4.1. Descriptive Analysis

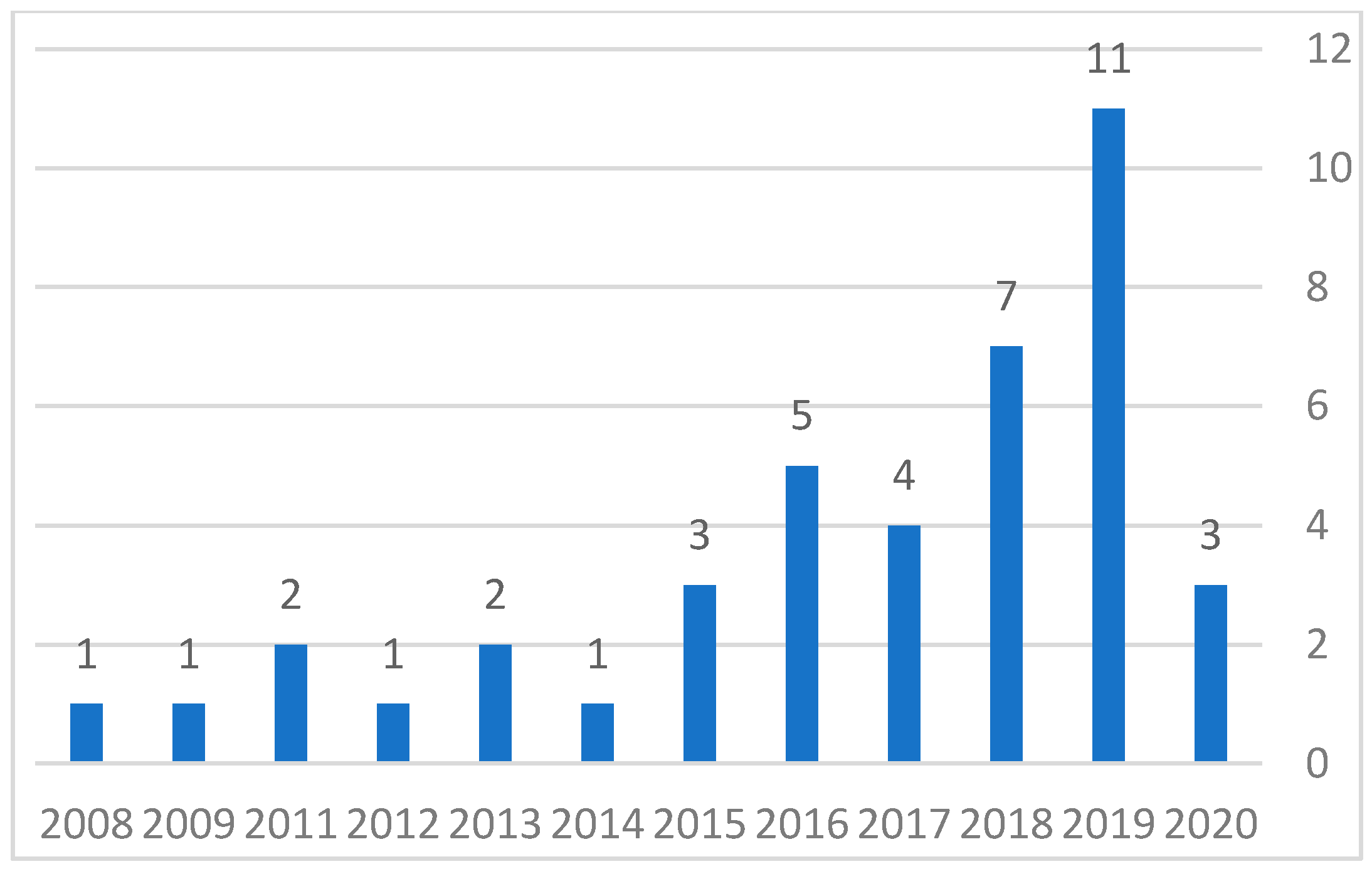

The number of articles published each year is shown in

Figure 2. From

Figure 2, we can see that the first article about RL supplier selection was published in 2008; thus, the articles selected for this review were published between 2008 and 2020. Starting in 2015, the number of relevant articles has increased, and the growth rate has increased rapidly in the past two years. There were 11 articles published in 2019 and 7 in 2018, but no articles related to the topic were found among the articles published in 2010. It should be noted that the number of articles for 2020 is not complete, and there may be further growth after data collection.

Among the 41 articles, 12 were from the

Journal of Cleaner Production (

Table 1), which is the journal with the most published articles, accounting for 29%, followed by the

International Journal of Advanced Manufacturing Technology (10%). The top contributing countries are shown in

Table 2. (Since many articles are jointly published by scholars from multiple countries, only the countries of the first author of the articles are listed, and

Table 2 only shows countries with more than three published articles.) India has the largest number of publications on the subject (15), followed by China (10). In addition, some articles are based on studies of enterprises in particular countries (

Table 3). Overall, 14 articles chose Indian companies for case studies, 7 articles chose Iranian companies and 6 chose Chinese companies. The logistics industry in India has been developing rapidly due to its rapid economic growth, which has prompted more research on RL subjects in India. The implementation of circular economy promotion laws in China might be a driving force for the interest and the number of papers in China.

The top 10 most-cited articles were identified among the 41 articles analyzed (See

Table 4), three of which were published in

the Journal of Cleaner Production.

Resources Conservation and Recycling published the most-cited articles, while the article with the highest average annual citation rate [

42] was published in the

Journal of Cleaner Production.

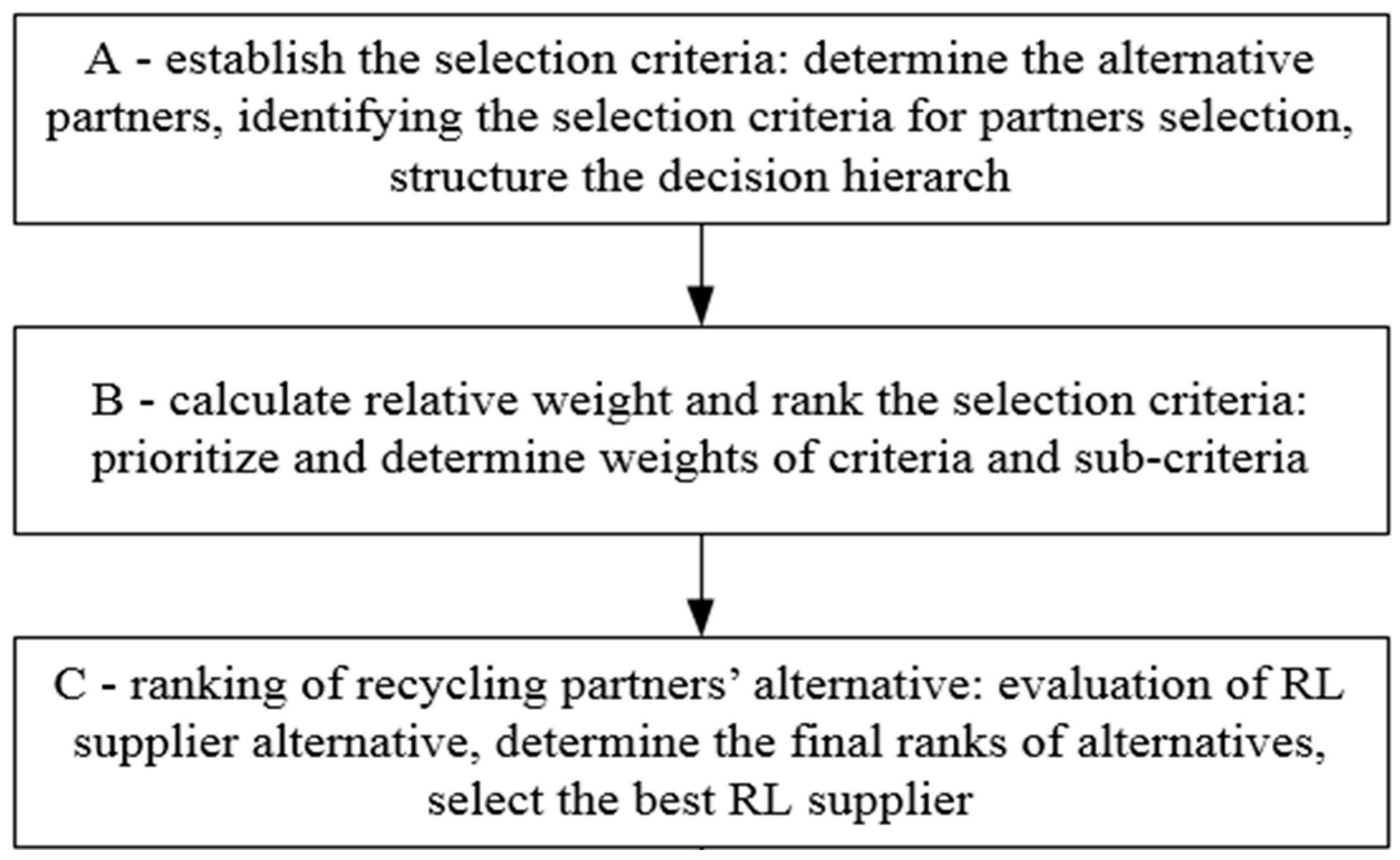

Each article is categorized based on the three stages of the RL supplier selection process, as described in

Figure 1 (see

Table 5). The following section describes the findings and analysis of these stages; the theories and methods used in each stage in the papers are discussed in detail in

Section 4.2 to

Section 4.4. It is important to note that [

42] is discussed in a particular section as its content is a conceptual framework.

4.2. Stage A: Establish the Selection Criteria

In terms of the theoretical approaches used in the 41 articles selected, researchers mainly focus on “sustainability”, which is utilized in 18 papers. Six papers use green supply chain management (GSCM) to investigate how to select RL suppliers. “Green” focuses more on the environment aspect than “sustainability”. In addition, only one article uses circular economy (CE), which focuses more on the economic aspect than “sustainability”. The remaining half mainly apply two theories to complete the classification of criteria. Of these, 11 papers summarize several “performance dimensions” [

57] based on the business capabilities of the RL supplier. Organizational performance, RL Functions, IT application, service quality and user satisfaction are the most commonly used main groups. Four papers consider firms’ requirements and operating strategies [

36] to complete the classification of criteria. One article completes the criteria classification through strengths–weaknesses–opportunities–threats (SWOT) analysis [

49] (

Table 6).

Generally identifying the most-used criteria to select the 3PRLP was based on a systematic literature review (SLR), and several papers proposed a similar set of criteria: forward logistics; reverse logistics; financial; capacity; environmental; alliances [

43,

50,

57,

65]. In addition, different main parameters determine the selection process for an appropriate 3PRLP in different situations. Some of these parameters are common, such as the use of third-party logistics [

46], service quality and service ability [

63], and application of information technology [

28,

47,

58], and some are used in special cases, like noise pollution [

36]. Both Li et al. [

40] and Prakash and Barua [

52,

71] consider firms’ requirements and operating strategies. Momeni et al. [

61], P.Sasikumar and A.Noorul Haq [

59] determine the criteria according to the process of reverse logistics.

Sustainability is a popular research topic; many articles divide criteria into three categories, reflecting their impacts on society, economy and environment, respectively. The specific criteria, from economic, social and environmental perspectives according to previous sustainable/green practices and literature reviews, are explored [

38,

62,

67]. Silva et al. define EES (economic, environmental and social) considerations as the three dimensions of sustainable development [

8]. It should be noted that ISO14000 is often used as a reference for formulation of environmental criteria. Some authors add the consideration of risk, which includes operational risk and financial risk [

48,

66,

68]; sometimes safety practices and health, along with compliance with the International Labour Organization (ILO) code [

53] or respect for local rules and policies [

45] are grouped together into the category of social factors. In the following research, Zarbakhshnia et al. [

3] improve “risk and safety” by using the Delphi method to update the content of the criteria, and add two sub-criteria—organizational risk and safety— into the new dimension of “risk and safety”. Garg et al. [

56] take all sustainable outsourcing partners (SOPs) as alternative objects; reverse logistics and waste minimization are regarded as sub-criteria under the aspect of environmental factors, in which practices recovering materials, minimization of waste and disposal in an environmental friendly way are emphasized. Liu et al. [

29] transform the criteria of the three sustainability dimensions based on customer needs (CNs) into engineering characteristics (ECs), which have nine criteria, including reverse logistics. Bai and Sarkis summarize cost, quality, time, flexibility, and innovativeness as five economic/business attributes that can be considered from a sustainability perspective [

55].

The papers also link a range of other criteria to RL supplier selection. Pourjavad et al. divides the crucial criteria of 3PRLP selection into environmental, social and cost [

64]. The cost criteria consists of the quality of products, value-added services, transport capacity and level of advanced equipment. Jung [

70] set social sustainability as the main aspect, with focuses on three social criteria: philanthropy, average salary and management policy.

When selecting suppliers in the sustainable supply chain, both the collection capability as well as green technology capability are considered [

44]; others employ waste management and pollution prevention as evaluation criteria [

42]. Gardas et al. add the “sustainable eco-friendly process/recycling” to the 3PLP selection criteria of the pharmaceutical industry [

60]. Govindan et al. developed a model for circular supplier selection, in which three criteria are identified: quality, on-time delivery and circularity, among which the sub-criterion “environmental standards” requires suppliers to utilize environmental standards to recycle products [

1].

Chatterjee et al. present the dimensions and corresponding criteria of the GSCM, including green design, green production, green warehousing, green transportation and green purchasing [

41]. Tosarkani and Amin added “social-cultural enablers” to various criteria, representing green logistics practices [

39]. EES assessment is also cited by some authors to select reverse logistics centers [

69]. Efendigil et al. proposed that RL is an important part of the effective operation of “green supply chains”. However, their twelve performance indicators for 3PRLP are biased towards logistics practices and neglect of green practices [

54]. In contrast, the criteria for selection and evaluation of green suppliers summarized by Santos et al. [

37] are more oriented towards green practices. A set of more comprehensive criteria is proposed in further research; Kumar and Dixit [

28] studied recycling partner evaluation for the disposal of waste electrical and electronic equipment (WEEE) using green competencies (GC), and proposed a mode for GC and recycling partner selection, using opportunism, service and delivery performance, resource and environmental management capabilities, social responsibility benefits, green core competencies, management and organizational competencies, regulatory obligations and risk compliances as the criteria.

4.3. Stage B: Calculate the Relative Weights

In stage B, in order to determine the degree of importance of the criteria, the weights for each dimension and then the weights of the sub-criteria are calculated in their separate dimensions. For articles that use the concept of sustainability to establish criteria, the most heavily weighted dimensions are generally environment [

28,

42,

56] and economy [

45,

48,

67,

68]. Some articles are specific to cost or price [

64,

70]. Only one of the selected articles places the highest weight on the society dimension [

3]. Often, the most critical criteria are tailored to different situations and objectives. Tavana et al. conclude that the third-party logistics services (3PLS) criterion has the most important impact on the selection of 3PRLPs [

46]. That is, the highest priority should be given to the 3PLS criterion if a decision maker aims at improving the performance when selecting 3PRLPs [

47,

52,

71]. Articles with green practices as the purpose place the most emphasis on various environmental criteria, such as “circular” [

1], environmental practice [

37,

39,

40], environmental expenditure [

54] and green design [

41]. Others focus on technical/engineering capability [

27,

36,

58].

According to decision making techniques, the majority of articles employ fuzzy theory to assist in this process. These articles use fuzzy logic to deal with the uncertainty of qualitative criteria. FAHP was used in 13 articles; four articles used FANP (fuzzy analysis network process). BWM (best–worst method), DEA (data envelopment analysis) and ISM (interpretive structural modeling) were employed in three papers each. SWARA (stepwise weight assessment ratio analysis) was employed in two papers each. CPT (cumulative prospect theory) and AEW (anti-entropy weighting) are used in one article each. More details are listed in

Table 7.

Although most articles do not mention it, there is some basis for the method selection. Kumar and Dixit [

28] consider that, compared with ANP, the ease of applicability in pairwise comparisons made AHP become a more useful tool. However, the weakness of AHP is that the process of AHP is time consuming because there will be a large number of required pairwise comparisons [

67]. Chatterjee et al. find that, in the R’DEMATEL method (rough Decision Making Trial and Evaluation Laboratory Model), the relationship between the criteria is closer to the real systems compared with ANP, because the levels of interdependence of criteria and dimensions do not have any reciprocal values [

41].

4.4. Stage C: Ranking of Alternatives

In stage C, the articles determine the final results using appropriate ranking methods. As can be seen from the

Table 8, VIKOR (ViseKriterijumska Optimizacija I Kompromisno Resenje) and TOPSIS (technique for order of preference by similarity to ideal solution) are the two commonly used methods; MOORA (multi-objective optimization by ratio analysis) and DEA were applied in three papers each, two papers used the FANP method, and the rest of the articles used a variety of novel approaches including IPHFS (interval Pythagoras hesitant fuzzy set), MAIRCA (multi-attribute ideal-real comparative analysis), COPRAS (complex proportional assessment), NRS (neighborhood rough set), PROMETHEE (preference ranking organization method for enrichment evaluation), F-AIO (fuzzy artificial immune optimization).

Luo et al. [

66] compared the results of PDHFLT (possibility distribution based hesitant fuzzy linguistic term sets)-MOORA with those of PDHFLT-TOPSIS and PDHFLT-VIKOR. Although there was no difference in the final results, the overall ranking was still different. TOPSIS ignores individual regret, while the VIKOR-based method considers individual regret, but the result is very sensitive to individual regret proportion, which is difficult to determine. The PDHFL-MULTIMOORA method considers both the group utility values and individual regret values and can overcome this shortcoming. Bai and Sarkis [

55] mainly make innovations in ranking methods. The NRS theory is used to reduce the number of 3PRLPs to be selected at first, and then a preferred 3PRLP is eventually selected by using VIKOR combined with the TOPSIS. The solution with the shortest distance from the ideal solution and the longest distance from the negative ideal solution can be determined by TOPSIS, but the relative importance and conflict criterion of distance could not be taken into account. The proposed new method integrated the advantages of the TOPSIS and VIKOR methods and can take into account factors such as the ideal solution, the negative ideal solution and conflicting criteria, which can make results more reliable [

55].

The IPHFS adopted by Liu et al. [

36] can more accurately show the attitude of decision makers than traditional ANP, TOPSIS and BWM methods because it has more liberal restrictions on membership and non-affiliation. Govindan et al. consider that widely used approaches such as AHP, TOPSIS, and DEA, which require decision makers to make great cognitive effort, may lead decision makers to make some arbitrary transformation of the performances scales, or provide poor recognition ability [

67]. The advantage of the new proposed ELECTRE and SMAA approaches is that they allow the qualitative nature of some criteria and heterogeneous criteria scales, and they provide the possibility of modeling the effects of high strengths or critical weaknesses in the comparison of a pair of alternatives. Li et al. [

40] proposed the CPT-based hybrid-information MCDM method, which takes into consideration the bounded rationality of DM. This approach offers better consistency with reality, as it addresses the shortcomings of FTOPSIS. Chatterjee et al. compared the ranking results of rough TOPSIS, rough COPRAS, rough MAIRCA and rough VIKOR; the conclusion is that the R’VIKOR method focuses on seeking a balance between total and individual satisfaction, while the R’MAIRCA method emphasizes ranking and selecting from a set of alternatives in the presence of conflicting criteria. R’TOPSIS introduces the ranking index, including the distances from the ideal point and from the negative ideal point, but these distances are simply summed as numerical values, without taking into account their relative importance; similar problems may appear in the R’COPRAS method [

41].