Model-Based Analysis of Feedback Control Strategies in Aerobic Biotrickling Filters for Biogas Desulfurization

Abstract

1. Introduction

2. Materials and Methods

2.1. Liquid-Gas Transfer Correlations

- = Global mass transfer coefficient in liquid for component i, m h−1

- = Packing material specific constant

- = Liquid density, kg m−3

- g = Gravitational constant, m s−2

- = Liquid viscosity, kg m−1 s−1

- = packing material specific surface area, m−1

- = hydraulic diameter of packing material defined by 4ε/ap, m

- = superficial liquid velocity, m s−1

- = Diffusion coefficient, m2 s−1

- = Mass transfer coefficient in liquid for component i, m h−1

- L = Superficial mass velocity of liquid, kg m−2 h−1

- = Liquid density, kg m−3

- = Liquid viscosity, kg m−1 h−1

- gc = Gravitational constant, m h−2

- = wetted area, m2

- D = Diffusion coefficient, m2 h−1

- a = packing material specific surface area, m−1

- Dp = nominal size of packing, m

2.2. Open-Loop Study

2.3. Closed-Loop Study

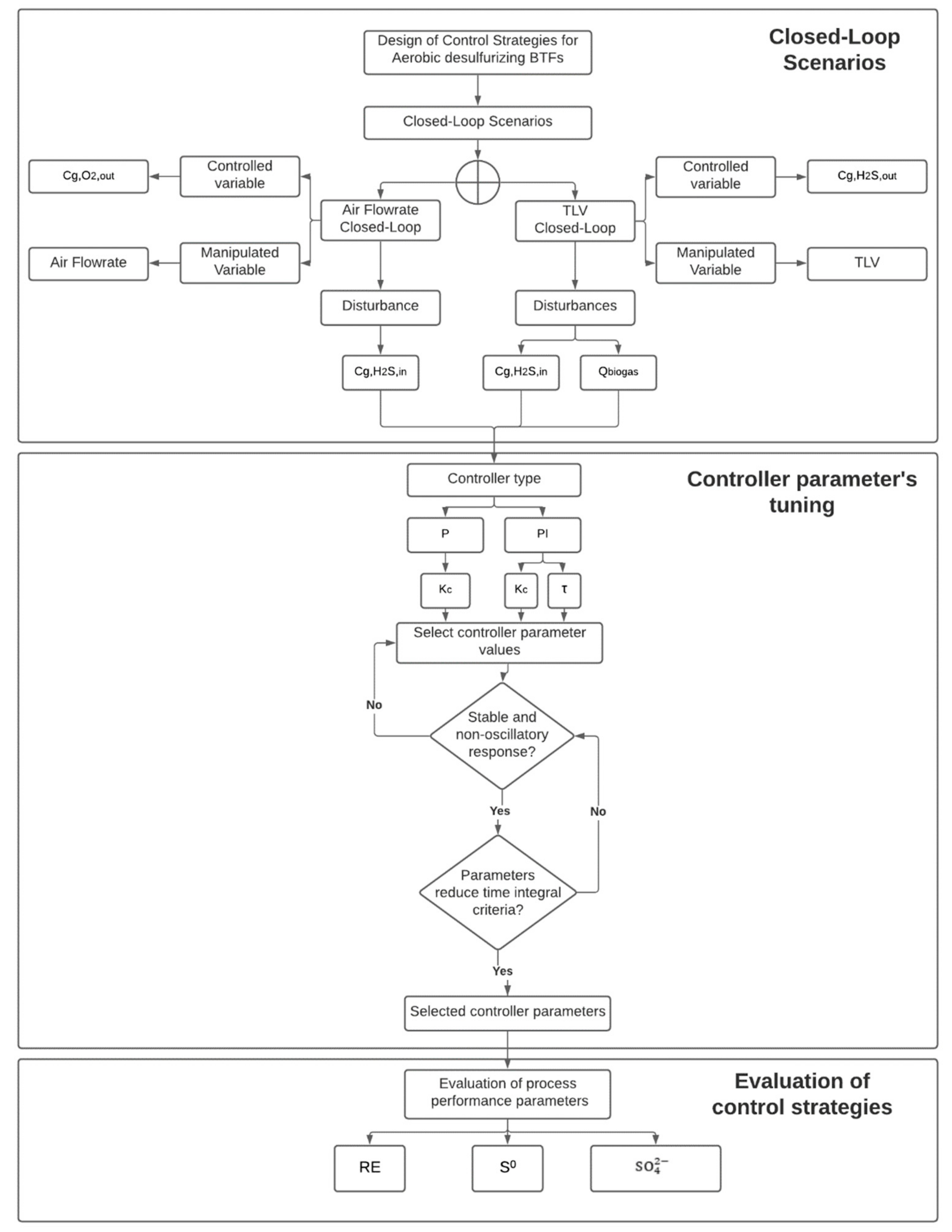

2.3.1. Definition of Closed-Loop Scenarios

2.3.2. Controller Tuning

2.3.3. Added Value of Feedback Control Strategies on Biogas Desulfurization in Aerobic Biotrickling Filters

3. Results

3.1. Selection of a Suitable Oxygen Mass Transfer Correlation

Effect of Mass Transfer Correlation on BTF Model Performance

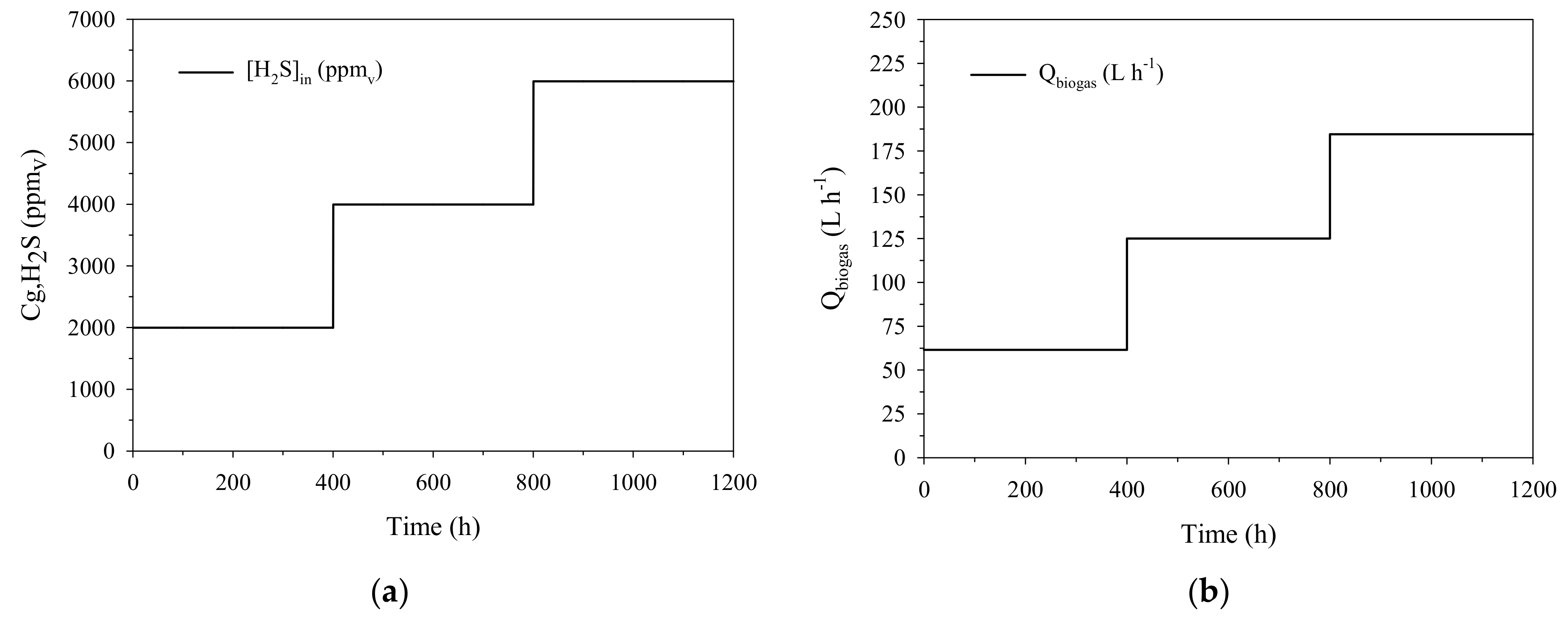

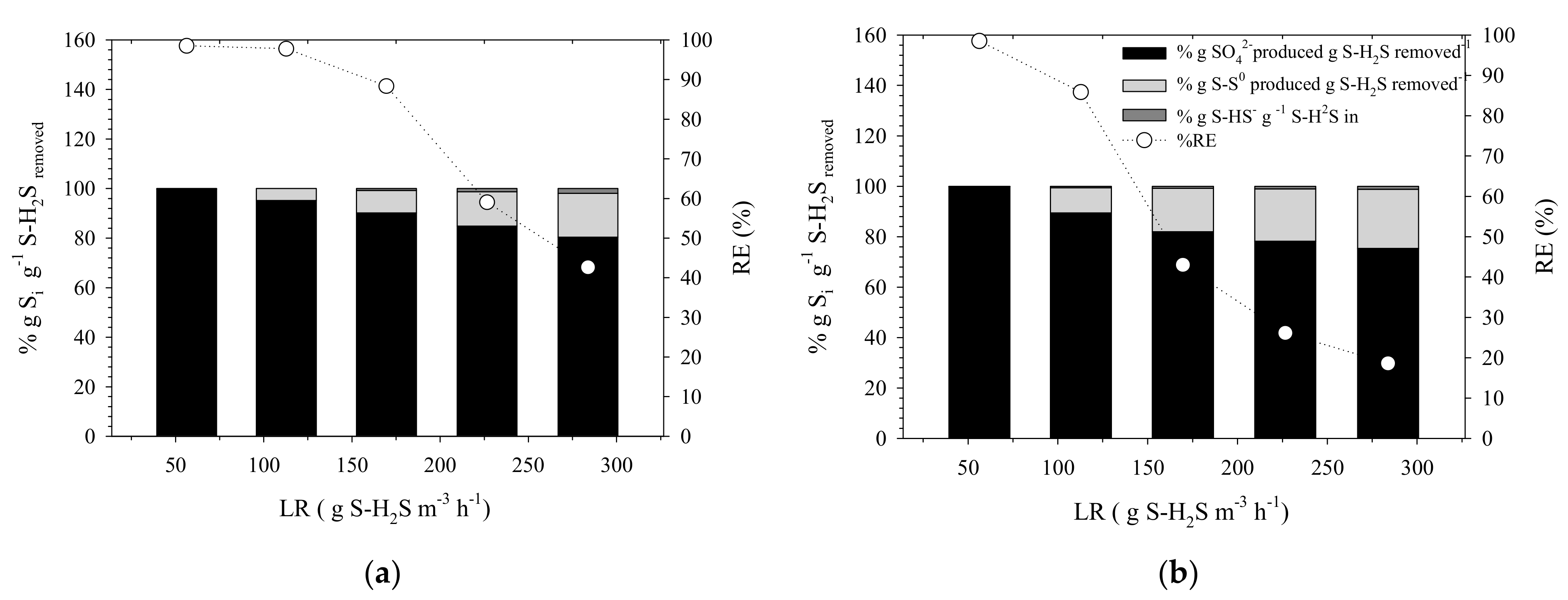

3.2. Analysis of Open-Loop Behavior: Effect of H2S LR Changes Due to H2S Inlet Concentration and Biogas Flowrate Changes on BTF Performance

3.3. Controller Tuning

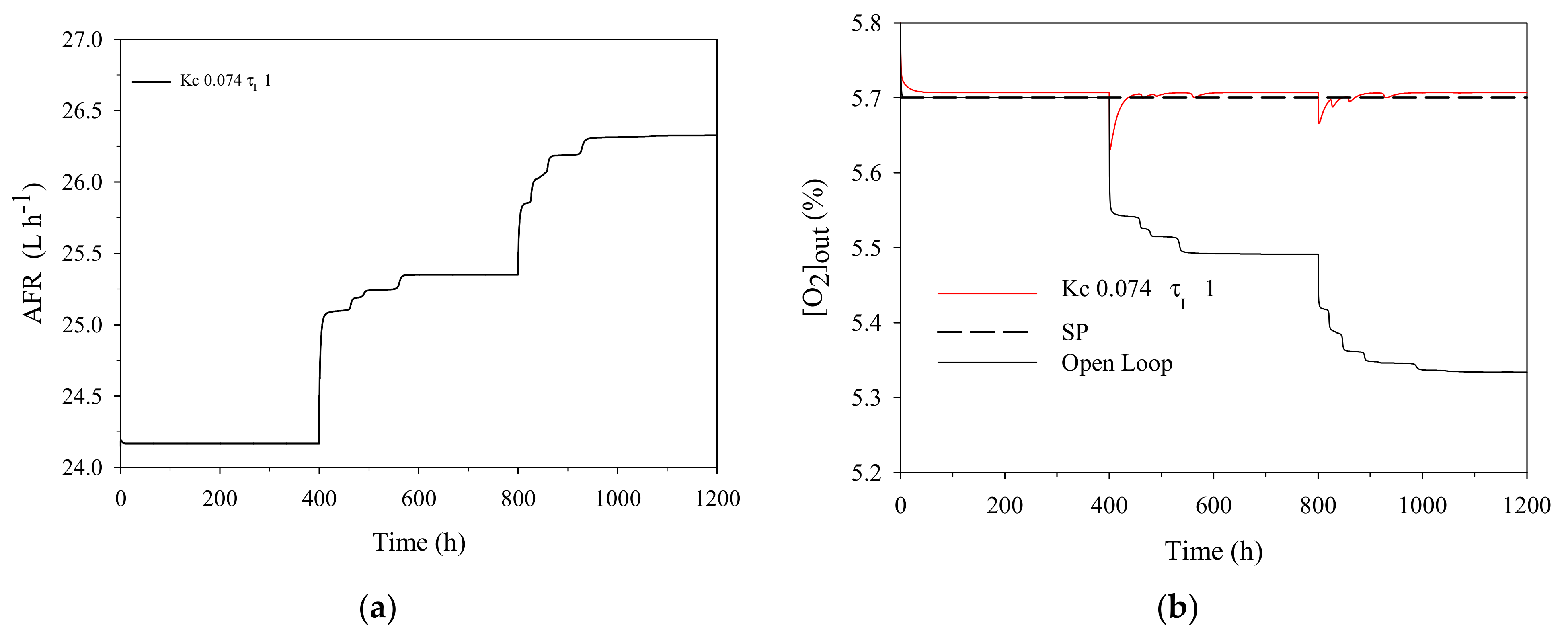

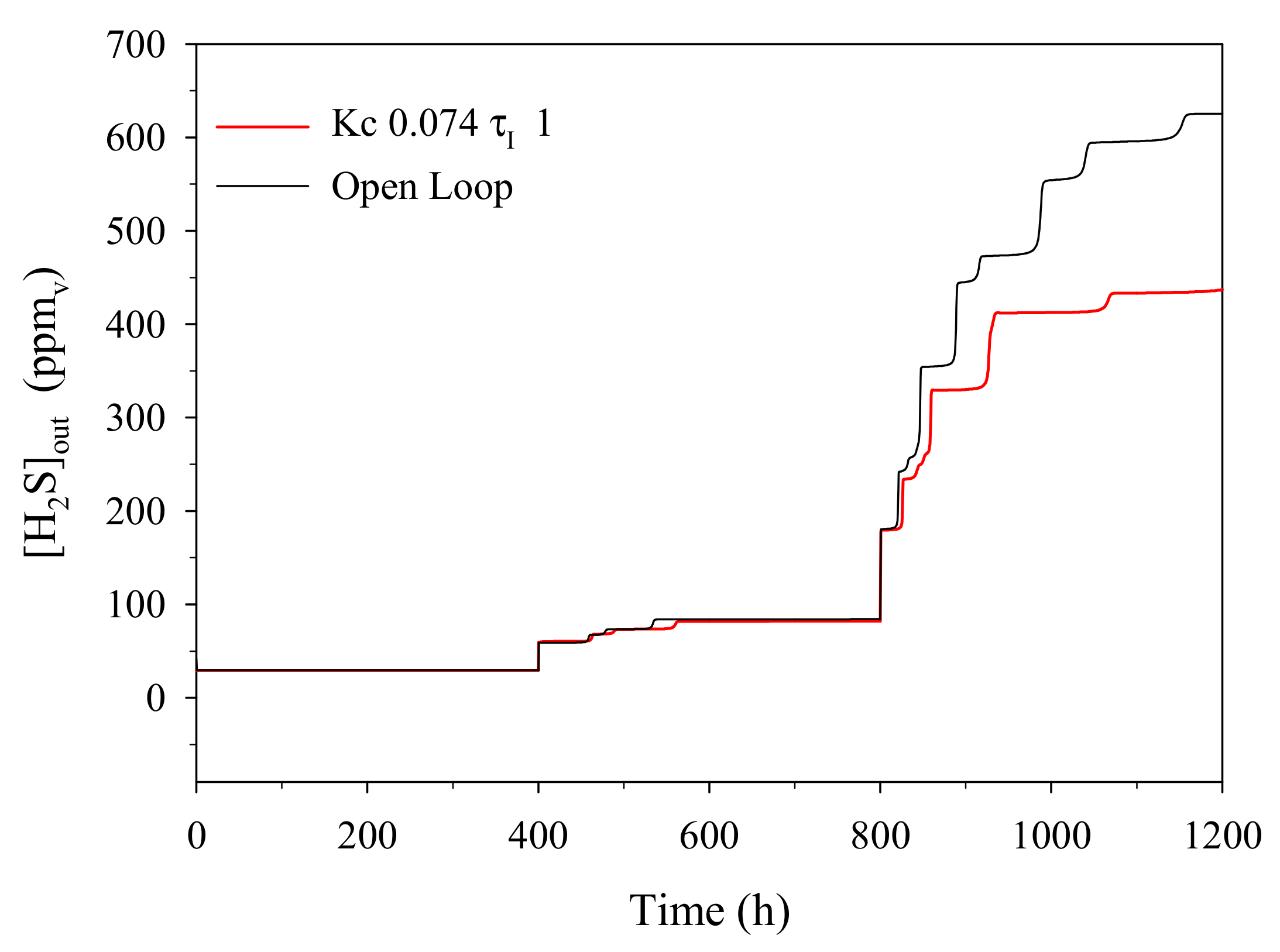

3.3.1. Air Flowrate Closed-Loop Scenario

3.3.2. Trickling liquid velocity Closed-Loop Scenario

- Disturbance: H2S inlet concentration

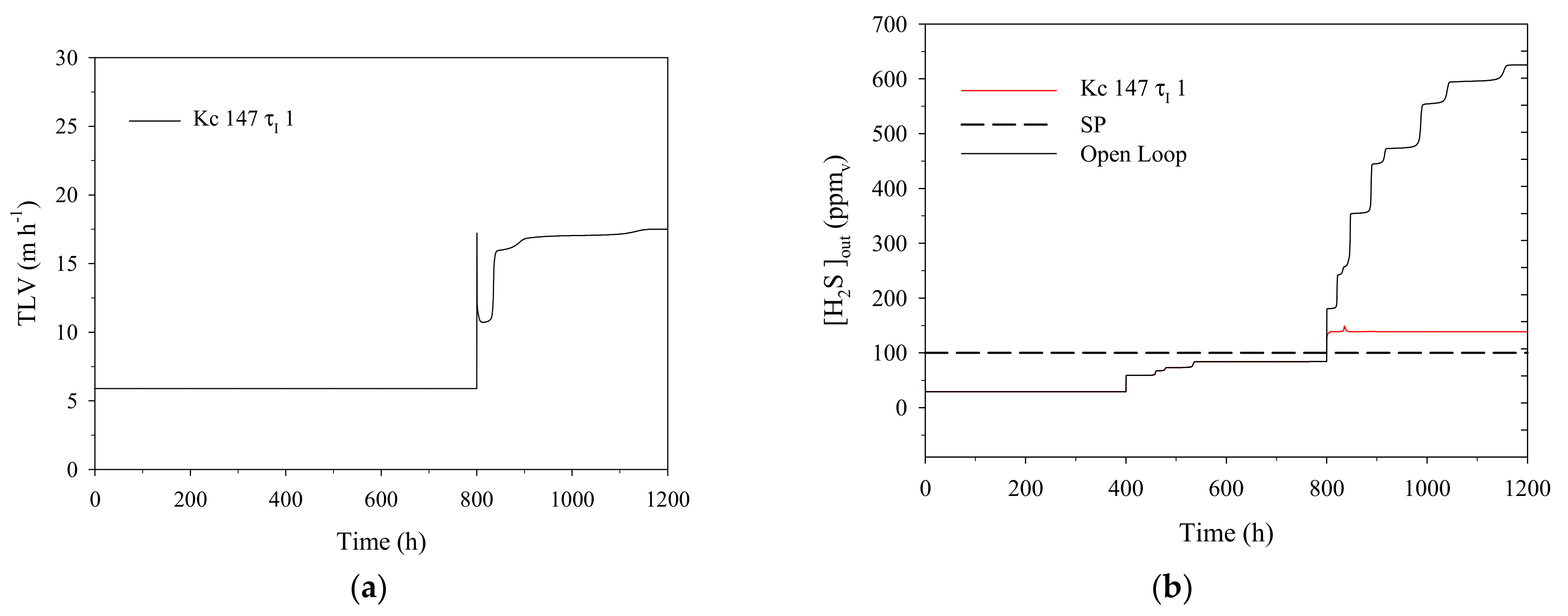

- Disturbance: gas flowrate

3.4. Selecting the Most Suitable Feedback Controller and Control Strategy

3.4.1. Selecting the Most Suitable Feedback Controller and Control Strategy to Face Disturbances in Inlet H2S Concentration

3.4.2. Selecting the Most Suitable Feedback Controller Using a TLV-CL Control Strategy to Face Variable Biogas Flowrate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Flowchart of the Methodology Followed for Feedback Control Strategies Evaluation

Appendix A.2. Equations for Sulfur Mass Balances and the Amount of O2 Consumed

Appendix A.3. Constants Needed for the Calculation of Mass Transfer Correlations

| Parameter | Description | Value | Units |

|---|---|---|---|

| Packing material specific constant | 0.905 | - | |

| Liquid density | 1000 | kg m−3 | |

| g | Gravitational constant | 9.81 | m s−2 |

| Liquid viscosity | kg m−1 s−1 | ||

| packing material specific surface area | 354 | m−1 | |

| Hydraulic diameter of packing material defined by 4ε/ap | m |

| Parameter | Description | Value | Units |

|---|---|---|---|

| Liquid density | 1000 | kg m−3 | |

| Liquid viscosity | kg m−1 s−1 | ||

| gc | Gravitational constant | 9.81 | m s−2 |

| wetted area | 0.993 | m2 | |

| D,O2 | Diffusion coefficient of O2 | m2 h−1 | |

| D,H2S | Diffusion coefficient of H2S | m2 h−1 | |

| a | packing material specific surface area | 354 | m−1 |

| Dp | nominal size of packing | 0.016 | m |

References

- Pöschl, M.; Ward, S.; Owende, P. Evaluation of energy efficiency of various biogas production and utilization pathways. Appl. Energy 2010, 87, 3305–3321. [Google Scholar] [CrossRef]

- Persson, M.; Wellinger, A.; Braun, R.; Holm-nielsen, J.B.; Seadi, T.A.L.; Baxter, D.; Jormanainnen, M. Biogas Upgrading to Vehicle Fuel Standards and Grid Injection; IEA Bioenergy: Aadorf, Switzerland, 2006. [Google Scholar]

- Rodriguez, G.; Dorado, A.D.; Fortuny, M.; Gabriel, D.; Gamisans, X. Biotrickling filters for biogas sweetening: Oxygen transfer improvement for a reliable operation. Process Saf. Environ. Prot. 2014, 92, 261–268. [Google Scholar] [CrossRef]

- Walsh, J.L.; Ross, C.C.; Smith, M.S.; Harper, S.R. Utilization of biogas. Biomass 1989, 20, 277–290. [Google Scholar] [CrossRef]

- Choudhury, A.; Shelford, T.; Felton, G.; Gooch, C.; Lansing, S. Evaluations of hydrogen sulfide scrubbing systems for anaerobic digesters on two U.S. dairy farms. Energies 2019, 12, 4605. [Google Scholar] [CrossRef]

- Fortuny, M.; Gamisans, X.; Deshusses, M.A.; Lafuente, J.; Casas, C.; Gabriel, D. Operational aspects of the desulfurization process of energy gases mimics in biotrickling filters. Water Res. 2011, 45, 5665–5674. [Google Scholar] [CrossRef] [PubMed]

- Cox, H.H.J.; Deshusses, M.A. Biological waste air treatment in biotrickling filters. Curr. Opin. Biotechnol. 1998, 9, 256–262. [Google Scholar] [CrossRef]

- Tomàs, M.; Fortuny, M.; Lao, C.; Gabriel, D.; Lafuente, J.; Gamisans, X. Technical and economical study of a full-scale biotrickling filter for H2S removal from biogas. Water Pract. Technol. 2009, 4. [Google Scholar] [CrossRef]

- Montebello, A.M.; Fernández, M.; Almenglo, F.; Ramírez, M.; Cantero, D.; Baeza, M.; Gabriel, D. Simultaneous methylmercaptan and hydrogen sulfide removal in the desulfurization of biogas in aerobic and anoxic biotrickling filters. Chem. Eng. J. 2012, 200–202, 237–246. [Google Scholar] [CrossRef]

- Montebello, A.M.; Mora, M.; López, L.R.; Bezerra, T.; Gamisans, X.; Lafuente, J.; Baeza, M.; Gabriel, D. Aerobic desulfurization of biogas by acidic biotrickling filtration in a randomly packed reactor. J. Hazard. Mater. 2014, 280, 200–208. [Google Scholar] [CrossRef]

- López, L.R.; Bezerra, T.; Mora, M.; Lafuente, J.; Gabriel, D. Influence of trickling liquid velocity and flow pattern in the improvement of oxygen transport in aerobic biotrickling filters for biogas desulfurization. J. Chem. Technol. Biotechnol. 2016, 91, 1031–1039. [Google Scholar] [CrossRef]

- Munz, G.; Gori, R.; Mori, G.; Lubello, C. Monitoring biological sulphide oxidation processes using combined respirometric and titrimetric techniques. Chemosphere 2009, 76, 644–650. [Google Scholar] [CrossRef] [PubMed]

- Krayzelova, L.; Bartacek, J.; Díaz, I.; Jeison, D.; Volcke, E.I.P.; Jenicek, P. Microaeration for hydrogen sulfide removal during anaerobic treatment: A review. Rev. Environ. Sci. Biotechnol. 2015, 14, 703–725. [Google Scholar] [CrossRef]

- Syed, M.; Soreanu, G.; Falletta, P.; Béland, M. Removal of hydrogen sulfide from gas streams using biological processes—A review. Can. Biosyst. Eng. 2006, 48, 2.1–2.14. [Google Scholar]

- Krayzelova, L.; Bartacek, J.; Kolesarova, N.; Jenicek, P. Bioresource technology microaeration for hydrogen sulfide removal in UASB reactor. Bioresour. Technol. 2014, 172, 297–302. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, D.; Gadhamshetty, V.; Nitayavardhana, S.; Khanal, S.K. Automatic process control in anaerobic digestion technology: A critical review. Bioresour. Technol. 2015, 193, 513–522. [Google Scholar] [CrossRef]

- Brito, J.; Almenglo, F.; Ramírez, M.; Cantero, D. Feedback and feedforward control of a biotrickling filter for H2S desulfurization with nitrite as electron acceptor. Appl. Sci. 2019, 9, 2669. [Google Scholar] [CrossRef]

- López, L.R.; Brito, J.; Mora, M.; Almenglo, F.; Baeza, J.A.; Ramírez, M.; Lafuente, J.; Cantero, D.; Gabriel, D. Feedforward control application in aerobic and anoxic biotrickling filters for H2S removal from biogas. J. Chem. Technol. Biotechnol. 2018, 93, 2307–2315. [Google Scholar] [CrossRef]

- Guimerà, X.; Mora, M.; López, L.R.; Gabriel, G.; Dorado, A.D.; Lafuente, J.; Gamisans, X.; Gabriel, D. Coupling dissolved oxygen microsensors measurements and heterogeneous respirometry for monitoring and modeling microbial activity within sulfide-Oxidizing biofilms. Chem. Eng. J. 2020, 400, 125846. [Google Scholar] [CrossRef]

- Bonilla-Blancas, W.; Mora, M.; Revah, S.; Baeza, J.A.; Lafuente, J.; Gamisans, X.; Gabriel, D.; González-Sánchez, A. Application of a novel respirometric methodology to characterize mass transfer and activity of H2S-oxidizing biofilms in biotrickling filter beds. Biochem. Eng. J. 2015, 99, 24–34. [Google Scholar] [CrossRef]

- Almenglo, F.; Ramírez, M.; Gómez, M.; Cantero, D.; David, A. Modeling and control strategies for anoxic biotrickling filtration in biogas purification. J. Chem. Technol. Biotechnol. 2015, 91, 1782–1793. [Google Scholar] [CrossRef]

- López, L.R.; Dorado, A.D.; Mora, M.; Gamisans, X.; Lafuente, J.; Gabriel, D. Modeling an aerobic biotrickling filter for biogas desulfurization through a multi-step oxidation mechanism. Chem. Eng. J. 2016, 294, 447–457. [Google Scholar] [CrossRef]

- Onda, K.; Takeuchi, H.; Okumoto, Y. Mass transfer coefficients between gas and liquid phases in packed columns. J. Chem. Eng. Japan 1968, 1, 173–180. [Google Scholar] [CrossRef]

- Billet, R.; Schultes, M. Predicting mass transfer in packed columns. Chem. Eng. Technol. 1993, 16, 1–9. [Google Scholar] [CrossRef]

- Wang, G.Q.; Yuan, X.G.; Yu, K.T. Review of mass-transfer correlations for packed columns. Ind. Eng. Chem. Res. 2005, 44, 8715–8729. [Google Scholar] [CrossRef]

- Andreasen, R.R.; Nicolai, R.E.; Poulsen, T.G. Pressure drop in biofilters as related to dust and biomass accumulation. J. Chem. Technol. Biotechnol. 2012, 87, 806–816. [Google Scholar] [CrossRef]

- Al Seadi, T.; Rutz, D.; Prassl, H.; Kottner, M.; Finsterwalder, T.; Volk, R.J.S. Biogas Handbook; University of Southern Denmark Esbjerg: Esbjerg, Denmark, 2008; ISBN 9788799296200. [Google Scholar]

- Stephanopoulus, G. Chemical Process Control: An Introduction to Theory and Practice; Prentice Hall: Englewood Cliffs, NJ, USA, 1984. [Google Scholar]

- Åström, K.J.; Hägglund, T. PID Controllers: Theory, Design, and Tuning; ISA—The Instrumentation, Systems and Automation Society: Durham, NC, USA, 1995; Volume 2. [Google Scholar]

- Van der Heyden, C.; Vanthillo, B.; Pieters, J.G.; Demeyer, P.; Volcke, E.I.P. Mechanistic modeling of pollutant removal, temperature, and evaporation in chemical air scrubbers. Chem. Eng. Technol. 2016, 39, 1785–1796. [Google Scholar] [CrossRef][Green Version]

- Nash, J.E.; Sutcliffe, J.V. River flow forecasting through conceptual models part I—A discussion of principles. J. Hydrol. 1970, 10, 282–290. [Google Scholar] [CrossRef]

- Mora, M.; López, L.R.; Lafuente, J.; Pérez, J.; Kleerebezem, R.; Van Loosdrecht, M.; Gamisans, X.; Gabriel, D. Respirometric characterization of aerobic sulfide, thiosulfate and elemental sulfur oxidation by S-oxidizing biomass. Water Res. 2016, 89, 282–292. [Google Scholar] [CrossRef]

| [H2S] | [H2S] LR | O2/H2S | TLV |

|---|---|---|---|

| (ppmv) | (g S-H2S m−3 h−1) | (% v/v) | (m h−1) |

| 2000 | 56.3 | 42.2 | 4.4 |

| 4000 | 112.9 | 21.0 | |

| 6000 | 169.6 | 14.0 | |

| 8000 | 226.6 | 10.5 | |

| 10,000 | 283.8 | 8.4 |

| Variable (Units) | Reference Case Conditions | Open-Loop (Variable Inlet H2S Concentration) | Open-Loop (Variable EBRT) |

|---|---|---|---|

| [H2S] (ppmv) | 2000 | 2000 to 10,000 | 2000 |

| H2S LR (g S-H2S m−3 h−1) | 56.3 | 56.3 to 281.55 | 56.3 to 281.55 |

| Qbiogas (L h−1) | 61.5 | 61.5 | 61.5 to 307.5 |

| Qair (L h−1) | 24.15 | 24.15 | 24.15 |

| O2/H2S (% v/v) | 42.2 | 42.2 to 8.4 | 42.2 to 14.10 |

| TLV (m h−1) | 5.9 | 5.9 | 5.9 |

| EBRT(s) | 118 | 118 | 118 to 48.4 |

| Closed-Loop Scenario | Controlled Variable | Manipulated Variable | Disturbances | Controller Type | Parameter | Range |

|---|---|---|---|---|---|---|

| Air flowrate regulation | P | Kc | 0.05–0.2 | |||

| PI | Kc | 0.05–0.2 | ||||

| τI | 1–5 | |||||

| TLV regulation | TLV | & | P | Kc | 1–1000 | |

| PI | Kc | 1–1000 | ||||

| τI | 0.1–10 |

| Correlation | NSE RE | NSE g S-H2Sin−1 | NSE g S-H2Sin−1 |

|---|---|---|---|

| Onda’s | −7.65 | 0.26 | 0.70 |

| Billet and Schultes | 0.26 | 0.85 | 0.95 |

| Closed-Loop Scenario | Disturbance | Kc | 0.05 | 0.074 | 0.1 | 0.12 | 0.15 | 0.2 | |

|---|---|---|---|---|---|---|---|---|---|

| τI | |||||||||

| AFR-CL | - | 60.20 | - | 43.9 | 141 | 907 | 1748 | ||

| 1 | 3.27 | 0.24 | 5.95 | - | - | - | |||

| 2.5 | 1.89 | 0.64 | 0.49 | - | - | - | |||

| 5 | 0.93 | 1.31 | 1747 | - | - | - | |||

| Closed-Loop Scenario | Disturbance | Kc | 1 | 73.75 | 110.63 | 147.5 | 200 | 300 | 368.75 | 500 | 1000 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| τI | ||||||||||||

| TLV regulation | - | 7.268 | - | 3.333 | - | 2.2129 | 1.808 | - | 1.927 | 1.8018 | ||

| 0.1 | - | 2.101 | 2.101 | 2.098 | 2.083 | 2.088 | 2.078 | 2.083 | - | |||

| 1 | - | 2.106 | 2.103 | 2.102 | 2.110 | 2.092 | 2.120 | 2.088 | - | |||

| 10 | - | 2.121 | 2.12 | 2.118 | 2.139 | 2.137 | 2.134 | 2.133 | - | |||

| Closed-Loop Scenario | Disturbance | Kc | 1 | 73.75 | 110.63 | 147.5 | 200 | 300 | 369 | 500 | 1000 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| τI | ||||||||||||

| TLV regulation | Qbiogas | - | 17.79 | 8.316 | - | 7.11 | 7.701 | 7.054 | 7.735 | 7.732 | - | |

| 0.1 | - | 7.736 | 7.724 | 7.714 | 7.703 | 7.705 | 7.703 | - | - | |||

| 1 | - | 7.757 | 7.743 | 7.340 | 7.724 | 7.718 | 7.724 | - | - | |||

| 10 | - | 8.134 | 7.754 | 8.112 | 8.101 | 8.095 | 8.101 | - | - | |||

| Cg,in H2S (ppmv) | Control Type and Parameters | Manipulated Variable | Change | Change | Change | Change |

|---|---|---|---|---|---|---|

| S-produced | S-S0produced | g H2S Outlet | g O2 Consumed | |||

| (%) | (%) | (%) | (%) | |||

| 4000 | P Kc = 0.1 | AFR | 0.4 | 4.5 | 1.6 | 0.3 |

| 6000 | 1.7 | 3.8 | 14.1 | 2.1 | ||

| 4000 | PI Kc = 0.074 τI = 1 | AFR | 0.5 | 6.2 | 2.5 | 0.4 |

| 6000 | 3.1 | 8.5 | 23.7 | 3.0 | ||

| 6000 | P Kc = 300 | TLV | 17.5 | 91.0 | 75.6 | 9.0 |

| 6000 | PI Kc = 147 τI = 1 | TLV | 14.9 | 70.7 | 71.9 | 8.7 |

| Fbiogas | Control Type and | Manipulated Variable | Improvement | Reduction | Reduction | Improvement |

|---|---|---|---|---|---|---|

| S-produced | S-S0produced | g H2S Outlet | g O2 Consumed | |||

| (L h−1) | Parameters | (%) | (%) | (%) | (%) | |

| 123 | P Kc = 300 | TLV | 22.40 | 85.60 | 53.00 | 7.30 |

| 123 | PI Kc = 110 τI = 1 | TLV | 15.23 | 51.52 | 43.22 | 6.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

López, L.R.; Mora, M.; Van der Heyden, C.; Baeza, J.A.; Volcke, E.; Gabriel, D. Model-Based Analysis of Feedback Control Strategies in Aerobic Biotrickling Filters for Biogas Desulfurization. Processes 2021, 9, 208. https://doi.org/10.3390/pr9020208

López LR, Mora M, Van der Heyden C, Baeza JA, Volcke E, Gabriel D. Model-Based Analysis of Feedback Control Strategies in Aerobic Biotrickling Filters for Biogas Desulfurization. Processes. 2021; 9(2):208. https://doi.org/10.3390/pr9020208

Chicago/Turabian StyleLópez, Luis Rafael, Mabel Mora, Caroline Van der Heyden, Juan Antonio Baeza, Eveline Volcke, and David Gabriel. 2021. "Model-Based Analysis of Feedback Control Strategies in Aerobic Biotrickling Filters for Biogas Desulfurization" Processes 9, no. 2: 208. https://doi.org/10.3390/pr9020208

APA StyleLópez, L. R., Mora, M., Van der Heyden, C., Baeza, J. A., Volcke, E., & Gabriel, D. (2021). Model-Based Analysis of Feedback Control Strategies in Aerobic Biotrickling Filters for Biogas Desulfurization. Processes, 9(2), 208. https://doi.org/10.3390/pr9020208