Implementation of Common Rail Direct Injection System and Optimization of Fuel Injector Parameters in an Experimental Single-Cylinder Diesel Engine

Abstract

1. Introduction

1.1. Common Rail Direct Injection (CRDI) System

1.2. Prior Studies

1.3. Motivation of Work

2. Experimental Apparatus and Procedure

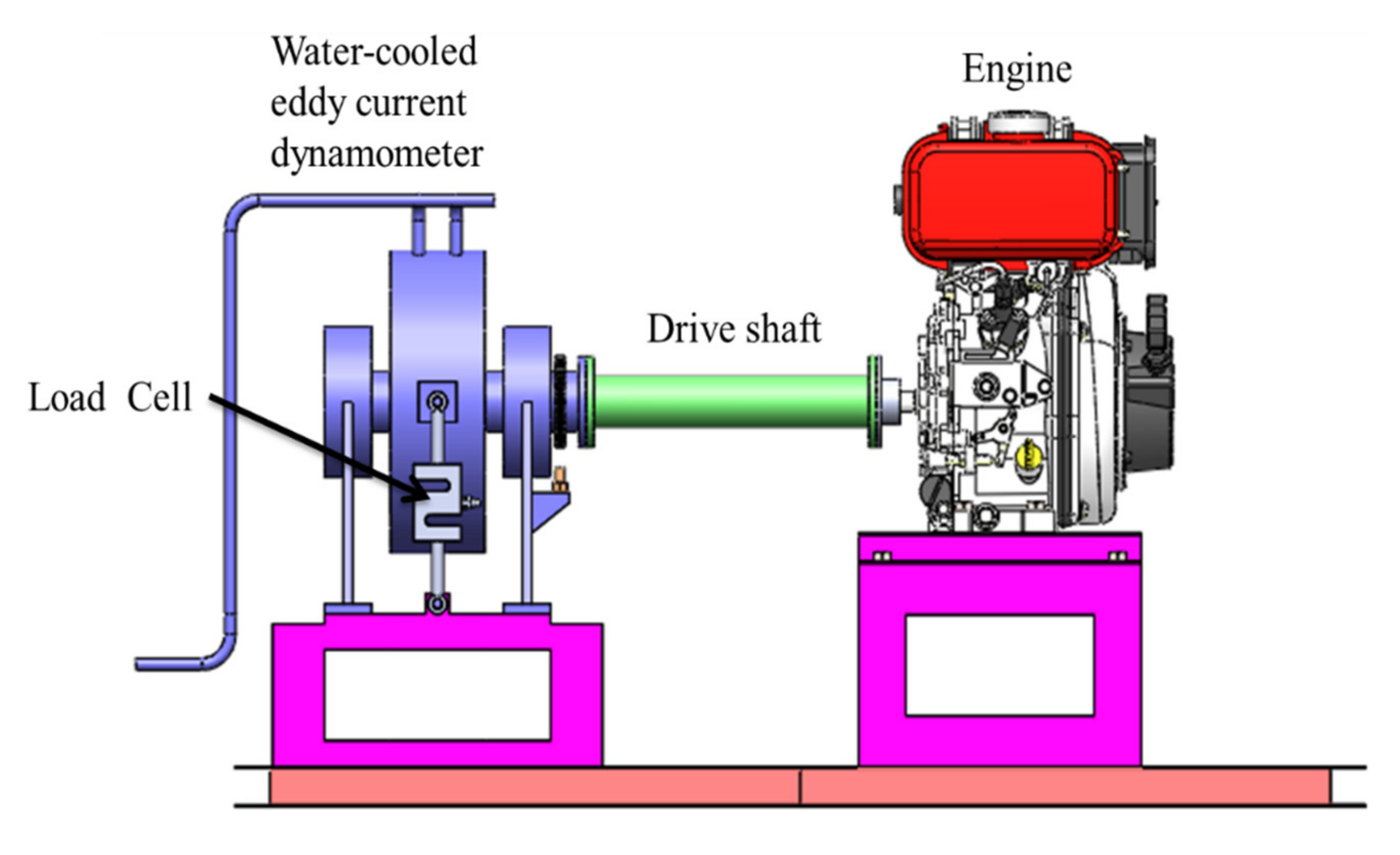

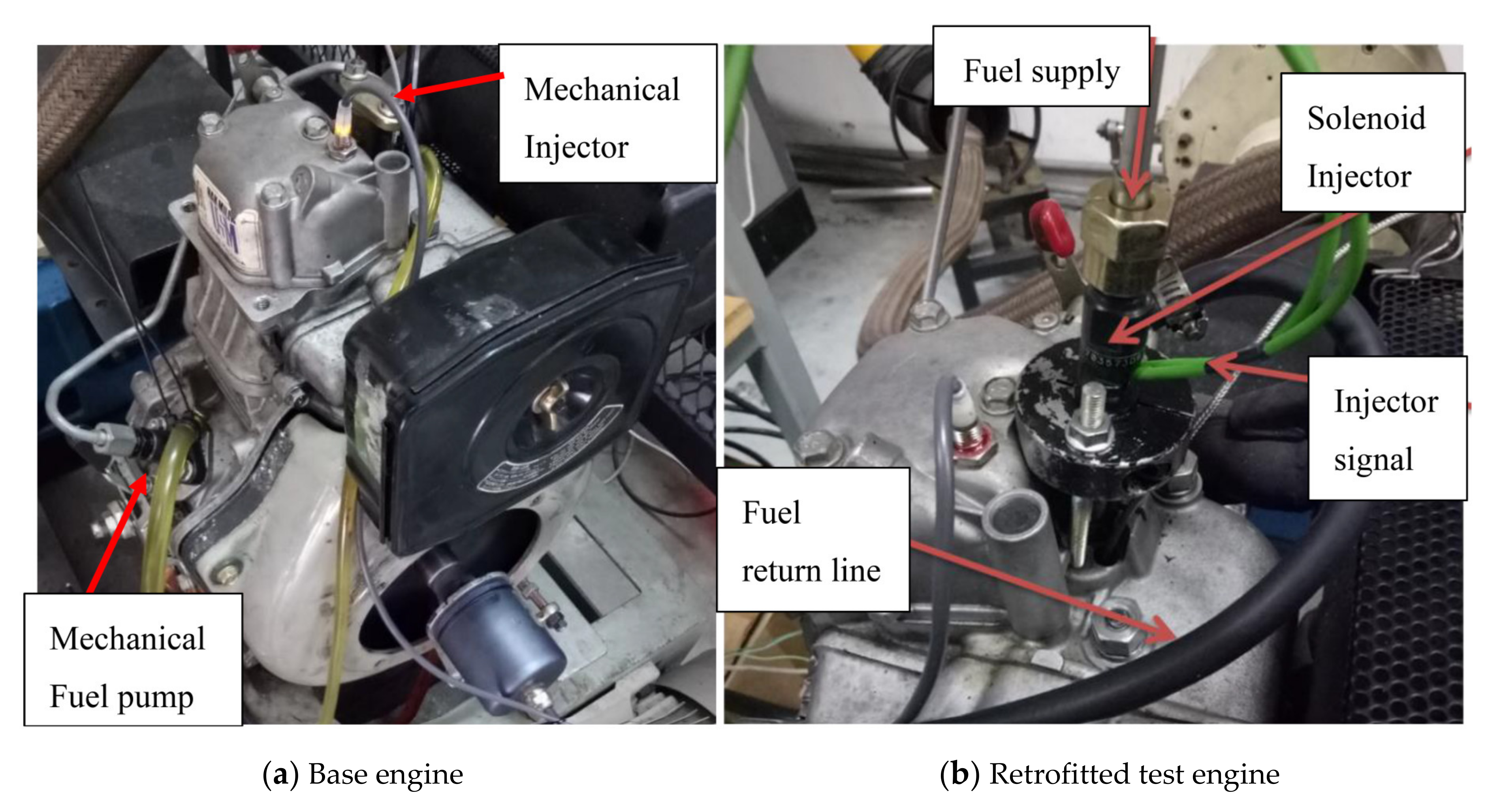

2.1. Apparatus Setup

2.2. Experimental Procedure

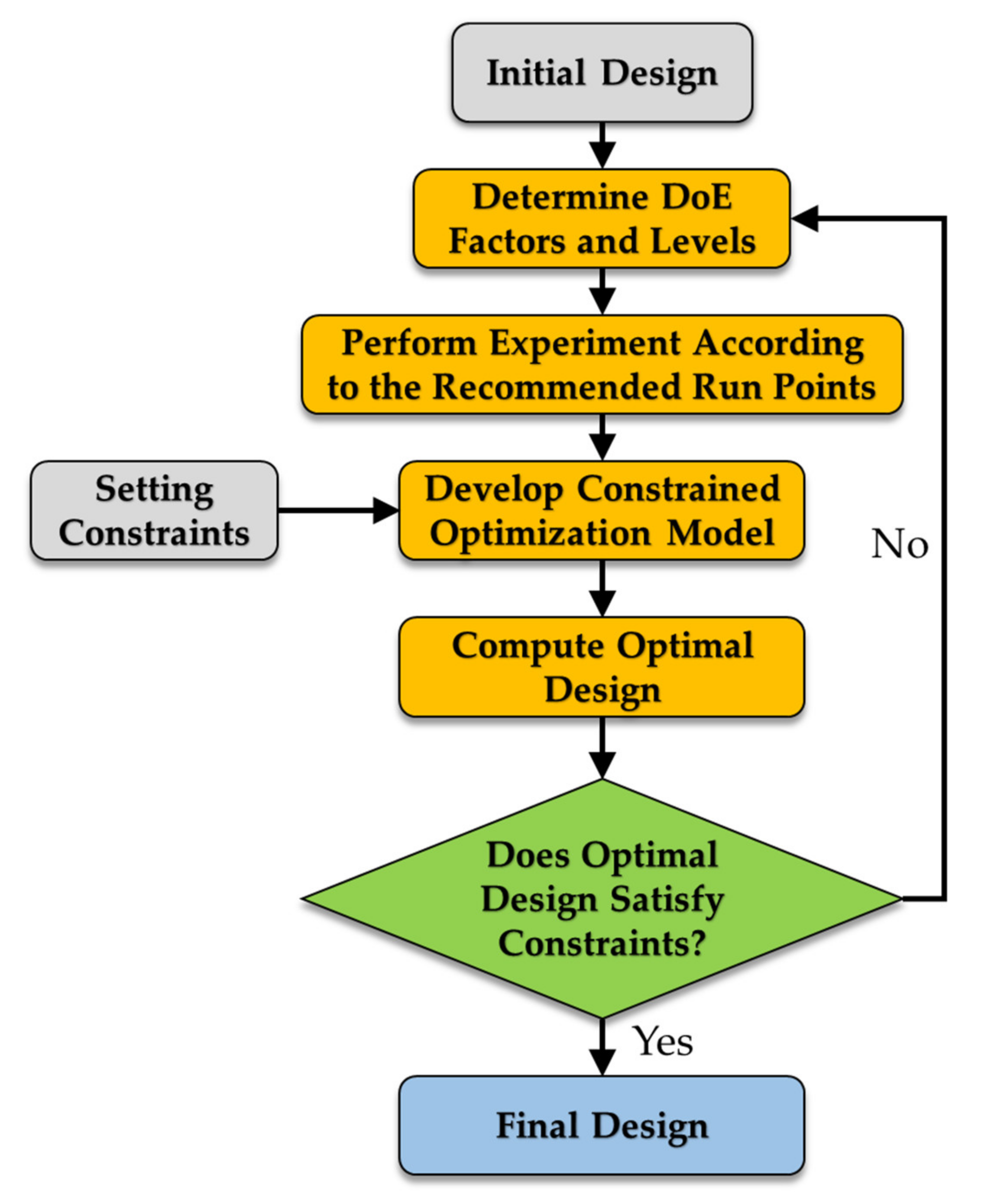

2.3. Optimization of Injector Parameters

3. Results and Discussion

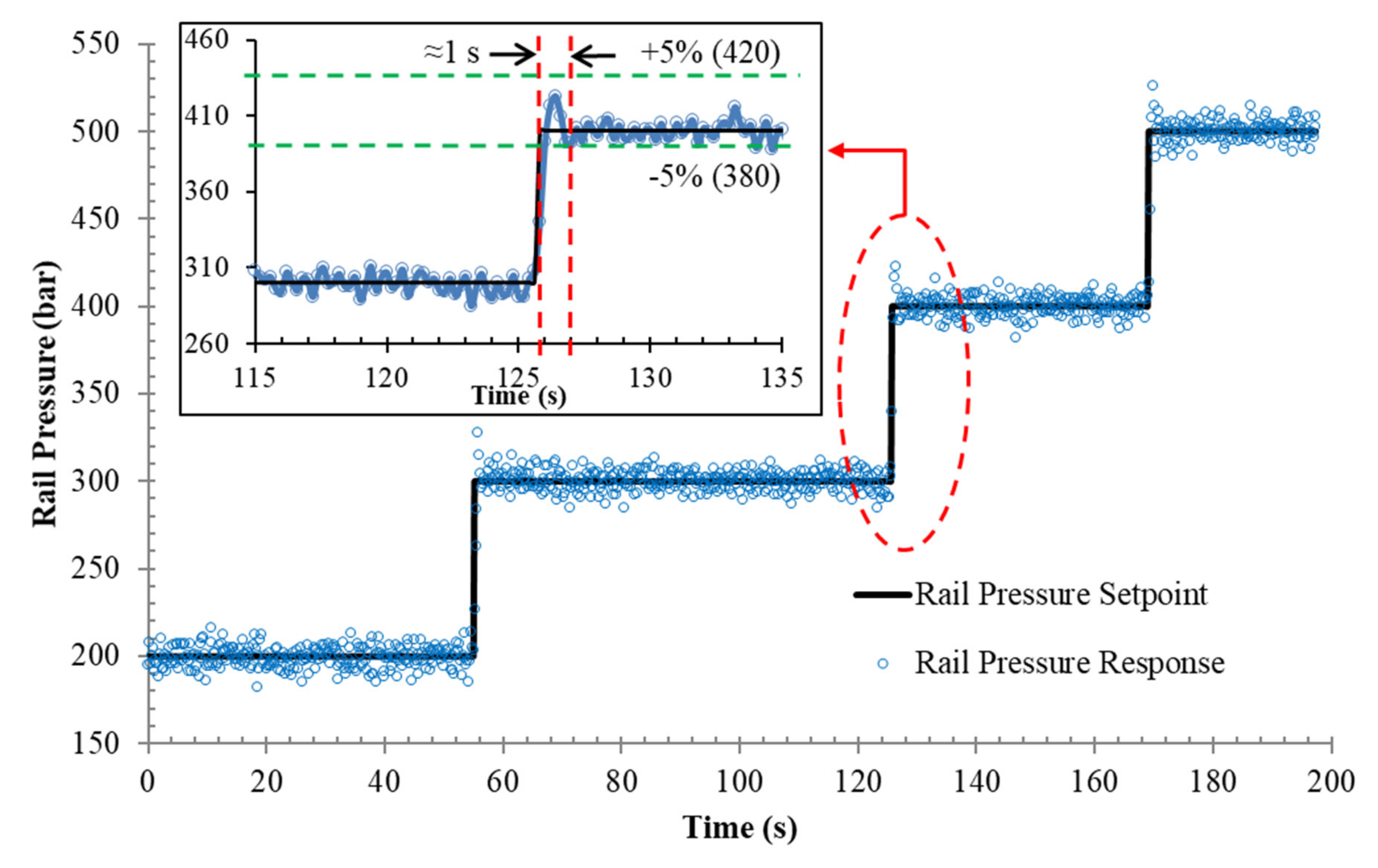

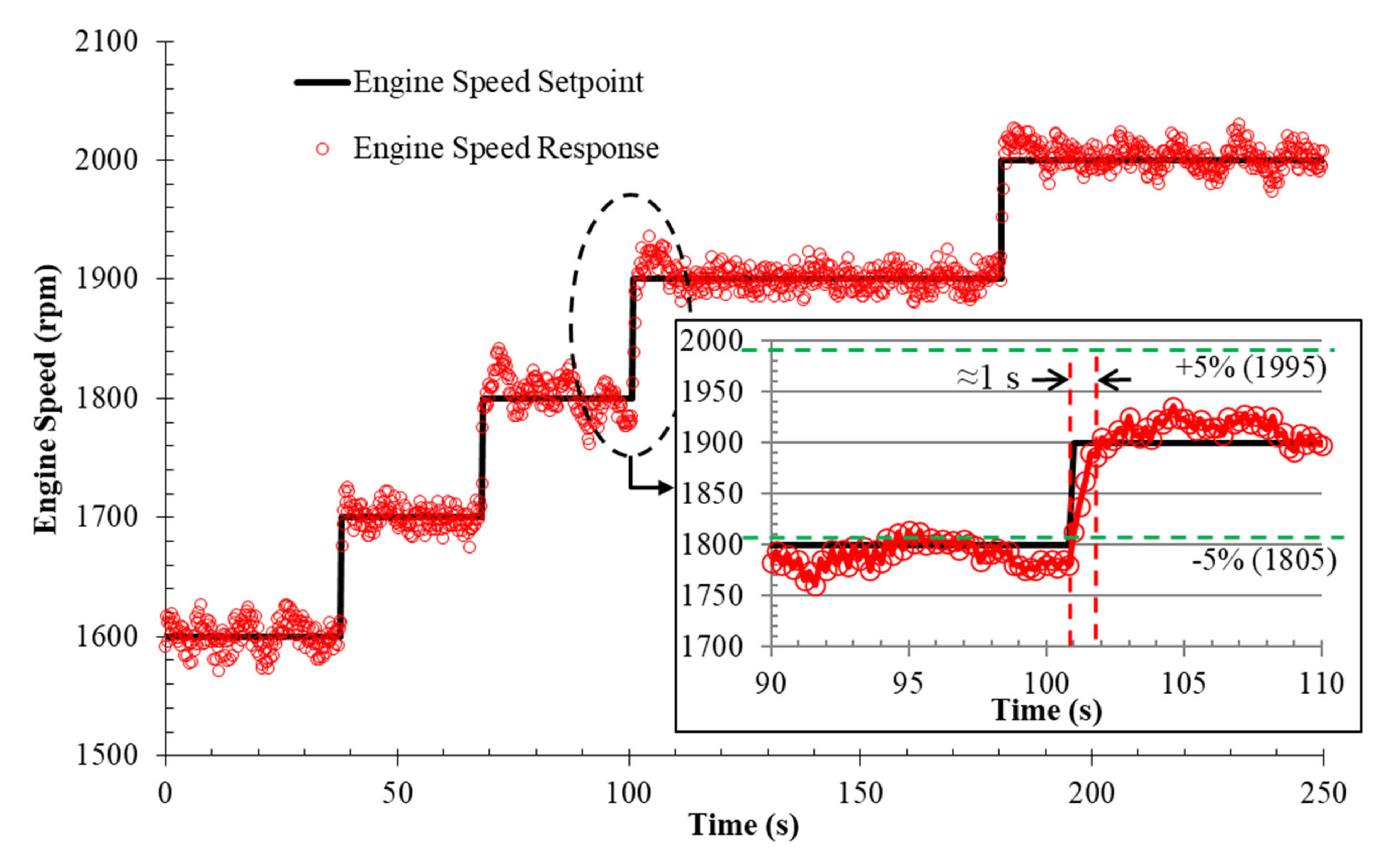

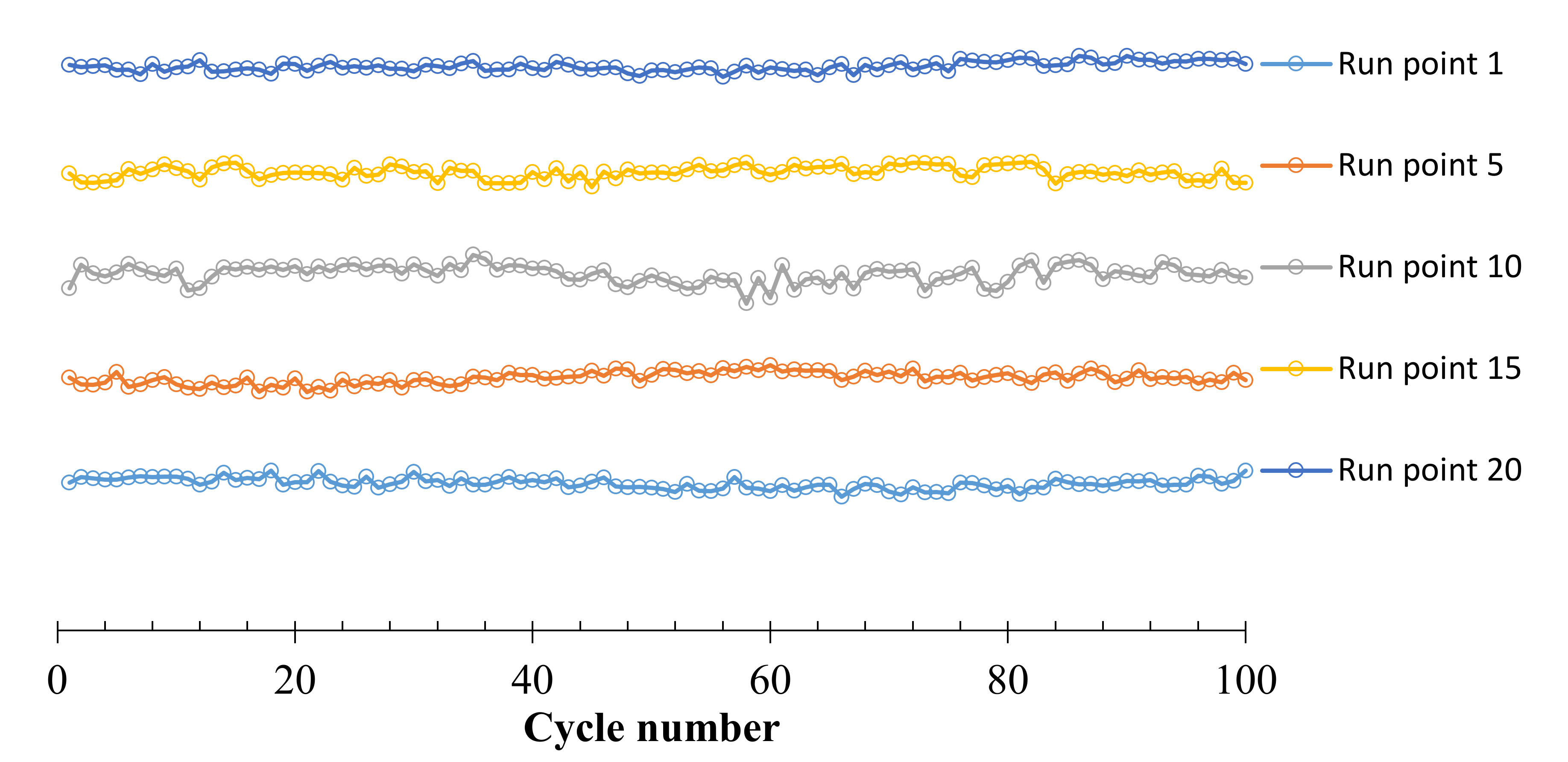

3.1. Response Characteristics

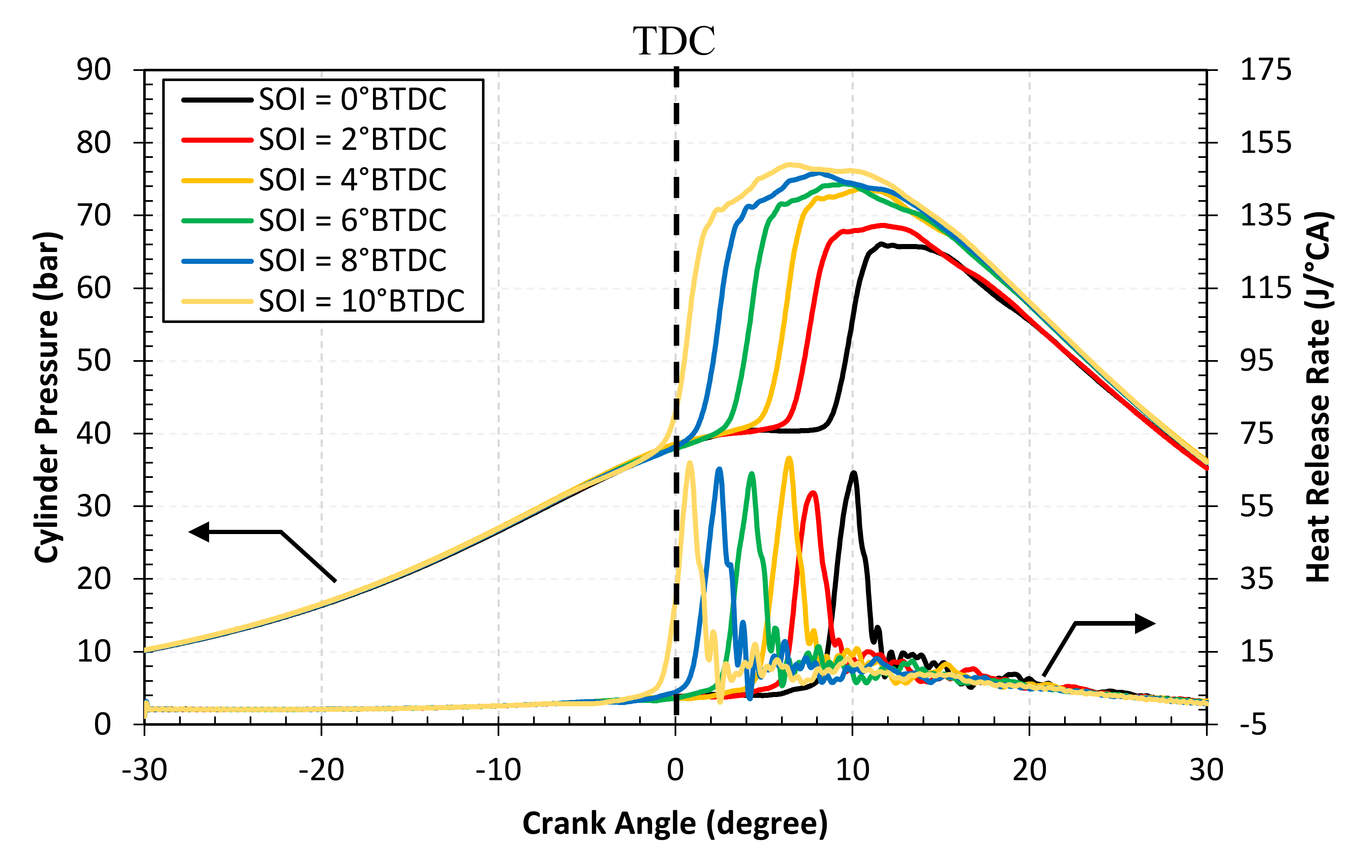

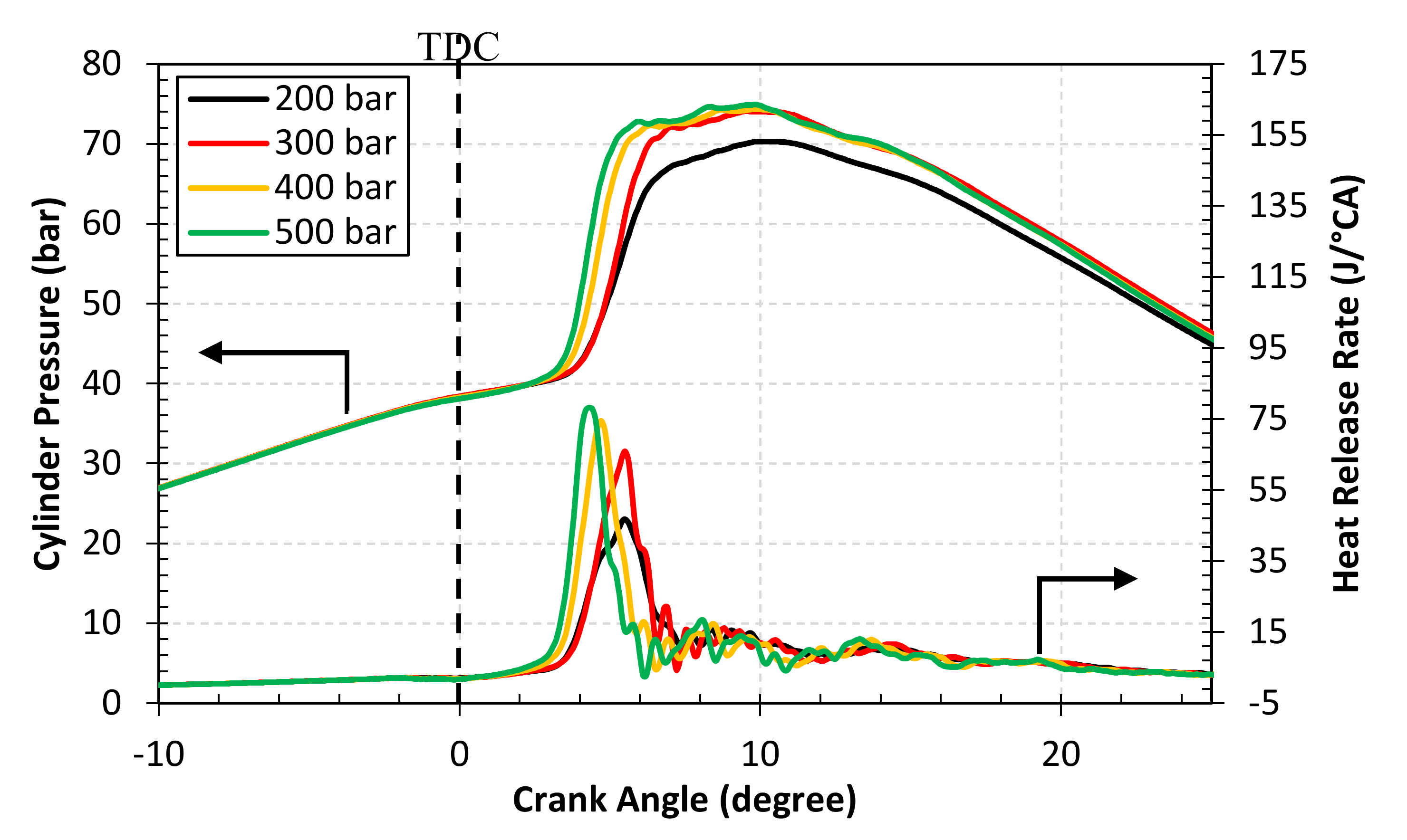

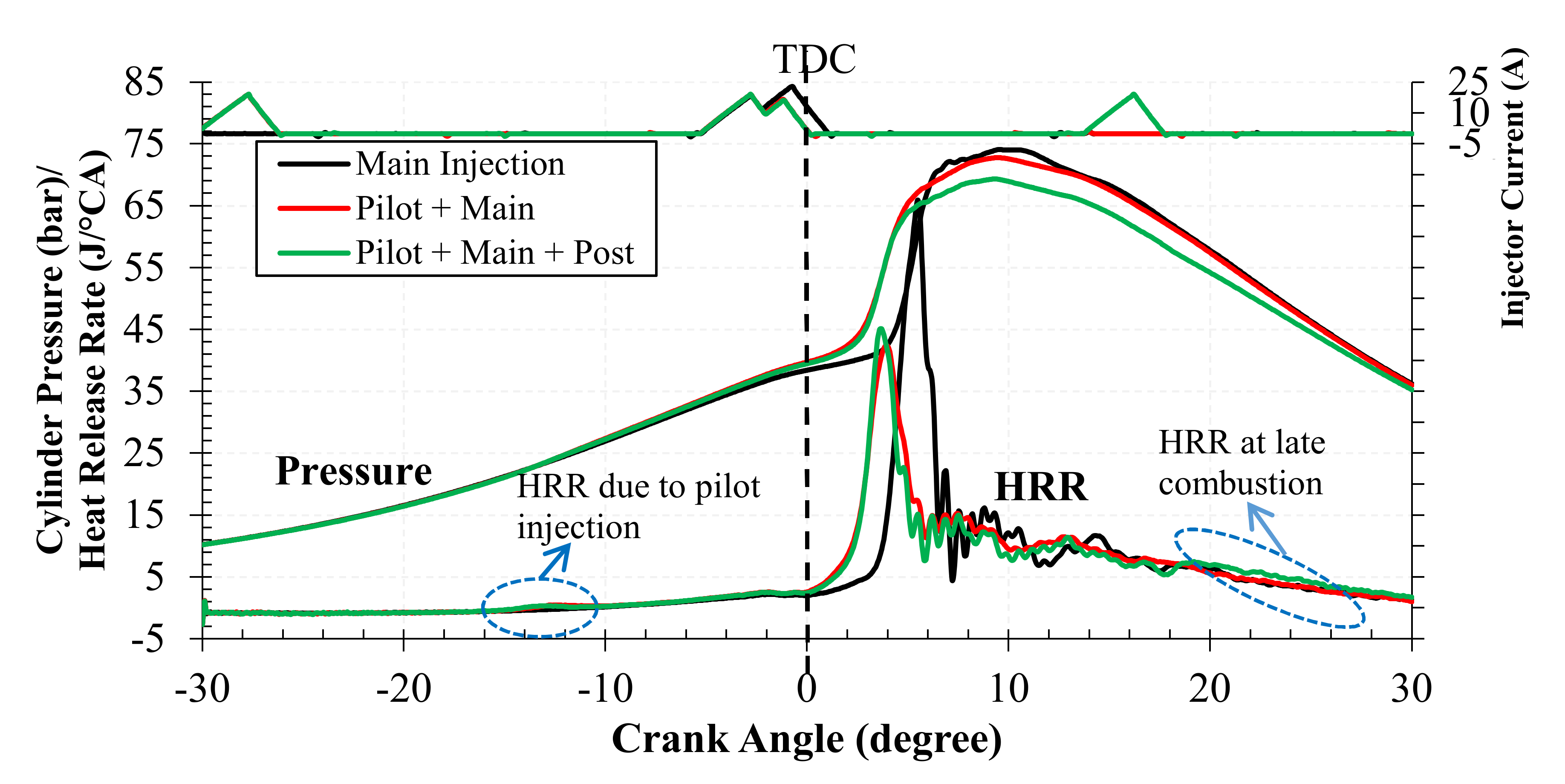

3.2. Combustion Characteristics

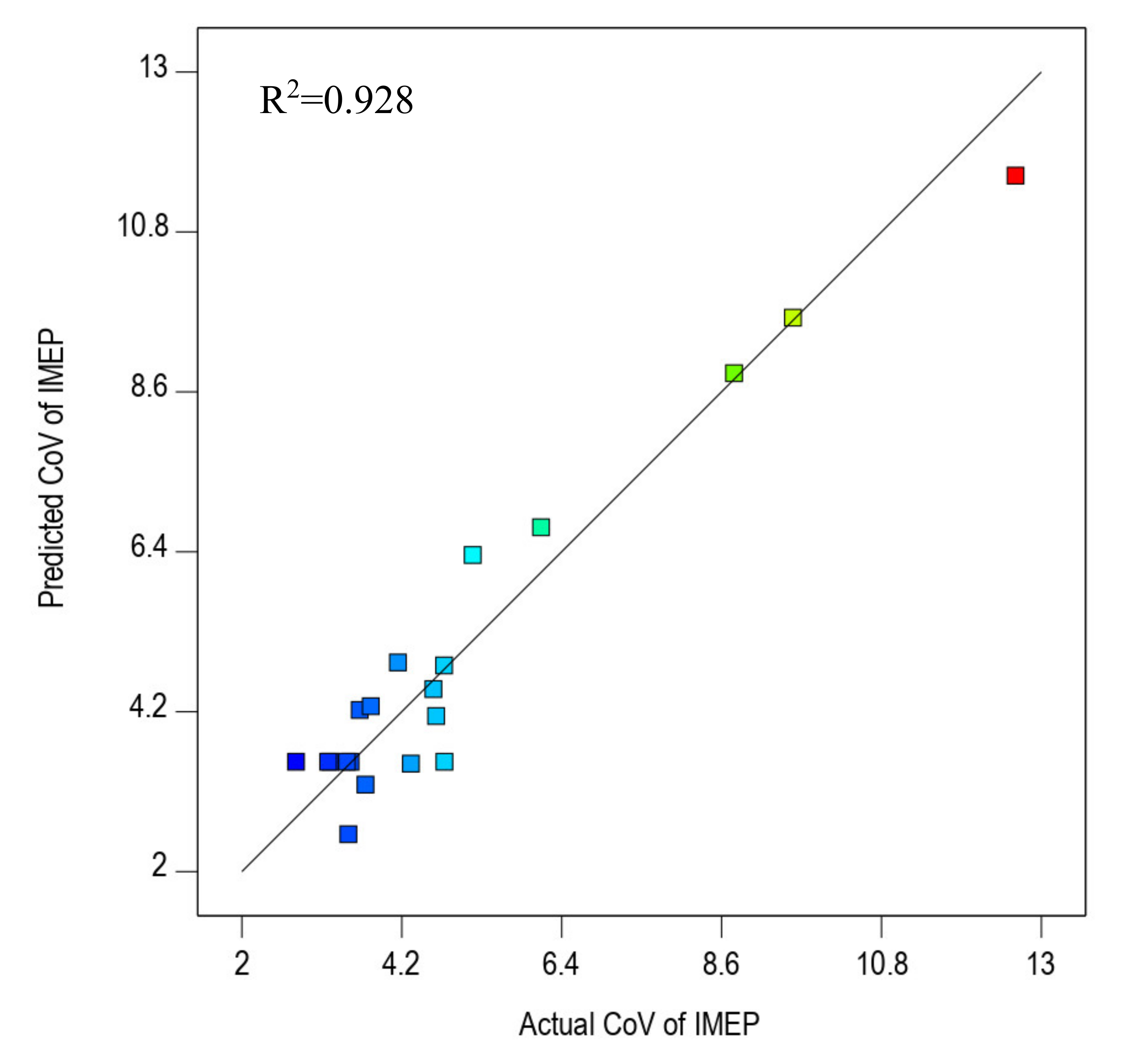

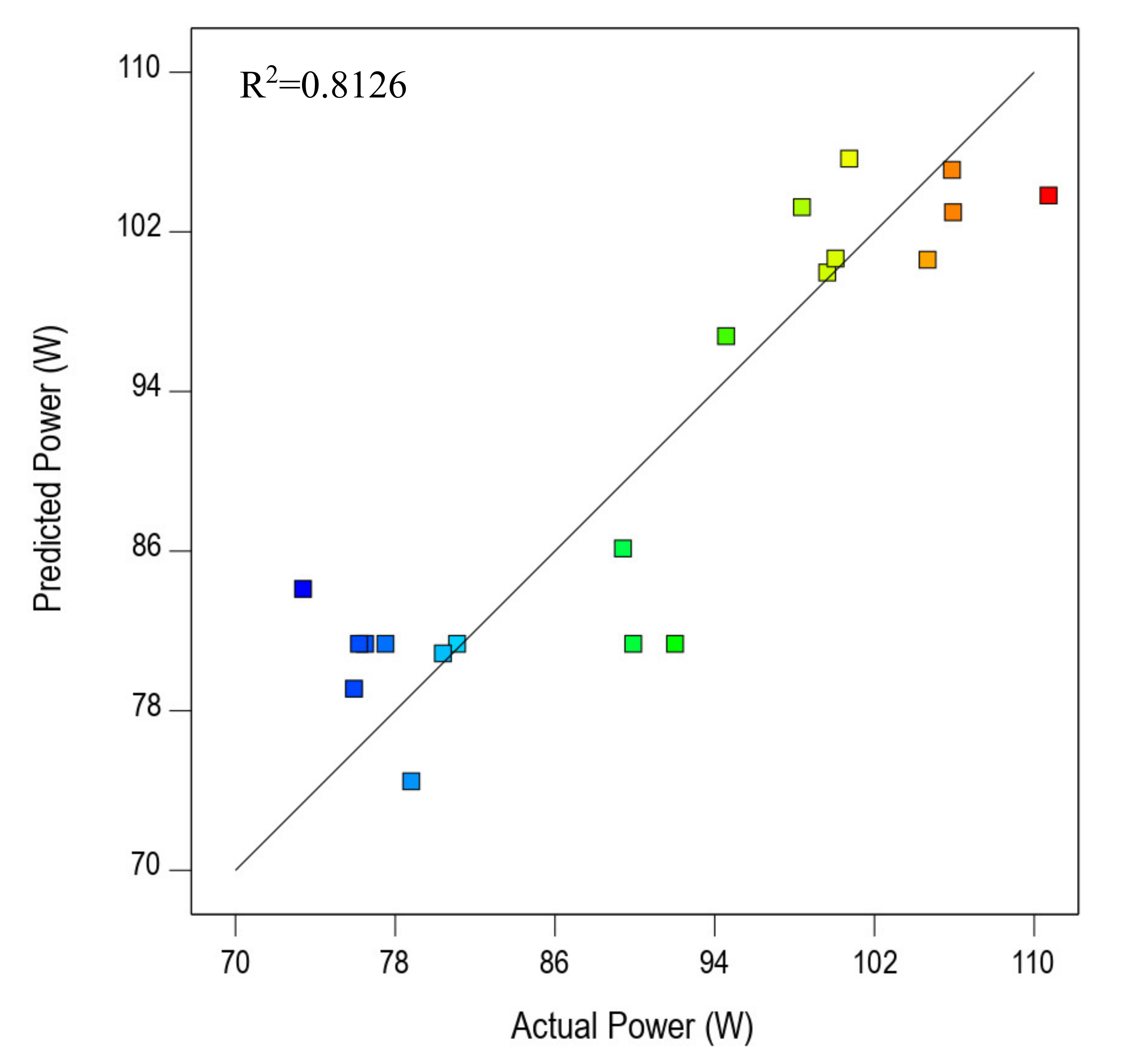

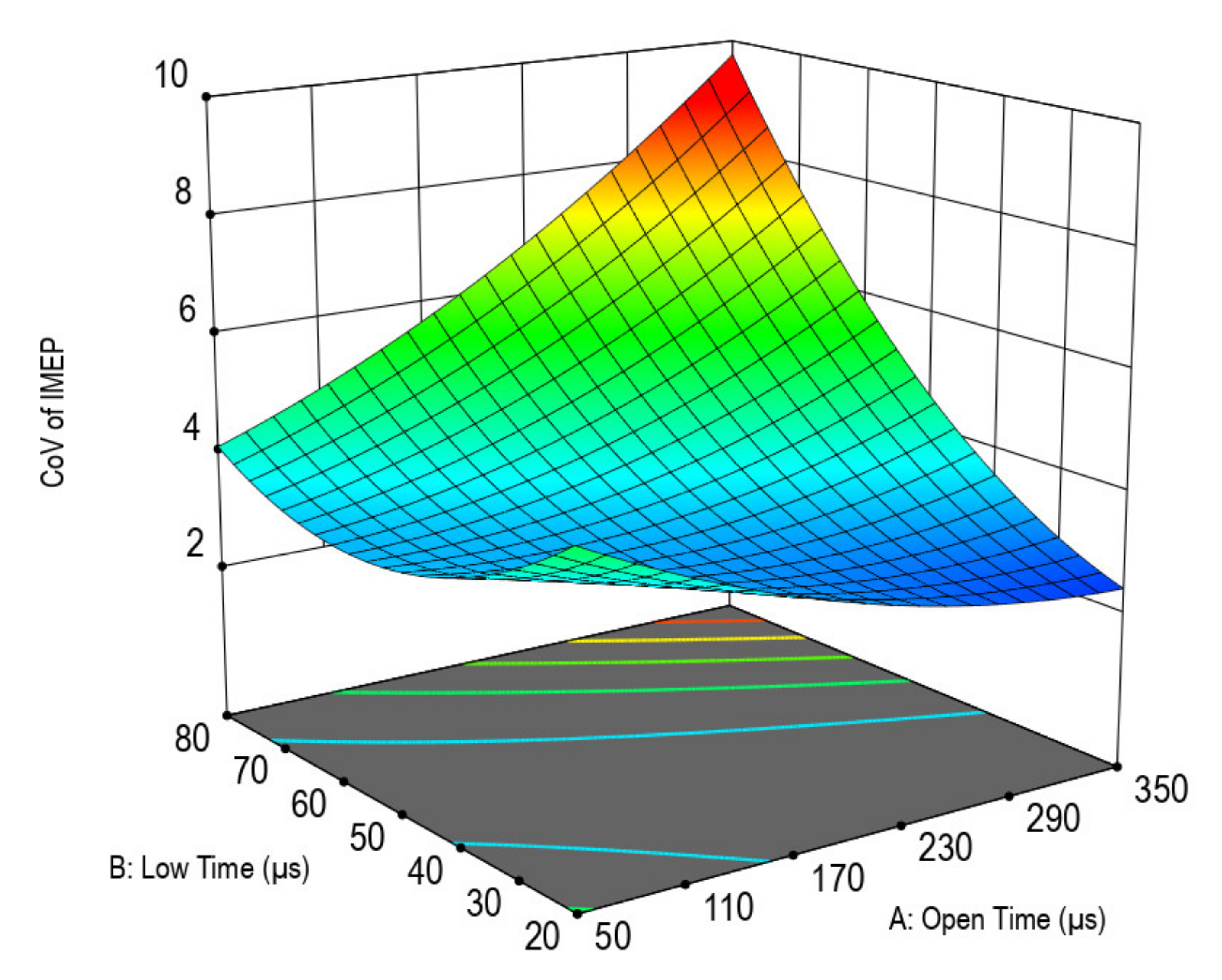

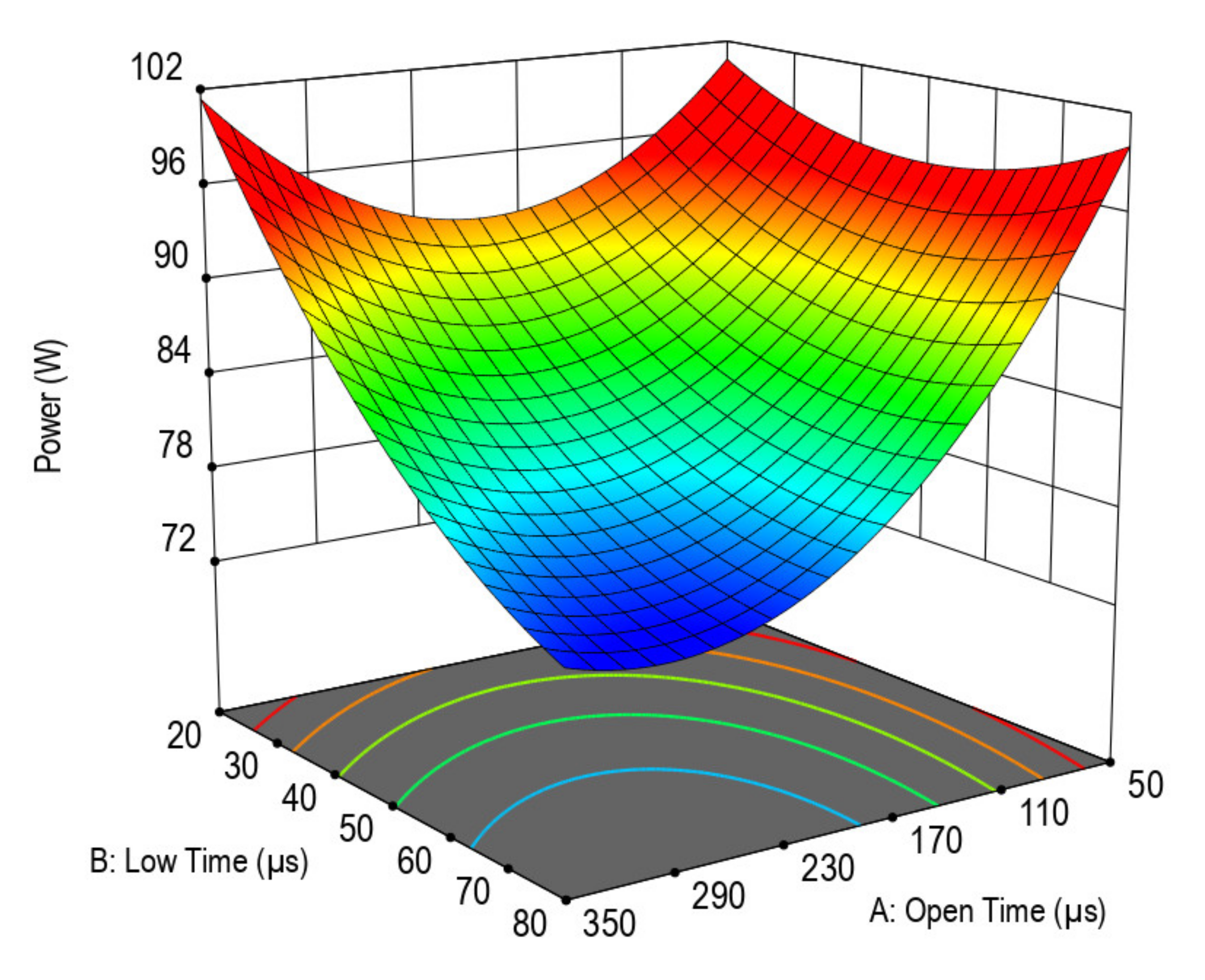

3.3. Optimization of Injector Parameters

3.4. Result Validation

4. Conclusions

- The rail pressure response showed an error of less than 5% at steady state and rising time of less than 1 s. Hence, the rail pressure response was accurate and sufficiently quick.

- The engine speed response showed an error of less than 5% at steady state and rising time of around 1 s. Hence, the engine speed response was accurate and sufficiently quick.

- When SOI timing was advanced, the in-cylinder peak pressure increased and was shifted towards TDC, causing an increase in brake torque.

- When rail pressure was increased, the in-cylinder peak pressure increased and was shifted towards TDC, causing an increase in brake torque.

- Implementation of multiple injection scheme caused a decrease in maximum PRR and peak HRR.

- Application of post injection increased the late combustion HRR.

- The optimum injector parameters to achieve lowest CoV of IMEP and injector power were 230 µs Open time with 53 µs Low time and 27.5% duty cycle.

- Percentage of error between predicted and experimental results of injector power when optimum injector parameters were applied was 0.033%.

- Percentage of error between predicted and experimental results of CoV of IMEP when optimum injector parameters were applied was 4.83%.

Author Contributions

Funding

Conflicts of Interest

References

- United Nation. World Population Prospects The 2017 Revision: Key Findings and Advance Tables. 2017. Available online: https://esa.un.org/unpd/wpp/Publications/Files/WPP2017_KeyFindings.pdf (accessed on 11 August 2020).

- ExxonMobile. 2018 Outlook for Energy: A View to 2040. 2018. Available online: http://cdn.exxonmobil.com/~/media/global/files/outlook-for-energy/2018/2018-outlook-for-energy.pdf (accessed on 11 July 2020).

- International Energy Agency (IEA). Southeast Asia Energy Outlook. 2017. Available online: https://www.iea.org/publications/freepublications/publication/WEO2017SpecialReport_SoutheastAsiaEnergyOutlook.pdf (accessed on 11 July 2020).

- Mofijur, M.; Masjuki, H.H.; Kalam, M.; Rahman, S.A.; Mahmudul, H. Energy scenario and biofuel policies and targets in ASEAN countries. Renew. Sustain. Energy Rev. 2015, 46, 51–61. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Southeast Asia Energy Outlook—WEO Special Report. 2013. Available online: https://www.iea.org/publications/freepublications/publication/SoutheastAsiaEnergyOutlook_WEO2013SpecialReport.pdf (accessed on 30 July 2020).

- IEA. IEA (2020), European Union 2020. 2020. Available online: https://www.iea.org/reports/european-union-2020 (accessed on 11 July 2020).

- BP. Statistical Review of World Energy 2016. 2016. Available online: https://www.bp.com/content/dam/bp/pdf/energy-economics/statistical-review-2016/bp-statistical-review-of-world-energy-2016-full-report.pdf (accessed on 11 July 2020).

- Behera, S.R.; Dash, D.P. The effect of urbanization, energy consumption, and foreign direct investment on the carbon dioxide emission in the SSEA (South and Southeast Asian) region. Renew. Sustain. Energy Rev. 2017, 70, 96–106. [Google Scholar] [CrossRef]

- Gonzalez-Sanchez, M.; Martín-Ortega, J.L. Greenhouse Gas Emissions Growth in Europe: A Comparative Analysis of Determinants. Sustainability 2020, 12, 1012. [Google Scholar] [CrossRef]

- Virginie Marchal, R.D.; van Vuuren, D.; Clapp, C.; Château, J.; Lanzi, E.; Magné, B.; van Vliet, J. OECD ENVIRONMENTAL OUTLOOK TO 2050. CHAPTER 3: CLIMATE CHANGE. 2011. Available online: https://www.oecd.org/env/cc/49082173.pdf (accessed on 15 January 2018).

- Liaquat, A.M.; Kalam, M.A.; Masjuki, H.H.; Jayed, M.H. Potential emissions reduction in road transport sector using biofuel in developing countries. Atmos. Environ. 2010, 44, 3869–3877. [Google Scholar] [CrossRef]

- Gilpin, G.; Hanssen, O.J.; Czerwinski, J. Biodiesel’s and advanced exhaust aftertreatment’s combined effect on global warming and air pollution in EU road-freight transport. J. Clean. Prod. 2014, 78, 84–93. [Google Scholar] [CrossRef]

- Borecki, M.; Prus, P.; Korwin-Pawlowski, M.L. Capillary Sensor with Disposable Optrode for Diesel Fuel Quality Testing. Sensors 2019, 19, 1980. [Google Scholar] [CrossRef]

- Borecki, M.; Gęca, M.; Korwin-Pawlowski, M.L.; Prus, P. Capillary Sensor with UV-Forced Degradation and Examination of Fluorescence for Determination of Chemical Stability of Diesel and Biodiesel Fuels. Sens. Transducers 2018, 220, 20–30. [Google Scholar]

- Tamilselvan, P.; Nallusamy, N.; Rajkumar, S. A comprehensive review on performance, combustion and emission characteristics of biodiesel fuelled diesel engines. Renew. Sustain. Energy Rev. 2017, 79, 1134–1159. [Google Scholar] [CrossRef]

- Wierzbicka, A.; Nilsson, P.T.; Rissler, J.; Sällsten, G.; Xu, Y.; Pagels, J.; Albin, M.; Österberg, K.; Strandberg, B.; Eriksson, A.; et al. Detailed diesel exhaust characteristics including particle surface area and lung deposited dose for better understanding of health effects in human chamber exposure studies. Atmos. Environ. 2014, 86, 212–219. [Google Scholar] [CrossRef]

- Tan, X.-G.; Sang, H.-L.; Qiu, T.; Fan, Z.-Q.; Yin, W.-H. The Impact of Common Rail System’s Control Parameters on the Performance of High-power Diesel. Energy Procedia 2012, 16, 2067–2072. [Google Scholar]

- Natarajan, S.; Trasy, K.A.; Srihari, N.; Raja, S. Effects of Injection Timing on CI Engine Fuelled with Algae Oil Blend with Taguchi Technique. Energy Procedia 2017, 105, 1043–1050. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Raj, R.T.K.; Bhasker, J.P.; Vignesh, D.S. Influence of injection timing and exhaust gas recirculation of a Calophyllum inophyllum methyl ester fuelled CI engine. Fuel Process. Technol. 2017, 167, 18–30. [Google Scholar] [CrossRef]

- Lim, G.; Lee, S.; Park, C.; Choi, Y.; Kim, C.G. Effect of ignition timing retard strategy on NOx reduction in hydrogen-compressed natural gas blend engine with increased compression ratio. Int. J. Hydrog. Energy 2014, 39, 2399–2408. [Google Scholar] [CrossRef]

- How, H.; Masjuki, H.H.; Kalam, M.; Teoh, Y. Influence of injection timing and split injection strategies on performance, emissions, and combustion characteristics of diesel engine fueled with biodiesel blended fuels. Fuel 2018, 213, 106–114. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Srivastava, D.K.; Dhar, A.; Maurya, R.K.; Shukla, P.C.; Singh, A.P. Effect of fuel injection timing and pressure on combustion, emissions and performance characteristics of a single cylinder diesel engine. Fuel 2013, 111, 374–383. [Google Scholar] [CrossRef]

- Park, S.H.; Yoon, S.H.; Lee, C.S. HC and CO emissions reduction by early injection strategy in a bioethanol blended diesel-fueled engine with a narrow angle injection system. Appl. Energy 2013, 107, 81–88. [Google Scholar] [CrossRef]

- Khalid, A.; Manshoor, B. Effect of high injection pressure on mixture formation, burning process and combustion characteristics in diesel combustion. World Acad. Sci. Eng. Technol. 2012. [Google Scholar] [CrossRef]

- Chen, P.-C.; Wang, W.-C.; Roberts, W.L.; Fang, T. Spray and atomization of diesel fuel and its alternatives from a single-hole injector using a common rail fuel injection system. Fuel 2013, 103, 850–861. [Google Scholar] [CrossRef]

- Srinath, P.; Abdul, S.; Shreeprakash, B. Study of the Effect of Fuel Injection Pressure on Diesel Engine Performance and Emission—A Review. In Proceedings of the IEEE -International Conference on Research and Development Prospectus on Engineering and Technology (ICRDPET), EGS Pillay Engineering College, Nagapattinam, Tamil Nadu, India, 29–30 March 2013. [Google Scholar]

- Hwang, J.; Qi, D.; Jung, Y.; Bae, C. Effect of injection parameters on the combustion and emission characteristics in a common-rail direct injection diesel engine fueled with waste cooking oil biodiesel. Renew. Energy 2014, 63, 9–17. [Google Scholar] [CrossRef]

- Aalam, C.S.; Saravanan, C.; Anand, B.P. Impact of high fuel injection pressure on the characteristics of CRDI diesel engine powered by mahua methyl ester blend. Appl. Therm. Eng. 2016, 106, 702–711. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Ashok, B.; Rajagopal, T.K.R. Influence of fuel injection pressures on Calophyllum inophyllum methyl ester fuelled direct injection diesel engine. Energy Convers. Manag. 2016, 116, 165–173. [Google Scholar] [CrossRef]

- Gumus, M.; Sayin, C.; Canakci, M. The impact of fuel injection pressure on the exhaust emissions of a direct injection diesel engine fueled with biodiesel–diesel fuel blends. Fuel 2012, 95, 486–494. [Google Scholar] [CrossRef]

- Labecki, L.; Ganippa, L. Effects of injection parameters and EGR on combustion and emission characteristics of rapeseed oil and its blends in diesel engines. Fuel 2012, 98, 15–28. [Google Scholar] [CrossRef]

- Sperl, A. The Influence of Post-Injection Strategies on the Emissions of Soot and Particulate Matter in Heavy Duty Euro V Diesel Engine. SAE Tech. Pap. Ser. 2011. [Google Scholar] [CrossRef]

- Wang, Z.; Wyszynski, M.L.; Xu, H.; Abdullah, N.R.; Piaszyk, J. Fuel injection and combustion study by the combination of mass flow rate and heat release rate with single and multiple injection strategies. Fuel Process. Technol. 2015, 132, 118–132. [Google Scholar] [CrossRef]

- Busch, S.; Zha, K.; Miles, P.C. Investigations of closely coupled pilot and main injections as a means to reduce combustion noise in a small-bore direct injection Diesel engine. Int. J. Engine Res. 2014, 16, 13–22. [Google Scholar] [CrossRef]

- Badami, M.; Mallamo, F.; Millo, F.; Rossi, E.E. Influence of Multiple Injection Strategies on Emissions, Combustion Noise and BSFC of a DI Common Rail Diesel Engine. SAE Tech. Pap. Ser. 2002. [Google Scholar] [CrossRef]

- D’Ambrosio, S.; Ferrari, A. Potential of double pilot injection strategies optimized with the design of experiments procedure to improve diesel engine emissions and performance. Appl. Energy 2015, 155, 918–932. [Google Scholar] [CrossRef]

- Zhuang, J.; Qiao, X.; Bai, J.; Hu, Z. Effect of injection-strategy on combustion, performance and emission characteristics in a DI-diesel engine fueled with diesel from direct coal liquefaction. Fuel 2014, 121, 141–148. [Google Scholar] [CrossRef]

- Goldwine, G. The Effect of Fuel Injection Profile on Diesel Engine Performance. Ph.D. Thesis, The Senate of Ben-Gurion University, Beersheba, Israel, 2008. [Google Scholar]

- Ergenç, A.T.; Koca, D.Ö. PLC controlled single cylinder diesel-LPG engine. Fuel 2014, 130, 273–278. [Google Scholar] [CrossRef]

- Carpenter, A.L.; Mayo, R.E.; Wagner, J.G.; Yelvington, P.E. High-Pressure Electronic Fuel Injection for Small-Displacement Single-Cylinder Diesel Engines. J. Eng. Gas Turbines Power 2016, 138, 102808. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Gupta, P.; Dhar, A. Combustion, performance and emissions characteristics of a newly developed CRDI single cylinder diesel engine. Sadhana 2015, 40, 1937–1954. [Google Scholar] [CrossRef]

- Mäkelä, M. Experimental design and response surface methodology in energy applications: A tutorial review. Energy Convers. Manag. 2017, 151, 630–640. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Deng, Y.; Xu, X.; He, X.; Zhao, Y.; Zou, Y.; Liu, Z.; Yue, J. Optimization of air jet impingement drying of okara using response surface methodology. Food Control. 2016, 59, 743–749. [Google Scholar] [CrossRef]

- Gunst, R.F. Response Surface Methodology: Process and Product Optimization Using Designed Experiments. Technometrics 1996, 38, 284–286. [Google Scholar] [CrossRef]

- Gilmour, S.G. Response Surface Designs for Experiments in Bioprocessing. Biometrics 2005, 62, 323–331. [Google Scholar] [CrossRef]

- Yusri, I.; Majeed, A.P.P.A.; Mamat, R.; Ghazali, M.; Awad, O.I.; Azmi, W. A review on the application of response surface method and artificial neural network in engine performance and exhaust emissions characteristics in alternative fuel. Renew. Sustain. Energy Rev. 2018, 90, 665–686. [Google Scholar] [CrossRef]

- Singh, Y.; Sharma, A.; Singh, G.K.; Singla, A.; Singh, N.K. Optimization of performance and emission parameters of direct injection diesel engine fuelled with pongamia methyl esters-response surface methodology approach. Ind. Crop. Prod. 2018, 126, 218–226. [Google Scholar] [CrossRef]

- Sharma, A.; Singh, Y.; Singh, G.K.; Habte, A.T.; Singh, N. Production of polanga methyl esters and optimization of diesel engine parameters through response surface methodology approach. Process. Saf. Environ. Prot. 2019, 121, 94–102. [Google Scholar] [CrossRef]

- Patel, H.; Rajai, V.; Das, P.; Charola, S.; Mudgal, A.; Maiti, S. Study of Jatropha curcas shell bio-oil-diesel blend in VCR CI engine using RSM. Renew. Energy 2018, 122, 310–322. [Google Scholar] [CrossRef]

- Khoobbakht, G.; Karimi, M.; Kheialipour, K. Effects of biodiesel-ethanol-diesel blends on the performance indicators of a diesel engine: A study by response surface modeling. Appl. Therm. Eng. 2019, 148, 1385–1394. [Google Scholar] [CrossRef]

- Gopal, K.; Sathiyagnanam, A.; Kumar, B.R.; Saravanan, S.; Rana, D.; Sethuramasamyraja, B. Prediction of emissions and performance of a diesel engine fueled with n-octanol/diesel blends using response surface methodology. J. Clean. Prod. 2018, 184, 423–439. [Google Scholar] [CrossRef]

- Buxton, R. Design Expert 7: Introduction. 2007. Available online: https://www.lboro.ac.uk/media/media/schoolanddepartments/mlsc/downloads/Design-Expert-7.pdf (accessed on 8 September 2020).

- Jeon, J.; Park, S. Effects of pilot injection strategies on the flame temperature and soot distributions in an optical CI engine fueled with biodiesel and conventional diesel. Appl. Energy 2015, 160, 581–591. [Google Scholar] [CrossRef]

- Li, H.; Song, C.; Lv, G.; Pang, H.; Qiao, Y. Assessment of the impact of post-injection on exhaust pollutants emitted from a diesel engine fueled with biodiesel. Renew. Energy 2017, 114, 924–933. [Google Scholar] [CrossRef]

| Parameter | (a) Construction Base Engine | (b) Test Engine |

|---|---|---|

| Bore Stroke | 70 mm 57 mm | |

| Displacement | 219 cm3 | |

| Rated power | 3.5 kW @3600 rpm | |

| Compression ratio | 20.1:1 | |

| Fuel injection system | Mechanical cam driven injection | Electronic common rail fuel injection |

| Fuel pump | Engine mechanically driven | Electrically driven |

| Component | Specification | |

|---|---|---|

| Fuel Injector | Model | Delphi |

| Number of injector nozzle | 5 | |

| Nominal injector nozzle diameter | 0.134 mm | |

| Supply voltage | 12 V | |

| Fuel Supply Pump | Model | Denso HP 3 gear pump |

| Maximum working pressure | 1800 bar | |

| Variable Investigated | Value Tested | Constant |

|---|---|---|

| SOI timing | 0, 2, 4, 6, 8, 10°BTDC | Engine speed: 1600 rpm Load: 5 Nm |

| Rail pressure | 200, 300, 400, 500 bar | Engine speed: 1600 rpm Load: 5 Nm SOI timings: 4°BTDC |

| Multiple injection scheme | Main injection Pilot + main injection Pilot + main + post injection | Engine speed: 1600 rpm Load: 5 Nm SOI timings: 4°BTDC |

| Std | Run | Factor 1 | Factor 2 | Factor 3 |

|---|---|---|---|---|

| A: Open Time | B: Low Time | C: PWM | ||

| (µs) | (µs) | (%) | ||

| 6 | 1 | 350 | 20 | 40 |

| 17 | 2 | 450 | 50 | 30 |

| 15 | 3 | 50 | 20 | 40 |

| 18 | 4 | 200 | 100 | 30 |

| 10 | 5 | 200 | 50 | 47 |

| 16 | 6 | 200 | 50 | 30 |

| 7 | 7 | 200 | 50 | 30 |

| 20 | 8 | 50 | 80 | 20 |

| 13 | 9 | 200 | 50 | 15 |

| 19 | 10 | 50 | 20 | 20 |

| 9 | 11 | 200 | 50 | 30 |

| 1 | 12 | 200 | 0 | 30 |

| 11 | 13 | 350 | 80 | 20 |

| 3 | 14 | 350 | 20 | 20 |

| 12 | 15 | 0 | 50 | 30 |

| 8 | 16 | 200 | 50 | 30 |

| 2 | 17 | 350 | 80 | 40 |

| 4 | 18 | 200 | 50 | 30 |

| 5 | 19 | 50 | 80 | 40 |

| 14 | 20 | 200 | 50 | 30 |

| Run Point | Open Time (µs) | Low Time (µs) | Duty Cycle (%) |

|---|---|---|---|

| 1 | 350 | 20 | 40 |

| 5 | 200 | 50 | 47 |

| 10 | 50 | 20 | 20 |

| 15 | 0 | 50 | 30 |

| 20 | 200 | 50 | 30 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 111.48 | 9 | 12.39 | 14.32 | 0.0001 | significant |

| A-Open Time | 7.19 | 1 | 7.19 | 8.32 | 0.0163 | |

| B-Low Time | 35.54 | 1 | 35.54 | 41.08 | < 0.0001 | |

| C-PWM | 0.0118 | 1 | 0.0118 | 0.0137 | 0.9092 | |

| AB | 33.98 | 1 | 33.98 | 39.28 | < 0.0001 | |

| AC | 5.38 | 1 | 5.38 | 6.22 | 0.0318 | |

| BC | 2.07 | 1 | 2.07 | 2.39 | 0.1529 | |

| A2 | 3.37 | 1 | 3.37 | 3.9 | 0.0767 | |

| B2 | 21.36 | 1 | 21.36 | 24.69 | 0.0006 | |

| C2 | 2.66 | 1 | 2.66 | 3.08 | 0.1098 | |

| Residual | 8.65 | 10 | 0.8651 | |||

| Lack of Fit | 6.25 | 5 | 1.25 | 2.6 | 0.1591 | not significant |

| Pure Error | 2.4 | 5 | 0.4809 | |||

| Cor Total | 120.13 | 19 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 2314.49 | 9 | 257.17 | 4.82 | 0.0109 | significant |

| A-Open Time | 440.76 | 1 | 440.76 | 8.26 | 0.0166 | |

| B-Low Time | 610.25 | 1 | 610.25 | 11.44 | 0.007 | |

| C-Duty cycle | 1.78 | 1 | 1.78 | 0.0333 | 0.8589 | |

| AB | 320.05 | 1 | 320.05 | 6 | 0.0343 | |

| AC | 29.36 | 1 | 29.36 | 0.5501 | 0.4753 | |

| BC | 0.0097 | 1 | 0.0097 | 0.0002 | 0.9895 | |

| A2 | 893.12 | 1 | 893.12 | 16.74 | 0.0022 | |

| B2 | 210.06 | 1 | 210.06 | 3.94 | 0.0754 | |

| C2 | 26.61 | 1 | 26.61 | 0.4986 | 0.4962 | |

| Residual | 533.65 | 10 | 53.36 | |||

| Lack of Fit | 285.83 | 5 | 57.17 | 1.15 | 0.4397 | not significant |

| Pure Error | 247.82 | 5 | 49.56 | |||

| Cor Total | 2848.13 | 19 |

| CoV of IMEP | = | Power | = |

|---|---|---|---|

| 18.69484 | 133.4455 | ||

| −0.044174 | *Open Time | −0.171042 | *Open Time |

| −0.224953 | *Low Time | −0.374014 | *Low Time |

| −0.469936 | *Duty cycle | −1.10553 | *Duty cycle |

| 0.000458 | *Open Time * Low Time | −0.001406 | *Open Time * Low Time |

| 0.000547 | *Open Time * Duty cycle | 0.001277 | *Open Time * Duty cycle |

| 0.001696 | *Low Time * Duty cycle | 0.000116 | *Low Time * Duty cycle |

| 0.000025 | *(Open Time)2 | 0.000407 | *(Open Time)2 |

| 0.001365 | *(Low Time)2 | 0.00428 | *(Low Time)2 |

| 0.004648 | *(Duty cycle)2 | 0.014689 | *(Duty cycle)2 |

| Experimental | Predicted | ||

|---|---|---|---|

| CoV of IMEP | 4.0244 | 3.8299 | 4.83% |

| Power (W) | 79.8338 | 79.8077 | 0.033% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teoh, Y.H.; How, H.G.; Peh, C.G.; Le, T.D.; Nguyen, H.T. Implementation of Common Rail Direct Injection System and Optimization of Fuel Injector Parameters in an Experimental Single-Cylinder Diesel Engine. Processes 2020, 8, 1122. https://doi.org/10.3390/pr8091122

Teoh YH, How HG, Peh CG, Le TD, Nguyen HT. Implementation of Common Rail Direct Injection System and Optimization of Fuel Injector Parameters in an Experimental Single-Cylinder Diesel Engine. Processes. 2020; 8(9):1122. https://doi.org/10.3390/pr8091122

Chicago/Turabian StyleTeoh, Yew Heng, Heoy Geok How, Ching Guan Peh, Thanh Danh Le, and Huu Tho Nguyen. 2020. "Implementation of Common Rail Direct Injection System and Optimization of Fuel Injector Parameters in an Experimental Single-Cylinder Diesel Engine" Processes 8, no. 9: 1122. https://doi.org/10.3390/pr8091122

APA StyleTeoh, Y. H., How, H. G., Peh, C. G., Le, T. D., & Nguyen, H. T. (2020). Implementation of Common Rail Direct Injection System and Optimization of Fuel Injector Parameters in an Experimental Single-Cylinder Diesel Engine. Processes, 8(9), 1122. https://doi.org/10.3390/pr8091122