Biomethanation Potential (BMP) Study of Mesophilic Anaerobic Co-Digestion of Abundant Bio-Wastes in Southern Regions of Tunisia

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrates

2.2. Experimental Conditions

2.2.1. Inoculums

2.2.2. Inoculums to Substrate Ratio (ISR)

2.2.3. Carbon to Nitrogen Ratio (C/N)

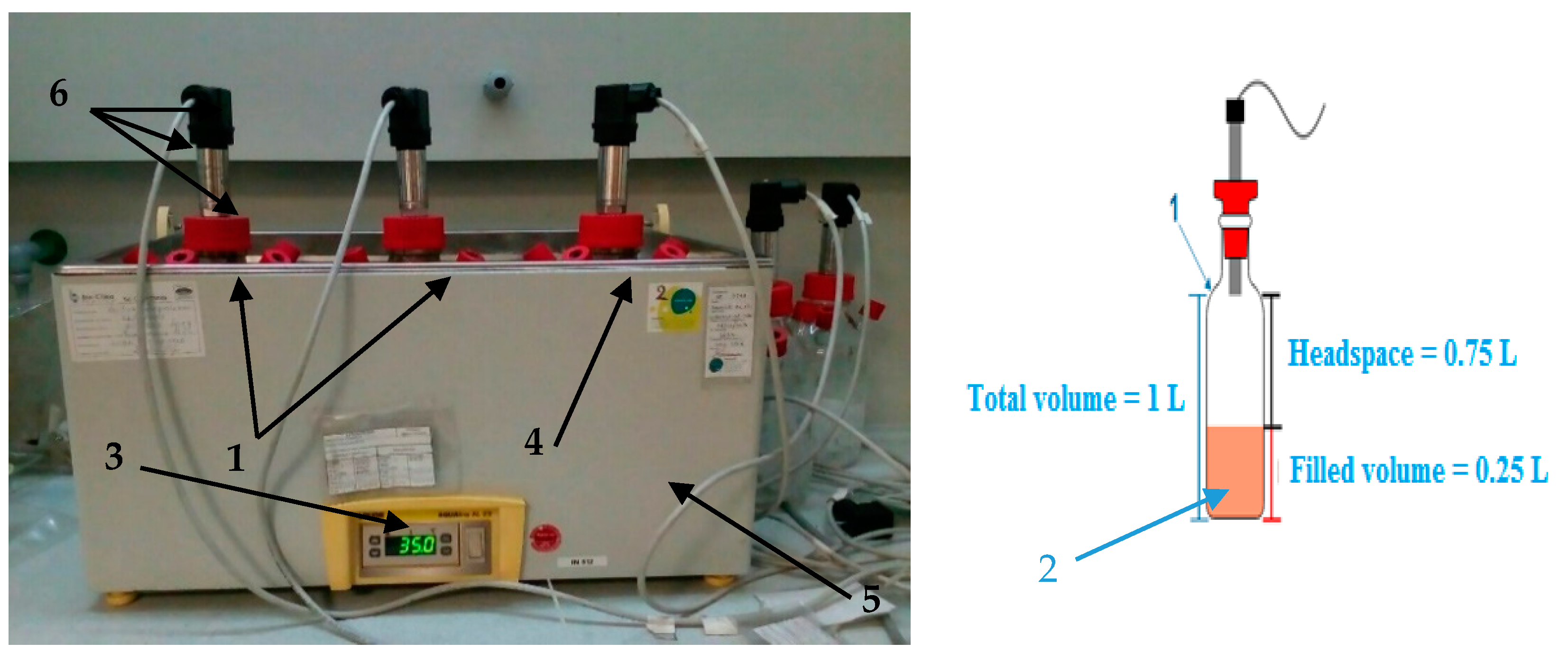

2.3. BMP Test Materials

2.4. Analytical Procedures

2.5. Experimental Procedure

2.6. Mathematical Equations

3. Results and Discussion

3.1. Physicochemical Characterization

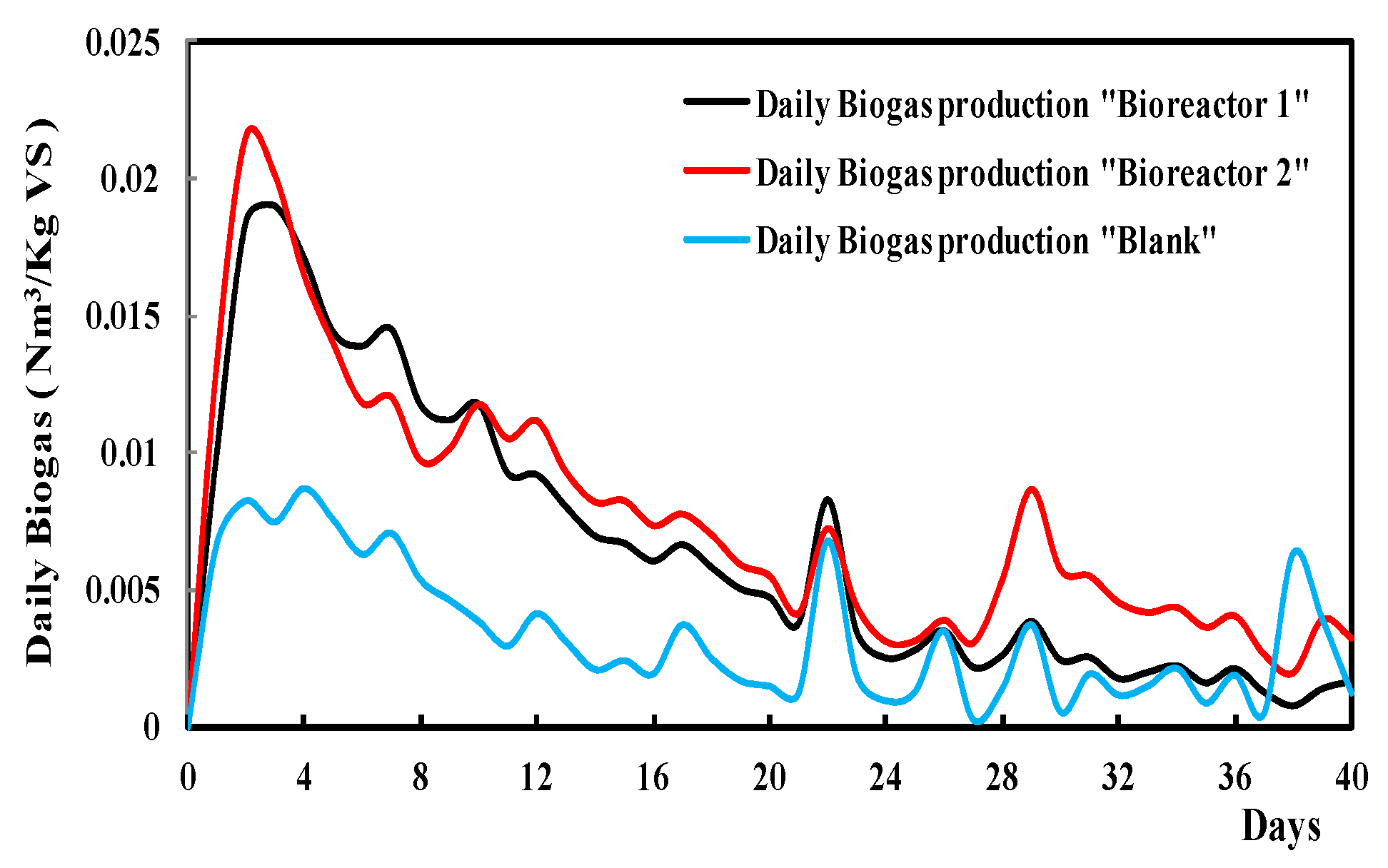

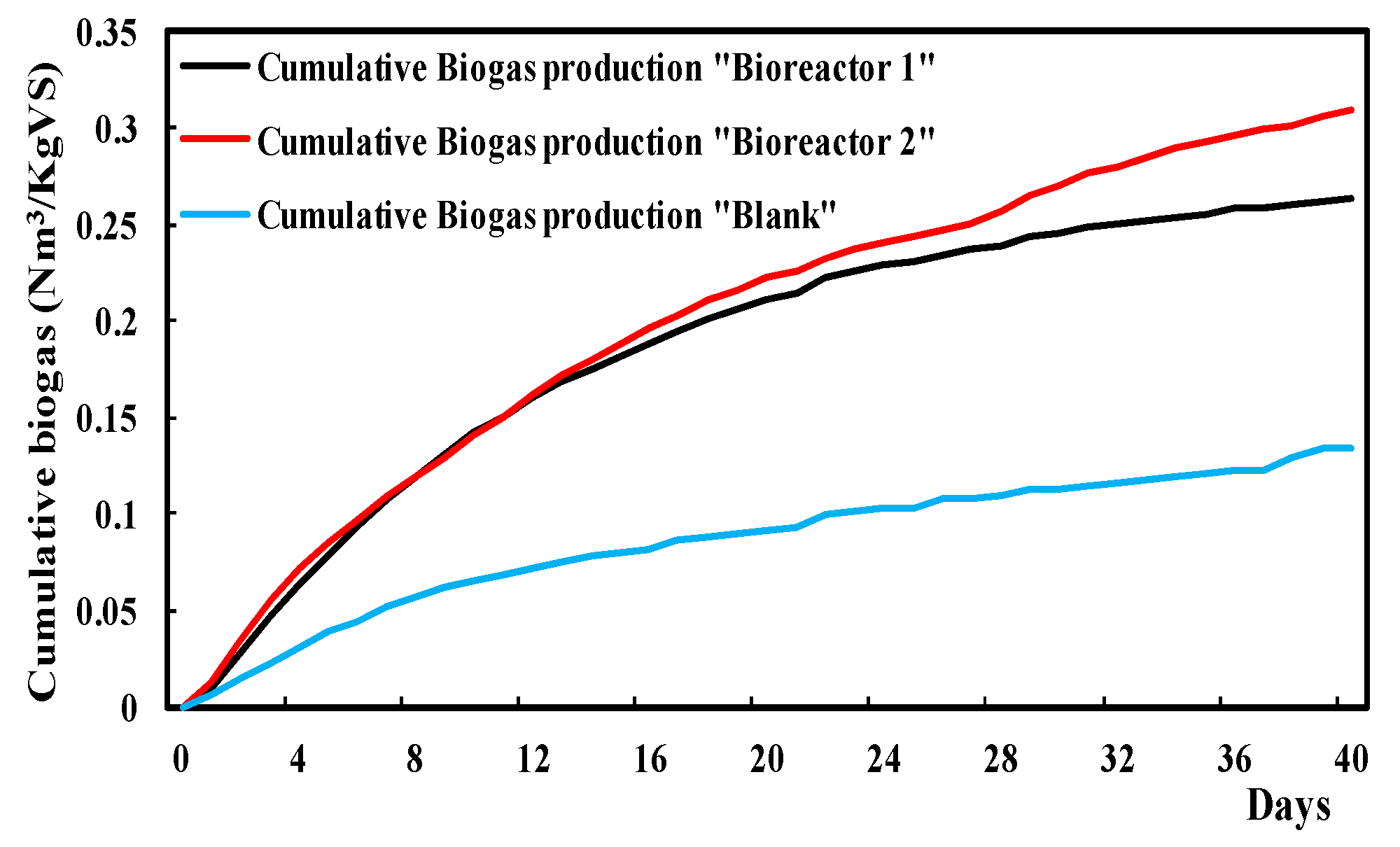

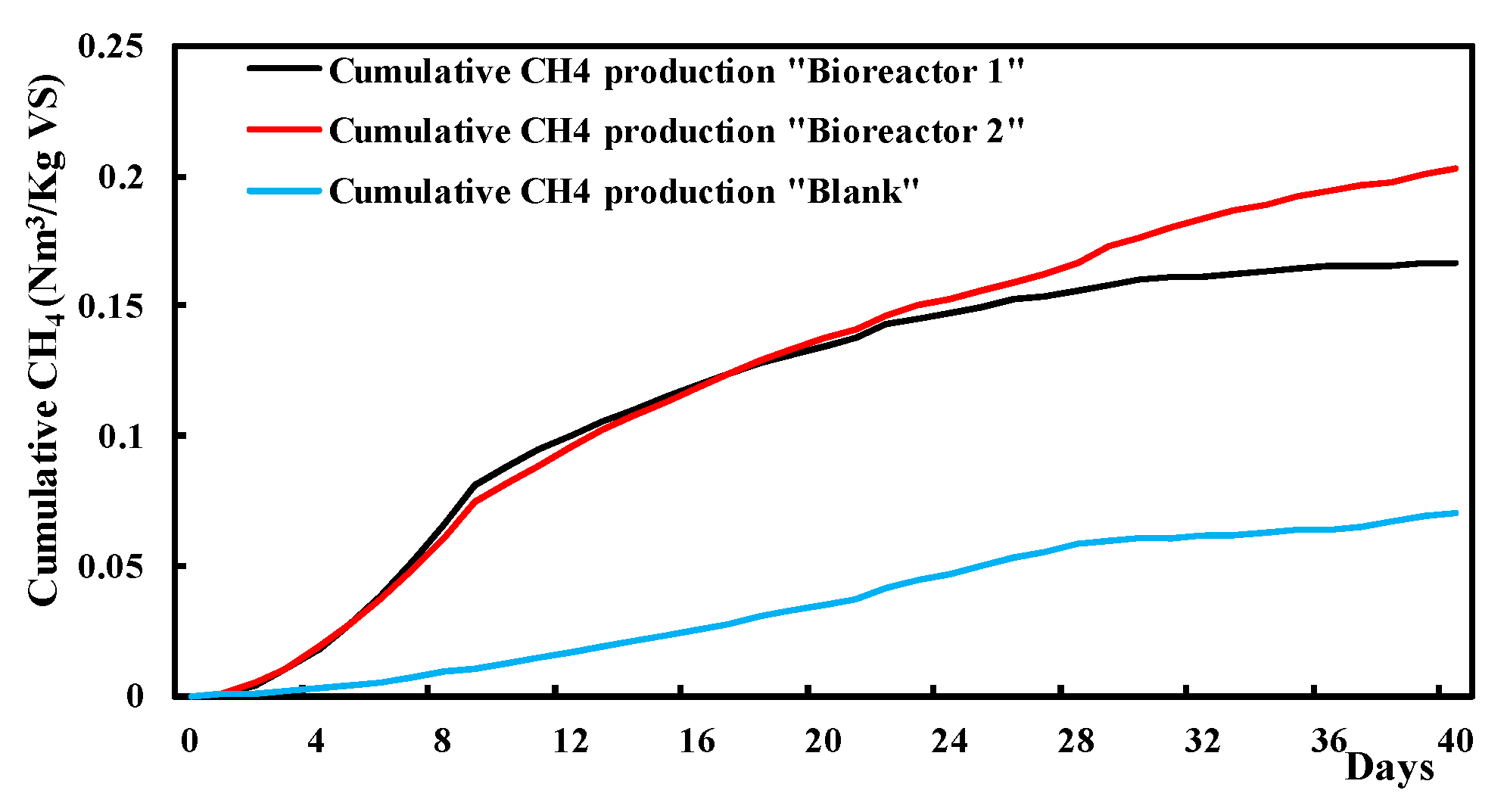

3.2. Biogas and Bio-Methane Production

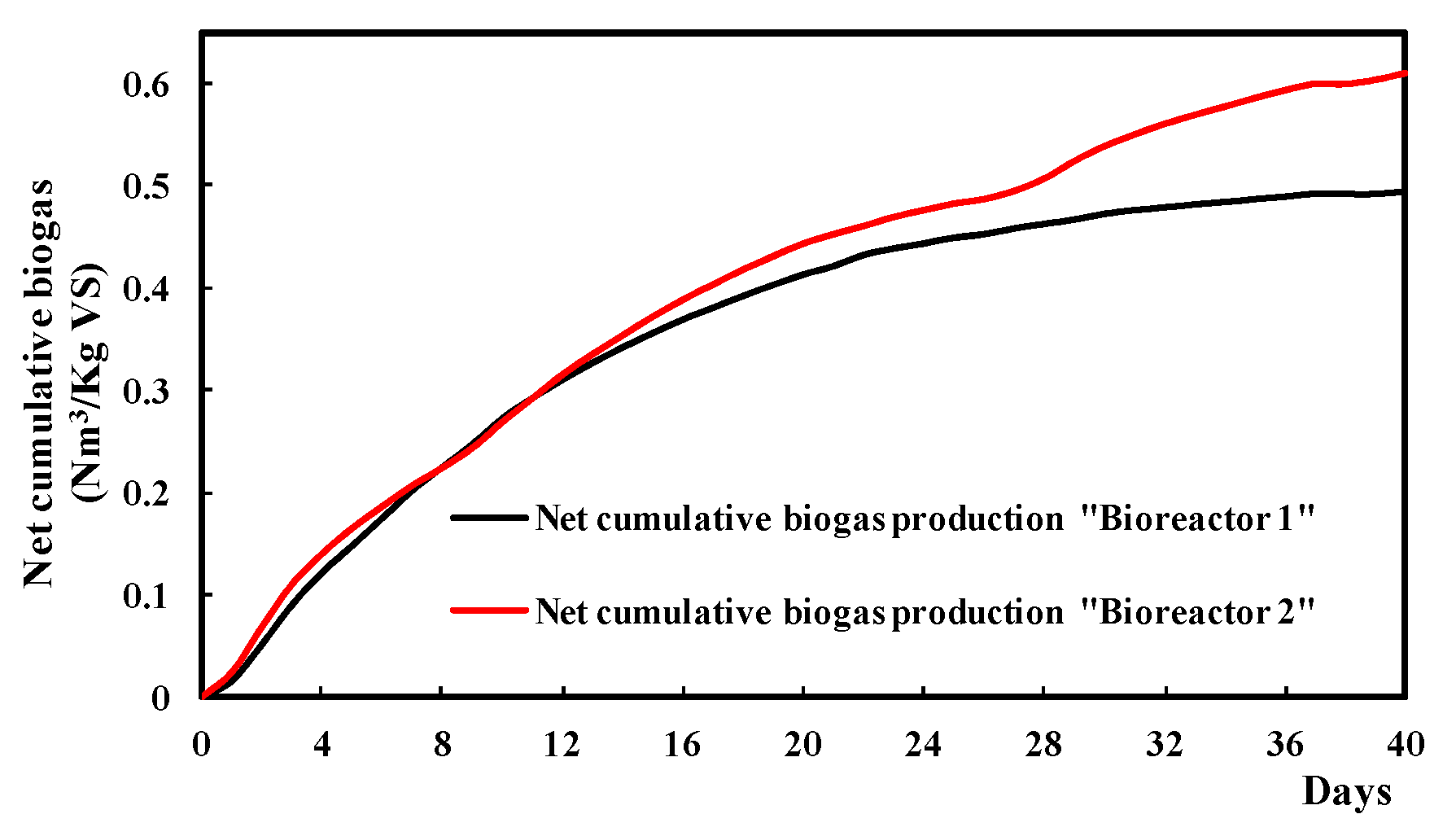

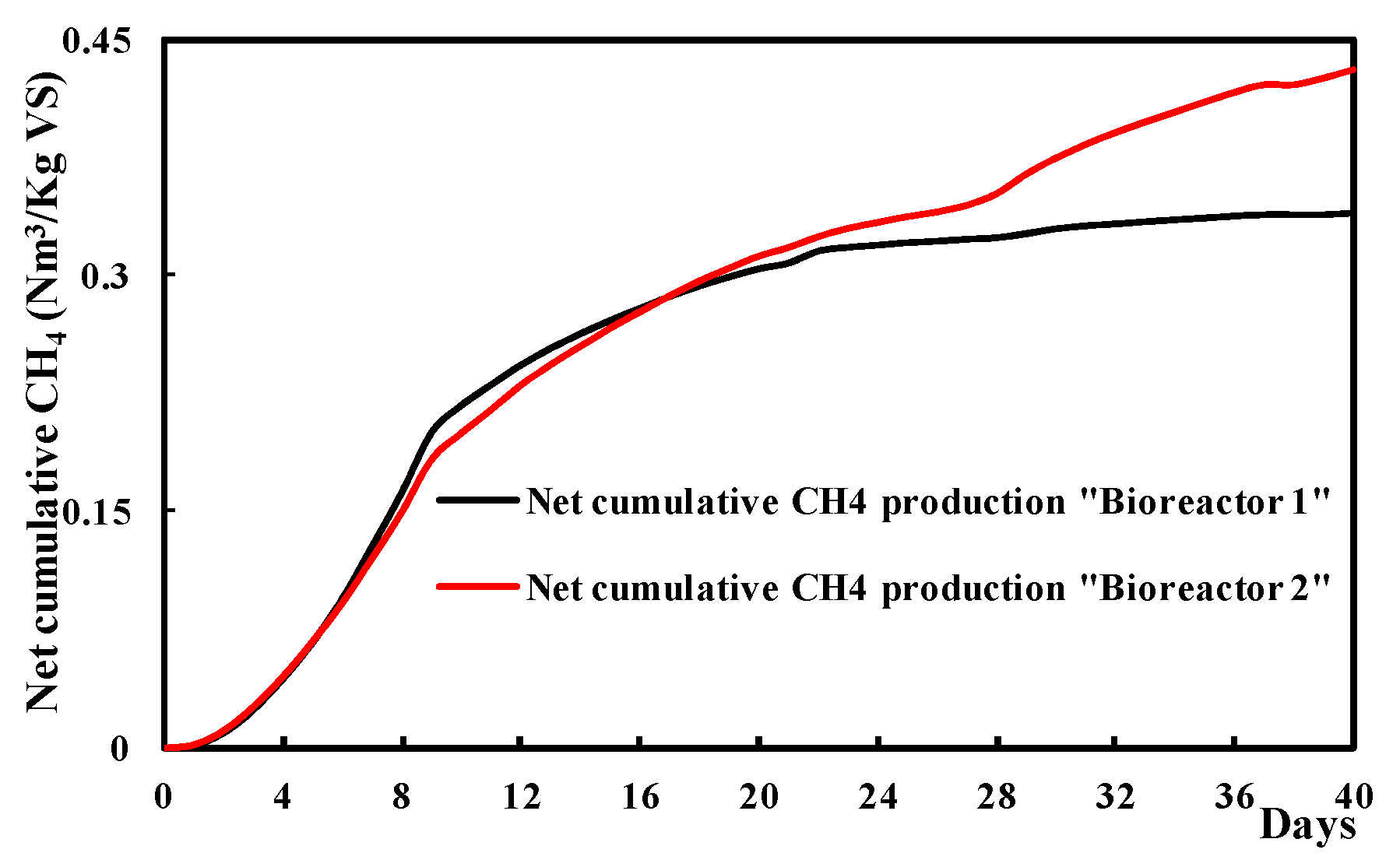

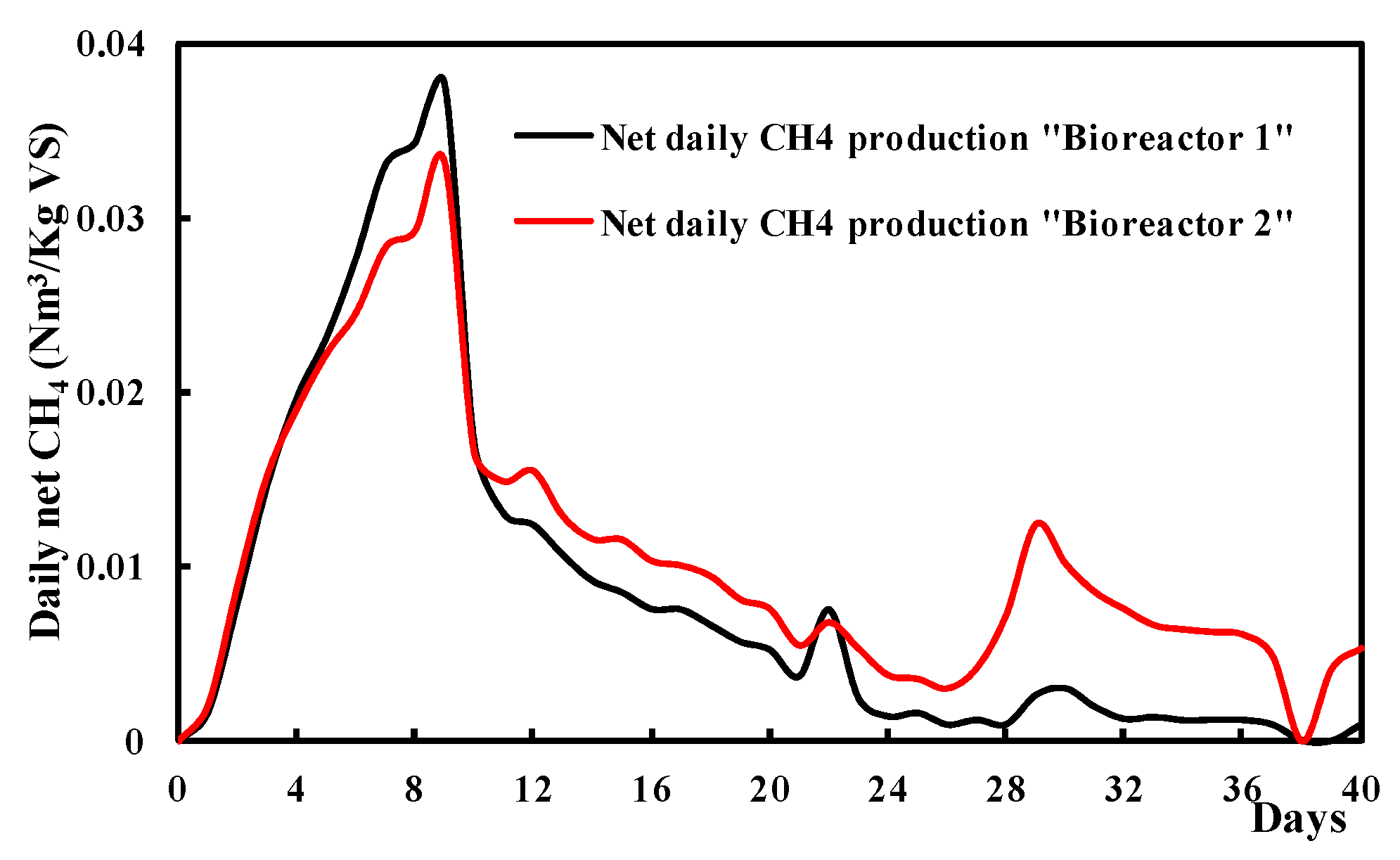

3.3. Net Production of Biogas and Bio-Methane

3.4. VS Reduction during the Anaerobic Digestion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AD | Anaerobic digestion |

| ANGeD | National waste management agency |

| BMP | Bio-methanation potential test |

| CW | Chicken wastes or chicken dropping |

| (C/N)mix | Carbon to nitrogen ratio of the mixture of the used bio-wastes |

| HRT | Hydraulic retention times |

| i | Bio-waste type |

| mi | Mass of the substrate i (in g) |

| minoculums | Mass of the inoculums (in g) |

| OFMSW | Organic fraction of municipal solid wastes |

| OMWW | Olive mill wastewater |

| OLRs | Organic loading rates |

| P0 | Normal pressure (1 atm) |

| Pmes | Measured gas pressure before the gas sampling (in bar), |

| Q | Cumulative production of biogas/biomethane (in Nm3) |

| qjnet | Net produced quantity of biogas/biomethane during day j (in Nm3) |

| qjbioreactor (1 or 2) | Produced quantity of biogas/biomethane in bioreactor 1 or 2 during day (j) |

| qjinoculums | Produced quantity of biogas/biomethane in the blank during day (j) |

| Qnet | Net cumulative production of biogas/biomethane (in Nm3) |

| (S/I) | Ratio between the (VS) of the substrate and the (VS) of the inoculums |

| Tr | Bioreactor temperature (in K) |

| T0 | Normal temperature (273.15 K) |

| VFA | Volatile fatty acids |

| (VS) | Volatile solids |

| VS | Used mass in the bottles and/or in the inoculums |

| (VS)substrate | Volatile solid of the substrates |

| (VS)inoculums | Volatile solid of the inoculums |

| (VS)global mixture | Volatile solid of the global mixture |

| (VS)i | Used mass of the VS for the substrate i |

| Vnetj | Daily biogas production (in(Nm3) |

| (VS)0 | Used initial mass of (VS) of the used substrates. |

| Vbiogas | Daily biogas production volume (in NL) |

| Vr | Headspace volume of the bioreactor |

| xi = ((Mi/mmix) × 100) | Mass percentage of the substrate i in the mass of the mixture |

| Percent of (VS) in the substrate i | |

| Percentage of the (VS) in the inoculums | |

| Y | Specific yield of biogas/biomethane (in Nm3/Kg VS) |

| Ynet | Specific net potential value of biogas/biomethane (in Nm3/kg VS) |

References

- Araujo, V.K.A.; de Almeida, S.; de Oliveira, S.B.; Calixto, W.P.; Furriel, G.P.; Barbosa, D.P. Anaerobic Digestion Using Residue of Soybean Processing: Biogas Production and It Is Potential to Generate Energy. In Proceedings of the 2017 18th International Scientific Conference on Electric Power Engineering (EPE), Kouty nad Desnou, Czech Republic, 17–19 May 2017; IEEE: Kouty nad Desnou, Czech Republic, 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Achinas, S.; Achinas, V.; Euverink, G.J.W. A Technological Overview of Biogas Production from Biowaste. Engineering 2017, 3, 299–307. [Google Scholar] [CrossRef]

- Amon, T.; Amon, B.; Kryvoruchko, V.; Machmüller, A.; Hopfner-Sixt, K.; Bodiroza, V.; Hrbek, R.; Friedel, J.; Pötsch, E.; Wagentristl, H.; et al. Methane Production through Anaerobic Digestion of Various Energy Crops Grown in Sustainable Crop Rotations. Bioresour. Technol. 2007, 98, 3204–3212. [Google Scholar] [CrossRef] [PubMed]

- Khan, I.U. Biogas as a Renewable Energy Fuel—A Review of Biogas Upgrading, Utilisation and Storage. Energy Convers. Manag. 2017, 150, 277–294. [Google Scholar] [CrossRef]

- Barragán-Escandón, A.; Ruiz, J.M.O.; Tigre, J.D.C.; Zalamea-León, E.F. Assessment of Power Generation Using Biogas from Landfills in an Equatorial Tropical Context. Sustainability 2020, 12, 2669. [Google Scholar] [CrossRef] [Green Version]

- Kaparaju, P.; Rintala, J. Generation of Heat and Power from Biogas for Stationary Applications: Boilers, Gas Engines and Turbines, Combined Heat and Power (CHP) Plants and Fuel Cells. In The Biogas Handbook; Elsevier: Amsterdam, The Netherlands, 2013; pp. 404–427. [Google Scholar] [CrossRef]

- Asam, Z.-Z.; Poulsen, T.G.; Nizami, A.-S.; Rafique, R.; Kiely, G.; Murphy, J.D. How Can We Improve Biomethane Production per Unit of Feedstock in Biogas Plants? Appl. Energy 2011, 88, 2013–2018. [Google Scholar] [CrossRef]

- Yan, H.; Zhao, C.; Zhang, J.; Zhang, R.; Xue, C.; Liu, G.; Chen, C. Study on Biomethane Production and Biodegradability of Different Leafy Vegetables in Anaerobic Digestion. AMB Express 2017, 7, 27. [Google Scholar] [CrossRef] [Green Version]

- Seppälä, M.; Pyykkönen, V.; Väisänen, A.; Rintala, J. Biomethane Production from Maize and Liquid Cow Manure—Effect of Share of Maize, Post-Methanation Potential and Digestate Characteristics. Fuel 2013, 107, 209–216. [Google Scholar] [CrossRef]

- Sghari, M.B.A.; Hammami, S. Energy, Pollution, and Economic Development in Tunisia. Energy Rep. 2016, 2, 35–39. [Google Scholar] [CrossRef] [Green Version]

- Rocher, L.; Verdeil, É. Energy Transition and Revolution in Tunisia: Politics and Spatiality. Arab World Geogr. 2013, 16, 26. [Google Scholar]

- Available online: https://www.reeep.org/tunisia-2012 (accessed on 20 November 2019).

- ANME; GTZ. Etude Sur Le Développement de La Méthanisation Industrielle: Etat Des Lieux de La Méthanisation Industrielle En Tunisie; Alcor, Tunisia, 2010. Available online: https://energypedia.info/images/7/77/FR_M%C3%A9thanisation_industrielle_Alcor_2010_GIZ_-_ANME.pdf (accessed on 9 October 2020).

- Getahun, T.; Gebrehiwot, M.; Ambelu, A.; Van Gerven, T.; Van der Bruggen, B. The Potential of Biogas Production from Municipal Solid Waste in a Tropical Climate. Environ. Monit. Assess. 2014. [Google Scholar] [CrossRef]

- Jurgutis, L.; Slepetiene, A.; Volungevicius, J.; Amaleviciute-Volunge, K. Biogas Production from Chicken Manure at Different Organic Loading Rates in a Mesophilic Full Scale Anaerobic Digestion Plant. Biomass Bioenergy 2020, 141, 105693. [Google Scholar] [CrossRef]

- Alrawashdeh, K.A.b.; Gul, E.; Yang, Q.; Yang, H.; Bartocci, P.; Fantozzi, F. Effect of Heavy Metals in the Performance of Anaerobic Digestion of Olive Mill Waste. Processes 2020, 8, 1146. [Google Scholar] [CrossRef]

- Ulusoy, Y.; Ulukardesler, A.H. Biogas Production Potential of Olive-Mill Wastes in Turkey. In Proceedings of the 2017 IEEE 6th International Conference on Renewable Energy Research and Applications (ICRERA), San Diego, CA, USA, 5–8 November 2017; IEEE: San Diego, CA, USA, 2017; pp. 664–668. [Google Scholar] [CrossRef]

- Cheong, D.-Y.; Harvey, J.T.; Kim, J.; Lee, C. Improving Biomethanation of Chicken Manure by Co-Digestion with Ethanol Plant Effluent. Int. J. Environ. Res. Public Health 2019, 16, 5023. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Pei, M.; Qiu, L.; Yao, Y.; Zhang, C.; Qiang, H. Performance of Anaerobic Digestion of Chicken Manure Under Gradually Elevated Organic Loading Rates. Int. J. Environ. Res. Public Health 2019, 16, 2239. [Google Scholar] [CrossRef] [Green Version]

- Stan, C.; Collaguazo, G.; Streche, C.; Apostol, T.; Cocarta, D. Pilot-Scale Anaerobic Co-Digestion of the OFMSW: Improving Biogas Production and Startup. Sustainability 2018, 10, 1939. [Google Scholar] [CrossRef] [Green Version]

- Al bkoor Alrawashdeh, K. Improving Anaerobic Co-Digestion of Sewage Sludge with Thermal Dried Olive Mill Wastewater. Waste Biomass Valor. 2019, 10, 2213–2219. [Google Scholar] [CrossRef]

- Kulkarni, M.B. Pretreatment Methods in Anaerobic Digestion for Biogas Generation: A Review. Int. J. New Innov. Eng. Technol. 2015, 4, 5. [Google Scholar]

- Tyagi, V.K.; Fdez-Güelfo, L.A.; Zhou, Y.; Álvarez-Gallego, C.J.; Garcia, L.I.R.; Ng, W.J. Anaerobic Co-Digestion of Organic Fraction of Municipal Solid Waste (OFMSW): Progress and Challenges. Renew. Sustain. Energy Rev. 2018, 93, 380–399. [Google Scholar] [CrossRef]

- Achinas, S.; Euverink, G. Effect of Combined Inoculation on Biogas Production from Hardly Degradable Material. Energies 2019, 12, 217. [Google Scholar] [CrossRef] [Green Version]

- Holliger, C.; Alves, M.; Andrade, D.; Angelidaki, I.; Astals, S.; Baier, U.; Bougrier, C.; Buffière, P.; Carballa, M.; de Wilde, V.; et al. Towards a Standardization of Biomethane Potential Tests. Water Sci. Technol. 2016, 74, 2515–2522. [Google Scholar] [CrossRef]

- Liberti, F.; Pistolesi, V.; Mouftahi, M.; Hidouri, N.; Bartocci, P.; Massoli, S.; Zampilli, M.; Fantozzi, F. An Incubation System to Enhance Biogas and Methane Production: A Case Study of an Existing Biogas Plant in Umbria, Italy. Processes 2019, 7, 925. [Google Scholar] [CrossRef] [Green Version]

- Sri Bala Kameswari, K.; Kalyanaraman, C.; Porselvam, S.; Thanasekaran, K. Optimization of Inoculum to Substrate Ratio for Bio-Energy Generation in Co-Digestion of Tannery Solid Wastes. Clean Technol. Environ. Policy 2012, 14, 241–250. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Z.; Nakamoto, T.; Li, Y.; Yang, Y.; Utsumi, M.; Sugiura, N. Influence of Substrate-to-Inoculum Ratio on the Batch Anaerobic Digestion of Bean Curd Refuse-Okara under Mesophilic Conditions. Biomass Bioenergy 2011, 35, 3251–3256. [Google Scholar] [CrossRef]

- Nazaitulshila, R.; Idris, A.; Harun, R.; Wan Azlina, W.A.K.G. The Influence of Inoculum to Substrate Ratio on the Biochemical Methane Potential of Fat, Oil, and Grease in Batch Anaerobic Assays. Energy Sources Part A Recovery Util. Environ. Eff. 2015, 37, 590–597. [Google Scholar] [CrossRef]

- Giovanna, G.; Claudia, C.; Filomena, D.C.; Stefania, P.; Biagio, M.; Mario, M. Does the c/n Ration Really Affect the Biomethane Yield? A Three Years Investigation of Buffalo Manure Digestion. Chem. Eng. Trans. 2016, 49, 463–468. [Google Scholar] [CrossRef]

- Tanimu, M.I.; Ghazi, T.I.M.; Harun, R.M.; Idris, A. Effect of Carbon to Nitrogen Ratio of Food Waste on Biogas Methane Production in a Batch Mesophilic Anaerobic Digester. Int. J. Innov. 2014, 5, 4. [Google Scholar]

- Teklehaimanot, T.G. Biogas Generation and Main Factors Affecting in the Production of Biogas: Review. Int. J. Adv. Technol. Innov. Res. 2018, 10, 4. [Google Scholar]

- Fantozzi, F.; Buratti, C. Anaerobic Digestion of Mechanically Treated OFMSW: Experimental Data on Biogas/Methane Production and Residues Characterization. Bioresour. Technol. 2011, 102, 8885–8892. [Google Scholar] [CrossRef]

- Fantozzi, F.; Pistolesi, V.; Massoli, S.; Pugliese, A.; Bidini, G. Anaerobic Digestion of Spoiled Milk in Batch Reactors: Technical and Economic Feasibility. Energy Procedia 2015, 81, 309–318. [Google Scholar] [CrossRef] [Green Version]

- Buratti, C.; Barbanera, M.; Bartocci, P.; Fantozzi, F. Thermogravimetric Analysis of the Behavior of Sub-Bituminous Coal and Cellulosic Ethanol Residue during Co-Combustion. Bioresour. Technol. 2015, 186, 154–162. [Google Scholar] [CrossRef]

- European Committee for Standardization. CEN/TS 14774. Methods for Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in the Analysis Sample; European Committee for Standardization: Brussels, Belgium, 2015. [Google Scholar]

- European Committee for Standardization. CEN/TS 14775. Method for the Determination of Ash Content; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- European Committee for Standardization. CEN/TS 15148. Solid Biofuels—Method for the Determination of the Content of Volatile Matter; European Committee for Standardization: Brussels, Belgium, 2015. [Google Scholar]

- European Committee for Standardization. CEN/TS 14780. Solid Biofuels—Methods for Sample Preparation; European Committee for Standardization: Brussels, Belgium, 2017. [Google Scholar]

- European Committee for Standardization. CEN/TS 15104. Solid biofuels. Determination of Total Content of Carbon, Hydrogen and Nitrogen—Instrumental Methods; European Committee for Standardization: Brussels, Belgium, 2001. [Google Scholar]

- Hajji, A.; Rhachi, M.; Garoum, M.; Laaroussi, N. The Effects of PH, Temperature and Agitation on Biogas Production under Mesophilic Regime. In Proceedings of the 2016 3rd International Conference on Renewable Energies for Developing Countries (REDEC), Zouk Mosbeh, Lebanon, 13–15 July 2016; IEEE: Zouk Mosbeh, Lebanon, 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Mawaheb, M.; Nejib, H.; Nawel, T.; Ammar, B.B. Experimental Study of Biomethane Production from Organic Discharges. In Proceedings of the 2019 10th International Renewable Energy Congress (IREC), Sousse, Tunisia, 26–28 March 2019; IEEE: Sousse, Tunisia, 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Angelidaki, I.; Alves, M.; Bolzonella, D.; Borzacconi, L.; Campos, J.L.; Guwy, A.J.; Kalyuzhnyi, S.; Jenicek, P.; van Lier, J.B. Defining the Biomethane Potential (BMP) of Solid Organic Wastes and Energy Crops: A Proposed Protocol for Batch Assays. Water Sci. Technol. 2009, 59, 927–934. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Björn, A.; Strömberg, S.; Nges, I.A.; Nistor, M.; Liu, J. Evaluating the Influences of Mixing Strategies on the Biochemical Methane Potential Test. J. Environ. Manag. 2017, 185, 54–59. [Google Scholar] [CrossRef]

- Rahman, M.A.; Møller, H.B.; Saha, C.K.; Alam, M.M.; Wahid, R.; Feng, L. Optimal Ratio for Anaerobic Co-Digestion of Poultry Droppings and Lignocellulosic-Rich Substrates for Enhanced Biogas Production. Energy Sustain. Dev. 2017, 39, 59–66. [Google Scholar] [CrossRef]

- Pecorini, I.; Olivieri, T.; Bacchi, D.; Paradisi, A.; Corti, A.; Carnevale, E. Evaluation of Gas Production in a Industrial Anaerobic Digester by Means of Biochemical Methane Potential of Organic Municipal Solid Waste Components. Proteins 2012, 33, 24. [Google Scholar]

- Wellinger, A.; Murphy, J.; Baxter, D. The Biogas Handbook; Woodhead Publishing Limited: Sawston, UK; Cambridge, UK, 2013. [Google Scholar] [CrossRef]

- Voicea, I.; Gageanu, I.; Matache, M.; Vladut, V. Innovative technology for obtaining bioenergy through the process of advanced anaerobic digestion. Eng. Rural Dev. 2017, 6, 24–26. [Google Scholar]

- Ahn, H.K.; Smith, M.C.; Kondrad, S.L.; White, J.W. Evaluation of Biogas Production Potential by Dry Anaerobic Digestion of Switchgrass–Animal Manure Mixtures. Appl. Biochem. Biotechnol. 2010, 160, 965–975. [Google Scholar] [CrossRef]

- Puyuelo, B.; Ponsá, S.; Gea, T.; Sánchez, A. Determining C/N Ratios for Typical Organic Wastes Using Biodegradable Fractions. Chemosphere 2011, 85, 653–659. [Google Scholar] [CrossRef] [Green Version]

- García-Gómez, A. Composting of the Solid Fraction of Olive Mill Wastewater with Olive Leaves: Organic Matter Degradation and Biological Activity. Bioresour. Technol. 2003, 86, 59–64. [Google Scholar] [CrossRef]

- Şevik, F.; Tosun, İ.; Ekinci, K. Composting of Olive Processing Wastes and Tomato Stalks Together with Sewage Sludge or Dairy Manure. Int. J. Environ. Sci. Technol. 2016, 13, 1207–1218. [Google Scholar] [CrossRef] [Green Version]

- Mir, M.A.; Hussain, A.; Verma, C. Design Considerations and Operational Performance of Anaerobic Digester: A Review. Cogent Eng. 2016, 3. [Google Scholar] [CrossRef]

- Dioha, I.J.; Ikeme, C.H.; Nafi’u, T.; Soba, N.I. Effect of carbon to nitrogen ratio on biogas production. Int. Res. J. Nat. Sci. 2013, 1, 10. [Google Scholar]

- Rabii, A.; Aldin, S.; Dahman, Y.; Elbeshbishy, E. A Review on Anaerobic Co-Digestion with a Focus on the Microbial Populations and the Effect of Multi-Stage Digester Configuration. Energies 2019, 12, 1106. [Google Scholar] [CrossRef] [Green Version]

- Palaniveloo, K.; Amran, M.A.; Norhashim, N.A.; Mohamad-Fauzi, N.; Peng-Hui, F.; Hui-Wen, L.; Kai-Lin, Y.; Jiale, L.; Chian-Yee, M.G.; Jing-Yi, L.; et al. Food Waste Composting and Microbial Community Structure Profiling. Processes 2020, 8, 723. [Google Scholar] [CrossRef]

- Wang, X.; Lu, X.; Li, F.; Yang, G. Effects of Temperature and Carbon-Nitrogen (C/N) Ratio on the Performance of Anaerobic Co-Digestion of Dairy Manure, Chicken Manure and Rice Straw: Focusing on Ammonia Inhibition. PLoS ONE 2014, 9, e97265. [Google Scholar] [CrossRef] [Green Version]

- Caillet, H.; Lebon, E.; Akinlabi, E.; Madyira, D.; Adelard, L. Influence of Inoculum to Substrate Ratio on Methane Production in Biochemical Methane Potential (BMP) Tests of Sugarcane Distillery Waste Water. Procedia Manuf. 2019, 35, 259–264. [Google Scholar] [CrossRef]

- Maamri, S.; Amrani, M. Biogas Production from Waste Activated Sludge Using Cattle Dung Inoculums: Effect of Total Solid Contents and Kinetics Study. Energy Procedia 2014, 50, 352–359. [Google Scholar] [CrossRef] [Green Version]

- Ali Shah, F.; Mahmood, Q.; Maroof Shah, M.; Pervez, A.; Ahmad Asad, S. Microbial Ecology of Anaerobic Digesters: The Key Players of Anaerobiosis. Sci. World J. 2014, 2014, 1–21. [Google Scholar] [CrossRef]

- Liu, C.; Tong, Q.; Li, Y.; Wang, N.; Liu, B.; Zhang, X. Biogas Production and Metal Passivation Analysis during Anaerobic Digestion of Pig Manure: Effects of a Magnetic Fe3O4 /FA Composite Supplement. RSC Adv. 2019, 9, 4488–4498. [Google Scholar] [CrossRef] [Green Version]

- Filer, J.; Ding, H.H.; Chang, S. Biochemical Methane Potential (BMP) Assay Method for Anaerobic Digestion Research. Water 2019, 11, 921. [Google Scholar] [CrossRef] [Green Version]

- Stuhli, V. Defining key parameters to control the anaerobic digestion of organic matter. In Proceedings of the 4th International Symposium on Environmental Management—Towards Circular Economy, Zagreb, Croatia, 7–9 December 2016. [Google Scholar]

- Koch, K.; Hafner, S.D.; Weinrich, S.; Astals, S. Identification of Critical Problems in Biochemical Methane Potential (BMP) Tests From Methane Production Curves. Front. Environ. Sci. 2019, 7, 178. [Google Scholar] [CrossRef]

- Singh, B.; Szamosi, Z.; Siménfalvi, Z. Impact of Mixing Intensity and Duration on Biogas Production in an Anaerobic Digester: A Review. Crit. Rev. Biotechnol. 2020, 40, 508–521. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Angelidaki, I.; Batstone, D.J. Anaerobic Digestion: Process. In Solid Waste Technology & Management; Christensen, T.H., Ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2010; pp. 583–600. [Google Scholar] [CrossRef]

- Dimitrov, R.; Ivanov, Z.; Zlateva, P.; Mihaylov, V. Optimization of Biogas Composition in Experimental Studies. E3S Web Conf. 2019, 112, 02007. [Google Scholar] [CrossRef]

- Teng, Z.; Hua, J.; Wang, C.; Lu, X. Design and Optimization Principles of Biogas Reactors in Large Scale Applications. In Reactor and Process Design in Sustainable Energy Technology; Elsevier: Amsterdam, The Netherlands, 2014; pp. 99–134. [Google Scholar] [CrossRef]

- Ponsá, S.; Gea, T.; Sánchez, A. Anaerobic Co-Digestion of the Organic Fraction of Municipal Solid Waste with Several Pure Organic Co-Substrates. Biosyst. Eng. 2011, 108, 352–360. [Google Scholar] [CrossRef] [Green Version]

- El-Mashad, H.M.; Zhang, R. Biogas Production from Co-Digestion of Dairy Manure and Food Waste. Bioresour. Technol. 2010, 101, 4021–4028. [Google Scholar] [CrossRef]

- Meena, K.; Kumar, V.; Vijay, V.K. Anaerobic Technology Harnessed Fully by Using Different Techniques: Review. In Proceedings of the 2011 IEEE Conference on Clean Energy and Technology (CET), Kuala Lumpur, Malaysia, 27–29 June 2011; IEEE: Kuala Lumpur, Malaysia, 2011; pp. 78–82. [Google Scholar] [CrossRef]

- Toklu, E. Biomass Energy Potential and Utilization in Turkey. Renew. Energy 2017, 107, 235–244. [Google Scholar] [CrossRef]

- Rubio, J.A.; Romero, L.I.; Wilkie, A.C.; García-Morales, J.L. Mesophilic Anaerobic Co-Digestion of Olive-Mill Waste With Cattle Manure: Effects of Mixture Ratio. Front. Sustain. Food Syst. 2019, 3, 9. [Google Scholar] [CrossRef]

- Deepanraj, B.; Senthilkumar, N.; Ranjitha, J. Effect of Solid Concentration on Biogas Production through Anaerobic Digestion of Rapeseed Oil Cake. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 1–8. [Google Scholar] [CrossRef]

- Pramanik, S.K.; Suja, F.B.; Porhemmat, M.; Pramanik, B.K. Performance and Kinetic Model of a Single-Stage Anaerobic Digestion System Operated at Different Successive Operating Stages for the Treatment of Food Waste. Processes 2019, 7, 600. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharya, S.K.; Madura, R.L.; Walling, D.A.; Farrell, J.B. Volatile Solids Reduction in Two-Phase and Conventional Anaerobic Sludge Digestion. Water Res. 1996, 30, 1041–1048. [Google Scholar] [CrossRef]

- Shi, X.-S.; Dong, J.-J.; Yu, J.-H.; Yin, H.; Hu, S.-M.; Huang, S.-X.; Yuan, X.-Z. Effect of Hydraulic Retention Time on Anaerobic Digestion of Wheat Straw in the Semicontinuous Continuous Stirred-Tank Reactors. BioMed Res. Int. 2017, 2017, 1–6. [Google Scholar] [CrossRef]

- Bauer, A.; Mayr, H.; Hopfner-Sixt, K.; Amon, T. Detailed Monitoring of Two Biogas Plants and Mechanical Solid–Liquid Separation of Fermentation Residues. J. Biotechnol. 2009, 142, 56–63. [Google Scholar] [CrossRef] [PubMed]

| Bio-Waste | % in the Bioreactor | Weight: mi (g) | % in the Substrate: xi (Bio-Waste) |

|---|---|---|---|

| OFMSW | 4.4 | 11 | 40 |

| CW | 2.2 | 5.5 | 20 |

| OMWW | 4.4 | 11 | 40 |

| Inoculums | 89 | 222.5 | - |

| Total | 100 | 250 | 100 |

| Samples | Humidity (%) | Volatile (%) | Ash (%) | Fixed Carbon (%) | Volatile Dry (%) | Ash Dry (%) |

|---|---|---|---|---|---|---|

| CW | 50 | 29 | 14 | 7 | 58.45 | 28.26 |

| OFMSW | 50.30 | 44.49 | 1.81 | 3.40 | 89.51 | 3.64 |

| OMWW | 65.33 | 25.92 | 7.21 | 1.54 | 74.77 | 20.80 |

| Inoculum | 89.74 | 7.14 | 1.67 | 1.44 | 69.62 | 16.33 |

| Global mixture * | 86.06 | 10.06 | 2.19 | 1.65 | 64.64 | 16.22 |

| Samples | Mass (g) | N (%) | C (%) | H (%) | C/N Ratio |

|---|---|---|---|---|---|

| CW | 0.1085 | 3.6022 | 29 | 5.43 | 8.051 |

| OFMSW | 0.1761 | 2.66 | 65.6 | 8.91 | 24.662 |

| OMWW | 0.0977 | 0.54075 | 20.7 | 10.8 | 38.280 |

| Digester | Y (Nm3/kg VS) | |

|---|---|---|

| Biogas | Bio-Methane | |

| Bioreactor 1 | 0.263 | 0.166 |

| Bioreactor 2 | 0.308 | 0.202 |

| Inoculums | 0.134 | 0.069 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mouftahi, M.; Tlili, N.; Hidouri, N.; Bartocci, P.; Alrawashdeh, K.A.b.; Gul, E.; Liberti, F.; Fantozzi, F. Biomethanation Potential (BMP) Study of Mesophilic Anaerobic Co-Digestion of Abundant Bio-Wastes in Southern Regions of Tunisia. Processes 2021, 9, 48. https://doi.org/10.3390/pr9010048

Mouftahi M, Tlili N, Hidouri N, Bartocci P, Alrawashdeh KAb, Gul E, Liberti F, Fantozzi F. Biomethanation Potential (BMP) Study of Mesophilic Anaerobic Co-Digestion of Abundant Bio-Wastes in Southern Regions of Tunisia. Processes. 2021; 9(1):48. https://doi.org/10.3390/pr9010048

Chicago/Turabian StyleMouftahi, Mawaheb, Nawel Tlili, Nejib Hidouri, Pietro Bartocci, Khalideh Al bkoor Alrawashdeh, Eid Gul, Federica Liberti, and Francesco Fantozzi. 2021. "Biomethanation Potential (BMP) Study of Mesophilic Anaerobic Co-Digestion of Abundant Bio-Wastes in Southern Regions of Tunisia" Processes 9, no. 1: 48. https://doi.org/10.3390/pr9010048

APA StyleMouftahi, M., Tlili, N., Hidouri, N., Bartocci, P., Alrawashdeh, K. A. b., Gul, E., Liberti, F., & Fantozzi, F. (2021). Biomethanation Potential (BMP) Study of Mesophilic Anaerobic Co-Digestion of Abundant Bio-Wastes in Southern Regions of Tunisia. Processes, 9(1), 48. https://doi.org/10.3390/pr9010048