A General Stroke-Based Model for the Straightening Process of D-Type Shaft

Abstract

1. Introduction

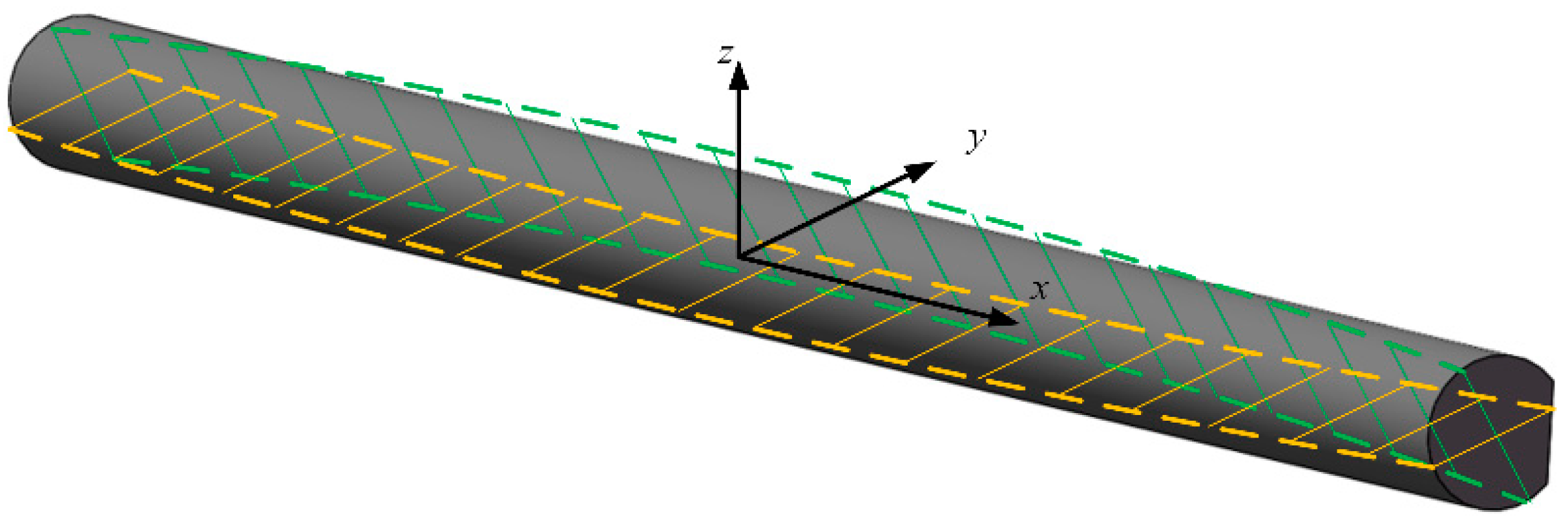

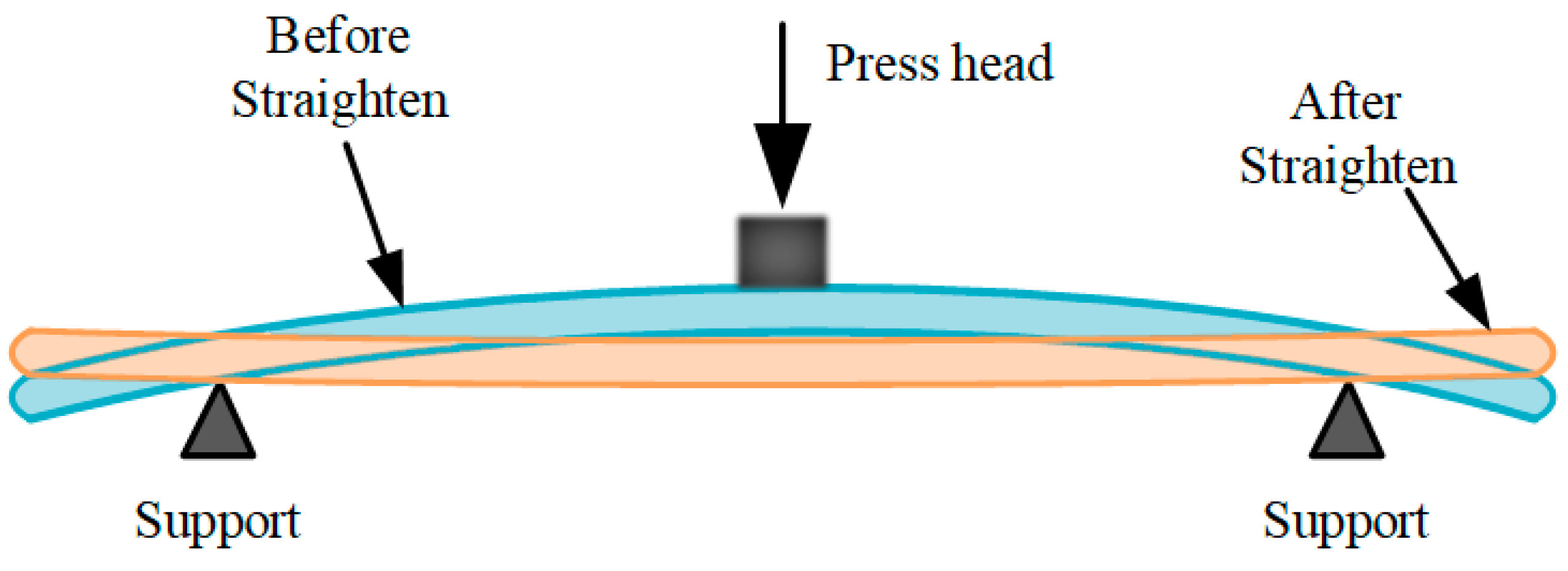

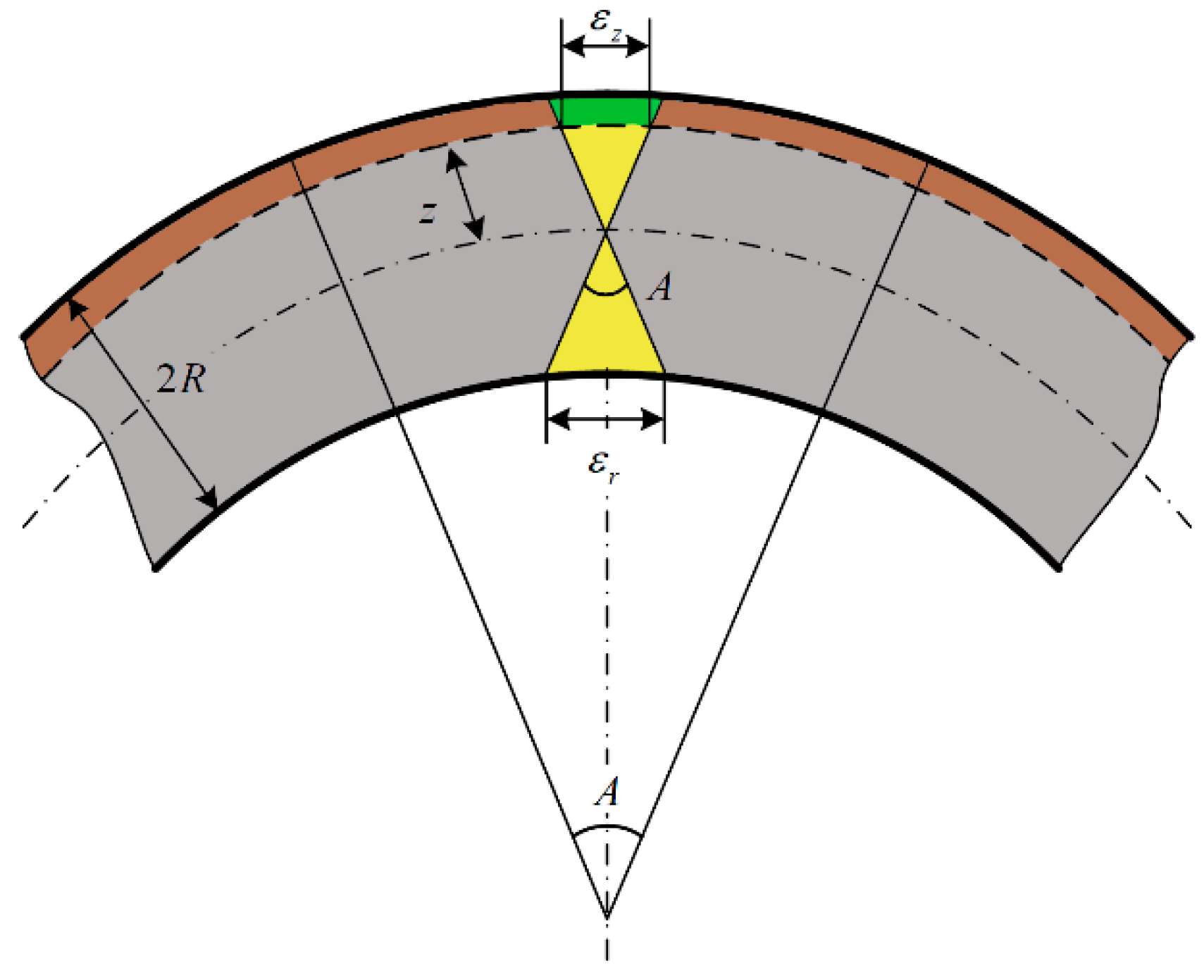

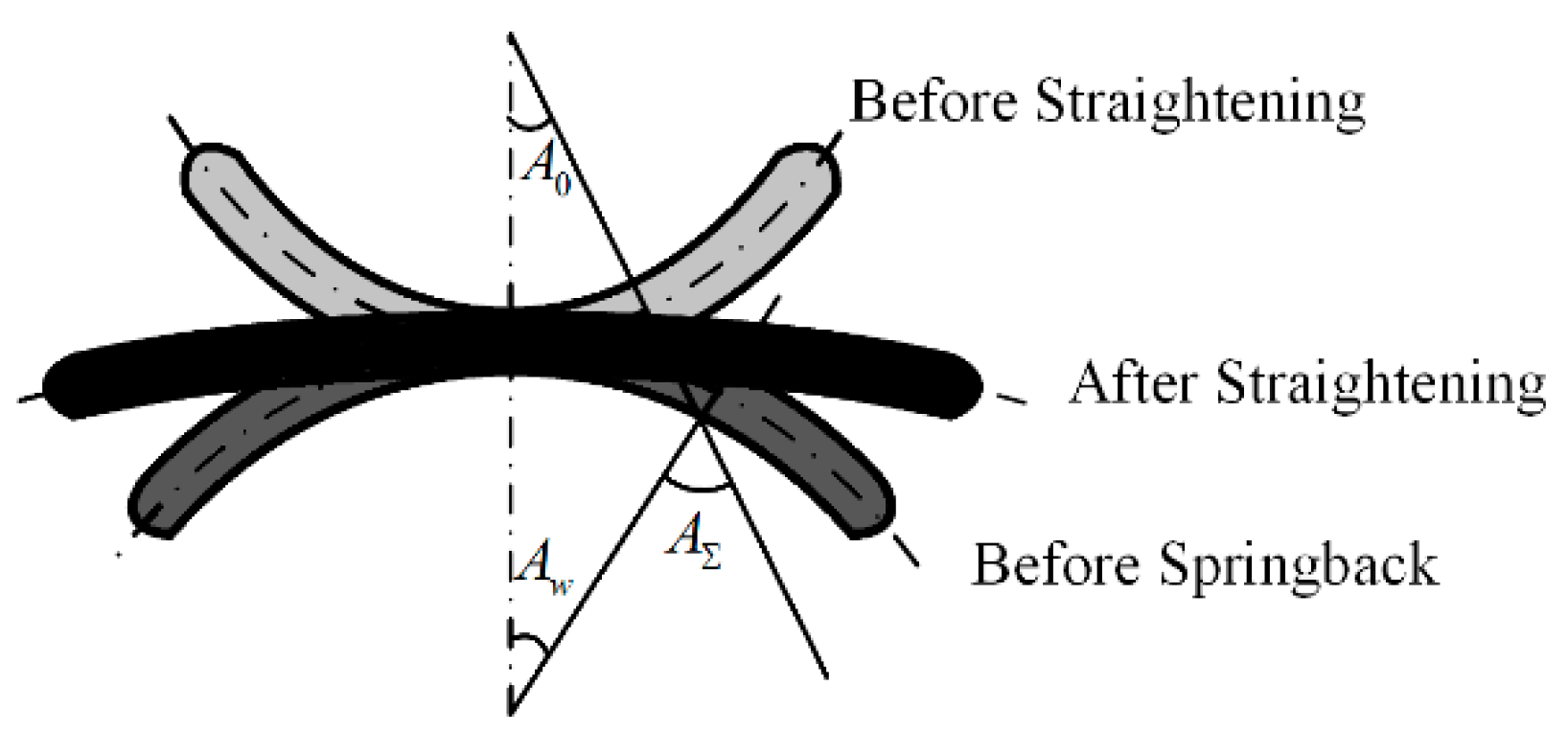

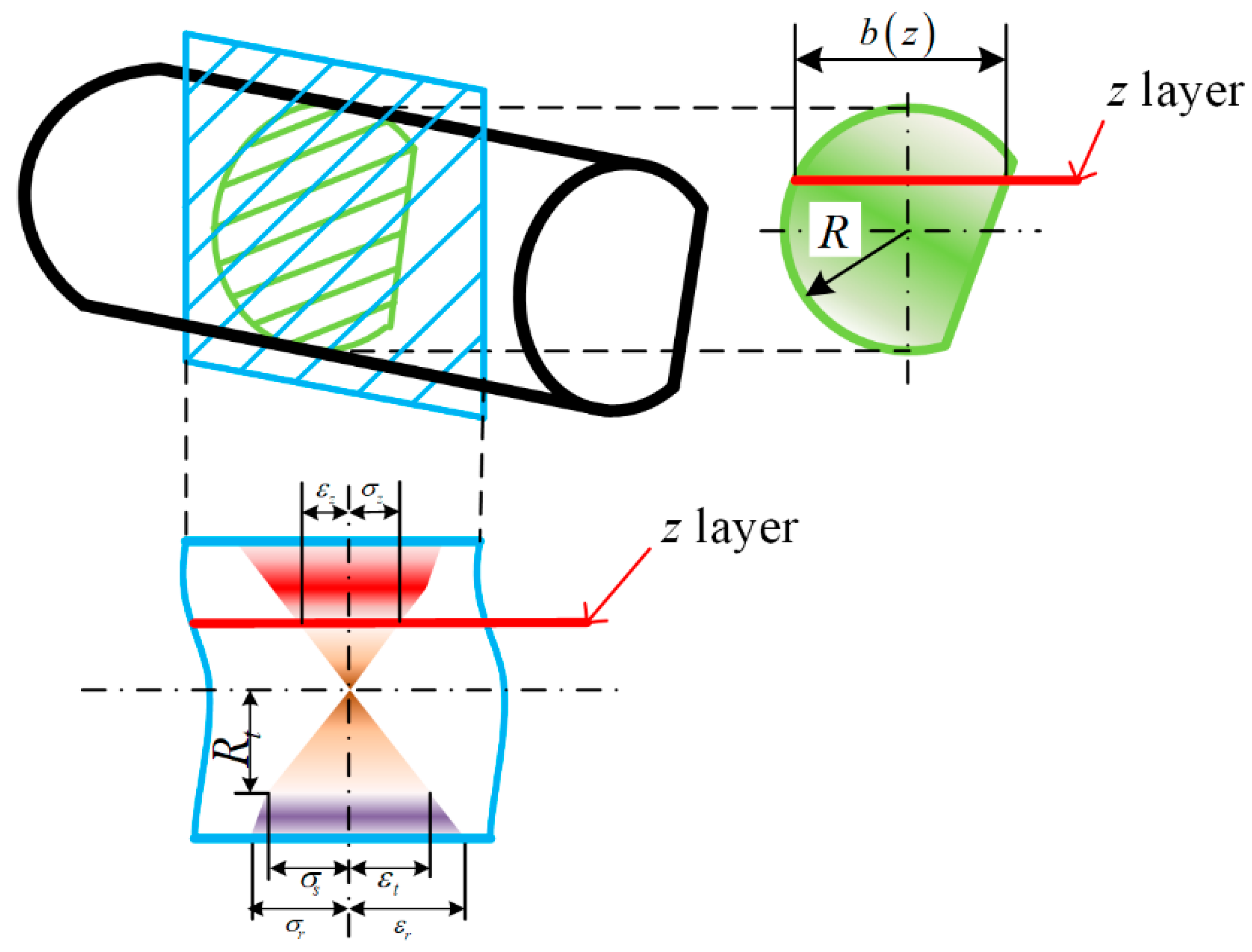

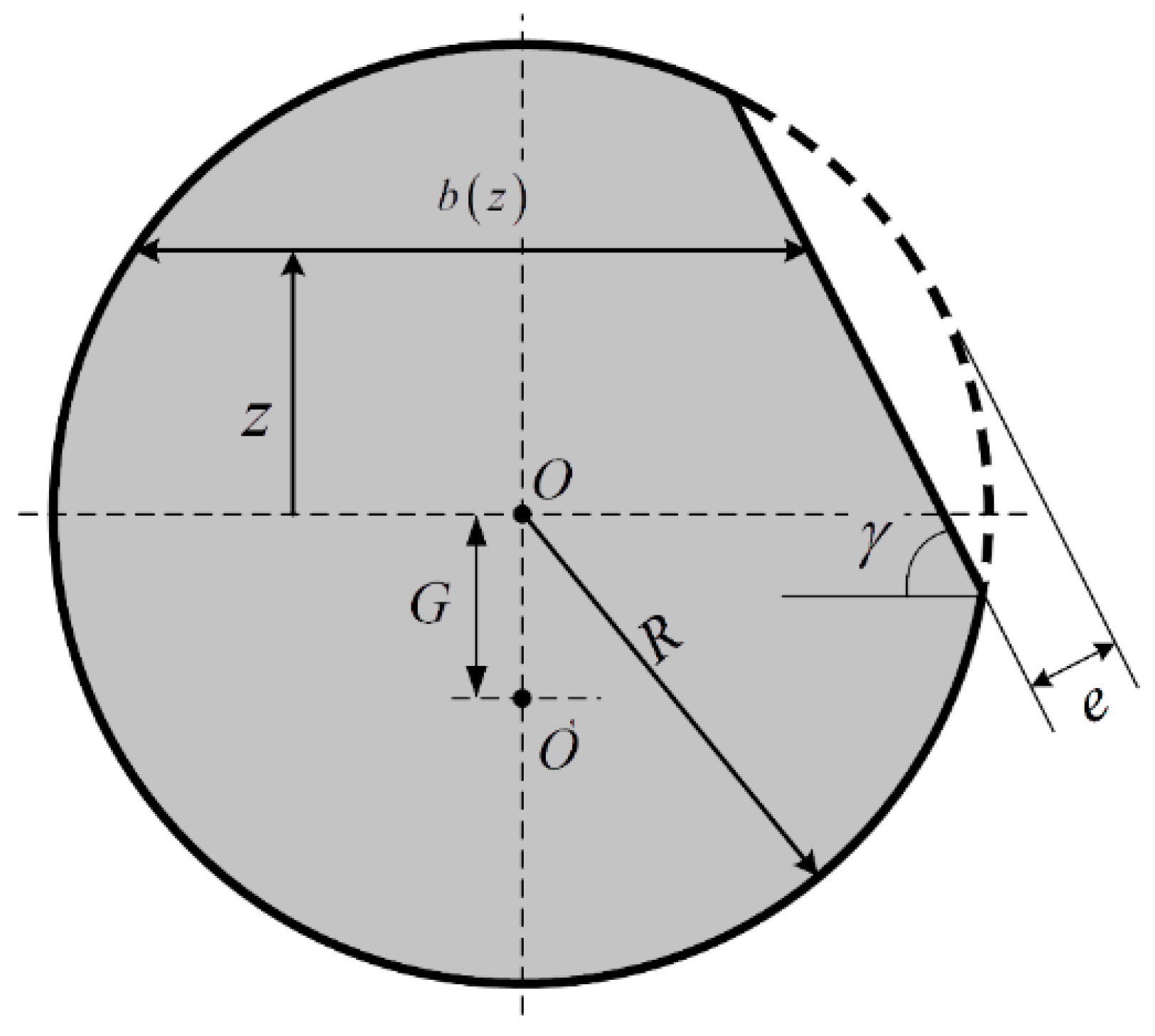

2. Deformation during the Straightening Process

3. Stroke-Based Modeling Principle for the Straightening Process

3.1. Elastic-Plastic Analysis

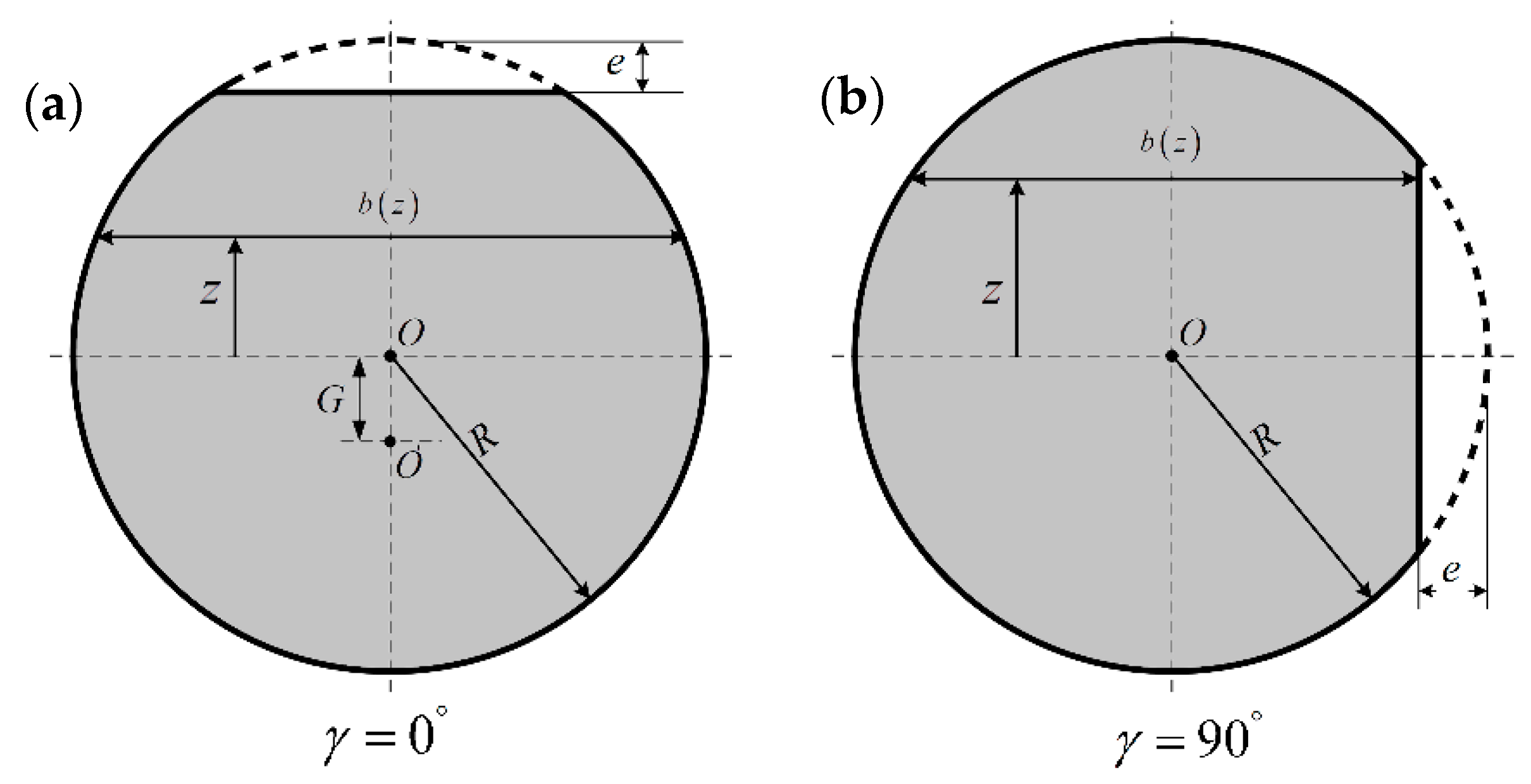

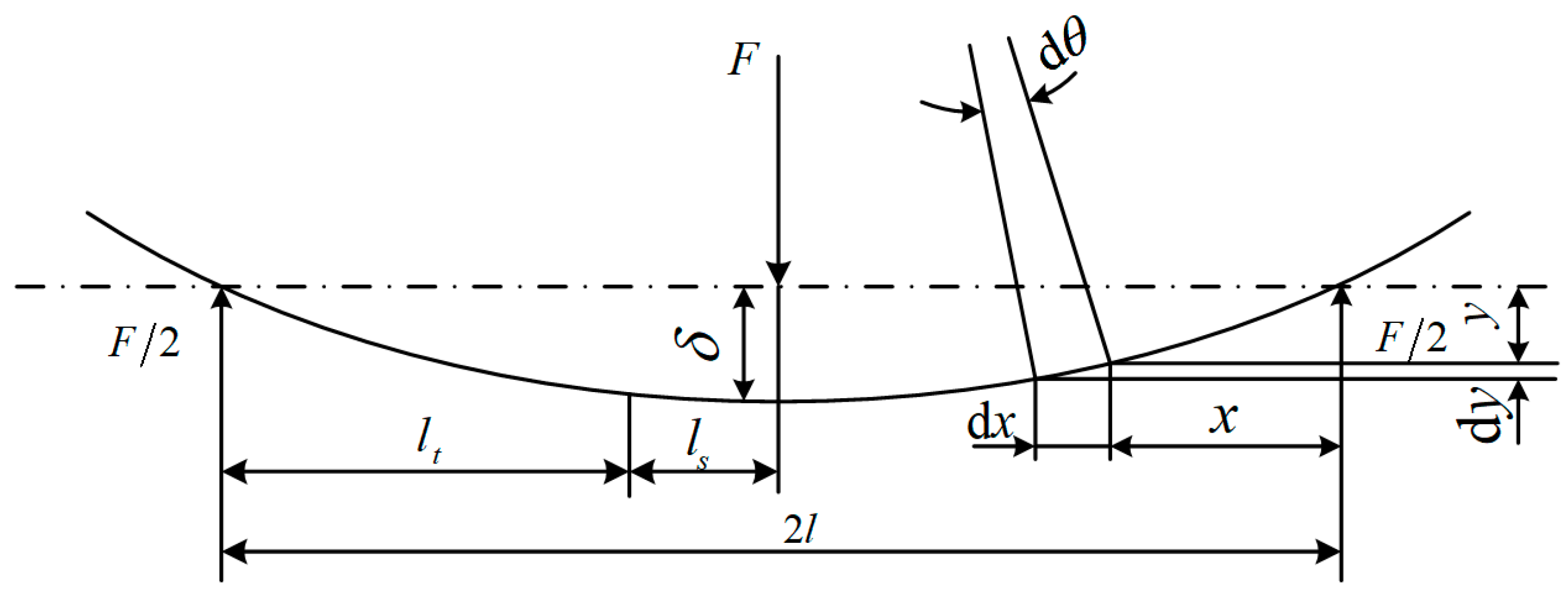

3.2. Deflection Analysis of D-Type Shaft Straightening

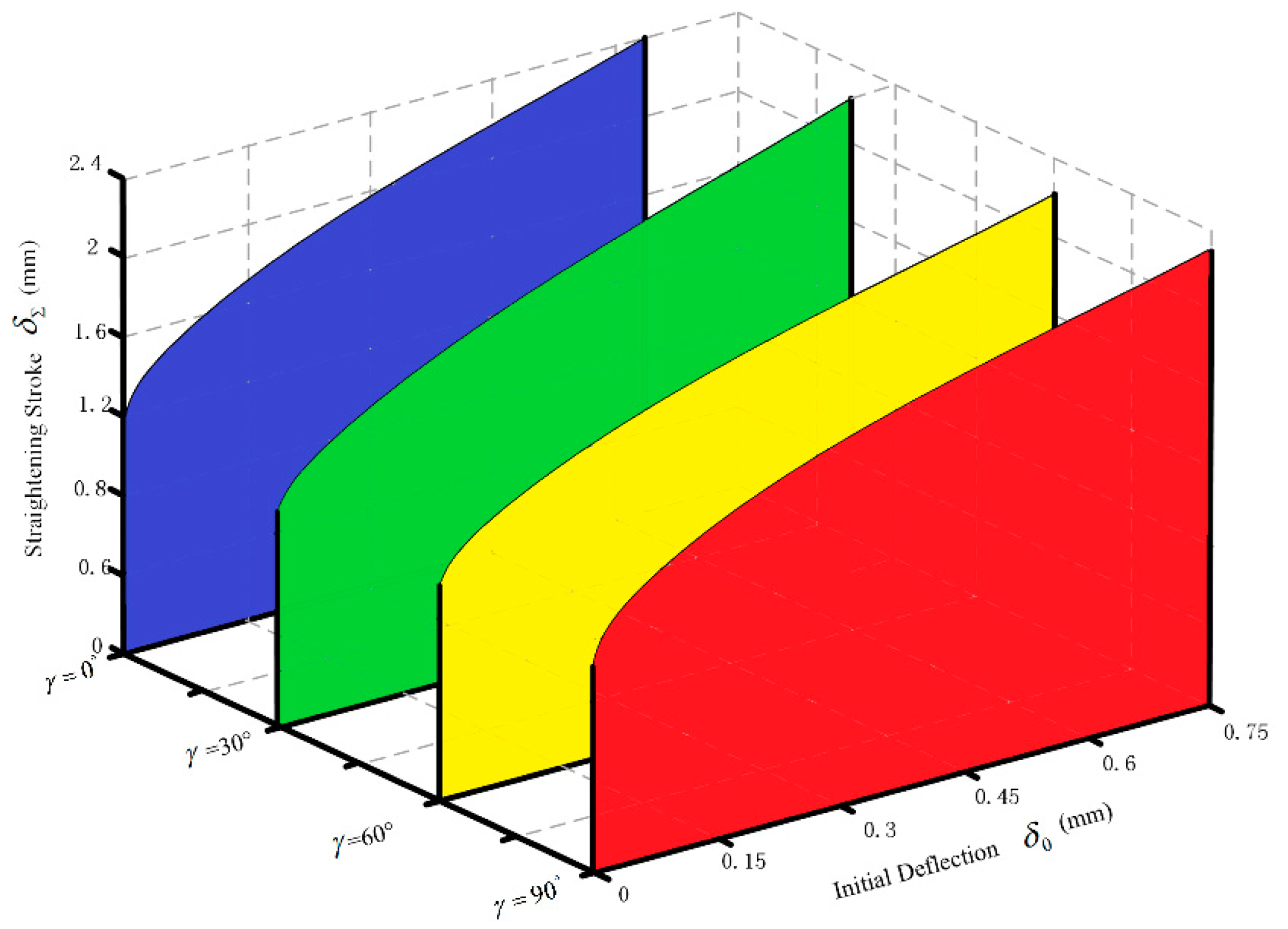

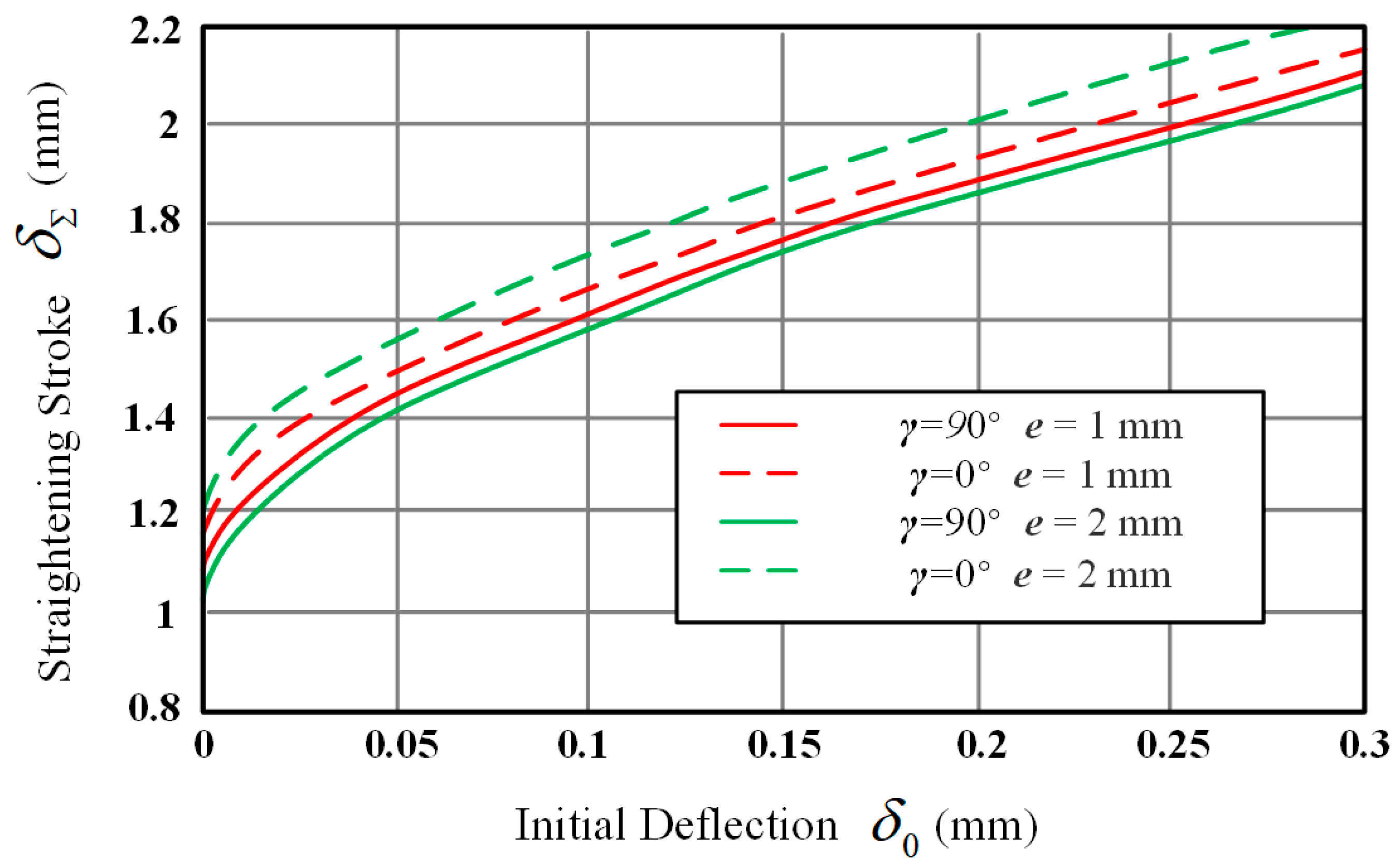

3.3. Straightening Stroke Model

4. Verifications

4.1. FEM Simulation Verification

4.1.1. FEM Model

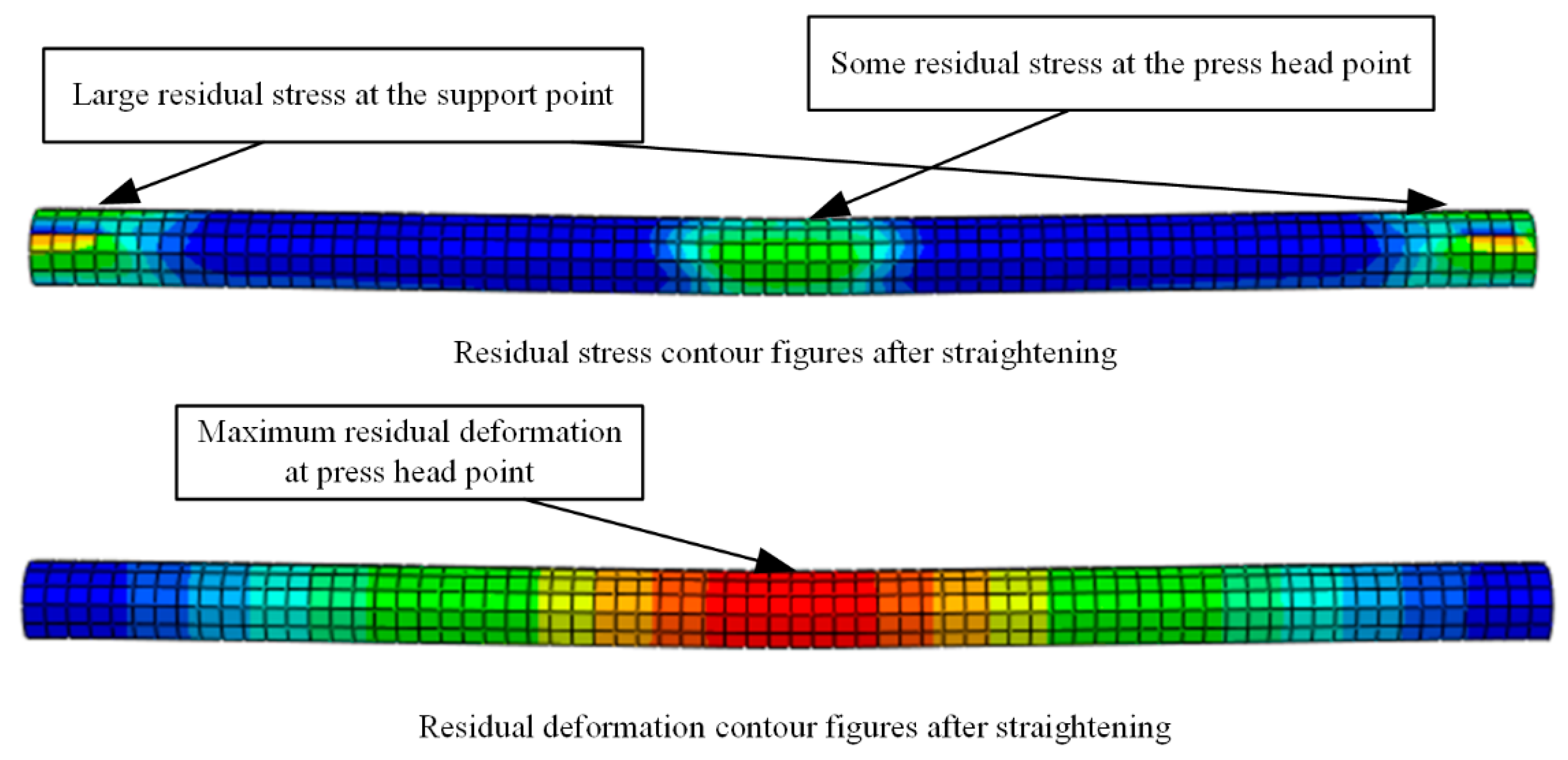

4.1.2. Simulation Results

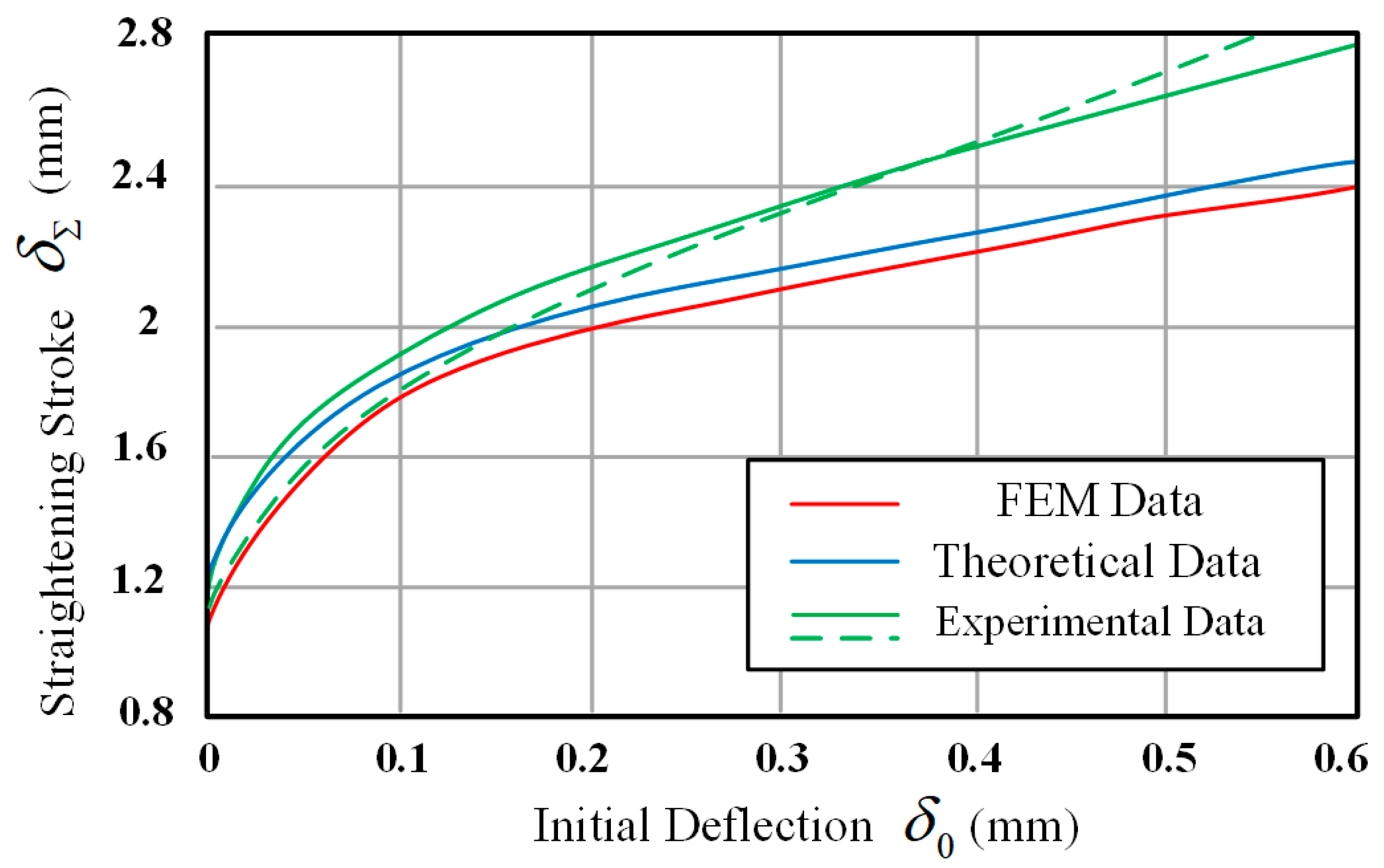

4.2. Experimental Verification

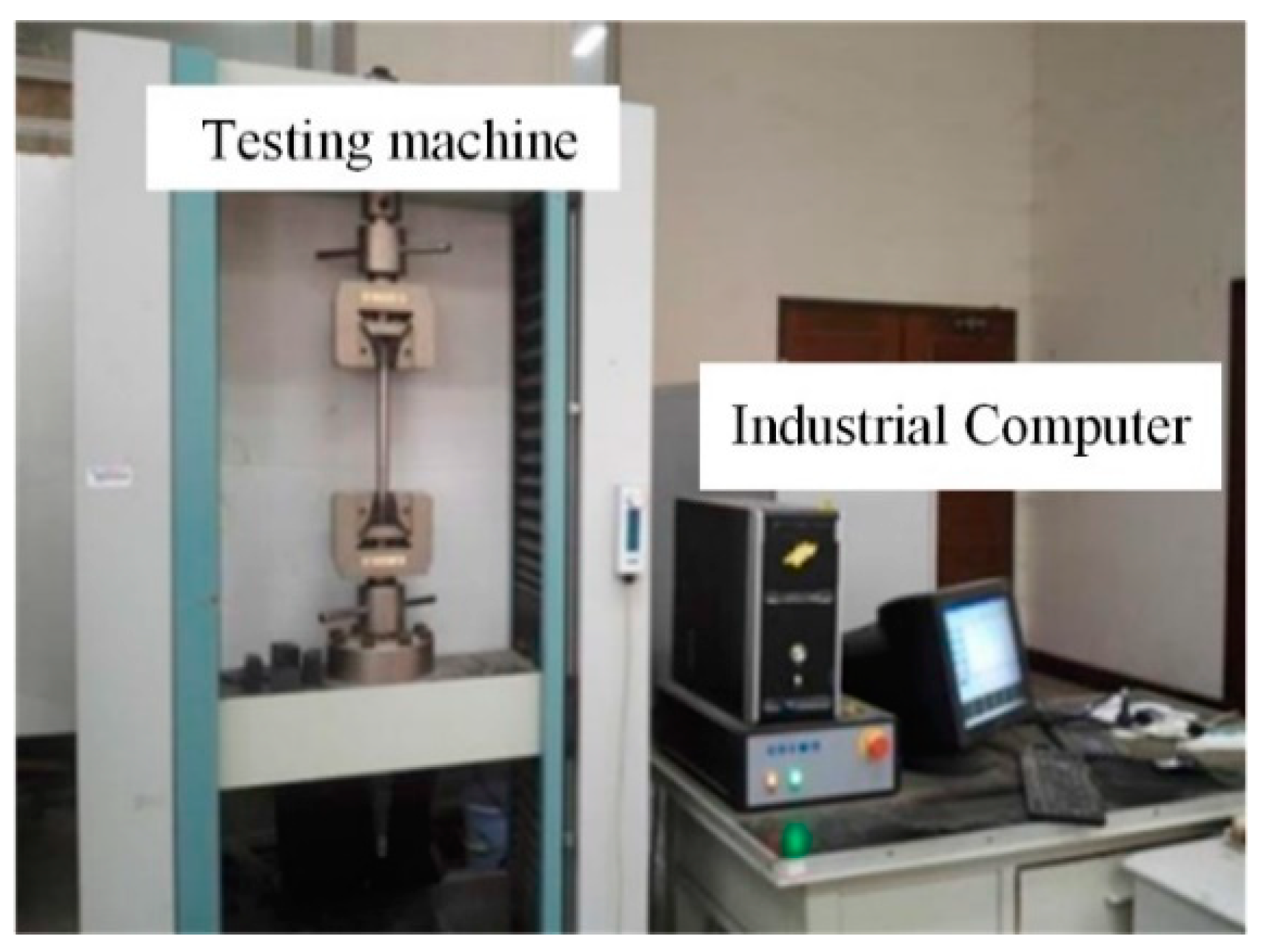

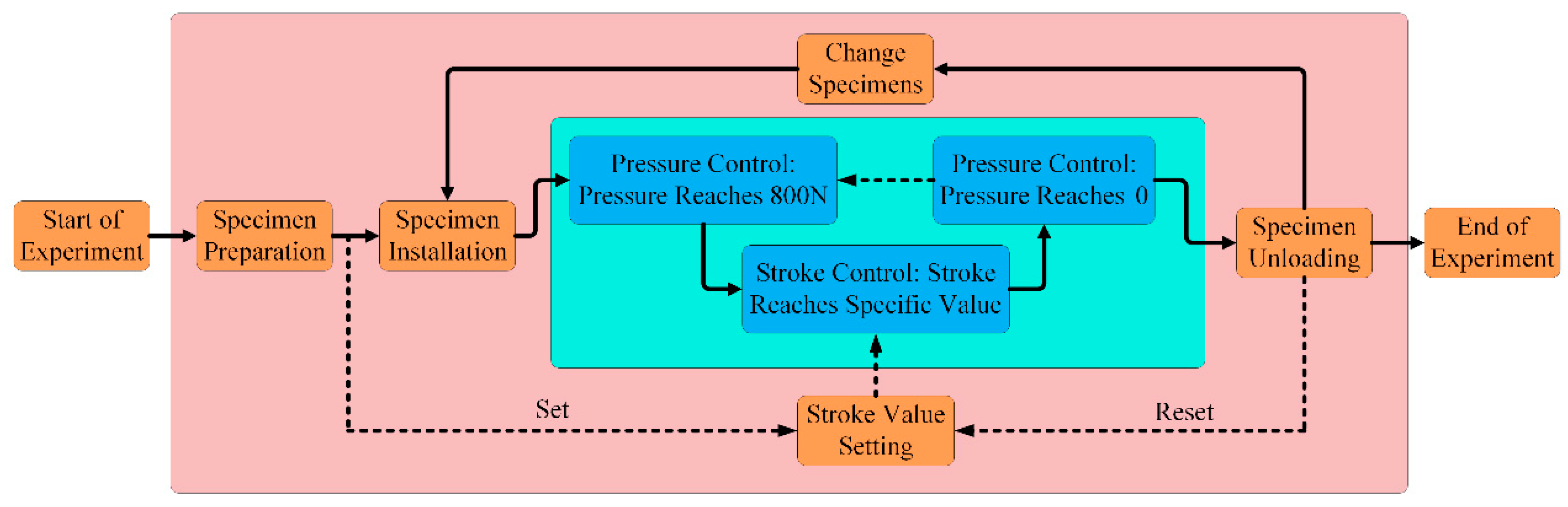

4.2.1. Experimental Design

4.2.2. Experimental Process and Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.Q.; Lu, H.; Wang, Y.J.; Zhang, X.B.; Zhang, J.L.; Ling, H. Variable Span Multistep Straightening Process for Long/Extra-Long Linear Guideways. IEEE Access 2019, 7, 107491–107505. [Google Scholar] [CrossRef]

- Eggertsen, P.-A.; Mattiasson, K. On the modelling of the bending–unbending behaviour for accurate springback predictions. Int. J. Mech. Sci. 2009, 51, 547–563. [Google Scholar] [CrossRef]

- Megharbel, A.E.; Nasser, G.A.E.; Domiaty, A.E. Bending of tube and section made of strain-hardening materials. J. Mater. Process. Technol. 2008, 203, 372–380. [Google Scholar] [CrossRef]

- Sofuoğlu, A. Prediction of stable depth of cuts in turning and milling operations: A new probabilistic approach. J. Br. Soc. Mech. Sci. Eng. 2019, 41, 1007. [Google Scholar] [CrossRef]

- Pei, Y.C.; Wang, J.W.; Tan, Q.C. An investigation on the bending straightening process of D-type cross section shaft. Int. J. Mech. Sci. 2017, 131, 1082–1091. [Google Scholar] [CrossRef]

- Ma, L.F.; Ma, Z.Y.; Jia, W.T.; Lv, Y.Y. Research and verification on neutral layer offset of bar in two-roll straightening process. Int. J. Adv. Manuf. Technol. 2015, 79, 1519–1529. [Google Scholar] [CrossRef]

- Li, J.; Xiong, G.L. Study on calculation method of press straightening stroke based on straightening process model. Key Eng. Mater. 2007, 340, 1345–1350. [Google Scholar] [CrossRef]

- Lu, H.; Ling, H.; Leopold, J.; Zhang, X.; Guo, C.Q. Improvement on straightness of metal bar based on straightening stroke-deflection model. Sci. China Ser. E Technol. Sci. 2009, 52, 1866–1873. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, Y.Q.; Gao, S.; Ling, H. Research on straightening stroke prediction model considering Stress Superposition. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2016, 44, 65–70. [Google Scholar]

- Zhang, Y.; Lu, H.; Zhang, X.; Fan, W.; Ling, H.; Wei, Q.; Ma, M. A novel analytical model for straightening process of rectangle-section metal bars considering asymmetrical hardening features. Adv. Mech. Eng. 2018, 10, 1–14. [Google Scholar] [CrossRef]

- Tsai, S.H.; Kan, H.C. The exact solution of the load-deflection model of a uniformly loaded rectangular cross-section cantilever beam. J. Phys. D Appl. Phys. 2008, 41, 095502. [Google Scholar] [CrossRef]

- Tsai, S.H.; Wang, Y.T.; Kan, H.C. Analysis on the uniformly loaded rectangular cross-section cantilever by a modified load–deflection model. J. Phys. D Appl. Phys. 2009, 42, 045505. [Google Scholar] [CrossRef]

- Chakrabarty, J.; Lee, W.B.; Chan, K.C. An exact solution for the elastic/plastic bending of anisotropic sheet metal under conditions of plane strain. Int. J. Mech. Sci. 2001, 43, 1871–1880. [Google Scholar] [CrossRef]

- Kosel, F.; Videnic, T.; Kosel, T. Elasto-Plastic Springback of Beams Subjected to Repeated Bending/Unbending Histories. J. Mater. Eng. Perform. 2011, 20, 846–854. [Google Scholar] [CrossRef]

- Galvis, J.C.; Maury, H.E.; Hernandez, R.J. Elasto-plastic model to determine the maximum force for shaft straightening process. Ing. Investig. 2017, 37, 107–110. [Google Scholar] [CrossRef]

- Natarajan, A.; Peddieson, J. Simulation of beam plastic forming with variable bending moment. Int. J. Non-Linear Mech. 2011, 46, 14–22. [Google Scholar] [CrossRef]

- Kim, S.-C.; Chung, S.-C. Synthesis of the multi-step straightness control system for shaft straightening processes. Mechatronics 2002, 12, 139–156. [Google Scholar] [CrossRef]

- Cui, F. Straightening Principle and Straightening Machine, 2nd ed.; Met-Allergically Industry Press: Beijing, China, 2007; pp. 7–83. [Google Scholar]

- Li, J.; Xiong, G.L.; Zou, H.J. Process modeling and stroke calculation for shaft straightening. Heavy Mach. 2004, 6, 41–44. [Google Scholar]

- Chen, Z.X.; Chen, H.; Yang, K. A method of the calculation of straightening stroke for automatic precise pressure straightening. J. East China Jiaotong Univ. 2007, 2, 127–130. [Google Scholar]

- Gere, J.M.; Timoshenko, S.P. Mechanics of Materials, 3rd ed.; PWS-Kent Publishing Company: Boston, MA, USA, 1990; pp. 264–353. [Google Scholar]

- Hartley, P. Introduction to computational plasticity. J. Phys. A Math. Gen. 2006, 39, 3850–3851. [Google Scholar] [CrossRef]

- Hodhigere, Y.; Jha, J.S.; Tewari, A. Finite Element Analysis-Based Approach for Stress Concentration Factor Calculation. Proc. Fatigue Durab. Fract. Mech. 2018, 10, 1–6. [Google Scholar]

- Zhao, J.; Cao, H.; Zhan, P.; MA, R. Pure Bending Equivalent Principle for Over-bend Straightening and Its Experimental Verification. J. Mech. Eng. 2012, 48, 28–33. [Google Scholar] [CrossRef]

| Young’s Modulus(GPa) | Poisson’s Ratio | Yield Strength(MPa) | Tensile Strength(MPa) | Elongation(%) | Reinforced Modulus(GPa) |

|---|---|---|---|---|---|

| 210 | 0.269 | 235 | 450 | 26 | 0.89 |

| D-Type Shaft Style | Initial Deflection (mm) | Straightening Stroke (mm) | Error (%) | |

|---|---|---|---|---|

| FEM Results | Theoretical Results | |||

| 0.047 | 1.52 | 1.61 | 5.9 | |

| 0.134 | 1.86 | 1.93 | 3.7 | |

| 0.312 | 2.12 | 2.21 | 4.2 | |

| 0.041 | 1.42 | 1.49 | 4.0 | |

| 0.163 | 1.74 | 1.75 | 0.5 | |

| 0.347 | 2.03 | 1.98 | 2.4 | |

| 0.033 | 1.23 | 1.29 | 4.8 | |

| 0.212 | 1.59 | 1.63 | 2.5 | |

| 0.581 | 2.13 | 2.07 | 2.8 | |

| 0.057 | 1.39 | 1.40 | 0.7 | |

| 0.284 | 1.71 | 1.75 | 2.3 | |

| 0.510 | 2.05 | 1.94 | 4.4 | |

| D-Type Shaft Style | Residual Deflection (mm) | Straightening Stroke (mm) | Error (%) | |

|---|---|---|---|---|

| Experimental Results | Theoretical Results | |||

| 0.05 | 1.62 | 1.61 | 0.6 | |

| 0.13 | 1.98 | 1.93 | 2.5 | |

| 0.31 | 2.43 | 2.21 | 8.9 | |

| 0.04 | 1.50 | 1.49 | 0.6 | |

| 0.16 | 1.79 | 1.75 | 2.2 | |

| 0.35 | 2.13 | 1.98 | 7.0 | |

| 0.03 | 1.31 | 1.29 | 1.5 | |

| 0.21 | 1.70 | 1.63 | 4.1 | |

| 0.58 | 2.21 | 2.07 | 6.3 | |

| 0.06 | 1.37 | 1.40 | 2.1 | |

| 0.28 | 1.91 | 1.75 | 8.3 | |

| 0.51 | 2.10 | 1.94 | 6.7 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, H.; Zang, Y.; Zhang, X.; Zhang, Y.; Li, L. A General Stroke-Based Model for the Straightening Process of D-Type Shaft. Processes 2020, 8, 528. https://doi.org/10.3390/pr8050528

Lu H, Zang Y, Zhang X, Zhang Y, Li L. A General Stroke-Based Model for the Straightening Process of D-Type Shaft. Processes. 2020; 8(5):528. https://doi.org/10.3390/pr8050528

Chicago/Turabian StyleLu, Hong, Yue Zang, Xinbao Zhang, Yongquan Zhang, and Le Li. 2020. "A General Stroke-Based Model for the Straightening Process of D-Type Shaft" Processes 8, no. 5: 528. https://doi.org/10.3390/pr8050528

APA StyleLu, H., Zang, Y., Zhang, X., Zhang, Y., & Li, L. (2020). A General Stroke-Based Model for the Straightening Process of D-Type Shaft. Processes, 8(5), 528. https://doi.org/10.3390/pr8050528