Modulating Structure and Properties of Glutinous Rice Flour and Its Dumpling Products by Annealing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Annealing Treatment of Glutinous Rice Flour

2.3. The Extraction of Glutinous Rice Starch

2.4. Determination of Average Molecular Weight of Glutinous Rice Starch

2.5. Determination of Crystallinity

2.6. Determination of Hydration Ability

2.7. Determination of Gel Consistency

2.8. Determination of Thixotropic Properties

2.9. Methods of Making Fresh and Fast-Frozen Glutinous Dumplings

2.10. Determination of Water Distribution in Fresh Glutinous Dumplings

2.11. Determination of Freezing Point of Fresh Glutinous Dumplings

2.12. Determination of the Transmittance of Soup of Fast-Frozen Dumpling after Cooking

2.13. Statistical Methods

3. Results and Discussion

3.1. Average Molecular Weight of Glutinous Rice Starch

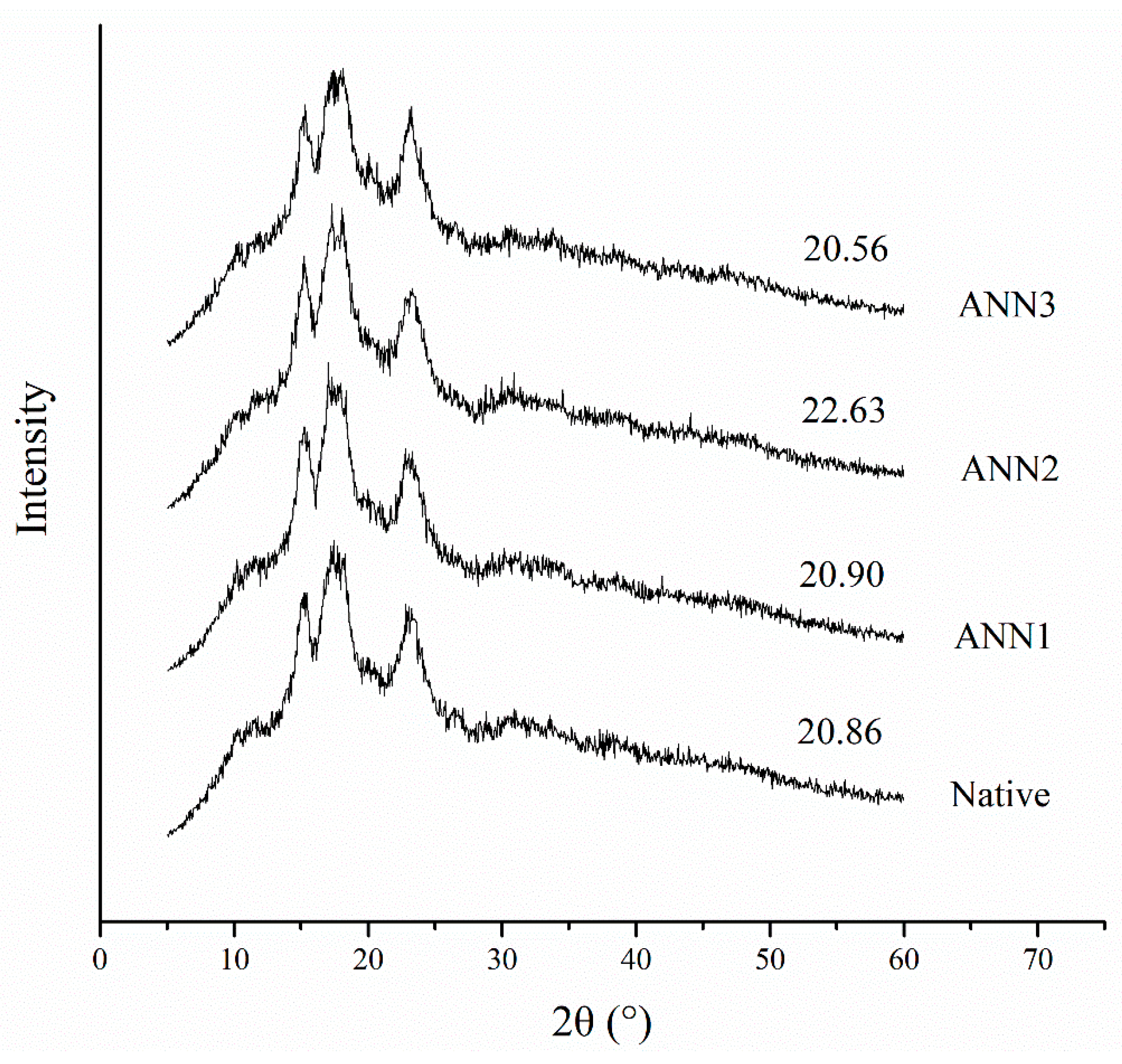

3.2. Crystalline Structure of Glutinous Rice Flour

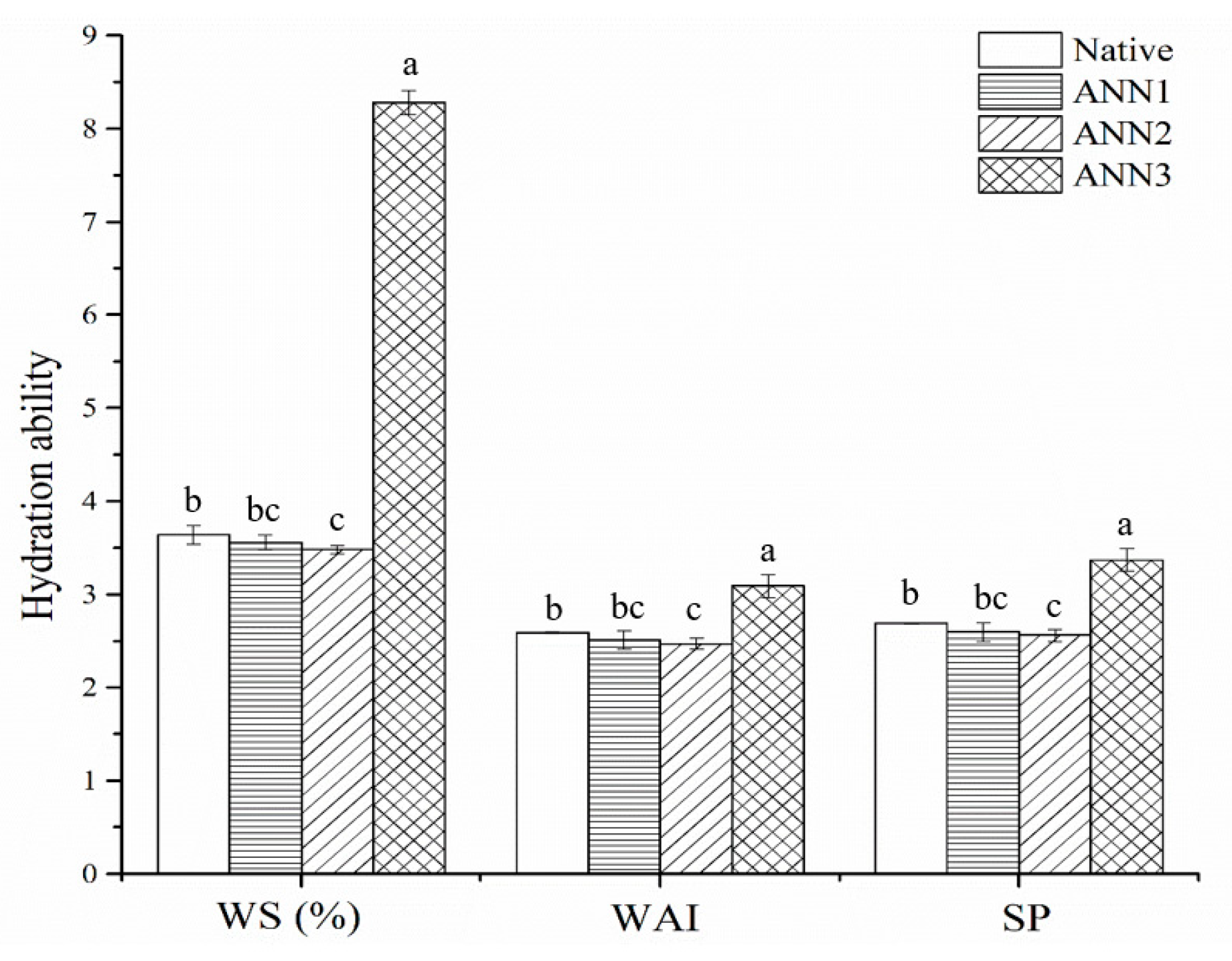

3.3. Hydration Ability of Glutinous Rice Flour

3.4. Gel Consistency and Thixotropic Properties of Glutinous Rice Flour

3.5. Freezing Point of Dumplings Made from Glutinous Rice Flour

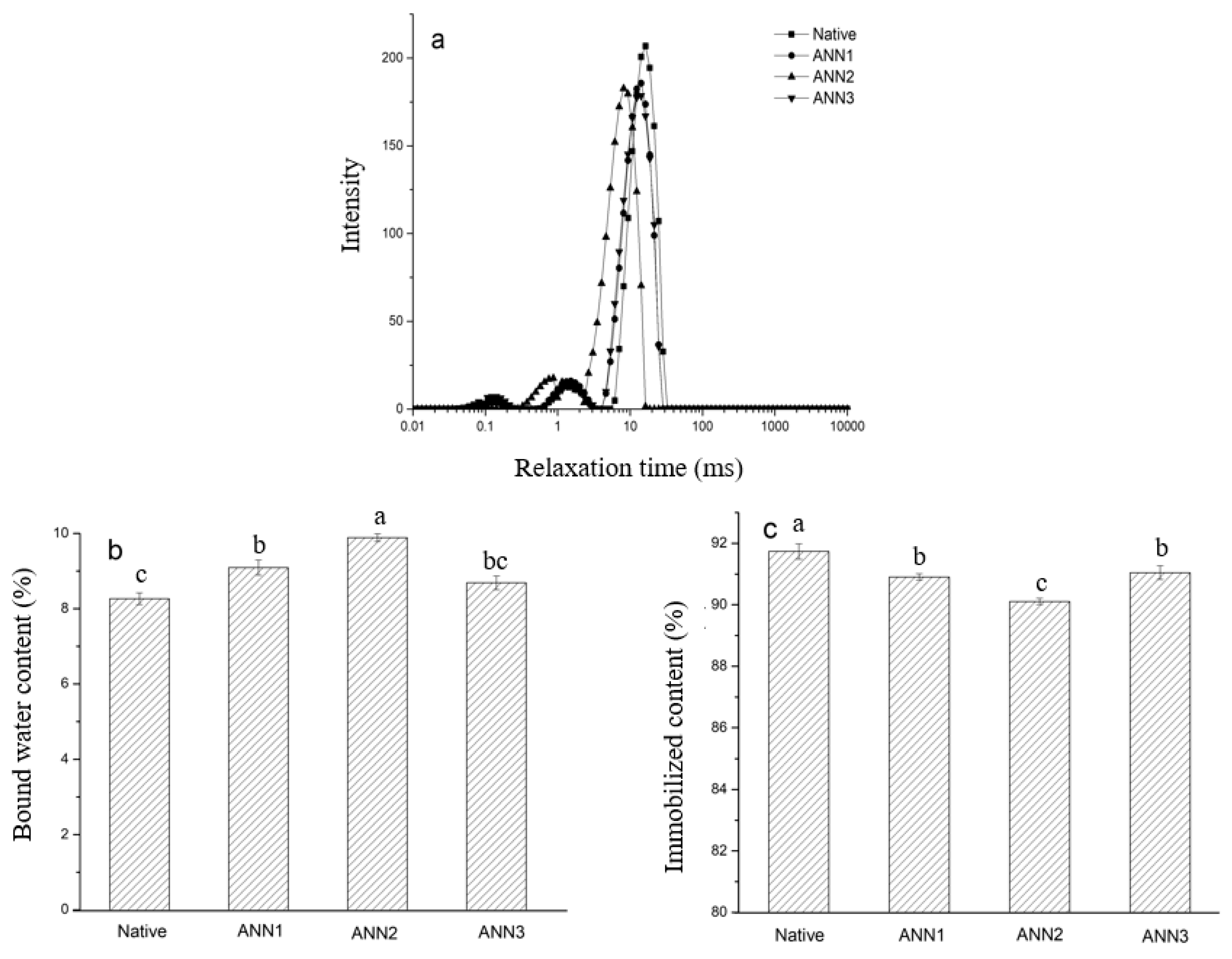

3.6. Water Distribution in Dumplings Made from Glutinous Rice Flour

3.7. Paste Soup Ratio of Fast-Frozen Dumpling after Cooking

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Z.; Wang, L.; Chen, Z.; Yu, Q.; Feng, W. Impact of protein content on processing and texture properties of waxy rice flour and glutinous dumpling. J. Cereal Sci. 2018, 81, 30–36. [Google Scholar] [CrossRef]

- Lin, Z.; Geng, D.; Qin, W.; Huang, J.; Wang, L.; Liu, L.; Tong, L. Effects of damaged starch on glutinous rice flour properties and sweet dumpling qualities. Int. J. Biol. Macromol. 2021, 181, 390–397. [Google Scholar] [CrossRef]

- Li, Y.; Ding, G.; Yokoyama, W.; Zhong, F. Characteristics of annealed glutinous rice flour and its formation of fast-frozen dumplings. J. Cereal Sci. 2018, 79, 106–112. [Google Scholar] [CrossRef]

- Laokuldilok, T.; Surawang, S.; Klinhom, J. Effect of Milling on the Color, Nutritional Properties, and Antioxidant Contents of Glutinous Black Rice. Cereal Chem. 2013, 90, 552–557. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, J.; Song, H.; Huang, W.J.; Yang, Q.H.; Pan, Y.L.; Li, Z.; Ai, Z.L. Correlation analysis between characteristics of glutinous rice flour and quality of quick-frozen dumplings. Sci. Technol. Food Ind. 2019, 4, 93–99. [Google Scholar]

- Zhou, X.Q.; Hu, Y.N.; Zhang, Y.R.; Deng, F.; Zhang, Z.C. Status and prospects of processing and quality control for the frozen rice dumplings in China. Sci. Technol. Cereals Oils Foods 2014, 2, 6–11. [Google Scholar]

- Laura, M.F.; Shanise, L.M.; Alvaro, R.G.; Elessandra, R.Z. Physical modification of starch by heat-moisture treatment and annealing and their applications: A review. Carbohydr. Polym. 2021, 274, 118665. [Google Scholar]

- Guo, B.; Wang, Y.; Pang, M.; Wu, J.; Liu, C. Annealing treatment of amylose and amylo pectin extracted from rice starch. Int. J. Biol. Macromol. 2020, 164, 3496–3500. [Google Scholar] [CrossRef]

- Jayakody, L.; Hoover, R. Effect of annealing on the molecular structure and physicochemical properties of starches from different botanical origins—A review. Carbohydr. Polym. 2008, 74, 691–703. [Google Scholar] [CrossRef]

- Tsutsui, K.; Katsuta, K.; Matoba, T.; Takemasa, M.; Funami, T.; Sato, E.; Nishinari, K. Effects of time and temperature of annealing on rheological and thermal properties of rice starch suspensions during gelatinization. J. Text. Stud. 2013, 44, 21–33. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, C.; Chen, Z.; Wang, X.; Wang, K.; Li, Y.; Wang, R.; Luo, X.; Li, Y.; Li, J. Effect of annealing on the physico-chemical properties of rice starch and the quality of rice noodles. J. Cereal Sci. 2018, 84, 125–131. [Google Scholar] [CrossRef]

- Ghani, M.B.A.; Man, Y.B.C.; Hashim, D.M.; Rahman, R.A. A differential scanning calorimetric (DSC) study on the effects of annealing and sugars-emulsifiers on gelatinization of sago starch (Metroxylon sagu). J. Food Process. Preserv. 2007, 23, 443–462. [Google Scholar] [CrossRef]

- Chang, R.; Xiong, L.; Li, M.; Liu, J.; Wang, Y.; Chen, H.; Sun, Q. Fractionation of debranched starch with different molecular weights via edible alcohol precipitation. Food Hydrocoll. 2018, 83, 430–437. [Google Scholar] [CrossRef]

- Abebe, W.; Collar, C.; Ronda, F. Impact of variety type and particle size distribution on starch enzymatic hydrolysis and functional properties of tef flours. Carbohydr. Polym. 2015, 115, 260–268. [Google Scholar] [CrossRef] [Green Version]

- Tran, N.; Daygon, V.; Resurreccion, A.; Cuevas, R.; Corpuz, H.; Fitzgerald, M. A single nucleotide polymorphism in the Waxy gene explains a significant component of gel consistency. Theor. Appl. Genet. 2011, 123, 519–525. [Google Scholar] [CrossRef]

- Yue, L.; Shoemaker, C.F.; Ma, J.; Luo, C.; Zhong, F. Effects of Alcalase/Protease N treatments on rice starch isolation and their effects on its properties. Food Chem. 2009, 114, 821–828. [Google Scholar]

- Yokoyama, W.; Renner-Nantz, J.J.; Shoemaker, C.F. Starch Molecular Mass and Size by Size-Exclusion Chromatography in DMSO-LiBr Coupled with Multiple Angle Laser Light Scattering. Cereal Chem. 1998, 75, 530–535. [Google Scholar] [CrossRef]

- Zeng, F.; Ma, F.; Kong, F.; Gao, Q.; Yu, S. Physicochemical properties and digestibility of hydrothermally treated waxy rice starch. Food Chem. 2015, 172, 92–98. [Google Scholar] [CrossRef]

- Millard, M.M.; Dintzis, F.R.; Willett, J.; Klavons, J.A. Light-scattering molecular weights and intrinsic viscosities of processed waxy maize starches in 90% dimethyl sulfoxide and H2O. Cereal Chem. 1997, 74, 687–691. [Google Scholar] [CrossRef]

- Wang, S.; Jin, F.; Yu, J. Pea starch annealing: New insights. Food Bioprocess Technol. 2013, 6, 3564–3575. [Google Scholar] [CrossRef]

- Wang, S.; Wang, J.; Yu, J.; Wang, S. A comparative study of annealing of waxy, normal and high-amylose maize starches: The role of amylose molecules. Food Chem. 2014, 164, 332–338. [Google Scholar] [CrossRef]

- Villanueva, M.; De Lamo, B.; Harasym, J.; Ronda, F. Microwave radiation and protein addition modulate hydration, pasting and gel rheological characteristics of rice and potato starches. Carbohydr. Polym. 2018, 201, 374–381. [Google Scholar] [CrossRef]

- Chen, J.J.; Lu, S.; Lii, C.Y. Effects of Milling on the Physicochemical Characteristics of Waxy Rice in Taiwan. Cereal Chem. 1999, 76, 796–799. [Google Scholar] [CrossRef]

- Iromidayoolu-Owolabi, B.; Adeniyiafolabi, T.; Adebowale, K. Pasting, Thermal, Hydration, and Functional Properties of Annealed and Heat-Moisture Treated Starch of Sword Bean (Canavalia gladiata). Int. J. Food Prop. 2011, 14, 157–174. [Google Scholar] [CrossRef]

- Xu, M.; Saleh, A.S.M.; Gong, B.; Li, B.; Jing, L.; Gou, M.; Jiang, H.; Li, W. The effect of repeated versus continuous annealing on structural, physicochemical, and digestive properties of potato starch. Food Res. Int. 2018, 111, 324–333. [Google Scholar] [CrossRef]

- Alimi, B.A.; Workneh, T.S.; Sibomana, M.S. Effect of hydrothermal modifications on functional, pasting and structural properties of false banana (Ensete ventricosum) starch. Food Biophys. 2016, 11, 248–256. [Google Scholar] [CrossRef]

- Sikora, M.; Adamczyk, G.; Krystyjan, M.; Dobosz, A.; Tomasik, P.; Berski, W.; Lukasiewicz, M.; Izak, P. Thixotropic properties of normal potato starch depending on the degree of the granules pasting. Carbohydr. Polym. 2015, 121, 254–264. [Google Scholar] [CrossRef]

- Wang, B.; Wang, L.J.; Li, D.; Özkan, N.; Li, S.J.; Mao, Z.H. Rheological properties of waxy maize starch and xanthan gum mixtures in the presence of sucrose. Carbohydr. Polym. 2009, 77, 472–481. [Google Scholar] [CrossRef]

- Adamczyk, G.; Krystyjan, M.; Jaworska, G. The Effect of the Addition of Dietary Fibers from Apple and Oat on the Rheological and Textural Properties of Waxy Potato Starch. Polymers 2020, 12, 321. [Google Scholar] [CrossRef] [Green Version]

- Ma, S.; Zhu, P.; Wang, M. Effects of konjac glucomannan on pasting and rheological properties of corn starch. Food Hydrocoll. 2019, 89, 234–240. [Google Scholar] [CrossRef]

- Wang, S.; Lin, R.; Cheng, S.; Wang, Z.; Tan, M. Assessment of Water Mobility in Surf Clam and Soy Protein System during Gelation Using LF-NMR Technique. Foods 2020, 9, 213. [Google Scholar] [CrossRef] [Green Version]

- Shao, J.H.; Deng, Y.M.; Jia, N.; Li, R.R.; Cao, J.X.; Liu, D.Y.; Li, J.R. Low-field NMR determination of water distribution in meat batters with NaCl and polyphosphate addition. Food Chem. 2016, 200, 308–314. [Google Scholar] [CrossRef]

- Niu, M.; Xiong, L.; Zhang, B.; Jia, C.; Zhao, S. Comparative study on protein polymerization in whole-wheat dough modified by transglutaminase and glucose oxidase. LWT-Food Sci. Technol. 2018, 90, 323–330. [Google Scholar] [CrossRef]

- Wang, H.; Xiao, N.; Wang, X.; Zhao, X.; Zhang, H. Effect of pregelatinized starch on the characteristics, microstructures, and quality attributes of glutinous rice flour and dumplings. Food Chem. 2019, 283, 248–256. [Google Scholar] [CrossRef] [PubMed]

| Samples | Mw (×108) | Rz (nm) |

|---|---|---|

| Native | 5.985 ± 0.023 a | 84.6 ± 0.3 a |

| ANN1 | 2.709 ± 0.044 b | 79.2 ± 0.7 b |

| ANN2 | 2.685 ± 0.033 b | 80.8 ± 0.1 b |

| ANN3 | 1.873 ± 0.012 c | 84.0 ± 1.6 a |

| Samples | Tfo (°C) | Tfp (°C) | Tfc (°C) | Tfc-Tfo (°C) | △Hf (J/g) |

|---|---|---|---|---|---|

| Native | −8.90 ± 0.01 a | −8.96 ± 0.00 a | −10.03 ± 0.01 a | 1.13 ± 0.02 a | −94.54 ± 0.02 b |

| ANN1 | −17.85 ± 0.01 d | −17.72 ± 0.01 d | −18.39 ± 0.03 d | 0.54 ± 0.04 b | −92.36 ± 0.03 a |

| ANN2 | −13.80 ± 0.02 b | −13.87 ± 0.02 b | −14.40 ± 0.01 b | 0.60 ± 0.03 b | −92.75 ± 0.05 a |

| ANN3 | −16.97 ± 0.01 c | −16.98 ± 0.02 c | −17.55 ± 0.01 c | 0.58 ± 0.02 b | −93.01 ± 0.03 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, C.; Zhu, S.; Ding, G.; Du, C.; Huang, D.; Li, Y. Modulating Structure and Properties of Glutinous Rice Flour and Its Dumpling Products by Annealing. Processes 2021, 9, 2248. https://doi.org/10.3390/pr9122248

Shi C, Zhu S, Ding G, Du C, Huang D, Li Y. Modulating Structure and Properties of Glutinous Rice Flour and Its Dumpling Products by Annealing. Processes. 2021; 9(12):2248. https://doi.org/10.3390/pr9122248

Chicago/Turabian StyleShi, Chengming, Song Zhu, Guangqin Ding, Chaodong Du, Dejian Huang, and Yue Li. 2021. "Modulating Structure and Properties of Glutinous Rice Flour and Its Dumpling Products by Annealing" Processes 9, no. 12: 2248. https://doi.org/10.3390/pr9122248

APA StyleShi, C., Zhu, S., Ding, G., Du, C., Huang, D., & Li, Y. (2021). Modulating Structure and Properties of Glutinous Rice Flour and Its Dumpling Products by Annealing. Processes, 9(12), 2248. https://doi.org/10.3390/pr9122248