Energy Management Strategy for Fuel Cell and Battery Hybrid Vehicle Based on Fuzzy Logic

Abstract

:1. Introduction

2. FCHV Configuration and Calculations

2.1. Drive Structure of FCHV

2.2. Parameter of Motor

2.2.1. Maximum Power and Rated Power

2.2.2. Maximum Speed and Rated Speed

2.2.3. Maximum Torque and Rated Torque

2.3. Fuel Cell Power

2.4. Battery Power

3. Energy Management Strategy for FCHV

3.1. Power Following Control (PFC) Strategy

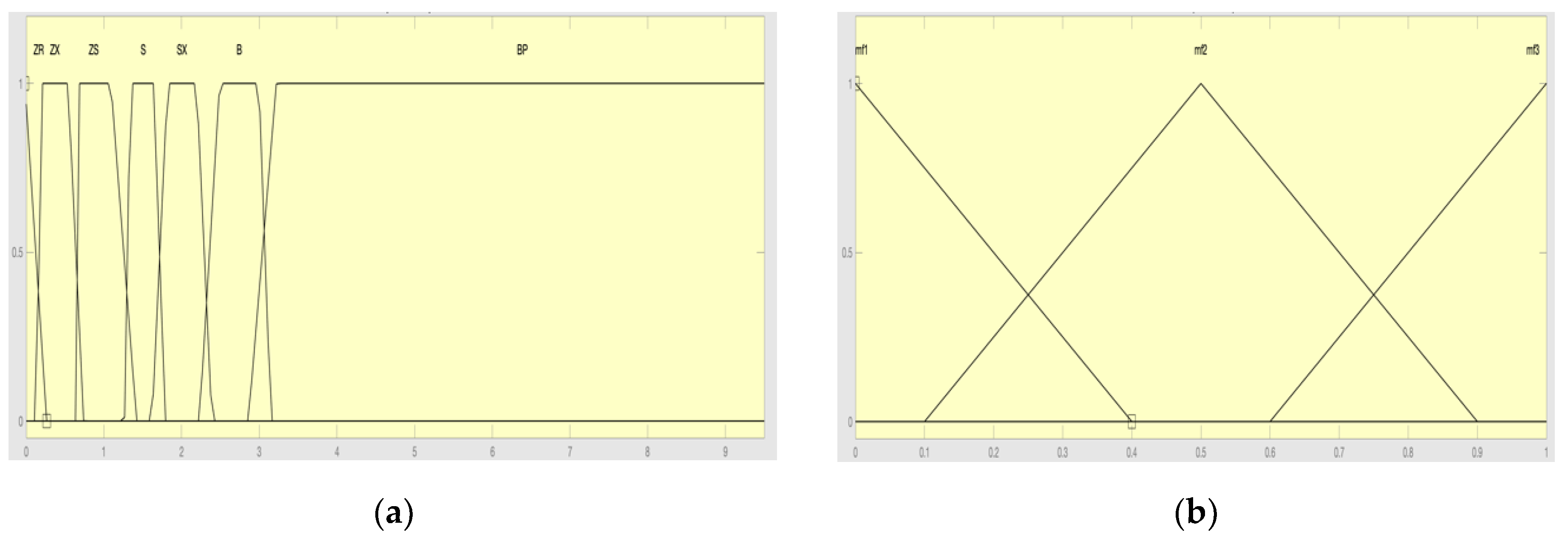

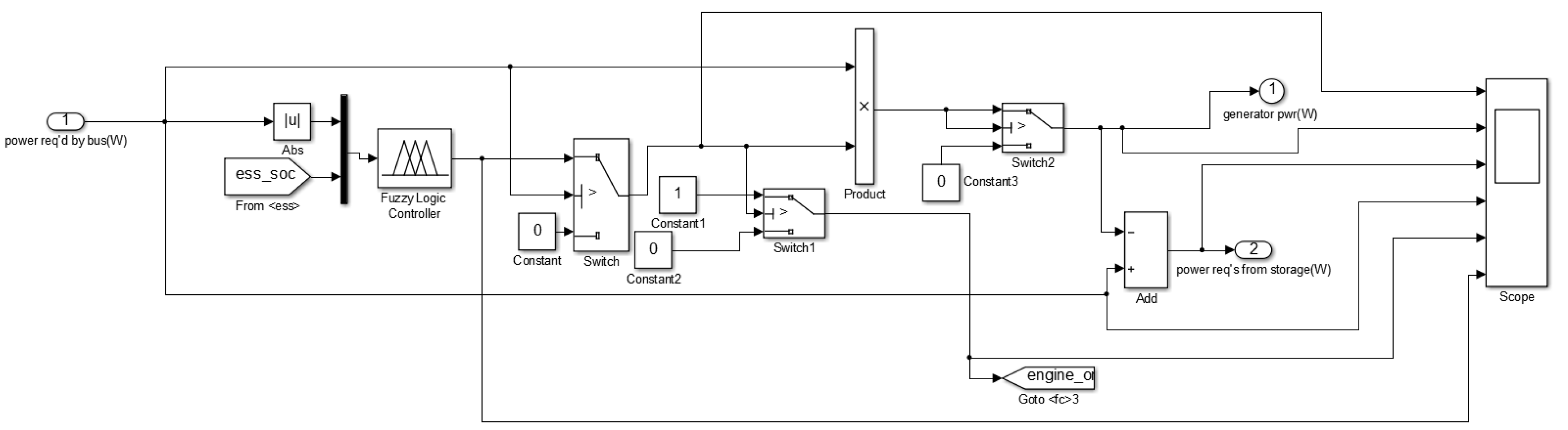

3.2. Fuzzy Logic Control (FLC) Strategy

3.2.1. Selection of Input and Output Variables

3.2.2. Fuzzy Field Scope

3.2.3. Fuzzy Reasoning Rules

- (1)

- The sum of the power provided by the fuel cell and the battery must meet the bus required power.

- (2)

- The battery can always work in the ideal working area that SOC is between 0.6 and 0.8, and the fuel cell can work in the efficient area that the efficiency is more than 40%.

- (3)

- The equivalent fuel consumption of fuel cell is reduced, and the economic performance of the vehicle is improved.

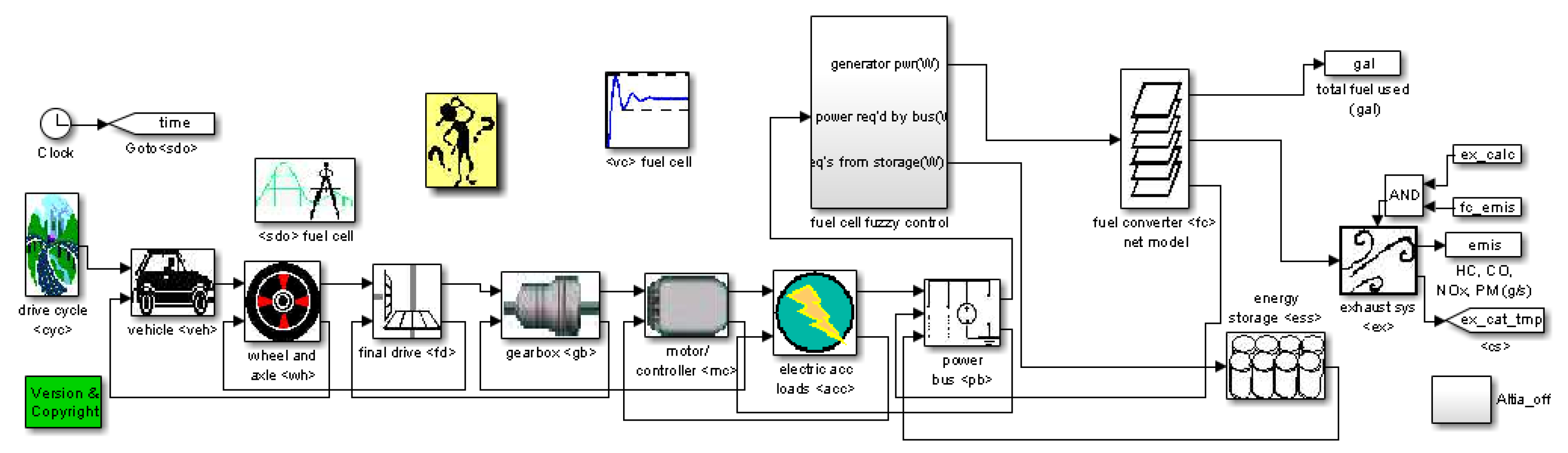

4. FCHV Modelling and Simulation

Simulation Parameters

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Guenther, M.B. Modelling and Design Optimization of Low Speed Fuel Cell Hybrid Electric Vehicles. Master’s Thesis, University of Victoria, Victoria, BA, Canada, 2005. [Google Scholar]

- Montazeri-Gh, M.; Mahmoodi-k, M. Development a new power management strategy for power split hybrid electric vehicles. Transp. Res. Part D Transp. Environ. 2015, 37, 79–96. [Google Scholar] [CrossRef]

- Djerioui, A. Energy management strategy of Supercapacitor/Fuel Cell energy storage devices for vehicle applications. Int. J. Hydrogen Energy 2019, 44, 23416–23428. [Google Scholar] [CrossRef]

- Hong, Z.H.; Zhu, Y.N.; Shang, W.L.; Li, Q.; Chen, W.E. Research of energy management strategy for Fuel Cell/Battery hybrid locomotive. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (Itec Asia-Pacific), Harbin, China, 7–10 August 2017; pp. 546–550. [Google Scholar]

- Chen, Z.; Guo, N.Y.; Zhang, Q.; Shen, J.W.; Xiao, R.X. An optimized rule based energy management strategy for a Fuel Cell/Battery vehicle. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (Vppc), Belfort, France, 11–14 December 2017. [Google Scholar]

- Carignano, M.G.; Costa-Castello, R.; Roda, V.; Nigro, N.; Junco, S.; Feroldi, D. Energy management strategy for fuel cell-supercapacitor hybrid vehicles based on prediction of energy demand. J. Power Sources 2017, 360, 419–433. [Google Scholar] [CrossRef] [Green Version]

- Xu, L.F. Application of Pontryagin’s Minimal Principle to the energy management strategy of plugin fuel cell electric vehicles. Int. J. Hydrogen Energy 2013, 38, 10104–10115. [Google Scholar] [CrossRef]

- Bendjedia, B.; Rizoug, N.; Boukhnifer, M.; Bouchafaa, F. Improved energy management strategy for a hybrid fuel cell/battery system Simulation and experimental results. COMPEL 2017, 36, 1008–1027. [Google Scholar] [CrossRef]

- Aouzellag, H.; Ghedamsi, K.; Aouzellag, D. Energy management and fault tolerant control strategies for fuel cell/ultra-capacitor hybrid electric vehicles to enhance autonomy, efficiency and life-time of the fuel cell system. Int. J. Hydrogen Energy 2015, 40, 7204–7213. [Google Scholar] [CrossRef]

- Lü, X.Q.; Wu, Y.B.; Lian, J. Energy management of hybrid electric vehicles: A review of energy optimization of fuel cell hybrid power system based on genetic algorithm. Energy Convers. Manag. 2020, 205, 112474. [Google Scholar] [CrossRef]

- Song, K.; Wang, X.D.; Li, F.Q. Pontryagin’s minimum principle-based real-time energy management strategy for fuel cell hybrid electric vehicle considering both fuel economy and power source durability. Energy 2020, 205, 118064. [Google Scholar] [CrossRef]

- Li, X.Y.; Wang, Y.J.; Yang, D.; Chen, Z.H. Adaptive energy management strategy for fuel cell/battery hybrid vehicles using Pontryagin’s Minimal Principle. J. Power Sources 2019, 440, 227105. [Google Scholar] [CrossRef]

- Fu, Z.N.; Li, Z.H.; Si, P.J.; Tao, F.Z. A hierarchical energy management strategy for fuel cell/battery/supercapacitor hybrid electric vehicles. Int. J. Hydrogen Energy 2019, 44, 22159–22416. [Google Scholar] [CrossRef]

- Odeim, F.; Roes, J.; Heinzal, A. Power management optimization of a fuel cell/battery/supercapacitor hybrid system for transmit bus applications. IEEE Transp. Veh. Technol. 2016, 65, 5783–5788. [Google Scholar] [CrossRef]

- Hu, Z.Y.; Li, J.Q.; Xu, L.F. Muti-objective energy management optimization and parameter sizing proton exchange membrane hybrid fuel cell vehicles. Energy Convers. Manag. 2016, 129, 108–121. [Google Scholar] [CrossRef]

- Zhang, W.B.; Li, J.Q.; Xu, L.F. Optimization for a fuel cell/battery/capacity tram with equivalent consumption minimization strategy. Energy Convers. Manag. 2017, 134, 59–69. [Google Scholar] [CrossRef]

- Kim, M.; Sohn, Y.J.; Lee, W.Y.; Kim, C.S. Fuzzy control based on engine sizing optimization for a fuel cell/battery hybrid mini-bus. J. Power Sources 2008, 178, 706–710. [Google Scholar] [CrossRef]

- Li, Q.; Chen, W.R.; Li, Y.K.; Liu, S.K.; Huang, J. Energy management strategy for fuel cell/battery/ultracapacitor hybrid vehicle based on fuzzy logic. Int. J. Electr. Power Energy Syst. 2012, 43, 514–525. [Google Scholar] [CrossRef]

- Zhang, G.R.; Chen, W.R.; Li, Q. Modeling, optimization and control of a FC/battery hybrid locomotive based on ADVISOR. Int. J. Hydrogen Energy 2017, 42, 18568–18583. [Google Scholar] [CrossRef]

- Chen, J.; Xu, C.F.; Wu, C.S. Adaptive fuzzy logic control of fuel-cell-battery hybrid systems for electric vehicles. IEEE Trans. Ind. Inform. 2018, 14, 292–300. [Google Scholar] [CrossRef]

- Ahmadi, S.; Bathaee, S.M.T.; Hosseinpour, A.H. Improving fuel economy and performance of a fuel-cell hybrid electric vehicle (fuel-cell, battery, and ultra-capacitor) using optimized energy management strategy. Energy Convers. Manag. 2018, 160, 74–84. [Google Scholar] [CrossRef]

- Fu, Z.M.; Zhu, L.L.; Tao, F.Z.; Si, J.P.; Sun, L.F. Optimization based energy management strategy for fuel cell/battery/ultracapacitor hybrid vehicle considering fuel economy and fuel cell lifespan. Int. J. Hydrogen Energy 2020, 45, 8875–8886. [Google Scholar] [CrossRef]

- Nymand, M.; Andersen, M.A. High-efficiency isolated boost DCDC converter for high-power low-voltage fuel-cell applications. IEEE Trans. Ind. Electron. 2010, 57, 505–514. [Google Scholar] [CrossRef] [Green Version]

- Tu, X. Research on Design and Optimization of Power System of Fuel Cell/Battery Hybrid Vehicle. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2013. [Google Scholar]

- Triche, E.J.; Beno, J.H.; Tims, H.E. Shock loading experiments and requirements for electric wheel motors military vehicles. SAE Tech. Pap. 2005, 0261–0278. [Google Scholar] [CrossRef]

- Tanaka, K. A sum of squares approach modeling and control of nonlinear dynamical systems with polynomial fuzzy systems. IEEE Trans. Fuzzy Syst. 2009, 04, 911–920. [Google Scholar] [CrossRef]

- Amirabadi, M.; Farhangi, S. Fuzzy control of hybrid fuel cell/battery power source in electric vehicle. In Proceedings of the IEEE Conference on Industrial Electronics and Applications, Singapore, 24–26 May 2006; pp. 1–3. [Google Scholar]

- Zhang, D.H.; Zhou, J.Y.; Su, Y.X. Research of regenerative braking energy recovery of HEV based on fuzzy logic. J. Wuhan Univ. Technol. 2011, 33, 717–720. [Google Scholar]

| Vehicle Parameters | Value | Design Goals | Value |

|---|---|---|---|

| Mass (kg) | 1800 | Maximum gradeability at 30 km/h (%) | ≥30 |

| Coefficient of air resistance | 0.31 | Maximum speed (km/h) | ≥150 |

| Coefficient of rolling resistance | 0.016 | 0–50 km/h acceleration time (s) | ≤8 |

| Frontal area (m2) | 2.68 | 0–100 km/h acceleration time (s) | ≤15 |

| Wheelbase (m) | 2.67 | Equivalent oil consumption (L/100 km) | 6 |

| Wheel rolling radius (m) | 0.35 |

| Motor | |||

|---|---|---|---|

| Rated power (kW) | 30 | Maximum power (kW) | 95 |

| Rated speed (r/min) | 4800 | Maximum speed (r/min) | 11,500 |

| Rated torque (n·m) | 80 | Maximum torque (n·m) | 210 |

| Fuel cell | |||

| Type | PEMFC | Rated power (kW) | 35 |

| Battery | |||

| Type | Lithium-ion | Number | 85 |

| Rated capacity (Ah) | 6 | Capacity (Ah) | ≥8.0 |

| Maximum discharge rate | 30C | Rated voltage (V) | 3.8 |

| SOC | p | ||||||

|---|---|---|---|---|---|---|---|

| ZR | ZX | ZS | S | SX | B | BP | |

| L | 1.6 | 1.5 | 1.4 | 1.3 | 1.2 | 1.1 | 1.1 |

| M | 0 | 0 | 0.3 | 0.4 | 0.4 | 0.4 | 0.6 |

| H | 0 | 0 | 0 | 0.3 | 0.4 | 0.6 | 0.7 |

| Parameters | China | ECE+EUDC | UDDS | NEDC |

|---|---|---|---|---|

| Time (s) | 1314 | 1225 | 1369 | 1184 |

| Distance (km) | 5.94 | 10.93 | 11.99 | 10.93 |

| Average speed (km/h) | 16.27 | 32.10 | 31.51 | 33.21 |

| Maximum speed (km/h) | 60.35 | 120 | 91.25 | 120 |

| Average acceleration (m/s2) | 0.30 | 0.54 | 0.50 | 0.54 |

| Average deceleration (m/s2) | −0.43 | −0.79 | −0.58 | −0.79 |

| Maximum acceleration (m/s2) | 0.92 | 1.06 | 1.48 | 1.06 |

| Maximum deceleration (m/s2) | −1.05 | −1.39 | −1.48 | −1.39 |

| Idle time (s) | 381 | 339 | 259 | 298 |

| Number of stop | 14 | 13 | 17 | 13 |

| Grade (%) | 0 | 0 | 0 | 0 |

| Dynamic Property | PFC | FLC | Design Goal |

|---|---|---|---|

| 0–50 km/h Acceleration time (s) | 4 | 4.4 | 8 |

| 0–100 km/h Acceleration time (s) | 11.1 | 13.5 | 15 |

| Maximum speed (km/h) | 156.8 | 157.3 | 150 |

| Maximum gradeability at 30 km/h (%) | 40 | 32 | 30 |

| Economic Property | |||

| Hydrogen consumption (L/100 km) | 79.6 | 74.1 | |

| Gasoline equivalent (L/100 km) | 5.5 | 5.0 | 6 |

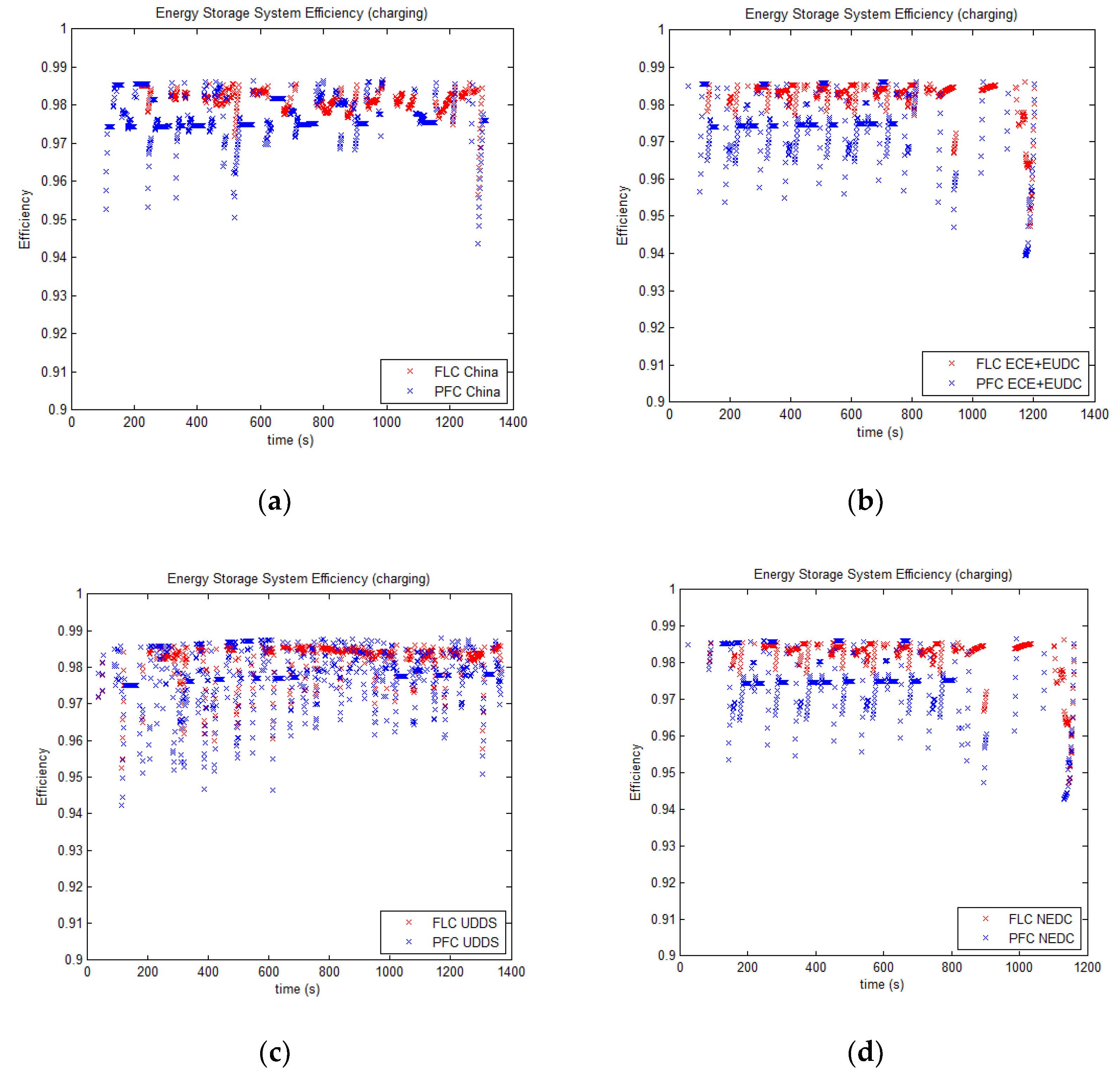

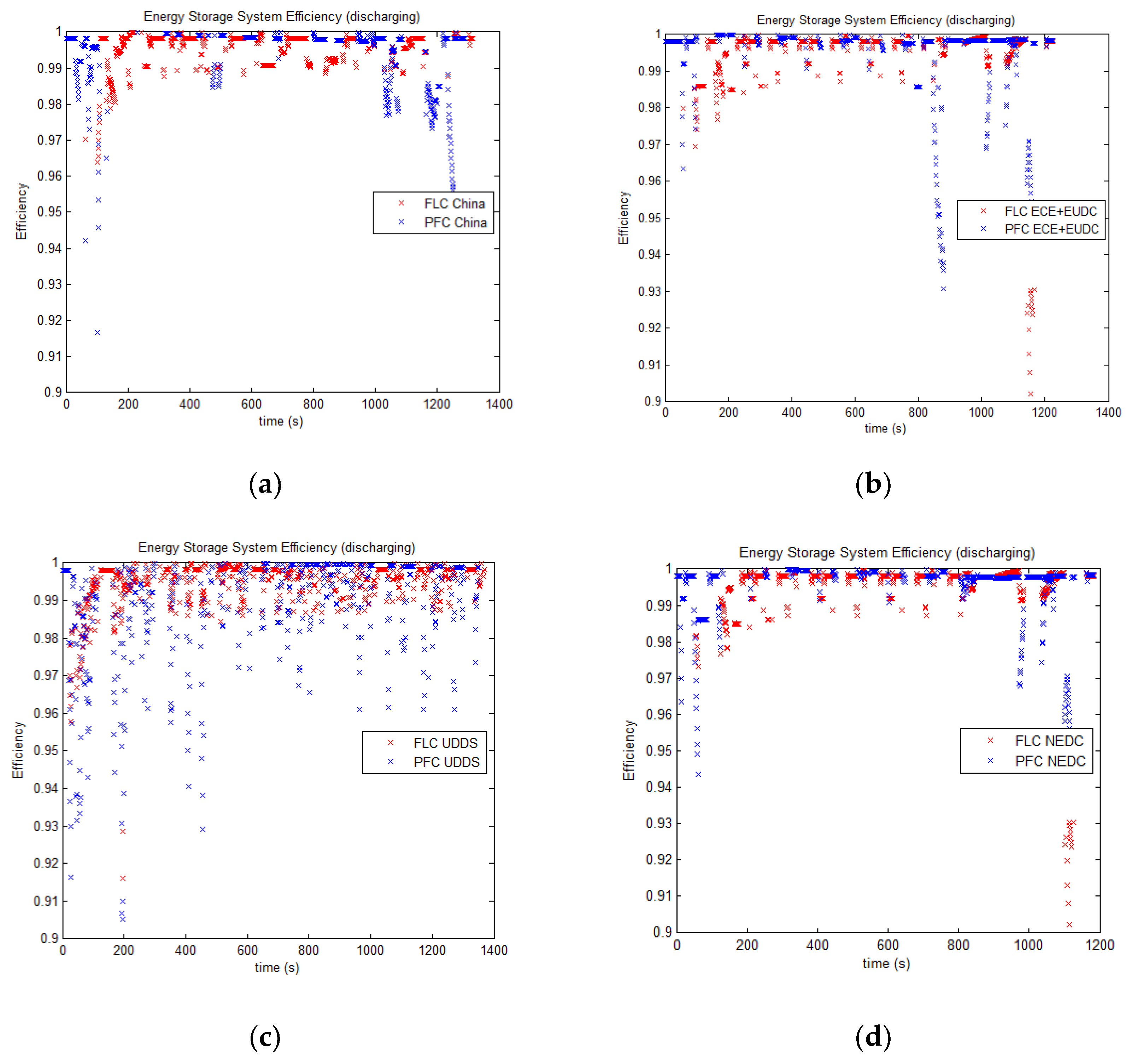

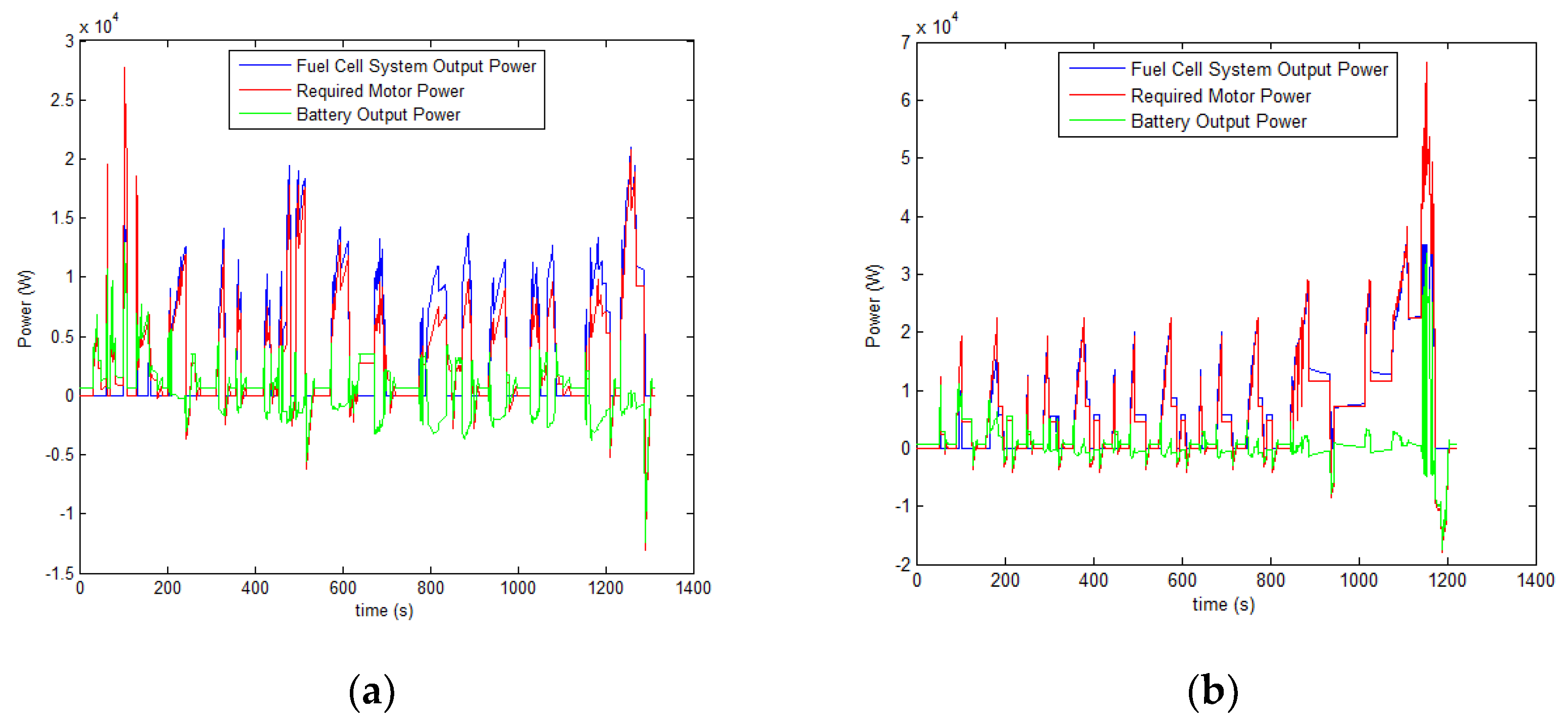

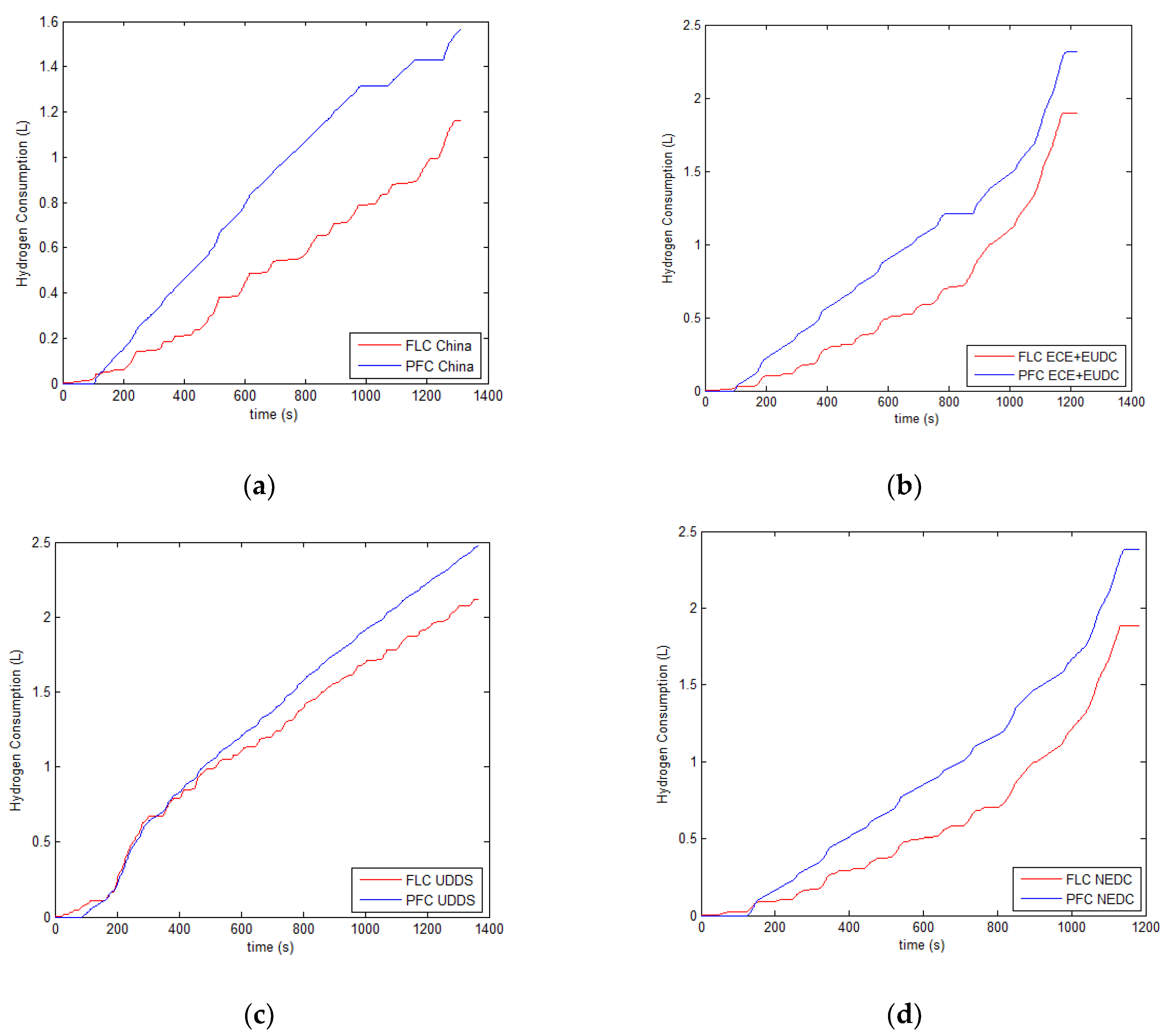

| Cycle | Parameter | PFC | FLC |

|---|---|---|---|

| China | Hydrogen consumption (L/100 km) | 79.6 | 74.1 |

| Gasoline equivalent (L/100 km) | 5.5 | 5.0 | |

| Eff_FCS | 52.54 | 53.26 | |

| Eff_Bat | 96.15 | 97.45 | |

| SOC | 0.08 | −0.03 | |

| ECE+EUDC | Hydrogen consumption (L/100 km) | 70.4 | 65.8 |

| Gasoline equivalent (L/100 km) | 4.8 | 4.5 | |

| Eff_FCS | 55.54 | 55.78 | |

| Eff_Bat | 95.32 | 95.48 | |

| SOC | 0.07 | −0.04 | |

| UDDS | Hydrogen consumption (L/100 km) | 71.6 | 66.9 |

| Gasoline equivalent (L/100 km) | 4.8 | 4.5 | |

| Eff_FCS | 56.22 | 56.92 | |

| Eff_Bat | 95.16 | 96.53 | |

| SOC | 0.06 | −0.03 | |

| NEDC | Hydrogen consumption (L/100 km) | 71 | 65.4 |

| Gasoline equivalent (L/100 km) | 4.8 | 4.4 | |

| Eff_FCS | 54.61 | 55.32 | |

| Eff_Bat | 95.44 | 95.87 | |

| SOC | 0.09 | −0.04 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Xu, B.; Tian, J.; Ma, Z. Energy Management Strategy for Fuel Cell and Battery Hybrid Vehicle Based on Fuzzy Logic. Processes 2020, 8, 882. https://doi.org/10.3390/pr8080882

Li D, Xu B, Tian J, Ma Z. Energy Management Strategy for Fuel Cell and Battery Hybrid Vehicle Based on Fuzzy Logic. Processes. 2020; 8(8):882. https://doi.org/10.3390/pr8080882

Chicago/Turabian StyleLi, Dongxu, Bing Xu, Jie Tian, and Zheshu Ma. 2020. "Energy Management Strategy for Fuel Cell and Battery Hybrid Vehicle Based on Fuzzy Logic" Processes 8, no. 8: 882. https://doi.org/10.3390/pr8080882

APA StyleLi, D., Xu, B., Tian, J., & Ma, Z. (2020). Energy Management Strategy for Fuel Cell and Battery Hybrid Vehicle Based on Fuzzy Logic. Processes, 8(8), 882. https://doi.org/10.3390/pr8080882