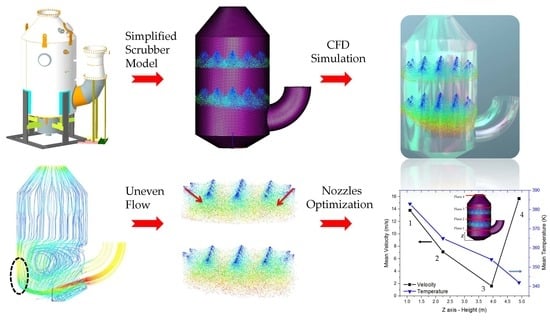

A Numerical Investigation on the Optimization of Uneven Flow in a Marine De-SOx Scrubber

Abstract

1. Introduction

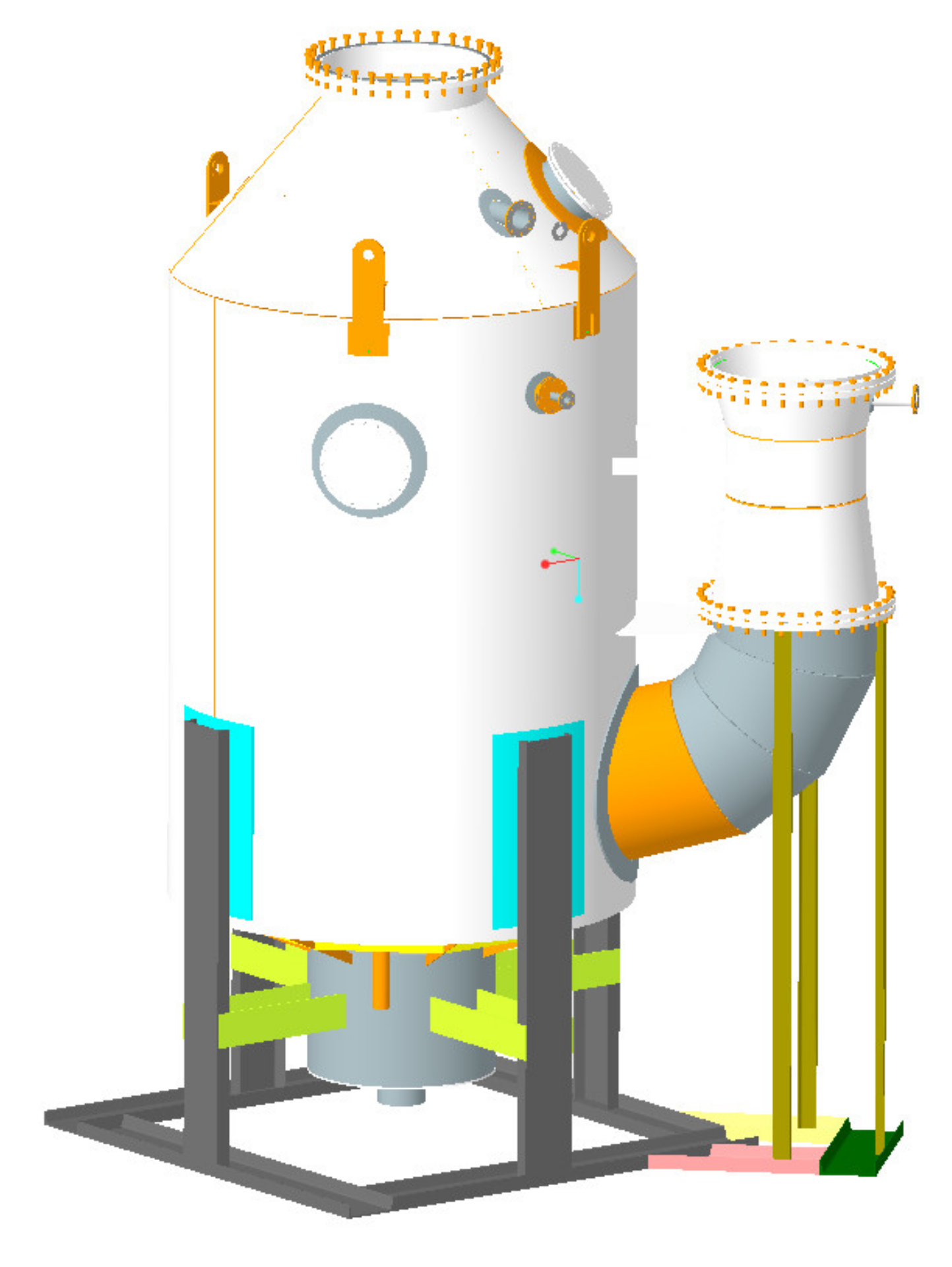

2. Model Description

2.1. Governing Equations

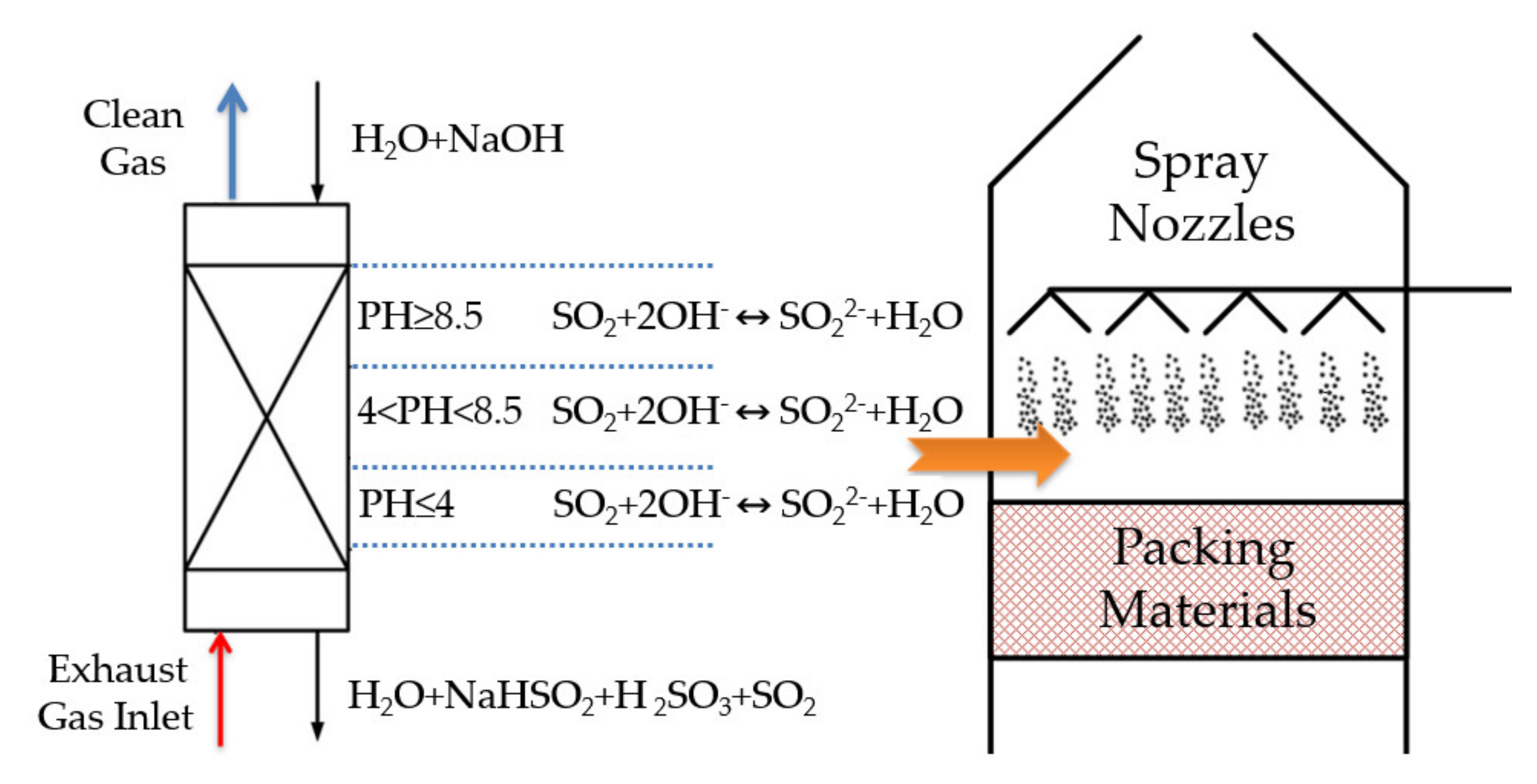

2.2. SO2 Absorption Process inside the Scrubber

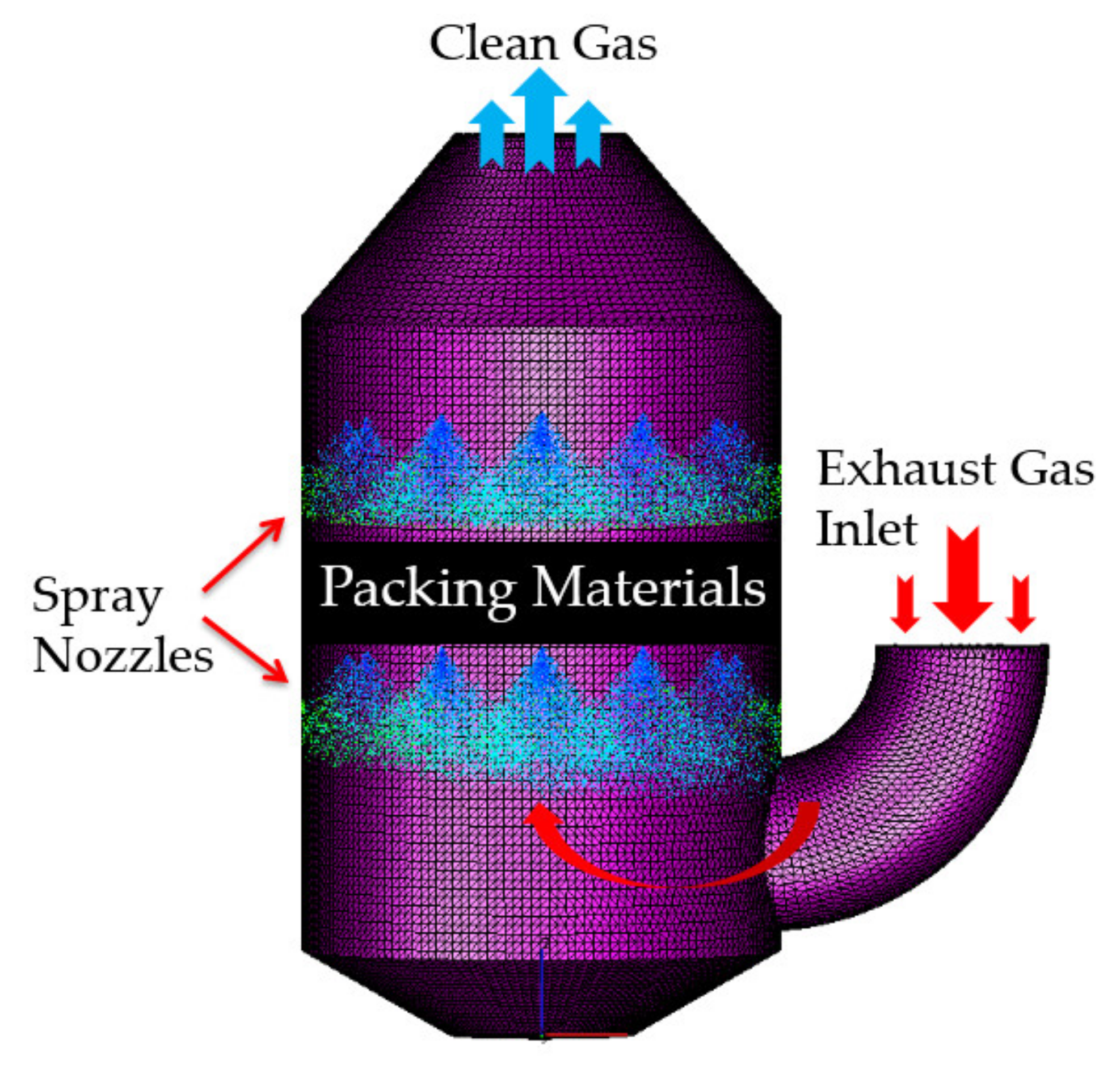

2.3. Computational Fluid Dynamics (CFD) Model Description

2.4. Exhaust Gas Cleaning System (EGCS) Design Objectives

3. Results and Discussion

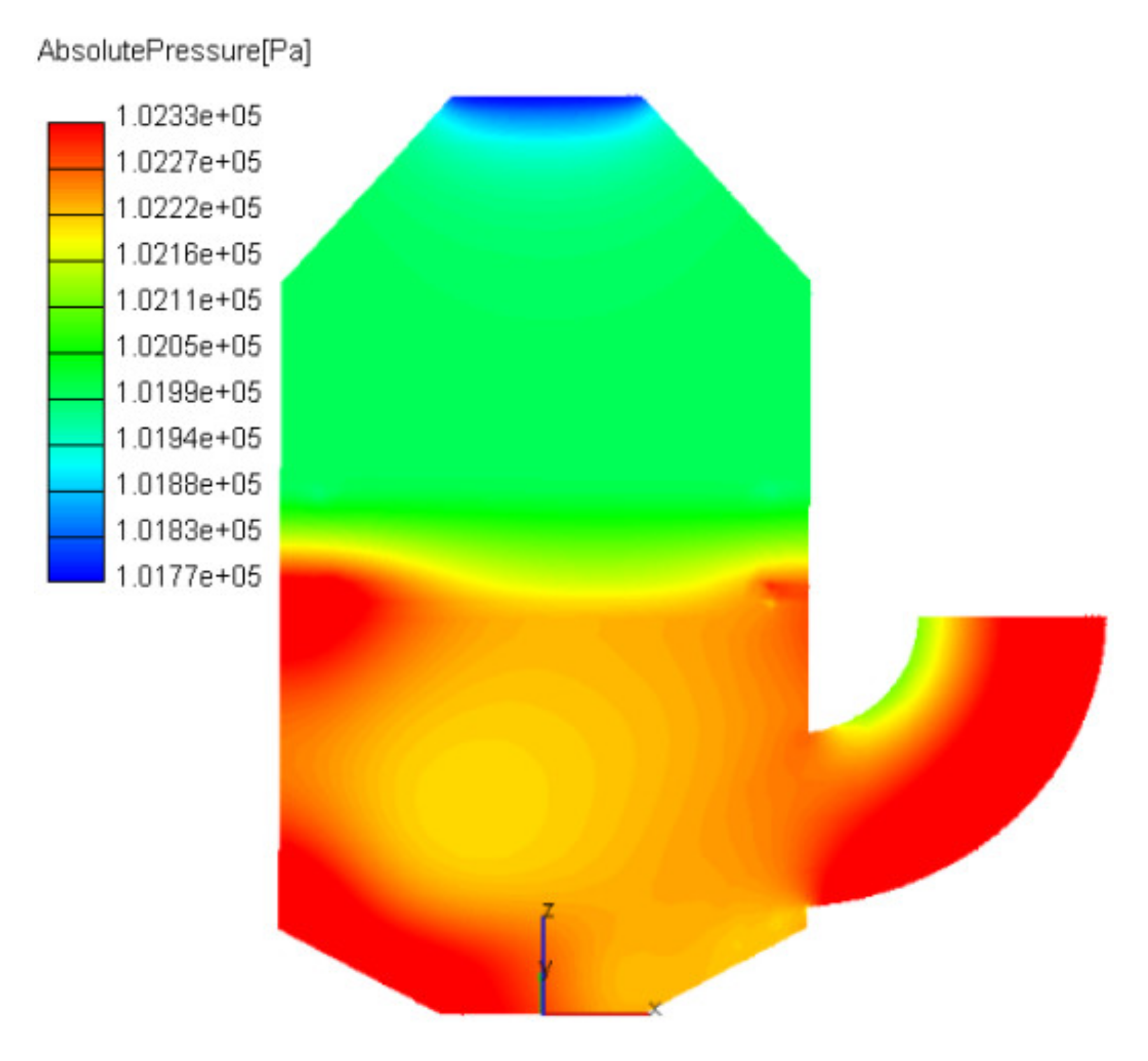

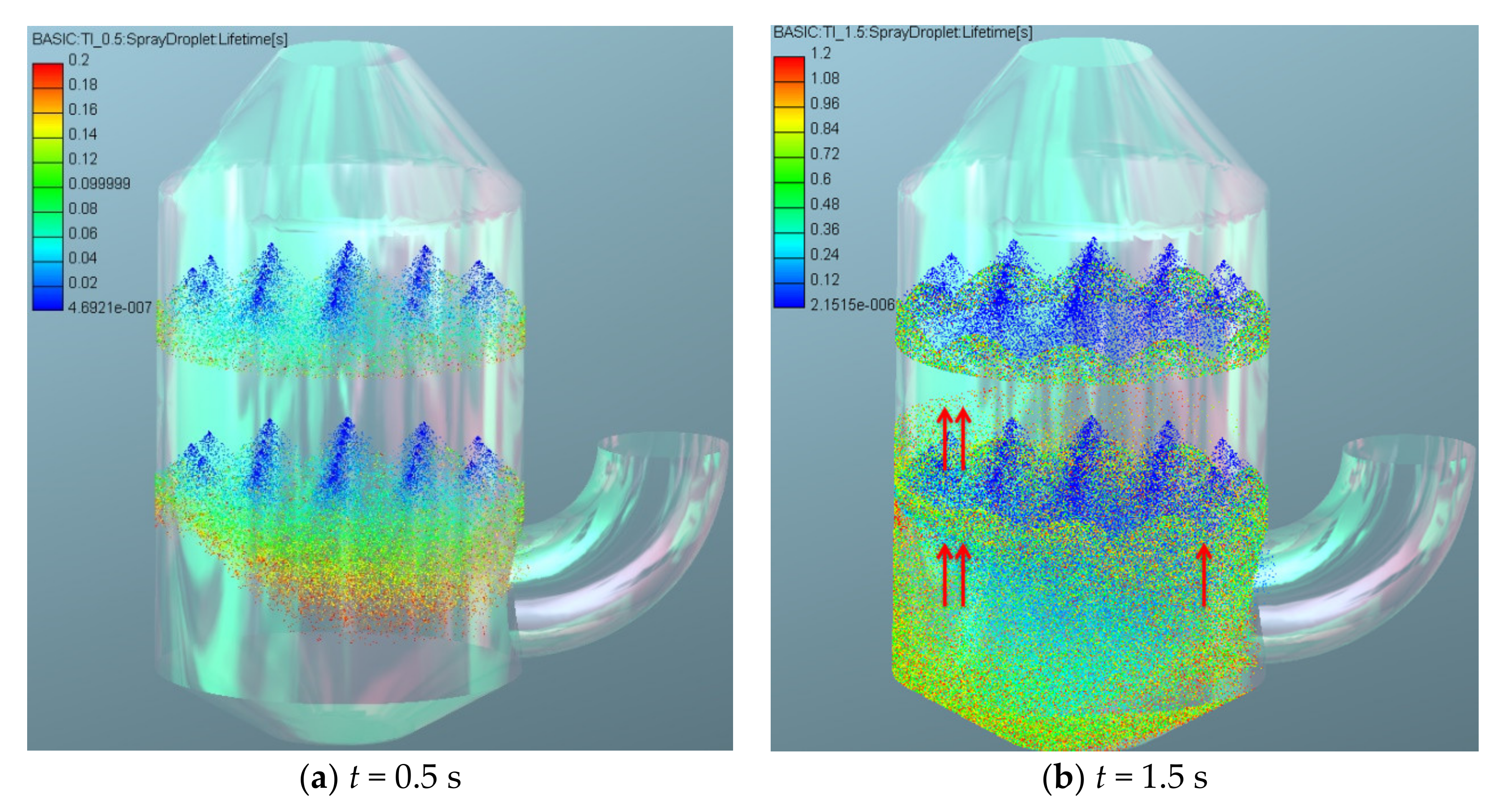

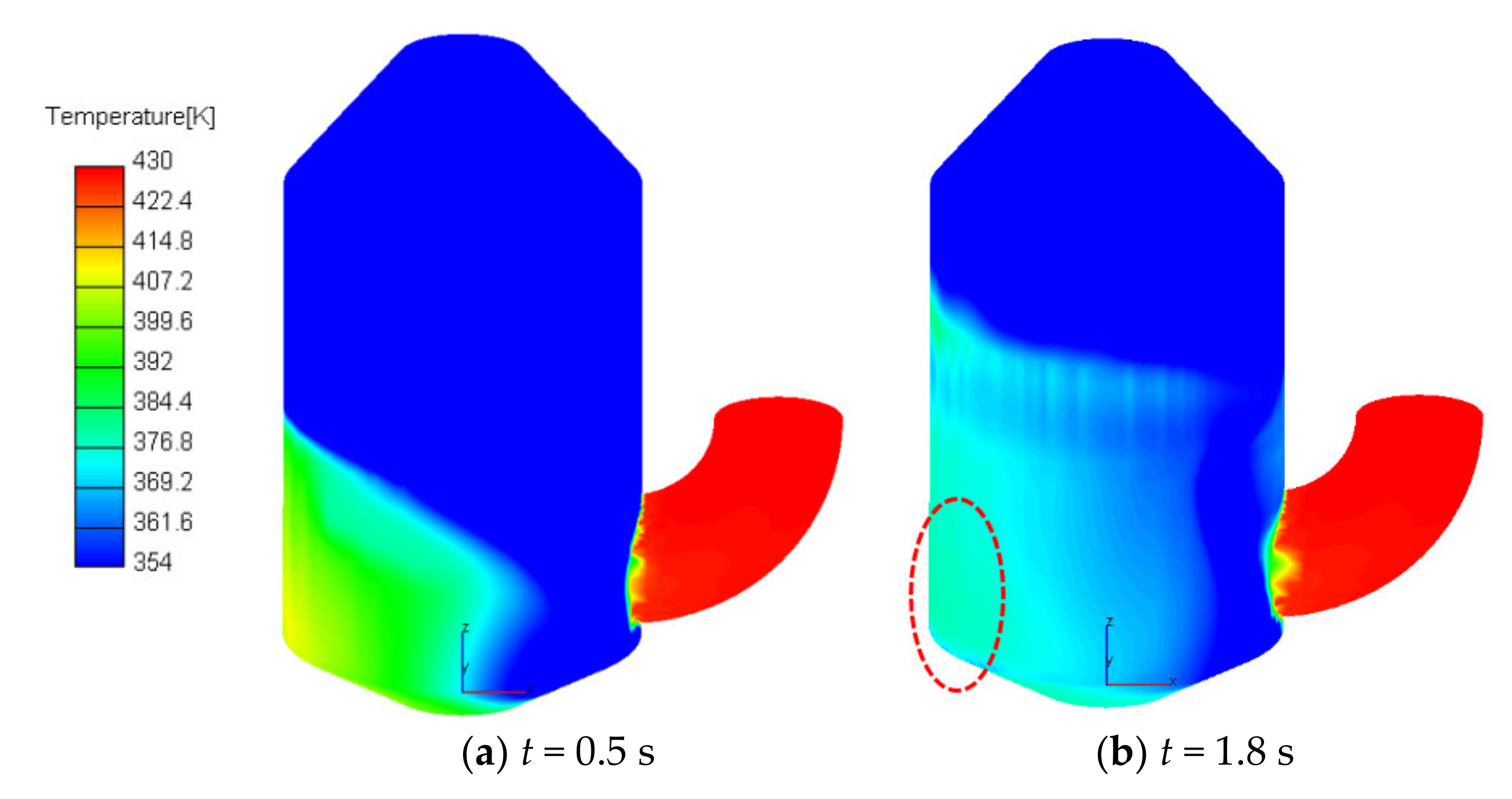

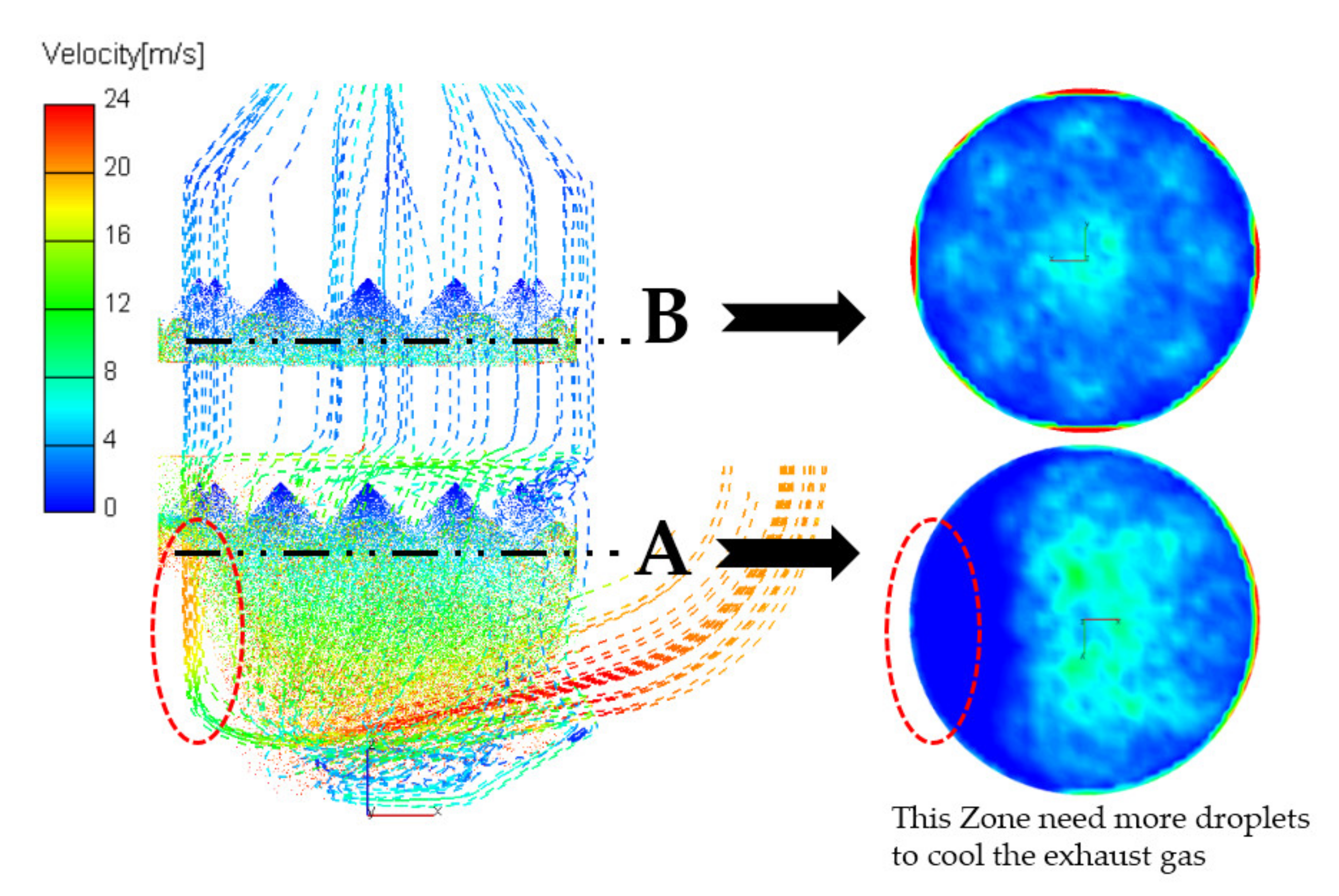

3.1. Flow Characteristics and Spray Behavior Inside the Scrubber

3.2. Adjustment of the Sprays Position

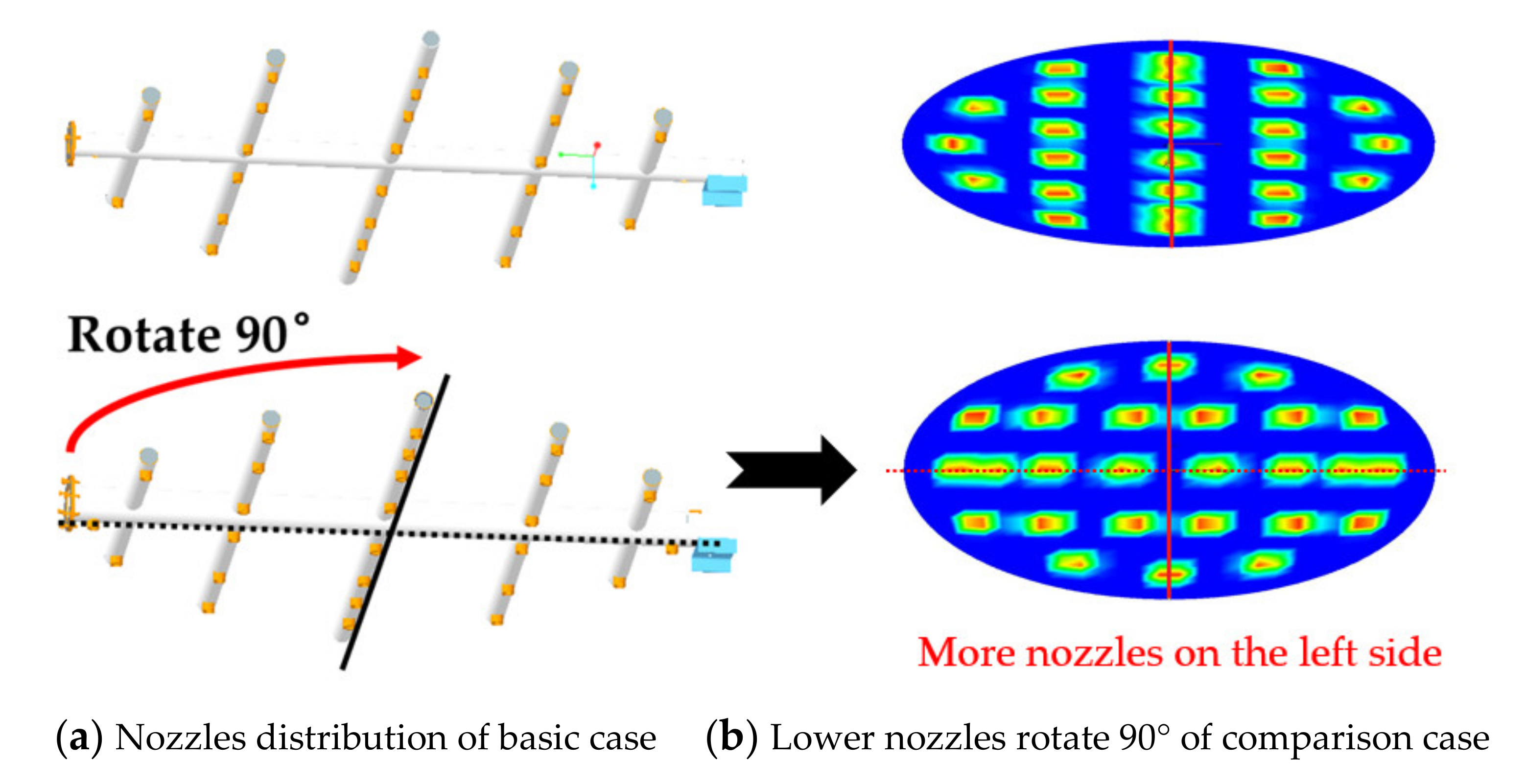

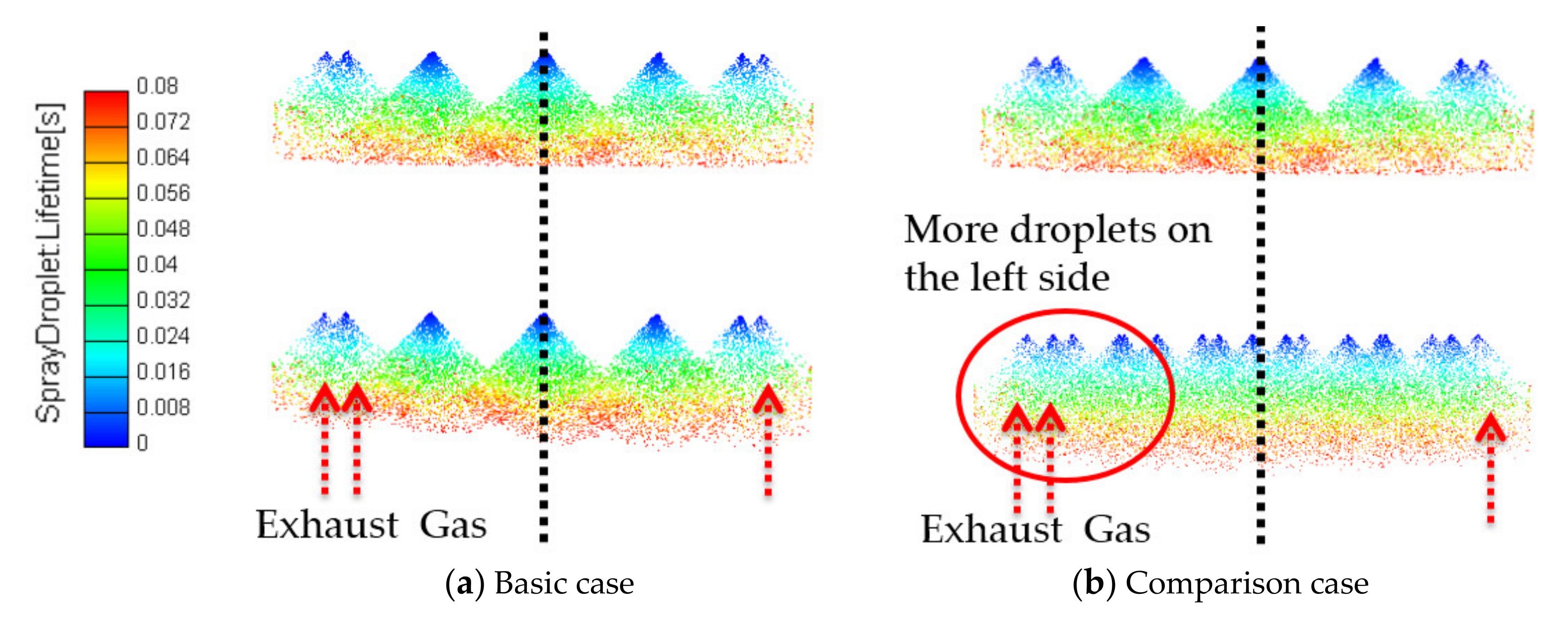

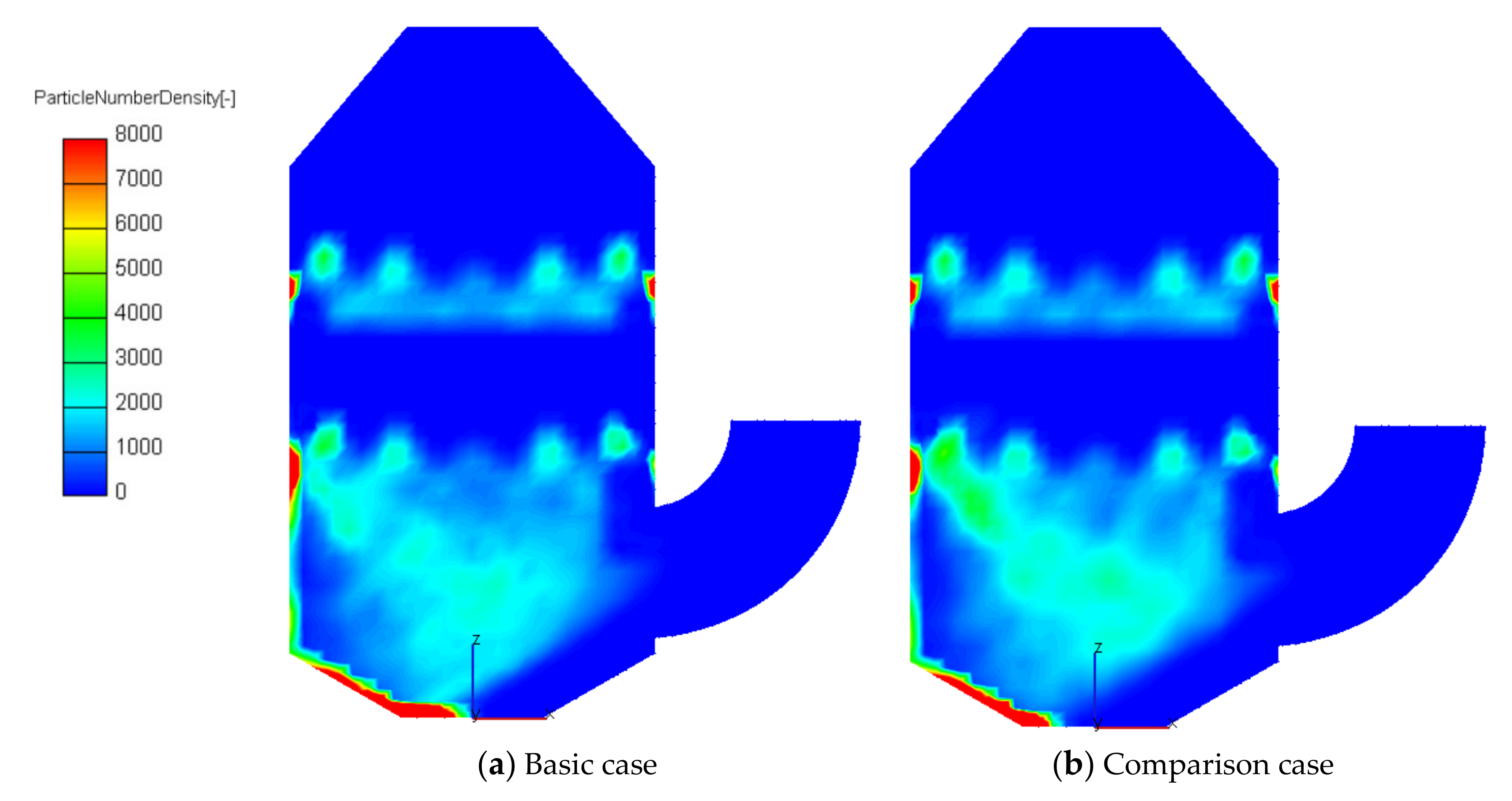

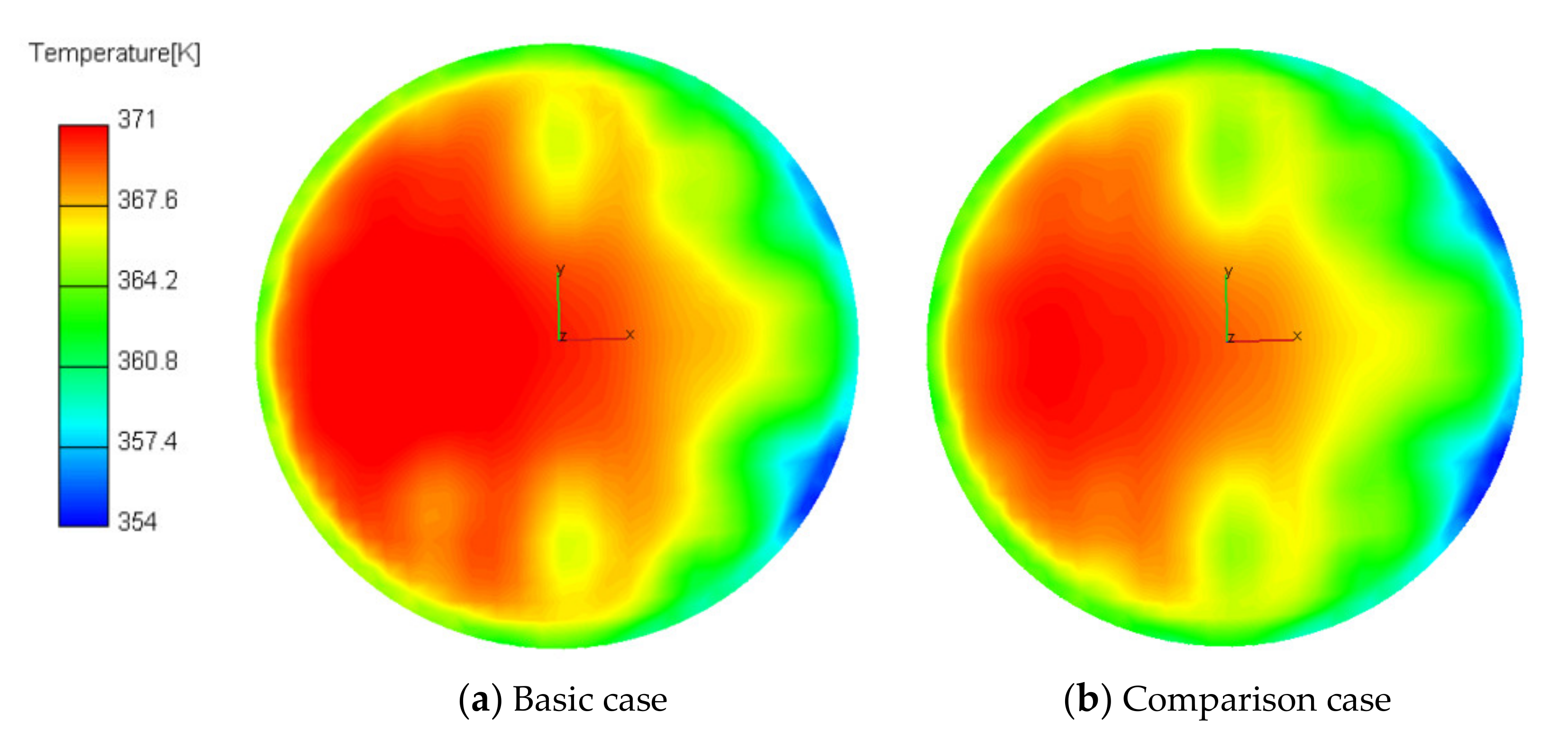

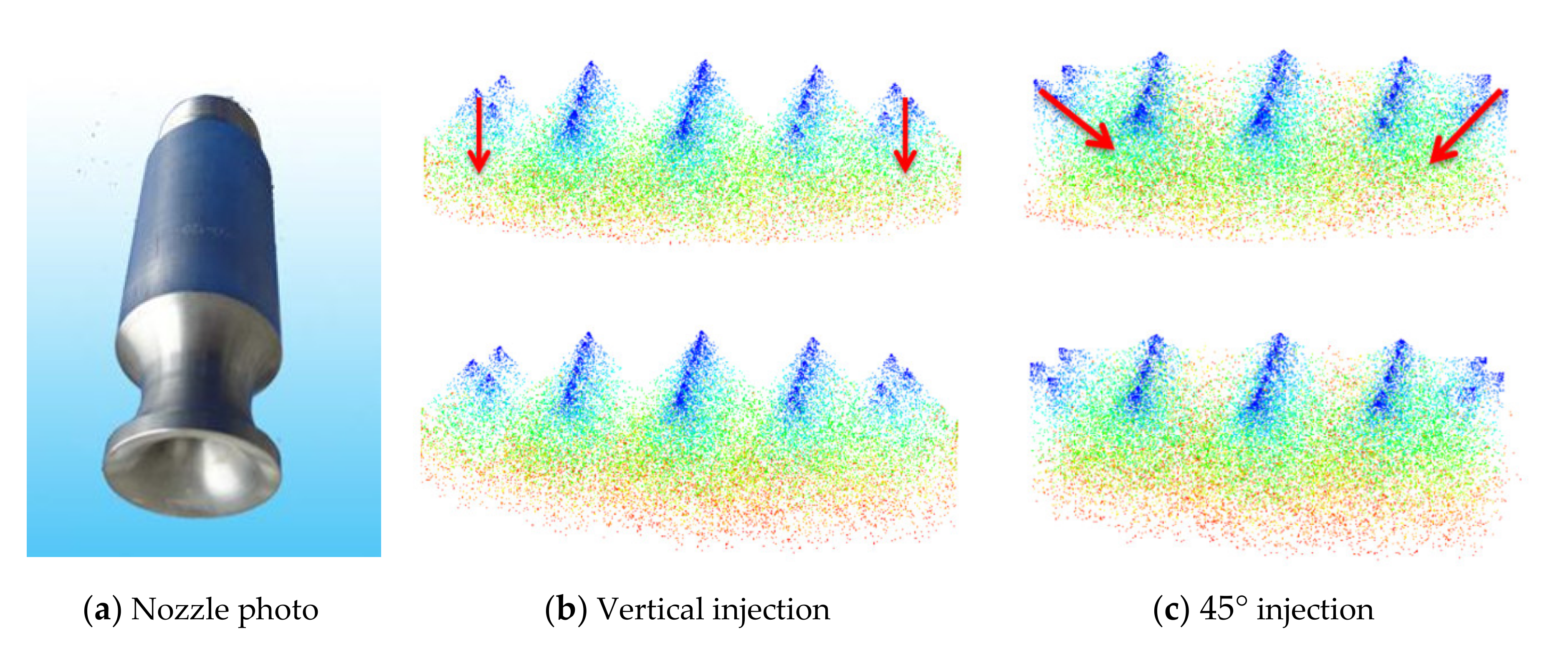

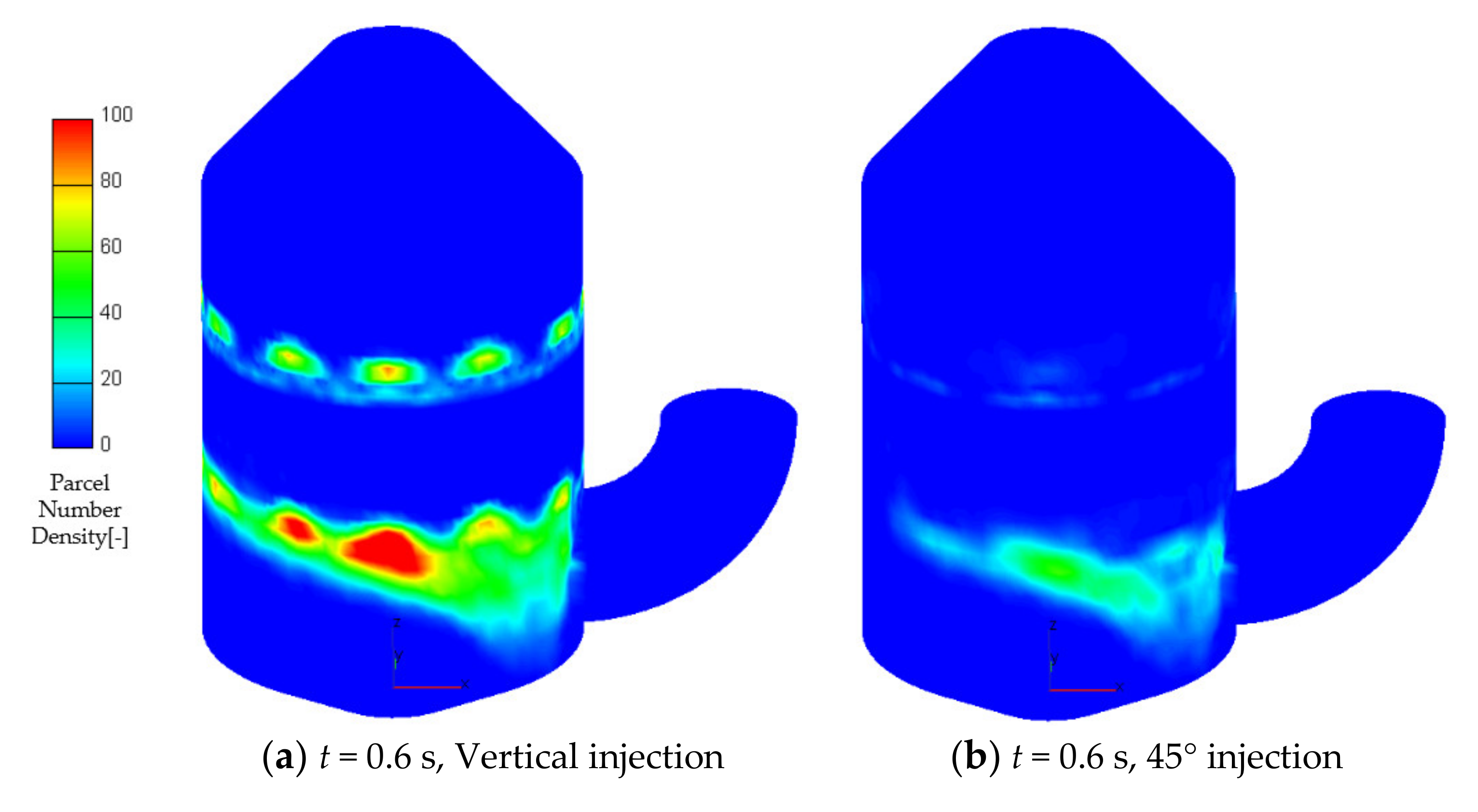

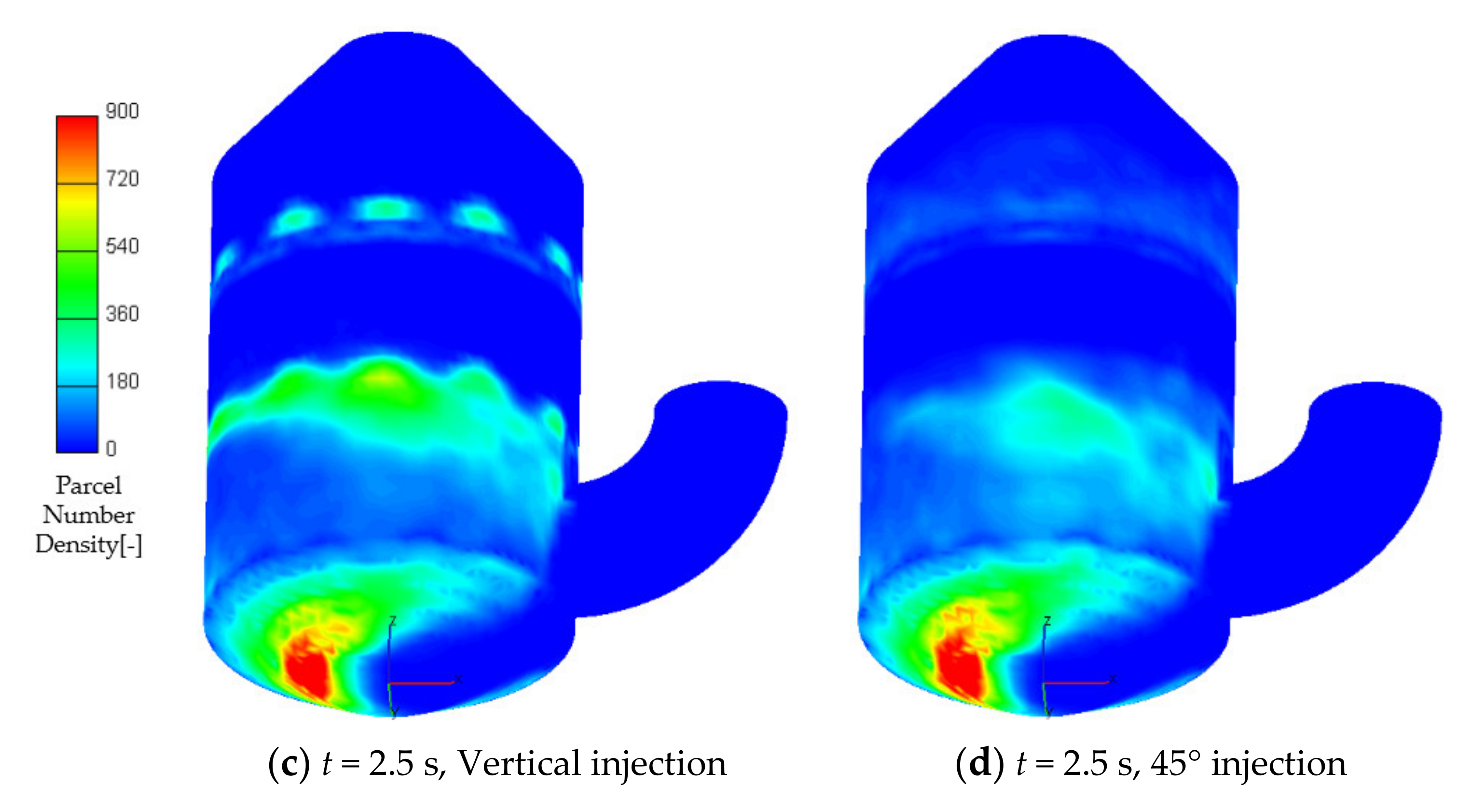

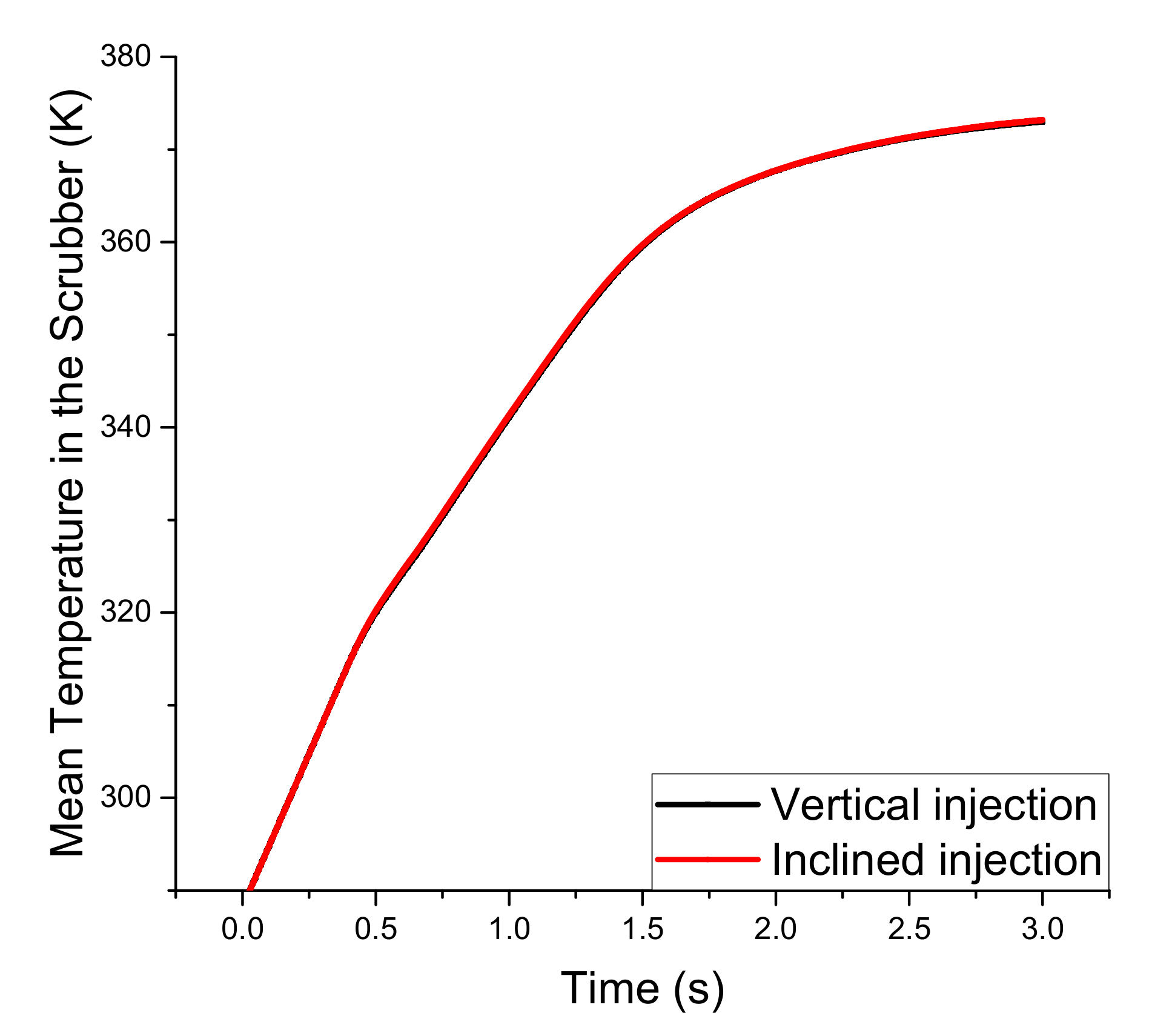

3.3. Adjustment of the Sprays Angle

4. Conclusions

- (1)

- The exhaust gas was concentrated in the left side area of the scrubber and this part of exhaust gas could escape from the scrubber with a bad De-SOx efficiency. In the lower area of the scrubber, the temperature dropped the fastest of all. The influence of droplets velocity and temperature was the reason for the rise and fall of pressure in the marine De-SOx scrubber design.

- (2)

- Controlling the nozzles distribution reduced the droplets to hit the wall and improved the utilization rate of the washing liquid. The nozzles were arranged up and down in different positions, which increased the spray density in the strong offset area of exhaust gas on the left side of the scrubber and reduced the escape amount of exhaust gas. Moreover, the new arrangement of nozzles made the flow field distribution in the scrubber more uniform and increased the gas–liquid reaction time, which further improved the desulfurization efficiency of the scrubber.

- (3)

- By controlling the outermost nozzles angle, it was possible to reduce the droplets to hit the wall as much as possible and improve the utilization rate of the washing liquid. The number of wall droplets with vertical spray was much larger than that of the outermost nozzles 45° injection. Although the pressure drop under outermost nozzles 45° injection was smaller than the vertical injection, the flow field in the scrubber under outermost nozzles 45° injection became more complex and the outlet gas velocity became larger.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| IMO | International Maritime Organization |

| ECAs | Emission Control Areas |

| NOx | Nitrogen Oxides |

| SOx | Sulfur Oxides |

| De-SOx | Desulfurization |

| PM | Particulate Matter |

| HFO | Heavy Fuel Oil |

| FGD | Flue Gas Desulphurization |

| CFD | Computational Fluid Dynamics |

| 3D | Three-Dimensional |

| EGCS | Exhaust Gas Cleaning System |

| EGR | Exhaust Gas Recirculation |

| CAD | Computer Aided Design |

| CSTC | China Shipbuilding Industry Trading Company |

| BSFC | Brake Specific Fuel Consumption |

| L/G | Liquid-to-Gas Ratios |

| DC | Direct Current |

References

- Fuglestvedt, J.; Berntsen, T.; Eyring, V.; Isaksen, I.; Lee, D.S.; Sausen, R. Shipping emissions: From cooling to warming of impacts on health. Environ. Sci. Technol. 2009, 43, 9057–9062. [Google Scholar] [CrossRef] [PubMed]

- Mehdi, G.; Zhou, S.; Zhu, Y.; Shah, A.H.; Chand, K. Numerical investigation of SCR mixer design optimization for improved performance. Processes 2019, 7, 168. [Google Scholar] [CrossRef]

- Murphy, S.M.; Agrawal, H.; Sorooshian, A.; Padró, L.T.; Gates, H.; Hersey, S.; Welch, W.; Jung, H.; Miller, J. Comprehensive simultaneous shipboard and airborne characterization of exhaust from a modern container ship at sea. Environ. Sci. Technol. 2009, 43, 4626–4640. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.X.; Yu, W.B. Experimental and numerical study on the influence of intake swirl on fuel spray and in-cylinder combustion characteristics on large bore diesel engine. Fuel. 2019, 237, 209–221. [Google Scholar] [CrossRef]

- Jiang, L.; Kronbak, J.; Christensen, L. The costs and benefits of Sulphur reduction measures: Sulphur scrubbers versus marine gas oil. Transp. Res. Part D Transp. Environ. 2014, 28, 19–27. [Google Scholar] [CrossRef]

- Diantao, L.; Song, Z. Experimental study and model analysis sodium desulfurization in marine application. J. Chem. Eng. Jpn. 2015, 11, 909–914. [Google Scholar]

- Song, Z.; Jinxi, Z.; Yongming, F. Marine emission pollution abatement by a wet scrubbing method. Ind. Eng. Chem. Res. 2016, 55, 5825–5831. [Google Scholar]

- Ariana, I.; Fujita, H.; Nishida, O. Using water-plate collector and water spray on ESP to reduce marine diesel exhaust emission. J. Mar. Environ. Eng. 2007, 9, 35–44. [Google Scholar]

- Carotenuto, C.; Di Natale, F.; Lancia, A. Wet electrostatic scrubbers for the abatement of submicronic particulate. Chem. Eng. J. 2010, 165, 35–45. [Google Scholar] [CrossRef]

- Di Natale, F.; Carotenuto, C.; D’Addio, L. New technologies for marine diesel engine emission control. Chem. Eng. Trans. 2013, 32, 361–366. [Google Scholar]

- Youfeng, L.; Liangjun, X. Development of low-fuel consumption and low-emission locomotive engine. In Proceedings of the CIMAC Congress, Vancouver, BC, Canada, 10–14 June 2019; p. 51. [Google Scholar]

- Yin, B. Economic assessment of ship gas emission control. J. Dalian Marit. Univ. 2008, 34 (Suppl. 2), 130–132. [Google Scholar]

- Andreasen, A.; Mayer, S. Use of seawater scrubber for SO2 removal from marine engine exhaust gas. Energy Fuels 2007, 21, 3274–3279. [Google Scholar] [CrossRef]

- Jamil, R.; Ming, L.; Jamil, I.; Jamil, R. Application and development trend of flue gas desulfurization (FGD) process. Int. J. Innov. Appl. Stud. 2013, 4, 286–297. [Google Scholar]

- Ma, H.; Steernberg, K.; Riera-Palou, X. Well-to-wake energy and greenhouse gas analysis of SOx abatement options for the marine industry. Transp. Res. Part D Transp. Environ. 2012, 17, 301–308. [Google Scholar] [CrossRef]

- Caiazzo, G.; Di Nardo, A.; Langella, G. Seawater scrubbing desulfurization: A model for SO2 absorption in fall-down droplets. Environ. Prog. Sustain. Energy 2012, 31, 277–287. [Google Scholar] [CrossRef]

- Wärtsilä Corporation. Exhaust Gas Scrubber Installed Onboard mt “Suula” Public Test Report; Wärtsilä: Helsinki, Finland, 2010. [Google Scholar]

- Caiazzo, G.; Langella, G.; Miccio, F. An experimental investigation on seawater SO2 scrubbing for marine application. Environ. Prog. Sustain. Energy 2013, 32, 1179–1186. [Google Scholar] [CrossRef]

- Wu, X.C.; Wang, Z.J. Investigation on a novel seawater exhaust gas cleaning system applied for SOx emissions reduction of marine diesel engine. Adv. Mater. Res. 2014, 12, 765–771. [Google Scholar]

- Jenkins, G.E.; Sampson, K.G.; Dumont, D.S. Marine Exhaust Gas Cleaning System. World Patent WO2015106355A1, 23 July 2015. [Google Scholar]

- Fridell, E.; Kent, S. Measurements of abatement of particles and exhaust gases in a marine gas scrubber. J. Eng. Marit. Environ. 2016, 1, 154–162. [Google Scholar] [CrossRef]

- Chelluboyana, V.R.; Mondal, M.K. Removal of SO2 and NO by complex absorbent using wet scrubbing. Int. J. Appl. Eng. Res. 2014, 9, 345–350. [Google Scholar]

- Zhou, J.; Zhou, S.; Zhu, Y. Experiment and prediction studies of marine exhaust gas SO2 and particle removal based on NaOH solution with a U-type scrubber. Ind. Eng. Chem. Res. 2017, 56, 12376–12384. [Google Scholar] [CrossRef]

- Zhang, S.; Duan, X.; Liu, Y. Experimental and numerical study the of combustion chamber shapes on combustion and emissions characteristics on combustion and emissions characteristics in a heavy-duty lean burn SI natural gas engine coupled with detail combustion mechanism. Fuel 2019, 258, 116–130. [Google Scholar] [CrossRef]

- Guo, H.; Zhou, S.; Shreka, M.; Feng, Y. Effect of pre-combustion chamber nozzle parameters on the performance of a marine 2-stroke dual fuel engine. Processes 2019, 7, 876. [Google Scholar] [CrossRef]

- Zhou, S.; Gao, R.F.; Feng, Y.M. Evaluation of Miller cycle and fuel injection direction strategies for low NOx emission in marine two-stroke engine. Int. J. Hydrogen Energy 2017, 42, 20351–20360. [Google Scholar] [CrossRef]

- Kumaresh, S.; Kim, M.Y. A numerical study on the fluid flow and thermal characteristics inside the scrubber with water injection. J. Mech. Sci. Technol. 2016, 30, 915–923. [Google Scholar]

- Peng, X.; Boming, Y. Developing a new form of permeability and Kozeny–Carman constant for homogeneous porous media by means of fractal geometry. Adv. Water Resources. 2008, 31, 74–81. [Google Scholar]

| Parameter | Value |

|---|---|

| Bore | 500 mm |

| Stroke | 2000 mm |

| Cylinder Number | 6 |

| Engine Speed | 127 r/min |

| Power | 9480 kW |

| Peak Combustion Pressure | 15.4 MPa |

| Brake Specific Fuel Consumption (BSFC) | 171 g/kWh |

| Piston Speed | 8.5 m/s |

| Index | Boundary Condition | Data |

|---|---|---|

| Inlet | Mass flow rate | 23.72 kg/s |

| Temperature | 485 K | |

| Outlet | Pressure | 101325 Pa |

| Wall | No slip wall | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, H.; Zhou, S.; Shreka, M.; Feng, Y. A Numerical Investigation on the Optimization of Uneven Flow in a Marine De-SOx Scrubber. Processes 2020, 8, 862. https://doi.org/10.3390/pr8070862

Guo H, Zhou S, Shreka M, Feng Y. A Numerical Investigation on the Optimization of Uneven Flow in a Marine De-SOx Scrubber. Processes. 2020; 8(7):862. https://doi.org/10.3390/pr8070862

Chicago/Turabian StyleGuo, Hao, Song Zhou, Majed Shreka, and Yongming Feng. 2020. "A Numerical Investigation on the Optimization of Uneven Flow in a Marine De-SOx Scrubber" Processes 8, no. 7: 862. https://doi.org/10.3390/pr8070862

APA StyleGuo, H., Zhou, S., Shreka, M., & Feng, Y. (2020). A Numerical Investigation on the Optimization of Uneven Flow in a Marine De-SOx Scrubber. Processes, 8(7), 862. https://doi.org/10.3390/pr8070862