New, Aqueous Radical (Co)Polymerization of Olefins at Low Temperature and Pressure

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

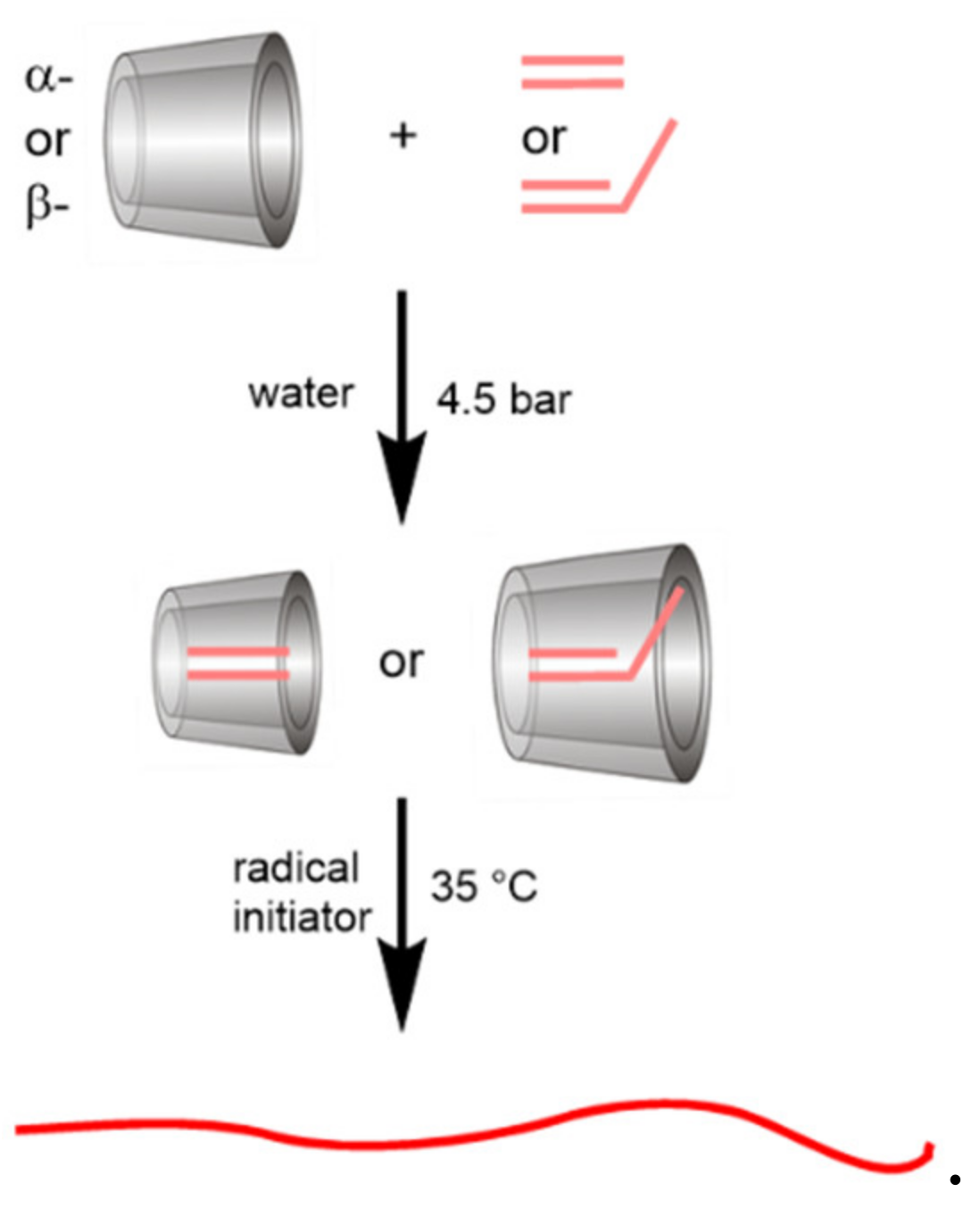

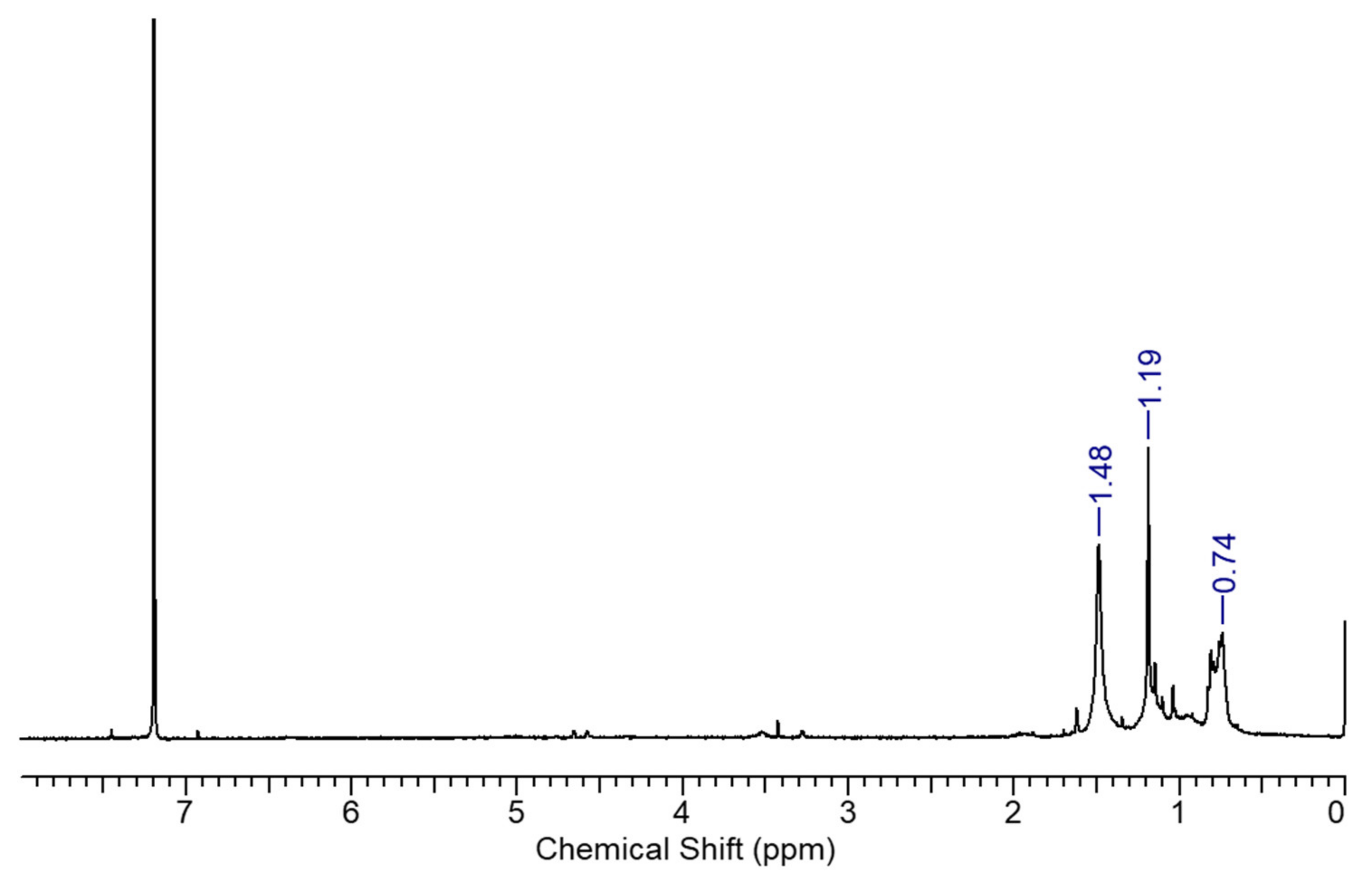

2.2.1. Polyethylene Prepared via Free Radical Polymerization

2.2.2. Polypropylene Prepared via Free Radical Polymerization

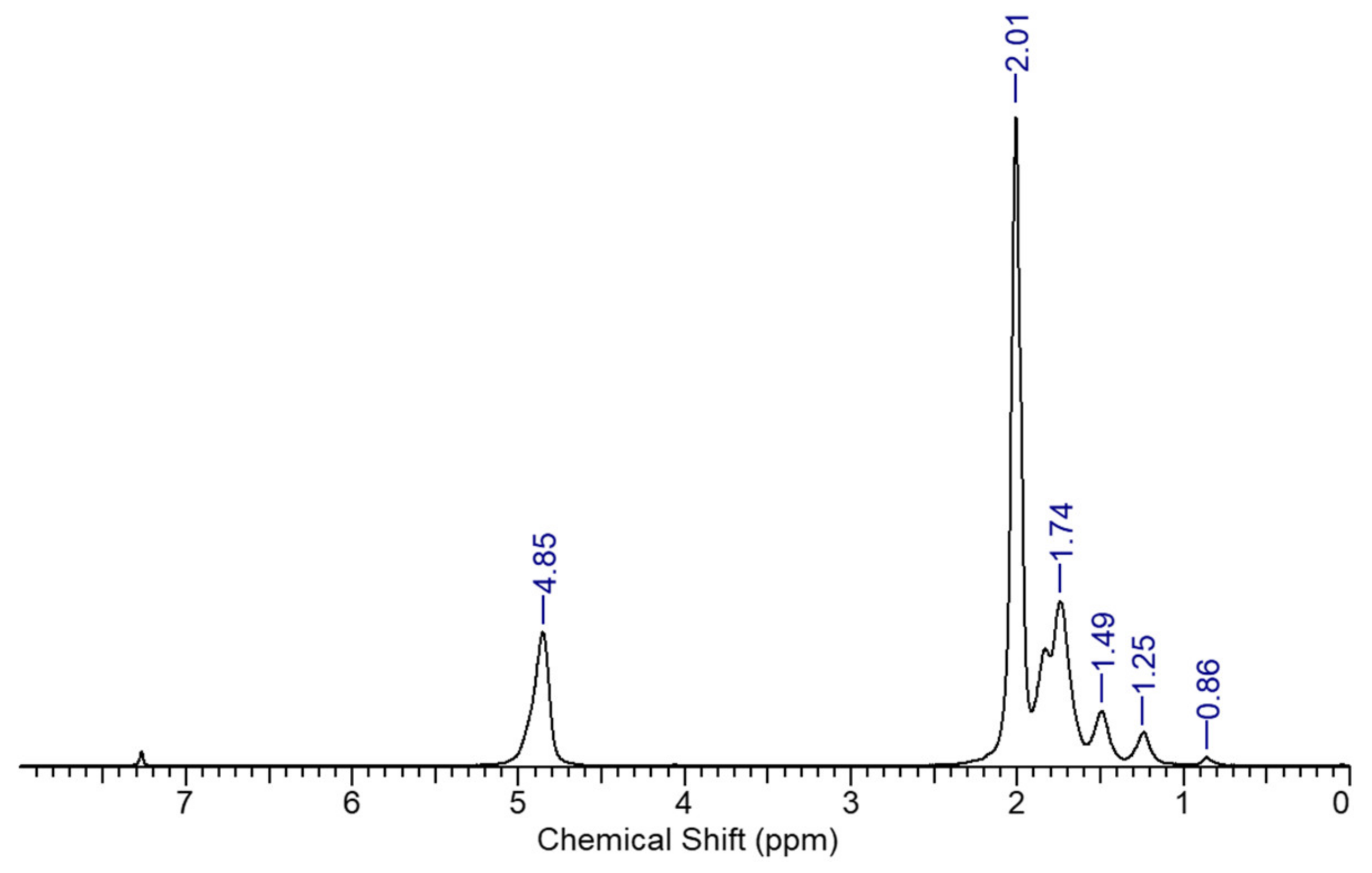

2.2.3. Poly(Ethylene-co-Vinyl Acetate) Prepared via Free Radical Polymerization

2.2.4. Blind Tests and Reproducibility

2.3. Analytical Methods

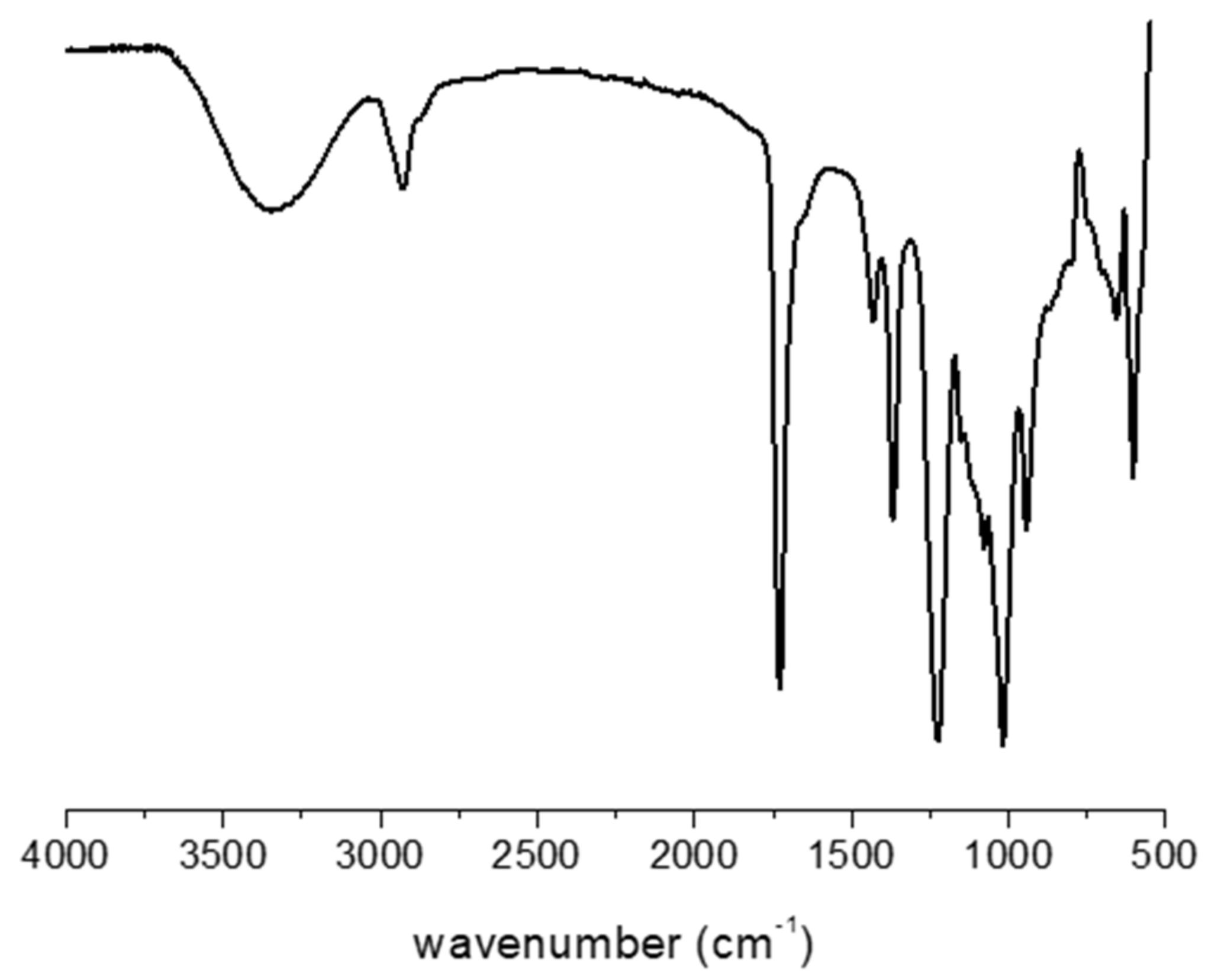

3. Results and Discussion

3.1. Recovery of the CD

3.2. Reproducibility of the Reactions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hines, R.A.; Bryant, W.M.D.; Larchar, A.W.; Pease, D.C. Synthesis of linear polyethylene by a free radical route at very high pressures. Ind. Eng. Chem. 1957, 49, 1071–1074. [Google Scholar] [CrossRef]

- Malpass, D.B. Introduction to Industrial Polyethylene: Properties, Catalysts, Processes, Scrivener Pub; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Helin, A.F.; Stryker, H.K.; Mantell, G.J. Emulsion polymerization of ethylene. I. Polymerization formulas and conditions. J. Appl. Polym. Sci. 1965, 9, 1797–1805. [Google Scholar] [CrossRef]

- Stryker, H.K.; Helin, A.F.; Mantell, G.J. Emulsion polymerization of ethylene. II. Effect of recipe on particle size and distribution. J. Appl. Polym. Sci. 1965, 9, 1807–1822. [Google Scholar] [CrossRef]

- Stryker, H.K.; Helin, A.F.; Mantell, G.J. Emulsion polymerization of ethylene. III. Factors affecting the stability of polyethylene latexes. J. Appl. Polym. Sci. 1966, 10, 81–96. [Google Scholar] [CrossRef]

- Mantell, G.J.; Stryker, H.K.; Helin, A.F.; Jamieson, D.R.; Wright, C.H. Emulsion polymerization of ethylene. IV. Effect of recipe and polymerization conditions on polymer properties. J. Appl. Polym. Sci. 1966, 10, 1845–1862. [Google Scholar] [CrossRef]

- Stryker, H.K.; Mantell, G.J.; Helin, A.F. Emulsion polymerization of ethylene. V. Kinetics and mechanism. J. Appl. Polym. Sci. 1967, 11, 1–22. [Google Scholar] [CrossRef]

- Stryker, H.K.; Mantell, G.J.; Helin, A.F. Kinetics and mechanism of the emulsion polymerization of ethylene. J. Polym. Sci. Part C Polym. Symp. 1969, 27, 35–48. [Google Scholar] [CrossRef]

- Suwa, T.; Nakajima, H.; Takehisa, M.; Machi, S. Preparation of emulsifier-free polyethylene latecies by radiation polymerization. J. Polym. Sci. Polym. Lett. Ed. 1975, 13, 369–375. [Google Scholar] [CrossRef]

- Brocks, R.E.; Peterson, M.D.; Weber, A.G. Process for Polymerizing Olefinic Materials. U.S. Patent US2388225A, 15 March 1941. [Google Scholar]

- Dewey, P.M. Polymerization Process. U.S. Patent US2388178A, 30 October 1945. [Google Scholar]

- Grau, E.; Dugas, P.-Y.; Broyer, J.-P.; Boisson, C.; Spitz, R.; Monteil, V. Aqueous dispersions of nonspherical polyethylene nanoparticles from free-radical polymerization under mild conditions. Angew. Chem. Int. Ed. 2010, 49, 6810–6812. [Google Scholar] [CrossRef] [PubMed]

- Billuart, G.; Bourgeat-Lami, E.; Lansalot, M.; Monteil, V. Free radical emulsion polymerization of ethylene. Macromolecules 2014, 47, 6591–6600. [Google Scholar] [CrossRef]

- Brunel, F.; Billuart, G.; Dugas, P.-Y.; Lansalot, M.; Bourgeat-Lami, E.; Monteil, V. Crystallization of nanodomains in polyethylene latexes. Macromolecules 2017, 50, 9742–9749. [Google Scholar] [CrossRef]

- Morgen, T.O.; Krumova, M.; Luttikhedde, H.; Mecking, S. Free-radical dispersion polymerization of ethylene with laponite to polyethylene−clay nanocomposite particles. Macromolecules 2018, 51, 4118–4128. [Google Scholar] [CrossRef]

- Fawcett, E.W.; Gibson, R.O.; Perrin, M.W. Polymerization of Olefins. U.S. Patent US2153553A, 11 April 1939. [Google Scholar]

- Lyubetskii, S.G.; Dolgoplosk, B.A.; Erusalimskii, B.L. Free radical polymerization of ethylene—III. Polymerization of ethylene under conditions of heterogeneity of the monomer-polymer system. Polym. Sci. USSR 1962, 3, 751–752. [Google Scholar] [CrossRef]

- Wiley, R.H.; Lipscomb, N.T.; Johnston, F.J.; Guillet, J.E. Kinetics of the γ-radiation-induced polymerization of ethylene. J. Polym. Sci. 1962, 57, 867–879. [Google Scholar] [CrossRef]

- Machi, S.; Hagiwara, M.; Gotoda, M.; Kagiya, T. Existence of long-lived radicals in the γ-radiation induced polymerization of ethylene. J. Polym. Sci. Part A Gen. Pap. 1965, 3, 2931–2934. [Google Scholar] [CrossRef]

- Machi, S.; Sakai, T.; Tamura, T.; Gotoda, M.; Kagiya, T. The free radical polymerization of ethylene at low temperature. J. Polym. Sci. Part B Polym. Lett. 1965, 3, 709–713. [Google Scholar] [CrossRef]

- Machi, S.; Hagiwara, M.; Gotoda, M.; Kagiya, T. Initiation and propagation in γ-radiation-induced polymerization of ethylene. J. Polym. Sci. Part A-1 Polym. Chem. 1966, 4, 1517–1529. [Google Scholar] [CrossRef]

- Godoy Lopez, R.; D’Agosto, F.; Boisson, C. Synthesis of well-defined polymer architectures by successive catalytic olefin polymerization and living/controlled polymerization reactions. Prog. Polym. Sci. 2007, 32, 419–454. [Google Scholar] [CrossRef]

- Chen, E.Y.-X. Coordination polymerization of polar vinyl monomers by single-site metal catalysts. Chem. Rev. 2009, 109, 5157–5214. [Google Scholar] [CrossRef] [PubMed]

- German, A.L.; Heikens, D. Copolymerization of ethylene and vinyl acetate at low pressure: Determination of the kinetics by sequential sampling. J. Polym. Sci. Part A-1 Polym. Chem. 1971, 9, 2225–2232. [Google Scholar] [CrossRef]

- Ehrlich, P.; Mortimer, G.A. Fundamentals of the free-radical polymerization of ethylene. Adv. Polym. Sci. 1970, 7, 386–448. [Google Scholar]

- Buback, M.; Dröge, T. High-pressure free-radical copolymerization of ethene and butyl methacrylate . Macromol. Chem. Phys. 1999, 200, 256–264. [Google Scholar]

- Buback, M.; Wittkowski, L.; Lehmann, S.A.; Mähling, F.-O. High-pressure free-radical copolymerization of ethene-methacrylic acid and of ethene-acrylic acid, 1. (Meth)acrylic acid reactivity ratios. Macromol. Chem. Phys. 1999, 200, 1935–1941. [Google Scholar] [CrossRef]

- Buback, M.; Wittkowski, L. High-pressure free-radical copolymerization of ethene with methacrylic acid and ethene with acrylic acid, 2. Ethene reactivity ratios. Macromol. Chem. Phys. 2000, 201, 419–426. [Google Scholar] [CrossRef]

- Bryaskova, R.; Willet, N.; Degée, P.; Dubois, P.; Jérôme, R.; Detrembleur, C. Copolymerization of vinyl acetate with 1-octene and ethylene by cobalt-mediated radical polymerization. J. Polym. Sci. Part A Polym. Chem. 2007, 45, 2532–2542. [Google Scholar] [CrossRef]

- Borkar, A.; Sen, S. Controlled copolymerization of vinyl acetate with 1-alkenes and their fluoro derivatives by degenerative transfer. J. Polym. Sci. Part A Polym. Chem. 2005, 43, 3728–3736. [Google Scholar] [CrossRef]

- Ritter, H.; Tabatabai, M. Cyclodextrin in polymer synthesis: A green way to polymers. Prog. Polym. Sci. 2002, 27, 1713–1720. [Google Scholar] [CrossRef]

- Glöckner, P.; Metz, N.; Ritter, H. Cyclodextrins in polymer synthesis: Free-radical polymerization of methylated β-cyclodextrin complexes of methyl methacrylate and styrene controlled by N-acetyl-L-cysteine as a chain-transfer agent in aqueous medium. Macromolecules 2000, 33, 4288–4290. [Google Scholar] [CrossRef]

- Choi, S.W.; Amajjahe, S.; Ritter, H. Polymerization of included monomers and behaviour of resulting polymers. Adv. Polym. Sci. 2009, 222, 79–113. [Google Scholar]

- Choi, S.W.; Ritter, H. Novel polymerization of myrcene in aqueous media via cyclodextrin-complexes. e-Polymers 2007, 7. [Google Scholar] [CrossRef][Green Version]

- Storsberg, J.; Ritter, H. Cyclodextrins in polymer synthesis: Free radical polymerization of cyclodextrin host-guest complexes of methyl methacrylate or styrene from homogenous aqueous solution. Macromol. Rapid Commun. 2000, 21, 236–241. [Google Scholar] [CrossRef]

- Casper, P.; Glöckner, P.; Ritter, H. Cyclodextrins in polymer synthesis: Free radical copolymerization of methylated-cyclodextrin complexes of hydrophobic monomers with N-isopropylacrylamide in aqueous medium. Macromolecules 2000, 33, 4361–4364. [Google Scholar] [CrossRef]

- Ritter, H.; Steffens, C.; Storsberg, J. Cyclodextrin in polymer chemistry: Kinetic studies on the free-radical polymerization of cyclodextrin-complexed styrene from homogeneous aqueous solution. e-Polymers 2013, 5. [Google Scholar] [CrossRef][Green Version]

- Alupei, I.C.; Alupei, V.; Ritter, H. Cyclodextrins in polymer synthesis: Crosslinking water-soluble unsaturated polyester resins using a cyclodextrin/styrene complex in aqueous medium. Macromol. Rapid Commun. 2003, 24, 527–531. [Google Scholar] [CrossRef]

- Jeromin, J.; Ritter, H. Cyclodextrins in polymer synthesis: Free radical polymerization of a N-methacryloyl-11-aminoundecanoic acid/cyclodextrin pseudorotaxane in an aqueous medium. Macromolecules 1999, 32, 5236–5239. [Google Scholar] [CrossRef]

- Glöckner, P.; Ritter, H. Cyclodextrins in polymer chemistry: Influence of methylated β-cyclodextrin as host on the free radical copolymerization reactivity ratios of isobornyl acrylate and butyl acrylate as guest monomers in aqueous medium. Macromol. Rapid Commun. 1999, 20, 602–605. [Google Scholar] [CrossRef]

- Choi, S.; Ritter, H. Formation of physical polymeric gels during polymerization of cyclodextrin complexed tert-butyl methacrylate in aqueous medium. J. Macromol. Sci.-Pure Appl. Chem. 2005, 42, 321–325. [Google Scholar] [CrossRef]

- Ritter, H.; Schwarz-Barac, S.; Stein, P. Cyclodextrins in polymer synthesis: Two-step reaction to aliphatic poly(methacrylimide) foams by thermal treatment of copolymers obtained from cyclodextrin complexes of tert-butyl methacrylate and various N-alkyl methacrylamides. Macromolecules 2003, 36, 318–322. [Google Scholar] [CrossRef]

- Schwarz-Barac, S.; Ritter, H. Cyclodextrins in polymer synthesis: Free radical polymerization of a tert-butylmethacrylate-cyclodextrin host–guest system in aqueous medium. J. Macromol. Sci.-Pure Appl. Chem. 2003, 40, 437–448. [Google Scholar] [CrossRef]

- Sarvothaman, M.K.; Ritter, H. Discriminating influence of α- and methylated β-cyclodextrins on complexation and polymerization of diacrylate and dimethacrylate monomers. Macromol. Rapid Commun. 2004, 25, 1948–1952. [Google Scholar] [CrossRef]

- Reihmann, M.H.; Ritter, H. Oxidative oligomerization of cyclodextrin-complexed bifunctional phenols catalyzed by horseradish peroxidase in water. Macromol. Chem. Phys. 2000, 201, 798–804. [Google Scholar] [CrossRef]

- Pang, Y.J.; Ritter, H.; Tabatabai, M. Cyclodextrins in polymer chemistry: Enzymatically catalyzed oxidative polymerization of para-functionalized phenol derivatives in aqueous medium by use of horseradish peroxidase. Macromolecules 2003, 36, 7090–7093. [Google Scholar] [CrossRef]

- Choi, S.; Frank, W.; Ritter, H. Novel polymerization of diethyl fumarate and maleate in aqueous media via cyclodextrin-complexes. React. Funct. Polym. 2006, 66, 149–156. [Google Scholar] [CrossRef]

- Choi, S.W.; Ritter, H. Towards green routes for polymer synthesis: Polymerization of cyclodextrin host-guest complexed diethyl fumarate and copolymerization with complexed styrene in homogenous aqueous solution. Macromol. Rapid Commun. 2004, 25, 716–719. [Google Scholar] [CrossRef]

- Groenendaal, L.; Ritter, H.; Storsberg, J. Method for Producing Polymers on the Basis of 1,3. Dienes. Patent WO2001038408A2, 31 May 2001. [Google Scholar]

- Van Aert, H.; Storsberg, J.; Ritter, H.; Van Roost, C. Method of Preparing Polymer Particles Having Narrow Particle Size Distribution. U.S. Patent US6800709B2, 18 May 2001. [Google Scholar]

- Kretschmann, O.; Ritter, H. Copolymerization of fluorinated monomers with hydrophilic monomers in aqueous solution in presence of cyclodextrin. Macromol. Chem. Phys. 2006, 207, 987–992. [Google Scholar] [CrossRef]

- Choi, S.W.; Kretschmann, O.; Ritter, H.; Ragnoli, M.; Galli, G. Novel polymerization of fluorinated 2-vinylcyclopropane in aqueous solution via cyclodextrin complexes. Macromol. Chem. Phys. 2003, 204, 1475–1479. [Google Scholar] [CrossRef]

- Storsberg, J.; Ritter, H. Cyclodextrins in polymer synthesis: A “green” route to fluorinated polymers via cyclodextrin complexes in aqueous solution. Macromol. Chem. Phys. 2002, 203, 812–818. [Google Scholar] [CrossRef]

- Fischer, M.; Ritter, H. Cyclodextrins in polymer synthesis: Free radical polymerization of cyclodextrin complexes with oxazoline-functionalized vinyl monomers as guest molecules in aqueous medium. Macromol. Rapid Commun. 2000, 21, 236–241. [Google Scholar] [CrossRef]

- Storsberg, J.; Ritter, H.; Pielartzik, H.; Groenendaal, L. Cyclodextrins in polymer synthesis: Supramolecular cyclodextrin complexes of pyrrole and 3,4-ethylenedioxythiophene and their oxidative polymerization. Adv. Mater. 2000, 12, 567–569. [Google Scholar] [CrossRef]

- Schönenberg, L.; Ritter, H. Infl uence of β-Cyclodextrin on the Free-Radical Copolymerization of N-(4-Methylphenyl) maleimide with N-vinylpyrrolidone in Water. Macromol. Chem. Phys. 2013, 214, 2540–2545. [Google Scholar] [CrossRef]

- Ritter, H.; Mondrzik, B.; Rehahn, M.; Gallei, M. Free radical homopolymerization of a vinylferrocene/cyclodextrin complex in water. Beilstein. J. Org. Chem. 2010, 6, 60. [Google Scholar] [CrossRef]

- Mejias, L.; Schollmeyer, D.; Sepulveda-Boza, S.; Ritter, H. Cyclodextrins in polymer synthesis: Enzymatic polymerization of a 2,6-dimethyl-β-cyclodextrin/2,4-dihydroxyphenyl-4’-hydroxybenzylketone host-guest complex catalyzed by horseradish peroxidase (HRP). Macromol. Biosci. 2003, 3, 395–399. [Google Scholar] [CrossRef]

- Schwarz-Barac, S.; Ritter, H.; Schollmeyer, D. Cyclodextrins in polymer synthesis: enantiodiscrimination in free-radical polymerization of cyclodextrin-complexed racemic. Macromol. Rapid Commun. 2003, 24, 325–330. [Google Scholar] [CrossRef]

- Theis, A.; Ritter, H. Cyclodextrins in polymer synthesis: Free radical polymerization of β−cyclodextrin complexes of photosensitive mesoionic 6-Oxo-1,6-dihydropyrimidin-3-ium-4-olates in aqueous medium. Macromol. Chem. Phys. 2003, 204, 1297–1304. [Google Scholar] [CrossRef]

- Heinenberg, M.; Ritter, H. Cyclodextrins in polymer synthesis: Steric retardation of the free-radical polymerization in aqueous medium of 4-vinylbenzaldehyde/methylated β-cyclodextrin complex. Macromol. Chem. Phys. 2002, 203, 1804–1810. [Google Scholar] [CrossRef]

- Uyar, M.; Rusa, A.E.; Tonelli, T. Polymerization of styrene in cyclodextrin channels: Can confined free-radical polymerization yield stereoregular polystyrene? Macromol. Rapid Commun. 2004, 25, 1382–1386. [Google Scholar] [CrossRef]

- Wenz, G. Recognition of monomers and polymers by cyclodextrins. Adv. Polym. Sci. 2009, 222, 1–54. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hero, D.; Kali, G. New, Aqueous Radical (Co)Polymerization of Olefins at Low Temperature and Pressure. Processes 2020, 8, 688. https://doi.org/10.3390/pr8060688

Hero D, Kali G. New, Aqueous Radical (Co)Polymerization of Olefins at Low Temperature and Pressure. Processes. 2020; 8(6):688. https://doi.org/10.3390/pr8060688

Chicago/Turabian StyleHero, Devid, and Gergely Kali. 2020. "New, Aqueous Radical (Co)Polymerization of Olefins at Low Temperature and Pressure" Processes 8, no. 6: 688. https://doi.org/10.3390/pr8060688

APA StyleHero, D., & Kali, G. (2020). New, Aqueous Radical (Co)Polymerization of Olefins at Low Temperature and Pressure. Processes, 8(6), 688. https://doi.org/10.3390/pr8060688