Numerical Simulation of the Aerosol Particle Motion in Granular Filters with Solid and Porous Granules

Abstract

1. Introduction

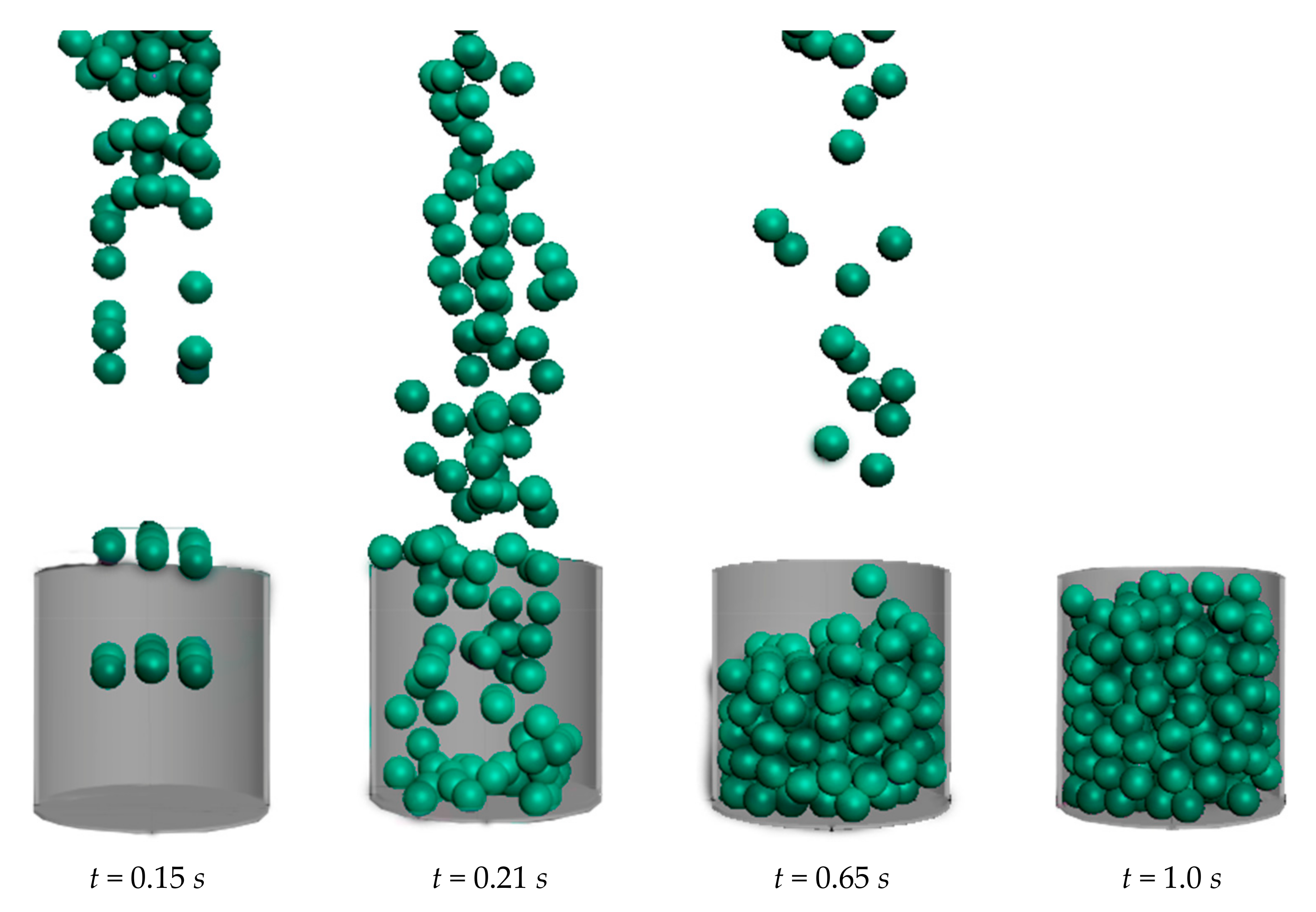

2. Problem Formulation and Solution Method

2.1. Filter Model

2.2. Mathematical Formulation

3. Results

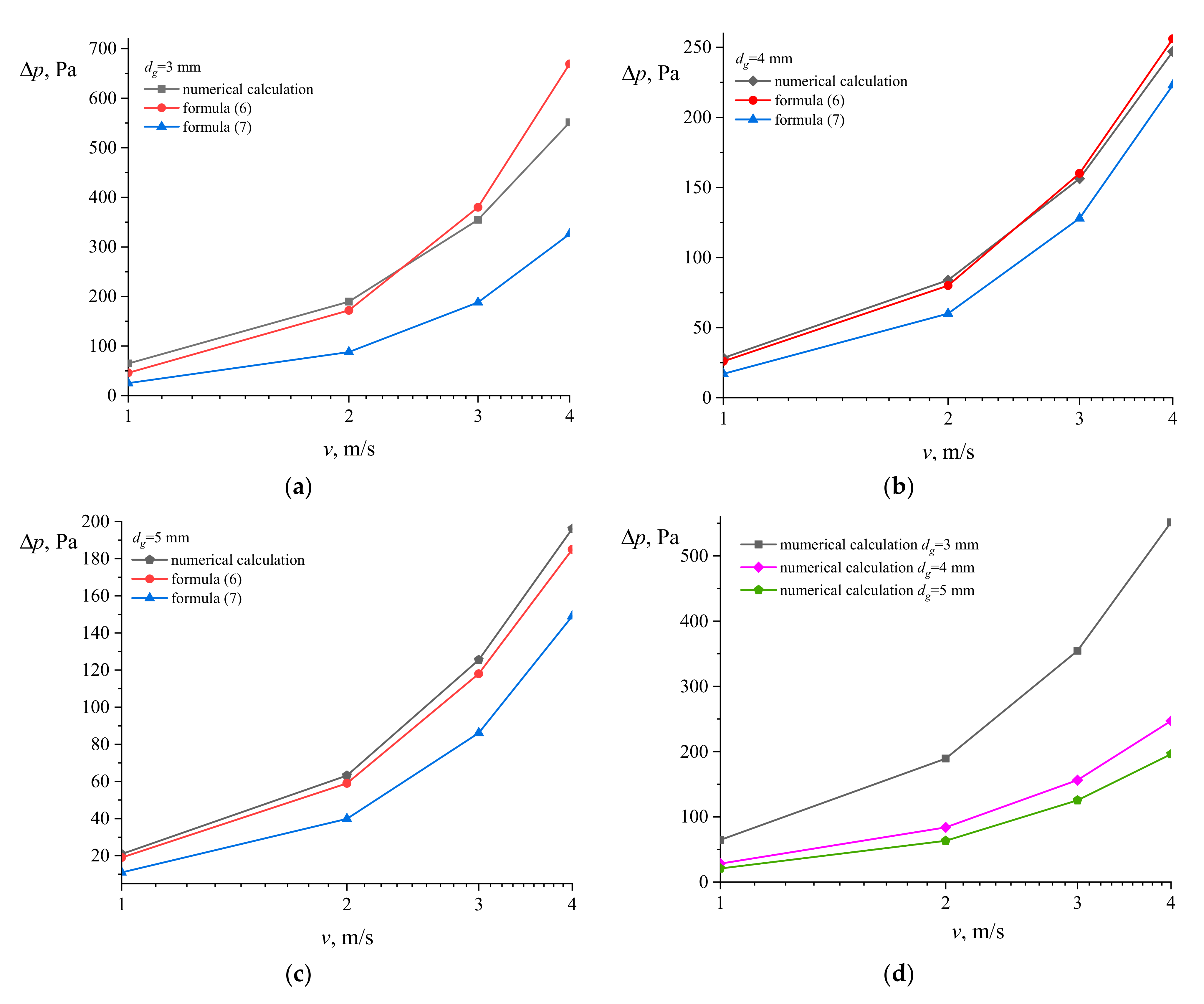

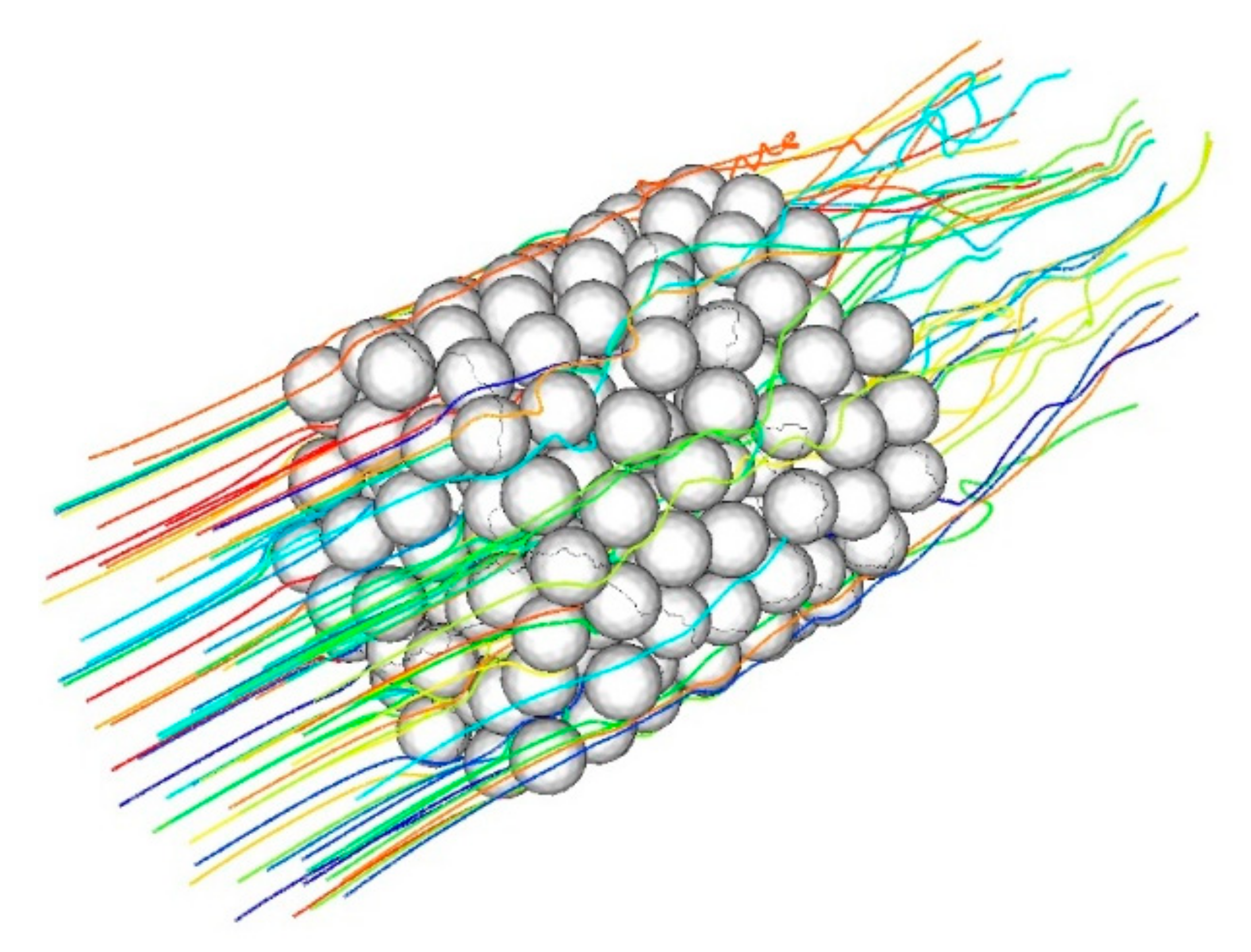

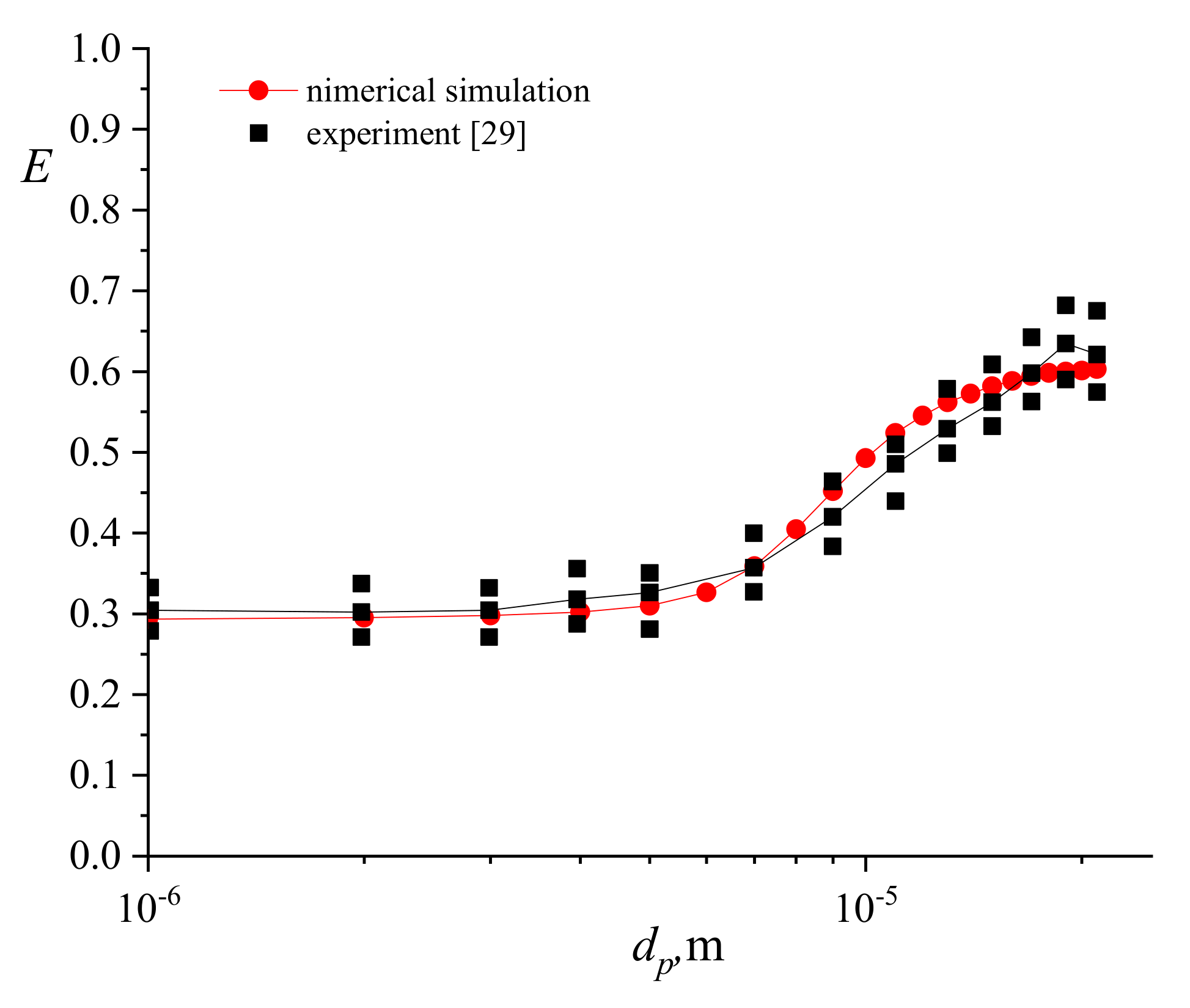

3.1. Numerical Simulation of the Aerosol Motion in a Granular Filter with Solid Spherical Granules

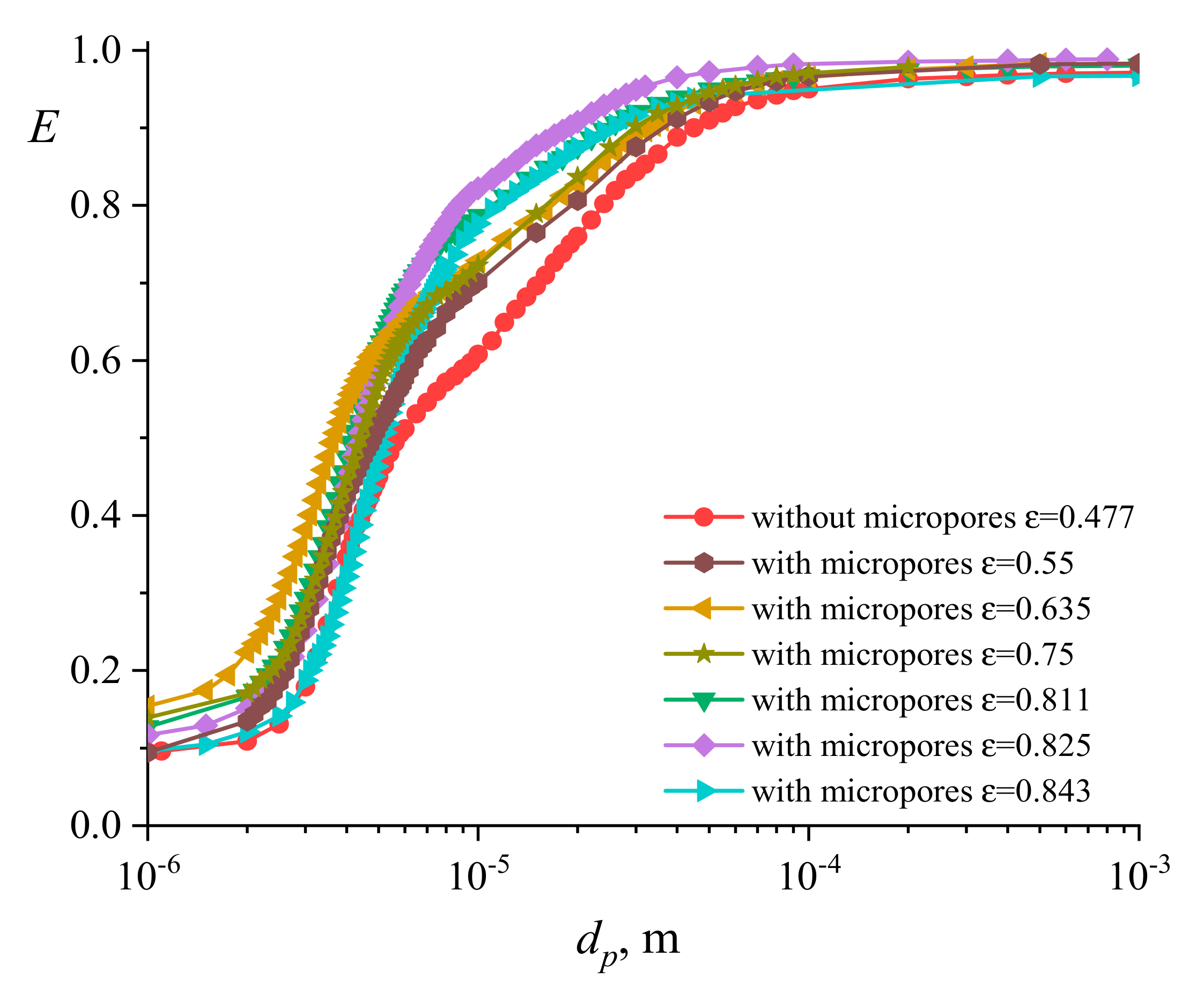

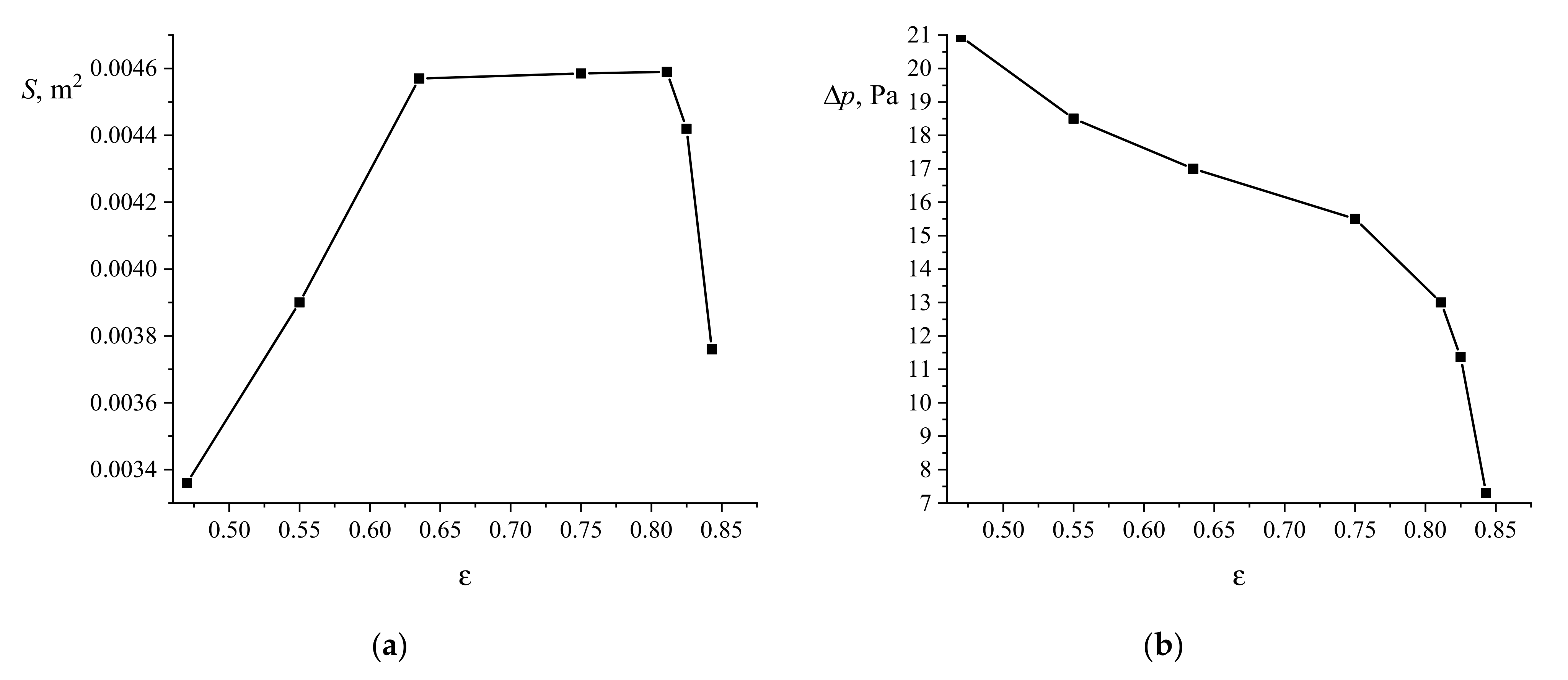

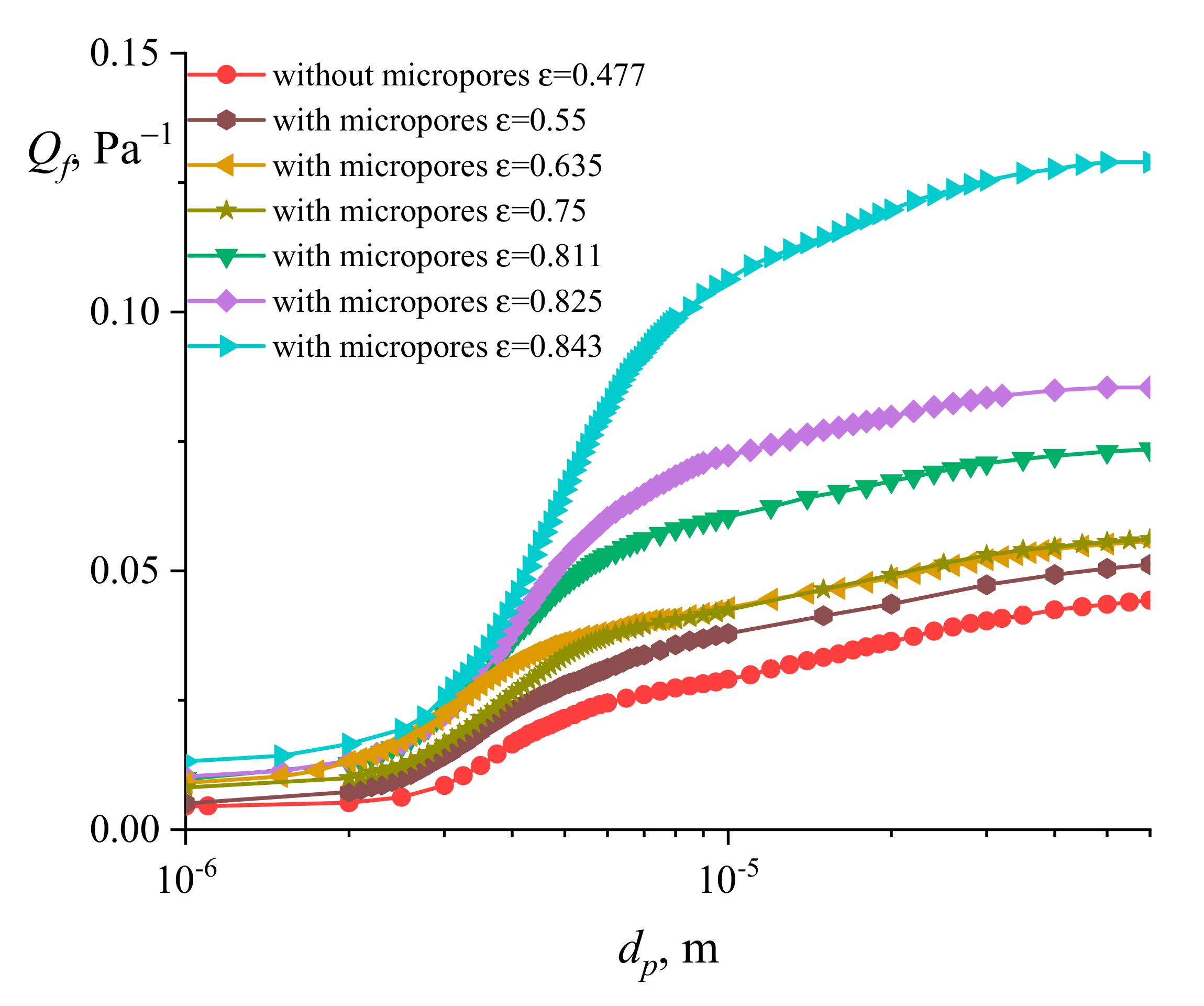

3.2. Numerical Simulation of the Aerosol Motion in a Granular Filter with Porous Spherical Granules

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jaeger, H.M.; Nagel, S.R.; Behringer, R.P. Granular solids, liquids, and gases. Rev. Mod. Phys. 1996, 68, 1259–1273. [Google Scholar] [CrossRef]

- Cai, J.; Dong, H.; Fu, W. Study on Particle Flow in Shaft Moving Beds. J. Northeast. Univ. Nat. Sci. 2007, 28, 1599–1603. [Google Scholar]

- Tien, C.; Ramarao, B.V. Macroscopic description of fixed-bed granular filtration. In Granular Filtration of Aerosols and Hydrosols; Elsevier: Amsterdam, The Netherlands, 1989; pp. 17–47. [Google Scholar]

- El-Hedok, I.A.; Whitmer, L.; Brown, R.C. The influence of granular flow rate on the performance of a moving bed granular filter. Powder Technol. 2011, 214, 69–76. [Google Scholar] [CrossRef]

- Altmann, J.; Rehfeld, D.; Träder, K.; Sperlich, A.; Jekel, M. Combination of granular activated carbon adsorption and deep-bed filtration as a single advanced wastewater treatment step for organic micropollutant and phosphorus removal. Water Res. 2016, 92, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Hsu, C.J.; Hsiau, S.S. A study of filtration performance in a cross-flow moving granular bed filter: The influence of gas flow uniformity. Powder Technol. 2015, 274, 20–27. [Google Scholar] [CrossRef]

- Hsu, C.J.; Hsiau, S.S.; Chen, Y.S.; Smid, J. Investigation of the gas inlet velocity distribution in a fixed granular bed filter. Adv. Powder Technol. 2010, 21, 614–622. [Google Scholar] [CrossRef]

- Xiao, G.; Wang, X.; Zhang, J.; Ni, M.; Gao, X.; Luo, Z.; Cen, K. Granular bed filter: A promising technology for hot gas clean-up. Powder Technol. 2013, 244, 93–99. [Google Scholar] [CrossRef]

- Gutfinger, C.; Tardos, G.I. Theoretical and experimental investigation on granular bed dust filters. Atmos. Environ. 1979, 13, 853–867. [Google Scholar] [CrossRef]

- Brown, R.C.; Shi, H.; Colver, G.; Soo, S.C. Similitude study of a moving bed granular filter. Powder Technol. 2003, 138, 201–210. [Google Scholar]

- Çarpinlioğlu, M.Ö.; Özahi, E. A simplified correlation for fixed bed pressure drop. Powder Technol. 2008, 187, 94–101. [Google Scholar]

- Kuo, Y.M.; Huang, S.H.; Lin, W.Y.; Hsiao, M.F.; Chen, C.C. Filtration and loading characteristics of granular bed filters. J. Aerosol Sci. 2010, 41, 223–229. [Google Scholar] [CrossRef]

- Solovev, S.A.; Soloveva, O.V.; Popkova, O.S. Numerical simulation of the motion of aerosol particles in open cell foam materials. Russ. J. Phys. Chem. A 2018, 92, 601–604. [Google Scholar] [CrossRef]

- Zaripov, S.K.; Soloveva, O.V.; Skvortsov, E.V. Analytical model of the transport of aerosol particles in a circular hole inside a porous medium. Transp. Porous Media 2015, 107, 141–151. [Google Scholar] [CrossRef]

- Soloveva, O.V.; Solovev, S.A.; Khusainov, R.R. Evaluation of the efficiency of prefilter models using numerical simulation. J. Phys. Conf. Ser. 2019, 1399, 022059. [Google Scholar] [CrossRef]

- Soloveva, O.V.; Solovev, S.A.; Yafizov, R.R. Study of the influence of the add of micropores on filtering characteristics of high porous structures. Ecol. Ind. Russ. 2020, 24, 39–43. [Google Scholar] [CrossRef]

- Soloveva, O. Study of aerosol motion in granular and foam filters with equal porosity of the structure. Adv. Intell. Syst. Comput. 2021, 1259, 638–649. [Google Scholar]

- Soloveva, O.; Solovev, S.; Khusainov, R.; Yafizov, R. Mathematical modelling of heat transfer in open cell foam of different porosities. Adv. Intell. Syst. Comput. 2021, 1259, 371–382. [Google Scholar]

- Choi, J.H.; Choi, K.B.; Kim, P.; Shun, D.W.; Kim, S.D. The effect of temperature on particle entrainment rate in a gas fluidized bed. Powder Technol. 1997, 92, 127–133. [Google Scholar] [CrossRef]

- Wey, M.Y.; Chen, K.H.; Liu, K.Y. The effect of ash and filter media characteristics on particle filtration efficiency in fluidized bed. J. Hazard. Mater. 2005, 121, 175–181. [Google Scholar] [CrossRef]

- Liu, K.Y.; Wey, M.Y. Filtration of nano-particles by a gas–solid fluidized bed. J. Hazard. Mater. 2007, 147, 618–624. [Google Scholar] [CrossRef]

- Tian, S.R.; Yang, G.H.; Li, Z.; Shi, K.Y.; Ding, G.Z.; Hu, F.X. Cascade filtration properties of a dual-layer granular bed filter. Powder Technol. 2016, 301, 545–556. [Google Scholar] [CrossRef]

- Paenpong, C.; Pattiya, A. Filtration of fast pyrolysis char fines with a cross-flow moving-bed granular filter. Powder Technol. 2013, 245, 233–240. [Google Scholar] [CrossRef]

- Yang, G.; Zhou, J. Experimental study on a new dual-layer granular bed filter for removing particulates. J. China Univ. Min. Technol. 2007, 17, 201–204. [Google Scholar] [CrossRef]

- Yu, Y.S.; Tao, Y.B.; Ma, Z.; He, Y.L. Experimental study and optimization on filtration and fluid flow performance of a granular bed filter. Powder Technol. 2018, 333, 449–457. [Google Scholar] [CrossRef]

- Bakhshian, S.; Sahimi, M. Computer simulation of the effect of deformation on the morphology and flow properties of porous media. Phys. Rev. E 2016, 94, 042903. [Google Scholar] [CrossRef]

- Bakhshian, S.; Sahimi, M. Adsorption-induced swelling of porous media. Int. J. Greenh. Gas Control 2017, 57, 1–13. [Google Scholar] [CrossRef]

- Guan, L.; Gu, Z.; Yuan, Z.; Yang, L.; Zhong, W.; Wu, Y.; Sun, S. Numerical study on the penetration of ash particles in a three-dimensional randomly packed granular filter. Fuel 2016, 163, 122–128. [Google Scholar] [CrossRef]

- Guan, L.; Yuan, Z.; Gu, Z.; Yang, L.; Zhong, W.; Wu, Y.; Sun, Sh.; Gu, C. Numerical simulation of ash particle deposition characteristics on the granular surface of a randomly packed granular filter. Powder Technol. 2017, 314, 78–88. [Google Scholar] [CrossRef]

- Wang, F.L.; He, Y.L.; Tang, S.Z.; Kulacki, F.A.; Tao, Y.B. Particle filtration characteristics of typical packing granular filters used in hot gas clean-up. Fuel 2018, 234, 9–19. [Google Scholar] [CrossRef]

- Wang, F.L.; He, Y.L.; Tang, S.Z.; Kulacki, F.A.; Tao, Y.B. Real-time particle filtration of granular filters for hot gas clean-up. Fuel 2019, 237, 308–319. [Google Scholar] [CrossRef]

- Chen, J.; Li, X.; Huai, X.; Wang, Y.; Zhou, J. Numerical study of collection efficiency and heat-transfer characteristics of packed granular filter. Particuology 2019, 46, 75–82. [Google Scholar] [CrossRef]

- Yang, J.; Bu, S.; Dong, Q.; Wu, J.; Wang, Q. Experimental study of flow transitions in random packed beds with low tube to particle diameter ratios. Exp. Therm. Fluid Sci. 2015, 66, 117–126. [Google Scholar] [CrossRef]

- Freund, H.; Zeiser, T.; Huber, F.; Klemm, E.; Brenner, G.; Durst, F.; Emig, G. Numerical simulations of single phase reacting flows in randomly packed fixed-bed reactors and experimental validation. Chem. Eng. Sci. 2003, 58, 903–910. [Google Scholar] [CrossRef]

- Gunjal, P.R.; Ranade, V.V. Modeling of laboratory and commercial scale hydro-processing reactors using CFD. Chem. Eng. Sci. 2007, 62, 5512–5526. [Google Scholar] [CrossRef]

- Gunjal, P.R.; Kashid, M.N.; Ranade, V.V.; Chaudhari, R.V. Hydrodynamics of trickle-bed reactors: Experiments and CFD modeling. Ind. Eng. Chem. Res. 2005, 44, 6278–6294. [Google Scholar] [CrossRef]

- Gunjal, P.R.; Ranade, V.V.; Chaudhari, R.V. Computational study of a single-phase flow in packed beds of spheres. AIChE J. 2005, 51, 365–378. [Google Scholar] [CrossRef]

- Ranade, V.V. Computational Flow Modeling for Chemical Reactor Engineering; Academic Press: San Diego, CA, USA, 2002; 452p. [Google Scholar]

- Cundall, P.A.; Strack, O.D. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Shire, T.; O’Sullivan, C. Constriction size distributions of granular filters: A numerical study. Geotechnique 2016, 66, 826–839. [Google Scholar] [CrossRef]

- Zhang, H.; Li, S. DEM simulation of wet granular-fluid flows in spouted beds: Numerical studies and experimental verifications. Powder Technol. 2017, 318, 337–349. [Google Scholar] [CrossRef]

- Kh, A.B.; Mirghasemi, A.A.; Mohammadi, S. Numerical simulation of particle breakage of angular particles using combined DEM and FEM. Powder Technol. 2011, 205, 15–29. [Google Scholar]

- Santos, D.A.; Barrozo, M.A.; Duarte, C.R.; Weigler, F.; Mellmann, J. Investigation of particle dynamics in a rotary drum by means of experiments and numerical simulations using DEM. Adv. Powder Technol. 2016, 27, 692–703. [Google Scholar] [CrossRef]

- Khan, H.J.; Mirabolghasemi, M.S.; Yang, H.; Prodanović, M.; DiCarlo, D.A.; Balhoff, M.T. Study of formation damage caused by retention of bi-dispersed particles using combined pore-scale simulations and particle flooding experiments. J. Pet. Sci. Eng. 2017, 158, 293–308. [Google Scholar] [CrossRef]

- Guo, Y.; Wassgren, C.; Ketterhagen, W.; Hancock, B.; James, B.; Curtis, J. A numerical study of granular shear flows of rod-like particles using the discrete element method. J. Fluid Mech. 2012, 713, 1–26. [Google Scholar] [CrossRef]

- He, Y.; Bayly, A.E.; Hassanpour, A.; Muller, F.; Wu, K.; Yang, D. A GPU-based coupled SPH-DEM method for particle-fluid flow with free surfaces. Powder Technol. 2018, 338, 548–562. [Google Scholar] [CrossRef]

- Guo, Y.; Curtis, J.S. Discrete element method simulations for complex granular flows. Annu. Rev. Fluid Mech. 2015, 47, 21–46. [Google Scholar] [CrossRef]

- Shams, A.; Roelofs, F.; Komen, E.M.J.; Baglietto, E. Large eddy simulation of a nuclear pebble bed configuration. Nucl. Eng. Des. 2013, 261, 10–19. [Google Scholar] [CrossRef]

- Matuttis, H.G. Simulation of the pressure distribution under a two-dimensional heap of polygonal particles. Granul. Matter 1998, 1, 83–91. [Google Scholar] [CrossRef]

- Matuttis, H.G.; Luding, S.; Herrmann, H.J. Discrete element simulations of dense packings and heaps made of spherical and non-spherical particles. Powder Technol. 2000, 109, 278–292. [Google Scholar] [CrossRef]

- Lu, G.; Third, J.R.; Müller, C.R. Discrete element models for non-spherical particle systems: From theoretical developments to applications. Chem. Eng. Sci. 2015, 127, 425–465. [Google Scholar] [CrossRef]

- Zhu, J.; Liang, Y.; Zhou, Y. The effect of the particle aspect ratio on the pressure at the bottom of sandpiles. Powder Technol. 2013, 234, 37–45. [Google Scholar] [CrossRef]

- Zhou, Z.Y.; Zou, R.P.; Pinson, D.; Yu, A.B. Angle of repose and stress distribution of sandpiles formed with ellipsoidal particles. Granul. Matter 2014, 16, 695–709. [Google Scholar] [CrossRef]

- Van Buijtenen, M.S.; Buist, K.; Deen, N.G.; Kuipers, J.A.M.; Leadbeater, T.; Parker, D.J. Numerical and experimental study on spout elevation in spout-fluidized beds. AIChE J. 2012, 58, 2524–2535. [Google Scholar] [CrossRef]

- Yu, Y.-S.; Tao, Y.-B.; He, Y.; He, Y.-L. Structure optimization of granular bed filter for industrial flue gas filtration containing coagulative particles: An experimental and numerical study. Adv. Powder Technol. 2020, 31, 2244–2256. [Google Scholar] [CrossRef]

- Wang, F.-L.; Tang, S.-Z.; He, Y.-L.; Kulacki, F.A.; Tao, Y.-B. Parameter study of filtration characteristics of granular filters for hot gas clean-up. Powder Technol. 2019, 353, 267–275. [Google Scholar] [CrossRef]

- Yu, Y.-S.; Tao, Y.-B.; Wang, F.-L.; Chen, X.; He, Y-L. Filtration performance of the granular bed filter used for industrial flue gas purification: A review of simulation and experiment. Sep. Purif. Technol. 2020, 251, 117318. [Google Scholar] [CrossRef]

- Cheng, H.; Shuku, T.; Thoeni, K.; Tempone, P.; Luding, S.; Magnanimo, V. An iterative Bayesian filtering framework for fast and automated calibration of DEM models. Comput. Methods Appl. Mech. Eng. 2019, 350, 268–294. [Google Scholar] [CrossRef]

- Benyahia, F.; O’Neill, K.E. Enhanced voidage correlations for packed beds of various particle shapes and sizes. Part. Sci. Technol. 2005, 23, 169–177. [Google Scholar] [CrossRef]

- Gosman, A.D.; Ioannides, E. Aspects of computer simulation of liquid-fuelled combustors. J. Energy 1983, 7, 482–490. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Tafreshi, H.V. Modeling particle filtration in disordered 2-D domains: A comparison with cell models. Sep. Purif. Technol. 2010, 74, 160–169. [Google Scholar] [CrossRef]

- Jin, X.; Yang, L.; Du, X. Modeling filtration performance of elliptical fibers with random distributions. Adv. Powder Technol. 2017, 28, 1193–1201. [Google Scholar] [CrossRef]

- Ergun, S.; Orning, A.A. Fluid flow through randomly packed columns and fluidized beds. Ind. Eng. Chem. 1949, 41, 1179–1184. [Google Scholar] [CrossRef]

- Eisfeld, B.; Schnitzlein, K. The influence of confining walls on the pressure drop in packed beds. Chem. Eng. Sci. 2001, 56, 4321–4329. [Google Scholar] [CrossRef]

- Hinds, W.C. Aerosol Technology Properties, Behavior, and Measurement of Airborne Particles; John Wiley and Sons: Hoboken, NJ, USA, 1999; 504p. [Google Scholar]

| Granule Diameter , mm | Tube to Granule Diameter Ratio | Porosity | Porosity, Calculated by the Formula (1) |

|---|---|---|---|

| 3 | 6.67 | 0.439 | 0.418 |

| 4 | 5 | 0.466 | 0.436 |

| 5 | 4 | 0.477 | 0.455 |

| Macroporosity | Microporosity | Total Porosity |

|---|---|---|

| 0.477 | 0.073 | 0.550 |

| 0.158 | 0.635 | |

| 0.273 | 0.750 | |

| 0.334 | 0.811 | |

| 0.348 | 0.825 | |

| 0.366 | 0.843 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soloveva, O.V.; Solovev, S.A.; Yafizov, R.R. Numerical Simulation of the Aerosol Particle Motion in Granular Filters with Solid and Porous Granules. Processes 2021, 9, 268. https://doi.org/10.3390/pr9020268

Soloveva OV, Solovev SA, Yafizov RR. Numerical Simulation of the Aerosol Particle Motion in Granular Filters with Solid and Porous Granules. Processes. 2021; 9(2):268. https://doi.org/10.3390/pr9020268

Chicago/Turabian StyleSoloveva, Olga V., Sergei A. Solovev, and Ruzil R. Yafizov. 2021. "Numerical Simulation of the Aerosol Particle Motion in Granular Filters with Solid and Porous Granules" Processes 9, no. 2: 268. https://doi.org/10.3390/pr9020268

APA StyleSoloveva, O. V., Solovev, S. A., & Yafizov, R. R. (2021). Numerical Simulation of the Aerosol Particle Motion in Granular Filters with Solid and Porous Granules. Processes, 9(2), 268. https://doi.org/10.3390/pr9020268