1. Introduction

Air pollution affects the health of millions of people worldwide [

1]. The importance of air pollution is even higher for cities, where, according to statistics, >70% of the population lives (>50% for Asia) [

2,

3]. Many countries have introduced policies to mitigate the increasing anthropogenic contribution to air pollution. Airborne particulate matter (PM) is one of the most relevant pollutants to human health, with both short- and long-term exposure linked to increased mortality [

4,

5]. PM can be emitted directly by the sources (primary) or formed in the atmosphere by gaseous precursors (secondary) [

6,

7]. Globally, between 2010 and 2016, 55.3% of the world’s population was exposed to increased levels of PM

2.5 [

8]. It was estimated that in 2019, exposure to PM

2.5 caused 7% of total global mortality and accounted for about 4.1 million deaths [

4], largely in developing countries such as China and India. A review that summarised European data from 2000 to 2012 showed that transport was a major contributor to urban air pollution, with 27% of PM originating from road transport in the cities [

9] (the percentage was 20% for overall Europe). The stricter emission standards (the so-called Euro standards), along with fuel improvements and traffic management, decreased both primary and secondary aerosol contributions from vehicles [

10]. In Europe, for example, the (total) particulate emissions from road transport decreased significantly over the years even though the transport activity increased [

11]. In 2018 the road transport contribution to primary PM (overall Europe) was 11% [

11]. During the COVID-19 lockdowns, the decreases in PM in cities were modest [

12,

13,

14,

15], confirming that in terms of mass, other sources are more important than transport (e.g., residential heating, manufacturing industry). Still, the reductions in urban sites were much higher compared to rural sites, indicating that traffic still contributes in cities. However, a study concluded that further controls on traffic emissions will have limited benefit in reducing the concentration of fine particles, except in countries where the use of diesel particle filters is not mandatory (e.g., outside the EU) [

8,

16]. Indeed, where policies and strategies are not implemented, air quality continues to worsen due to the increasing number of vehicles and power plants [

17,

18].

Controlling the PM mass does not necessarily address the problem of ultrafine particles concentration in the air. A study confirmed that the sources dominating the particle number emissions are different to those dominating the mass emissions [

19,

20]. The particle number concentration is highly affected by road transport and the mass by aged and transported aerosol [

19]. In 2010, the major global particle number source was road transport (40%) [

21]. In Europe, the percentage was 60%, ranging from 32% to 97% [

22]. Another study with data from 2013 to 2016 showed that road transport was the main contributor in all cities examined, with a contribution up to 94% (annual average) [

23]. The recent WHO (World Health Organization) Guidelines recommended the measurement of ambient ultrafine particles at monitoring stations and suggested that low particle number counts should be considered less than 1000 #/cm

3 (as a 24-h mean), while typical levels observed in urban background areas typically exceed 10,000 #/cm

3 [

24]. The non-volatile part is typically less than one-third [

25].

The methodology to assess the emissions of a vehicle is traditionally based on the weight increase in a filter sampling diluted exhaust over a test [

26]. The vehicle is fixed on a chassis dynamometer, and the driver follows a pre-defined speed profile (test cycle). The exhaust is diluted in a dilution tunnel, where various analysers determine the pollutants. A part of the diluted exhaust gas is extracted and passes through a filter. The quantity collected during the test determines the PM mass emissions. With the introduction of particulate filters at the exhaust aftertreatment of diesel vehicles, the collected mass on the filter reached values close to the background levels. For this reason, the PMP (Particle Measurement Programme) group was tasked by the UNECE (Unite Nations Economic Commission for Europe) with developing a complementary method (to PM mass) with better sensitivity at low emission levels. The JRC (Joint Research Centre) of the European Commission actively participated in the PMP, providing data and drafting the relevant regulations since almost the beginning. The candidate method that was finally selected was based on counting solid particles with diameter > 23 nm [

27]. The choice of not measuring smaller particles, which are very sensitive to the sampling conditions, was based on technical reasons (better accuracy, repeatability, acceptable cost) rather than on health reasons. Additionally, the limits were selected on the basis of what was achievable with the best available technology (wall flow particulate filters) and not on health-related considerations. The reason for this choice was based on the fact that, while a clear relationship between adverse effects and exposure to PM had been already demonstrated, there was a lack of robust epidemiological studies on the health effects of ultrafine particles levels [

28]. The solid particle number (SPN) methodology was initially introduced in the EU (European Union) regulation in 2011 for light-duty diesel vehicles (Euro 5b). Since then, it has been extended to other sectors and regulations (EU and Global). Other than the EU, many other countries have introduced SPN in their regulations. For example, China (China 5 for light-duty diesel vehicles, China 6/VI all), India (BS VI all since 2020), and Korea have SPN limits. At the time of writing, in addition to the EU, only China has on-road SPN limits, and India will introduce them in 2023. Interestingly, even though only solid particles are limited, a review (years 1994–2019) showed that for gasoline direct injection vehicles where the SPN emissions decreased over the years, the total particles (i.e., solids and volatile primary particles) also decreased. On the other hand, for port fuel injection vehicles, where no SPN limit applies, the solid particle emissions remained at the same levels or even increased, as well as the total particles [

29]. Similarly, DPFs were found to be very effective in reducing secondary aerosol formation [

30]. It should be emphasised, though, that total particles are more sensitive than solid particles, and they do not necessarily correlate for all cases (vehicles, fuels, test cycles etc.). Consequently, large differences between the two can sometimes be found [

31].

Since the latest reviews in 2015 and 2018 [

32,

33], corrections and improvements to the methodologies used to measure particle numbers from motor vehicles took place, sometimes with important differences. The aim of this paper is to update on the status of current particle number regulations and, most importantly, to summarise the technical specifications, differences, improvements, and lower detections sizes (from 23 nm to 10 nm), which are not so easy to identify. To our knowledge, this is the first study that summarises all particle number regulations.

2. Regulatory Background

This section will give the background and regulatory context of the group and committees that were responsible for preparing the particle number technical specifications and adopting the relative regulations.

2.1. World Forum for Harmonization of Vehicle Regulations (WP.29)

The circulation of vehicles in a country requires the approval of the vehicle type and/or its components. Different national regulations and approval procedures mean additional time and costs for the manufacturers due to additional designs, tests, and approvals. Thus, it is highly desirable to harmonise the technical requirements and regulations for the vehicle type approval at an international or even a global level. The main organisation where such effort is taking place is the World Forum for Harmonization of Vehicle Regulations (WP.29) [

34] under the United Nations Economic Commission for Europe (UNECE) [

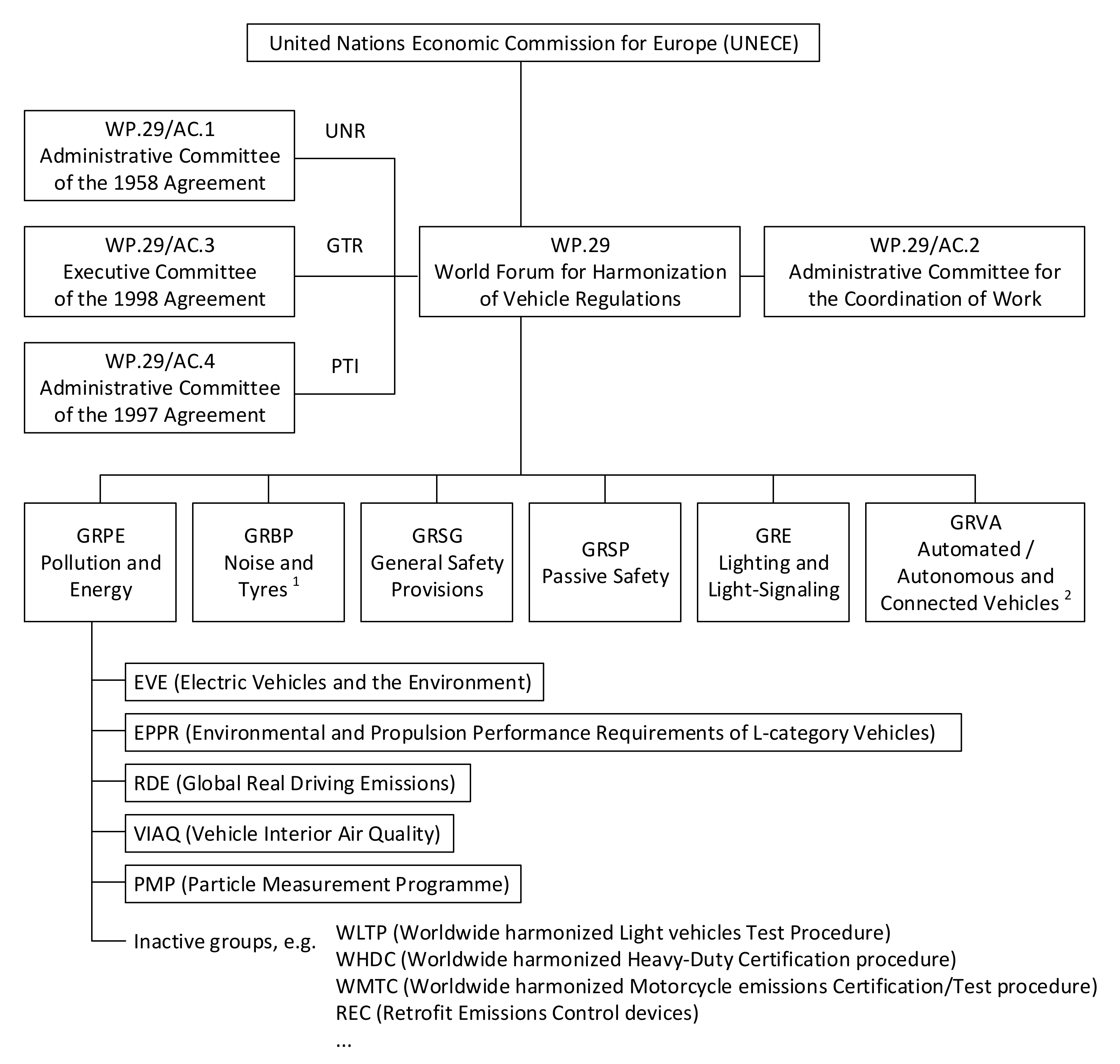

35]. There are six subsidiary bodies, also known as GRs (Groups of Rapporteurs) (

Figure 1). The one relevant to vehicle emissions is the Working Party on Pollution and Energy (GRPE) [

36]. Any United Nations (UN) member country and any of their regional economic integration organisations may participate in the activities of the World Forum and may become a contracting party to the Agreements (which will be discussed below). Governmental and non-governmental organisations (NGOs) may also participate in a consultative capacity in WP.29 or in its subsidiary working groups. The WP.29 convenes three times a year (March, June, and November). The sessions of each subsidiary body are usually held twice a year. The work of the World Forum is transparent: all agendas, working documents and reports are openly accessible on the Internet website of the World Forum.

Three UN Agreements, adopted in 1958, 1997, and 1998, provide the legal framework allowing contracting parties to establish internationally harmonised regulatory instruments concerning the certification of motor vehicles and their equipment and parts, as well as rules for technical inspections of vehicles in use [

37].

2.1.1. UN 1958 Agreement

The UN 1958 Agreement provides the legal and administrative framework for developing harmonised technical UN Regulations on uniform performance requirements, for granting type-approvals and documentation, for the conformity of production, and for the assessment of technical services. The basic main principles of the 1958 Agreement are: (i) the mutual recognition of the type-approvals granted by contracting parties, and; (ii) a contracting party can choose which, if any, of the UN Regulations annexed to the Agreement it would like to apply. Furthermore, even when a contracting party applies a UN Regulation, it may keep its own alternative national/regional legislation. The regulations were formerly called “UNECE Regulations” or, less formally, “ECE Regulations” in reference to the Economic Commission for Europe (ECE). However, since many non-European countries are now contracting parties to the 1958 Agreement, the regulations are officially entitled “UN Regulations” or sometimes abbreviated as “UNRs”. Some important regulations for vehicle exhaust emissions are:

UN Regulation 40 for motorcycles. There is no particle number measurement requirement.

UN Regulation 47 for mopeds. There is no particle number measurement requirement.

UN Regulation 49 for heavy-duty engines.

UN Regulation 83 for light-duty vehicles.

UN Regulation 96 for non-road mobile machinery.

UN Regulation 132 for retrofitting.

UN Regulation 154 for light-duty vehicles following the worldwide harmonised light vehicles test procedure (WLTP) [

41].

The oldest of the above are UNR 40 (entry into force 1979) and UNR 47 (entry into force 1981), and the latest is UNR 154 (entry into force 2020). At the time of writing, 159 UN Regulations exist, which can be found at the relative website [

42].

2.1.2. UN 1998 Agreement

The UN 1998 Agreement (or Global Agreement) stipulates that contracting parties establish, by consensus vote, UN Global Technical Regulations (UN GTRs) in a Global Registry on globally harmonised performance requirements and test procedures. Each UN GTR contains extensive notes on its purpose and development. The technical rationale, the research sources used, the cost and benefit considerations, and the references to data that were consulted are recorded. GTRs are not binding to contracting parties, and they should apply their national rulemaking procedures if and when transposing UN GTRs into national legislation. At the time of writing, 21 UN GTRs exist, which can be found at the relative websites [

43]. The most important for vehicle exhaust regulations are:

GTR 2 for L-category vehicles (test cycle: worldwide harmonised motorcycle test cycle—WMTC). There is no particle number measurement description.

GTR 4 for heavy-duty engines (worldwide harmonised heavy-duty certification procedure—WHDC) (test cycles: worldwide harmonised transient cycle—WHTC; worldwide harmonised stationary cycle—WHSC). There is no particle number measurement description.

GTR 11 for non-road mobile machinery (NRMM) (test cycles: non-road transient cycle—NRTC; non-road stationary cycle—NRSC). There is no particle number measurement description.

GTR 15 for light-duty vehicles (worldwide harmonised light vehicles test procedure—WLTP) (test cycle: worldwide harmonised light vehicles test cycle—WLTC).

2.1.3. UN 1997 Agreement

The UN 1997 Agreement allows contracting parties to establish UN Rules for the periodic technical inspections (PTI) of vehicles in use. The contracting parties reciprocally recognise the international inspection certificates that were granted according to the UN Rules annexed to the Agreement. The topic will not be discussed in more detail here.

2.1.4. Differences between UN 1958 and 1998 Agreements

While both the 1958 and 1998 Agreements prepare regulations on similar technical topics, the UN Regulations (1958 Agreement) prescribe the conditions for reciprocal recognition of approvals granted on the basis of the regulations (i.e., approved once and accepted everywhere). UN Regulations are annexed to the 1958 Agreement and therefore are part of it; they are considered international law. Contracting parties are free to be bound by all, some, or no UN Regulations. UN GTRs instead do not contain administrative provisions (for certification and conformity of production). Adoption of UN GTRs needs consensus vote, while UN Regulations need a four-fifths majority of the relevant Committees.

2.1.5. The Agreements Worldwide

The countries that have signed the 1958 and 1998 Agreements can be found in the Blue Book [

44]. They are referred to as contracting parties. For example, Japan and Korea have signed the 1958 Agreement, but not the USA (United States of America), Canada, China, or India. The 1998 Agreement has been signed by many countries, including the USA, Canada, Japan, Russia, China, Korea, India, and Australia.

The EU is a contracting party of the 1958 and 1998 Agreements, but not of the 1997 Agreement. In recent years, the EU decided to replace as many EU Directives as possible with the 1958 Agreement UN Regulations and to make direct reference to these UN Regulations in EU legislation [

45,

46]. The UN Regulations, which are applicable under EU law, must be translated into all official EU languages and published in the Official Journal of the EU.

It should be added that an EU Regulation is a binding legislative act. It must be applied in its entirety across the EU. An EU Directive is a legislative act that sets out a goal that all EU countries must achieve. However, it is up to the individual countries to devise their own laws on how to reach these goals.

2.2. Working Party on Pollution and Energy (GRPE)

The Working Party on Pollution and Energy (GRPE) is the subsidiary body of the World Forum for Harmonization of Vehicle Regulations (WP.29) that prepares regulatory proposals on pollution and energy efficiency which are submitted for approval to WP.29. Final decisions are taken by representatives of the contracting parties by vote at the World Forum WP.29 level. Some of the informal working groups (IWGs), active or inactive at the time of writing, can be found in

Figure 1. Each informal working group operates on the basis of Terms of Reference (ToR) and a mandate that have to be approved by the GRPE during its plenary sessions.

The Particle Measurement Programme (PMP) group is the one responsible for the development of the technical specifications for particulate instruments and relevant regulations, and they provide feedback to other IWGs whenever requested on particulates topics. All the documents can be found on the relative website [

47].

2.3. Particle Measurement Programme (PMP)

The Particle Measurement Program (PMP) group was launched in 2001 on the initiative of several UNECE contracting parties, and since then, it has evolved into an international group comprising governments, the European Commission, industry (associations of car and engine manufacturers, instrument manufacturers), and national vehicle emission laboratories and research institutions [

48]. The original aim was to develop a sensitive and accurate methodology that would replace or complement the regulated gravimetric procedure, requiring low investment costs, with special consideration to particle emissions at very low levels. The PMP group was initially chaired by the UK (United Kingdom) and since 2013 by the JRC.

In the first two phases (2001–2003), a wide range of measurement techniques and sampling systems were assessed. Phase three consisted of inter-laboratory exercises (2004–2006 light-duty, 2007–2009 heavy-duty) evaluating the repeatability and reproducibility of the two final recommended systems (improved PM mass method, new particle number method). The measurement method proposed by PMP in 2007, based on the counting of solid particles with a diameter larger than 23 nm, was integrated into the European Emissions Regulation in 2011 for diesel light-duty vehicles (Euro 5b) and in 2013 for heavy-duty engines (Euro VI). The methodology was also added in UN Regulation 83 and UN Regulation 49.

PMP group activities stopped at the end of 2011 with the introduction of the method in light-duty European regulation and the proposal for heavy-duty engines. The number methodology was included in the light-duty GTR 15 (WLTP) since this was developed after the introduction of the particle number for light-duty vehicles in EU. However, heavy-duty GTR 4 (WHDC) was developed before the introduction of the particle number in the EU heavy-duty regulation, so it does not include the particle number methodology.

In 2013, the EU and Switzerland requested further investigation of particle number emissions from spark ignition engines, in particular below 23 nm, the lower size in the regulated method. The new Terms of References (ToR) included topics such as:

Emissions from gasoline direct injection (GDI) vehicles.

Development of equipment to measure particles below 23 nm.

Calibration procedures update (and if necessary for lower size).

Engine dynamometer raw exhaust particle measurements for type-approval of heavy-duty engines.

Emissions during regeneration events.

Non-exhaust particle emissions.

The work of the PMP group was the basis of the extension of the particle regulation to light-duty gasoline direct injection vehicles in 2014. A limit was introduced for non-road mobile machinery in 2019.

A major part of the work was the preparation of a sub-23 nm protocol. The final 10 nm proposal was introduced as an option to GTR 15 and is also ready for heavy-duty regulations. The principles that have guided the development of the sub-23 nm methodology are summarised below:

Aim at the best compromise between accuracy, repeatability, reproducibility, and test complexity/cost.

Try to avoid, as much as possible, requiring heavy changes and investments to update the existing facilities/measuring equipment.

Take into account the possible different approaches in different regions (in some regions there is the intention to regulate sub-23 nm, while others could decide to do this at a later stage).

Regarding on-road particle measurements, the measurement methodology was developed in Europe by the RDE expert group and the JRC. RDE testing was introduced into EU regulation in 2017 for light-duty vehicles and in 2021 for heavy-duty vehicles. After the introduction in the EU regulation, the PMP refined and extended the methodology to 10 nm. The proposal was submitted to the UN RDE group in 2021.

An important amount of work has also been done and still continues within the PMP on defining the brake emissions protocol (cycle, sampling, instrumentation). This topic will not be addressed in this paper. The details of the particle number technical specifications for exhaust emissions will be described in the next chapter.

3. Technical Specifications

3.1. Terminology

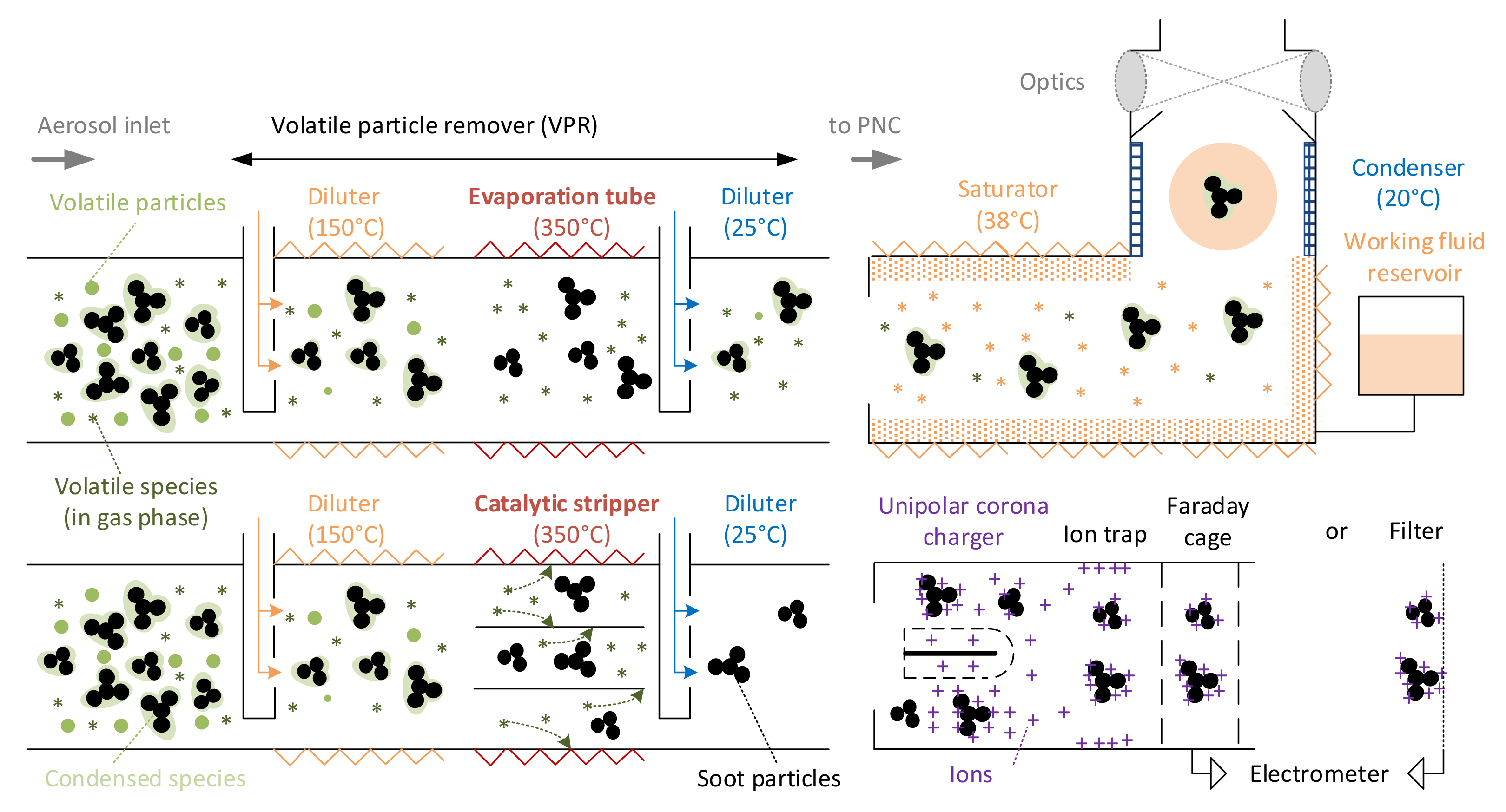

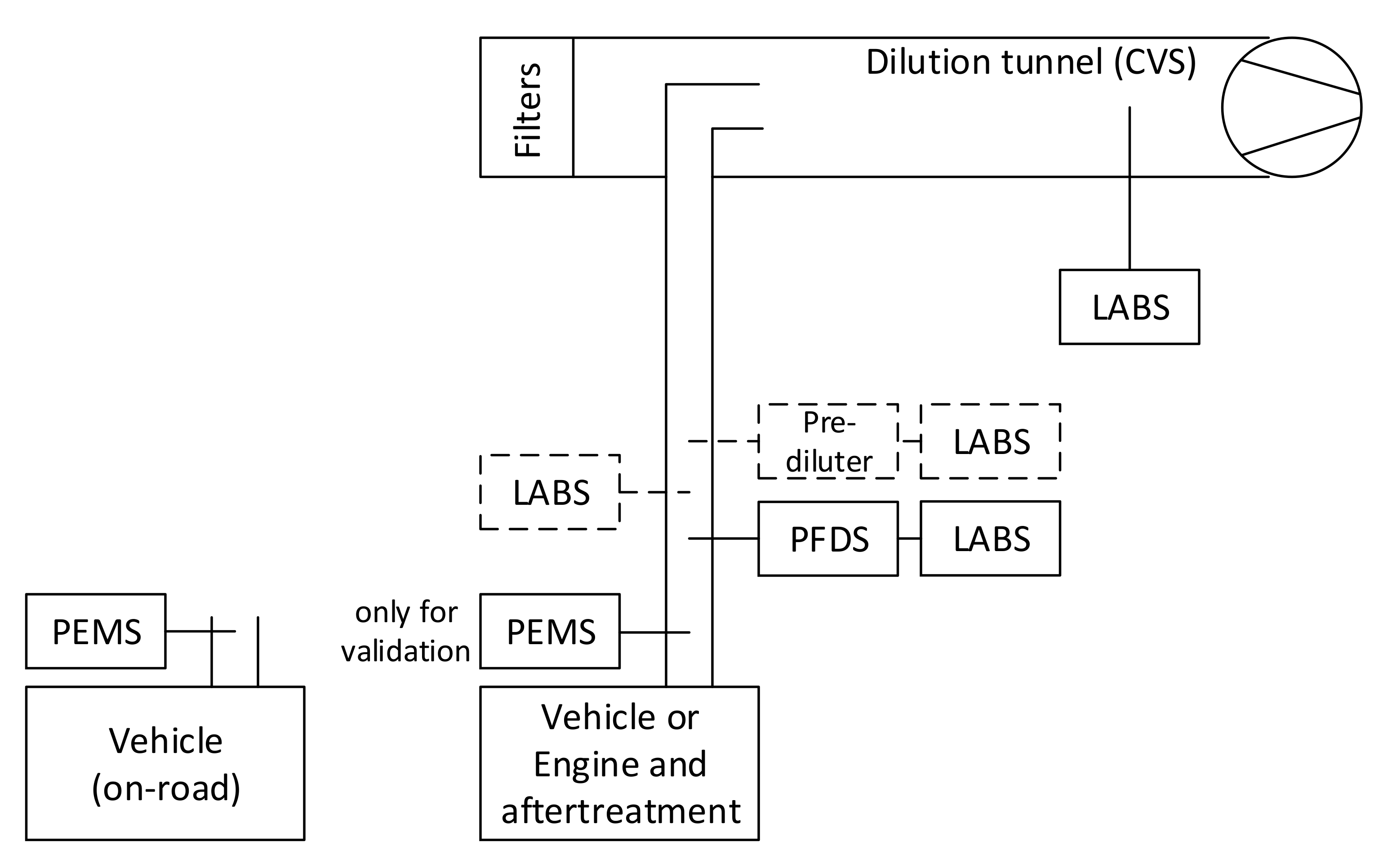

The definition of a solid particle is not simple. The intention of the regulation is to measure “solid” particles, with the main focus being on soot particles in the past. The PMP protocol, as drafted in 2003, requires sampling from the full dilution tunnel with constant volume sampling (CVS). Thus, the exhaust gas sample is already diluted at approximately ambient temperature, around 25 °C. The decision to sample from the dilution tunnel was made because the dilution tunnels was already used for the measurement of other pollutants. For heavy-duty and non-road mobile machinery, in addition to the dilution tunnel, sampling from the proportional partial flow dilution system (PFDS) is allowed (see

Figure 2). The diluted sample temperature is also expected to be low, around 25 °C. The sample preconditioning in the laboratory particle number system (LABS) includes hot dilution at >150 °C followed by an evaporation tube at 300–400 °C. Any surviving particles large enough to be detected with a particle counter having approximately 50% counting efficiency at 23 nm are defined as “solids” in the PMP protocol. These operationally defined solid particles may also include semivolatile material not evaporating at 300–400 °C (e.g., heavy molecular hydrocarbons) or at least not shrinking to a sufficiently small size that would not activate and grow to a size to be detected by the particle counter. Thus, the term “nonvolatiles” may be more appropriate; nevertheless, the commonly used term “solids” will be used in this paper.

The latest terminology in the regulations (in GTR 15) uses the term “particle” for the matter being characterised (measured) in the airborne phase (suspended matter) and the term “particulate” for the deposited matter. Particle number (PN) emissions mean the total number of solid particles emitted from the vehicle exhaust quantified according to the dilution, sampling, and measurement methods as specified in the regulation. Particulate matter (PM) emissions mean the mass of any particulate material from the vehicle exhaust quantified according to the dilution, sampling, and measurement methods as specified in the regulation. UNR 49 defines as PM any material collected on a specified filter medium after diluting exhaust with a clean filtered diluent to a temperature between 42 °C and 52 °C; this is primarily carbon, condensed hydrocarbons, and sulphates with associated water. In the same regulation, instead of PN, mistakenly, the term “PM number” is used. Recently, the abbreviation SPN (solid particle number) instead of PN was suggested to emphasise that solid particles are measured and not total particles (i.e., solids and volatiles).

The on-board portable emission measurement systems (PEMS) measure directly from the tailpipe (undiluted exhaust), as the measurements are done on the road. Permitting direct sampling from the tailpipe also in the laboratory is an attractive approach. However, for light-duty vehicles, there is no exhaust gas flow rate information, which is necessary for the calculation of the emissions. On the other hand, for heavy-duty engines, direct sampling of gaseous pollutants is already permitted, and the exhaust flow rate can be measured by various methods. Thus, allowing direct particle sampling from the tailpipe for type-approval of engines is easier to introduce in the regulation. One approach is directly connecting the particle number system to the tailpipe using a heated sampling line (see

Figure 2). Another is using a (cold) pre-diluter at ambient temperature, with something similar happening with CVS or the PFDS. PEMS with both concepts exist already for light-duty vehicles (i.e., cold dilution or heated line and hot dilution).

Figure 2 summarises the possibilities of particle number measurements with laboratory or portable systems. Such possibilities may result in differences regarding the final SPN concentration due to incomplete removal of volatiles, particle losses (e.g., due to thermophoresis in sampling lines), and particle transformations (e.g., due to agglomeration in sampling lines). Furthermore, the optical detectors of PEMS are not necessarily the same as those of laboratory systems, further enhancing the differences between PEMS and LABS (see

Appendix A for details).

In the following sections, the term LABS will be used for the laboratory systems and PEMS for the on-board systems, followed by a number (10 or 23) indicating the approximate lower detection size (e.g., LABS23 or PEMS10). The term solid particle number (SPN) will be used for all the above protocols regardless of the application (laboratory or on-board). Any differences to the final SPN result due to the different design characteristics of the systems are taken into account with the limit values and the conformity factors in Regulation (EU) 2017/1151 for light-duty vehicles and Regulation (EU) 2019/1939 for heavy-duty vehicles.

3.2. Laboratory Systems (LABS) Specifications

3.2.1. Description of the System

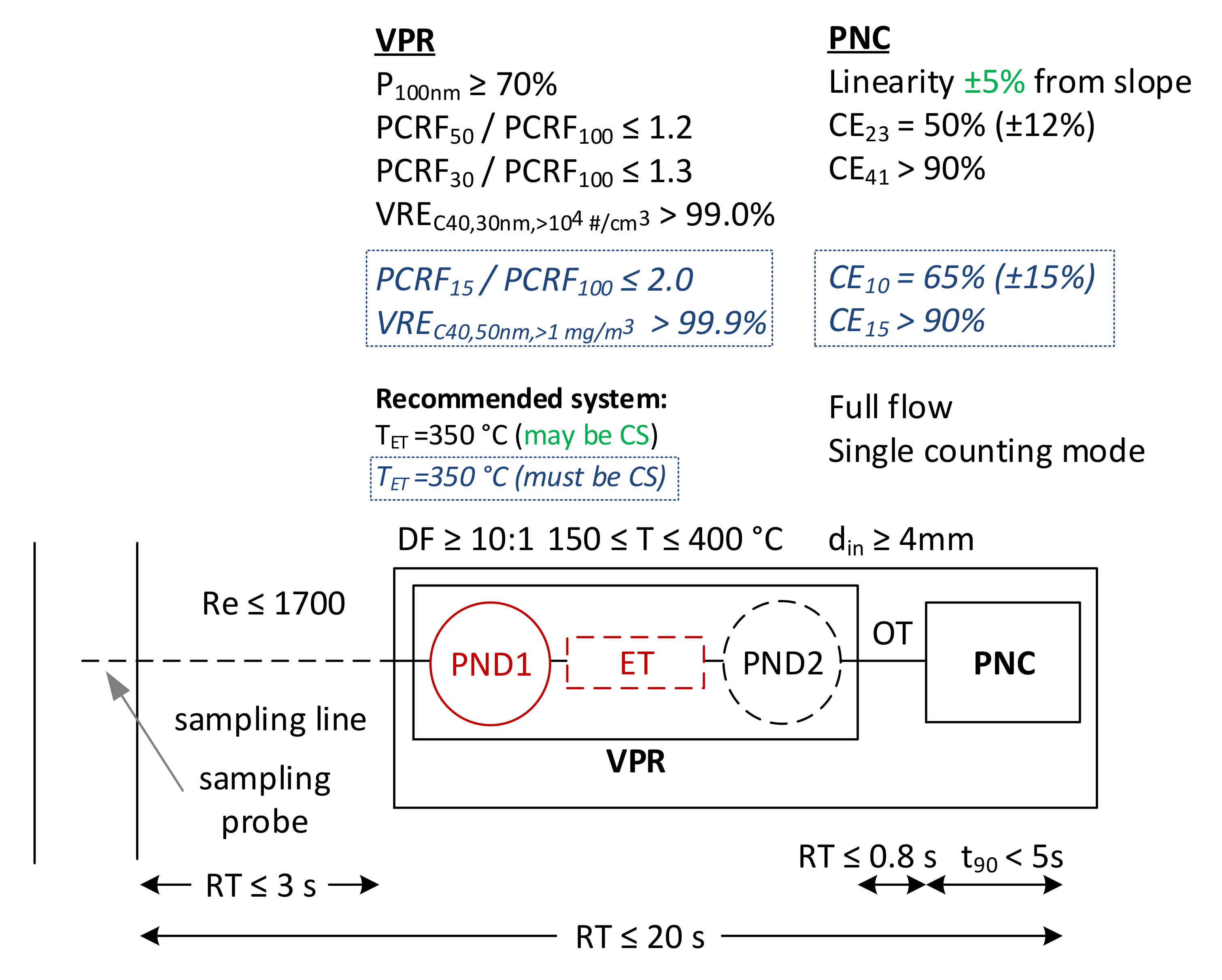

Figure 3 plots a LABS according to the current (23 nm) technical specifications. It also gives the improvements of the 23 nm systems and the future 10 nm requirements. The laboratory systems (LABS) consist of a volatile particle remover (VPR) and a particle number counter (PNC). The VPR extracts a small flow, having a probe in a dilution tunnel (full flow or proportional partial flow). Optionally, a sampling line connects the VPR to the sampling probe. The VPR has to dilute the sample at least ten times, and the mixture temperature has to be at least 150 °C. Theoretically, a system heated at, for example, 160 °C fulfils the design requirements of the regulation (but would still have to fulfil the performance requirements for volatile removal efficiency, see below). Nevertheless, the recommended system described in the regulation, which was based on the PMP suggested system, includes an evaporation tube at 350 °C. The PNC has to be full flow and count particles in the single counting mode. Other calibration requirements regarding the particle concentration reduction factor (PCRF) and the volatile removal efficiency (VRE) of the VPR, as well as the counting efficiency (CE) of the PNC, are summarised in

Figure 3. The PCRF, VRE, and CE are determined during the calibration of the device, with an appropriate aerosol measuring monodisperse in parallel with a reference instrument. For a given dilution setting of the VPR, PCRF is the ratio of the upstream to downstream concentration of solid particles of a specific size, and it is an indication of the dilution and the particle losses at the specific size for the VPR. Volatile removal efficiency is one minus the ratio of downstream to upstream concentration of volatile (tetracontane) particles with size >30 nm. Counting efficiency is the ratio of inlet to outlet concentration of particles for the PNC. Details can be found elsewhere [

49].

3.2.2. Comparison of the Specifications

Table 1 summarises the technical and calibration requirements for the original laboratory system counting >23 nm (LABS

23) as introduced in the regulations. The next columns summarise the improved LABS

23 and the LABS

10 based on the recent PMP recommendations. Note that the terms SPN

23 and SPN

10 are used in GTR 15. The main improvements of the LABS

23 systems are:

A catalytic stripper (CS) may be included in the VPR (while in the past it was not allowed).

The PNC calibration material should be soot or PAO (polyalphaolefin) (commonly known as emery oil), while in the past there was no material definition.

The k-factor from the linearity test has to be included in the counting efficiencies (while in the past it was not necessary).

The differences from the reference instrument have to be within 5% (k-factor included) and not 10% as in the past.

There are no more restrictions on internal PNC corrections (in the past, up to 10% of coincidence correction was allowed).

Table 1.

Comparison of original LABS23, improved LABS23, and new (improved) LABS10 technical specifications and calibration requirements. Dashed lines separate the calibration requirements.

Table 1.

Comparison of original LABS23, improved LABS23, and new (improved) LABS10 technical specifications and calibration requirements. Dashed lines separate the calibration requirements.

| Part | LABS23 Original | LABS23 Improved | LABS10 (Improved) |

|---|

| Sampling line | optional | optional | optional |

| RT ≤ 3 s | RT ≤ 3 s | RT ≤ 3 s |

| Re ≤ 1700 | Re ≤ 1700 | Re ≤ 1700 |

| Volatile Particle Remover (VPR) | PND1 (DF ≥ 10:1) | PND1 (DF ≥ 10:1) | PND1 (DF ≥ 10:1) |

| 150 ≤ T ≤ 400 (±10) °C | 150 ≤ T ≤ 400 (±10) °C | 150 ≤ T ≤ 400 (±10) °C |

| 300–400 °C (Rec. system) | 350 °C (Rec. system) | 350 °C (Rec. system) |

| No CS | May be CS | With CS (Rec. system) |

| Tin,PNC < 35 °C | Tin,PNC < PNC specs | Tin,PNC < PNC specs |

| P100 ≥ 70% | P100 ≥ 70% | P100 ≥ 70% |

| (each instrument) | (once for family) | (once for family) |

| PCRF50/PCRF100 ≤ 1.2 | PCRF50/PCRF100 ≤ 1.2 | PCRF50/PCRF100 ≤ 1.2 |

| PCRF30/PCRF100 ≤ 1.3 | PCRF30/PCRF100 ≤ 1.3 | PCRF30/PCRF100 ≤ 1.3 |

| - | - | PCRF15/PCRF100 ≤ 2.0 |

| VREC40,30nm,≥104 #/cm3 > 99.0% | VREC40,30nm,104 #/cm3 > 99.0% | VREC40,≥50nm,1 mg/m3 > 99.9% |

| VRE yearly | VRE according to manuf. | VRE according to manuf. |

| Thermally stable material | Thermally stable material | Thermally stable material |

| Calibration 12 months | Calibration 13 months | Calibration 13 months |

| PCRF validation 30, 50, 100 nm or polydisperse (50 nm): ±10% | PCRF validation 30, 50, 100 nm or polydisperse (50 nm): ±10% | PCRF validation 30, 50, 100 nm: ±10% |

| Particle Number Counter (PNC) | Full flow | Full flow | Full flow |

| t90 < 5 s | t90 < 5 s | t90 < 5 s |

| Single counting mode | Single counting mode | Single counting mode |

| Any material | Soot or PAO | Soot or PAO |

| 0.9 < kslope < 1.1, R2 > 0.97 | 0.9 < kslope < 1.1, R2 > 0.97 | 0.9 < kslope < 1.1, R2 > 0.97 |

| Linearity ± 10% | Linearity ±5% from slope | Linearity ±5% from slope |

| CE23 = 50% (±12%) | CE23 = 50% (±12%) | CE10 = 65% (±15%) |

| CE41 > 90% | CE41 > 90% | CE15 > 90% |

| kslope may be included in CE | kslope included in CE | kslope included in CE |

| Coincidence correction <10% | Any internal correction | Any internal correction |

| Certificate 12 months | Certificate 13 months | Certificate 13 months |

| Combined | PCRFave of 30, 50, 100 nm | PCRFave of 30, 50, 100 nm | PCRFave of 30, 50, 100 nm |

| Total RT ≤ 20 s | Total RT ≤ 20 s | Total RT ≤ 20 s |

| Checks | Daily zero VPR < 0.5 #/cm3 | Daily zero VPR <0.5 #/cm3 | Daily zero VPR <0.5 #/cm3 |

| Daily zero PNC ≤ 0.2 #/cm3 | Daily zero PNC ≤0.2 #/cm3 | Daily zero PNC ≤0.2 #/cm3 |

| Daily amb. PNC: > 100 #/cm3 | No error | No error |

| Monthly flow PNC ± 5% nominal | Flow ±5% last certificate | Flow ±5% last certificate |

| 6 mos. monitor or wick exchange or ±10% of PNCRef or ≥ 2 PNCs | 6 mos. monitor or wick exchange or ±10% of PNCRef or ≥ 2 PNCs | 6 mos. monitor or wick exchange or ±10% of PNCRef or ≥ 2 PNCs |

The main differences between the LABS10 and improved LABS23 are:

The counting efficiencies of the PNC are different and shifted to smaller particles.

The CS is obligatory in the VPR (but only for the recommended system).

The volatile removal efficiency has to be >99.9% with a challenging aerosol of 1 mg/m3 tetracontane.

3.2.3. Pre-Diluter

For heavy-duty particle number sampling from the tailpipe, two approaches are allowed in the proposed Resolution:

Using the LABS, but the sampling line must be heated at a temperature ≥150 °C, and the residence time must be ≤ 1 s.

Using a pre-diluter and then the LABS.

Pre-diluter is defined as a diluter located after the sampling probe and in front of the sampling line of the VPR (thus, it is not part of the VPR) (

Table 2). A fixed dilution ratio of >5.1 is required, and the diluter temperature has to be ≥20 °C. If there is a sampling line between pre-diluter and sampling probe, it must be heated at a temperature ≥150 °C and have a residence time ≤1 s. The current proposal for the calibration requirements is that the pre-diluter and the sampling line after the VPR shall fulfil the penetration and PCRF requirements of the LABS with an approximately 10% “worsening” of the performance.

3.3. Portable Emission Measurement Systems (PEMS) Specifications

The requirements for the on-board SPN

23 portable emissions measurement systems (PEMS

23) were developed in the EU Real-Driving Emissions (RDE) group (the term “PN analyzer” is used in the regulation). The specifications had to be strict enough to be comparable with the laboratory systems but “relaxed” enough to allow small and light systems or novel concepts (e.g., hot condensation particle counters) [

50] (

Figure 4). In order to allow possible future innovative concepts, the main requirements for the PEMS

23 were to:

Include a heated section of at least 300 °C.

Have a volatile removal efficiency of at least 99% for 1 mg/m3 tetracontane particles with count median diameter (CMD) ≥50 nm.

Be linear, within ±15% of a reference instrument.

Have the efficiencies of

Table 3. Efficiency is the ratio of the downstream to upstream concentration of solid particles with a specific size, as determined during the calibration of the system. The instruments have to take into account the internal dilution and any other correction factors for losses or the particle detector. These efficiencies were based on simulations of laboratory systems LABS

23 (combination of VPR and PNC) and an additional flexibility for on-board systems.

Figure 4.

Schematic of a particle number portable emissions measurement system (PEMS). Dashed lines show optional parts. In red are heated parts. PND = particle number diluter; RT = residence time; t = time; T = temperature.

Figure 4.

Schematic of a particle number portable emissions measurement system (PEMS). Dashed lines show optional parts. In red are heated parts. PND = particle number diluter; RT = residence time; t = time; T = temperature.

The terminology of the on-board systems is also slightly different in order to not be confused with the laboratory systems. For example, the particles are counted with a “particle detector” that could be a CPC (condensation particle counter)- or a DC (diffusion charger)-based instrument. In contrast, in a laboratory system, the particles are counted with the PNC, which is CPC-based. A VPR, which is called “pre-conditioning system” (e.g., it could be part of the particle detector), is not obligatory in the PEMS. The sampling line, as with the laboratory systems, is not obligatory. If used, though, it has to be heated at ≥100 °C (while there is no temperature requirement for the laboratory systems because they measure diluted exhaust).

The SPN PEMS calibration has to be done annually with soot-like particles. For the efficiencies (

Table 3), monodisperse particles have to be used, and the correction for multiply charged particles must be <10% (and reported). For the linearity, monodisperse (≥ 45 nm) or polydisperse aerosol (CMD ≥ 45 nm) can be used, and at least five concentrations covering the whole measurement range have to be checked. The slope has to be within 0.85 and 1.15 with R

2 > 0.95. The offset has to be ≤ 10% of x

max and standard error of the estimate (SEE) ≤ 10% of x

max. The zero level has to be <5000 #/cm

3 (averaging of 30 s) and remain <5000 #/cm

3 (averaging of 30 s) after 4 h of testing. Note that the 30 s averaging will change to 60 s in order to be more in line with the ISO 27891 for CPCs.

The differences between the 10 nm to the 23 nm system are:

At the time of writing, the 10 nm proposal is for the light-duty UN RDE, but they will be the same for heavy-duty applications (see Discussion).

3.4. Summary of SPN Regulations

The following sections summarise the SPN regulations in the EU. Note that up until November 2009, all EU legislation references the European Community (EC), as only this body had legal personality. Since 1 December 2009, the EU is referenced, because due to the Lisbon Treaty, the European Union (EU) has been given a single legal personality.

3.4.1. Light-Duty Vehicles

In the EU, a SPN

23 limit of 6 × 10

11 #/km applied for the first time in 2011 (Euro 5b) for diesel vehicles (Regulation (EC) 692/2008) (

Table 4). Regulation (EU) 459/2012 introduced the same limit for GDIs in 2014 (Euro 6), with the possibility of a 10-times-higher limit for the first 3 years, upon request of the vehicle manufacturer. Regulation (EU) 2017/1151 (Euro 6c) repealed Regulation (EC) 692/2008 and introduced the worldwide harmonised light vehicles test procedure, or WLTP. Real-driving emissions (RDE) testing with portable emissions measurement systems (PEMS) was introduced in 2017 (Euro 6d-Temp) initially only for type-approval (Regulations (EU) 2016/427, 2016/646), with a conformity factor (CF) of 1.5 for particle number (Regulation (EU) 2017/1154), and later for in-service conformity (ISC) (Regulation (EU) 2018/1832). The CF for on-road SPN

23 with PEMS

23 remained the same for Euro 6d, which entered into force in 2020. All RDE regulations were consolidated in Regulation (EU) 2017/1151. Regulation (EU) 2018/858 replaced Directive 2007/46/EC and introduced a new EU type-approval framework (from September 2020) with an effective market surveillance system to control the conformity of vehicles already in circulation (from September 2019).

3.4.2. Heavy-Duty Vehicles

In EU SPN

23, limits were initially applied to compression ignition (CI) (diesel) engines in 2013 (Euro VI) (Regulation (EU) 582/2011) and in 2014 to positive ignition (PI) engines (Regulation (EU) 133/2014) (

Table 5). The limit is 6 × 10

11 #/kWh for the combined (14% cold, 86% hot) WHTC and 8 × 10

11 #/kWh for the WHSC (only diesel). The methodology (Regulation (EU) 64/2012) refers to UNR 49.

Regulation (EU) 582/2011 introduced on-road PEMS testing for ISC (instead of removing the engine from a vehicle and testing it on the engine dynamometer) for gaseous pollutants. Regulation (EU) 2019/1939 (Euro VI step E) added the cold start in the evaluation of the emissions and SPN23 with a CF = 1.63 with PEMS23 from 2021 for CI engines and 2023 for PI engines.

3.4.3. Non-Road Mobile Machinery

In the EU, Regulation (EU) 2016/1628 repealed Directive 97/68/EC in 2016 and introduced SPN

23 limits to non-road engines (19–560 kW), inland waterway vessels (>300 kW), and rail traction engines in 2019 (Stage V) (

Table 6). The procedures and test cycles (non-road transient cycle—NRTC; non-road stationary cycle—NRSC) are described in Regulation (EU) 2017/654 and 2017/655 for on-road monitoring. At the moment, there is no particle number limit for on-road testing with PEMS.

3.4.4. Worldwide

Worldwide, many countries in Asia have introduced SPN

23 limits in the laboratory (6 × 10

11 #/km for light-duty vehicles, 6 × 10

11 #/kWh for heavy-duty engines) in the last few years (

Table 7). On-road testing will be required from 2023 in India (CF to be defined) and China (CF = 2.0–2.1). Korea has limits only for diesel vehicles [

54] whereas India also includes gasoline vehicles with direct injection engines, and China limits all technologies (with CN 6).

5. Conclusions

The PMP (Particle Measurement Programme) working group of the UNECE (United Nations Economic Commission for Europe) GRPE (Working Party on Pollution and Energy) developed the solid particle number (SPN) methodology that was introduced in various regulations. The methodology includes a heated section and counting of particles with diameter >23 nm (SPN23). A SPN23 limit was initially introduced in the European laboratory type-approval regulation for light-duty diesel vehicles in 2011 (6 × 1011 #/km). The methodology was expanded to light-duty gasoline direct injection vehicles (2014), heavy-duty engines (6 × 1011 #/kWh) (2013), and non-road mobile machinery (1 × 1012 #/kWh) (2019). A test for on-road light-duty SPN23 emissions was introduced in 2017 and for heavy-duty vehicles in 2021.

UN regulations that include the particle number methodology with emission limits are UN Regulation 83 and UN Regulation 154 for light-duty vehicles and UN Regulation 49 for heavy-duty engines. The only Global Technical Regulation that includes the particle number methodology (without emission limits) is GTR 15 for light-duty vehicles. GTR 4 for heavy-duty vehicles and GTR 11 for non-road mobile machinery will probably follow. UN regulations for on-road testing are under development and will also include the particle number methodology.

The PMP group extended the methodology to cover particles larger than 10 nm (SPN10). The SPN10 option (i.e., in addition to the SPN23 method) is at the moment included only in GTR 15 for laboratory testing of light-duty vehicles. A heavy-duty resolution was also prepared including the 10 nm methodology and the option to measure directly from the tailpipe. The UN Regulation for on-road testing will also include it in the future. The major differences between the 10 nm and 23 nm methodologies, other than the different lower detection sizes, are the obligatory inclusion of a catalytic stripper and the stricter volatile removal efficiency requirements. Improvements to both methodologies focused on the particle number counter, namely the definition of the calibration material, inclusion of the calibration factor in the counting efficiencies, and differences from the calibration reference instrument within ±5% (instead of ±10%). The PMP work is moving forward with final refinements of the calibration procedures and possibly bringing them closer for laboratory and on-board systems.