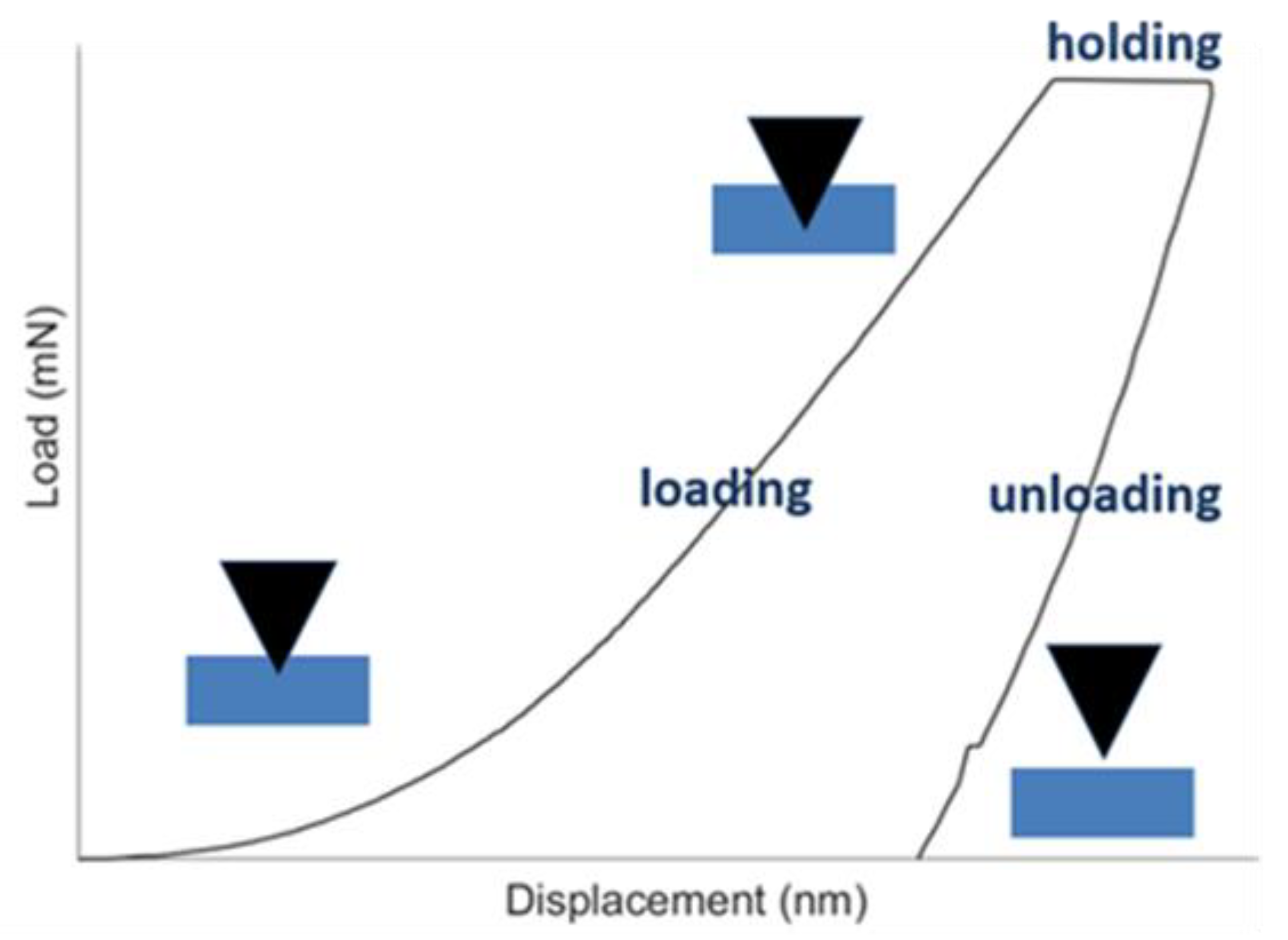

2.3. Nanoindentation Test

2.4. Statistical Analysis

3. Results

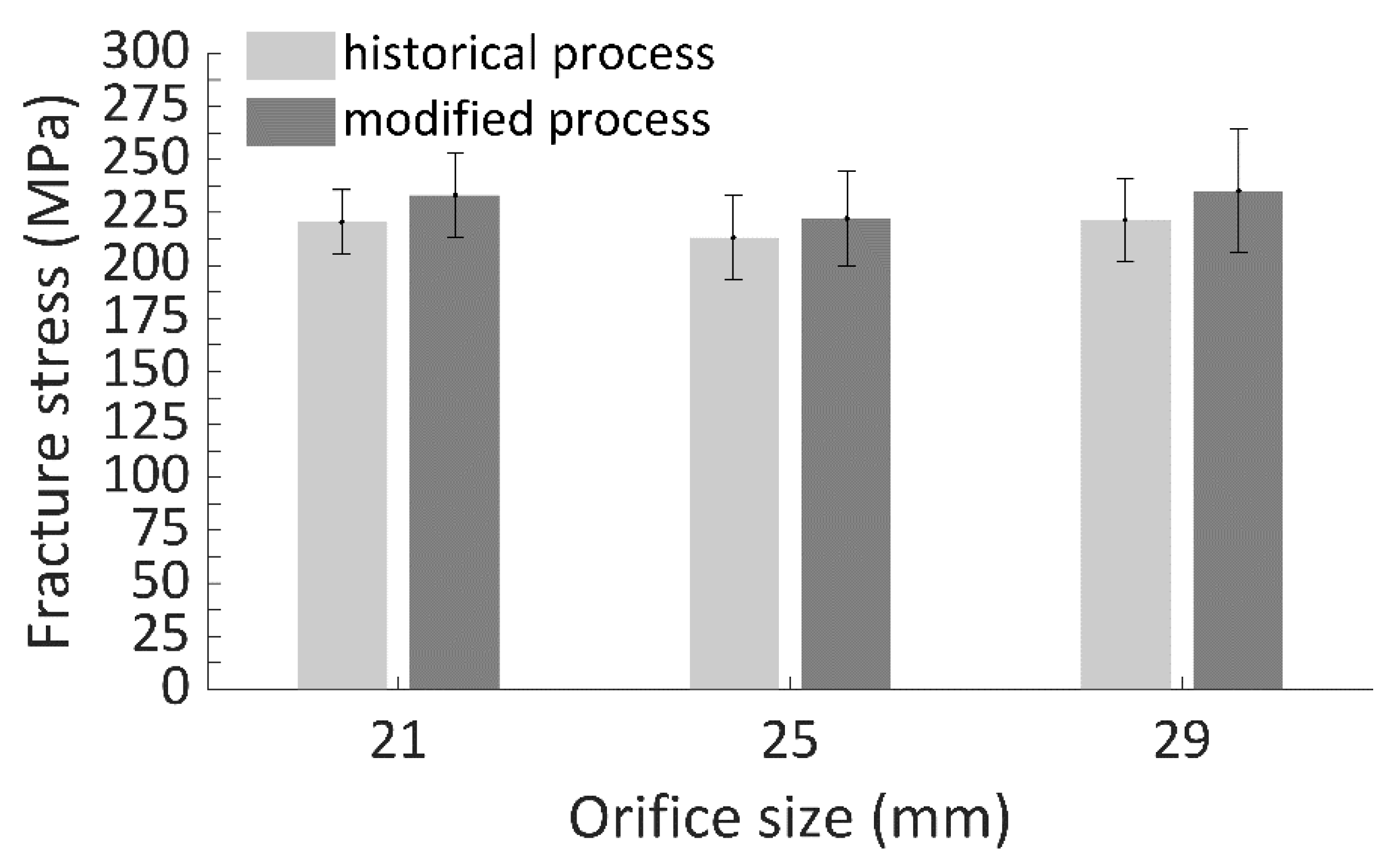

3.1. Three-Point Bending Test

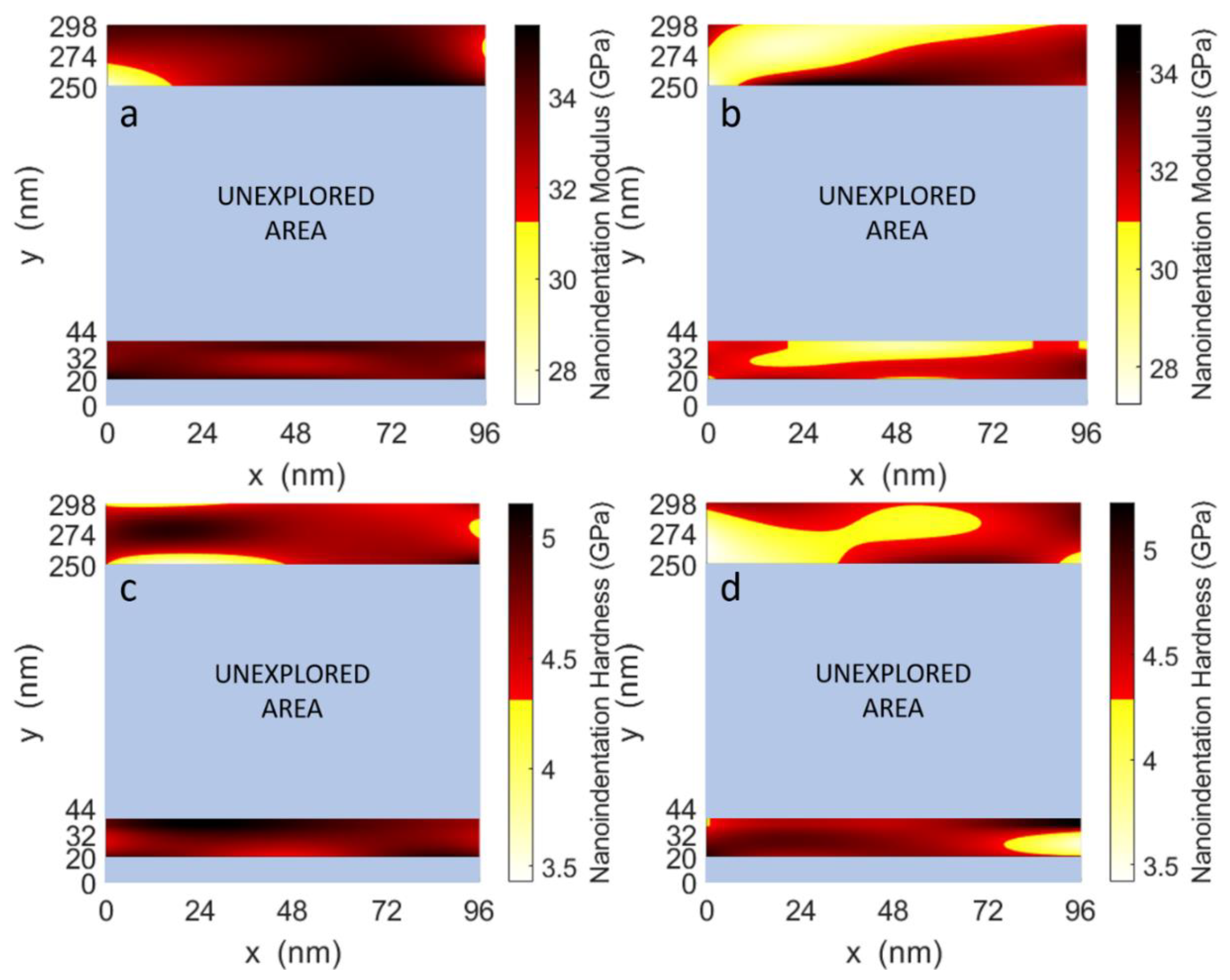

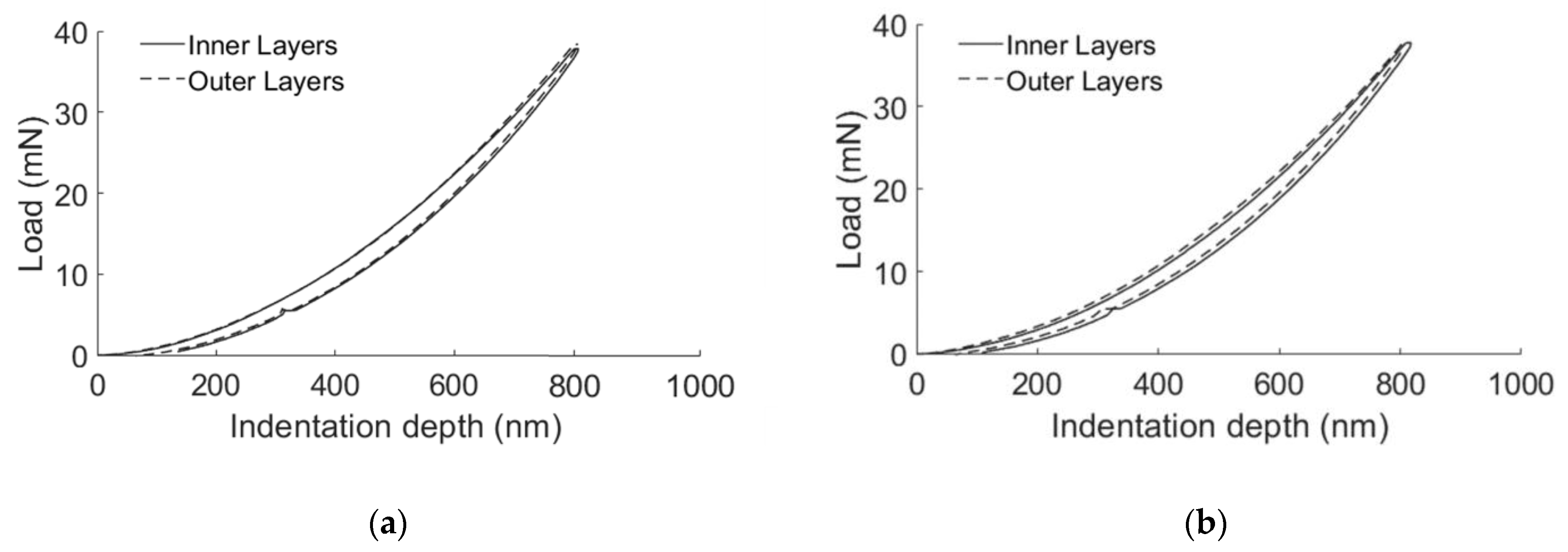

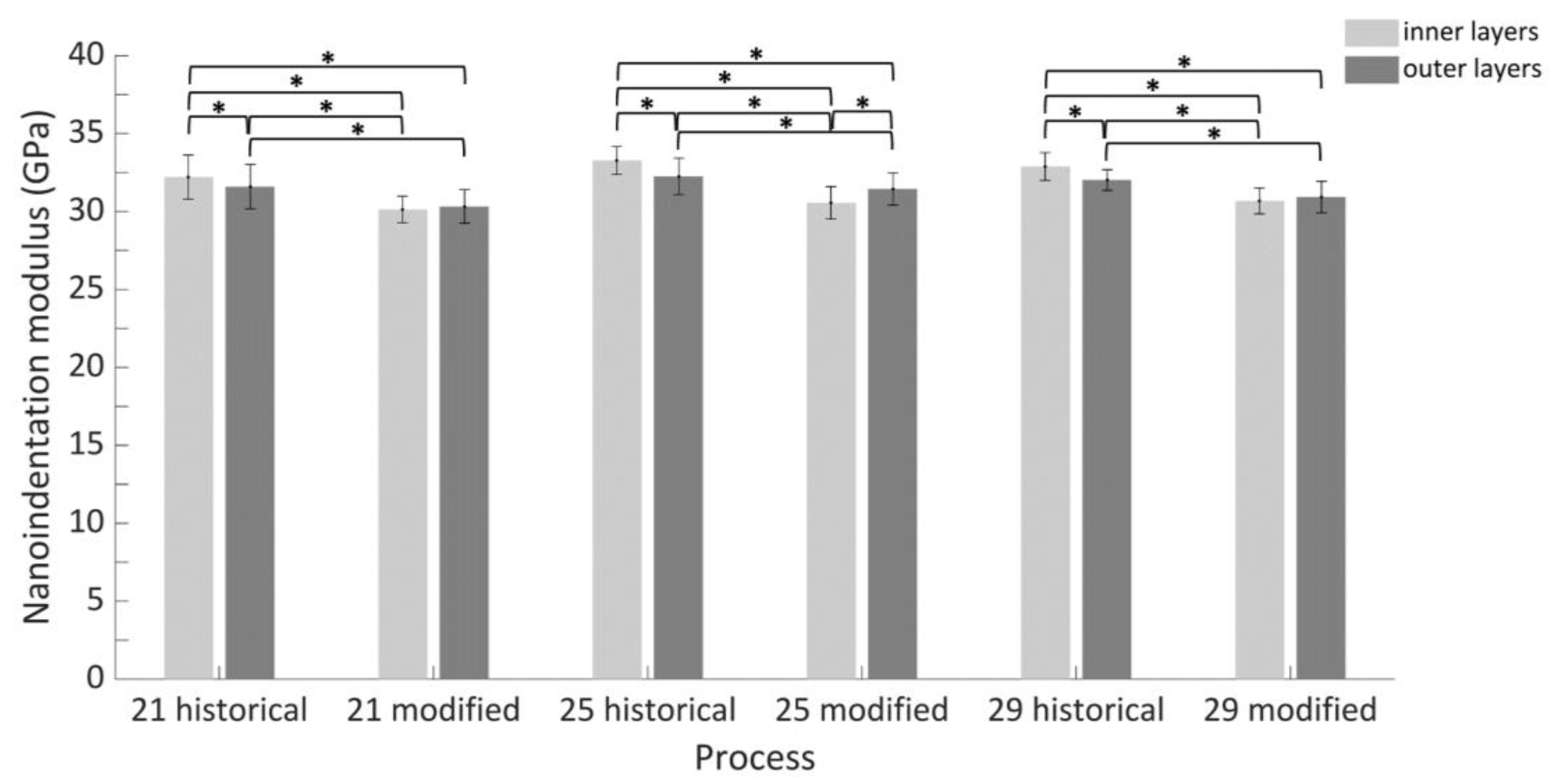

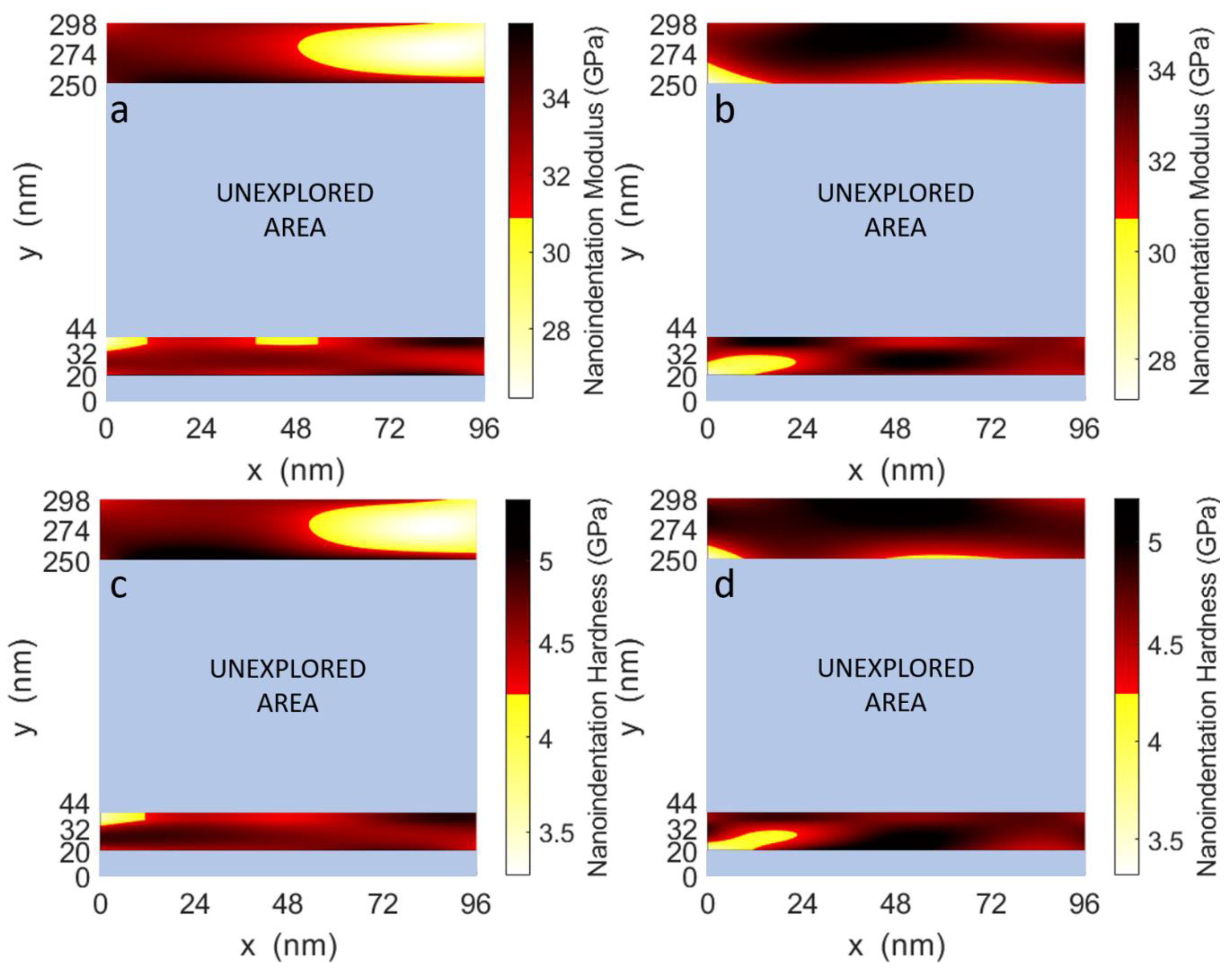

3.2. Nanoindentation Test

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Size ∅ (mm) | Ri (mm) | t (mm) | b (mm) | d (mm) | α (°) | s (mm) |

|---|---|---|---|---|---|---|

| 21 | 8.59 ± (0.01) | 0.73 ± (0.01) | 6.64 ± (0.02) | 1.5 | 34.95 ± (0.06) | 4.47 |

| 25 | 10.56 ± (0.03) | 0.74 ± (0.01) | 7.70 ± (0.02) | 1.5 | 26.93 ± (0.09) | 4.47 |

| 29 | 12.51 ± (0.02) | 0.75 ± (0.01) | 8.67 ± (0.02) | 1.5 | 30.37 ± (0.07) | 5.97 |

| Size ∅ (mm) | Ri (mm) | t (mm) | b (mm) | d (mm) | α (°) | s (mm) |

|---|---|---|---|---|---|---|

| 21 | 8.57 ± (0.01) | 0.73 ± (0.01) | 6.65 ± (0.01) | 1.5 | 34.95 ± (0.06) | 4.47 |

| 25 | 10.56 ± (0.01) | 0.73 ± (0.01) | 7.70 ± (0.02) | 1.5 | 26.93 ± (0.02) | 4.47 |

| 29 | 12.54 ± (0.01) | 0.72 ± (0.01) | 8.66 ± (0.01) | 1.5 | 30.37 ± (0.03) | 5.97 |

| Size ∅ (mm) | P (N) | δ (mm) |

|---|---|---|

| 21 | 41.12 ± (2.74) | 0.24 ± (0.02) |

| 25 | 53.34 ± (5.83) | 0.18 ± (0.01) |

| 29 | 46.71 ± (4.49) | 0.33 ± (0.03) |

| Size ∅ (mm) | P (N) | δ (mm) |

|---|---|---|

| 21 | 43.52 ± (4.24) | 0.26 ± (0.02) |

| 25 | 54.01 ± (6.12) | 0.20 ± (0.02) |

| 29 | 46.55 ± (6.51) | 0.37 ± (0.04) |

References

- Dasi, L.P.; Simon, H.A.; Sucosky, P.; Yoganathan, A.P. Fluid mechanics of artificial heart valves. Clin. Exp. Pharmacol. Physiol. 2009, 36, 225–237. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.C.; Davidson, M.J.; Lamy, A.; Eikelboom, J.W. Antithrombotic management of patients with prosthetic heart valves: Current evidence and future trends. Lancet 2009, 374, 565–576. [Google Scholar] [CrossRef]

- Yacoub, M.H.; Takkenberg, J.J.M. Will heart valve tissue engineering change the world? Nat. Clin. Pract. Cardiovasc. Med. 2005, 2, 60–61. [Google Scholar] [CrossRef] [PubMed]

- Black, M.M.; Drury, P.J. Mechanical and Other Problems of Artificial Valves. In The Pathology of Devices; Berry, C., Ed.; Springer: Berlin/Heidelberg, Germany, 1994; pp. 127–159. ISBN 978-3-642-76846-0. [Google Scholar]

- Schoen, F.J.; Levy, R.J. Founder’s Award, 25th Annual Meeting of the Society for Biomaterials, perspectives. Providence, RI, April 28–May 2, 1999. Tissue heart valves: Current challenges and future research perspectives. J. Biomed. Mater. Res. 1999, 47, 439–465. [Google Scholar] [CrossRef]

- Fioretta, E.S.; Dijkman, P.E.; Emmert, M.Y.; Hoerstrup, S.P. The future of heart valve replacement: Recent developments and translational challenges for heart valve tissue engineering. J. Tissue Eng. Regen. Med. 2018, 12, e323–e335. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, H.; Mequanint, K. Prosthetic aortic heart valves: Modeling and design. Med Eng. Phys. 2011, 33, 131–147. [Google Scholar] [CrossRef] [PubMed]

- Ohlmann, L.; Mohammadi, H. Soft robotic in the construction of prosthetic heart valve: A novel approach. J. Med. Eng. Technol. 2020, 44, 76–81. [Google Scholar] [CrossRef] [PubMed]

- Gott, V.L.; Alejo, D.E.; Cameron, D.E. Mechanical Heart Valves: 50 Years of Evolution. Ann. Thorac. Surg. 2003, 76. [Google Scholar] [CrossRef]

- Bokros, J.C.; Gott, V.L.; La Grange, L.D.; Fadall, A.M.; Vos, K.D.; Ramos, M.D. Correlations between blood compatibility and heparin adsorptivity for an impermeable isotropic pyrolytic carbon. J. Biomed. Mater. Res. 1969, 3, 497–528. [Google Scholar] [CrossRef]

- Oveissi, F.; Naficy, S.; Lee, A.; Winlaw, D.S.; Dehghani, F. Materials and manufacturing perspectives in engineering heart valves: A review. Mater. Today Bio 2020, 5. [Google Scholar] [CrossRef]

- Schoen, F.J. On the fatigue behavior of pyrolytic carbon. Carbon 1973, 11, 413–414. [Google Scholar] [CrossRef]

- Ritchie, R.O.; Dauskardt, R.H.; Yu, W.; Brendzel, A.M. Cyclic fatigue-crack propagation, stress-corrosion, and fracture-toughness behavior in pyrolytic carbon-coated graphite for prosthetic heart valve applications. J. Biomed. Mater. Res. 1990, 24, 189–206. [Google Scholar] [CrossRef]

- Ma, L.; Sines, G. Fatigue behavior of a pyrolytic carbon. J. Biomed. Mater. Res. 2000, 51, 61–68. [Google Scholar] [CrossRef]

- Pierson, H.O. Pyrolytic Graphite. Handb. Carbon, Graph. Diam. Fuller. 1993, 141–165. [Google Scholar] [CrossRef]

- Akins, R.J.; Bokros, J.C. The deposition of pure and alloyed isotropic carbons in steady-state fluidized beds. Carbon 1974, 12, 439–452. [Google Scholar] [CrossRef]

- Ely, J.L.; Emken, M.R.; Accuntius, J.A.; Wilde, D.S.; Haubold, A.D.; More, R.B.; Bokros, J.C. Pure pyrolyric carbon: Preparation and properties of a new material, on- X® carbon for mechanical heart valve prostheses. J. Heart Valve Dis. 1998, 7, 626–632. [Google Scholar] [PubMed]

- Gwinnett, A.J.; Matsui, A. A study of enamel adhesives. The physical relationship between enamel and adhesive. Arch. Oral Biol. 1967. [Google Scholar] [CrossRef]

- Bokros, C.J. Control of Structure of Carbon for Use in Bioengineering. Chem. Phys. Carbon 1972, 9, 103–171. [Google Scholar]

- DeWall, R.A.; Qasim, N.; Carr, L. Evolution of mechanical heart valves. Ann. Thoracic Surg. 2000, 69, 1612–1621. [Google Scholar] [CrossRef]

- Wium, E.; Jordaan, C.J.; Botes, L.; Smit, F.E. Alternative mechanical heart valves for the developing world. Asian Cardiovasc. Thorac. Ann. 2020, 28, 431–443. [Google Scholar] [CrossRef]

- Mitamura, Y.; Hosooka, K.; Matsumoto, T.; Otaki, K.; Sakai, K.; Tanabe, T.; Yuta, T.; Mikami, T. Development of a Ceramic Heart Valve. J. Biomater. Appl. 1989, 4, 33–55. [Google Scholar] [CrossRef]

- Bokros, J.C. JACK C. BOKROS The fourth Charles, E. Pettinos Award was presented at the Twelfth Biennial Conference on Carbon in Pittsburgh, Pennsylvania to J. C. Bokros in recognition of his. Carbon 1971, 15, 353–371. [Google Scholar] [CrossRef]

- Ryder, J.K.; Cao, H. Structural integrity assessment of heart valve prostheses: A damage tolerance analysis of the CarboMedics Prosthetic Heart Valve. J. Heart Valve Dis. 1996, 5 (Suppl. 1), S86–S96. [Google Scholar]

- Kaae, J.L. Structure and mechanical properties of isotropic pyrolytic carbons deposited below 1600 °C. J. Nucl. Mat. 1971, 38, 42–50. [Google Scholar] [CrossRef]

- Price, J. Deformation and Fracture of Pyrolytic Bed. Carbon 1965, 3, 503–519. [Google Scholar]

- Shim, H.S. The Behavior of isotropic Pyroiytic Carbons under Cyclic Loading. Biomater. Med. Devices Artif. Organs 1974, 2, 55–64. [Google Scholar] [CrossRef] [PubMed]

- Peluccio, M.S.; Bignardi, C.; Lombardo, S.; Montevecchi, F.M.; Carossa, S. Comparative study of nanomechanical properties of cements used in teeth restoration. J. Phys. Condens. Matter 2007, 19. [Google Scholar] [CrossRef]

- Bignardi, C.; Petraroli, M.; Pugno, N. Nanoindentations on Conch Shells of Gastropoda and Bivalvia Molluscs Reveal Anisotropic Evolution Against External Attacks. J. Nanosci. Nanotechnol. 2010, 10, 6453–6460. [Google Scholar] [CrossRef]

- Hofmann, G.; Wiedenmeier, M.; Freund, M.; Beavan, A.; Hay, J.; Pharr, G.M. Investigation of the relationship between position within coater and pyrolytic carbon characteristics using nanoindentation. Carbon 2000, 38, 645–653. [Google Scholar] [CrossRef]

- López-Honorato, E.; Meadows, P.J.; Xiao, P.; Marsh, G.; Abram, T.J. Structure and mechanical properties of pyrolytic carbon produced by fluidized bed chemical vapor deposition. Nucl. Eng. Des. 2008, 238, 3121–3128. [Google Scholar] [CrossRef]

- Gross, T.S.; Timoshchuk, N.; Tsukrov, I.I.; Piat, R.; Reznik, B. On the ability of nanoindentation to measure anisotropic elastic constants of pyrolytic carbon. ZAMM Z. Angew. Math. Mech. 2013, 93, 301–312. [Google Scholar] [CrossRef]

- Gross, T.S.; Timoshchuk, N.; Tsukrov, I.; Reznik, B. Unique nanoindentation damage for highly textured pyrolytic carbon. Carbon 2013, 60, 273–279. [Google Scholar] [CrossRef]

- Zhang, H.; López-Honorato, E.; Xiao, P. Fluidized bed chemical vapor deposition of pyrolytic carbon-III. Relationship between microstructure and mechanical properties. Carbon 2015, 91, 346–357. [Google Scholar] [CrossRef]

- Beer, F.P.; Jhonston, R.E.; DeWolf, J.T. Mechanics of Materials; McGraw-Hill: New York, NY, USA, 1992. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Kaae, J.L. Relations between the structure and the mechanical properties of fluidized-bed pyrolytic carbons. Carbon 1971, 9, 291–299. [Google Scholar] [CrossRef]

- Marx, D.T.; Riester, L. Mechanical properties of carbon-carbon composite components determined using nanoindentation. Carbon 1999, 37, 1679–1684. [Google Scholar] [CrossRef]

- Stanley, J.; Klawitter, J.; More, R. Replacing joints with pyrolytic carbon. Jt. Replace. Technol. 2008, 631–656. [Google Scholar] [CrossRef]

- Reznik, B.; Hüttinger, K.J. On the terminology for pyrolytic carbon. Carbon 2002, 40, 621–624. [Google Scholar] [CrossRef]

| Size ∅ (mm) | |||

|---|---|---|---|

| Deposition process | 21 | 25 | 29 |

| Historical | 26 | 26 | 26 |

| Modified | 26 | 26 | 26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serino, G.; Gusmini, M.; Audenino, A.L.; Bergamasco, G.; Ieropoli, O.; Bignardi, C. Multiscale Characterization of Isotropic Pyrolytic Carbon Used for Mechanical Heart Valve Production. Processes 2021, 9, 338. https://doi.org/10.3390/pr9020338

Serino G, Gusmini M, Audenino AL, Bergamasco G, Ieropoli O, Bignardi C. Multiscale Characterization of Isotropic Pyrolytic Carbon Used for Mechanical Heart Valve Production. Processes. 2021; 9(2):338. https://doi.org/10.3390/pr9020338

Chicago/Turabian StyleSerino, Gianpaolo, Mattia Gusmini, Alberto Luigi Audenino, Giovanni Bergamasco, Ornella Ieropoli, and Cristina Bignardi. 2021. "Multiscale Characterization of Isotropic Pyrolytic Carbon Used for Mechanical Heart Valve Production" Processes 9, no. 2: 338. https://doi.org/10.3390/pr9020338

APA StyleSerino, G., Gusmini, M., Audenino, A. L., Bergamasco, G., Ieropoli, O., & Bignardi, C. (2021). Multiscale Characterization of Isotropic Pyrolytic Carbon Used for Mechanical Heart Valve Production. Processes, 9(2), 338. https://doi.org/10.3390/pr9020338