Energy Saving for Tissue Paper Mills by Energy-Efficiency Scheduling under Time-of-Use Electricity Tariffs

Abstract

1. Introduction

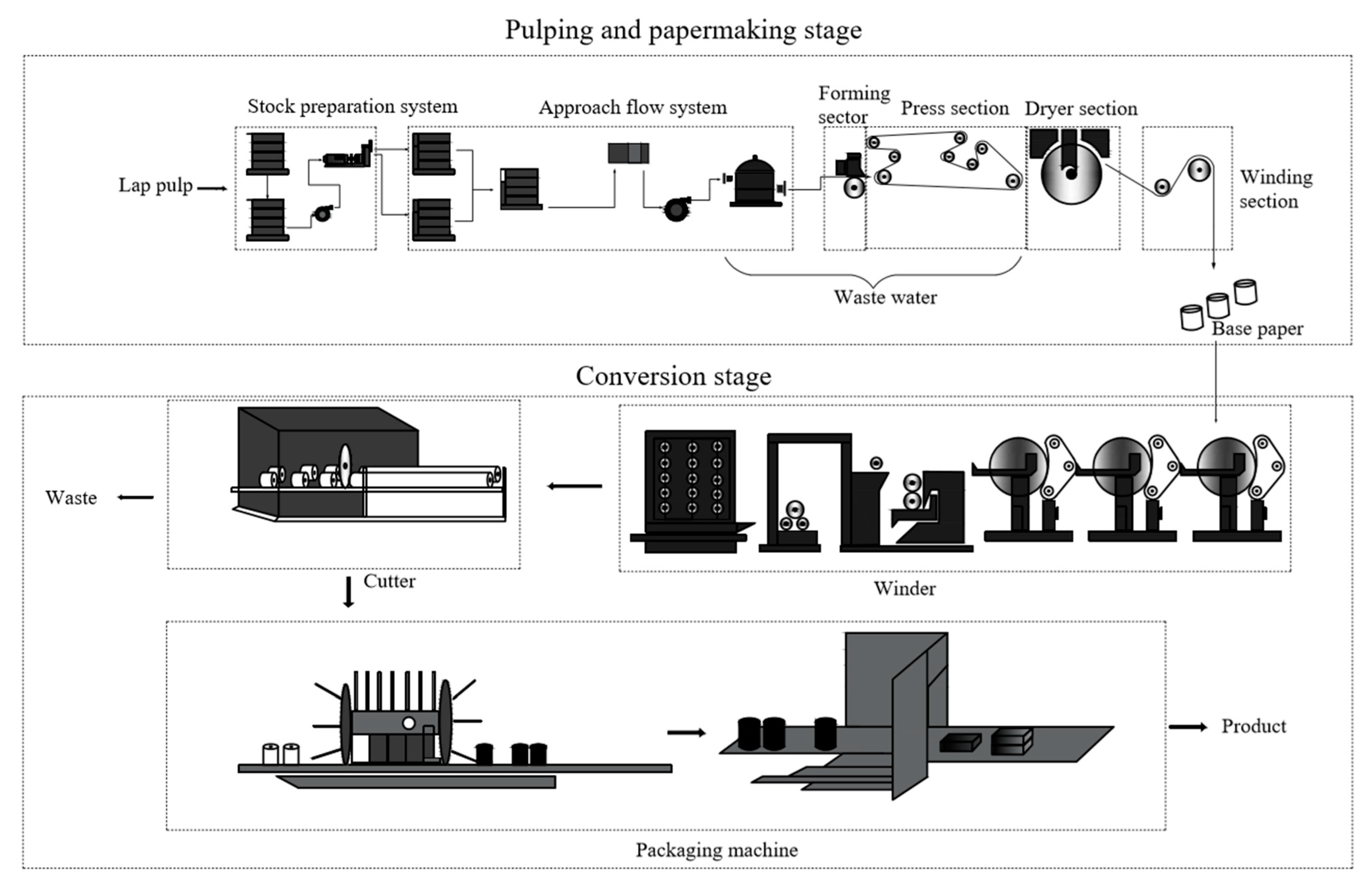

2. Problem Description and Modeling

2.1. Energy Cost Modeling

2.2. Energy-Efficiency Scheduling Modeling

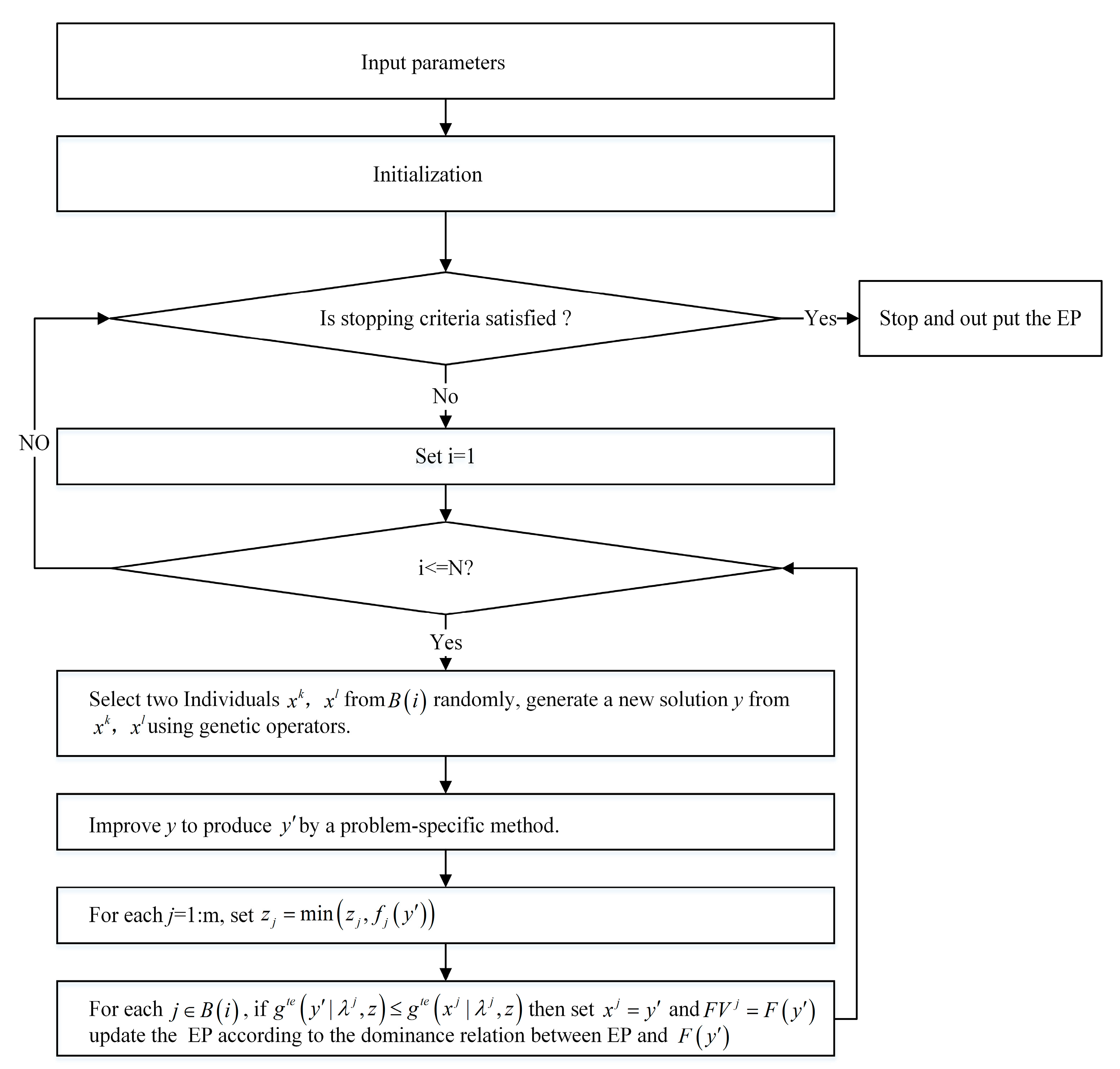

3. The Proposed Optimization Algorithm

3.1. MOEA/DTL

| Algorithm 1 MOEA/DTL |

| 1. Initialize the population scale and the number of subproblems. 2. Initialize the maximum number of iterations (Mt). 3. Initialize a set of weight vectors with uniform distribution (). 4. Initialize the number of neighbors for every weight vector (T). 5. Set the external population . 6. for each do 7. The nearest weight vectors of the i-th weight vector is calculated according to Euclidean distances. 8. Set , where is the neighbors of with weight vectors. 9. end for 10. Generate by a specific method. 11. is set by the decomposition approach. 12. Set , where , is the j-th objective of solution . 13. while true do 14. for do 15. Teaching phase: 16. if is not the best individual among its neighbors 17. An individual from its neighbors is randomly set as teacher with a probability Ps, or an individual is randomly selected from as teacher with a probability 1-Ps. 18. else 19. An individual is randomly selected from as . 20. end if 21. A new individual is generated by a crossover operation from and . 22. Mutation operation is applied to with probability to generate a new individual . 23. for each do 24. Set . If , set and . 25. end for 26. Learning phase: 27. for each do 28. if is not the best individual in the neighbors of 29. A new individual is first generated by crossover operation from and . 30. A new individual is generated by applying the mutation operation to with probability . 31. else 32. Continue to the next iteration. 33. end if 34. for each do 35. set . 36. if 37. Set and . 38. end if 39. end for 40. end for 41. end for 42. Update : a new non-dominated set is selected from and the new population as the new , and get rid of the duplicate solution. If the size of is smaller than the setting value, some randomly generated individuals () are added to until the size of is equal to the setting value. 43. for each do 44. An individual is randomly selected from , and an individual is ran- bdomly selected from with a probability , or an individual is selected from with a probability . 45. A new is generated by crossover operation from and . 46. Mutation operation is applied to with probability to generate a new . 47. end for 48. Update : select a new non-dominated set from and the new population as the new 49. if the stopping criterion is not satisfied 50. Continue. 51. else 52. Stop and output . 53. end if 54. end while |

- Step (1) Set , where For each , do:

- Step (2) Generate weight vectors by randomly selecting vectors from .

3.2. Variable Neighborhood Search

| Algorithm 2 VNS |

| 1. Construct the set of neighborhood structures , . 2. Set the maximum iterations for searching in the first, second, and third neighborhood structures , , . 3. Set the initial solution. 4. for each do 5. for each do 6. Based on the current solution, the first neighborhood structure is used to search for better solutions than the current solution, and it means that the solutions found can dominate the current solution. 7. end for 8. for each do 9. Based on the current solution, the second neighborhood structure is used to search for better solutions than the current solution, and it means that the solutions found can dominate the current solution. 10. end for 11. for each do 12. Based on the current solution, the third neighborhood structures is used to search for better solutions than the current solution, and it means that the solutions found can dominate the current solution. 13. end for 14. If the stopping criteria are not satisfied, continue; otherwise, stop and output the best solution. 15. end for |

3.3. IMOEA/DTL

| Algorithm 3 Combination method of VNS and MOEA/DTL |

| 1. for each do 2. 3. end for 4. Output the new population. |

4. Case Study

4.1. Experiment Data

4.2. Performance Metrics

4.3. Parameters Setting

4.4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- EIA. Available online: https://www.eia.gov/outlooks/aeo/data/browser/#/?id=37-AEO2020&cases=ref2020&sourcekey=1 (accessed on 22 December 2020).

- EIA. Available online: https://www.eia.gov/outlooks/aeo/data/browser/#/?id=22-AEO2020&cases=ref2020&sourcekey=0 (accessed on 22 December 2020).

- Mouzon, G.; Yildirim, M.B. A framework to minimise total energy consumption and total tardiness on a single machine. Int. J. Sustain. Eng. 2008, 1, 105–116. [Google Scholar] [CrossRef]

- Che, A.; Wu, X.; Peng, J.; Yan, P. Energy-efficient bi-objective single-machine scheduling with power-down mechanism. Comput. Oper. Res. 2017, 85, 172–183. [Google Scholar] [CrossRef]

- Lu, C.; Gao, L.; Li, X.; Pan, Q.; Wang, Q. Energy-efficient permutation flow shop scheduling problem using a hybrid multi-objective backtracking search algorithm. J. Clean. Prod. 2017, 144, 228–238. [Google Scholar] [CrossRef]

- Mokhtari, H.; Hasani, A. An energy-efficient multi-objective optimization for flexible job-shop scheduling problem. Comput. Chem. Eng. 2017, 104, 339–352. [Google Scholar] [CrossRef]

- Nolde, K.; Morari, M. Electrical load tracking scheduling of a steel plant. Comput. Chem. Eng. 2010, 34, 1899–1903. [Google Scholar] [CrossRef]

- Wu, N.; Li, Z.; Qu, T. Energy efficiency optimization in scheduling crude oil operations of refinery based on linear programming. J. Clean. Prod. 2017, 166, 49–57. [Google Scholar] [CrossRef]

- Wu, X.L.; Sun, Y.L. A green scheduling algorithm for flexible job shop with energy-saving measures. J. Clean. Prod. 2018, 172, 3249–3264. [Google Scholar] [CrossRef]

- Che, A.; Zhang, S.; Wu, X. Energy-conscious unrelated parallel machine scheduling under time-of-use electricity tariffs. J. Clean. Prod. 2017, 156, 688–697. [Google Scholar] [CrossRef]

- Cheng, J.; Chu, F.; Liu, M.; Wu, P.; Xia, W. Bi-criteria single-machine batch scheduling with machine on/off switching under time-of-use tariffs. Comput. Int. Eng. 2017, 112, 721–734. [Google Scholar] [CrossRef]

- Lee, S.; Chung, B.D.; Jeon, H.W.; Chang, J. A dynamic control approach for energy-efficient production scheduling on a single machine under time-varying electricity pricing. J. Clean. Prod. 2017, 165, 552–563. [Google Scholar] [CrossRef]

- Zhou, S.; Li, X.; Du, N.; Pang, Y.; Chen, H. A multi-objective differential evolution algorithm for parallel batch processing machine scheduling considering electricity consumption cost. Comput. Oper. Res. 2018, 96, 55–68. [Google Scholar] [CrossRef]

- Gong, X.; De Pessemier, T.; Martens, L.; Joseph, W. Energy- and labor-aware flexible job shop scheduling under dynamic electricity pricing: A many-objective optimization investigation. J. Clean. Prod. 2019, 209, 1078–1094. [Google Scholar] [CrossRef]

- Luo, H.; Du, B.; Huang, G.Q.; Chen, H.; Li, X. Hybrid flow shop scheduling considering machine electricity consumption cost. Int. J. Prod. Econ. 2013, 146, 423–439. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, F.; Fang, K.; Sutherland, J.W. Energy-conscious flow shop scheduling under time-of-use electricity tariffs. CIRP Ann. Manuf. Technol. 2014, 63, 37–40. [Google Scholar] [CrossRef]

- Pan, R.L.; Li, Z.H.; Gao, J.H.; Zhang, H.L.; Xia, X. Electrical load tracking scheduling of steel plants under time-of-use tariffs. Comput. Int. Eng. 2019, 137, 106049. [Google Scholar] [CrossRef]

- Sharma, A.; Zhao, F.; Sutherland, J.W. Econological scheduling of a manufacturing enterprise operating under a time-of-use electricity tariff. J. Clean. Prod. 2015, 108, 256–270. [Google Scholar] [CrossRef]

- Tan, Y.; Liu, S. Models and optimisation approaches for scheduling steelmaking–refining–continuous casting production under variable electricity price. Int. J. Prod. Res. 2014, 52, 1032–1049. [Google Scholar] [CrossRef]

- Zeng, Y.J.; Sun, Y.G. Short-term scheduling of steam power system in iron and steel industry under time-of-use power price. J. Iron. Steel. Res. Int. 2015, 22, 795–803. [Google Scholar] [CrossRef]

- Zhao, X.; Bai, H.; Shi, Q.; Lu, X.; Zhang, Z. Optimal scheduling of a byproduct gas system in a steel plant considering time-of-use electricity pricing. Appl. Energy 2017, 195, 100–113. [Google Scholar] [CrossRef]

- Ramos, A.G.; Leal, J. ILP model for energy-efficient production scheduling of flake ice units in food retail stores. J. Clean. Prod. 2017, 156, 953–961. [Google Scholar] [CrossRef]

- Yan, J.; Li, L.; Zhao, F.; Zhang, F.; Zhao, Q. A multi-level optimization approach for energy-efficient flexible flow shop scheduling. J. Clean. Prod. 2016, 137, 1543–1552. [Google Scholar] [CrossRef]

- Fang, K.; Uhan, N.A.; Zhao, F. Scheduling on a single machine under time-of-use electricity tariffs. Ann. Oper. Res. 2016, 238, 199–227. [Google Scholar] [CrossRef]

- Tan, M.; Duan, B.; Su, Y. Economic batch sizing and scheduling on parallel machines under time-of-use electricity pricing. Oper. Res. Ger. 2016, 18, 105–122. [Google Scholar] [CrossRef]

- Zeng, Z.Q.; Hong, M.N.; Man, Y.; Li, J.G.; Zhang, Y.Z.; Liu, H.B. Multi-object optimization of flexible flow shop scheduling with batch process—Consideration total electricity consumption and material wastage. J. Clean. Prod. 2018, 183, 925–939. [Google Scholar] [CrossRef]

- Zeng, Z.Q.; Hong, M.N.; Li, J.G.; Man, Y.; Liu, H.B.; Li, Z.; Zhang, H.H. Integrating process optimization with energy-efficiency scheduling to save energy for paper mills. Appl. Energ. 2018, 225, 542–558. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, H. MOEA/D: A multiobjective evolutionary algorithm based on decomposition. IEEE Trans. Evolut. Comput. 2007, 11, 712–731. [Google Scholar] [CrossRef]

- Adasme, P.; Lisser, A. Uplink scheduling for joint wireless orthogonal frequency and time division multiple access networks. J. Sched. 2016, 19, 349–366. [Google Scholar] [CrossRef]

- Anjana, V.; Sridharan, R.; Kumar, P.N.R. Metaheuristics for solving a multi-objective flow shop scheduling problem with sequence-dependent setup times. J. Sched. 2019, 23, 49–69. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Q.; Li, H.; Ishibuchi, H.; Jiao, L. On the use of two reference points in decomposition based multiobjective evolutionary algorithms. Swarm. Evol. Comput. 2017, 34, 89–102. [Google Scholar] [CrossRef]

- Schulz, S.; Neufeld, J.S.; Buscher, U. A multi-objective iterated local search algorithm for comprehensive energy-aware hybrid flow shop scheduling. J. Clean. Prod. 2019, 224, 421–434. [Google Scholar] [CrossRef]

- Kantour, N.; Bouroubi, S.; Chaabane, D. A parallel MOEA with criterion-based selection applied to the Knapsack Problem. Appl. Soft Comput. 2019, 80, 358–373. [Google Scholar] [CrossRef]

- Zhang, R.; Chiong, R. Solving the energy-efficient job shop scheduling problem: A multiobjective genetic algorithm with enhanced local search for minimizing the total weighted tardiness and total energy consumption. J. Clean. Prod. 2016, 112, 3361–3375. [Google Scholar] [CrossRef]

- Li, M.; Lei, D.; Cai, J. Two-level imperialist competitive algorithm for energy-efficient hybrid flow shop scheduling problem with relative importance of objectives. Swarm. Evol. Comput. 2019, 49, 34–43. [Google Scholar] [CrossRef]

| Period Type | Time Periods | Electricity Price (CNY/kWh) |

|---|---|---|

| Off-peak | 00:00–08:00 | 0.3351 |

| Mid-peak | 08:00–09:00; 12:00–19:00; 22:00–24:00 | 0.6393 |

| On-peak | 09:00–12:00; 19:00–22:00 | 1.0348 |

| Problems | Job Number |

|---|---|

| Job1 | 50 |

| Job2 | 60 |

| Job3 | 70 |

| Job4 | 80 |

| Job5 | 90 |

| Job6 | 100 |

| Job7 | 110 |

| Job8 | 120 |

| Job9 | 130 |

| Job10 | 140 |

| Job11 | 150 |

| Job12 | 160 |

| Job13 | 170 |

| Job14 | 180 |

| Job15 | 190 |

| Job16 | 200 |

| Pulping and Papermaking Stage | Speed (m/min) | Converting Stage | Speed (bag/min) |

|---|---|---|---|

| PL1 | 990 | BL1 | 260 |

| PL2 | 950 | BL2 | 320 |

| PL3 | 1010 | BL3 | 330 |

| PL4 | 970 | BL4 | 325 |

| PL5 | 1050 | BL5 | 335 |

| PL6 | 1110 | BL6 | 360 |

| BL7 | 400 |

| Pulping and Papermaking Stage | Power (kW) | Converting Stage | Power (kW) |

|---|---|---|---|

| PL1 | 1210 | BL1 | 130 |

| PL2 | 1280 | BL2 | 145 |

| PL3 | 1380 | BL3 | 148 |

| PL4 | 1470 | BL4 | 120 |

| PL5 | 1330 | BL5 | 138 |

| PL6 | 1490 | BL6 | 135 |

| BL7 | 137 |

| Pulping and Papermaking Stage | Power (kW) | Converting Stage | Power (kW) |

|---|---|---|---|

| PL1 | 813 | BL1 | 82 |

| PL2 | 821 | BL2 | 97 |

| PL3 | 878 | BL3 | 104 |

| PL4 | 902 | BL4 | 70 |

| PL5 | 870 | BL5 | 87 |

| PL6 | 922 | BL6 | 91 |

| BL7 | 88 |

| BL1 | BL2 | BL3 | BL4 | BL5 | BL6 | BL7 | |

|---|---|---|---|---|---|---|---|

| PL1 | 4 | 6 | 16 | 17 | 18 | 20 | 24 |

| PL2 | 5 | 3 | 15 | 16 | 19 | 23 | 25 |

| PL3 | 16 | 18 | 3 | 4 | 6 | 19 | 21 |

| PL4 | 17 | 15 | 5 | 2 | 3 | 15 | 16 |

| PL5 | 26 | 27 | 22 | 20 | 17 | 4 | 3 |

| PL6 | 27 | 26 | 23 | 21 | 18 | 3 | 5 |

| MOEA/D-MR | SPEA2 | NSGA-II | IMOEA/DTL |

|---|---|---|---|

| N: 100 Mt: 100 F: 0.5 CR: 0.2 H: 99 Tm: 10 Tr: 10 | N: 100 Size of archive: 100 Mt: 100 Pc: 0.8 Pm: 0.2 | N: 100 Mt: 100 Pc: 0.8 Pm: 0.2 | N: 100 Mt: 100 Size of EP: 100 T: 10 Ps: 0.7 Pm: 0.3 Pc: 0.7 M: 5 M1: 10 M2: 5 M3: 3 |

| Problems | ||||||

|---|---|---|---|---|---|---|

| Job1 | 0 | 1 | 0 | 0.98 | 0 | 1 |

| Job2 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job3 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job4 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job5 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job6 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job7 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job8 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job9 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job10 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job11 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job12 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job13 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job14 | 0 | 1 | 0 | 1 | 0 | 0.98 |

| Job15 | 0 | 1 | 0 | 1 | 0 | 1 |

| Job16 | 0 | 1 | 0 | 1 | 0 | 1 |

| Problems | P1 | P2 | P3 |

|---|---|---|---|

| Job1 | 0.0020 | 0.0020 | 0.0020 |

| Job2 | 0.0020 | 0.0020 | 0.0020 |

| Job3 | 0.0020 | 0.0020 | 0.0020 |

| Job4 | 0.0020 | 0.0020 | 0.0020 |

| Job5 | 0.0020 | 0.0020 | 0.0020 |

| Job6 | 0.0020 | 0.0020 | 0.0020 |

| Job7 | 0.0020 | 0.0020 | 0.0020 |

| Job8 | 0.0020 | 0.0020 | 0.0020 |

| Job9 | 0.0020 | 0.0020 | 0.0020 |

| Job10 | 0.0020 | 0.0020 | 0.0020 |

| Job11 | 0.0020 | 0.0020 | 0.0020 |

| Job12 | 0.0020 | 0.0020 | 0.0020 |

| Job13 | 0.0020 | 0.0020 | 0.0020 |

| Job14 | 0.0020 | 0.0020 | 0.0020 |

| Job15 | 0.0020 | 0.0020 | 0.0020 |

| Job16 | 0.0020 | 0.0020 | 0.0020 |

| Problems | MOEA/D-MR | NSGA-II | SPEA2 | IMOEA/DTL |

|---|---|---|---|---|

| Job1 | 3.46 × 107 | 3.32 × 107 | 3.42 × 107 | 5.43 × 107 |

| Job2 | 1.75 × 107 | 1.65 × 107 | 1.58 × 107 | 2.79 × 107 |

| Job3 | 7.02 × 107 | 6.38 × 107 | 6.60 × 107 | 9.82 × 107 |

| Job4 | 5.33 × 107 | 5.04 × 107 | 5.15 × 107 | 8.27 × 107 |

| Job5 | 3.33 × 107 | 3.06 × 107 | 3.09 × 107 | 4.92 × 107 |

| Job6 | 3.40 × 107 | 3.53 × 107 | 3.37 × 107 | 5.87 × 107 |

| Job7 | 4.22 × 107 | 3.74 × 107 | 4.03 × 107 | 6.29 × 107 |

| Job8 | 2.40 × 107 | 2.01 × 107 | 2.07 × 107 | 3.65 × 107 |

| Job9 | 5.99 × 107 | 5.44 × 107 | 5.75 × 107 | 8.79 × 107 |

| Job10 | 2.66 × 107 | 2.62 × 107 | 2.60 × 107 | 4.32 × 107 |

| Job11 | 4.41 × 107 | 4.49 × 107 | 4.45 × 107 | 7.30 × 107 |

| Job12 | 4.43 × 107 | 4.07 × 107 | 4.18 × 107 | 6.58 × 107 |

| Job13 | 5.43 × 107 | 5.43 × 107 | 5.46 × 107 | 8.77 × 107 |

| Job14 | 3.32 × 107 | 3.27 × 107 | 3.35 × 107 | 5.16 × 107 |

| Job15 | 4.83 × 107 | 4.54 × 107 | 4.62 × 107 | 7.67 × 107 |

| Job16 | 8.19 × 107 | 7.78 × 107 | 8.15 × 107 | 1.19 × 107 |

| Problems | P1 | P2 | P3 |

|---|---|---|---|

| Job1 | 0.0020 | 0.0020 | 0.0020 |

| Job2 | 0.0020 | 0.0020 | 0.0020 |

| Job3 | 0.0020 | 0.0020 | 0.0020 |

| Job4 | 0.0020 | 0.0020 | 0.0020 |

| Job5 | 0.0020 | 0.0020 | 0.0020 |

| Job6 | 0.0020 | 0.0020 | 0.0020 |

| Job7 | 0.0020 | 0.0020 | 0.0020 |

| Job8 | 0.0020 | 0.0020 | 0.0020 |

| Job9 | 0.0020 | 0.0020 | 0.0020 |

| Job10 | 0.0020 | 0.0020 | 0.0020 |

| Job11 | 0.0020 | 0.0020 | 0.0020 |

| Job12 | 0.0020 | 0.0020 | 0.0020 |

| Job13 | 0.0020 | 0.0020 | 0.0020 |

| Job14 | 0.0020 | 0.0020 | 0.0020 |

| Job15 | 0.0020 | 0.0020 | 0.0020 |

| Job16 | 0.0020 | 0.0020 | 0.0020 |

| Problems | Makespan (Minute) | Energy Cost (CNY) | ||||||

|---|---|---|---|---|---|---|---|---|

| MOEA/D-MR | NSGA-II | SPEA2 | IMOEA/DTL | MOEA/D-MR | NSGA-II | SPEA2 | IMOEA/DTL | |

| Job1 | 10,049 | 10,064 | 10,053 | 9939 | 801,309 | 803,965 | 804,358 | 795,656 |

| Job2 | 11,817 | 11,864 | 11,881 | 11,800 | 964,677 | 966,456 | 966,000 | 957,500 |

| Job3 | 14,104 | 14,139 | 14,175 | 14,033 | 1,158,100 | 1,161,747 | 1,159,518 | 1,150,038 |

| Job4 | 16,030 | 16,089 | 16,128 | 16,008 | 1,302,626 | 1,304,014 | 1,303,485 | 1,291,973 |

| Job5 | 18,534 | 18,537 | 18,567 | 18,460 | 1,520,818 | 1,521,966 | 1,521,371 | 1,511,605 |

| Job6 | 19,603 | 19,680 | 19,642 | 19,531 | 1,610,892 | 1,608,901 | 1,610,826 | 1,596,377 |

| Job7 | 21,236 | 21,348 | 21,337 | 21,222 | 1,777,566 | 1,779,676 | 1,778,261 | 1,768,963 |

| Job8 | 23,006 | 23,044 | 23,063 | 22,953 | 1,916,511 | 1,921,468 | 1,918,722 | 1,908,951 |

| Job9 | 27,008 | 27,075 | 27,079 | 26,922 | 2,223,799 | 2,226,399 | 2,224,613 | 2,213,336 |

| Job10 | 26,571 | 26,585 | 26,584 | 26,501 | 2,193,870 | 2,193,213 | 2,193,967 | 2,183,339 |

| Job11 | 28,920 | 28,914 | 29,001 | 28,886 | 2,427,444 | 2,426,101 | 2,424,184 | 2,408,955 |

| Job12 | 30,127 | 30,167 | 30,219 | 30,117 | 2,565,900 | 2,568,756 | 2,566,343 | 2,551,189 |

| Job13 | 32,440 | 32,451 | 32,510 | 32,358 | 2,699,366 | 2,700,491 | 2,697,074 | 2,684,005 |

| Job14 | 35,034 | 35,093 | 35,078 | 34,972 | 2,887,249 | 2,887,706 | 2,886,665 | 2,876,694 |

| Job15 | 35,787 | 35,835 | 35,768 | 35,712 | 2,984,084 | 2,985,389 | 2,985,440 | 2,971,161 |

| Job16 | 40,290 | 40,241 | 40,253 | 40,185 | 3,380,449 | 3,385,432 | 3,383,498 | 3,368,202 |

| Average Makespan (Minute) | Average Energy cost (CNY) | Maximum Makespan (Minute) | Minimum Energy Cost (CNY) | Minimum Makespan (Minute) | Maximum Energy Cost (CNY) |

|---|---|---|---|---|---|

| 15,754 | 1,347,737 | 18,675 | 1,333,494 | 15,367 | 1,375,361 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Z.; Chen, X.; Wang, K. Energy Saving for Tissue Paper Mills by Energy-Efficiency Scheduling under Time-of-Use Electricity Tariffs. Processes 2021, 9, 274. https://doi.org/10.3390/pr9020274

Zeng Z, Chen X, Wang K. Energy Saving for Tissue Paper Mills by Energy-Efficiency Scheduling under Time-of-Use Electricity Tariffs. Processes. 2021; 9(2):274. https://doi.org/10.3390/pr9020274

Chicago/Turabian StyleZeng, Zhiqiang, Xiaobin Chen, and Kaiyao Wang. 2021. "Energy Saving for Tissue Paper Mills by Energy-Efficiency Scheduling under Time-of-Use Electricity Tariffs" Processes 9, no. 2: 274. https://doi.org/10.3390/pr9020274

APA StyleZeng, Z., Chen, X., & Wang, K. (2021). Energy Saving for Tissue Paper Mills by Energy-Efficiency Scheduling under Time-of-Use Electricity Tariffs. Processes, 9(2), 274. https://doi.org/10.3390/pr9020274