Abstract

In recent times two or more desalination processes have been combined to form integrated systems that have been widely used to resolve the limitations of individual processes as well as producing high performance systems. In this regard, a simple integrated system of the Multi Effect Distillation (MED)/Thermal Vapour Compression (TVC) and Permeate Reprocessing Reverse Osmosis (PRRO) process was developed by the same authors and confirmed its validity after a comparison study against other developed configurations. However, this design has a considerable amount of retentate flowrate and low productivity. To resolve this issue, two novel designs of MED and double reverse osmosis (RO) processes including Permeate and Retentate Reprocessing designs (PRRP and RRRO) are developed and modelled in this paper. To systematically assess the consistency of the presented designs, the performance indicators of the novel designs are compared against previous simple designs of MED and PRRO processes at a specified set of operating conditions. Results show the superiority of the integrated MED and double permeate reprocessing design. This has specifically achieved both economic and environmental advantages where total productivity is increased by around 9% and total retentate flowrate (disposed to water bodies) is reduced by 5% with a marginally reduced energy consumption.

1. Introduction

Ideally, the design of desalination technologies such as thermal and membrane processes should be periodically improved to meet the increased demand for drinking water as a consequence of an increase in population. Interestingly, the integrated system of both thermal and membrane technologies was one of the best presented options to resolve the shortcomings of individual processes. Multi Effect Distillation (MED) combined with Thermal Vapour Compression (TVC) is one example of thermal desalination methods. However, this technology is energy intensive and hence expensive and also suffers from a high quantity of disposed brine. On the other hand, fouling and scaling propensities and low productivity are the main issues of the membrane technology such as reverse osmosis (RO) processes. These disadvantages have significantly impacted their performance and have resulted in the decrease in the productivity of drinking water especially for a long-operation term. In this regard, Mahbub et al. [1] confirmed the dominance of MED_TVC system as it generates high-productivity of fresh water from high-salinity water at low-operating temperatures. Moreover, the MED_TVC system has lower fouling and scaling compared to RO processes. However, RO processes have lower energy consumption. More importantly, the RO process has seen a significant improvement including the membrane texture that has improved their production capacity in the seawater desalination market [2,3]. Therefore, the improvement of integrated thermal and membrane systems, which have been proposed in the literature, is vital especially since they would surpass the performance of single processes. Basically, whilst increasing freshwater productivity of high-quality, it is important to attain the minimum freshwater production cost [4].

Several successful examples of integrated systems of thermal and membrane desalination technologies are briefly discussed in the following section.

An integrated system of MED and RO processes was presented by Weiner at al. [5] to desalt brackish water with a simple performance comparison against standalone processes of membrane and thermal technologies. The design of their integrated system is characterised by using a solar power system to provide the required energy and feeding the brine of the RO process to the MED process for further water-quality enhancement whilst producing water with less than 500 ppm of total dissolved salts. Their integrated system also had lower energy consumption and an acceptable freshwater production cost when compared to standalone processes.

The performance of an integrated scheme of the MED_TVC process and a seven-membrane RO process was assessed by Sadri et al. [6]. This system showed an increase of Gain Output Ratio (GOR) when compared to a standalone thermal process.

Filippini et al. [7] assessed the performance of four layouts of integrated systems of MED_TVC and retentate reprocessing RO (RRRO) processes via a sensitivity analysis study. Specifically, a simple integrated, one block RO upstream process, MED upstream and RO upstream are represented. Their study showed the advantage of implementing a RO process upstream in the integrated system as it resulted in the highest water productivity besides attaining the lowermost energy consumption. In addition, the calculated product concentration was within the permissible limits of the World Health Organization (WHO) standards.

Recently, Al-hotmani et al. [8] implemented an improved integrated system of MED_TVC and RO process that looked at several configurations including permeate reprocessing RO (PRRO) design constructed on the considered upstream process. The assessment applied the same operating conditions of seawater used by Filippini et al. [7] i.e., 25 °C and 39,000 ppm of seawater temperature and salinity, respectively. The simple design of combination of PRRO and MED_TVC processes affirmed its consistency as the best layout that gives the lowest freshwater salinity and specific energy consumption after a simple comparison against all the layouts investigated by Filippini et al. [7]. Moreover, the simple design of PRRO and MED_TVC is characterised by a low brine flowrate and salinity that is commensurate with the requirements of a clean environment. However, the low production flowrate is the noted downside of the best layout of Al-hotmani et al. [8] and needs to be further improved.

This research presents new novel designs of MED_TVC and RO units by incorporating double RO processes combined with MED_TVC. Specifically, the integrated system of PRRO+MED_TVC of Al-hotmani et al. [8] is combined with another RO process of two configurations. The second RO process is demonstrated in two layouts of permeate reprocessing and retentate reprocessing RO (PRRO and RRRO) designs. Therefore, two new hybrid systems of PRRO+MED_TVC+PRRO and PRRO+MED_TVC+RRRO are developed. To quantify the feasibility of the proposed schemes of the MED_TVC process and double RO processes, their performances are assessed based on various performance pointers including freshwater production flowrate, rejected flowrate and their salinities, total energy consumption, and total water recovery in a simple comparison against the best layout presented by Al-hotmani et al. [8] (simple PRRO+MED_TVC). Therefore, it is fair to claim that this research can be considered as a complementary section in a series of integrated systems developed by the authors as well as Filippini et al. [7] and Al-hotmani et al. [8].

2. Description of Novel Designs of Integrated Systems of MED_TVC and Double RO Processes of PPRO and RRRO

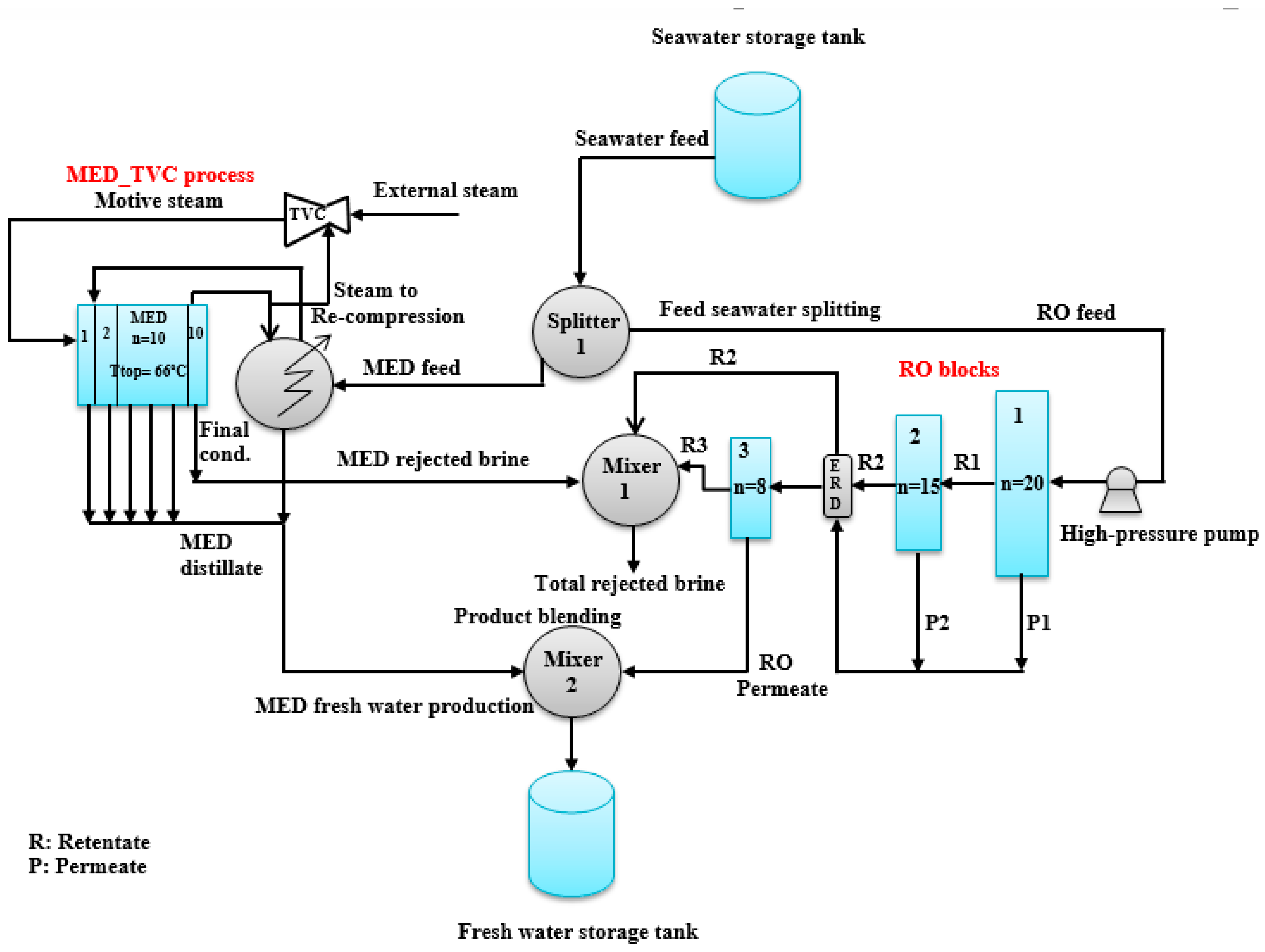

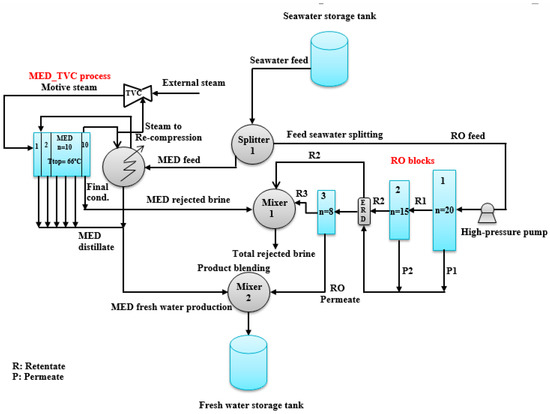

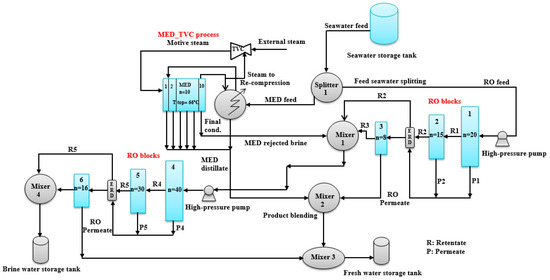

Figure 1 shows a graphic diagram of the simple integrated system of PRRO and MED_TVC processes, developed by Al-hotmani et al. [8] to treat seawater with 39,000 ppm salt concentration at 25 °C. The system is a forward feed MED design with 10 effects combined to a TVC as an external source of steam. Each effect consists of a seawater spray nozzle, an evaporator, a demister, and a feed preheater. The PRRO process is designed as a three-block system that has twenty, fifteen, and eight pressure vessels (PVs) in parallel where each PV holds eight spiral wound membranes connected in series. The feed flowrate of the first block of the PRRO process is set within the reasonable feed flowrate of each membrane. A centrifugal pump is used to supply the seawater at high-pressure into the PRRO system. Moreover, an energy recovery device (ERD) was included to absorb the energy from the retentate stream of the second block and deliver it to the permeate stream of low-pressure corresponding to the first and second blocks. This in turn would guarantee feeding the permeate to the third block at high pressure to be further processed in the final block. Thus, the PRRO process would produce low salinity water with low energy consumption due to the presence of the ERD, which characterises the most interesting part of this design compared to the RRRO process. The PRRO process, however, is expected to have a low percentage of freshwater flowrate per seawater feed flowrate, which is its shortcoming.

Figure 1.

Schematic diagram of a simple integrated system of multi effect distillation and thermal vapour compression and permeate reprocessing reverse osmosis processes.

The simple integrated system of PRRO and MED_TVC units is characterised by simultaneously feeding seawater into MED and RO systems. The condensate distillate of MED process and the permeate stream of RO process are combined to constitute the main product freshwater line. However, the brine streams of the two processes are combined to process the main disposed stream of the integrated system to be sent back to the sea as depicted in Figure 1. The detail operation of both MED_TVC and RO processes can be found in Al-hotmani et al. [8]. Table 1 shows the specifications of feed seawater and MED_TVC process whilst Table 2 shows the specifications of the RO process including membrane manufacturer data.

Table 1.

Specifications of feed seawater and the multi effect distillation/thermal vapour compression (MED_TVC) process (adapted from [8]).

Table 2.

Specifications of reverse osmosis (RO) process and membrane manufacturer data (adapted from [8]).

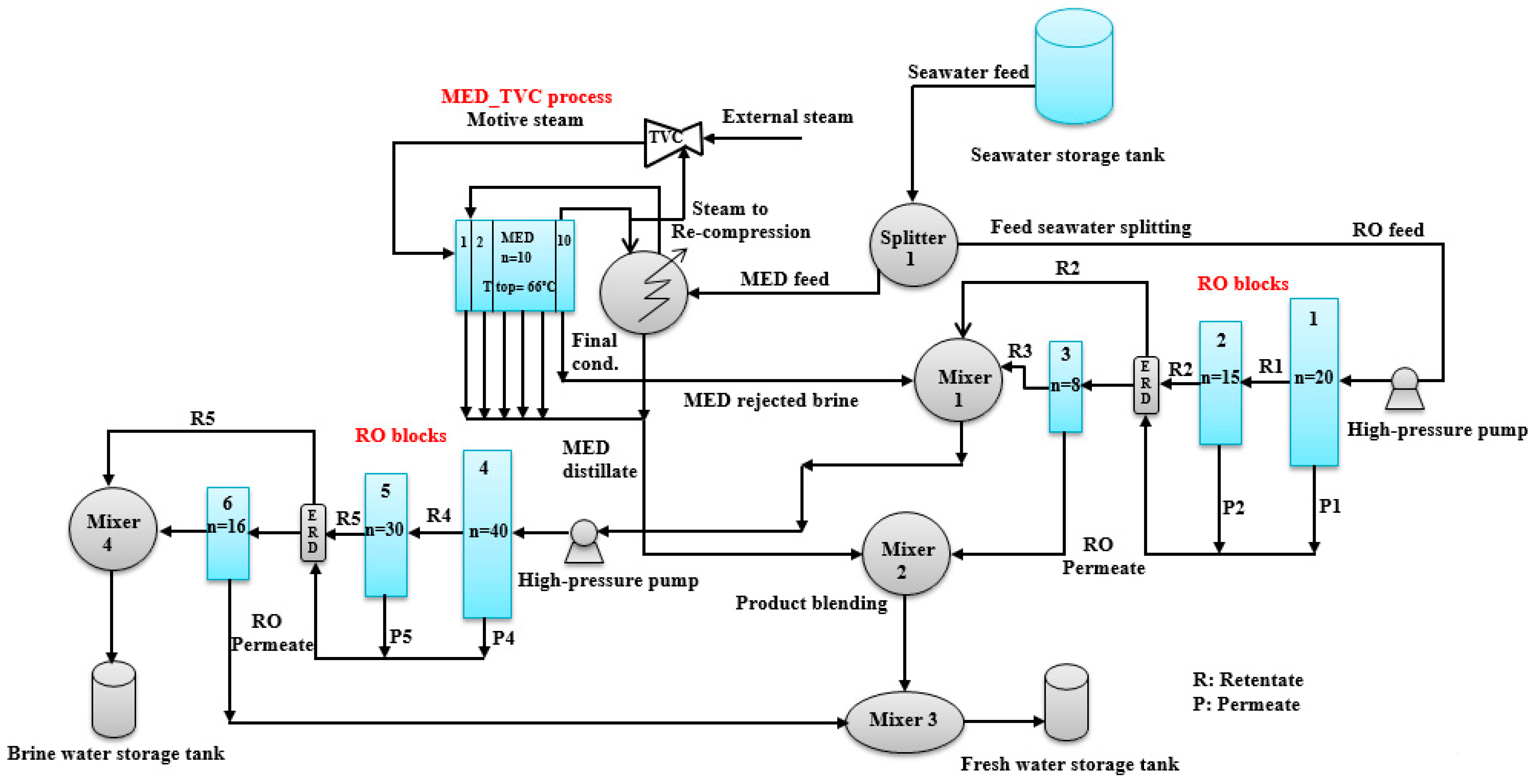

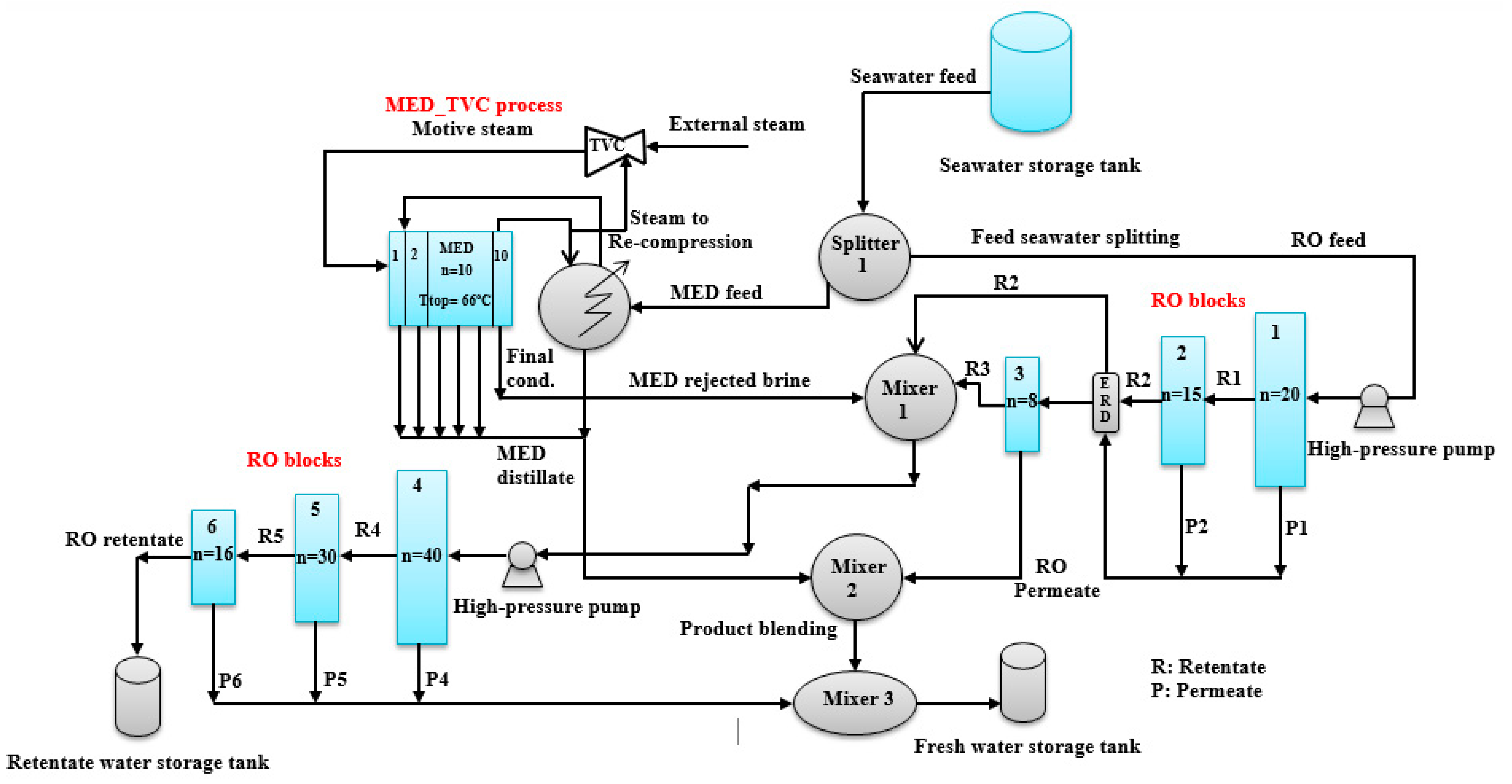

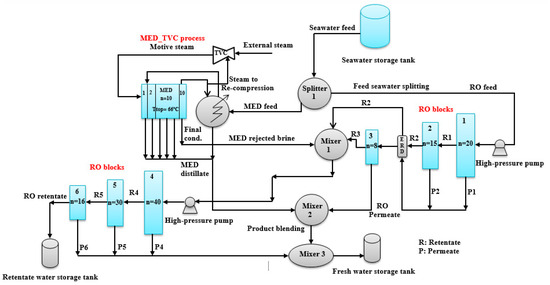

This study proposes two new integrated systems comprising of MED_TVC and RO process where each system is characterised by double RO processes connected to MED_TVC. The integrated systems are shown schematically in Figure 2 and Figure 3. Figure 2 shows two RO processes of permeate reprocessing design and MED_TVC, whilst Figure 3 shows two RO processes of permeate reprocessing and retentate reprocessing designs and MED_TVC. More importantly, the retentate of the first two linked processes of the simple integrated design MED_TVC and permeate reprocessing RO process is fed to the second RO process for further filtration as shown in Figure 2 and Figure 3 and therefore the retentate of the last RO stage represents the total retentate of the integrated system. However, the permeates of the first and second stages are combined with the one produced from the last RO stage to form the main product water stream of the integrated system. Therefore, this research will focus on investigating the feasibility of the novel method to upgrade the combination of thermal and membrane processes presented by Al-hotmani et al. [8]. The novel design of the integrated system presented in this study would definitely reduce the quantity of disposed brine into seawater despite the possibility of carrying out a higher performance (will be explored later) when compared to the original integrated system presented by Al-hotmani et al. [8] (Figure 1). Therefore, it is fair to expect that this design would be preferable and a more environmentally friendly method.

Figure 2.

Schematic diagram of an integrated system of multi effect distillation and thermal vapour compression and double permeate reprocessing reverse osmosis processes.

Figure 3.

Schematic diagram of an integrated system of multi effect distillation and thermal vapour compression and double permeate reprocessing and retentate reprocessing reverse osmosis processes.

3. Mathematical Model of Integrated MED_TVC and Double RO System

Mathematical modelling of any industrial process is an essential task to discreetly forecast and extrapolate the performance indicators in a wide or specified set of operating conditions. The modelling of MED_TVC desalination process is crucial in the design of an efficient process and to accomplish an optimisation of the plant performance. The integrated model developed by Al-hotmani et al. [8] to predict the performance of the integrated system of MED_TVC and permeate reprocessing RO process has been used as a base to develop a new model for the double RO processes and MED_TVC system. Therefore, two models of PRRO and RRRO processes are combined with the one developed by Al-hotmani et al. [8] (MED_TVC and PRRO) to form the models of two novel hybrid systems of PRRO+MED_TVC+PRRO processes and PRRO+MED_TVC+RRRO processes. For the convenience of the reader, the models’ equations of a single MED, single RO, RRRO and PRRO of three blocks RO process, integrated MED_TVC and RO processes, and TVC part are given in Table A1, Table A2, Table A3, Table A4 and Table A5, respectively, in Appendix A.

4. Performance Assessment of Integrated MED_TVC and Double RO System

This section evaluates the projected two integrated systems of PPRO+MED_TVC+PPRO and PPRO+MED_TVC+RRRO based on a performance comparison against the Al-hotmani et al. [8] integrated system of PRRO+MED_TVC. The integrated system of PRRO+MED_TVC has been modelled by Al-hotmani et al. [8] and confirmed as the best layout after a simple comparison against several adopted configurations of MED_TVC and RO processes of different upstream processes. Here, the simulation of the integrated systems will be carried out using the models given in Table A1, Table A2, Table A3, Table A4 and Table A5 presented in Appendix A considering the characteristics of the feed seawater, MED_TVC process and RO process given in Table 1 and Table 2. The performance keys of the integrated system under focus include the productivity, freshwater salinity, rejected flowrate and its salinity, total water recovery measured by the division of total production of freshwater and feed flowrate fed to both MED and RO processes and finally the total specific energy consumption based on one cubic meter of produced freshwater. The aim is to determine the best layout of the integrated systems shown in Figure 1, Figure 2 and Figure 3. The final simulation results for the novel integrated systems of MED_TVC and double RO processes are depicted in Table 3 with the calculation of the benefit percentage based on the base case of the Al-hotmani et al. [8] integrated system.

Table 3.

Performance indicators of novel hybrid systems of MED_TVC and double RO processes compared to the base case design of [8].

Table 3 confirms the advantage of employing the novel integrated system of MED_TVC and double RO processes as it produces a noticeable increased productivity (freshwater flowrate) compared to the base case of MED_TVC and single RO process of Al-hotmani et al. [8]. Statistically, PRRO+MED_TVC+PRRO and PRRO+MED_TVC+RRRO systems increase the productivity by 8.96% and 9.65%, respectively, based on the original integrated system of PRRO_MED_TVC. Therefore, one of the main advantages of the novel layout of MED_TVC and double RO processes is the enhanced productivity that fits the requirements of any industrial desalination technology.

The new novel integrated systems show increased freshwater salinity compared to the base case of MED_TVC and single PRRO process. The freshwater salinity increases from 10.882 ppm to 38.474 ppm for PRRO+MED_TVC+PRRO system and 278.667 ppm for PRRO+MED_TVC+RRRO system. More importantly, the two novel integrated systems still maintain low and acceptable freshwater salinity concentrations which are within the permissible limit of WHO. WHO stipulate that the salinity of drinking water must be lower than 300 ppm and lower than 200 ppm for tap water [9]. However, the integrated system PRRO+MED_TVC+RRRO shows a considerable increase of freshwater salinity which may be a disadvantage.

Basically, it is conceivable that thermal desalination systems such as MED_TVC dispose a large amount of brine into water bodies. For instance, the integrated system of Al-hotmani et al. [8] rejected 158.87 kg/s of high-concentration brine (13,726 m3/day) into the sea, which signifies the main issue of the integrated system because it negatively impacts the ecosystem. This has been pointed out by several researchers such as Dawoud [10] who confirmed the discharging of high salinity brine from a MED_TVC system. Therefore, it is essential to modify the design of MED_TVC system and its integrated layouts and reduce the amount of brine rejected to levels below those stipulated by the United Nations [11]. Interestingly, the novel integrated systems of PRRO+MED_TVC+PRRO and PRRO+MED_TVC+RRRO showed a reduction in total rejected flowrate by 5.07% and 5.46%, respectively, based on the original integrated system of MED_TVC+PRRO. The improvement made on the rejected flowrate can be considered to be a successful approach that would arguably reduce the quantity of discharged brine into the sea if it was to be applied to the entire thermal desalination plants of integrated MED_TVC and RO processes. Moreover, a reduction in the freshwater production cost of the thermal desalination plant, due to the reduction of total volume of disposed brine, would be expected. It is important to mention that reducing the quantity of disposed brine is one of the suggested options of Jones et al. [11]. The cost of discharging brine into the sea ranges between 5% and 33% of total freshwater production cost [12,13]. Table 3 shows that the improvement of the discharged volume of brine comes with negligible increase in its salinity after applying the novel integrated systems of MED_TVC and double RO processes compared to MED_TVC and single RO process. Statistically, an increase of around 5.5% was obtained for the new integrated designs compared to the original base case.

The total water recovery is another important metric that needs to be analysed in order to measure the consistency of any integrated system of thermal and membrane technologies. Basically, the ratio of total freshwater flowrate and seawater feed flowrate is a measure of the total water recovery. Table 3 shows improvements of total water recovery of 9.15% and 9.8% for the integrated systems of PRRO+MED_TVC+PRRO and PRRO+MED_TVC+RRRO, respectively, based on the original integrated system of MED_TVC and PRRO processes. This is a good indicator which confirms the reliability of the new integrated systems.

The final metric used to evaluate the performance of the developed integrated systems is the total specific energy consumption. Table 3 shows that the novel integrated systems of PRRO+MED_TVC+PRRO and PRRO+MED_YVC+RRRO consume 14.25 kWh/m3 and 15.704 kWh/m3 of energy, respectively, compared to 14.295 kWh/m3 of the original integrated system of Al-hotmani et al. [8]. This is specifically highlighted as a negligible energy saving of 0.29% for the novel design of PRRO+MED_TVC+PRRO with an increase of specific energy consumption of 9.85% for PRRO+MED_TVC+RRRO when compared with the original design of Al-hotmani et al. [8]. In other words, the new proposed system of PRRO+MED_TVC+PRRO has achieved the lowest specific energy consumption due to the existence of two ERDs fixed in the first and second PRRO processes that are used to absorb the surplus energy of the high-concentration-pressure streams and transport it to the low-pressure low salinity stream. Therefore, by using a PRRO+MED_TVC+PRRO system, it is possible to decrease the total freshwater production cost especially when the system is in operation for a long time; this is another merit of this design. Moreover, the calculation of total specific energy consumption of PRRO+MED_TVC+RRRO confirmed the demerits of this design besides the highest brine salinity compared to PRRO+MED_TVC+PRRO system. Up to this point, the simulation results of Table 3 confirm the superiority and the preference of PRRO+MED_TVC+PRRO integrated system as it achieves the highest performance metrics compared to other studied layouts. The deployment of the novel design presented in this study would arguably improve both technical and economical features of the integrated system of thermal and membrane technologies. More importantly, this would probably reduce the water production cost whilst increasing the energy saving with lower CO2 emissions which has obvious benefits for the environment. Therefore, it would be advantageous to carry out a specific simulation study to calculate the freshwater production cost for the proposed novel integrated designs. However, it must be noted that the suggested integrated design of MED_TVC and double RO processes has not yet been practically tested in the desalination industry and remains therefore theoretical at this stage.

5. Conclusions

This study presents the development of a novel design of a MED_TVC thermal desalination system and RO desalination processes. Specifically, two RO processes were connected to a MED_TVC system considering permeate and retentate reprocessing designs of RO processes. The viability of the integrated systems was assessed via a comparison study of their performance against the latest successful design of MED_TVC and single permeate reprocessing RO process (base case) that is confirmed as a superior integrated system to those presented in the literature. Several performance indicators were analysed for the integrated systems including the productivity, freshwater salinity, brine flowrate and its salinity, total water recovery and total specific energy consumption. Interestingly, the simulation results confirmed the high-performance of MED_TVC and double permeate reprocessing RO process that obtained the highest productivity and total water recovery, lowest specific energy consumption with a competitive reduction of brine flowrate. Statistically, the productivity was improved by around 9%, commensurate with a reduced brine flowrate of around 5% compared to the base case. Therefore, it is necessary to suppose that the application of the novel layout of PRRO+MED_TVC+PRRO would enable the seawater desalination technology to operate at an optimum level considering both economic and environmental aspects besides producing high-quality drinking water.

Author Contributions

Conceptualization, O.M.A.A.-h. and M.A.A.A.-O.; methodology, Y.M.J. and R.P.; formal analysis, O.M.A.A.-h.; resources, M.A.A.A.-O.; writing—original draft preparation, O.M.A.A.-h. and M.A.A.A.-O.; writing—review and editing, I.M.M., R.P. and Y.M.J.; visualization, R.P.; supervision, I.M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Membrane area (m2) | |

| Water transport parameter at feed temperature of RO process (m/s atm) | |

| Exchange area of i-th evaporator of MED process (m2) | |

| Exchange area of i-th pre-heater of MED process (m2) | |

| Exchange area of final condenser of MED process (m2) | |

| Mean exchange area of evaporators of MED process (m2) | |

| Mean exchange area of pre-heaters of MED process (m2) | |

| Bi | Rejected brine of the i-th effect (kg/s) |

| Solute transport parameter at feed temperature of RO process (m/s) | |

| Bulk concentration of a single membrane of RO process (kg/m3) | |

| Feed concentration of a single membrane of RO process (kg/m3) | |

| Plant feed concentration (kg/m3) | |

| Permeate concentration at the permeate channel of a single membrane of RO process (kg/m3) | |

| Brine concentration of a single membrane of RO process (kg/m3) | |

| Wall membrane concentration of a single membrane of RO process (kg/m3) | |

| CR | Compression ratio in the steam ejector of MED process (-) |

| Total distillate produced in i-th effect of MED process (kg/s) | |

| Diffusivity parameter (m2/s) | |

| Hydraulic diameter of the feed spacer channel of a membrane of RO process (m) | |

| Distillate produced by boiling in i-th evaporator of MED process (kg/s) | |

| Distillate produced by flashing in i-th flashing box of MED process (kg/s) | |

| Specific energy consumption of MED process (kJ/kg) | |

| Specific energy consumption of RO process (kWh/m3) | |

| Energy recovery device (-) | |

| Water flux through a single membrane of RO process (m/s) | |

| Mass transfer coefficient (m/s) | |

| Constant (-) | |

| Length of membrane of RO process (m) | |

| Length of filament in the spacer mesh of RO process (m) | |

| Coefficient | |

| Mb | Rejected brine flowrate of MED process (kg/s) |

| MCOND | Flowrate of steam in the final condenser of MED process (kg/s) |

| Md | Distillate from MED process (kg/s) |

| Mf | Water intake in the first effect of MED process (kg/s) |

| Mm | Motive steam flowrate of MED process (kg/s) |

| Ms | Total steam flow rate of MED process (kg/s) |

| Mw | Intake water flow rate of MED process (kg/s) |

| MTVC | Vapour flowrate entrained in TVC section of MED process (kg/s) |

| n | Number of effects of MED process (-) |

| Pcrit | Critical pressure of water (kPa) |

| Pev | Pressure of saturated entrained vapour of MED process (kPa) |

| Feed pressure of a single membrane of RO process (atm) | |

| Plant feed pressure of RO process (atm) | |

| PFC | Pressure Correction Factor of RO process (-) |

| Pm | Pressure of saturated steam at temperature Tm of MED process (kPa) |

| Permeate pressure at the permeate channel of RO process (atm) | |

| Retenate pressure of a single membrane of RO process (atm) | |

| Plant retenate pressure of RO process (atm) | |

| Retentate pressure of any block of RO process (atm) | |

| Ps | Pressure of saturated steam at temperature Ts of MED process (kPa) |

| Pv | Pressure of saturated steam at temperature Tv of MED process (kPa) |

| Bulk flow rate of a single membrane of RO process (m3/s) | |

| Feed flow rate of a single membrane of RO process (m3/s) | |

| Plant feed flow rate of RO process (m3/s) | |

| Feed flow rate of any block of RO process (m3/s) | |

| Total permeate flow rate of a single membrane of RO process (m3/s) | |

| Plant permeate flow rate of RO process (m3/s) | |

| Permeate flow rate of single pressure vessel of RO process (m3/s) | |

| Retentate flow rate of a single membrane of RO process (m3/s) | |

| Plant retentate flow rate of RO process (m3/s) | |

| Solute flux through the membrane of RO process (kg/m2 s) | |

| QCOND | Thermal load in final condenser of MED process (kW) |

| Qsensible | Sensible heat used in first effect of MED process (kJ/kg) |

| Qlatent | Latent heat used in first effect of MED process (kJ/kg) |

| Qi | Thermal load at i-th evaporator of MED process (kW) |

| Qs | Thermal load of steam of MED process (kW) |

| Ra | Entrainment ratio of MED process (-) |

| Reynolds number (-) | |

| Recovery rate of a single membrane of RO process (-) | |

| Total plant water recovery rate of RO process (-) | |

| Solute rejection of a single membrane of RO process (-) | |

| Total plant solute rejection of RO process (-) | |

| Schmidt number (-) | |

| Feed temperature after i-th pre-heater of MED process (°C) | |

| Height of feed channel of the membrane of RO process (m) | |

| tn | Feed temperature after final condenser of MED process (°C) |

| T1 | Top brine temperature (Ttop) of MED process (°C) |

| Tb | Temperature of rejected brine of MED process (°C) |

| Height of feed channel of the membrane of RO process (m) | |

| Plant operating temperature of RO process (°C) | |

| Retentate plant temperature of RO process (°C) | |

| Ts | Steam temperature of MED process (°C) |

| Tvi | Temperature of the vapour phase in i-th effect of MED process (°C) |

| Tw | Temperature of the cooling water of MED process (°C) |

| Tmean | Mean temperature in the plant (°C) |

| Tcrit | Critical temperature of water (°C) |

| TCF | Temperature Correction Factor of RO process (-) |

| Uev,i | Global heat exchange coefficient in i-th evaporator of MED process (kW/m2 °C) |

| Uph,i | Global heat exchange coefficient in i-th pre-heater of MED process (kW/m2 °C) |

| Ucond | Global heat exchange coefficient in final condenser of MED process (kW/m2 °C) |

| Cross flow velocity of a single membrane of RO process (m/s) | |

| Membrane width of RO process (m) | |

| xi | Salinity in i-th evaporator of MED process (ppm or w/w%) |

| xb | Salinity in rejected brine of MED process (ppm or w/w%) |

| xf | Salinity in the feed of MED process (ppm or w/w%) |

| xmean | Mean salinity in the plant (ppm or w/w%)1 |

Greek

| α | Fraction of rejected brine from previous effect flashed in the associated pre-heater of MED process (-) |

| β | Fraction of total distillate boiled in each evaporator of MED process (-) |

| Percentage error on evaporators’ areas of MED process (%) | |

| Percentage error on pre-heaters areas of MED process (%) | |

| Driving force for heat exchange in i-th evaporator of MED process (°C) | |

| Driving force for heat exchange in i-th pre-heater of MED process (°C) | |

| Driving force for heat exchange in final condenser of MED process (°C) | |

| Temperature drop between two evaporators of MED process (°C) | |

| Temperature increase between two pre-heaters of MED process (°C) | |

| Total pressure drop along the membrane element of RO process (atm) | |

| Latent heat of evaporation of MED process (kJ/kg) | |

| Total osmotic pressure at the permeate channel of RO process (atm) | |

| Total osmotic pressure at the membrane surface of RO process (atm) | |

| Density parameter (kg/m3) | |

| Kinematic viscosity (kg/m s) | |

| Membrane porosity (-) | |

| Pump efficiency (-) | |

| Efficiency of energy recovery device of RO process (-) |

Appendix A

Table A1.

Mathematical model of multi effect distillation system [7].

Table A1.

Mathematical model of multi effect distillation system [7].

| Description | Equation | Unit |

|---|---|---|

| Feed flowrate | kg/s | |

| Sensible heat in the 1st stage | kJ/s | |

| Latent heat existed in the 1st stage | kJ/s | |

| Temperature droplet along each stage | °C | |

| Temperature droplet along preheaters | °C | |

| Inlet temperature of the 1st effect | °C | |

| Temperature of vapour phase | °C | |

| Flowrate of flashed freshwater | kg/s | |

| Portion of freshwater by flashing | - | |

| Mean temperature | °C | |

| Mean salinity | ppm | |

| Portion of freshwater by evaporation | - | |

| Flowrate of evaporated freshwater | kg/s | |

| Total distilled water | kg/s | |

| Disposed brine flowrate | kg/s | |

| Salinity of each stage | ppm | |

| Estimated area of each stage | m2 | |

| Heat load in each stage | kJ/s | |

| Temperature droplet in heat exchangers | °C | |

| Area of each preheater | m2 | |

| Logarithmic temperature variance in preheater | °C | |

| Area of the final condenser | m2 | |

| Conductivity heat in the final condenser | ) | kJ/s |

| Logarithmic temperature variance in final condenser | °C |

Table A2.

Mathematical model of a single reverse osmosis process [7].

Table A2.

Mathematical model of a single reverse osmosis process [7].

| Description | Equation | Unit | |

|---|---|---|---|

| Freshwater Flux | m3/s | ||

| Solute flux | m3/s | ||

| Osmotic pressure in high-concentration and permeate sides | , | atm | |

| Effect of temperature on water transport coefficient | , | - | |

| Effect of temperature on solute transport coefficient | , | - | |

| Pressure droplet for each membrane and Reynolds number | . | atm, - | |

| lk flowrate and concentration | , | m3/s, ppm | |

| Membrane wall concentration | ppm | ||

| Schmidt number and Mass transfer coefficient, | , | -, m/s | |

| Physical properties | Density | , | kg/m3 |

| Diffusivity | m2/s | ||

| Viscosity | Pa s | ||

| Overall mass and material balances | - | ||

| Permeate concentration | ppm | ||

| Rejection and water recovery rate | , | - | |

Table A3.

Mathematical model of retentate reprocessing reverse osmosis and permeate reprocessing reverse osmosis designs of three blocks [8].

Table A3.

Mathematical model of retentate reprocessing reverse osmosis and permeate reprocessing reverse osmosis designs of three blocks [8].

| Description | Equation | Unit |

|---|---|---|

| Material balance of the RO plant | m3/s | |

| Mass balance of the RO plant | ppm | |

| Plant retentate flowrate of PRRO | m3/s | |

| Plant retentate flowrate of RRRO | m3/s | |

| Plant retentate concentration of PRRO | ppm | |

| Plant retentate concentration of RRRO | ppm | |

| Plant permeate concentration and permeate flowrate of PRRO | , | ppm, m3/s |

| Plant permeate concentration and permeate flowrate of RRRO | + | ppm, m3/s |

| Plant retentate pressure and retentate temperature of PRRO and RRRO | atm,°C | |

| Permeate flowrate, concentration, total rejection, and recovery rate of any block of PRRO and RRRO | , , , | m3/s, ppm, -, - |

| Feed flowrate, concentration, and pressure of block 3 of PRRO | , , | m3/s, ppm, atm |

| Plant recovery rate and solute rejection | , | -, - |

| Specific energy consumption of PRRO | kWh/m3 | |

| Specific energy consumption of RRRO | kWh/m3 |

Table A4.

Mathematical model of integrated multi effect distillation-thermal vapour compression and reverse osmosis system [7].

Table A4.

Mathematical model of integrated multi effect distillation-thermal vapour compression and reverse osmosis system [7].

| Description | Equation | Unit |

|---|---|---|

| Inlet feed water to MED system | kg/s | |

| Material balance for MED system | ppm | |

| Total freshwater production | kg/s | |

| Salinity of freshwater | ppm | |

| Total disposed brine | kg/s | |

| Salinity of disposed brine | ppm |

Table A5.

Mathematical model of thermal vapour compression part [14].

Table A5.

Mathematical model of thermal vapour compression part [14].

| Description | Equation | Unit |

|---|---|---|

| Temperature and pressure correction parameters | , | -, - |

| Pressure at vapour temperature | bar | |

| Pressure at steam temperature | bar | |

| Compression and entrainment ratios | , | -, - |

| Motive steam flowrate | kg/s |

Relationships for MED process: [14]

Boiling point elevation:

The applied range: 1% < w < 16%, 10°C < T < 180 °C

Specific heat at fixed pressure:

The applied range: 20,000 ppm < x < 160,000 ppm, 20 °C < T < 180 °C

Latent heat of evaporation:

Global heat exchange parameters:

References

- Mahbub, F.; Hawlader, M.N.A.; Mujumdar, A.S. Combined water and power plant (CWPP)—A novel desalination technology. Desalin. Water Treat. 2009, 5, 172–177. [Google Scholar] [CrossRef]

- Mujtaba, I.; Srinivasan, R.; Elbashir, N. (Eds.) The Water-Food-Energy Nexus; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Alsarayreh, A.A.; Al-Obaidi, M.; Al-Hroub, A.; Patel, R.; Mujtaba, I. Performance evaluation of reverse osmosis brackish water desalination plant with different recycled ratios of retentate. Comput. Chem. Eng. 2020, 135, 106729. [Google Scholar] [CrossRef]

- Al-Obaidi, M.; Filippini, G.; Manenti, F.; Mujtaba, I. Cost evaluation and optimisation of hybrid multi effect distillation and reverse osmosis system for seawater desalination. Desalination 2019, 456, 136–149. [Google Scholar] [CrossRef]

- Weiner, A.M.; Blum, D.H.; Lienhard, V.J.H.; Ghoniem, A.F. Design of a hybrid RO-MED solar desdalination system for training agricultural draining water in california. The International Desalination Association World Congress on Desalination and Water Reuse, San Diego, CA, USA. Desalination 2015, 182, 187–198. [Google Scholar]

- Sadri, S.; Ameri, M.; Khoshkhoo, R.H. Multi-objective optimization of MED-TVC-RO hybrid desalination system based on the irreversibility concept. Desalination 2017, 402, 97–108. [Google Scholar] [CrossRef]

- Filippini, G.; Al-Obaidi, M.; Manenti, F.; Mujtaba, I. Performance analysis of hybrid system of multi effect distillation and reverse osmosis for seawater desalination via modelling and simulation. Desalination 2018, 448, 21–35. [Google Scholar] [CrossRef]

- Al-Hotmani, O.; Al-Obaidi, M.; Patel, R.; Mujtaba, I. Performance analysis of a hybrid system of multi effect distillation and permeate reprocessing reverse osmosis processes for seawater desalination. Desalination 2019, 470, 114066. [Google Scholar] [CrossRef]

- Edition, F. Guidelines for drinking-water quality. WHO Chron 2011, 38, 104–108. [Google Scholar]

- Dawoud, M.A. Environmental Impacts of Seawater Desalination: Arabian Gulf Case Study. Int. J. Environ. Sustain. 2012, 1. [Google Scholar] [CrossRef]

- Jones, E.; Qadir, M.; Van Vliet, M.T.H.; Smakhtin, V.; Kang, S.-M. The state of desalination and brine production: A global outlook. Sci. Total. Environ. 2019, 657, 1343–1356. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.; Shayya, W.H.; Hoey, D.; Mahendran, A.; Morris, R.; Al-Handaly, J. Use of evaporation ponds for brine disposal in desalination plants. Desalination 2000, 130, 155–168. [Google Scholar] [CrossRef]

- Ahmed, M.; Shayya, W.H.; Hoey, D.; Al-Handaly, J. Brine disposal from reverse osmosis desalination plants in Oman and the United Arab Emirates. Desalination 2001, 133, 135–147. [Google Scholar] [CrossRef]

- El-Dessouky, H.T.; Ettouney, H.M. Fundamentals of Salt Water Desalination; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).