Application of Computational Fluid Dynamics (CFD) Simulation for the Effective Design of Food 3D Printing (A Review)

Abstract

1. Introduction

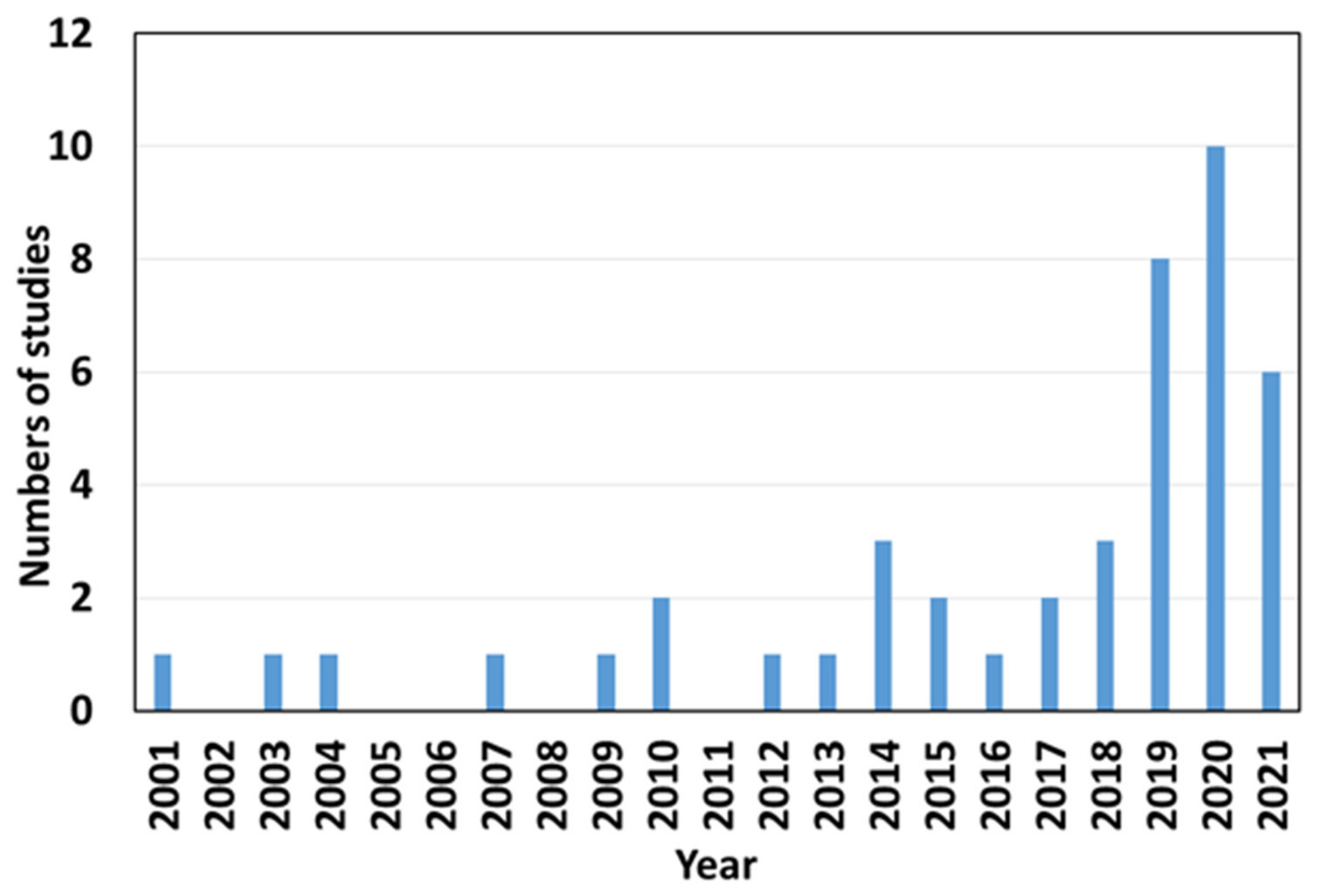

2. Overview of Studies on the CFD Analysis of 3DP

3. Fundamentals of the CFD Extrusion Process

3.1. Governing Equations

- i.

- The law of conservation of mass (continuity), which states that the mass flows entering and exiting a fluid product must be equal (Equation (1));where and are density and time ; is the Cartesian coordinates ; is the velocity component ; and i is the Cartesian coordinate index.

- ii.

- The law of conservation of momentum (Newton’s second law of motion), which states that the number of external forces acting on a fluid particle equals the rate of change in linear momentum (Equation (2));where is the Cartesian coordinate index; is the Kronecker delta; is the dynamic viscosity ; and is the acceleration due to gravity .

- iii.

- The law of conservation of energy (the first law of thermodynamics), which states that the rate of change of energy of a fluid particle is equal to the heat addition and the work done on the particle (Equation (3));where is specific heat capacity ; is the temperature (K); is the thermal conductivity ; and is the thermal source [36].

3.2. Numerical Analysis

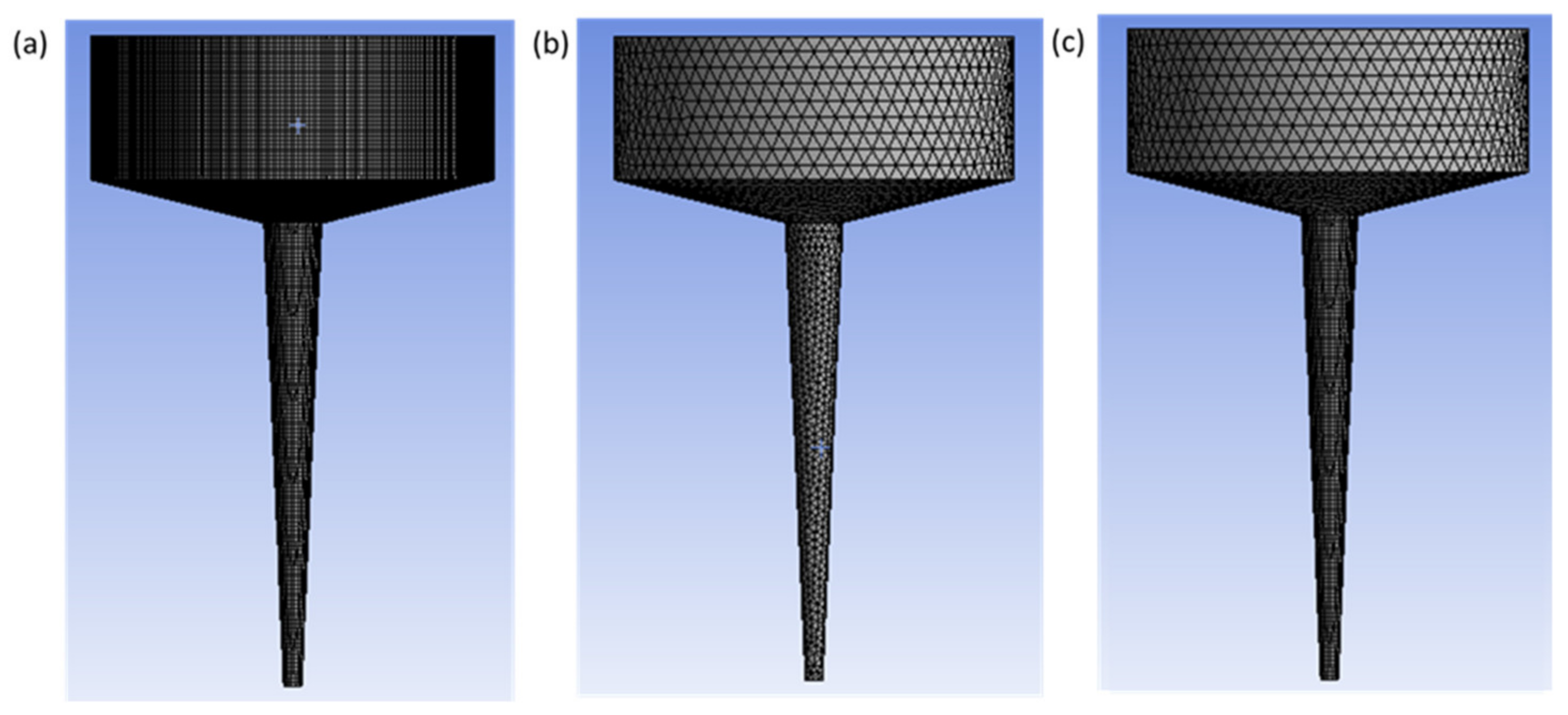

3.3. Generation of the Computational Grid (Meshing Process)

3.4. Boundary Conditions

4. CFD Applications in Food 3DP

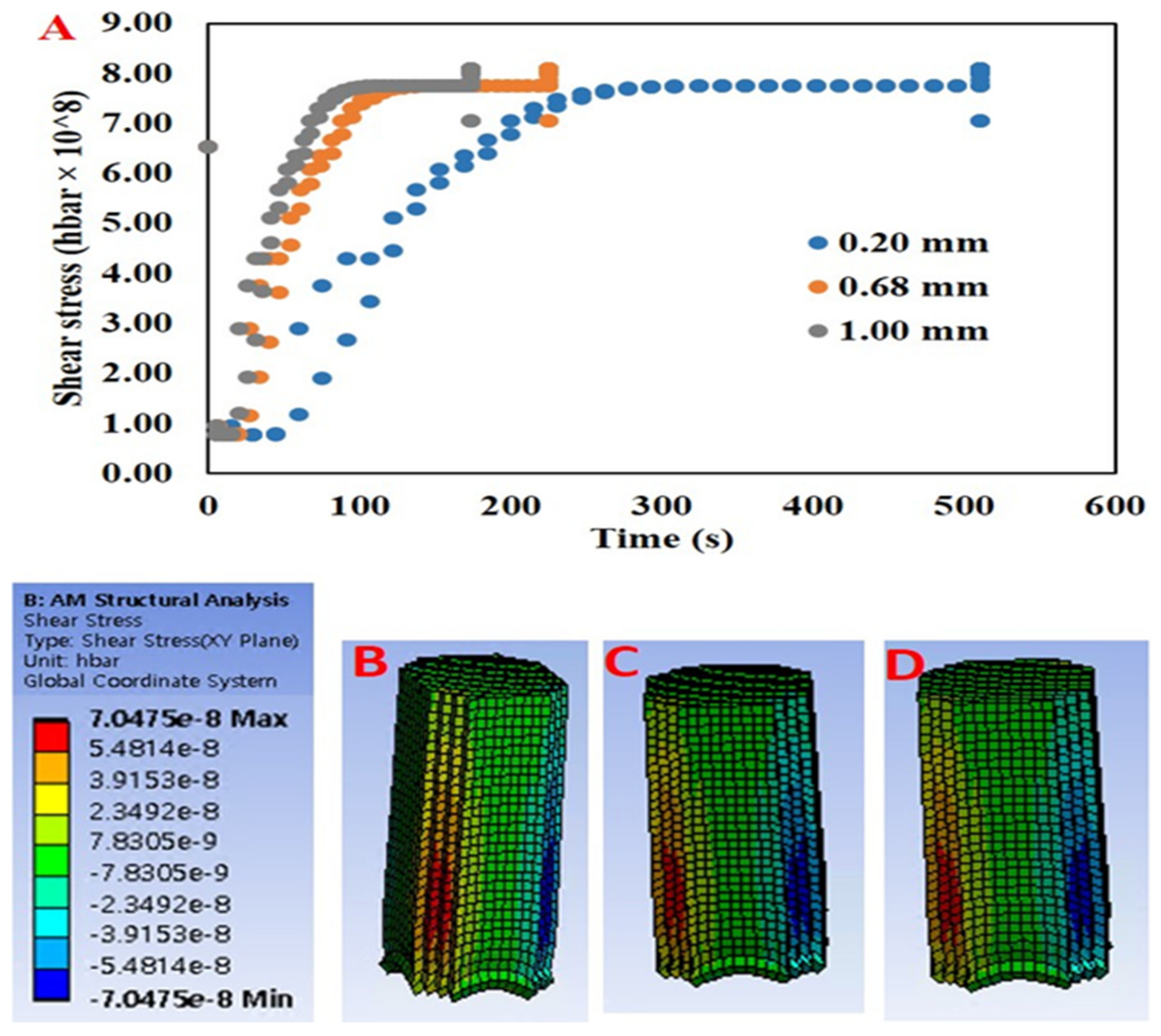

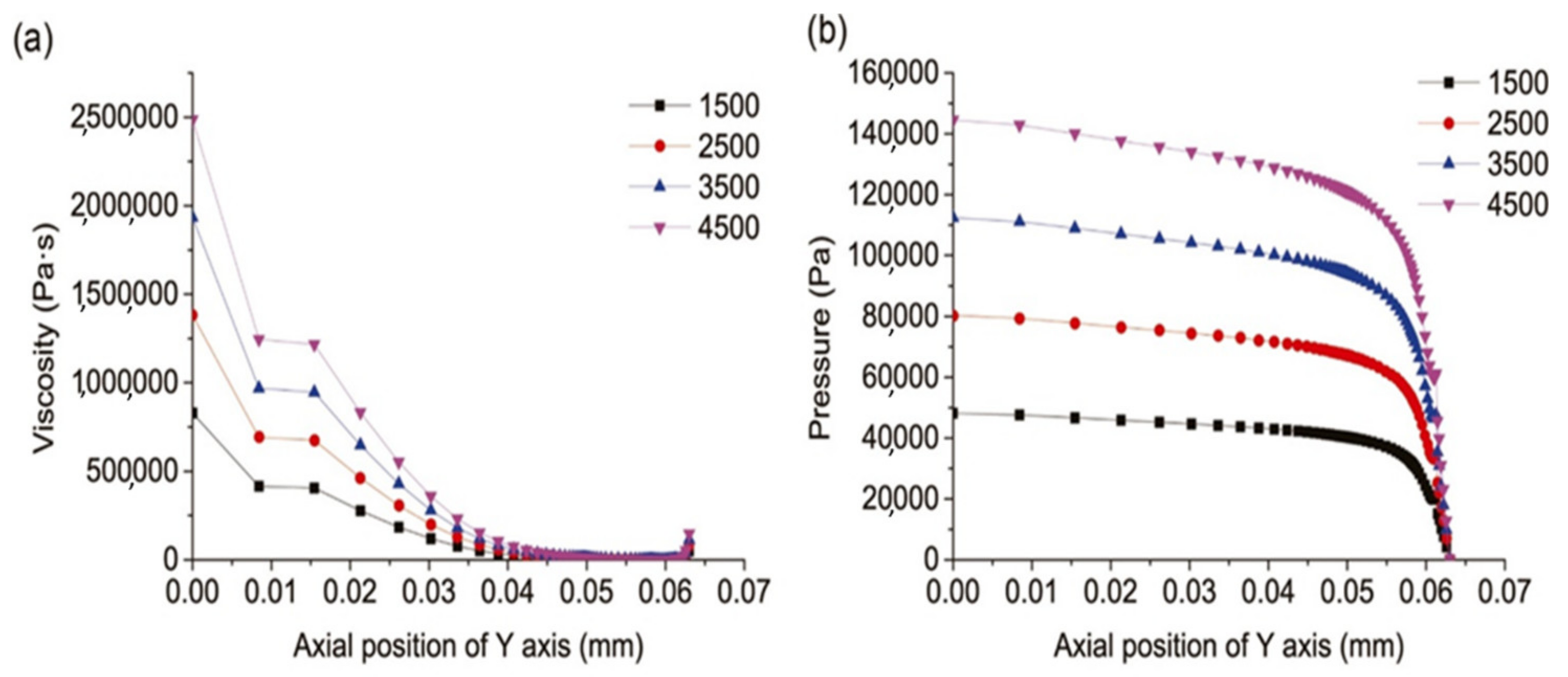

4.1. Thermal Mechanical Behavior in 3D Printed Food Material

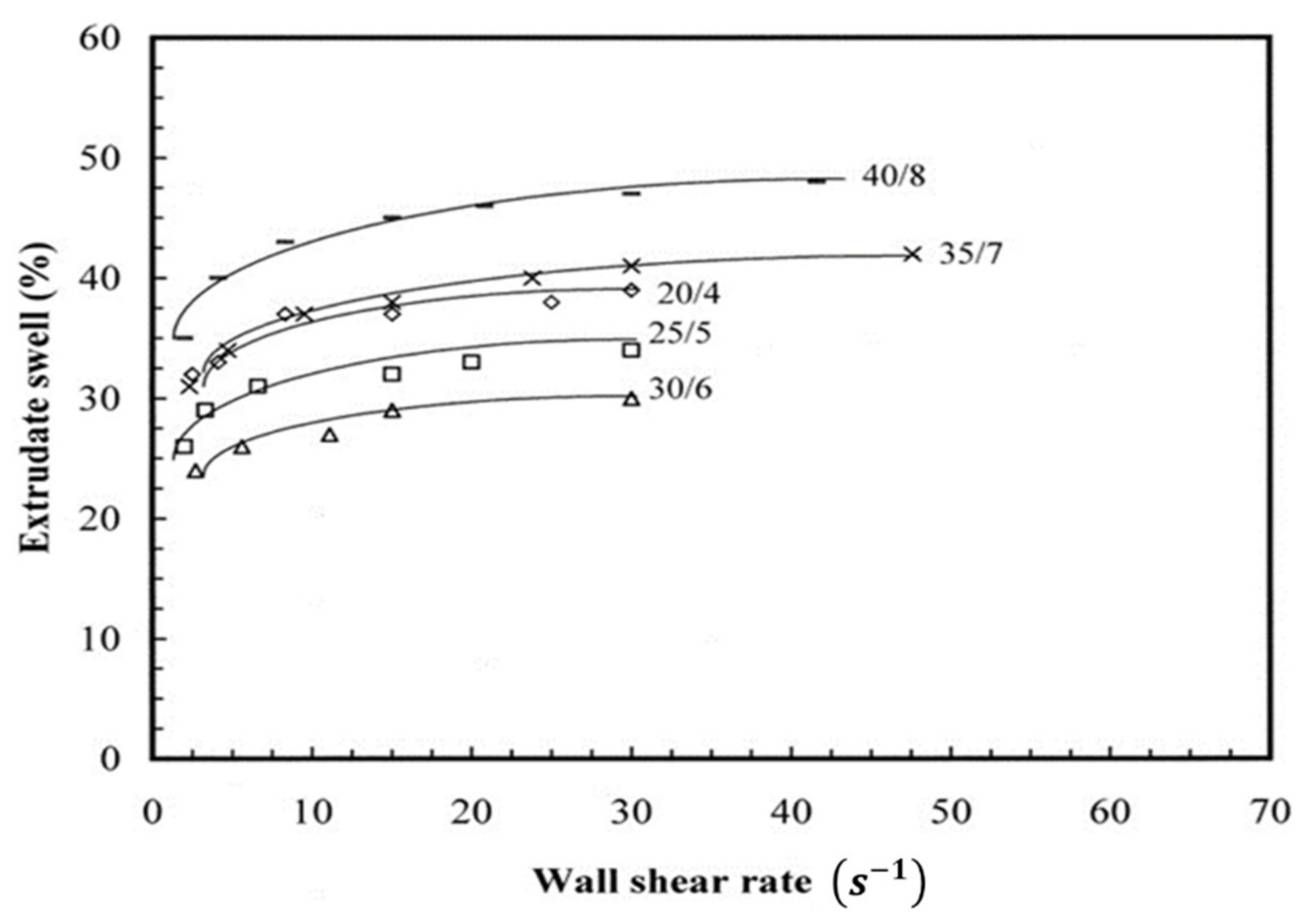

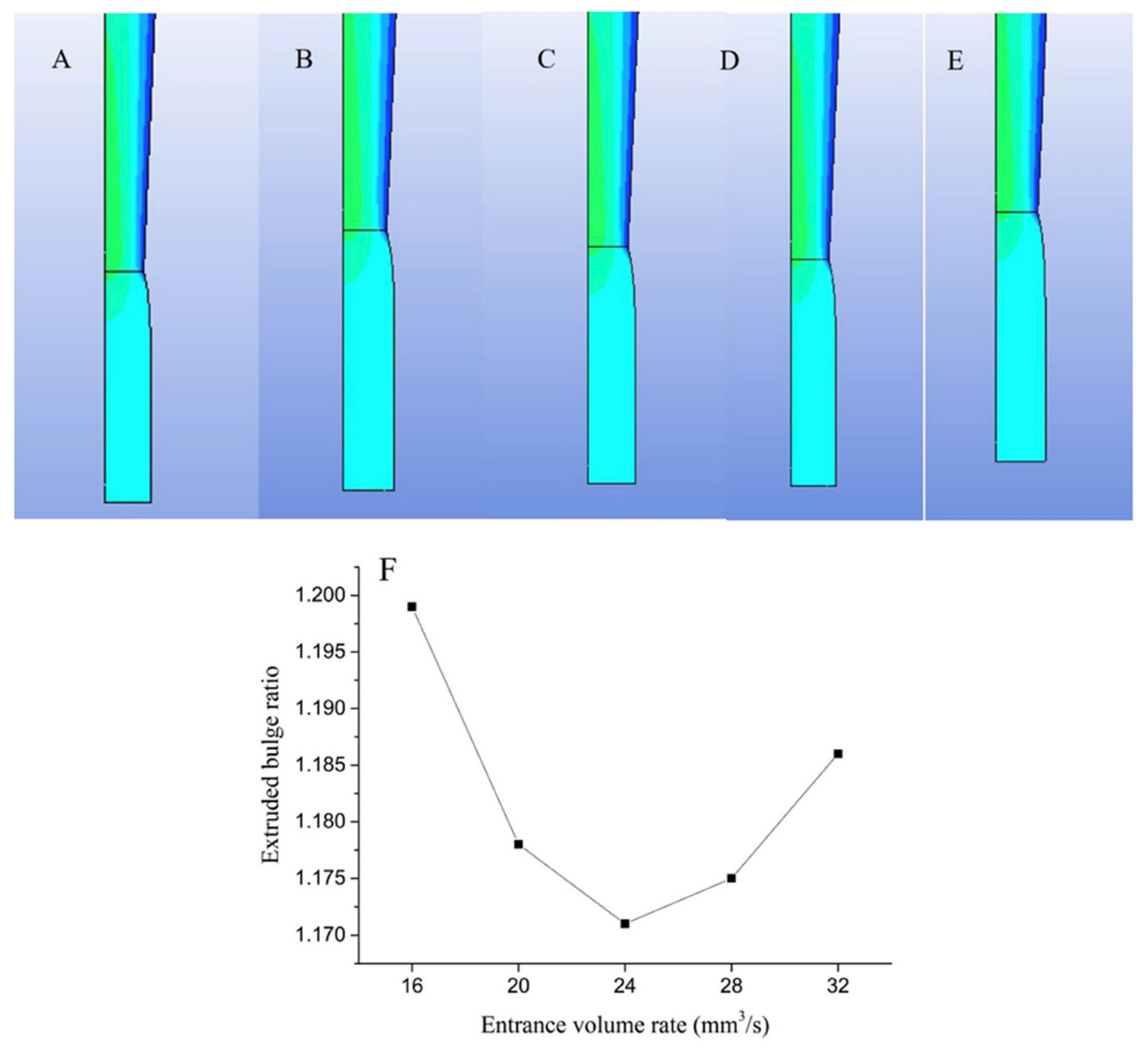

4.2. Die Swell Effect in the 3D Food Printing Process

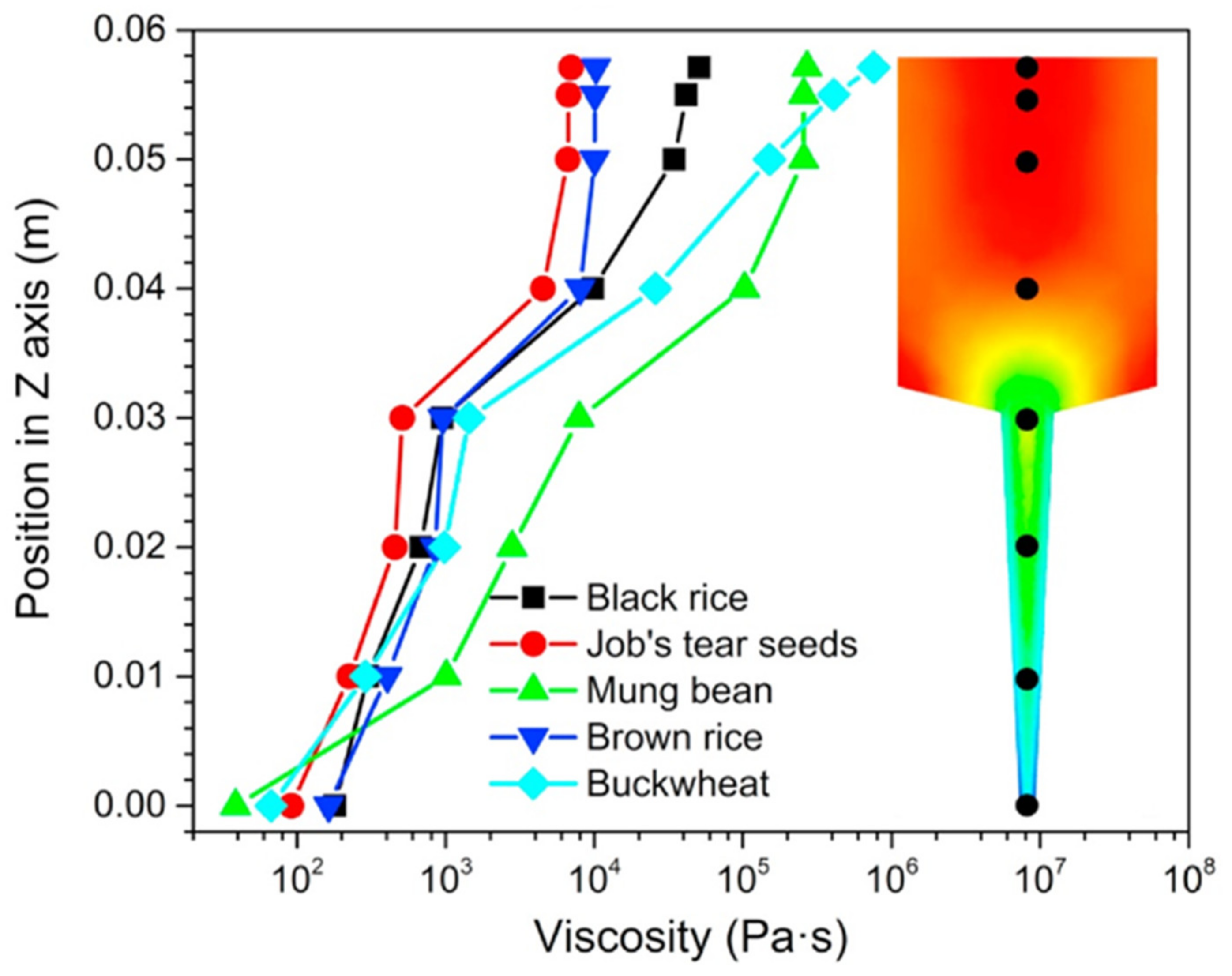

4.3. Assessment of Printing Quality with CFD

5. Challenging Issues Confronting the Application of CFD in 3DP and Possible Solutions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, F.; Guo, C.; Zhang, M.; Bhandari, B.; Liu, Y. Improving 3D printing process of lemon juice gel based on fluid flow numerical simulation. LWT-Food Sci. Technol. 2019, 102, 89–99. [Google Scholar] [CrossRef]

- Malone, E.; Lipson, H. Fab@Home: The Personal Desktop Fabricator Kit. Rapid Prototyp. J. 2007, 13, 245–255. [Google Scholar] [CrossRef]

- Periard, D.; Malone, E.; Lipson, H. Printing Embedded Circuits. Proceedings of the 2007 International Solid Freeform Fabrication Symposium. 2007. Available online: http://utw10945.utweb.utexas.edu/Manuscripts/2007/2007-43-Periard.pdf (accessed on 23 September 2021). [CrossRef]

- Lacerda, R.A.; Burgatti, J.C. Automatic Moulding Chocolate Depositing Line, Chocolate Depositing Machine. Rev. Da Esc. De Enferm. Da USP 2009, 43, 237–244. [Google Scholar] [CrossRef]

- Li, P.; Mellor, S.; Griffin, J.; Waelde, C.; Hao, L.; Everson, R. Intellectual property and 3D printing: A case study on 3D chocolate printing. J. Intellect. Prop. Law Pract. 2014, 9, 322–332. [Google Scholar] [CrossRef]

- Løland, G. Wiibooxsweetin High Accuracy Touch Panel China Impresora 3D for DIY Chocolate Printing. Ph.D. Thesis, Norwegian University of Science and Technology (NTNU), Trondheim, Norway, 1991. [Google Scholar]

- Dick, A.; Bhandari, B.; Prakash, S. 3D printing of meat. Meat Sci. 2019, 153, 35–44. [Google Scholar] [CrossRef] [PubMed]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Oyinloye, T.M.; Yoon, W.B. Stability of 3D printing using a mixture of pea protein and alginate: Precision and application of additive layer manufacturing simulation approach for stress distribution. J. Food Eng. 2021, 288, 110127. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Bhandari, B.; Liu, Y. Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT-Food Sci. Technol. 2018, 87, 67–76. [Google Scholar] [CrossRef]

- Zhang, S.; Vijayavenkataraman, S.; Lu, W.F.; Fuh, J.Y. A review on the use of computational methods to characterize, design, and optimize tissue engineering scaffolds, with a potential in 3D printing fabrication. J. Biomed. Mater. Res. Part B Appl. Biomater. 2019, 107, 1329–1351. [Google Scholar] [CrossRef]

- Duggleby, A.; Ball, K.; Sewall, E. Computational Fluid Dynamics (CFD) Coprocessor-Enhanced System and Method. U.S. Patent 20070219766 A1, 20 September 2007. [Google Scholar]

- Emin, M.A.; Schuchmann, H.P. Analysis of the dispersive mixing efficiency in a twin-screw extrusion processing of starch based matrix. J. Food Eng. 2013, 115, 132–143. [Google Scholar] [CrossRef]

- Emin, M.A.; Köhler, K.; Schlender, M.; Schuchmann, H.P. Characterization of Mixing in Food Extrusion and Emulsification Processes by Using CFD. In High Performance Computing in Science and Engineering ’10; Springer: Berlin/Heidelberg, Germany, 2011; pp. 443–462. [Google Scholar] [CrossRef]

- Xia, B.; Sun, D.W. Applications of computational fluid dynamics (CFD) in the food industry: A review. Comput. Electron. Agric. 2002, 34, 5–24. [Google Scholar] [CrossRef]

- Schaldach, G.; Berger, L.; Razilov, I.; Berndt, H. Computer Simulation for Fundamental Studies and Optimisation of ICP Spray Chambers; Current Research Reports; Institute of Spectrochemistry and Applied Spectroscopy: Berlin, Germany, 2000. [Google Scholar]

- Kuriakose, R.; Anandharamakrishnan, C. Computational fluid dynamics (CFD) applications in spray drying of food products. Trends Food Sci. Technol. 2010, 21, 383–398. [Google Scholar] [CrossRef]

- Smale, N.J.; Moureh, J.; Cortella, G. A review of numerical models of airflow in refrigerated food applications. Int. J. Refrig. 2006, 29, 911–930. [Google Scholar] [CrossRef]

- Holbrook, T.R.; Osborn, L.S. Digital patent infringement in an era of 3D printing. Univ. Campbell Davis Law Rev. 2014, 48, 1319. [Google Scholar] [CrossRef]

- Tabrizi, A.S.; Asadi, M.; Xie, G.; Lorenzini, G.; Biserni, C. Computational fluid-dynamics-based analysis of a ball valve performance in the presence of cavitation. J. Eng. Thermophys. 2014, 23, 27–38. [Google Scholar] [CrossRef]

- Guo, C.F.; Zhang, M.; Bhandari, B. A comparative study between syringe-based and screw-based 3D food printers by computational simulation. Comput. Electron. Agric. 2019, 162, 397–404. [Google Scholar] [CrossRef]

- Woodfield, T.B.; Malda, J.; De Wijn, J.; Peters, F.; Riesle, J.; van Blitterswijk, C.A. Design of porous scaffolds for cartilage tissue engineering using a three-dimensional fiber-deposition technique. Biomaterials 2004, 25, 4149–4161. [Google Scholar] [CrossRef]

- Li, M.G.; Tian, X.Y.; Chen, X.B. Modeling of flow rate, pore size, and porosity for the dispensing-based tissue scaffolds fabrication. J. Manuf. Sci. Eng. 2009, 131, 034501. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: I. Drying kinetics and product recovery. Dry. Technol. 2008, 26, 714–725. [Google Scholar] [CrossRef]

- Malekjani, N.; Jafari, S.M. Simulation of food drying processes by Computational Fluid Dynamics (CFD); recent advances and approaches. Trends Food Sci. Technol. 2018, 78, 206–223. [Google Scholar] [CrossRef]

- Moraga, N.O.; Rivera, D.R. Advantages in predicting conjugate freezing of meat in a domestic freezer by CFD with turbulence k-ɛ 3D model and a local exergy destruction analysis. Int. J. Refrig. 2021, 126, 76–87. [Google Scholar] [CrossRef]

- Norton, T.; Sun, D.W. Computational fluid dynamics (CFD)—An effective and efficient design and analysis tool for the food industry: A review. Trends Food Sci. Technol. 2006, 17, 600–620. [Google Scholar] [CrossRef]

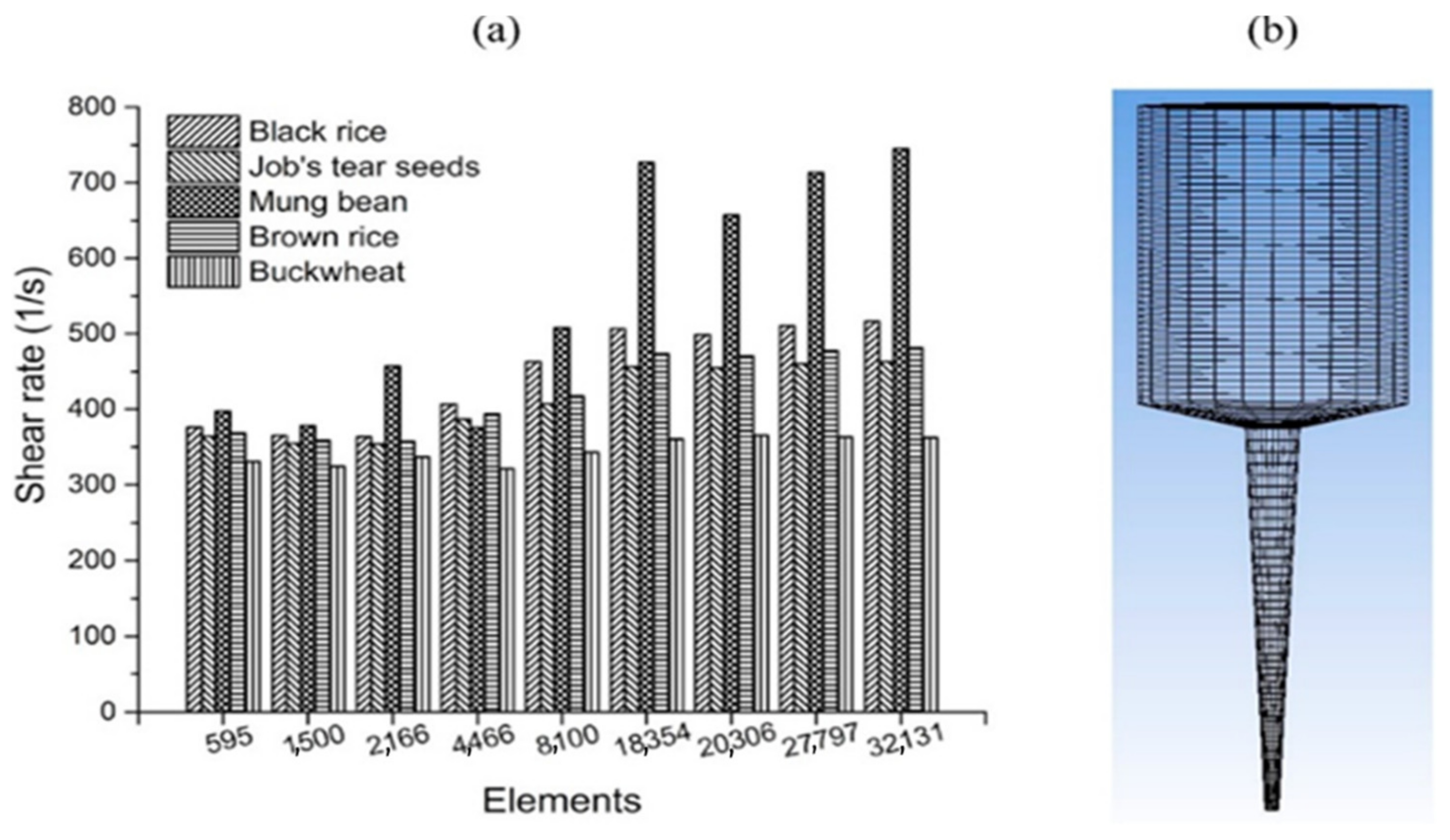

- Guo, C.; Zhang, M.; Devahastin, S. 3D extrusion-based printability evaluation of selected cereal grains by computational fluid dynamic simulation. J. Food Eng. 2020, 286, 110113. [Google Scholar] [CrossRef]

- Singh, S.K.; Muthukumarappan, K. Rheological characterization and CFD simulation of soy white flakes based dough in a single screw extruder. J. Food Process Eng. 2017, 40, e12368. [Google Scholar] [CrossRef]

- Singh, S.K.; Muthukumarappan, K. Effect of feed moisture, extrusion temperature and screw speed on properties of soy white flakes based aquafeed: A response surface analysis. J. Sci. Food Agric. 2016, 96, 2220–2229. [Google Scholar] [CrossRef]

- Euler, L.J. Principia Motus Fluidorum. In Novi Commentarii Academiae Scientiarum Petropolitanae; University of the Pacific, William Knox Holt Memorial Library: Stockton, CA, USA, 1761; pp. 271–311. [Google Scholar]

- Navier, C.L.M.H. Mémoire sur les lois du mouvement des fluides. Mém. Acad. R. Sci. Inst. Fr. 1823, 6, 389–440. [Google Scholar]

- Stokes, G.G. On the Effect of the Internal Friction of Fluids on the Motion of Pendulums. 1851. Available online: https://theindex.nawcc.org/Articles/Stokes-InternalFriction.pdf (accessed on 23 September 2021).

- Ferziger, J.H.; Perić, M.; Street, R.L. Computational Methods for Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2002; Volume 3. [Google Scholar] [CrossRef]

- Ghani, A.A.; Farid, M.M.; Chen, X.D.; Richards, P. Numerical simulation of natural convection heating of canned food by computational fluid dynamics. J. Food Eng. 1999, 41, 55–64. [Google Scholar] [CrossRef]

- Norton, T.; Sun, D.W.; Grant, J.; Fallon, R.; Dodd, V. Applications of computational fluid dynamics (CFD) in the modelling and design of ventilation systems in the agricultural industry: A review. Bioresour. Technol. 2007, 98, 2386–2414. [Google Scholar] [CrossRef] [PubMed]

- Defraeye, T.J. Advanced computational modelling for drying processes–A review. Appl. Energy 2014, 131, 323–344. [Google Scholar] [CrossRef]

- Alaluss, K.; Mayr, P. Additive Manufacturing of complex components through 3D plasma metal deposition—A simulative approach. Metals 2019, 9, 574. [Google Scholar] [CrossRef]

- Gheorghe, G.I. Proceedings of the International Conference of Mechatronics and Cyber-MixMechatronics; Springer: Berlin/Heidelberg, Germany, 2019; Volume 85. [Google Scholar]

- Peiró, J.; Sherwin, S. Finite Difference, Finite Element and Finite Volume Methods for Partial Differential Equations. In Handbook of Materials Modeling; Springer: Berlin/Heidelberg, Germany, 2005; pp. 2415–2446. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Pearson Education: London, UK, 2007. [Google Scholar]

- Katz, A.; Sankaran, V. Mesh quality effects on the accuracy of CFD solutions on unstructured meshes. J. Comput. Phys. 2011, 230, 7670–7686. [Google Scholar] [CrossRef]

- Opara, U.L.; Ambaw, A.; Berry, T. CFD Investigation of Fresh Produce Cooling Processes and Effects of Package Stacking. In Computational Fluid Dynamics in Food Processing; CRC Press: Boca Raton, FL, USA, 2018; pp. 121–148. [Google Scholar]

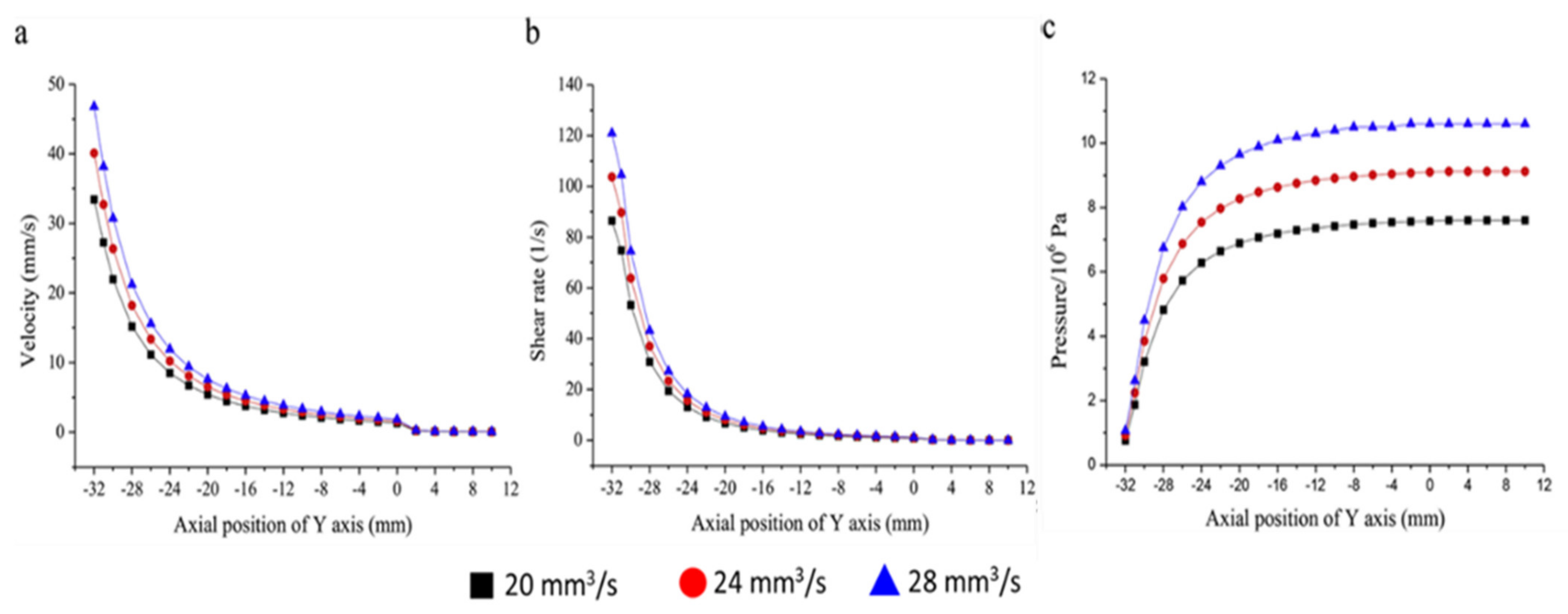

- Liu, Q.; Zhang, N.; Wei, W.; Hu, X.; Tan, Y.; Yu, Y.; Deng, Y.; Bi, C.; Zhang, L.; Zhang, H. Assessing the dynamic extrusion-based 3D printing process for power-law fluid using numerical simulation. J. Food Eng. 2020, 275, 109861. [Google Scholar] [CrossRef]

- Cilliers, J. Optimising small hydrocyclone design using 3D printing and CFD simulations. Chem. Eng. J. 2018, 350, 653–659. [Google Scholar] [CrossRef]

- Shahriar, B.B.; Arthur, C.; France, C.; Valérie, N. Influence of Parameters Controlling the Extrusion Step in Fused Filament Fabrication (FFF) Process Applied to Polymers Using Numerical Simulation. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018. [Google Scholar] [CrossRef]

- Lanaro, M.; Forrestal, D.P.; Scheurer, S.; Slinger, D.J.; Liao, S.; Powell, S.K.; Woodruff, M.A. 3D printing complex chocolate objects: Platform design, optimization and evaluation. J. Food Eng. 2017, 215, 13–22. [Google Scholar] [CrossRef]

- Prabhakara, S.; Deshpande, M.D. The no-slip boundary condition in fluid mechanics. Resonance 2004, 9, 61–71. Available online: https://link.springer.com/content/pdf/10.1007/BF02834016.pdf (accessed on 23 September 2021). [CrossRef]

- Augusto, P.E.D.; Cristianini, M. Evaluation of geometric symmetry condition in numerical simulations of thermal process of packed liquid food by computational fluid dynamics (CFD). Int. J. Food Eng. 2010, 6, 5. [Google Scholar] [CrossRef]

- Vrancken, B. Study of Residual Stresses in Selective Laser Melting, 2016. KU Leuven—Faculty of Engineering Science Web Site. Available online: https://lirias.kuleuven.be/1942277?limo=0 (accessed on 23 September 2021).

- Hopmann, C.; Michaeli, W. Extrusion Dies for Plastics and Rubber: Design and Engineering Computations; Carl Hanser Verlag: Munich, Germany, 2016. [Google Scholar]

- Bellini, A. Fused Deposition of Ceramics: A Comprehensive Experimental, Analytical and Computational Study of Material Behavior, Fabrication Process and Equipment Design; Drexel University: Philadelphia, PA, USA, 2002. [Google Scholar]

- Liang, J.Z. A relationship between extrudate swell ratio and entry stored elastic strain energy during die flow of tyre compounds. Polym. Test. 2004, 23, 441–446. [Google Scholar] [CrossRef]

- Sombatsompop, N.; Dangtangee, R. Effects of the actual diameters and diameter ratios of barrels and dies on the elastic swell and entrance pressure drop of natural rubber in capillary die flow. J. Appl. Polym. Sci. 2002, 86, 1762–1772. [Google Scholar] [CrossRef]

- Müllner, H.W.; Eberhardsteiner, J.; Fidi, W. Rheological characterization of the die swell phenomenon of rubber compounds. Polym. Test. 2007, 26, 1041–1048. [Google Scholar] [CrossRef]

- Aloku, G.O.; Yuan, X.F. Numerical simulation of polymer foaming process in extrusion flow. Chem. Eng. Sci. 2010, 65, 3749–3761. [Google Scholar] [CrossRef]

- Mezi, D.; Ausias, G.; Grohens, Y.; Férec, J. Numerical simulation and modeling of the die swell for fiber suspension flows. J. Non-Newton. Fluid Mech. 2019, 274, 104205. [Google Scholar] [CrossRef]

- Wang, Z.; Smith, D. The Effect of Polymer Melt Rheology on Predicted Die Swell and Fiber Orientation in Fused Filament Fabrication Nozzle Flow. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3d printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef]

- Liu, Z.; Bhandari, B.; Prakash, S.; Zhang, M. Creation of internal structure of mashed potato construct by 3D printing and its textural properties. Food Res. Int. 2018, 111, 534–543. [Google Scholar] [CrossRef]

- Kunii, K.; Ishida, T.; Duguet, Y.; Tsukahara, T. Laminar-turbulent coexistence in annular Couette flow. J. Fluid Mech. 2019, 879, 579–603. [Google Scholar] [CrossRef]

- Fluent, A. Technical Specifications Public Notice; ANSYS, Inc.: Canonsburg, PA, USA, 2009. [Google Scholar]

- D’Agaro, P.; Cortella, G.; Croce, G. Two-and three-dimensional CFD applied to vertical display cabinets simulation. Int. J. Refrig. 2006, 29, 178–190. [Google Scholar] [CrossRef]

- Mirade, P.S.; Rougier, T.; Daudin, J.D.; Picque, D.; Corrieu, G. Effect of design of blowing duct on ventilation homogeneity around cheeses in a ripening chamber. J. Food Eng. 2006, 75, 59–70. [Google Scholar] [CrossRef]

- Sarghini, F. Analysis and Simulation of Pasta Dough Extrusion Process by CFD. In Computational Fluid Dynamics in Food Processing; CRC Press: Boca Raton, FL, USA, 2018; pp. 463–486. [Google Scholar]

- Mohammadi, B.; Pironneau, O. Shape optimization in fluid mechanics. Annu. Rev. Fluid Mech. 2004, 36, 255–279. [Google Scholar] [CrossRef]

- Bertrand, F.; Leclaire, L.A.; Levecque, G. DEM-based models for the mixing of granular materials. Chem. Eng. Sci. 2005, 60, 2517–2531. [Google Scholar] [CrossRef]

- Li, M.; White, G.; Wilkinson, D.; Roberts, K.J. Scale up study of retreat curve impeller stirred tanks using LDA measurements and CFD simulation. Chem. Eng. J. 2005, 108, 81–90. [Google Scholar] [CrossRef]

- Fitzpatrick, J.J.; Ahrné, L. Food powder handling and processing: Industry problems, knowledge barriers and research opportunities. Chem. Eng. Process. Process. Intensif. 2005, 44, 209–214. [Google Scholar] [CrossRef]

| Application | Software Code | Aim | Time-Dependent State | Author |

|---|---|---|---|---|

| 3D printing of alginate and pea protein gel | ANSYS Discovery AIM | To predict the residual stress, total deformation, and printing precision requirement. | Transient | [9] |

| 3D printing of cereal grains. | ANSYS POLYFLOW | To investigate the use of cereal grains as alternative printing material. | Transient | [28] |

| 3D printing of lemon juice gel | ANSYS POLYFLOW | Evaluation of the fluid characteristics of lemon juice gel in the 3D printer flow channel. | Steady | [1] |

| Comparative study of a syringe and screw-based 3D food printer | COMSOL Multiphysics | Developing CFD models to investigate and compare the flow field characteristic of two 3D extrusion-based printing units (syringe and Screw based printing). | Transient | [21] |

| Soy white flakes based dough in a single screw extruder | ANSYS POLYFLOW | To characterize the rheological properties of soy white flakes-based dough in a single screw extruder and analyze the flow behavior in the high shear rate zone extruder. | Transient | [29] |

| Extrusion process of soy white flakes | Design Expert | To analyze the extrusion process of Jatropha seeds by a single screw extruder. | Steady | [30] |

| 3D deposition of porous scaffolds for cartilage tissue engineering | To establish the flow of biomaterials through the nozzle. | [22] | ||

| Mixing in food extrusion | ANSYS POLYFLOW and ANSYS Fluent | To characterize the dispersive mixing of oil in the plasticized starch matrix within a twin-screw extruder. | Transient | [14] |

| Sample | Model Geometry | Numerical Technique | Meshing | Software | References |

|---|---|---|---|---|---|

| Cereal paste | Fluid domain in a 3D printer syringe and nozzle | FEM | Hexahedral cell, structured grid | ANSYS Polyflow | [28] |

| Lemon juice |

| FEM | Hexahedral cell, structured grid | ANSYS Polyflow | [1] |

| Potato flakes |

| FEM | COMSOL Multiphysics | [21] | |

| Wheat flour | Fluid in syringe and nozzle | FEM | Hexahedral cell, structured grid | ANSYS Polyflow | [44] |

| Yeast | Fluid domain in hydrocyclone | FEM | Polyhedral cell, unstructured grid | ANSYS Fluent | [45] |

| Alginate and pea protein | Extruded paste domain | FEM | Hexahedral cell, structured grid | ANSYS Discovery AIM | [9] |

| Polymer | Extrudate flow | FEM | Tetrahedral cell, unstructured grid | COMSOL Multiphysics | [46] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oyinloye, T.M.; Yoon, W.B. Application of Computational Fluid Dynamics (CFD) Simulation for the Effective Design of Food 3D Printing (A Review). Processes 2021, 9, 1867. https://doi.org/10.3390/pr9111867

Oyinloye TM, Yoon WB. Application of Computational Fluid Dynamics (CFD) Simulation for the Effective Design of Food 3D Printing (A Review). Processes. 2021; 9(11):1867. https://doi.org/10.3390/pr9111867

Chicago/Turabian StyleOyinloye, Timilehin Martins, and Won Byong Yoon. 2021. "Application of Computational Fluid Dynamics (CFD) Simulation for the Effective Design of Food 3D Printing (A Review)" Processes 9, no. 11: 1867. https://doi.org/10.3390/pr9111867

APA StyleOyinloye, T. M., & Yoon, W. B. (2021). Application of Computational Fluid Dynamics (CFD) Simulation for the Effective Design of Food 3D Printing (A Review). Processes, 9(11), 1867. https://doi.org/10.3390/pr9111867