Abstract

In this paper, electrocoagulation (EC) treatment for the removal of chemical oxygen demand (COD) from cold meat industry wastewater is modeled and optimized using computational techniques. Methods such as artificial neural networks (ANNs) and response surface methodology (RSM), based on the Box–Behnken design using three levels, were employed to calculate the best control parameters for pH (5–9), current density (2–6 mA/cm2) and EC time (20–60 min). Analysis of variance (ANOVA) and 3D graphs revealed that pH and current density are the main parameters used for depicting the EC process. The developed models successfully describe the process with a correlation coefficient of R2 = 0.96 for RSM and R2 = 0.99 for ANN. The models obtained were optimized applying the moth-flame optimization (MFO) algorithm to find the best operating conditions for COD removal. ANN-MFO was used and showed superior COD removal (92.91%) under conditions of pH = 8.9, current density = 6.6 mA/cm2 and an EC time of 38.62 min. The energy consumption with these optimal conditions was 6.92 kWh/m3, with an operational cost of $3.14 (USD)/m3. These results suggest that the proposed computational model can be used to obtain more effective and economical treatments for this type of effluent.

1. Introduction

Water is one of the most important resources for life, and today the global population needs more water for industry, agricultural fields and personal use [1]. The extensive range of pollutants in wastewater is one of the most significant challenges for food industries. Wastewater from the cold meat industry has high pollutant concentrations in the form of color, fat, albumins, proteins, carbohydrates and chemical oxygen demand [2]. To remove the pollution of wastewater in this industrial sector, biological, chemical and physical treatments have been applied in the past [3]. However, due to the need for more sustainable and environment friendly methods, electrochemical treatments such as electrocoagulation (EC) have been preferred, as a way to remove a great variety of organic pollutants in wastewater for the cold meat industry sector [4]. Electrocoagulation is a process that consists of destabilizing pollutants present in wastewater through the action of a low-voltage direct electric current and by the action of sacrificial metal electrodes that are normally made of aluminum or iron [5]. When aluminum electrodes are used, the treatment starts with the dissolution of aluminum ions (Al3+) at the anode, followed by the generation of H2 and OH− ions at the cathode. This causes electrochemical reactions in both areas of the electrodes, which are necessary to eliminate any foreign substances present in the water. Subsequently, the generated coagulant salts (Al(OH)3) are employed to remove the contaminants of the aqueous system by an adsorption process. Finally, pollutants are extracted by flotation or sedimentation [6].

The advantages of electrocoagulation include reasonably slow sludge production, a reduced risk of secondary pollution, flexibility and a short treatment time, as well as the need for fewer chemicals for the operation of the process [5,7]. This process has been used for COD removal in diverse industrial sectors like pulp and paper wastewater [8,9], the sugar industry [10] and automobile washing water [11]. The disadvantages of electrocoagulation are that it is necessary to replace the sacrificial electrodes, the residual sludge contains high concentrations of iron and aluminum, depending on the material, and it can be an expensive treatment because it consumes a lot of energy. Therefore, it is necessary to model and optimize the electrocoagulation process in the search for a more economical and efficient process. This can be achieved using computational tools that allow the evaluation of the operating parameters of the process. Many parameters affect the efficiency of the elimination of pollution by EC, the most effective of which may be the conductivity of the solution, the type of power supply, the pH of the solution, the distance between the electrodes, the electrolysis time and the current density.

In the literature, studies have reported using artificial intelligence, such as artificial neural networks (ANNs), in the treatment of wastewater applying the (EC) method. ANN is a computational technique that reproduces the biological processing capacity of the human brain [12]. Another technique for modeling systems is the response surface methodology (RSM), which has been used to model the treatment of textile dyeing factory wastewater by EC [13]. ANN can be optimized using metaheuristic techniques such as moth-flame optimization (MFO) [14]. ANN and MFO have been used for multi-objective optimization in detecting brain tumors in hyperspectral images [15], determination of optimal machining parameters in manufacturing processes [16], and for multi-objective optimization in magnetic abrasive finishing of aluminum 6060 [17]. Other researchers have analyzed the procedure used to remove endosulfan from aqueous systems. This is a highly toxic endocrine disruptor detected in superficial water bodies. The authors utilized the EC process to remove the pollutant and employed ANNs to explain the physicochemical mechanisms in the removal process [18]. Based on these prior works, the novelty of the present study is the modeling of the removal of organic matter present in cold meat industry wastewater via electrocoagulation treatment through response surface methodology and artificial neural networks, optimizing the equations with the moth-flame technique. We carried this out with the objective of eliminating as many pollutants from these waters at the lowest possible energy cost. The contamination parameter evaluated was the chemical oxygen demand (COD), since it is a parameter widely used to measure the degree of contamination in wastewater [11,19,20].

2. Materials and Methods

2.1. Electrocoagulation for Cold Meat Industry Wastewater

To verify the efficiency of adsorption in the removal of organic matter present in cold meat industry wastewater by the EC process, discharge samples were acquired from an industry in the north of Mexico (16°3′42.88″ N; 93°22′9.41″ W). Samples were obtained every 24 h for five days, to generate a composed sample. These effluents were refrigerated at 4 °C until the experimentation was performed. The wastewater from the cold meat industry was analyzed at the beginning of the experiment for certain water quality parameters, according to the standard methods [21]. The specific standards for each parameter were the following: pH (pH meter (HANNA instruments, Mexico City, Mexico)), biochemical oxygen demand (BOD) (5210B), chemical oxygen demand (COD) (5220D), color (2120C), turbidity (2130B), total suspended solids (TSS) (2540D) and fats and oils (5520D).

The analysis of the quality of the residual water was carried out to determine the degree of contamination in the water at the beginning of the electrocoagulation treatment. For modeling and optimization by computational methods, the removal of a single parameter such as the COD was considered. This calculation was made with Equation (1) [13]:

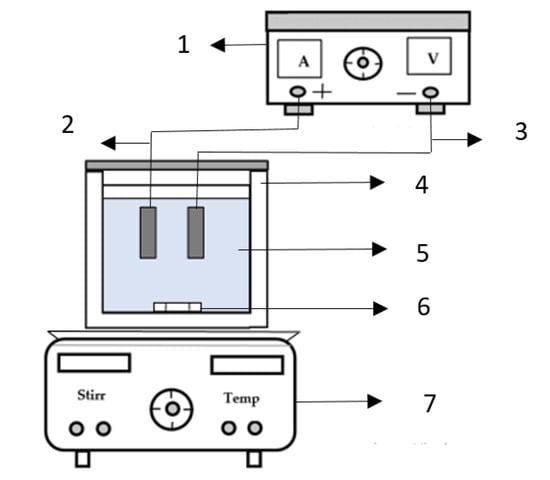

where R represents the removal efficiency, Y0 is the initial COD measurement and Y is the final COD measurement. The diagram of the electrochemical cell employed in this work can be seen in Figure 1. This system consisted of a 1200 mL reactor containing 1000-mL samples and two aluminum electrodes, measuring 5.3 cm wide and 12.7 cm long. There was a total contact area of 121.84 cm2 and a separation of 0.5 cm was maintained between the two electrodes. Aluminum electrodes were used in this study due to their good performance, as mentioned in [13]. A power supply (Extech model 382153) was employed to provide regulated electric power to the EC system. Electrodes were washed using a 10% nitric acid solution before each experiment in order to activate their surfaces for the process. The initial pH of the diverse working solutions was adjusted with 0.1 M NaOH or HCl (analytical grade) to assess the influence of the initial pH (5 to 9) on the adsorption efficiency. The parameters controlled in the experiment were pH, current density (mA/cm2) and electrochemical treatment time (minutes).

Figure 1.

Schematic diagram of electrocoagulation (EC) reactor: (1) DC power supply, (2) anode, (3) cathode, (4) reactor, (5) cold meat industry wastewater (6) magnetic stir bar and (7) magnetic stirrer.

2.2. ANN Modeling and Optimization

In order to quantify the contribution of proposed parameters in the efficiency of removal of COD from cold meat wastewater, three main factors, each with three levels, were chosen, as shown in Table 1. The ANN modeling of the process parameters for the cold meat industry wastewater was performed by employing the neural network toolbox of MATLAB R2016a (Mathworks Inc., Natick, MA, USA).

Table 1.

Independent variables and their levels.

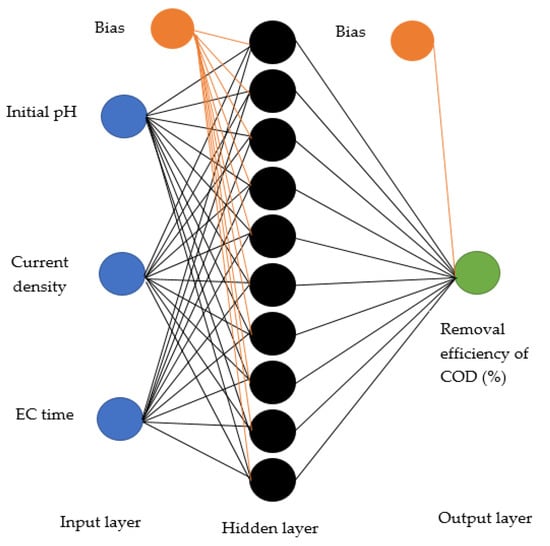

To obtain the model, a feedforward neural network was applied. As shown in Figure 2, the ANN architecture has one input layer with three neurons (initial pH, current density and electrocoagulation time), an output layer with one neuron (COD removal %). Since the network has only one hidden layer, it is considered a multilayered perceptron (MPL).

Figure 2.

Architecture for the artificial neural network (ANN) model. COD: chemical oxygen demand.

The hyperbolic tangent sigmoid transfer function (tansig) and pure-linear transfer function (purelin) were designated for the input and output layers, respectively, in order to formulate the activation function and the net input to the node in the output layer. These equations are found in [22]. The whole data set was organized into three groups: a training group (70%), a validation group (15%) and a test group (15%) [12], as shown in Table 2. Finally, in order to determine the number of hidden neurons, iterative tests were performed for a group of neural networks and the mean square error (MSE) was measured. All of the data were normalized using Equation (2); where xi represents the observed value, xmax is the highest value for the variables and xmin is the lowest value [18]. For metaheuristic optimization, the ANN model was employed as the fitness function and was used to measure the performance of individuals in the population [22]. MFO was used as a metaheuristic algorithm to improve the performance of the ANN [17].

Table 2.

ANN modeling for cold meat industry wastewater EC treatment.

2.3. RSM Modeling and Optimization

The Box–Behnken design (BBD) was used for the modeling and estimation of the EC process of COD removal from cold meat industry wastewater. The design matrix had the same three factors as the ANN modeling, which were pH (5–9), current density (2–6 mA/cm2), and EC time (20–60 min), each with three levels, and the response variable was the elimination of COD (Y1). The prediction of response values obtained by correlation of the three independent variables was made by applying a second-order polynomial equation 3, where Y represents response (COD removal efficiency, %); b0 is the intercept value; bi (i = 1, 2, 3, …, n) represents the first model coefficients for Xi; bii represents the quadratic coefficients of Xi; bij represents the correlation coefficients for Xi Xj and is the random error. For the numerical optimization of the RSM model, Design-Expert software 10.0.1 (Stat-Ease Inc., Minneapolis, MN, USA) was used. The parameter optimization was carried out by Derringer’s desired function methodology. Design-Expert software was used for analysis of variance (ANOVA) and numerical optimization [23].

2.4. Evaluation of the Developed Mathematical Models

The correlation coefficient (R), coefficient of determination (R2), adjusted R2, mean squared error (MSE) and root mean squared error (RMSE) were the statistical indices used in order to evaluate the predictive capability for the COD removal process present in cold meat wastewater [22].

2.5. Operational Cost

The operational cost is one of the main considerations when treating wastewater by EC. It includes the cost of the external chemical (Cchem (g/m3)), the cost of dissolved electrode (Celect (g/m3)) and energy consumption (Econ (Kwh/m3)). The operational cost incurred during the EC method can be calculated by Equations (4)–(7) [5,24], where V is the volume (L) of cold meat wastewater, F is the Faraday constant (96,485 C/mol), Z is the Al balance (+3), M is the atomic weight for Al (26.98 g/mol), t is the time (s) for electrolysis and I is functional current (Amperes), U denotes cell voltage (Volts). Equation (6) calculates the cost of the chemicals, where Ch is the quantity of chemical used (g) and Vol is the volume of wastewater (m3). The operational cost was evaluated using: (α) with an electricity price of 0.13 USD/KWh, obtained from the Mexican government’s energy secretary [24], (β) is the electrode material price 1.64 USD/kg Al, obtained from of the international metals market [25] and (γ) is the cost of the chemicals which can be added, (in this work, sodium hydroxide with a price of 0.4 USD/kg [26]).

3. Results

The physicochemical parameters of the wastewater obtained at the beginning of the experimentation are shown in Table 3. As can be seen, the wastewater samples were rich in organic matter [27]. The proportion of organic matter, expressed as COD and BOD, was approximately 3482 and 2470 mg/L, respectively. The fat, oil and grease (FOG) concentration is high, at approximately 1114 mg/L. These results are in agreement with those reported by other authors for wastewater from the meat industry [3,28]. The physicochemical parameters found are characteristic of this type of wastewater, generated as a result of meat processing and the cleaning of equipment in the cold meat industry [28]. This wastewater is appropriate for treatment in an electrocoagulation process [4,29].

Table 3.

Characteristics of cold meat industry wastewater.

3.1. Neural Network Modeling

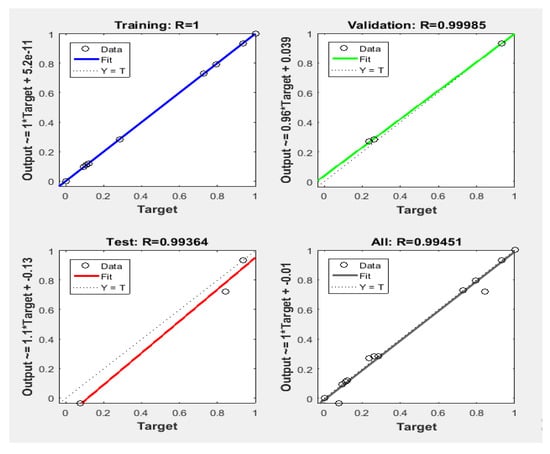

In order to obtain a suitable ANN-MFO model, the ANN was evaluated with 4, 6, 8, 10 and 12 hidden neurons. For each architecture, 200 simulations were performed and the average of the MSE was obtained. The results validated the performance for a 12-neuron model (MSE = 0.740), a 10-neuron model (MSE = 0.134), an 8-neuron model (MSE = 1.415), a 6-neuron model (MSE = 0.922) and a 4-neuron model (MSE = 0.885), as shown in Table 4. From these results, a hidden layer of 10 neurons was used in this work and a total of 12 moths were used as search agents for 50 iterations. For this investigation, the results for COD removal prediction using the ANN-MFO model are presented in Figure 3, showing the plot of predictions (output values) versus target (experimental) values, which results in R values of 0.9998 for validation, 0.9936 for testing, 1 for training and 0.9945 for the whole data set.

Table 4.

Effect of the number of hidden layer neurons on the performance of the neural network.

Figure 3.

Correlation plots of predicted versus experimental data for the artificial neural network-moth-flame optimization (ANN-MFO) model.

3.2. RSM Modeling

An empirical model was established in order to understand the interactive correlation between the response and process variables. This model, obtained in terms of coded factors, is given in Equation (8).

ANOVA analysis, shown in Table 5, was used to establish the conditioning of the developed model in terms of coded factors. The analysis solution is presented in terms of the sum of the square residuals, F and p values and the degrees of freedom. Finding a p value below (<0.05) shows that the model terms are important [29]. Regarding COD removal, ANOVA results for the factors of initial pH (A), current density (B) and EC time (C) present the best performance. A low p value (0.007) indicates that these parameters are the most important for the EC treatment of cold meat industry wastewater. Terms (A2), (B2) and (C2) have a p value <0.05, implying that these are significant. All other results showed higher p values (>0.05). At a confidence level of 96%, the R2 adjusted (0.951) value indicates good performance of RSM models [30].

Table 5.

Analysis of variance (ANOVA) response surface for COD (Y1).

Table 6 displays 17 experiments of EC using cold meat industry wastewater under diferent conditions, using a three-level-three factor Box–Behnken design (BBD) of RSM. This method was employed in the modeling of COD removal efficiency (%) from cold meat industry wastewater. In this case, the results are consistent, because the behavior in the removal efficiency of COD shows similarity to other works reported in the literature [4,24].

Table 6.

Box–Behnken design, observed and predicted values concerning COD removal.

3.3. Evaluation of the Predictive Performance of Proposed Models

The performances of the RSM and ANN models in predicting the COD removal from cold meat industry wastewater were evaluated using the equations from [22], and with these results the statistical parameters shown in Table 7 were calculated. The R value is higher when using the ANN than when using RSM, showing that the former method gave the best correlation between experimental and predicted values. The R2 values confirm the better performance of ANN over RSM, and the adjusted R2 was used to avoid overestimation of the correlation coefficient (R2), demonstrating the significance of the ANN model. To confirm the closeness of the fitted line to the data points, the MSE and RMSE were evaluated, and these values were higher for the RSM model compared to the ANN model. Based on the results obtained in Table 7, ANN was the best model [16].

Table 7.

Statistical indices for ANN and response surface methodology (RSM) models.

3.4. Effects of the Variables on COD Removal

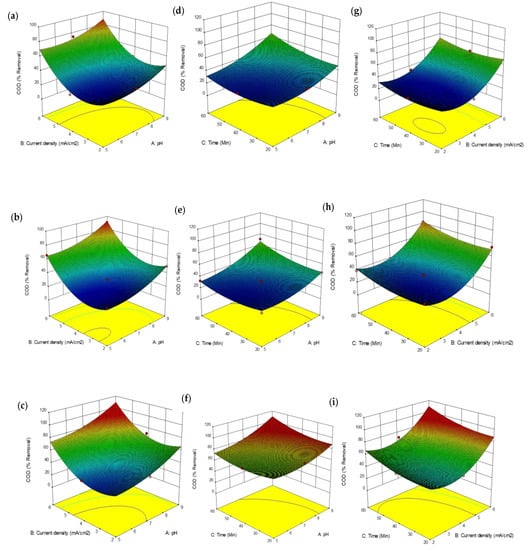

Tridimensional graphics were used to analyze the interactive effects of all variables, pH (A), current density (mA/cm2) (B) and EC time (min) (C), with the COD removal responses shown in Figure 4. They were obtained from the modeled data, as shown in Table 6.

Figure 4.

Three-dimensional surfaces for COD reduction effectiveness: First column current density vs. initial pH at an EC time of 20 min (a), 40 min (b) and 60 min (c). Second column EC time vs. initial pH at current density 2 mA/cm2 (d), 4 mA/cm2 (e) and 6 mA/cm2 (f). Third column EC time vs. current density at initial pH 5 (g), pH 7 (h) and pH 9 (i).

3.4.1. Effect of pH

In order to analyze the effect of initial pH on the EC treatment of cold meat wastewater, the operating range was varied from five to nine, and the results were represented in 3D graphics (first and second columns, Figure 4a–f). For current density vs. initial pH (Figure 4a) about 85% removal is linked and after 40 min (Figure 4b), there is a slight increase; however, a higher effect in the removal of COD was localized after 40 min (Figure 4c), in the range of eight to nine. Values between five and six are less efficient for all observed cases (Figure 4a–c). For the case of EC time vs. initial pH (Figure 4d,e), the same low performance was observed, with better results achieved by increasing the current to 6 mA/cm2 (Figure 4f), establishing the optimal area, with pH levels around eight to nine. This may be because pH values of 6.5–8.8 lead principally to the formation of Al(OH)3 and not to other chemical compounds, which helps remove pollutants by adsorption [31]. The results of this work agree with those found in the literature [31,32].

3D graphics show that initial pH levels (8–9) lead to a higher performance in the EC treatment of the COD (80%–90%). This behavior can be attributed to the fact that the medium pH (5–7), can promote the mechanism reaction of several chemical species which are relatively less absorbent, like Al(OH)3, when aluminum electrodes are used. The literature has reported similar results to those obtained in the present work [20,24,31]. For the EC treatment, the pH parameter is decisive; different chemical species can be formed depending on its value. In the anode reaction, the dissolution of the aluminum electrode produces Al3+ at a high pH. This reacts with other species such as OH− to produce salts of Al(OH)3, a chemical species which can be beneficial for the quick adsorption of soluble organic compounds due to its large capacity of retention, which makes the removal process by EC more efficient [11].

3.4.2. Effect of Current Density

To study the effect of current density in COD removal from cold meat industry wastewater, a range between 2 and 6 mA/cm2 was analyzed. 3D graphics (first and third columns, Figure 4a–c,g–i) show that EC treatment with low values (2 mA/cm2 to 4 mA/cm2) in current density do not have a good performance, and the best removal is achieved at 5 mA/cm2 and higher. This parameter achieves its best results at reaction times after 40 min, with an increase in COD removal (Figure 4c). Around 90% at lower times, the removal is lower, as shown in Figure 4a,b. Likewise, the best removals are achieved at pH levels around 8 to 9 (Figure 4i), obtaining minor results using neutral and acid pH conditions (Figure 4g,h). Current density shows excellent removal capacity when a value of 5.5 mA/cm2 is used. Once the current density acquires higher values, more hydrogen bubbles are generated at the cathode, augmenting the homogeneous conditions inside the system and favoring the contact between phases, increasing the velocity of COD removal from wastewater [32].

3.4.3. Effect of Electrolysis Time

Electrolysis time is represented by 3D graphs (second and third columns, Figure 4d–f,g–i) for COD removal. It can be observed that the range of action remains constant for the entire observed experimental range, with a slight increase around 60 min for the case of EC time vs. initial pH (Figure 4d,e), finding the best performance when a current density of 6 mA/cm2 was used (Figure 4f). Likewise, in the third column (EC time vs. current density), the removal of COD remains invariable until 45 min, when an increase is observed and enhanced using pH 9 (Figure 4i), decreasing removal performance by lowering initial pH for cases of pH 7 (Figure 4h) and pH 5 (Figure 4g). This tendency in relation to the EC time can be attributed to the better formation of Al3+. These ions enable an increase in the sludge at the end of the process [31].

3.5. Optimization Process

The optimization process consists in finding the values of pH, current density and EC time, which yield the best COD removal efficiency. Three different methods are proposed: RSM, ANN-MFO and RSM-MFO. RSM is the response surface method alone; ANN-MFO and RSM-MFO are the artificial neural network and response surface method, in which weights have been obtained by the moth-flame optimization algorithm. Table 8 shows the resulting parameters and their corresponding predicted removal efficiency. It can be seen that the ANN-MFO method obtained the highest predicted value, with 92.91, followed by the RSM and RSM-MFO methods, respectively. These results show a consistent and an overall improvement in performance compared to the removal efficiency obtained by the 17 experiments conducted in the laboratory, as previously shown in Table 6.

Table 8.

Evaluation of optimal values for RSM and ANN-MFO.

3.6. Operational Cost

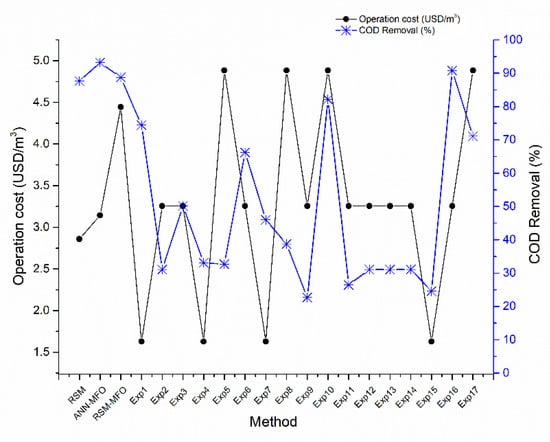

In the previous subsection, it is noted that the best removal efficiency was obtained using the highest current density value (6.6 mA/cm2), which means the system requires more electricity and may increase its overall energy consumption. Therefore, it is important to calculate the operational cost for every set of parameters, in order to assess the viability of the proposed computational techniques in terms of price. These calculations were performed as explained in Section 2.5, and the results are shown in Figure 5. The graph includes the operation cost and COD removal of the 17 laboratory experiments, together with the results from the RSM, ANN-MFO and RSM-MFO techniques. It can be observed that these three computational models achieved the maximum COD removal (with the exception of experiment 16). RSM and ANN-MFO obtained a relatively low cost compared to the average cost of the laboratory experiments. It is also shown that the laboratory experiments obtained erratic operation costs and, in many cases (experiments 11 to 15, for example) very low COD removal. These results suggest that these computational techniques are capable of finding the best parameters to maximize COD removal and minimize operation cost, and can be very helpful to perform more precise and sometimes less costly laboratory experiments.

Figure 5.

Operational cost in USD/m3 and COD removal percentage for RSM, ANN-MFO, RSM-MFO and the 17 laboratory experiments.

4. Conclusions

In this work, computational techniques to model and optimize the electrocoagulation process were proposed. COD removal from cold meat industry wastewater is a complex problem and is difficult to predict and describe. Artificial neural networks are tools that can handle such complex problems and are able to propose a computational system to describe the electrocoagulation process. This article showed that a neural network, trained by another artificial intelligence method such as moth-flame optimization, is able to outperform the techniques used in the past, such as response surface methodology. In this study, it was found that the best electrocoagulation parameter configuration was a pH of 8.9, a current density of 6.6 mA/cm2 and an electrocoagulation time of 38.62 min, which resulted in the maximum COD removal of 92.91%. These results are useful to better plan a future set of experiments or to test a higher-scale electrocoagulation process, and this simulation technique can be applied in diverse treatments of industrial water.

COD removal by electrocoagulation treatment, although a simple process, can be costly in terms of energy. This work showed that the more significant parameters—namely, current density and time—can be fine-tuned to reduce the electricity needed to achieve the same results or even outperform the results obtained in the laboratory, without the use of computational techniques. The model presented in this paper suggests that a high COD removal of 93.18% can be obtained with only an average cost of 3.14 USD/m3, thus allowing significant savings in larger scale wastewater treatment processes.

Author Contributions

Methodology, J.M.-R. and J.d.R.-O.; formal analysis, J.d.R.-O., K.J.G.-T., V.Z.-G.; writing—original draft preparation, J.M.-R.; writing—review and editing, B.S.-R., V.Z.-G. and supervision, V.Z.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

A graduate scholarship for Juan Morales-Rivera was provided by the National Council for Science and Technology (CONACyT) of México.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Palacios, H.; Urena, H.; Zurita, F.; de León, A.A.G.; Sundaram, G.; Sulbarán-Rangel, B. Nanocellulose and Polycaprolactone Nanospun Composite Membranes and Their Potential for the Removal of Pollutants from Water. Molecules 2020, 25, 683. [Google Scholar] [CrossRef]

- Hernández-Ramírez, D.A.; Herrera-López, E.J.; Rivera, A.L.; del Real-Olvera, J. Artificial Neural Network Modeling of Slaughterhouse Wastewater Removal of COD and TSS by Electrocoagulation; Springer International Publishing: Cham, Switzerland, 2014. [Google Scholar]

- León-Becerril, E.; García-Camacho, J.E.; del Real-Olvera, J.; López-López, A. Performance of an upflow anaerobic filter in the treatment of cold meat industry wastewater. Process Saf. Environ. Prot. 2016, 102, 385–391. [Google Scholar] [CrossRef]

- Thirugnanasambandham, K.; Sivakumar, V.; Maran, J.P. Response surface modelling and optimization of treatment of meat industry wastewater using electrochemical treatment method. J. Taiwan Inst. Chem. Eng. 2015, 46, 160–167. [Google Scholar] [CrossRef]

- Shahedi, A.; Darban, A.K.; Taghipour, F.; Jamshidi-Zanjani, A. A review on industrial wastewater treatment via electrocoagulation processes. Curr. Opin. Electrochem. 2020, 22, 154–169. [Google Scholar] [CrossRef]

- Thirugnanasambandham, K.; Sivakumar, V.; Maran, J.P. Optimization of process parameters in electrocoagulation treating chicken industry wastewater to recover hydrogen gas with pollutant reduction. Renew. Energy 2015, 80, 101–108. [Google Scholar] [CrossRef]

- Salari, D.; Niaei, A.; Khataee, A.; Zarei, M. Electrochemical treatment of dye solution containing C.I. Basic Yellow 2 by the peroxi-coagulation method and modeling of experimental results by artificial neural networks. J. Electroanal. Chem. 2009, 629, 117–125. [Google Scholar] [CrossRef]

- Azadi Aghdam, M.; Kariminia, H.-R.; Safari, S. Removal of lignin, COD, and color from pulp and paper wastewater using electrocoagulation. Desalin. Water Treat. 2016, 57, 9698–9704. [Google Scholar] [CrossRef]

- Pandey, N.; Thakur, C. Study on treatment of paper mill wastewater by electrocoagulation and its sludge analysis. Chem. Data Collect. 2020, 27, 100390. [Google Scholar] [CrossRef]

- Sahu, O.P.; Chaudhari, P.K. Electrochemical treatment of sugar industry wastewater: COD and color removal. J. Electroanal. Chem. 2015, 739, 122–129. [Google Scholar] [CrossRef]

- Priya, M.; Jeyanthi, J. Removal of COD, oil and grease from automobile wash water effluent using electrocoagulation technique. Microchem. J. 2019, 150, 104070. [Google Scholar] [CrossRef]

- Nasr, M.; Ateia, M.; Hassan, K. Artificial intelligence for greywater treatment using electrocoagulation process. Sep. Sci. Technol. 2016, 51, 96–105. [Google Scholar] [CrossRef]

- Sarve, A.; Sonawane, S.S.; Varma, M.N. Ultrasound assisted biodiesel production from sesame (Sesamum indicum L.) oil using barium hydroxide as a heterogeneous catalyst: Comparative assessment of prediction abilities between response surface methodology (RSM) and artificial neural network (ANN). Ultrason. Sonochem. 2015, 26, 218–228. [Google Scholar] [CrossRef] [PubMed]

- Mirjalili, S. Moth-flame optimization algorithm: A novel nature-inspired heuristic paradigm. Knowl.-Based Syst. 2015, 89, 228–249. [Google Scholar] [CrossRef]

- Thiyagupriyadharsan, M.R.; Suja, S. A Hybrid Approach for Detecting the Brain Tumor in Hyperspectral Images Using Moth Flame Optimized K-Means Clustering. J. Med. Imaging Health Inform. 2019, 9, 1354–1360. [Google Scholar] [CrossRef]

- Yıldız, B.S.; Yıldız, A.R. Moth-flame optimization algorithm to determine optimal machining parameters in manufacturing processes. Mater. Test. 2017, 59, 425–429. [Google Scholar] [CrossRef]

- Singh, R.K.; Gangwar, S.; Singh, D.K.; Pathak, V.K. A novel hybridization of artificial neural network and moth-flame optimization (ANN–MFO) for multi-objective optimization in magnetic abrasive finishing of aluminium 6060. J. Braz. Soc. Mechan. Sci. Eng. 2019, 41, 270. [Google Scholar] [CrossRef]

- Mirsoleimani-azizi, S.M.; Amooey, A.A.; Ghasemi, S.; Salkhordeh-panbechouleh, S. Modeling the Removal of Endosulfan from Aqueous Solution by Electrocoagulation Process Using Artificial Neural Network (ANN). Ind. Eng. Chem. Res. 2015, 54, 9844–9849. [Google Scholar] [CrossRef]

- Marín-Muñíz, J.L.; Adame-García, J.; del Ángel-Coronel, O.A.; Zurita, F.; Sandoval, L. Influence of a new ornamental species (Spathiphyllum blandum) on the removal of COD, nitrogen, phosphorus and fecal coliforms: A mesocosm wetland study with PET and tezontle substrates. Water Sci. Technol. 2020, 81, 961–970. [Google Scholar] [CrossRef]

- Tak, B.-Y.; Tak, B.-S.; Kim, Y.-J.; Park, Y.-J.; Yoon, Y.-H.; Min, G.-H. Optimization of color and COD removal from livestock wastewater by electrocoagulation process: Application of Box–Behnken design (BBD). J. Ind. Eng. Chem. 2015, 28, 307–315. [Google Scholar] [CrossRef]

- Baird, R.; Eaton, A.; Rice, E. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- Betiku, E.; Odude, V.O.; Ishola, N.B.; Bamimore, A.; Osunleke, A.S.; Okeleye, A.A. Predictive capability evaluation of RSM, ANFIS and ANN: A case of reduction of high free fatty acid of palm kernel oil via esterification process. Energy Convers. Manag. 2016, 124, 219–230. [Google Scholar] [CrossRef]

- Bui, H.M. Applying Response Surface Methodology to Optimize the Treatment of Swine Slaughterhouse Wastewater by Electrocoagulation. Pol. J. Environ. Stud. 2018, 27, 1975–1981. [Google Scholar] [CrossRef]

- CFE. Comision Fededal de Electricidad Tarifas 2020. Available online: https://app.cfe.mx/aplicaciones/ccfe/tarifas/tarifas/tarifas_casa.asp?Tarifa=DACTAR1&Anio=2020 (accessed on 10 October 2019).

- IndexMundi. Aluminum Futures End of Day Settlement Price. Available online: https://www.indexmundi.com/commodities/?commodity=aluminum (accessed on 10 October 2019).

- Alibaba. Soda Cáustica Hidróxido Sódico NaOH 99% Min de Gránulos. Available online: https://spanish.alibaba.com/g/caustic-soda-prices.html (accessed on 10 October 2019).

- Aziz, A.; Basheer, F.; Sengar, A.; Irfanullah; Khan, S.U.; Farooqi, I.H. Biological wastewater treatment (anaerobic-aerobic) technologies for safe discharge of treated slaughterhouse and meat processing wastewater. Sci. Total Environ. 2019, 686, 681–708. [Google Scholar] [CrossRef] [PubMed]

- Bustillo-Lecompte, C.F.; Mehrvar, M. Slaughterhouse wastewater characteristics, treatment, and management in the meat processing industry: A review on trends and advances. J. Environ. Manag. 2015, 161, 287–302. [Google Scholar] [CrossRef]

- Avramović, J.M.; Veličković, A.V.; Stamenković, O.S.; Rajković, K.M.; Milić, P.S.; Veljković, V.B. Optimization of sunflower oil ethanolysis catalyzed by calcium oxide: RSM versus ANN-GA. Energy Convers. Manag. 2015, 105, 1149–1156. [Google Scholar] [CrossRef]

- Merzouk, B.; Gourich, B.; Sekki, A.; Madani, K.; Vial, C.; Barkaoui, M. Studies on the decolorization of textile dye wastewater by continuous electrocoagulation process. Chem. Eng. J. 2009, 149, 207–214. [Google Scholar] [CrossRef]

- Barrera-Díaz, C.; Roa-Morales, G.; Ávila-Córdoba, L.; Pavón-Silva, T.; Bilyeu, B. Electrochemical Treatment Applied to Food-Processing Industrial Wastewater. Ind. Eng. Chem. Res. 2006, 45, 34–38. [Google Scholar] [CrossRef]

- Khandegar, V.; Saroha, A.K. Electrocoagulation for the treatment of textile industry effluent—A review. J. Environ. Manag. 2013, 128, 949–963. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).