1. Introduction

Bubble properties in a fluidized bed are of high interest for reaction modeling and the prediction of the behavior in scale-up. If the size, shape, distribution and velocity of bubbles are known, the volume-specific area of the bubble phase can be predicted, which is an important factor for modeling mass-transfer behavior. Furthermore, it enables predicting the expansion of the fluidized bed and consequent impact on the reactor design and reaction conversion.

Most investigations of bubble properties in fluidized beds were done in the bubbling fluidized bed regime [

1]. Different methods of measuring were used, such as surface photography, photography in quasi two-dimensional fluidized beds, capacitance probes, fiber optical probes, electro-resistive probes, X-ray photography, magnetic resonance imaging and more [

1,

2]. Capacitance probes were used by several authors as a reliable tool for fluid-dynamic and bubble flow investigations [

3,

4,

5,

6,

7,

8,

9]. This type of probe can be operated in extreme conditions, such as high temperature beds, for both the dilute and dense phases with high solids concentrations [

10,

11,

12].

Capacitance probes measure temporal local changes in the solid concentration. The simultaneous measurement of two channels aligned vertically above each other allows to determine the time lag of sudden changes in concentration induced by bubbles rising in the fluidized bed [

3]. Because movements of bubbles are much larger in the vertical direction than horizontally, the local measurements of these concentration variations give information about vertical movements and bubble sizes only.

Bubbles in fluidized beds are three dimensional and their horizontal size can only be determined by imaging measurement techniques, such as magnetic resonance imaging of miniature size plants or photography in quasi two-dimensional fluidized beds. The shape of bubbles in fluidized beds is known to be non-spherical. In the bubbling fluidized bed flow regime several studies were conducted to determine bubble shapes slightly above the minimum fluidization velocity [

1]. Most of the authors described bubbles as spherical caps pushing a cloud of particles above them and dragging particles in a wake below them [

1,

4]. The shape of a bubble was found to be of a cap, with different sizes in the horizontal and vertical directions. Determining the vertical length of a bubble using capacitance probes poses a challenge: depending on the radial position of the probe in which it penetrates in the bubble, different values will be measured. A stochastic distribution is thus observed [

13], and instead of referring to a definite vertical length, the term “pierced length” is employed. Superimposed to this are the statistic processes of bubble formation, movement, coalescence and preferred flow paths, leading to local distributions of bubble sizes [

4]. For this reason, vertical sizes measured are a product of the overlapping distributions of size and pierced length.

Horizontal bubble sizes can only be estimated from capacitance probe measurements when the ratio of vertical bubble size to horizontal bubble size is known. Bar-Cohen et al. [

5] assumed the vertical bubble size to be equal to the volume-equivalent diameter (bubbles are spheres), whereas Werther [

7] described the bubbles based on spherical caps as rotationally symmetrical ellipsoids with a size-independent shape factor. Some authors assumed a shape factor of 1.6 to calculate the volume-equivalent diameter from the pierced length [

13,

14,

15].

Most research about bubble sizes in a turbulent regime or at the regime transition from bubbling to turbulent was performed for particles of Geldart group A [

16,

17,

18,

19]. In fluidized beds with these particles, bubbles attain a maximum size and break up. Consequently, bubble size does not increase even if the gas flow rate is increased. This corresponds to a maximum in the pressure fluctuations, which is the most conventional regime change measurement technique [

16]. This phenomenon results in high heat and mass transfer in a turbulent fluidized bed in comparison to a bubbling fluidized bed thanks to higher particle and gas mixing.

For beds containing particles of Geldart group B, Lee and Kim found a decrease of bubble sizes in the turbulent regime just as for smaller particles [

20]. By contrast, Werther and Wein and Andreux et al. measured larger bubble sizes with increasing superficial gas velocity even beyond the point of transition to the turbulent regime under similar conditions [

21,

22]. These findings contradict the theory of the decrease of pressure fluctuation intensities at larger superficial gas velocities in the turbulent regime due to lower bubble sizes. The studies of Lee and Kim and Werther and Wein considered a constant shape factor of the bubbles to calculate the bubble diameter from the measured pierced length as described above [

20,

21]. Magnetic resonance imaging showed that bubbles are irregular in shape in the turbulent regime [

23]. Thus, the assumption of the same constant shape factor for bubbles in turbulent beds as well as for bubbling beds is questionable. Bubbles in turbulent beds are generally described to be transient and to have indistinct or irregular boundaries [

16]. For this reason, they are often termed void.

The behavior of bubbles in bubbling fluidized beds show similarities to the rise of large bubbles in highly viscous liquids. For the rise velocity of a single bubble (

UB,single), Davidson and Harrison [

24] found the relation of the volume-equivalent bubble diameter (

dB,V) given in Equation (1), which origins from gas-liquid systems.

Because bubbles in fluidized beds rise in large numbers simultaneously, they influence each other by coalescence or breakup depending on the superficial gas velocity. This swarm behavior is considered in several correlations [

1]. These correlations are mostly based on the velocity of a single bubble (Equation (1) or a similar relationship of

UB as a function of

dB,V0.5) added by the influence of the swarm in bubbling fluidized beds. Velocities of bubbles rising at large superficial gas velocities in turbulent beds were found to be overestimated by the correlation given by Davidson and Harrison [

16,

22].

In this study, superficial gas velocities were varied over a broad range from bubbling into the turbulent fluidized bed regime. In the available literature, most studies have focused on the bubbling fluidized bed regime covering only low gas velocities [

1]. Only few studies exist with contradicting statements describing bubble behavior in turbulent beds of Geldart group B particles [

16,

19,

20,

21,

22]. For this reason, we investigated the influence of fluidized bed size and radial and axial measurement for beds of particles of this group in this work to achieve a deeper understanding of the mechanisms on bubble properties, such as size, velocity and shape.

2. Materials and Methods

2.1. Fluidized Bed Setups

Three fluidized bed plants having diameters of 0.1 m (FB100), 0.4 m (CFB400) and 1 m (FB1000) were used for the investigation of the bubble properties. The scheme of the smallest plant is shown in

Figure 1a. Superficial gas velocities in a range of 0.18 to 1.4 m/s are set with a mass flow controller (F 203AC FA by Bronkhorst High-Tech B.V.), which is supplied from a pressurized air network. A porous plate is used as the gas distributor. The fluidized bed plant is made of acrylic glass. To prevent electrostatic charging, which influences capacitance probe measurements, the inner wall of the plant is layered and grounded with a thin layer of alumina up to a height of 0.3 m. The total height of the fluidized bed is 1 m with an extended section above to prevent solids entrainment. Probe ports are installed at heights of 0.05 m (P11), 0.1 m (P12), 0.15 m (P13) and 0.2 m (P14) above the gas distributor. Measurements are carried out at two different static bed heights of 0.2 and 0.3 m. At these static bed heights, transition velocities from bubbling to turbulent fluidization of 0.98 and 1.16 m/s were measured in previous works for the same type of particles [

25,

26].

The scheme of the fluidized bed plant with a diameter of 0.4 m can be found in

Figure 1b. Depending on the superficial gas velocity, two different roots blowers are used as air supply. In the range of 0.3 to 1 m/s the GMa 11.3 roots blower and in the range of 1 to 2 m/s the GMb 14.9 roots blower, both by Aerzen Maschinenfabrik GmbH, are used. The superficial gas velocity is measured by an orifice flowmeter. A porous plate is installed as a gas distributor. The fluidized bed has a total height of 15.6 m. Entrained solids material is separated by a cascade of two cyclones and returned into the fluidized bed via a loop-seal. Probe ports are installed at heights of 0.19 m (P21), 0.26 m (P22), 0.33 m (P23), 0.43 m (P24), 0.53 m (P25) and 0.73 m (P26). Static bed heights of 0.4 and 0.8 m are adjusted. Transition velocities from bubbling to turbulent fluidization of 0.94 and 1.09 m/s are measured at these static bed heights in previous works for the same type of particles [

25,

26].

The scheme of the fluidized bed plant with a diameter of 1 m is shown in

Figure 1c. Analog to the plant having a diameter of D = 0.4 m, two roots blowers, the GMa 13.8 for a superficial gas velocity range of 0.3 to 0.7 m/s and the GMb 16.12 for a range of 0.75 to 1.25 m/s, both by Aerzen Maschinenfabrik GmbH, are used as an air supply. The superficial gas velocity is determined by an orifice flowmeter. The plant is equipped with a porous plate as a gas distributor. To prevent electrostatic charging the supplied air is humidified by steam. The fluidized bed has a height of 4.6 m and entrained solid material is separated in a cyclone and lead back. Probe ports are installed at heights of 0.18 m (P31), 0.53 m (P32), 0.88 m (P33) and 1.23 m (P34). The static bed height is set to 1 m. Due to a maximum superficial gas velocity of 1.25 m/s, the transition velocity from bubbling to turbulent fluidization could not be determined.

All plants are operated at ambient conditions. Quartz sand belonging to Geldart group B was used as bed material in all plants. Mean diameter

d50,3, Sauter mean diameter, solids density

ρs, bulk density

ρb, fixed bed solids concentration

cV,fb and minimum fluidization velocity

Umf of the bed material can be found in

Table 1.

2.2. Capacitance Probes

The principle of the electrical capacitance measurement technique is based on the change of the dielectric constant depending on the amount of solid entering the electric field between two electrodes.

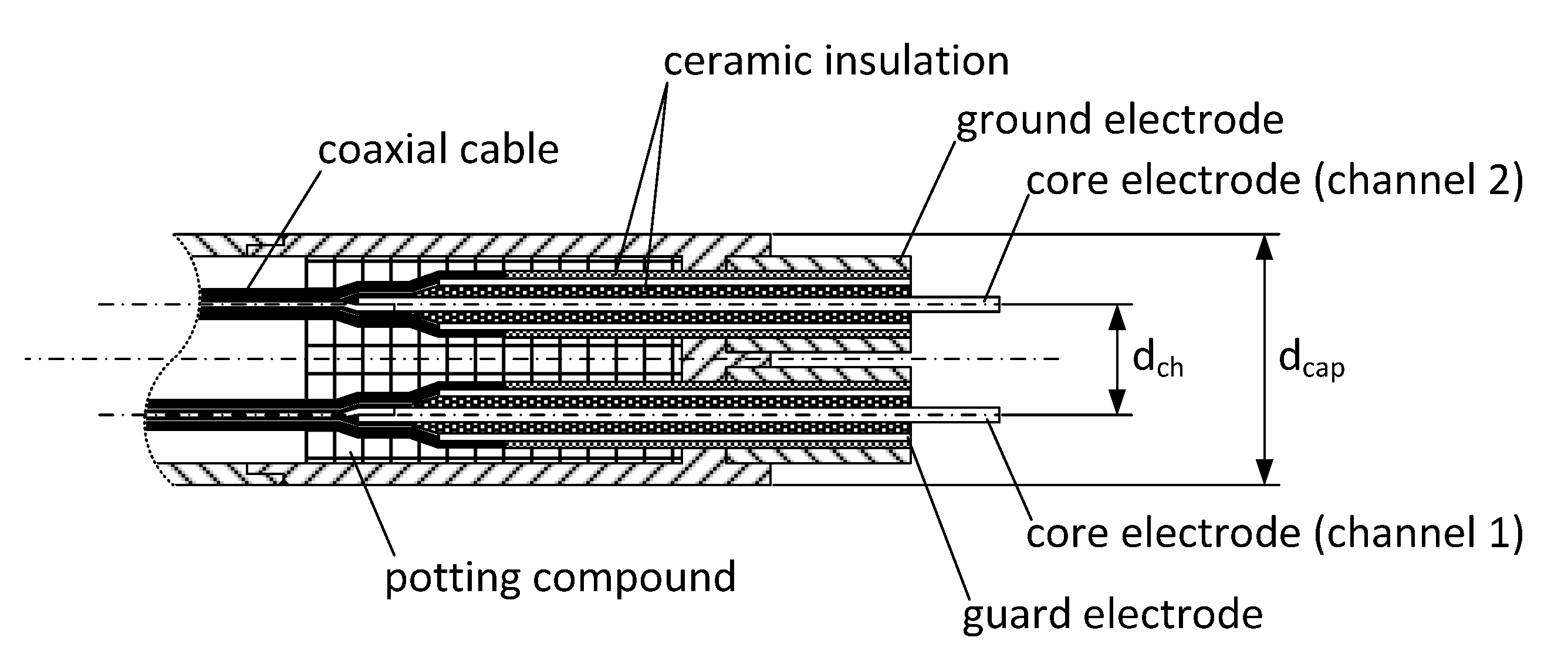

Figure 2 gives a schematic sketch of the two-channel probe tip used in this work. In this case, both channels consist of three electrodes each. In addition to the core (wolfram) and ground electrodes, a guard electrode is installed between them. This electrode shields the core from electric fields and guarantees the formation of a constant electric field for measurement. The working principle is explained in detail in [

11].

Three different capacitance probes were used for the investigations in the fluidized bed plants. Because capacitance probes are an invasive measurement technique, the aim was to construct probes as small as possible to minimize influences of the probe on the fluid dynamic behavior in the fluidized bed. Due to the reason of larger forces acting in larger beds in comparison to small ones, the size of the probe was constructed differently for each plant to withstand these forces. The combinations of probe diameters (

dcap), probe channel distances (

dch) and plants, as well as probe locations, are given in

Table 2.

The signal of each channel is treated by a pre-amplifier and amplifier (capaNCDT 600 system by Micro-Epsilon). The AD-converted voltages of the channels are recorded with a frequency of 10,000 Hz. For the determination of bubble properties, a recording duration of 10 min was chosen for each measurement point to measure an adequate amount of bubbles.

Different correlations for the calculation of the solids concentration

cV from the measured voltages by capacitance probe are given in the literature [

10,

11]. The linear approach proposed by Hage and Werther in Equation (2) is used in this work [

12].

This approach requires knowledge about the signal levels at fixed bed concentration Ufb and fluidizing fluid Uf. Both voltages are measured before and after the experiment for calibration. For experiments using humidified air, the voltages are measured under humidified conditions. The fixed bed concentration cV,fb is given by the bed material used.

Because a capacitance probe is a local measurement technique, different radial positions at each axial position in the bed are measured. In the smallest plant with a diameter of 0.1 m, axial symmetry was assumed. The dimensionless radial measurement positions (r/R) are given in

Table 2. Due to the high stresses acting on the probe at large depths of penetration in a plant having a diameter of 1 m, bubble properties are only measured over the radius of the plant.

2.3. Determination of Bubble Phase Holdup

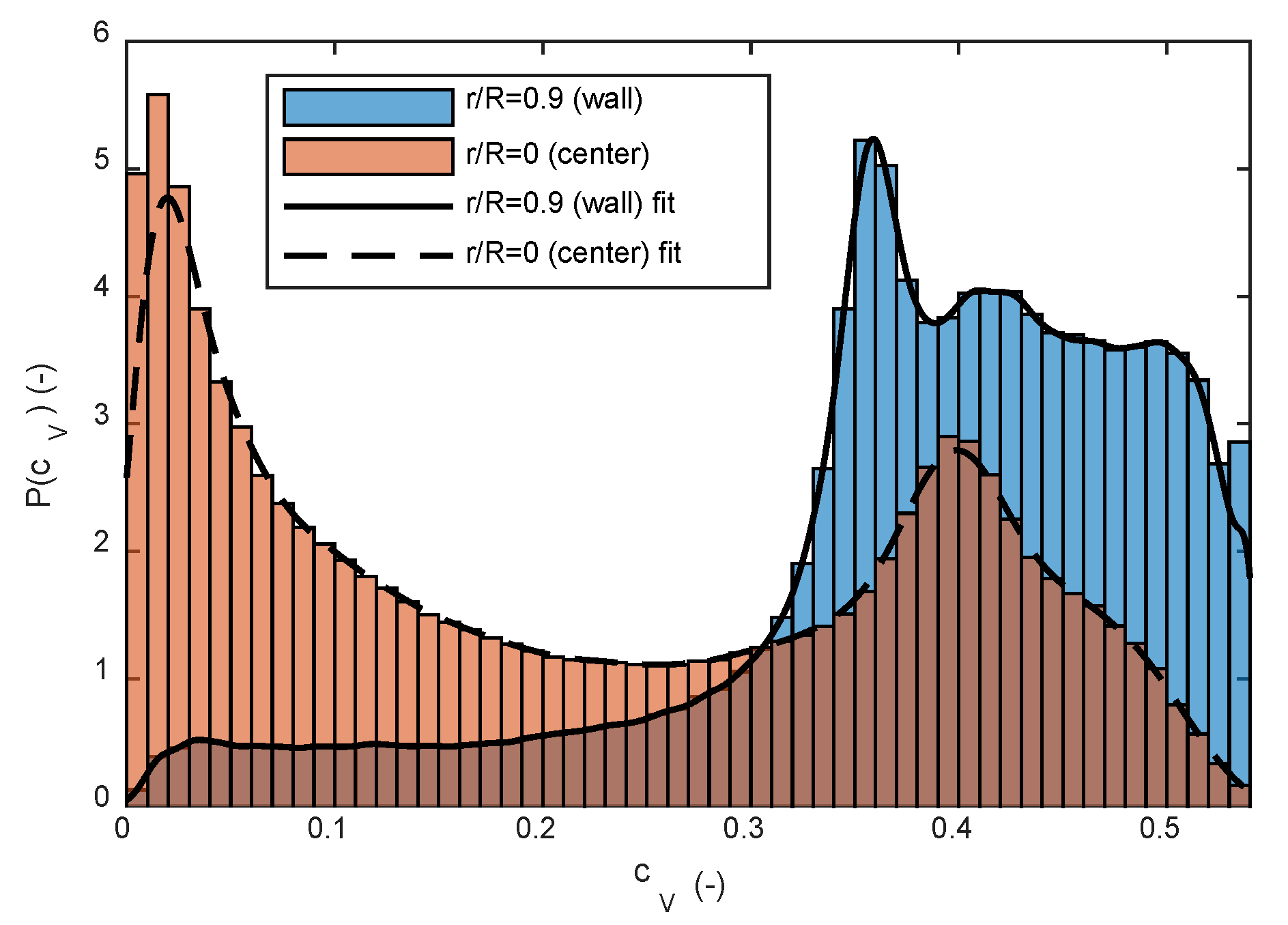

The determination of the bubble phase holdup was done by evaluation of the local probability distribution of concentrations measured in the fluidized bed under different conditions. Examples of two histograms are shown in

Figure 3. A kernel probability density distribution (non-parametric) is fitted to the concentration data, and estimates the measurement data well. Small deviations of the fit in contrast to the measured data at fixed bed concentration (

cV = 0.54) and air (

cV = 0) can be observed. The error due to these deviations was assumed to be negligible.

The peaks that can be found at high concentrations show the solids concentrations’ distributions of the dense phase whereas the peaks at low concentrations show the occurrence of the bubble phase. Bubble phase concentrations are not always completely at a value of zero. According to two-phase theory, the bubble phase is considered empty of solids. However, bubbles contain a small particle concentration due to continuous coalescence or breakup phenomena or dispersion. The concentration depends on the size of a bubble and the location at which the probe penetrates the bubble. The capacitance probe has a fixed measurement volume. If a bubble is small or measured at the phase border both phases can be measured simultaneously, and an averaged concentration of both phases is measured in this case. The capacitance probe is an invasive measurement method. Solids can be decelerated by the probe or stuck at the probe, which leads to larger concentrations measured inside the bubble. Contrary to a gas-liquid bubbles, in a fluidized bed, the transition from bubble to suspension phase is not a sharp transition. Thus, a distribution of different low concentrations represents the bubble phase in the probability density distribution.

The dense phase concentration changes as a function of radial and axial measurement position and superficial gas velocity. Different locations of peaks have been found by evaluation of the different measurement points. Therefore, the same effects of concentration variation that happen in the bubble phase can occur also in this case.

This study was based on the two-phase theory of dense fluidized beds. Probability density distributions are used to define these phases, as developed by Werther and Molerus [

3]. Peaks representing bubble and dense phase as shown in

Figure 3 occur at each superficial gas velocity investigated. Peak concentrations of the dense phase decrease with increasing superficial gas velocity, meaning a larger expansion of the dense phase. By contrast, bubble phase peak concentrations are independent of the superficial gas velocity and close to a value of zero. The mean value of the peaks of dense phase and bubble phase results in the fitted Equation (3) as a definition of the phase border concentration (

cV,border) in dependence on the superficial gas velocity (

U0).

All concentrations above this phase border are assumed to belong to the dense phase. The repeated occurrence of concentrations below Equation (3) due to the penetration of bubbles by the probe was further analyzed to determine bubble properties.

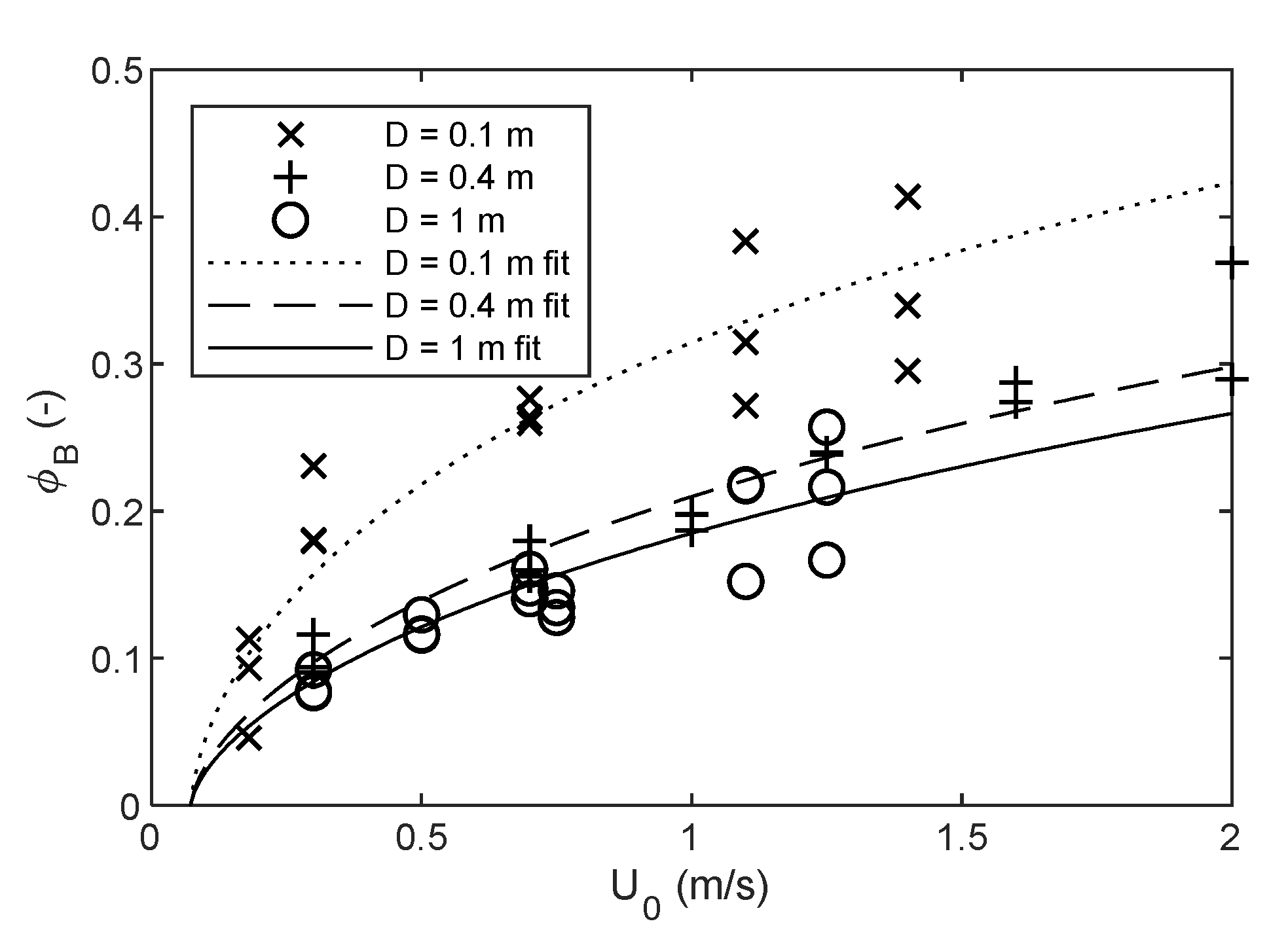

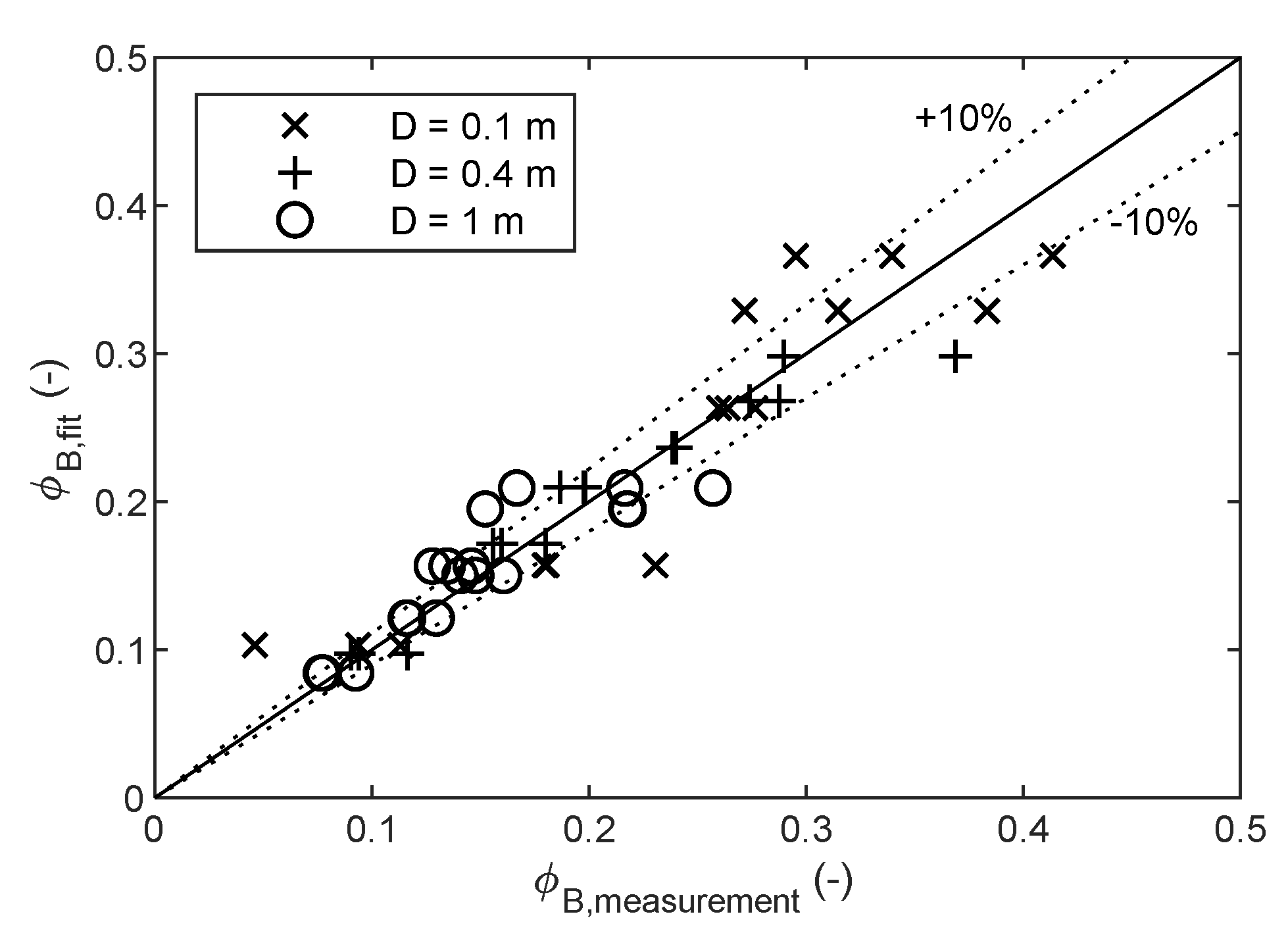

The bubble phase holdup (

ϕB) is calculated according to Equation (4), which describes the probability densities (

P(

cV)) of occurring bubble phase concentrations normalized by the integral of the whole probability density function.

2.4. Determination of Bubble Properties

The determination of bubble properties, such as their velocity, frequency and length, follow an algorithm that detects the presence of a bubble. A minimum bubble length is defined for two reasons:

Close passes of bubbles along the probe (probe not fully entering the bubble), as explained before (this is likely to happen in the turbulent state);

Electrostatic charging in the fluidized bed (occurring at larger velocities and larger diameters with dry air), leading to spontaneous discharges visible in the probe voltage signal.

The minimum bubble length time (t

B,length,min) was set to 5 ms. For bubbles rising with a velocity of 2 m/s the minimum bubble size would therefore be registered by the algorithm as 1 cm, which is far lower than the size a bubble rising with this velocity should have according to the literature and measurements [

1].

To prevent influences of electrostatic charging or short time crossing of the phase border on the bubble size, a minimum bubble distance time (tB,distance,min) of 2 ms was introduced. This means that bubbles occurring within the minimum bubble distance time are counted as one and as separate bubbles otherwise. The minimum bubble distance time was chosen to be small because a larger time would cause bubbles following each other closely to be counted as one bubble. If bubbles rise with a velocity of 2 m/s in this case the bubbles can have a maximum distance of 4 mm to be counted as one bubble. This is unlikely to happen unless the bubbles already started coalescing.

Two channels are recorded simultaneously with one in the flow shadow of the other. Slightly different signals at both channels are the result. To be sure to determine bubbles, an overlap check of bubbles of both channels is done. All detected bubbles fulfilling the conditions of the algorithm are counted and give the bubble frequency

fB when related to the signal length. For the determination of the bubble velocity (

UB), the time lag (

τ) between both channels is estimated. Equation (5) gives the normalized cross-covariance function (

ψcV1,cV2(

τ)) that directly yields the Pearson correlation coefficient (R) of both signals for each time step of the signal shift.

where

σcV1 and

σcV2 are the standard deviations and

and

are the mean values of the solid concentrations

cV1 and

cV2 of the channels, respectively;

t is the time and

T is the maximum integration time.

This approach additionally offers a comparison of the signals according to their self-similarity. The correlation coefficients can vary between −1 and 1 with the highest value being the highest similarity in the signals. For the determination of the lag of both signals the time shift location of the peaks with the highest values is determined. Only signals with a correlation coefficient above 0.9 are considered to guarantee a high similarity in the signals and avoid errors in the measurement. The time lag of the peaks is then determined. The knowledge about the vertical distance (

dch) of both channels to each other leads together with the time lag (

τ) to the velocity of the bubble (

UB) as given in Equation (6).

The occurrence of negative bubble velocities was neglected in this study. Assuming a bubble is not accelerated while passing the capacitance probe, the duration a bubble needs to pass the probe (

tB) and its velocity give the pierced length (

lp) of a bubble in Equation (7).

Coalescence and bubble formation are stochastic processes. Thus, bubble properties follow a natural distribution, which is a logarithmic normal distribution. The density function of the log-normal distribution

f(

x) of the parameter

x is defined by Equation (8) [

27].

where

µ and

σ are the expected value and the standard deviation of the parameter’s natural logarithm, respectively. The arithmetic mean value (

E(

X)) is given by Equation (9):

and the arithmetic standard deviation (

SD(

X)) is given by Equation (10).

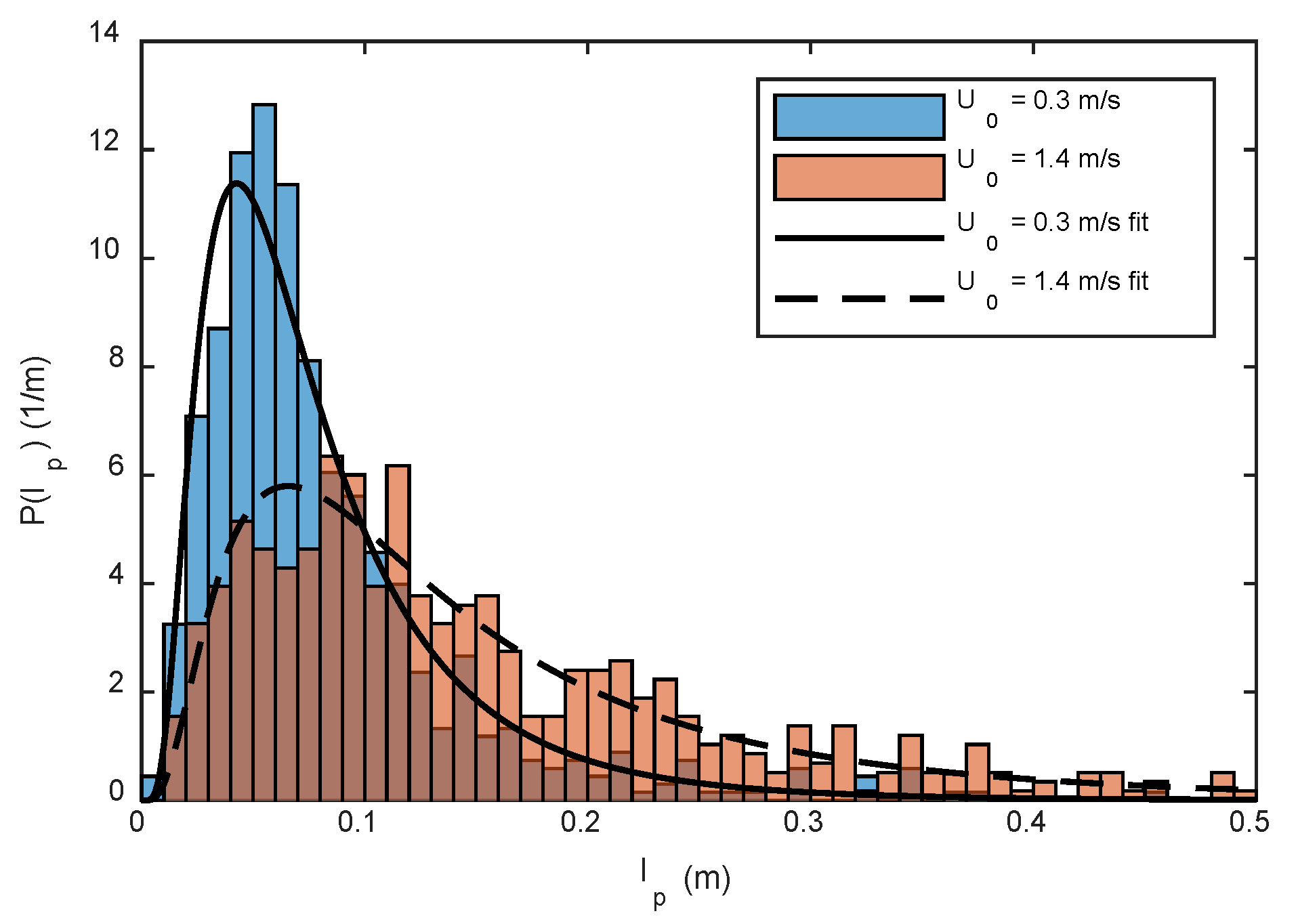

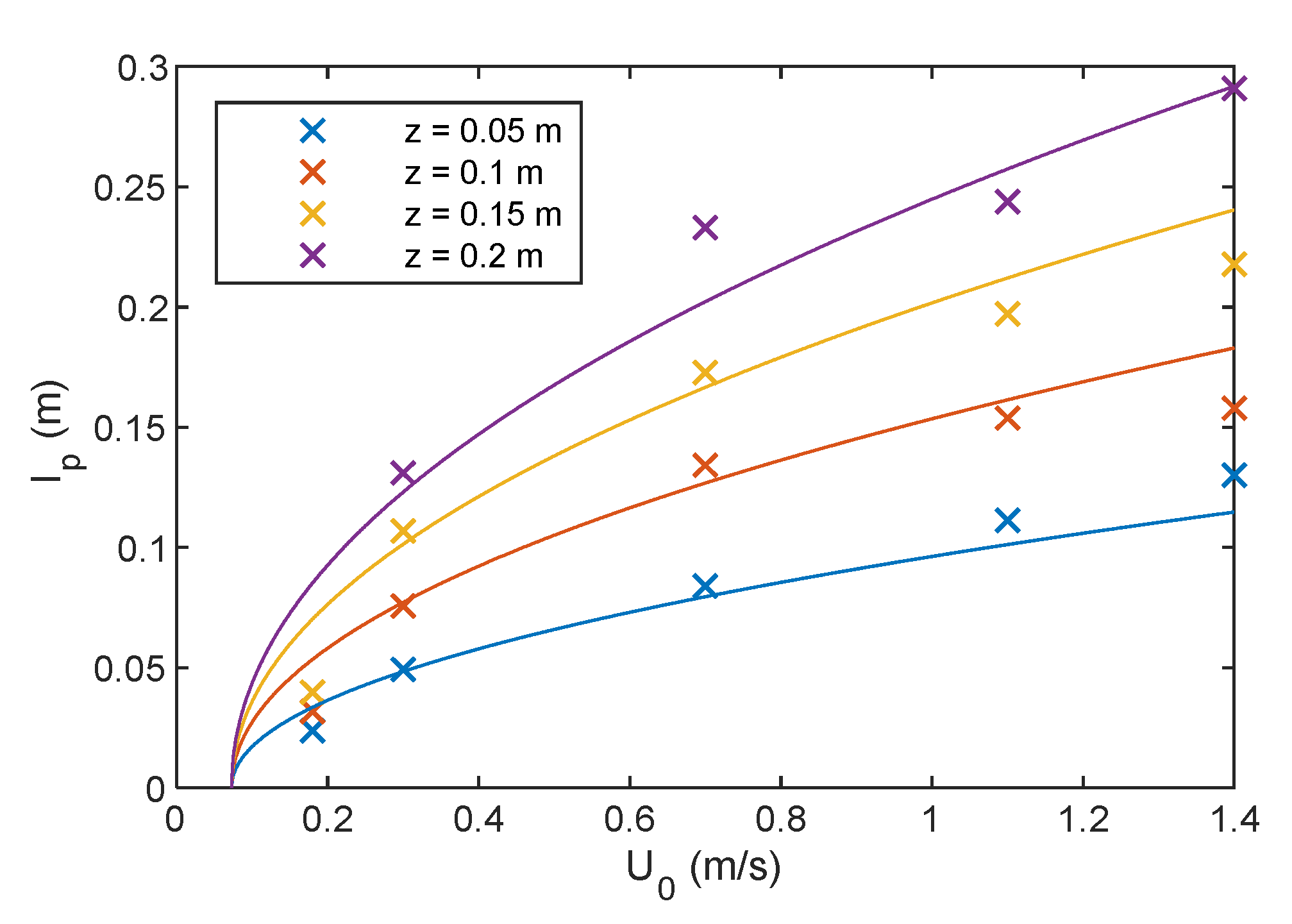

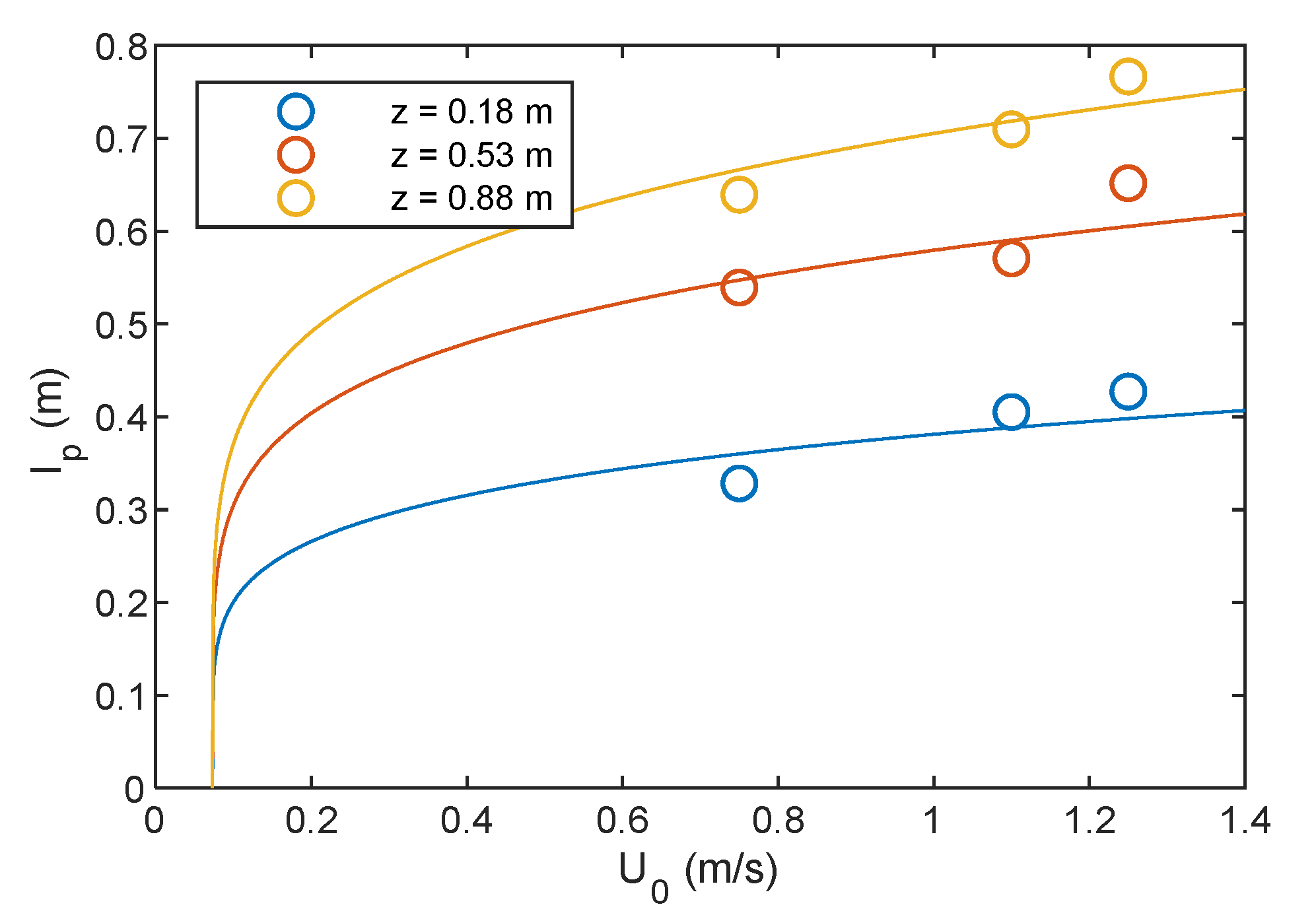

Examples for histograms of the pierced lengths measured at two different superficial gas velocities are given in

Figure 4. The log-normal distributions fit the measured histograms well. Higher gas velocities show a broader distribution of pierced lengths.

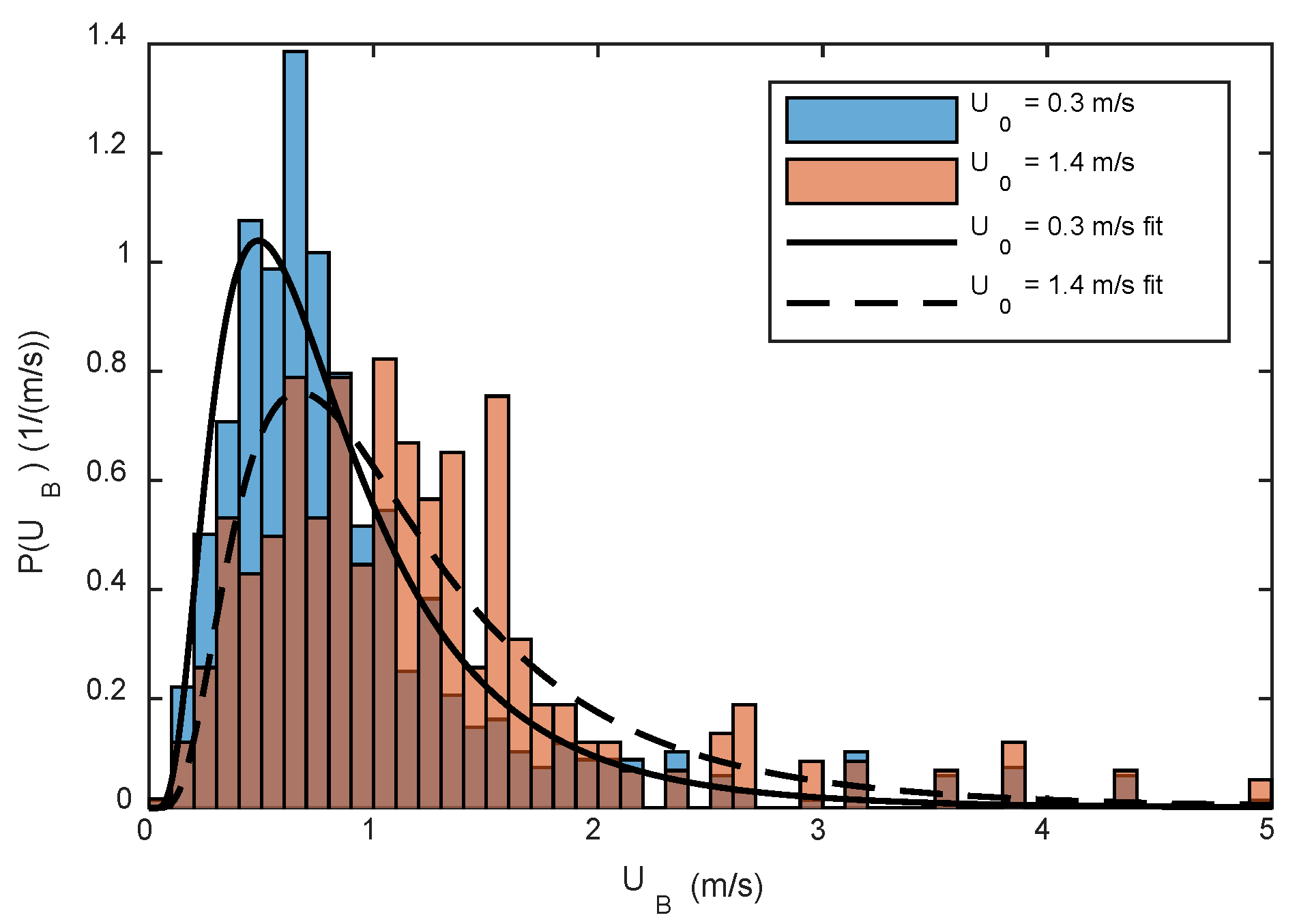

The same behavior as for the pierced lengths can be found for the bubble velocities in

Figure 5. Lags in the histogram at large velocities can be explained by the measurement frequency and the resulting minimum recorded time step, which has a large influence as given by Equation (6). Furthermore, the deviation of the histograms from the fitted log-normal distributions is larger than for the pierced lengths. Reason for these deviations are velocity variations due to mutual interactions of the bubbles (e.g., acceleration due to coalescence). These interactions increase with larger amounts of bubbles resulting in the largest fitting errors occurring in the turbulent regime.

The arithmetic mean values of the distribution functions calculated by Equation (9) were used in this study to compare the bubble velocities and mean pierced lengths under different conditions. Furthermore, the mean pierced length and the mean bubble velocity were cross-sectional averaged, separately. This was done in relation to the cross-sectional area belonging to a radial measurement position and the amount of bubbles occurring in this area.

4. Conclusions

Capacitance probes were used for the measurement of vertical bubble sizes and bubble velocities. Bubble phase behavior was investigated over a large range of superficial gas velocities ranging from bubbling fluidization (U0 of 0.18 m/s) up to turbulent fluidization (U0 of 1.6 m/s). Experiments were carried out in laboratory scale-fluidized bed facilities of different sizes of 0.1, 0.4 and 1 m in diameter.

Results of the investigation showed a clear dependence of the bubble phase holdup on the fluidized bed diameter and the superficial gas velocity. Bubble holdup was higher in beds with a smaller diameter. This was mainly due to the wall effects on the bubbles, which attain sizes comparable with the bed diameter.

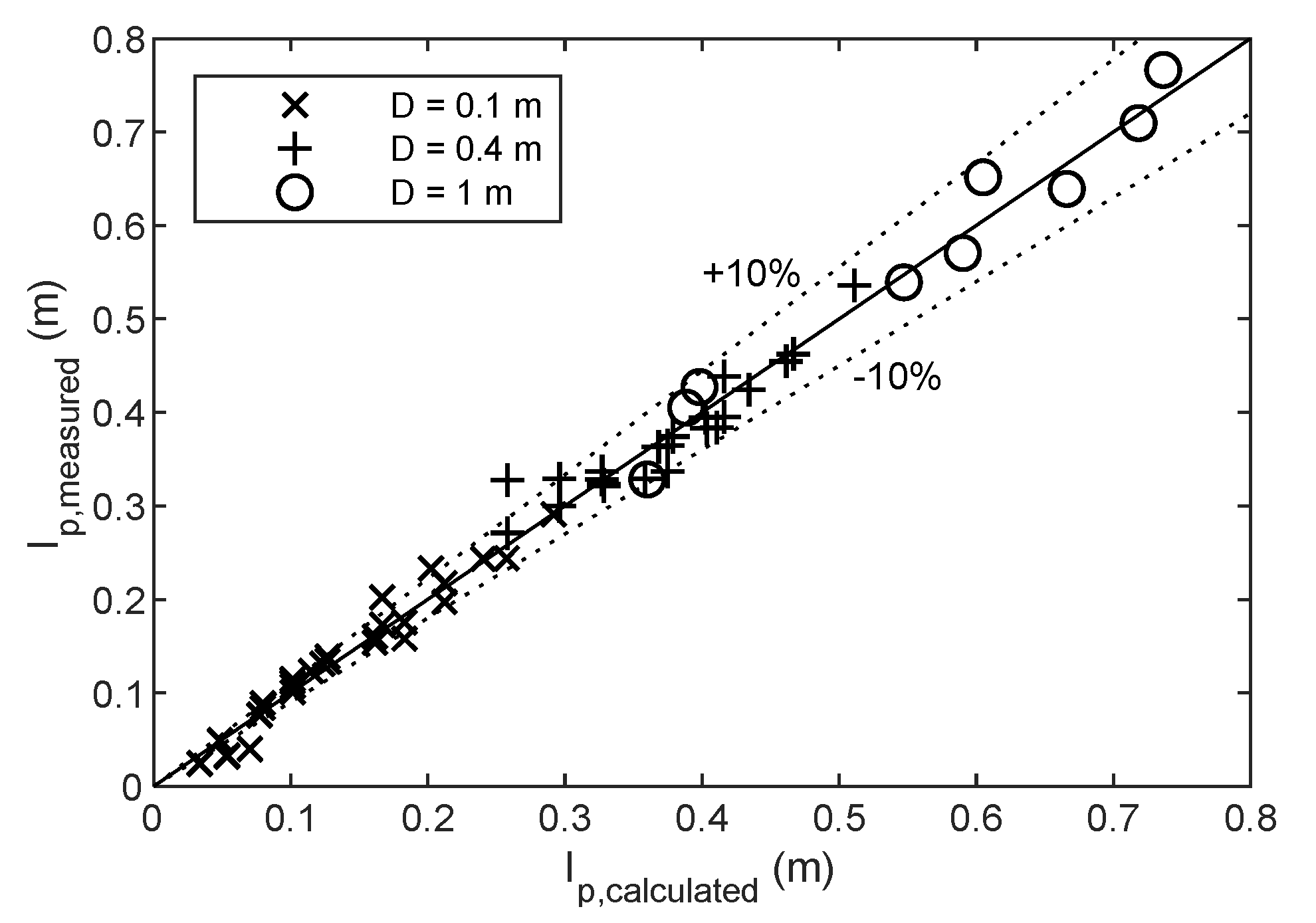

An empirical correlation was developed for the prediction of the cross-sectional averaged mean pierced length as a function of bed diameter, height above the gas distributor and superficial gas velocity. The vertical mean pierced length was found to grow even in the turbulent fluidization regime. Large measured mean pierced lengths in the turbulent regime led to the conclusion that the shape of bubbles was influenced by wall effects, superficial gas velocity and the size of the bubble itself. Small bubbles at low superficial gas velocity had a higher probability to have a spherical shape and spherical cap, whereas larger bubbles and velocities led to a deformation of the bubble into a vertical stretched shape.

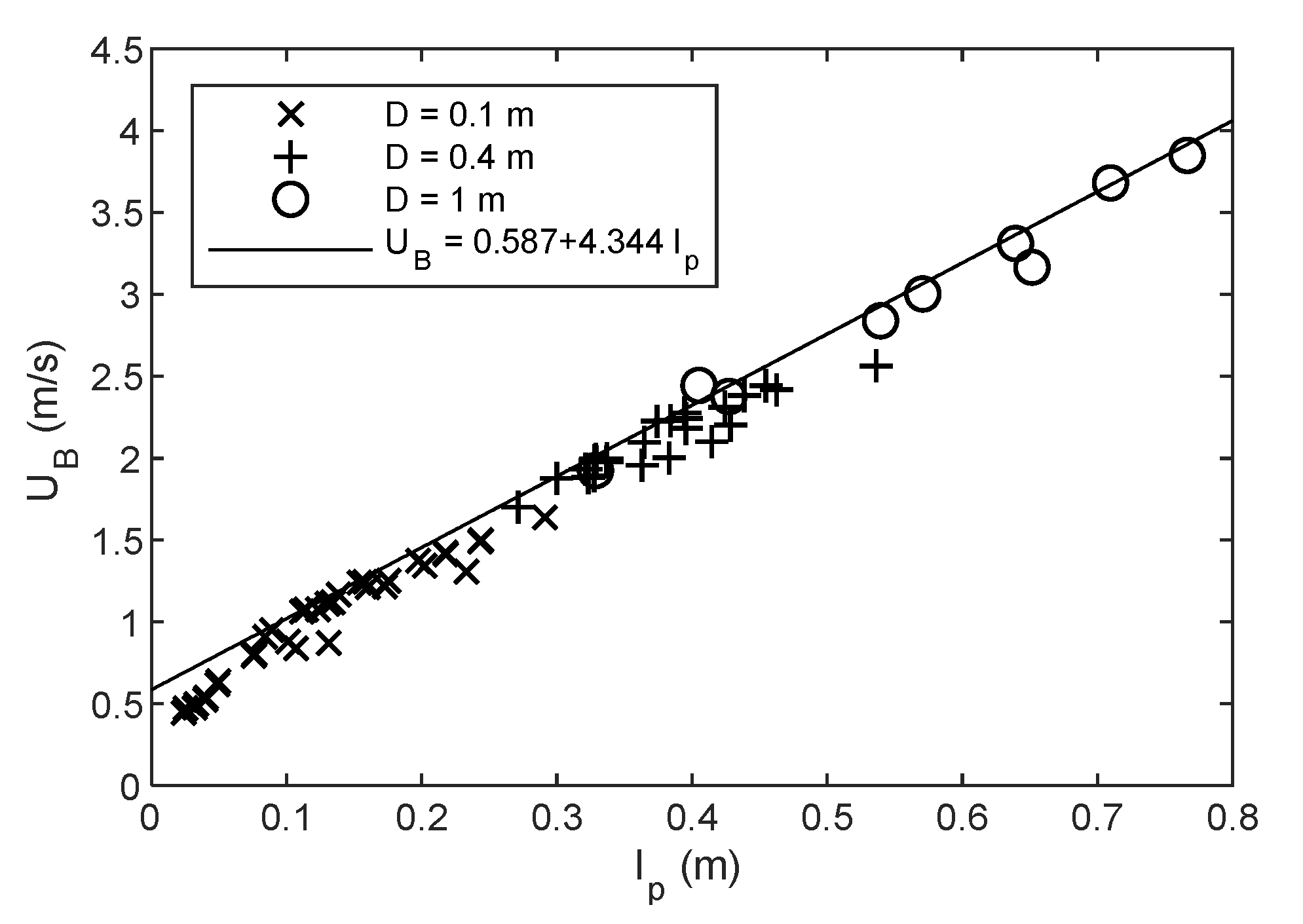

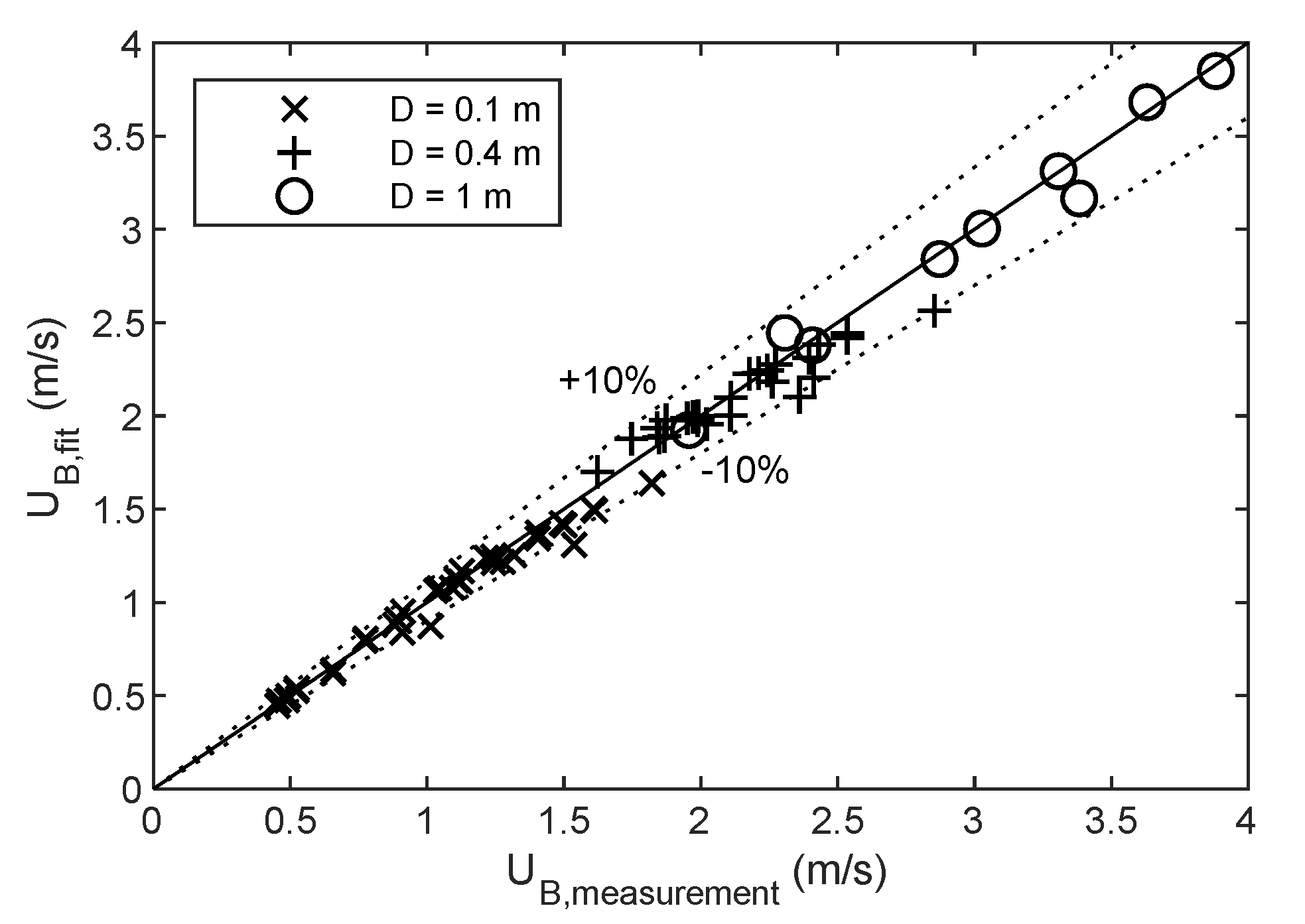

The velocity of a bubble mainly depends on its vertical size. Experimental results showed a linear dependence of the bubble velocity on its pierced length. The influence of the superficial gas velocity and thus the influence of swarm behavior are limited. The transition from bubbling to turbulent fluidization was found to mainly depend on the shape of the bubbles. The occurrence of vertical stretched bubbles having a small horizontal size compared to their vertical dimension leads to a reduction in the pressure fluctuations.