The Impact of Moisture and Number of Contact Points on the Process of Friction in Plant Granular Materials

Abstract

1. Introduction

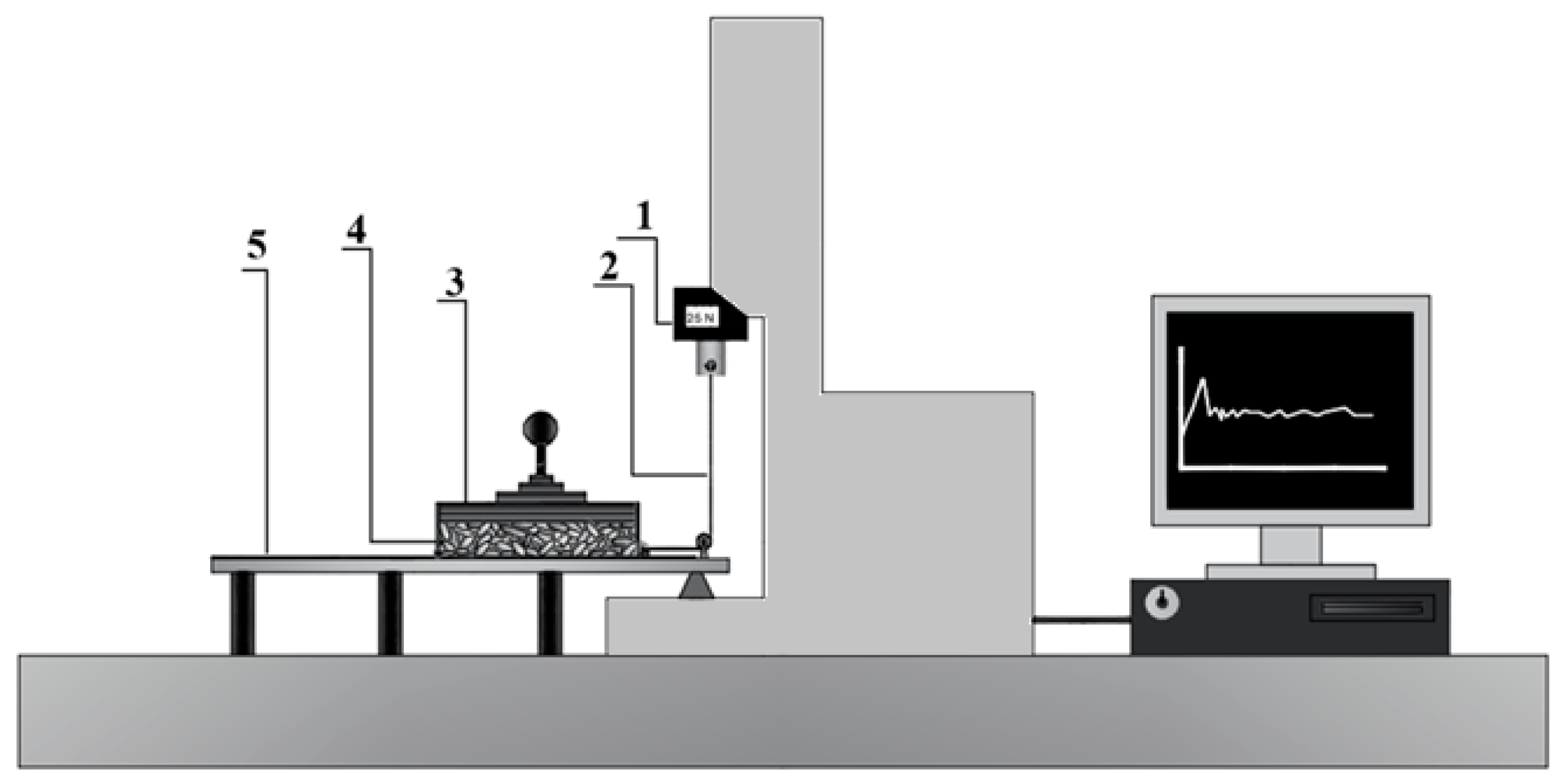

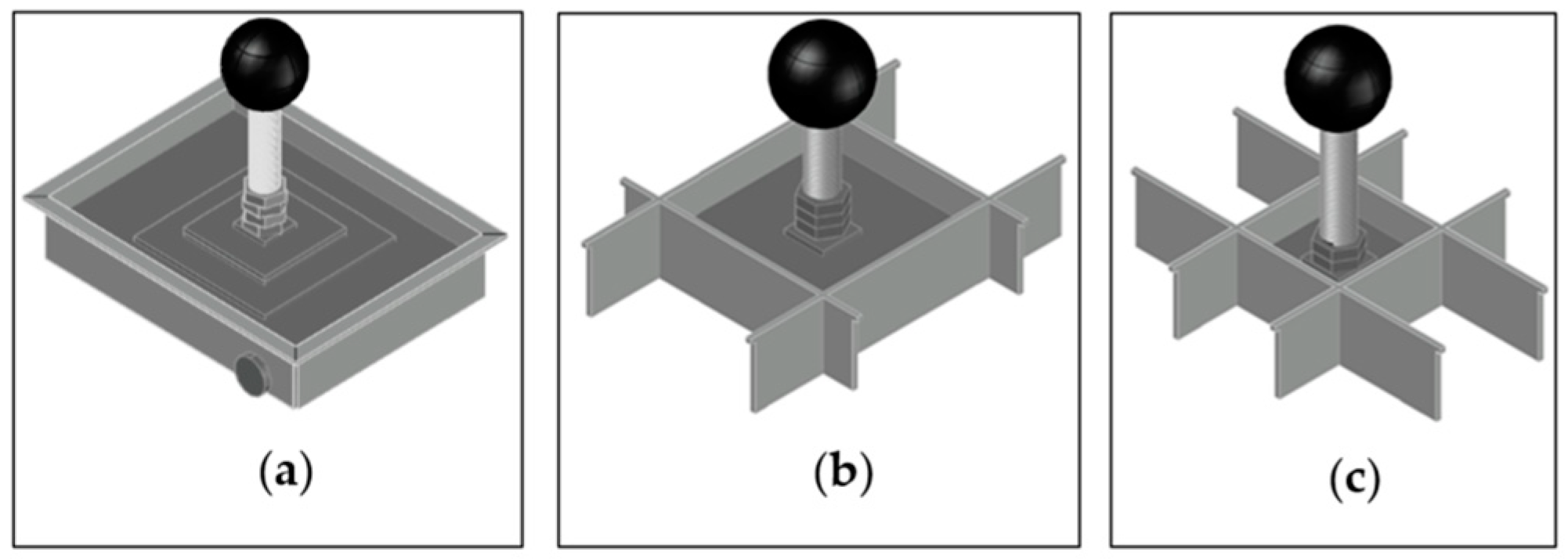

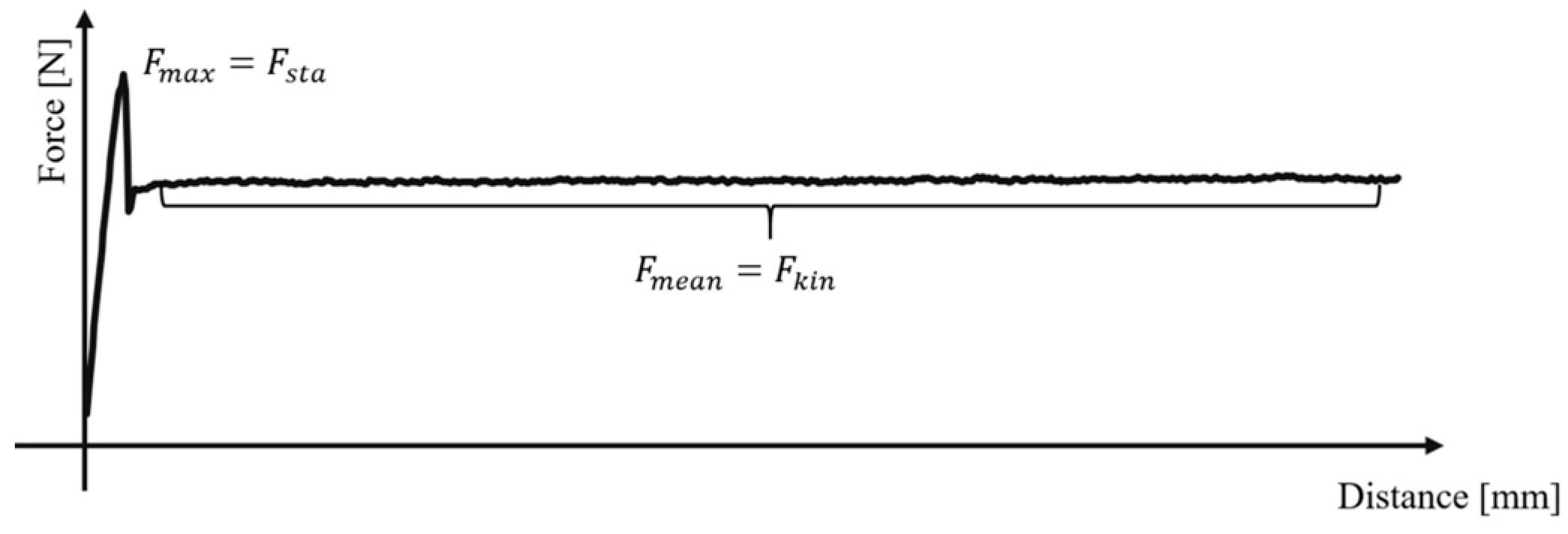

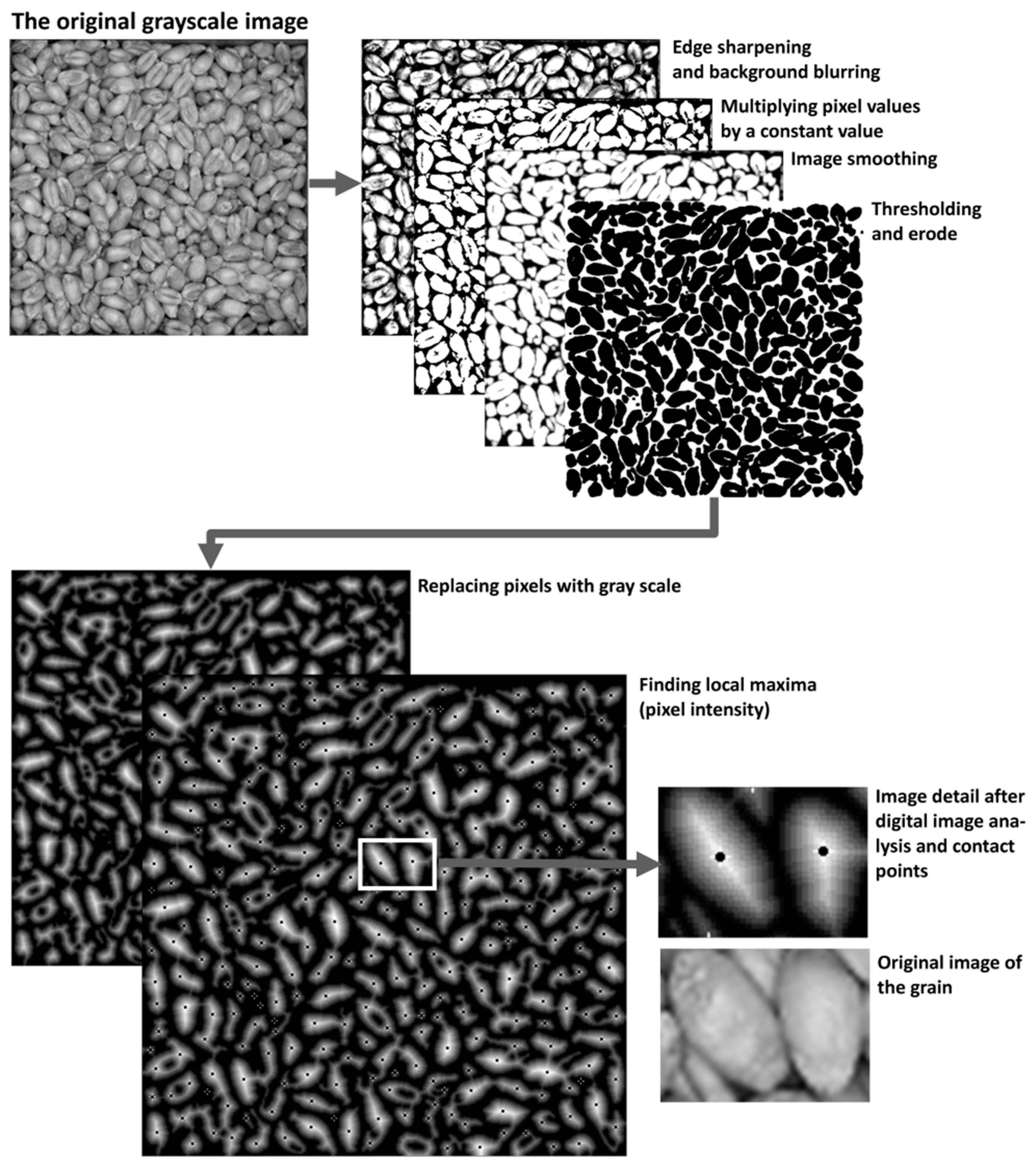

2. Materials and Methods

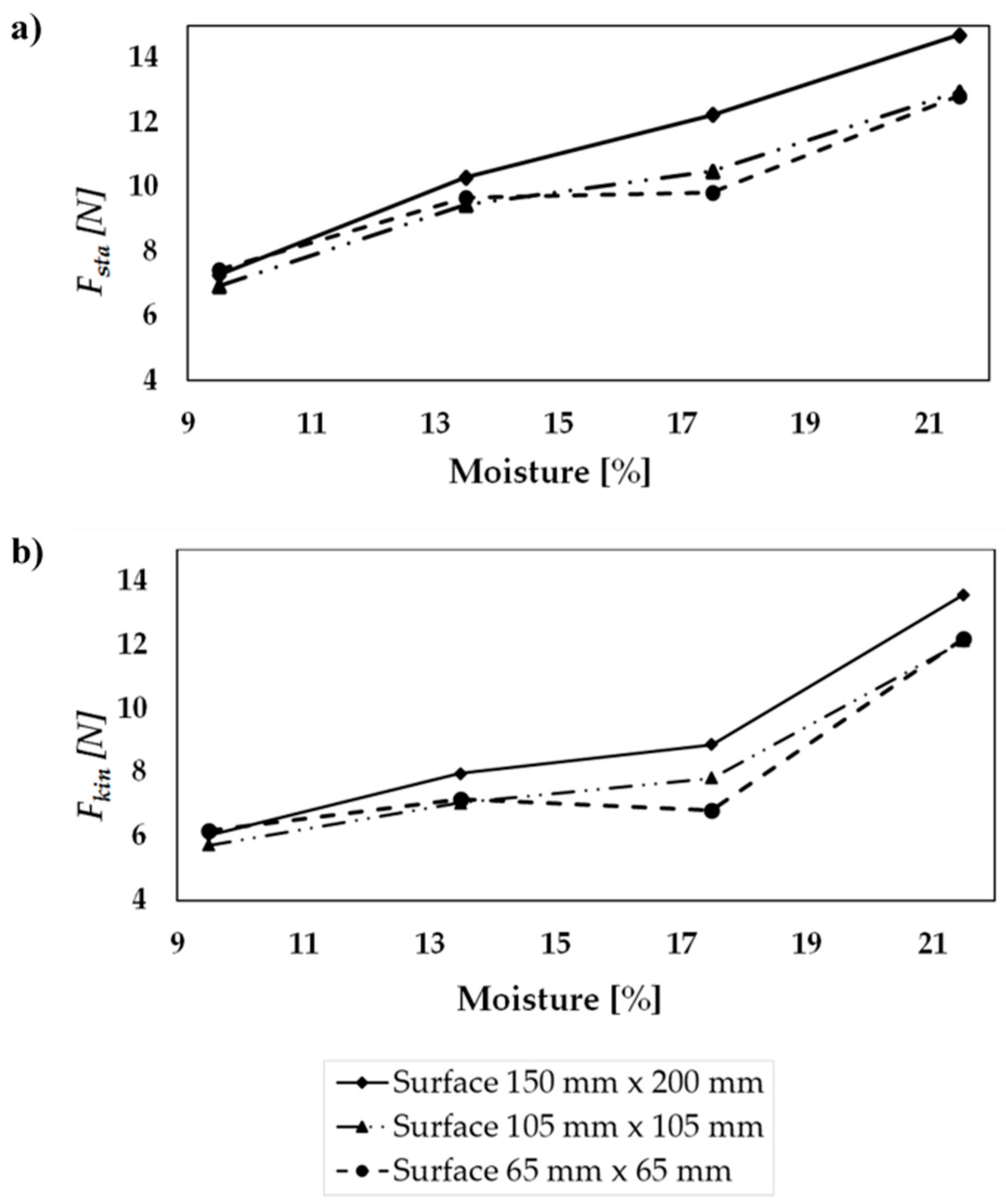

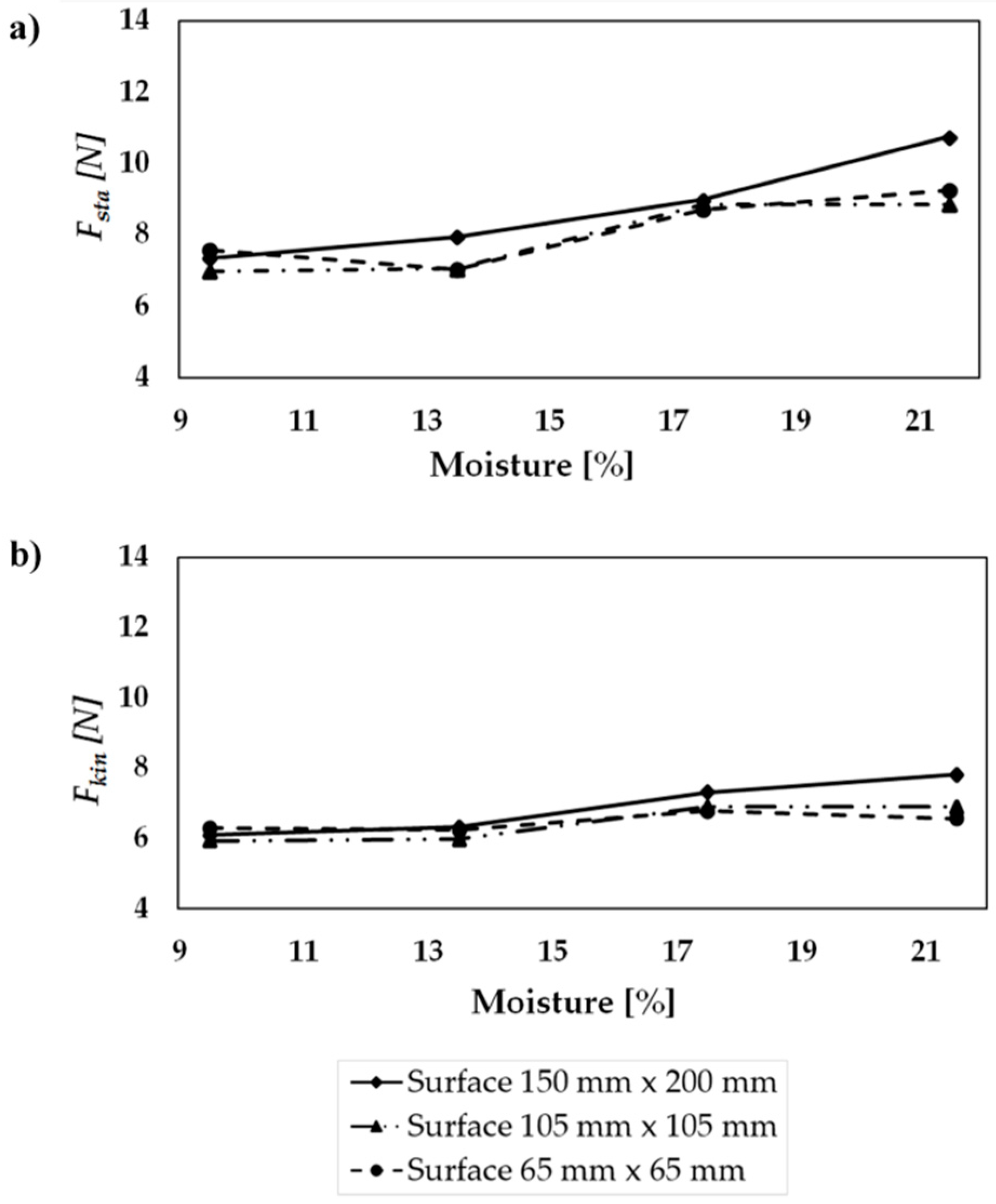

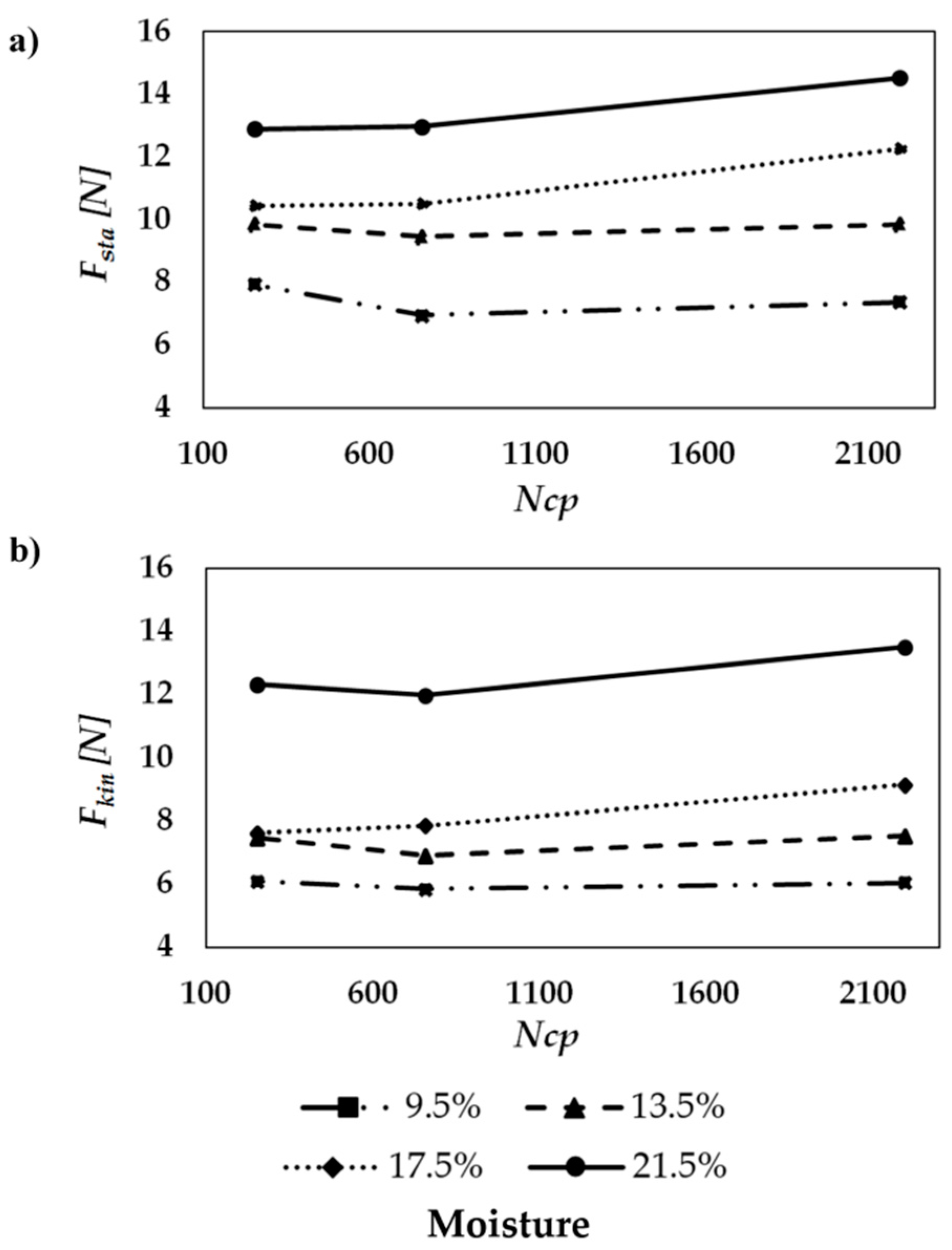

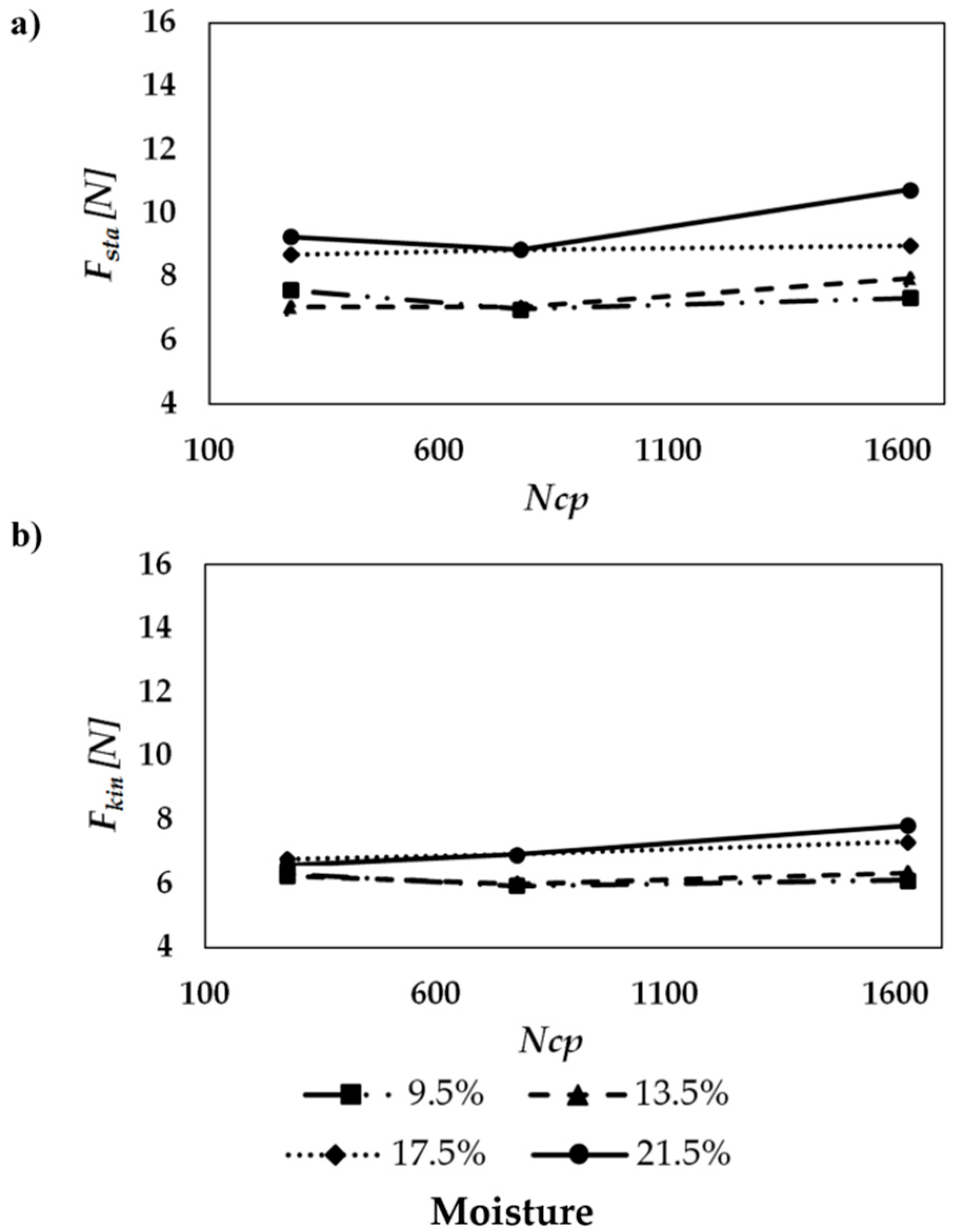

3. Results and Analysis

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Płaza, S.; Margielski, L.; Celichowski, G. Wstęp Do Tribologii i Trybochemia; Wydawnictwo uniwersytetu Łódzkiego: Łódź, Poland, 2015; pp. 5–13. [Google Scholar]

- Hebda, M.; Wachal, A. Trybologia; Wydawnictwo Naukowo-Techniczne: Warszawa, Polska, 1980; pp. 142–162. [Google Scholar]

- Maćkowiak, S. Własności Tribologiczne Układów Cząsteczek w Geometrii Szczeliny w Warunkach Kontrolowanego Ciśnienia Badane Metoda Dynamiki Molekularnej; Rozprawa Doktorska: Poznań, Polska, 2016. [Google Scholar]

- Slipek, Z.; Kaczorowski, J.; Fraczek, J. Theoretical and Experimental Analysis of Vegetable Materials Friction; PTIR: Krakow, Poland, 1999. (In Polish) [Google Scholar]

- Bek, M.; Gonzalez-Gutierrez, J.; Bregant, D.; Emri, I. Apparatus for measuring friction inside granular materials—Granular friction analyzer. Powder Technol. 2016, 288, 255–265. [Google Scholar] [CrossRef]

- Horabik, J.; Molenda, M. Właściwości fizyczne sypkich surowców spożywczych. Zarys Katalogu. Wydawnictwo Naukowe Instytutu Agrofizyki im. Bohdana Dobrzańskiego PAN w Lublinie. Acta Agroph. 2002, 74, 1–96. [Google Scholar]

- Wójcik, A.; Frączek, J.; Niemczewska-Wójcik, M. The relationship between static and kinetic friction for plant granular materials. Powder Technol. 2020, 361, 739–747. [Google Scholar] [CrossRef]

- Ajav, E.A.; Fakayode, O.A. Physical properties of moringa (Moringa oleifera) in relation to an oil expeller design. Agrosh. J. 2013, 13, 115–129. [Google Scholar] [CrossRef]

- Idowu, D.O.; Abegunrin, T.P.; Ola, F.A.; Adediran, A.A.; Olaniran, J.A. Measurement of some engineering properties of sandbox seeds (Huracrepitans). Agric. Biol. J. 2012, 2151–7525. [Google Scholar] [CrossRef]

- Işik, E. Moisture dependent physical and mechanical properties of organic beans (Phaseolus vulgaris L.). J. Food Agric. Environ. 2015, 11, 215–220. [Google Scholar]

- Izli, N. Effect of moisture on the physical properties of three varieties of kenaf seeds. J. Food Sci. Technol. 2015, 52, 3254–3263. [Google Scholar] [CrossRef]

- Markowska, A.; Warechowska, M.; Warechowski, J. Influence of moisture on external friction coefficient and basic physical properties of Astoria variety wheat grain. Tech. Sci. 2016, 19, 17–26. [Google Scholar]

- Mudryk, K.; Hutsol, T.; Wrobel, M.; Jewiarz, M.; Dziedzic, B. Determination of Friction Coefficients of Fast-Growing Tree Biomass. In Proceedings of the 18th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 22–24 May 2019; pp. 1568–1573. [Google Scholar]

- Wrobel, M.; Fraczek, J.; Francik, S.; Ślipek, Z.; Mudryk, K. Modelling of unit contact surface of bean seeds using artificial neural networks. In Proceedings of the 12th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23–24 May 2013; pp. 287–291. [Google Scholar]

- Wójcik, A.; Frączek, J.; Wota, A.K. The methodical aspects of the friction modeling of plant granular materials. Powder Technol. 2019, 344, 504–513. [Google Scholar] [CrossRef]

- Aghkhani, M.; Miraei Ashtiani, S.; Baradaran Motie, J.; Abbaspour-Fard, M. Physical properties of Christmas Lima bean at different moisture content. Int. Agrophys. 2012, 26, 341–346. [Google Scholar] [CrossRef]

- Saracoglu, T.; Ozarslan, C. Moisture-dependent geometric, frictional, mechanical properties of cabbage (Brassica oleraceae L. var. vapitata) seeds. Philipp. Agric. Sci. 2012, 95, 53–63. [Google Scholar]

- Kara, M.; Bastaban, S.; Öztürk, I.; Kalkan, F.; Yildiz, C. Moisture-dependent frictional and aerodynamic properties of safflower seeds. Int. Agrophys. 2012, 26, 203–205. [Google Scholar] [CrossRef]

- Shafaei, S.M.; Kamgar, S. A comprehensive investigation on static and dynamic friction coefficients of wheat grain with the adoption of statistical analysis. J. Adv. Res. 2017, 8, 351–361. [Google Scholar] [CrossRef] [PubMed]

- Adebowale, A.A.; Fetuga, G.O.; Apata, C.B.; Sanni, L.O. Effect of Variety and Initial Moisture Content on Physical Properties of Improved Millet Grains. NIFOJ 2012, 30, 5–10. [Google Scholar] [CrossRef]

- Alibas, I.; Koksal, N. Determination of physical, mechanical, and structural seed properties of pepper cultivars. Int. Agrophys. 2015, 29, 107–113. [Google Scholar] [CrossRef]

- Lenart, A.; Pawlus, P.; Dzierwa, A.; Wos, S.; Reizer, R. The Effect of Surface Texture on Lubricated Fretting. Materials 2020, 13, 4886. [Google Scholar] [CrossRef]

- Sandeep, C.S.; Senetakis, K. Effect of Young’s Modulus and Surface Roughness on the Inter-Particle Friction of Granular Materials. Materials 2018, 11, 217. [Google Scholar] [CrossRef]

- Liang, G.; Schmauder, S.; Lyu, M.; Schneider, Y.; Zhang, C.; Han, Y. An Investigation of the Influence of Initial Roughness on the Friction and Wear Behavior of Ground Surfaces. Materials 2018, 11, 237. [Google Scholar] [CrossRef]

- Askari, E.; Abbaspour-Gilandeh, Y.; Shojaei, S. Determination of dynamic friction coefficient of paddy grains on different surfaces. Int. Agrophys. 2010, 24, 101–105. [Google Scholar]

- Kabas, O.; Ozmerzi, A. Relationship between the friction coefficient and velocity of two cactus pear (Opuntiaficusindia L.) cultivars on different surfaces. Int. J. Food Sci. Technol. 2009, 44, 100–105. [Google Scholar] [CrossRef]

- Mudryk, K.; Francik, S.; Frączek, J.; Slipek, Z.; Wrobel, M. Model of actual contact area of rye and wheat grains with flat surface. In Proceedings of the 12th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23–24 May 2013; pp. 292–296. [Google Scholar]

- Wiącek, J.; Molenda, M.; Horabik, J. Mechanical properties of granular agro-materials. Continuum and discrete approach. Wydawnictwo Naukowe Instytutu Agrofizyki im. Bohdana Dobrzańskiego PAN w Lublinie. Acta Agroph. 2011, 190, 152. [Google Scholar]

- Eissa, A.A. Physical and aerodynamic properties of flaxseeds for proper separation by using airstream. J. Food Process Eng. 2011, 34, 983–1012. [Google Scholar] [CrossRef]

- Cetin, M. Physical properties of barbunia bean (Phaseolus vulgaris L. cv. ‘Barbunia’) seed. J. Food Eng. 2007, 80, 353–358. [Google Scholar] [CrossRef]

| Surfaces [mm] | Wheat | Buckwheat | ||

|---|---|---|---|---|

| Mean Ncp | Standard Deviation | Mean Ncp | Standard Deviation | |

| 150 × 200 | 2194 | 184.203 | 1624 | 46.476 |

| 105 × 105 | 757 | 53.035 | 777 | 58.731 |

| 65 × 65 | 253 | 22.298 | 276 | 23.373 |

| Wheat | Buckwheat | |||||||

|---|---|---|---|---|---|---|---|---|

| Mc | Ncp | Fsta | Fkin | Mc | Ncp | Fsta | Fkin | |

| Mc | 1 | 0.000 | 0.958 | 0.915 | 1 | 0.000 | 0.854 | 0.768 |

| Ncp | 0.000 | 1 | 0.163 | 0.136 | 0.000 | 1 | 0.254 | 0.344 |

| Fsta | 0.958 | 0.163 | 1 | 0.946 | 0.854 | 0.254 | 1 | 0.924 |

| Fkin | 0.915 | 0.136 | 0.946 | 1 | 0.768 | 0.344 | 0.924 | 1 |

| Mc | Wheat | Buckwheat | ||

|---|---|---|---|---|

| Fsta | Fkin | Fsta | Fkin | |

| 9.5% | −0.289 | 0.096 | −0.245 | −0.377 |

| 13.5% | 0.293 | 0.379 | 0.927 | 0.325 |

| 17.5% | 0.970 | 0.991 | 0.779 | 0.972 |

| 21.5% | 0.980 | 0.898 | 0.822 | 0.991 |

| Parameters of the Model | Value of the Parameter | p-Value | R2 | |

|---|---|---|---|---|

| Wheat | ||||

| Fsta | a | 48.7366 | 0.000000 | 0.9723 |

| b | 0.0004 | 0.000311 | ||

| c | 2.3891 | 0.000000 | ||

| Fkin | a | 51.7934 | 0.000000 | 0.9255 |

| b | 0.0004 | 0.045965 | ||

| c | 0.0655 | 0.918859 | ||

| Buckwheat | ||||

| Fsta | a | 21.1180 | 0.000000 | 0.8915 |

| b | 0.0005 | 0.002853 | ||

| c | 4.5606 | 0.000000 | ||

| Fkin | a | 9.4619 | 0.000000 | 0.8420 |

| b | 0.0003 | 0.000857 | ||

| c | 4.8367 | 0.000000 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kopeć-Jarosz, A.; Wójcik, A. The Impact of Moisture and Number of Contact Points on the Process of Friction in Plant Granular Materials. Processes 2021, 9, 215. https://doi.org/10.3390/pr9020215

Kopeć-Jarosz A, Wójcik A. The Impact of Moisture and Number of Contact Points on the Process of Friction in Plant Granular Materials. Processes. 2021; 9(2):215. https://doi.org/10.3390/pr9020215

Chicago/Turabian StyleKopeć-Jarosz, Aneta, and Artur Wójcik. 2021. "The Impact of Moisture and Number of Contact Points on the Process of Friction in Plant Granular Materials" Processes 9, no. 2: 215. https://doi.org/10.3390/pr9020215

APA StyleKopeć-Jarosz, A., & Wójcik, A. (2021). The Impact of Moisture and Number of Contact Points on the Process of Friction in Plant Granular Materials. Processes, 9(2), 215. https://doi.org/10.3390/pr9020215