Abstract

This paper explores a possible waste-based economy transition strategy. Digestate from the organic fraction of municipal solid waste (OFMSW) is considered, as well as a low-added value product to be properly valorized. In this regard, air gasification may be used to produce syngas. In this work, the production of methanol, hydrogen, or electricity from digestate-derived syngas was assessed by ChemCAD process simulation software. The process scheme of methanol production comprises the following parts: water gas shift (WGS) with carbon capture and storage units (CCS), methanol synthesis, and methanol purification. In the case of hydrogen production, after WGS-CCS, hydrogen was purified from residual nitrogen by pressure swing absorption (PSA). Finally, for electricity production, the digestate-derived syngas was used as fuel in an internal combustion engine. The main objective of this work is to compare the proposed scenarios in terms of CO2 emission intensity and the effect of CO2 storage. In particular, CCS units were used for methanol or hydrogen production with the aim of obtaining high equilibrium yield toward these products. On the basis of 100 kt/year of digestate, results show that the global CO2 savings were 80, 71, and 69 ktCO2eq/year for electricity, methanol, and hydrogen production, respectively. If carbon storage was considered, savings of about 105 and 99 ktCO2eq/year were achieved with methanol and hydrogen production, respectively. The proposed scenarios may provide an attractive option for transitioning into methanol or hydrogen economy of the future.

1. Introduction

Municipal solid waste (MSW) is a heterogeneous waste consisting of everyday items that are discarded by the citizens in a municipal context. It is composed of organic waste (e.g., food waste), waste paper, plastic waste, tin cans, aluminum cans, textile, glass, etc. Furthermore, the relative composition of municipal solid waste varies greatly from municipality to municipality, and it changes significantly with the season and along the years [1,2]. The global solid waste generation by urban residents is expected to increase from 3.5 Mtons/day in 2010 to 6.1 Mtons/day in 2025, with a total management cost of $375 billion in 2025 [3]. Therefore, the management of MSW is a very challenging issue to be addressed.

Municipal solid waste may be considered as a valuable source of carbon usable for both energy and chemical production. Incineration/thermo-valorization of MSW is the major solution adopted for unsorted MSW. On the contrary, an efficient MSW collection and sorting of MSW is the first step to recovering or recycling high-added value products pushing toward a circular economy system. In fact, the conversion of waste to energy or chemicals and fuels is considered strategic to address two issues simultaneously: a reduction in the amount of non-recyclable/non-reusable waste and the production of bio-energy and bio-products in order to satisfy, in a sustainable way, the increase in demand [4]. In this regard, anaerobic digestion (AD) is a process which not only reduces the amount of organic waste, i.e., organic fraction of MSW (OFMSW), sewage sludge, livestock manure, and so on, but also produces energy in the form of biogas [5]. Biogas, the primary end-product of the anaerobic digestion process is a mixture of methane and carbon dioxide (CH4/CO2 molar ratio ranges from 1.1 to about 2.5) with minor quantities of nitrogen, hydrogen sulfide, and volatile organic compounds. Biogas is usually used as fuel in combined heat and power (CHP) plants [6,7]. Emerging technologies provide a biogas upgrading system to obtain high-purity bio-methane that may be used as fuel for household cooking, lighting, heating, and the automotive sector. Moreover, up-graded bio-methane may be used obviously as an alternative to natural gas for the production of syngas. Syngas, a mixture of H2, CO, and CO2 is industrially used for the production of hydrogen and methanol, the main building blocks of industrial chemistry. Syngas may also be used for the synthesis of synthetic gasoline-cut hydrocarbons via the Fischer–Tropsch process [8].

Hydrogen is usually used in ammonia synthesis, in CO2-to-chemical hydrogenation, conventional refinery hydro-processing (e.g., hydro-cracking), and in bio-refinery for the production of alternative fuels, e.g., diesel and jet fuel, from vegetable oils [9,10,11,12,13,14,15,16,17,18]. Hydrogen may also be used as clean fuel for electricity generation in fuel cells [19].

Methanol, with an annual production of about 40 millions of metric tons, is one of the most important chemicals, as it is used for the synthesis of several high-added value products, such as acetic acid, methyl tert-butyl ether, synthetic gasoline (MTG process), synthetic olefins (MTO process), and dimethyl ether [20,21,22,23,24,25,26].

For these reasons, anaerobic digestion can play an important role in achieving the targets of the Paris Agreement on greenhouse gas (GHG) emission, as well as a positive contribution to increasing the share of renewable energy and to improving the energy efficiency, in agreement with international climate-related targets.

In addition to biogas, digestate containing a high amount of non-biodegradable components is also produced from an anaerobic digestion process. In the last decade, the number of anaerobic digestion plants grew significantly, causing a significant growth of digestate production. Currently, digestate is mainly used as nitrogen-rich organic fertilizer, avoiding the use of mineral fertilizers for agricultural soil. On the other hand, the large amount of digestate produced from anaerobic digestion plants is becoming a problem in terms of land occupancy, nitrogen over-loading, long-distance transportation, presence of microorganisms, and GHG emission. Particularly in regions with intensive livestock farming and with high production of OFMSW, digestate may be considered a by-product of the anaerobic digestion process [27,28,29,30].

The energy conversion efficiency of a typical anaerobic digestion process is estimated at about 30%–50%, meaning that more than half of the energy remains in the digestate [31]. Therefore, alternative strategies should be explored in order to recover energy or matter from anaerobic digestate [32]. In this regard, thermochemical processes, such as combustion, pyrolysis, and gasification, can be used for digestate valorization.

Pedrazzi et al. studied the combustion of dehydrated digestate, and they found that it is not a suitable technology due to the high ash content of digestate that causes ash sintering and agglomeration inside the combustor [33].

Pyrolysis may be used to transform digestate into value added products, such as syngas, bio-oil, and biochars. Digestate shows a fast degradation during pyrolysis due to relatively high volatile matter content. Only about 5% of digestate was converted to gas, while about 50% and 40% was converted to liquid and char, respectively [34]. The liquid fraction obtained from pyrolysis of the digestate is a complex mixture of condensed water and organics with a low stability, low energy content, and high corrosiveness [35]. Therefore, pyrolitic liquid needs complex and costly upgrading processes to be converted into fuel, severely limiting the viability of the pyrolysis process for digestate valorization [36]. Furthermore, pyrolysis is an endothermic process and external energy is required. Pyrolytic liquid from digestate pyrolysis can also be fed into the anaerobic digester in order to increase the bio-methane yield. However, the presence of aromatic compounds which may have a microbial toxicity hinders direct utilization in anaerobic digestion units, and pre-conditioning is requested [37].

Compared to pyrolysis, air gasification shows more advantages. Gasification is a thermal conversion process, which converts biomass- or fossil-derived carbonaceous materials into a gaseous product which mainly consists of hydrogen, carbon monoxide, and carbon dioxide and fractions of methane and light hydrocarbons. Gasification is usually carried out at high temperature (700–900 °C) under a controlled amount of oxygen and/or steam. In contrast to pyrolysis, the partial combustion of organic matter provides the energy for the process [38,39]. Few research works are available in the literature concerning the gasification of digestate [40,41]. Chen et al. studied the air gasification of biogas-derived digestate in an electrically heated downdraft gasifier at the laboratory scale [42]. The authors found that the optimum temperature in terms of gas production and quality (H2/CO = 1.08) was 800 °C, while the equivalence ratio was 0.28. An interesting preliminary work was carried out by Gnanendra et al., who investigated on the use of digester briquettes for gasification in an open-top gasifier coupled with an internal combustion engine. The digester waste mass rate was 40 kg/h. Engine operation indicated that gas quality was consistent with specific fuel consumption of 1.6 kg∙kWh−1, amounting to an overall electrical efficiency of 15%. The authors were very careful to establish the correct ash extraction rate. The high inorganic content together with relatively high moisture of the fuel, in the first tests, caused large amounts of ash to settle inside the reactor. The clinkers fused to the walls of the reactor near the air nozzle, occasionally posing a problem to material movement [43].

Freda et al. found that a rotary kiln reactor is suitable for air gasification of digestate [44]. About 20 kg/h of digestate pellets were successfully gasified at a pilot scale under different equivalence ratios (0.22–0.39). The collection of experimental data was mainly targeted at acquiring information about cold gas efficiency, permanent gas compositions, and gas yields. The syngas yields rose reasonably with the equivalence ratio. Specifically, values rising from 0.99 to 1.40 Nm3/kgfeedstock were observed, on an average basis, when increasing the equivalence ratio from 0.22 to 0.39. Syngas composition lay in the following range: H2 (9–12 vol.%), CO (10–14 vol.%), CO2 (12–14 vol.%), CH4 (3–4 vol.%), C2H6 (ca 1 vol.%), and N2 (56–62 vol.%), with a lower heating value of 4–5 MJ/Nm3dry gas. The highest cold gas efficiency of 47% was detected with an equivalence ratio 0.39.

The tests were carried out for several hours in steady state conditions without particular operative issues. In fact, rotary kilns are reliable in thermochemical processes of waste and biomass because they allow a good mixing of the feedstock, radial uniformity of bed temperature, and a continuous discharge of the process ashes [45,46,47,48,49] The good mixing of the bed prevents hot spots and the formation of slagging and clinkering; the continuous discharge of the produced ashes fits with the high ash content of the digestate. Moreover, the rotary kilns are easier to operate compared to a fluidized bed; compared to a fixed bed, they do not show the issues related to the ashes and are scalable up to several tens of thermal MW.

The interesting novelties of Freda’s work compared to the available literature are that the trials were planned to scout self-sustaining gasification that is a paramount condition for industrial development, and that the reactor was a rotary kiln at a pilot scale. The kind of reactor and the investigated scale of the plant are particularly meaningful for the further scale up of the process toward a technological readiness level of industrial relevance. Aiming to improve the sustainability of the existing AD plants, several biorefinery schemes were investigated during the last few decades. Monlau et al. [50] reported a review on opportunities for agricultural digestate valorization. Thermo-valorization via pyrolysis was indicated as a suitable strategy to produce pyrochar as a soil amender, bio-adsorbent, or starting material to produce activated carbons. Antoniou et al. [51] proposed a gasification–AD integrated scheme, where the produced syngas from digestate air gasification was used for electricity production, while the residual char was considered as soil amendment, with energetic and environmental benefits. A similar concept was also adopted by Milani et al., who co-gasified digestate with biomass and the combustible fraction of MSW to produce electricity [52]. Recently, Pecchi et al. [40] reported a review on the valorization of digestate via gasification, pyrolysis, or hydrothermal carbonization. Concerning gasification, on the basis of few studies reported on digestate, the attention was focused on the CHP application of syngas and on the utilization of residual char as an amendment or to improve the biogas yield in AD. Therefore, to the best of our knowledge, few studies were devoted on the conceptualization of valorization of digestate-derived syngas, and no study reported the production of methanol or hydrogen. The novelty of our study is to propose a strategy for digestate valorization going beyond the production of electricity. Currently, green electricity is produced at low cost from other renewable energy sources, such as solar and wind energy. On the contrary, biomass or waste-derived organic residues can be considered to be the sole true alternatives to fossil sources for the production of chemicals and fuels. Therefore, the novelties of our work may be summarized as follows: (i) proposing new scenarios for the valorization of MSW-digestate toward methanol and hydrogen, (ii) performing process simulations for syngas upgrading and conversion, and (ii) assessing the environmental impact in terms of equivalent CO2 emission for the three investigated cases (i.e., digestate to methanol, hydrogen, or electricity), pushing toward alternative strategies for valorizing the digestate-derived syngas.

2. Materials and Methods

In Table 1, the results of the proximate analyses and heating value of digestate pellets are reported. The main feature that can be argued is that, despite the high ash content, the volatile matter content and the heating value are interesting to investigate the feedstock for thermal treatments.

Table 1.

Chemical and physical analyses of digestate pellets. Data from Reference [44].

Briefly, a feeding system, with a capacity of 20 kg/h, conveys feedstock to the rotary kiln reactor where gasification occurs. The produced raw gas crosses the cleaning system where particulate and tar are removed. The stainless-steel rotary kiln reactor is 3 m long and its diameter is 0.3 m. Freda et al. [44] studied the effect of feeding rate and equivalence ratio on syngas quality. In this study, we adopted the syngas with the highest CO concentration and the lowest N2 concentration, as reported in Table 2.

Table 2.

Syngas compositions (%voldry) [44].

2.1. Process Simulation

Process design tools [53] were used in order to identify all process streams of plants to valorize syngas obtained by digestate gasification.

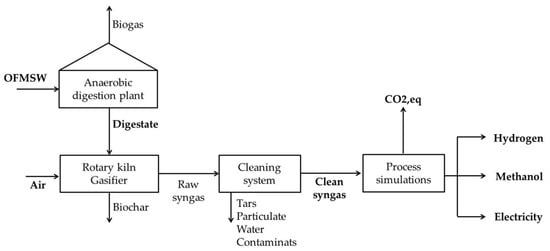

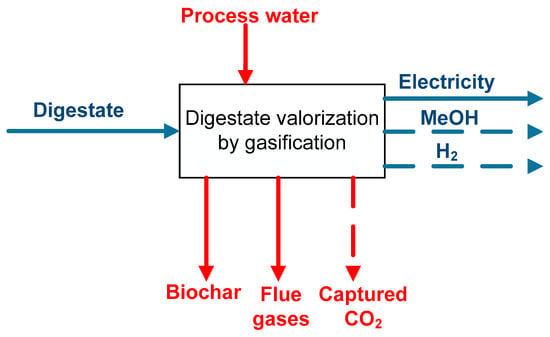

As previously reported, gasification-deriving syngas can be used to produce either energy or high-added value products, such as chemicals or fuels. In this section, three different scenarios for gas stream valorization are assessed according to the scheme reported in Figure 1.

Figure 1.

Scheme of the proposed integrated scheme for digestate valorization.

In this paper, the production of electricity (Case-EL), methanol (Case-MeOH), or pure hydrogen (Case-H2) was considered. In this regard, the commercial process simulation software ChemCAD was used. The Redlich–Kwong–Soave thermodynamic equation of state was adopted to simulate high-pressure systems, while NRTL-RK (NRTL: non-random two liquids model, RK: Redlich and Kwong model) was used for distillation columns and flash separation units. As the main aim of the paper was to assess the environmental impact of electricity, methanol, or hydrogen production from digestate-derived syngas, particular attention was focused on carbon dioxide capture. In this regard, in the cases of MeOH and H2 production, the removal of carbon dioxide is necessary. The syngas from gasification of solid material is often subjected to a water gas shift (WGS) process in order to enrich the mixture in hydrogen, to adjust the H/C ratio, or to convert CO into CO2 to proceed to the carbon capture subsequently [54]. In the case of methanol production, the syngas should have a ratio (H2 − CO2)/(CO + CO2) equal to the optimal one for the production of MeOH, i.e., 2. Since this is not verified for the adopted digestate-derived syngas, a WGS step followed by CO2 capture is implemented in order to increase the hydrogen content [55,56]. Similarly, in the case of production of pure hydrogen, the syngas must be enriched as much as possible in hydrogen in order to both maximize the yield in hydrogen and facilitate subsequent purification by PSA.

To facilitate the conversion of CO into CO2 + H2, two different methodologies can be carried out:

(1) Increase the steam-to-CO ratio in the inlet stream to the reactor, although the maximum energy-sustainable value of the ratio is 3.5; for higher values, the production of steam at high temperature (about 400 °C) is too expensive [57].

(2) Remove one or both of the reaction products (namely, CO2 or H2) from the mixture in intermediate steps of the reaction (for example, between the high and low temperature shift (HTS and LTS) stages) or continuously along the reactor (for example, through the use of membranes or material adsorbents) [58,59].

In the case of hydrogen production, both methods are suitable in order to favor the production of hydrogen as much as possible. In particular, an H2O/CO ratio of 3.5 may be set at the reactor, and the CO2 obtained in the HTS reactor may be partially removed before the LTS reactor.

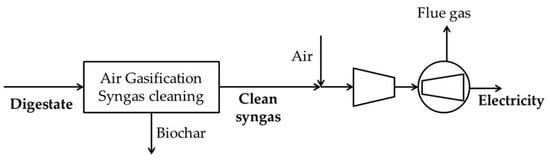

2.1.1. Case-EL

For Case-EL the gas stream produced from digestate gasification was used as fuel to an internal combustion engine for the production of electricity, according to the scheme reported in Figure 2.

Figure 2.

Flowsheet of valorization of anaerobic digestate for producing of electrical power.

After cleaning, the syngas is considered free of particulate or tars. An engine [60] was considered for the combustion of syngas after mixing with air. Air flowrate was optimized in order to maximize the electricity production.

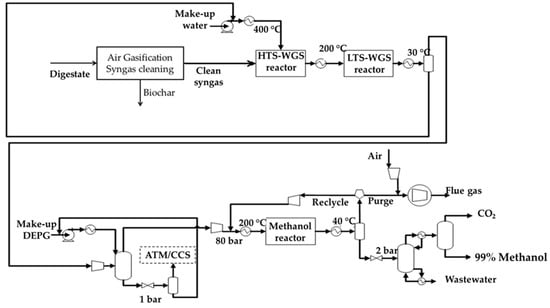

2.1.2. Case-MeOH

Methanol is one of the most important compounds of the chemical industry, with an annual production of about 40 million tons and an annual market increase rate of 4%. Currently, methanol is mainly produced from syngas obtained via steam reforming of fossil carbon sources, mainly natural gas and coal. In particular, a higher CO2 amount is emitted from coal-based plants. Aiming to reduce both CO2 emission and fossil source supply, alternative carbon sources may be considered in light of a sustainable energy economy. In this concern, the syngas obtained from gasification of biomass, residuals, and waste may be considered as a raw stream to obtain methanol.

In this regard, for Case-MeOH considered in this work, the clean syngas was sent to a (i) WGS section to convert CO into CO2 and hydrogen, followed by (ii) a carbon capture section using the Selexol process to obtain a (H2 − CO2)/(CO + CO2) ratio equal to 2. After that, (iii) a methanol production and purification section was considered for producing high-purity methanol. A flowsheet scheme is reported in Figure 3. Below, such sections are briefly detailed.

Figure 3.

Flowsheet of valorization of digestate for producing methanol.

Water Gas Shift (WGS) Section

The high-pressure capture of carbon dioxide and the production of methanol or pure hydrogen require the conversion of carbon monoxide and steam into CO2 and H2, coming with the clean syngas stream, by means of the water gas shift (WGS) reaction:

The WGS reaction is carried out in two steps, namely high temperature shift (HTS) and low temperature shift (LTS). The temperature was set to 400 °C and 200 °C for HTS and LTS, respectively. Similar conditions are adopted for industrial processes, where Fe2O4/Cr2O3 and Cu–ZnO–Al2O3 are used as catalysts for HTS and LTS, respectively. This sequence allows taking advantage of the faster conversion rate in the HTS path and finally approaching a higher equilibrium conversion value (larger than 99%) for the most favorable equilibrium conditions in the LTS [61]. The main operating parameter of this process is the H2O/CO molar ratio (steam to carbon, SC). The clean gas is mixed with a superheated steam (1 bar, 400 °C). The adopted feed ratio was chosen to obtain a H2O/CO molar ratio (steam to carbon, SC) equal to 2.5. The two fixed-bed reactors were modeled as equilibrium reactors. The pressure drop in the sequence of the two catalytic fixed bed was assumed of about 2 bar [57].

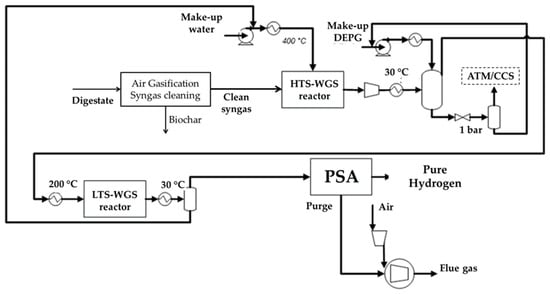

For the case of the traditional process sketched in Figure 4, the section for CO2 separation with the Selexol® technology was located after the WGS reactor and, thus, the inlet stream to the section was a clean syngas enriched in H2 and CO2 [45]. On the other hand, for the case of the innovative process sketched in Figure 3, the Selexol® section was located after the partial H2 separation by the membrane and, thus, the inlet stream was richer in CO2.

Figure 4.

Flowsheet of valorization of digestate for producing hydrogen.

The gas stream leaving the two WGS stages was cooled down to 30 °C to condense the steam.

CO2 Capture Section

Figure 3 shows the flowsheet of the section with the Selexol® technology. The separation of CO2 from the enriched syngas stream was carried out by absorption in the proprietary solvent Selexol®, a mixture of dimethyl ethers of polyethylene glycol (CH3O(C2H4O)nCH3), where “n” is between 3 and 9, in a packed tower with 75 mm IMTP® packing of Koch-Glitsch®.

The Selexol® solvent was compressed and sent to the top of the tower 30 °C. Solvent regeneration was carried out downstream the absorption tower to separate carbon dioxide and to recycle the solvent. However, a small make-up stream was necessary to replace the solvent entrained in the gaseous stream leaving the packed tower. In particular, the regeneration was performed by lowering the pressure in two stages by means of two expansion valves up to 1 bar.

A flash was used to recover the CO2 from the solvent. The regenerated solvent was mixed with the make-up stream and recycled back to the absorption tower after proper recompression and cooling. Low-pressure captured CO2 was considered emitted for the comparison with case of CO2 captured and stored at 110 bar. In this last case, the recovered CO2, which had the required purity (at least 98.5% by weight) was compressed up to 110 bar by a compressor train, formed by three compressors with intercooling by two heat exchangers, for storage conditions.

Methanol Production and Purification Section

The following reactions may be adopted to simulate methanol synthesis via both CO and CO2 hydrogenation:

In addition, unwanted side reactions, such as formation of methane, dimethyl ether, higher alcohols, and other oxygenates, e.g., aldehydes, can also take place. In this paper, WGS was considered as a side reaction only. Because methanol formation is an exothermic reaction, methanol synthesis is favored at low temperature, from a thermodynamic point of view. Nevertheless, kinetic aspects have to be taken into account. For these reasons, methanol synthesis is usually carried out in the temperature range 250–280 °C by using Cu–ZnO/alumina as catalyst. The inlet stream to the methanol reactor is mixed with the recycle stream (unreacted syngas), heated up to 200 °C, and fed to the methanol synthesis adiabatic reactor. An equilibrium reactor was adopted for the methanol synthesis unit by considering the reactions (ii), (iii), and (iv). A pressure drop equal to 2 bar was assumed along the reactor [61]. Concerning operating pressure, a pressure of 80 bar was considered to favor thermodynamics.

As mentioned before, crude methanol needs to be purified from water and impurities. As only WGS is considered, dissolved gases, such as CO2, CO, and H2, are the main impurities that need to be removed from the methanol stream. For this purpose, the output stream of the methanol synthesis reactor was cooled down at 40 °C, and the light gases were separated in a flash phase separator. A part of the separated gases was re-compressed at 80 bar and recycled to the reactor, while the rest was used as fuel for electricity production. The liquid streams, mainly consisting of methanol and water, were expanded in a throttling valve at 2 bar and distilled to produce a methanol-rich stream which was further purified in a flash phase separator to obtain 99% methanol.

2.1.3. Case-H2

Hydrogen is considered one promising alternative to fossil fuel, especially because of its combustion release energy with water as a “by-product”. The great interest toward hydrogen as an energy carrier is because it can be generated from a wide variety of renewable or non-renewable primary energy sources. Actually, most of the hydrogen is produced by fossil source-based processes, such as (i) steam reforming of methane, (ii) partial oxidation, (iii) auto-thermal reforming, and (iv) dry reforming [62]. Although most of the hydrogen is actually produced from fossil sources (about 95%), the utilization of renewables, such as biomass, received considerable attention in recent years. In particular, biomass gasification may be used as a suitable technology to produce syngas and then hydrogen. In fact, the syngas produced from gasification may be converted into a H2-rich stream via the water gas shift reaction [58,63].

In this regard, for Case-H2 considered in this work, the clean syngas streams obtained from the digestate gasification unit were sent to the WGS section. In this case, pure hydrogen production was maximized; thus, a higher H2O/CO ratio was set (equal to 3.5); after HTS-WGS, CO2 was removed by Selexol®. Intermediate CO2 removal coupled to a high H2O/CO ratio resulted in a higher conversion of CO to CO2 and a higher yield of H2. After HTS-WGS, CO2 capture, and LTS-WGS, the H2-rich syngas was sent to the pressure swing adsorption (PSA) section for purifying and then producing 99.99% hydrogen. A scheme of the simulated process is reported in Figure 4.

The PSA is a batch process consisting of a sequence of four steps: adsorption, depressurization, purge, and pressurization [57]. The adsorption pressure and the purge ratio (P/F) are the operating variables of the PSA process. In our case, the operating pressure was fixed equal to the output pressure from the absorption column. In the adsorption step, the adsorption time is a fraction of the breakthrough time of N2. In the purge step, the pure hydrogen, obtained during the adsorption step, is sent, in countercurrent, through the bed in order to allow further desorption of previously adsorbed species, primarily N2 and CO. Purge gas is sent to the engine to produce electricity. A lower content of H2 in the purge corresponds to higher pure hydrogen recovery and lower power output. Purge gas and air are mixed before the compression and engine section. Engine pressure was optimized to maximize the electricity production.

2.2. Environmental Impact Analysis

The environmental impact analysis was conducted through the use of equivalence relationships to calculate the CO2-equivalent emissions (or savings if negative values) for each inlet or outlet stream from the system [64].

Figure 5 shows a simplified scheme of the environmental analysis approach. Dashed lines indicate streams present in only some cases. In particular, the following inlet/outlet streams are associated with CO2 equivalent emissions:

Figure 5.

Simplified scheme for the environmental input data analysis (blue lines: CO2eq savings; red lines: CO2eq emissions).

- -

- Residual biochar disposal after the gasification process in a landfill (BC);

- -

- Process water utilization for the WGS reaction, also considering detoxification and demineralization processes (PW).

The direct CO2 emission streams are as follows:

- -

- CO2 in the flue gases of the combustion of purge gas or of syngas for the case EL (FG);

- -

- CO2 derived by carbon capture section for the cases without CO2 compression and storage (CC).

A negative CO2-equivalent emission value (CO2eq saving) is associated with digestate (DIG). The digestate valorization by gasification avoids the disposal in a landfill of this solid material; thus, the equivalent CO2 emitted from the landfill disposal [65] is avoided.

Savings are also associated with bio-based products for each case. Bio-based production of power, fuels, or chemicals substitutes the equivalent fossil-based product. Emissions associated with fossil-based production are avoided. In this work, the environmental savings estimated for the investigated bio-methanol (MeOH) production plants were considered for the production of methanol from coal (1643 kgCO2eq/tMeOH) [66]. The environmental savings for pure hydrogen (H2) production were considered for the case of utilization of the natural gas as feedstock for the steam reforming process (12000 kgCO2eq/tH2) [67]. Finally, the electricity (EL) production savings were considered equal to that of the fossil-based energy production system (600 kgCO2eq/MWhe) [50].

For each case, the values reported in Table 3 were adopted to calculate the CO2-equivalent emissions/savings [64].

where Fi is the input/output flowrate of the emission stream i of Figure 5 (t/year), Fj is the input/output flowrate (energy stream) of the saving stream j of Figure 5 (t/year or MWhe/year), emCO2,i and emCO2,j are the equivalent CO2 emission parameters of Table 3 related to the stream i or j, EMCO2,i is the CO2eq emission for the emission stream i (kgCO2eq/year), SAVCO2,j is the CO2eq saving for the saving stream j (kgCO2eq/year), and TOTCO2 is the total annual CO2eq emission (or saving, if negative) of the process (kgCO2eq/y).

Table 3.

CO2-equivalent emission parameters.

TOTCO2 is the global annual emission related to the supposed size of the plants of 100 kt/year of digestate. In order to calculate the specific emission for each main product, the following relationships were used:

where totCO2,EL is the specific emission (or saving, if negative) for case-EL related to each kWhe produced (kgCO2/kWhe), totCO2,MeOH is the specific emission (or saving, if negative) for case-MeOH related to each kg of methanol produced (kgCO2/kgMeOH), and totCO2,H2 is the specific emission (or saving, if negative) for case-H2 related to each kg of pure hydrogen produced (kgCO2/kgH2).

3. Results and Discussion

As previously reported, the valorization syngas was assessed by simulating the production of electricity, methanol, or pure hydrogen. Table 4 reports the main parameters adopted for the simulation. A plant size equal to 100,000 t/year of digestate was considered as a collective digestate treatment plant.

Table 4.

Process simulation parameters.

Table 5 shows the process results for the three cases considered. For the case MeOH, the obtained conversions of HTS-WGS and LTS-WGS were 31% and to 33%, respectively.

Table 5.

Process simulation main results.

These values are consistent with the literature [66], as the first WGS reaction step is influenced by the H2O/CO ratio and by the presence of products (CO2 and H2) within the currents entering the reactor. Lower H2/CO and CO2/CO ratios result in higher equilibrium conversion in the first HTS stage. In case-MeOH, the aim was to convert CO to CO2 having the maximum energy saving. The H2O/CO ratio was set equal to 2.5, and products from the first stage HTS were not removed. Thus, inlet ratios H2/CO and CO2/CO were equal to 0.87 and 0.94, respectively.

LTS-WGS conversion is higher than HTS-WGS because LTS-WGS conditions are thermodynamically optimal due low inlet temperature (200 °C). In order to obtain a (H2 − CO2)/(CO + CO2) ratio equal to 2, a 90% carbon capture section was necessary. Consequently, a rich-CO2 syngas at 40 bar was obtained.

For case-H2, HTS-WGS and LTS-WGS conversions were equal to 41% and 71%, respectively. In this case, CO and CO2 were not reactants of the next process step; thus, CO conversion was to be maximized. To obtain that, a H2O/CO ratio equal to 3.5 was set, and the CO2 removal was carried out between HTS and LTS stages. Therefore, in the first stage, a higher conversion than case-MeOH was obtained (41%) due to a higher H2O/CO ratio.

Moreover, in this case, a CO2 capture equal to 90% was performed; consequently, a Selexol pressure equal to 56 bar was necessary.

After carbon capture, the inlet LTS-WGS CO2/CO ratio was equal to 0.23. This low ratio and low inlet temperature (200 °C) allowed reaching a LTS-WGS conversion higher than in case-MeOH (71%).

The global WGS CO conversion (HTS + LTS) was equal to 83%, enriching the current by about 7 kmol/h of hydrogen. Total carbon (CO + CO2) conversion in the MeOH reactor was equal to 56%. This conversion was equal to 12% considering the single passage in the MeOH reactor. A purge split ratio equal to 10% was set in order to keep the (H2 − CO2)/(CO + CO2) ratio equal to 2 in the reactor inlet.

In the PSA process, an 85 % pure hydrogen recovery was obtained considering an inlet pressure of 35 bar.

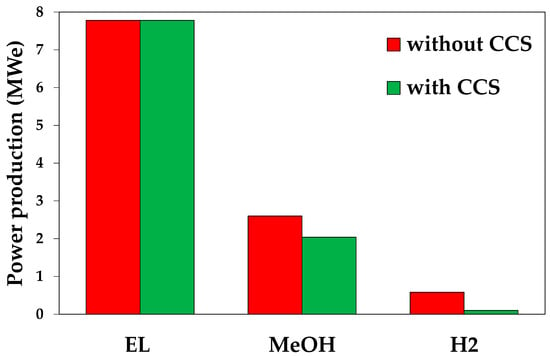

Electricity production was equal to 7.78 MWe for case-EL. In case-MeOH, purge gas combustion produced a gross power equal to 7.39 MWe. The compression for the carbon capture (−4.19 MWe), for the methanol reactor (−0.51 MWe), and for the recycle (−0.09 MWe) decreased the gross power to a net power equal to 2.60 MWe. In Case-H2, the only compression for the carbon capture was considered. In this case, a gross power equal to 4.28 MWe was obtained from the combustion of purge gas.

In the cases of MeOH and H2, captured CO2 compression was also considered. For this compression, an electrical power of 0.56 and 0.48 MWe for case-MeOH and case-H2 was requested, respectively. The net power productions are summarized in Figure 6.

Figure 6.

Electric power production for EL, MeOH, and H2 cases. Calculation base: 100 kt/year of digestate.

The low methanol yield obtained in this work, namely, about 8 kgMeOH/100 kgfeedstock,daf (daf: dry and ash free) may be related to the syngas quality produced from the gasification of digestate. In particular, in order to have the optimal (H2 − CO2)/(CO + CO2) molar ratio, i.e., 2, in the methanol reactor inlet, WGS and carbon capture units are usually implemented, especially for hydrogen-lean produced syngas. These steps cause a carbon loss, mainly occurring in the carbon capture step, leading to a lower biomass-to-methanol conversion. Both CO2 and N2 content in the produced syngas should also be taken into account in order to rationalize the obtained results. In fact, from a thermodynamic point of view, the CO-to-MeOH hydrogenation step is more favored than CO2-to-MeOH in terms of theoretical carbon conversion and methanol yield. For this reason, a CO2-lean syngas should be preferred in order to increase the incorporation of biomass-derived carbon into methanol. N2 content should be as low as possible in order to minimize its diluting effect, since a higher N2 content results in a lower partial pressure of H2/CO/CO2 reactants with a negative impact on the thermodynamic of methanol synthesis, which is favored at high reactant pressure. Furthermore, the presence of inerts, such as N2, increases both operational and capital costs, e.g., compression power, reactor volume, and so on. These conditions can be partially approached when the gasification agent is steam, as in the work of Zhang et al. [68] that simulated straw gasification in an interconnected gasifier-combustor fluidized bed. The authors calculated a methanol yield of about 40 kgMeOH/100 kgfeedstock,daf when the straw was gasified at 750 °C and 0.1 MPa with a steam-to-straw weight ratio in the range 0.4–0.5. Under such conditions, a clean syngas with H2/COx equal to about 1.5, CO2/CO equal to about 0.67, and N2 concentration equal to 0.5% was obtained. Ptasinski et al. [69] reported a study on gasification of partially dried sewage sludge (80 wt.% of solids) for the production of methanol. The authors obtained a methanol yield high as 77 kgMeOH/100 kgfeedstock,daf when the sewage sludge was gasified at 1000 °C to obtain a produced syngas with H2/COx equal to about 1.3, CO2/CO lower than 0.02, and N2 concentration equal to about 3%. High methanol yield was also obtained by Yang et al. [70]. The authors re-used the CO2 captured by Rectisol in a dual-stage entrained flow gasification unit, by using pure oxygen and steam as gasification agents and operating at 900 °C to obtain a methanol yield equal to about 63 kgMeOH/100 kgbiomass,daf under optimal conditions. In our study, we calculated a relatively low methanol yield, i.e., about 8 kgMeOH/100 kgfeedstock,daf. Such a result may be related to the relative low quality of produced syngas from digestate air gasification which has a H2/COx ratio <0.5 and a high CO2/CO ratio equal to about one, as well as high nitrogen content (i.e., about 56%). Nevertheless, a quantitative comparison between the proposed process schemes with the literature is very challenging because the boundary conditions are quite different, and the methods adopted in the simulation differ from one work to another. Furthermore, to the best of our knowledge, no studies on digestate-to-methanol conversion were previously published. As a general frame, steam gasification seems to perform better in terms of methanol yield, although external heat input is required. Heat may be provided by a gasification/combustion interconnected fluidized bed reactor that implies technical issues during the running. Similar results may also be obtained in nitrogen-lean oxygen/steam gasification, but addition costs of pure oxygen should be taken into account.

Similar considerations may be done for hydrogen production. In fact, a higher quality of produced syngas, such as higher H2 content or lower CO2 and N2 content, results in a higher e hydrogen yield. Toonssen et al. compared several commercial biomass-based gasification plants for hydrogen production [71]. Although the hydrogen yield may be affected by performances of either gas cleaning (e.g., low- or high-temperature cleaning system) or and upgrading (e.g., steam reforming of methane, water gas shift) systems, there is an evident effect of the syngas quality on hydrogen yield. For processes producing nitrogen-lean and hydrogen-rich syngas, e.g., Battelle, IGT (Institute of Gas Technology), FICFB (Fast Internal Circulating Fluidized Bed), and Blau Turm processes, the hydrogen yield is in the range 6.8–10.7 kgH2/kgfeedstock,daf, higher than the value obtained in this work, i.e., about 3 kgH2/kgfeedstock,daf. Moreover, in that case, the production of a nitrogen-lean syngas requires steam, oxygen, or a mixture of them as gasification agents, or advanced technologies (e.g., indirect gasification) should be used [72,73]. Similarly, syngas with a higher CO2 level leads to a lower hydrogen yield. In fact, the carbon contained in the feedstock should be mainly converted to CO which may be used in the WGS unit to increase the hydrogen content [74]. Despite the relatively low yield toward methanol and hydrogen, the strength of the process proposed in this work lies in a syngas obtained via a reliable and simple rotary kiln gasifier with air as the gasification agent. Therefore, the lower methanol or hydrogen yields might be balanced by the ease and the low cost in the rotary kiln gasifier management. Capital and operating expenditure analysis would be useful for a proper viability assessment of the proposed process.

The global electrical efficiency of the process calculated as the ratio between produced electrical power and the inlet digestate thermal power was 15.9%, which is lower compared to lignocellulosic biomass gasification for power production (about 20%). The electrical efficiency from syngas to power is 37%, and this value is close to data from the literature for internal combustion engine performance fueled by poor gas [75,76,77]. Therefore, the limiting step of the power production is digestate gasification. Digestate could be considered as a low-grade feedstock because of its high ash content (about 30 wt.%) that negatively affects gasification and other thermochemical valorization processes. In fact, the gas yield was relatively low (0.99 Nm3/kgfeedstock) compared to low ash content biomass (2–2.4 Nm3/kgfeedstock). Hence, the cold gas efficiency, i.e., the power that was converted from digestate to raw gas, was only 43%. Finally, despite the fact that digestate is not the best-performing biomass for gasification, its massive and localized production together with a not well-established fate highlights gasification as a solution to reduce its volume with useful power production.

CO2-Equivalent Emission Calculation

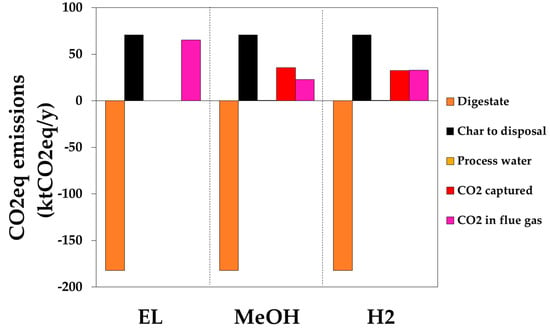

The annual CO2 equivalent emissions are shown in Figure 7. The direct emissions concern the CO2 captured in Selexol® if it is not also compressed and stored, as well as the flue gas of the syngas/purge gas combustion.

Figure 7.

Annual CO2-equivalent emissions for EL, MeOH, and H2 cases. Savings from digestate disposal (orange bars), emissions from solid residual after gasification (black bars, process water (yellow bars), CO2 captured in Selexol process (red bars), and combustion of syngas/purge gas (rose bars). Calculation base: 100 kt/year of digestate.

The indirect emissions concern the disposal of the solid residue of the char after the gasification process as water for the WGS reaction. The orange bars consider the savings derived from the avoided landfilling for the digestate disposal. This contribution is equal to −182 ktCO2eq/year; this value makes total emissions negative (i.e., saving), because, even without the syngas valorization, the carbon contained in the digestate is so low as to make the direct CO2 emissions (burning directly the digestate) lower than the environmental impact of the digestate disposal, due to the extremely high ash content (32%).

In terms of emissions, the highest emissions derive from the disposal of the solid residue. In fact, 39% of the solid material fed to the gasifier remains as a solid residue to be disposed. From this effect, the direct emissions of syngas combustion are also derived; they are lower than biochar disposal emissions.

Direct emissions from the combustion of the purge gas (cases MeOH and H2) are about 35% and 50% of the syngas combustion emissions for cases of MeOH and H2, respectively.

This occurs because the combustible material in the purge gases is lower. The CO2 captured is approximately equal to the difference between the flue gas in the EL case and the flue gas in the case of the combustion of the purge gas for case-H2. For Case-MeOH, emissions from captured CO2 are higher than Case-H2 because of the position of the carbon capture process after both HTS-WGS and LHS-WGS. Total CO2 direct emissions are lower than emissions for Case-EL and Case-H2 because a fraction of the carbon in the feedstock was contained in the methanol product.

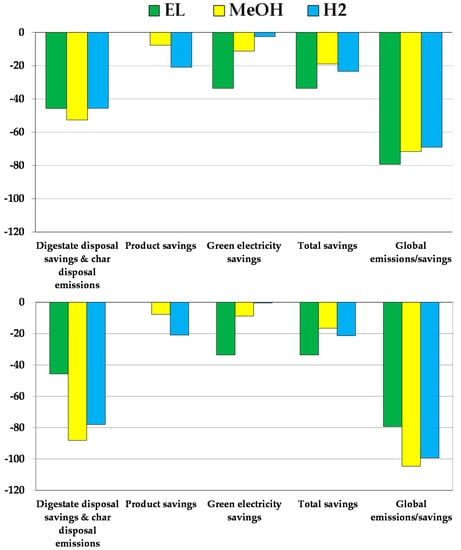

Figure 8 shows the total emissions shown in Figure 7 for each case under “digestate disposal savings and char disposal emissions”.

Figure 8.

Annual CO2 equivalent emissions (ktCO2,eq) for EL case (green bars), Case-MeOH (yellow bars), and Case-H2 (blue bars) without CO2 sequestration (up) and with CO2 sequestration (down).

All cases show negative emissions (savings) because of high savings from avoided digestate disposal. Case-MeOH has higher savings due to lower direct CO2 emissions.

Furthermore, with CO2 storage, the highest savings came from Case-H2, while the lowest ones came from Case-EL. This is due to the higher emissions derived from the syngas combustion. In Case-H2, the production of green power was reduced as the calorific value of the hydrogen was subtracted from the PSA, but the CO2 was released into the atmosphere together with the flue of the purge gas.

Figure 7 shows the savings of MeOH and pure H2 products (“product savings”) and the savings obtained from the production of green power. The total savings (product + electricity) were higher in the EL case and lower in the MeOH case. This is because the saving from green power is higher than the sum (product saving + green power) calculated for the other cases. This is due to the low overall yields of MeOH and pure H2 products, equal to 4.7% and 1.7%, respectively. Producing chemicals reduces the amount of electricity produced but obtains reduced quantities of product.

CO2 storage strongly affects CO2 emission as may be noted by comparing data reported in Figure 7. Considering the cases without CO2 storage, higher savings are seen in the EL case and lower savings are seen in Case-H2. The reason is the low savings from products in the MeOH and H2 cases and the high emissions in Case-H2, derived from the flue gas of the purge gas combustion. In Case-H2, the production of green power is reduced as the calorific value of the hydrogen is subtracted from the PSA, but the CO2 is released into the atmosphere in the fumes of the purge gas. In the MeOH case, on the other hand, the post-capture residual CO2 is partially converted into MeOH.

Considering the cases with CO2 storage, the highest savings are obtained for MeOH and H2 (very similar) and lower savings are obtained for EL. This is because 35.5 kt/year and 32.4 of CO2 captured and stored for Case-MeOH and Case-H2, respectively, represent about 27% and 24% of the total emissions in the MeOH and H2 cases, respectively.

Figure 8 shows the comparison between the specific equivalent CO2 emissions/savings of this work (without and with CCS) (totCO2,i, i = EL, MeOH, H2) and literature results using a fossil source or a bio-based source. In particular, this work’s results show the convenience of utilizing digestate as feedstock.

For all three products, the lowest emissions (the highest savings) were obtained for the digestate-as-feedstock stream. In accordance with literature results, the highest specific savings consisted of the savings derived from the feedstock [78]. In an environmental impact analysis, the saving from the feedstock is the principal one. Typical savings using biomass as feedstock are 1434 kgCO2/t [79] for corn stover, 1456 kgCO2/t [80] for cereal straw, and 1597 kgCO2/t [57] for the organic fraction of municipal solid waste. For the present work, a value equal to 1643 kgCO2/t was used as feedstock savings from Li et al. [66].

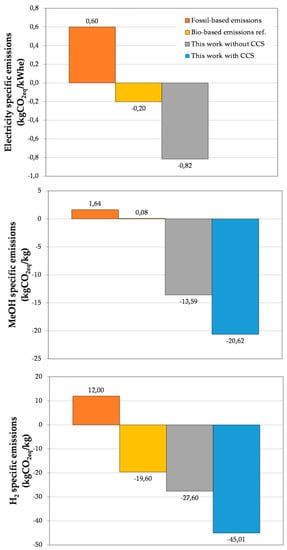

In particular, Figure 9 shows the comparison between the specific equivalent CO2 emissions/savings of this work (without and with CCS) (totCO2,i, i = EL, MeOH, H2) and literature results using a fossil source or a bio-based source. In particular, this work’s results show the convenience of utilizing digestate as feedstock.

Figure 9.

Equivalent CO2 emissions/savings comparison for each case and between fossil-based production (orange bars), biobased production in the literature from Reference [79] (yellow bars), and present work without (gray bars) and with (blue bars) CO2 storage.

For case-EL, the value for fossil-based emission was taken from Rodrigues Gurgel da Silva et al. [65], equal to 0.60 kgCO2/kWhe, which is higher than the negative bio-based literature value of −0.20 kgCO2/kWhe from Caposciutti et al. [79]. For electricity production, the specific impact is equal to −0.82 kgCO2/kWhe, due to high savings from the avoided digestate disposal in the landfill. Only this saving leads to −3.25 kgCO2/kWhe.

For case-MeOH, the fossil-based emission was taken from Li et al. [66], equal to 1.64 kgCO2/kgMeOH, which is higher than the bio-based literature value 0.08 kgCO2/kgMeOH from Giuliano et al. [53]. Without CCS, for methanol production, the specific impact is equal to −13.59 kgCO2/kgMeOH. In this case, the saving from digestate leads to −38.75 kgCO2/kgMeOH. Considering also the storage of captured CO2, the saving for each kg of methanol is equal to 20.62 kgCO2/kgMeOH, whereas the captured CO2 has an impact of −7.03 kgCO2/kgMeOH.

For case-H2, the fossil-based emission was taken from Bareiß et al. [68], equal to 12.00 kgCO2/kgH2, which is higher than negative bio-based literature value −19.60 kgCO2/kgH2 from Dean et al. [80]. Without CCS, for methanol production, the specific impact is equal to −27.60 kgCO2/kgH2. In this case, the saving from digestate leads to −104.52 kgCO2/kgH2. Considering also the storage of captured CO2, the saving for each kg of methanol is equal to 45.01 kgCO2/kgH2, while the captured CO2 has an impact of −17.41 kgCO2/kgH2.

4. Conclusions

Digestate may be considered a by-product of anaerobic digestion of the organic fraction of municipal solid waste. In this work, the valorization of digestate for the production of methanol, hydrogen, or green electric power was proposed. On the basis of previous experimental observation of syngas production via air gasification of digestate, process simulations were performed in order to assess the carbon footprint of the proposed valorization schemes.

In particular, two different process flowsheets were considered for the methanol and for pure hydrogen production. In the case of pure hydrogen production after the first step of HTS/water gas shift, the carbon capture unit was carried out in order to convert more CO to CO2 and H2. Calculations indicate that from syngas obtained via air gasification of 100 kt/year of digestate, about 4700 t/year of methanol, or 1700 t/year of hydrogen may be produced.

Syngas may also be used for the production of 560 kWhe/tDIGESTATE. In particular, the production of green electricity maximizes the saving of CO2 equivalent (about 790 tCO2eq/ktDIGESTATE). If the storage of CO2 is considered in addition to the capture, the optimal CO2eq-saving is similar for the production of methanol and pure hydrogen, i.e., 1050 tCO2eq/ktDIGESTATE and 990 tCO2eq/ktDIGESTATE, respectively. Although a cost analysis should be performed to complete the assessment, this study pushes toward new scenarios for the valorization of digestate from anaerobic digestion of municipal waste.

Author Contributions

Conceptualization, C.F. and E.C.; methodology and investigation, C.F.; computer-assisted simulations, A.G.; writing—original draft preparation and revision, E.C., C.F., and A.G.; supervision, G.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external founding

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Demirbas, A. Waste management, waste resource facilities and waste conversion processes. Energy Conv. Manag. 2011, 52, 1280–1287. [Google Scholar] [CrossRef]

- Ali, R.A.; Ibrahim, N.N.L.N.; Lam, H.L. Conversion technologies: Evaluation of economic performance and environmental impact analysis for municipal solid waste in Malesya. Processes 2019, 7, 752. [Google Scholar] [CrossRef]

- World Bank. What a Waste: A Global Review of Solid Waste Management; Urban Develop Series Knowledge Paper No. 15; World Bank: Washington, DC, USA, 2012; p. 116. [Google Scholar] [CrossRef]

- Arent, D.J.; Wise, A.; Gelman, R. The status and prospects of renewable energy for combating global warming. Energy Econ. 2011, 33, 584–593. [Google Scholar] [CrossRef]

- Migliori, M.; Catizzone, E.; Giordano, G.; Le Pera, A.; Sellaro, M.; Lista, A.; Zanardi, G.; Zoia, L. Pilot plant assessment in anaerobic digestion of organic fraction of municipal waste solids. Processes 2019, 7, 54. [Google Scholar] [CrossRef]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anerobic co-digestion of wastewater sludge: A review of potential co-substrates and operating factors for improved methane yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef]

- Ramachandran, A.; Rustum, R.; Adeloye, A.J. Review of anaerobic digestion modeling and optimization using nature-inspired techniques. Processes 2019, 7, 953. [Google Scholar] [CrossRef]

- Dry, M.E. High quality diesel via the Fischer-Tropsch process–a review. J. Chem. Technol. Biotechnol. 2002, 77, 43–50. [Google Scholar] [CrossRef]

- Catizzone, E.; Bonura, G.; Migliori, M.; Frusteri, F.; Giordano, G. CO2 recycling to dimethyl ether: State-of-the-art and perspectives. Molecules 2018, 23, 31. [Google Scholar] [CrossRef]

- Bonura, G.; Cannilla, C.; Frusteri, L.; Catizzone, E.; Todaro, S.; Migliori, M.; Giordano, G.; Frusteri, F. Interaction effects between CuO-ZnO-ZrO2 methanol phase and zeolite surface affecting stability of hybrid systems during one-step CO2 hydrogenation to DME. Catal.Today 2000, 345, 175–182. [Google Scholar] [CrossRef]

- Esmaeili, J.; Rahimpour, F. Regeneration of spent nickel catalyst from hydrogenation process of edible oils: Heat treatment with hydrogen injection. Int. J. Hydrogen Energy 2017, 42, 24197–24204. [Google Scholar] [CrossRef]

- Lanzafame, P.; Centi, G.; Perathoner, S. Catalysis for biomass and CO2 use through solar energy: Opening new scenarios for a sustainable and low-carbon chemical production. Chem. Soc. Rev. 2014, 43, 7562–7580. [Google Scholar] [CrossRef] [PubMed]

- Smolińaki, A.; Howaniec, N. Co-gasification of coal/sewage sludge blends to hydrogen-rich gas with the application of simulated high temperature reactor excess heat. Int. J. Hydrogen Energy 2016, 41, 8154–8158. [Google Scholar] [CrossRef]

- Bagnato, G.; Sanna, A. Process and techno-economic analysis for fuel and chemical production by hydrodeoxygenation of bio-oil. Catalysts 2019, 9, 1021. [Google Scholar] [CrossRef]

- Chiodini, A.; Bua, L.; Carnelli, L.; Zwart, R.; Vreugdenhil, B.; Vocciante, M. Enhancements in Biomass-to-Liquid processes: Gasification aiming at high hydrogen/carbon monoxide ratios for direct Fischer-Tropsch synthesis applications. Biomass Bioenergy 2017, 106, 104–114. [Google Scholar] [CrossRef]

- Giuliano, A.; Barletta, D.; De Bari, I.; Poletto, M. Techno-economic assessment of a lignocellulosic biorefinery co-producing ethanol and xylitol or furfural. Comput. Aided Chem. Eng. 2018, 43, 585–590. [Google Scholar]

- Fasolini, A.; Cucciniello, R.; Paone, E.; Mauriello, F.; Tabanelli, T. A Short Overview on the Hydrogen Production Via Aqueous Phase Reforming (APR) of Cellulose, C6-C5 Sugars and Polyols. Catalysts 2019, 9, 917. [Google Scholar] [CrossRef]

- Paone, E.; Tabanelli, T.; Mauriello, F. The rise of lignin biorefinery. Current Opin. Green Sus. Chem. 2020, 24, 1–6. [Google Scholar]

- Lin, R.-H.; Xi, X.-N.; Wang, P.-N.; Wu, B.-D.; Tian, S.-M. Review on hydrogen fuel cell condition monitoring and prediction methods. Int. J. Hydrogen Energy 2019, 44, 5488–5498. [Google Scholar] [CrossRef]

- Olah, G.A. Beyond oil and gas: The methanol economy. Angew. Chem. Int. Ed. 2005, 44, 2636–2639. [Google Scholar] [CrossRef]

- Qian, Q.; Zhang, J.; Cui, M.; Han, B. Synthesis of acetic acid via methanol hydrocarboxylation with CO2 and H2. Nat. Commun. 2016, 7, 11481. [Google Scholar] [CrossRef]

- Keil, F.J. Methanol-to-hydrocarbons: Process technology. Microp. Mesop. Mater. 1999, 29, 49–66. [Google Scholar] [CrossRef]

- Catizzone, E.; Cirelli, Z.; Aloise, A.; Lanzafame, P.; Migliori, M.; Giordano, G. Methanol conversion over ZSM-12, ZSM-22 and EU-1 zeolites: From DME to hydrocarbons production. Catal. Today 2018, 304, 39–50. [Google Scholar] [CrossRef]

- Catizzone, E.; Van Daele, S.; Bianco, M.; Di Michele, A.; Aloise, A.; Migliori, M.; Valtchev, V.; Giordano, G. Catalytic application of ferrierite nanocrystals in vapour-phase dehydration of methanol to dimethyl ether. Appl. Catal. B Environ. 2019, 243, 273–282. [Google Scholar] [CrossRef]

- Migliori, M.; Catizzone, E.; Aloise, A.; Bonura, G.; Gómez-Hortigüela, L.; Frusteri, L.; Cannilla, C.; Frusteri, F.; Giordano, G. New insights about coke deposition in methanol-to-DME reaction over MOR-, MFI-, and FER-type zeolites. J. Ind. Eng. Chem. 2018, 68, 196–208. [Google Scholar] [CrossRef]

- Catizzone, E.; Aloise, A.; Migliori, M.; Giordano, G. The effect of FER zeolite acid sites in methanol-to-dimethyl ether catalytic dehydration. J. Energy Chem. 2017, 26, 406–415. [Google Scholar] [CrossRef]

- Peng, W.; Lü, F.; Hao, L.; Zhang, H.; Shao, L.; He, P. Digestate management for high-solid anaerobic digestion of organic wastes: A review. Bioresour. Technol. 2020, 297, 122485. [Google Scholar] [CrossRef]

- Chiumenti, A.; Da Borso, F.; Chiumenti, R.; Segantin, P. Treatment of digestate from a co-digestion biogas plant by means of vacuum evaporation: Tests for process optimization and environmental sustainability. Waste Manag. 2013, 33, 1339–1344. [Google Scholar] [CrossRef]

- Rehl, T.; Müller, J. Life cycle assessment of biogas digestate processing technologies. Res. Convers. Recycl. 2011, 56, 92–104. [Google Scholar] [CrossRef]

- Calabrò, P.S.; Fazzino, F.; Folino, A.; Paone, E.; Komila, D. Semi-continuous anaerobic digestion of orange peel waste: Effect of activated carbon addition and alkaline pretreatment on the process. Sustainability 2019, 11, 3386. [Google Scholar] [CrossRef]

- Banks, C.J.; Chesshire, M.; Heaven, S.; Arnold, R. Anaerobic digestion of source-segregated domestic food waste: Performance assessment by mass and energy balance. Bioresour. Technol. 2011, 102, 612–620. [Google Scholar] [CrossRef]

- Monlau, F.; Francavilla, M.; Sambusiti, C.; Antoniou, N.; Solhy, A.; Libutti, A.; Zabaniotou, A.; Barakat, A.; Monteleone, M. Toward a functional integration of anaerobic digestion and pyrolysis for a sustainable resource management. Comparison between solid-digestate and its derived pyrochar as soil amendment. Appl. Energy 2016, 169, 652–662. [Google Scholar] [CrossRef]

- Pedrazzi, S.; Allesina, G.; Bellò, T.; Rinaldini, C.A.; Tartarini, P. Digestate as bio-fuel in domestic furnaces. Fuel Process. Technol. 2015, 130, 172–178. [Google Scholar] [CrossRef]

- Opatokun, S.A.; Kan, T.; Al Shoaibi, A.A.; Srinivasakannan, C.; Strezov, V. Characterization of food waste and its digestate as feedstock for thermochemical processing. Energy Fuel 2016, 30, 1589–1597. [Google Scholar] [CrossRef]

- Opatokun, S.A.; Strezov, V.; Kan, T. Product based evaluation of pyrolysis of food waste and its digestate. Energy 2015, 92, 349–354. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Sadeqzadeh, M.; Guo, M.; Borhani, T.; Konda, N.V.S.N.M.; Cortada Garcia, M.; Wang, L.; Hallet, J.; Shah, N. The multi-scale challenges of biomass fast pyrolysis and bio-oil upgrading: Review of the state of art and future research directions. Progress. Energy Comb. Sci. 2019, 71, 1–80. [Google Scholar] [CrossRef]

- Fabbri, D.; Torri, C. Linking pyrolysis and anaerobic digestion (Py-AD) for the conversion of lignocellulosic biomass. Curr. Opin. Biotechnol. 2016, 38, 167–173. [Google Scholar] [CrossRef]

- Barisano, D.; Freda, C.; Nanna, F.; Fanelli, E.; Villone, A. Biomass gasification and in-bed contaminants removal: Performance of iron enriched Olivine and bauxite in a process of steam/O2 gasification. Bioresour. Technol. 2012, 118, 187–194. [Google Scholar] [CrossRef]

- Freda, C.; Cornacchia, G.; Romanelli, A.; Valerio, V.; Grieco, M. Sewage sludge gasification in a bench scale rotary kiln. Fuel 2018, 212, 88–94. [Google Scholar] [CrossRef]

- Pecchi, M.; Baratieri, M. Coupling anaerobic digestion with gasification, pyrolysis or hydrothermal carbonization: A review. Renew. Sustain. Energy Rev. 2019, 105, 462–475. [Google Scholar] [CrossRef]

- Macrì, D.; Catizzone, E.; Molino, A.; Migliori, M. Supercritical waster gasification of biomass and agro-food residues: Energy assessment from modelling approach. Renew. Energy 2020, 150, 624–636. [Google Scholar] [CrossRef]

- Chen, G.; Guo, X.; Cheng, Z.; Yan, B.; Dan, Z.; Ma, W. Air gasification of biogas-derived digestate in a downdraft fixed bed gasifier. Waste Manag. 2017, 69, 162–169. [Google Scholar] [CrossRef] [PubMed]

- Gnanendra, P.M.; Ramesha, D.K.; Dasappa, S. Preliminary investigation on the use of biogas sludge for gasification. Intern. J. Sustain. Energy 2012, 31, 251–267. [Google Scholar] [CrossRef]

- Freda, C.; Nanna, F.; Villone, A.; Barisano, D.; Brandani, S.; Cornacchia, G. Air gasification of digestate and its co-gasification with residual biomass in a pilot scale rotary kiln. Int. J. Energy Environ. Eng. 2019, 10, 335–346. [Google Scholar] [CrossRef]

- Boateng, A. Rotary Kilns Transport Phenomena and Transport Processes; Butterworth-Heinemann by Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Notarnicola, M.; Cornacchia, G.; De Gisi, S.; Di Canio, F.; Freda, C.; Garzone, P.; Martino, M.; Valerio, V.; Villone, A. Pyrolysis of automotive shredder residue in a bench scale rotary kiln. Waste Manag. 2017, 65, 92–103. [Google Scholar] [CrossRef]

- Shi, H.; Si, W.; Li, X. The concept, design and performance of a novel rotary kiln type air-staged biomass gasifier. Energies 2016, 9, 67. [Google Scholar] [CrossRef]

- Benanti, E.; Freda, C.; Lorefice, V.; Braccio, G.; Sharma, V.K. Simulation of olive pits pyrolysis in a rotary kiln. Therm. Sci. 2011, 15, 145–158. [Google Scholar] [CrossRef]

- Fanelli, E.; Freda, C.; Canneto, G.; Barisano, D.; Nanna, F.; Braccio, G. Experimentation of a down-draft gasifier coupled with an Internal Combustion Engine (ICE) for theoretical model validation. In Proceedings of the 4th International Conference on Biomass for Energy, Kyiv, Ukraine, 22–24 September 2008. [Google Scholar]

- Monlau, F.; Sambusiti, C.; Aboulkas, A.; Barakat, A.; Carrère, H. New opportunities for agricultural digestate valorisation: Current situation and perspectives. Energy Environ. Sci. 2015, 8, 2600–2621. [Google Scholar] [CrossRef]

- Antoniu, N.; Monlau, F.; Sambusiti, C.; Ficara, E.; Barakat, A.; Zabaniotou, A. Contribution to Circular Economy options of mixed agricultural wastes management: Coupling anaerobic digestion with gasification for enhanced energy and material recovery. J. Clean. Prod. 2019, 209, 505–514. [Google Scholar] [CrossRef]

- Milani, M.; Montorsi, L.; Stefani, M. An integrated approach to energy recovery from biomass and waste: Anaerobic digestion-gasification-water treatment. Waste Manag. Res. 2014, 32, 614–625. [Google Scholar] [CrossRef]

- Giuliano, A.; Poletto, M.; Barletta, D. Process Design of a Multi-Product Lignocellulosic Biorefinery. Comput. Aided Chem. Eng. 2015, 37, 1313–1318. [Google Scholar]

- Borgogna, A.; Salladini, A.; Spadacini, L.; Pitrelli, A.; Annesini, M.C.; Iaquaniello, G. Methanol production from Refuse Derived Fuel: Influence of feedstock composition on process yield through gasification analysis. J. Clean. Prod. 2019, 235, 1080–1089. [Google Scholar] [CrossRef]

- Iaquaniello, G.; Centi, G.; Salladini, A.; Palo, E.; Spadacini, L. Waste-to-methanol: Process and economics assessment. Bioresour. Technol. 2017, 243, 611–619. [Google Scholar] [CrossRef] [PubMed]

- Bozzano, G.; Manenti, F. Efficient methanol synthesis: Perspectives, technologies and optimization strategies. Progr. Energy Comb. Sci. 2016, 56, 71–105. [Google Scholar] [CrossRef]

- Giuliano, A.; Poletto, M.; Barletta, D. Pure hydrogen co-production by membrane technology in an IGCC power plant with carbon capture. Int. J. Hydrogen Energy 2018, 43, 19279–19292. [Google Scholar] [CrossRef]

- Sofia, D.; Giuliano, A.; Poletto, M.; Barletta, D. Techno-economic analysis of power and hydrogen co-production by an IGCC plant with CO2 capture based on membrane technology. Comp. Aided Chem. Eng. 2015, 37, 1373–1378. [Google Scholar]

- Van Dijk, E.; Walspurger, S.; Cobden, P.; Van Den Brinck, R. Testing of hydrotalcite based sorbents for CO2 and H2S capture for use in sorption enhanced water gas shift. Energy Procedia 2011, 4, 1110–1117. [Google Scholar] [CrossRef]

- Ward, C.; Goldstein, H.; Maurer, R.; Thimsen, D.; Sheets, B.J.; Hobbs, R.; Isgrigg, F.; Steiger, R.; Madden, D.R.; Porcu, A.; et al. Making coal relevant for small scale applications: Modular gasification for syngas/engine CHP applications in challenging environments. Fuel 2020, 267, 117303. [Google Scholar] [CrossRef]

- Giuliano, A.; Catizzone, E.; Barisano, D.; Nanna, F.; Villone, A.; De Bari, I.; Cornacchia, G.; Braccio, G. Towards methanol economy: A techno-envoronmental assessment for a bio-methanol OFMSW/Biomass/Carbon Capture-based integrated plant. Int. J. Heat Technol. 2019, 37, 665–674. [Google Scholar] [CrossRef]

- Hilde, J.V.; Yiang, J. Catalysis in microstructured reactors: Short review on small-scale syngas production andfurther conversion into methanol, DME and Fisher-Tropsch products. Catal. Today 2017, 285, 135–146. [Google Scholar]

- Giuliano, A.; De Bari, I.; Motola, V.; Pierro, N.; Giocoli, A.; Barletta, D. Techno-environmental assessment of two biorefinery systems to valorise the residual lignocellulosic biomass of the Basilicata region. Math. Modell. Eng. Probl. 2019, 6, 317–323. [Google Scholar] [CrossRef]

- Rodrigues Gurgel da Silva, A.; Giuliano, A.; Errico, M.; Rong, B.-G.; Barletta, D. Economic value and environmental impact analysis of lignocellulosic ethanol production: Assessment of different pretreatment processes. Clean Technol. Environ. Policy 2019, 21, 637–654. [Google Scholar] [CrossRef]

- Perez, J.; De Andres, M.J.; Lumbreras, J.; Rodriguez, E. Evaluating carbon footprint of municipal solid waste treatment: Methodological proposal and application to a case study. J. Clean. Prod. 2018, 205, 419–431. [Google Scholar] [CrossRef]

- Li, J.; Ma, X.; Liu, H.; Zhang, X. Life cycle assessment and economic analysis of methanol production from coke oven gas compared with coal and natural gas routes. J. Clean. Prod. 2018, 185, 299–308. [Google Scholar] [CrossRef]

- Bareiß, K.; De, C.; Möckl, M.; Hamacher, T. Life cycle assessment of hydrogen from proton exchange membrane water electrolysis in future energy systems. Appl. Energy 2019, 237, 862–872. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, J.; Shen, L. Simulation of Methanol Production from Biomass Gasification in Interconnected Fluidized Beds. Ind. Eng. Chem. Res. 2009, 48, 5351–5359. [Google Scholar] [CrossRef]

- Ptasinski, K.J.; Hamelinck, C.; Kerkhof, P.J.A.M. Exergy analysis of methanol from the sewage sludge process. Energy Convers. Manag. 2002, 43, 1445–1457. [Google Scholar] [CrossRef]

- Yang, S.; Li, B.; Zheng, J.; Kankala, R.K. Biomass-to-Methanol by dual-stage entrained flow gasification: Design and techno-economic analysis based on system modelling. J. Clean. Prod. 2018, 205, 364–374. [Google Scholar] [CrossRef]

- Toonssen, R.; Woudstra, N.; Verkooijen, A.H.M. Exergy analysis of hydrogen production plants based on biomass gasification. Int. J. Hydrogen Energy 2008, 33, 4074–4082. [Google Scholar] [CrossRef]

- Heyne, S.; Thunman, H.; Harvey, S. Exergy-based comparison of indirect and direct biomass gasification technologies within the framework of bio-SNG production. Biomass Convers. Biorefinery 2013, 3, 337–352. [Google Scholar] [CrossRef]

- Hamelinck, C.N.; Faaij, P.C. Future prospects for production of methanol and hydrogen from biomass. J. Power Sources 2002, 111, 1–22. [Google Scholar] [CrossRef]

- Lv, P.; Yuan, Z.; Ma, L.; Wu, C.; Chen, Y.; Zhu, J. Hydrogen-rich gas production from biomass air and oxygen/steam gasification in downdraft gasifier. Renew. Energy 2007, 32, 2173–2185. [Google Scholar] [CrossRef]

- Ruiz, J.A.; Juárez, M.C.; Morales, M.P.; Munoz, P.; Mendívil, M.A. Biomass gasification for electricity generation: Review of current technology barriers. Renew. Sustain. Energy Rev. 2013, 18, 174–183. [Google Scholar] [CrossRef]

- Wang, L.; Weller, C.L.; Jones, D.D.; Hanna, M.A. Contemporary issues in thermal gasification of biomass and its application to electricity and fuel production. Biomass Bioenergy 2008, 32, 573–581. [Google Scholar] [CrossRef]

- Khoo, H.H.; Ee, W.L.; Isoni, V. Bio-chemicals from lignocellulose feedstock: Sustainability, LCA and the green conundrum. Green Chem. 2016, 18, 1912–1922. [Google Scholar] [CrossRef]

- Elsgaard, L. Greenhouse gas emissions from cultivation winter wheat and winter rapeseed for biofuels and from production of biogas from manure. Available online: https://www.forskningsdatabasen.dk/en/catalog/2389302373 (accessed on 1 April 2020).

- Caposciutti, G.; Baccioli, A.; Ferrari, L.; Desideri, U. Biogas from Anaerobic Digestion: Power Generation or Biomethane Production? Energies 2020, 13, 743. [Google Scholar] [CrossRef]

- Dean, J.; Braun, R.; Penev, M.; Kinchin, C.; Munoz, D. Leveling intermittent renewable energy production through biomass gasification-based hybrid systems. In Proceedings of the ASME 2010 4th International Conference on Energy Sustainability, Phoenix, AZ, USA, 17–22 May 2010. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).