Fault Detection and Identification of Blast Furnace Ironmaking Process Using the Gated Recurrent Unit Network

Abstract

1. Introduction

2. Methodologies

2.1. GRU Neural Network

2.1.1. The Structure of LSTM Cell

2.1.2. The Structure of GRU Cell

2.2. Support Vector Data Description

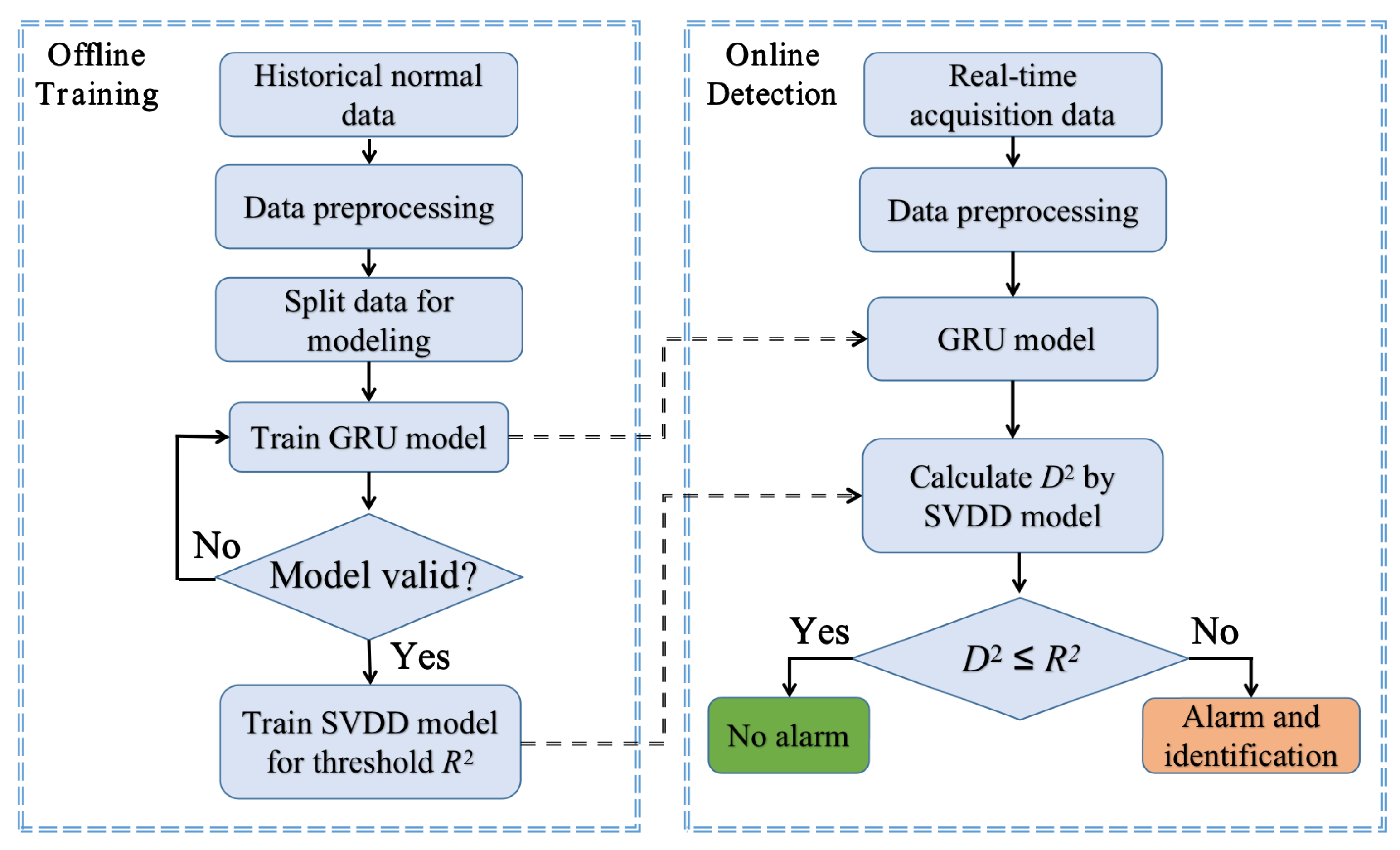

3. Fault Detection and Identification Strategy

3.1. Fault Detection

3.2. Fault Identification

- Obtain historical NOC data;

- Remove extreme values and normalize the training data to have a zero mean and unit variance.

- Set initial parameters of GRU model and train the model;

- If the GRU model is valid, the GRU residuals will be fed into the SVDD model, and the threshold of statistic is obtained.

- Collect online samples;

- Normalize the online samples;

- Use the GRU model trained in the offline process to make prediction and get the residuals;

- Calculate the statistic using SVDD;

- Determine whether to alarm by comparing the statistic and the threshold . If is greater than , the process is faulty, otherwise it is normal.

- If the process is faulty, isolate and identify which variables are most severely affected.

4. Application Studies

4.1. Case 1: Hanging Fault

4.1.1. Residual Generation Using the GRU Network

4.1.2. Fault Detection and Identification

4.2. Case 2: Abnormal Molten Iron Temperature

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Amano, S.; Takarabe, T.; Nakamori, T. Expert system for blast furnace operation at Kimitsu works. ISIJ Int. 1990, 30, 105–110. [Google Scholar] [CrossRef]

- Liao, S. Expert system methodologies and applications–a decade review from 1995 to 2004. Exp. Syst. Appl. 2005, 28, 93–103. [Google Scholar] [CrossRef]

- Tian, H.; Wang, A. A Novel Fault Diagnosis System for Blast Furnace Based on Support Vector Machine Ensemble. ISIJ Int. 2010, 50, 738–742. [Google Scholar] [CrossRef]

- Liu, L.; Wang, A.; Sha, M. Multi-class classification methods of cost-conscious LS-SVM for fault diagnosis of blast furnace. Ind. J. Iron Steel Res. Int. 2011, 18, 17–23. [Google Scholar] [CrossRef]

- An, R.; Yang, C.; Zhou, Z.; Wang, L. Comparison of Different Optimization methods with support vecto machine for blast furnace multi-fault classification. IFAC-PapersOnLine 2015, 48, 1204–1209. [Google Scholar]

- Vanhatalo, E. Multivariate process monitoring of an experimental blast furnace. Qual. Reliab. Eng. Int. 2010, 26, 495–508. [Google Scholar] [CrossRef]

- Zhang, T.; Ye, H.; Wang, W. Fault diagnosis for blast furnace ironmaking process based on two-stage principal component analysis. ISIJ Int. 2014, 54, 2334–2341. [Google Scholar] [CrossRef]

- Shang, J.; Chen, M.; Zhang, H. Increment-based recursive transformed component statistical analysis for monitoring blast furnace iron-making processes: An index-switching scheme. Control Eng. Pract. 2018, 77, 190–200. [Google Scholar] [CrossRef]

- Pan, Y.; Yang, C.; An, R. Robust principal component pursuit for fault detection in a blast furnace process. Ind. Eng. Chem. Res. 2017, 57, 283–291. [Google Scholar] [CrossRef]

- Zhou, B.; Ye, H.; Zhang, H. Process monitoring of iron-making process in a blast furnace with PCA-based methods. Control Eng. Pract. 2016, 47, 1–14. [Google Scholar] [CrossRef]

- Cai, J.; Zeng, J.; Luo, S. A state space model for monitoring of the dynamic blast furnace system. ISIJ Int. 2012, 52, 2194–2199. [Google Scholar] [CrossRef]

- Vanhatalo, E.; Kulahci, M. Impact of autocorrelation on principal components and their use in statistical process control. Qual. Reliab. Eng. Int. 2015, 32, 1483–1500. [Google Scholar] [CrossRef]

- Dong, Y.; Qin, S.J. A novel dynamic pca algorithm for dynamic data modeling and process monitoring. J. Process Control. 2018, 67, 1–11. [Google Scholar] [CrossRef]

- Chiang, L.; Braatz, R.; Russell, E.L. Fault Detection and Diagnosis in Industrial Systems; Springer Science & Business Media: Berlin, Germany, 2002; Volume 44, pp. 197–198. [Google Scholar]

- Qin, S. Survey on data-driven industrial process monitoring and diagnosis. Annu. Rev. Control 2012, 36, 220–234. [Google Scholar] [CrossRef]

- Wang, J.; Yan, J.; Li, C. Deep heterogeneous GRU model for predictive analytics in smart manufacturing: Application to tool wear prediction. Comput. Ind. 2019, 111, 1–14. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long Short-Term Memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Funahashi, K.; Nakamura, Y. Approximation of dynamical systems by continuous time recurrent neural networks. Neural Netw. 1993, 6, 801–806. [Google Scholar] [CrossRef]

- Kim, P.; Lee, D.; Lee, S. Discriminative context learning with gated recurrent unit for group activity recognition. Pattern Recognit. 2018, 76, 149–161. [Google Scholar] [CrossRef]

- Li, G.; Hu, Y.; Chen, H. An improved fault detection method for incipient centrifugal chiller faults using the PCA-R-SVDD algorithm. Comput. Sci. 2014, 116, 104–113. [Google Scholar] [CrossRef]

- Pearson, R.; Neuvo, Y.; Astola, J.; Gabbouj, M. Generalized Hampel filters. EURASIP J. Adv. Signal Process. 2016, 87. [Google Scholar] [CrossRef]

- Chang, Z.; Zhang, Y.; Chen, W. Electricity price prediction based on hybrid model of adam optimized LSTM neural network and wavelet transform. Energy 2019, 187. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are available from the authors. |

| No. | Variable | |

|---|---|---|

| quantity of blast | ||

| temperature of blast | ||

| pressure of blast | ||

| the quantity of oxygen blasted | ||

| CO concentration in top gas | ||

| concentration in top gas | ||

| concentration in top gas |

| Methods | Detection Rate | |

|---|---|---|

| No. | Variable | |

|---|---|---|

| quantity of blast | ||

| temperature of blast | ||

| pressure of blast | ||

| quantity of oxygen blasted | ||

| temperature of cold blast | ||

| top pressure | ||

| CO concentration in top gas | ||

| concentration in top gas | ||

| concentration in top gas | ||

| pressure of cold blast |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouyang, H.; Zeng, J.; Li, Y.; Luo, S. Fault Detection and Identification of Blast Furnace Ironmaking Process Using the Gated Recurrent Unit Network. Processes 2020, 8, 391. https://doi.org/10.3390/pr8040391

Ouyang H, Zeng J, Li Y, Luo S. Fault Detection and Identification of Blast Furnace Ironmaking Process Using the Gated Recurrent Unit Network. Processes. 2020; 8(4):391. https://doi.org/10.3390/pr8040391

Chicago/Turabian StyleOuyang, Hang, Jiusun Zeng, Yifan Li, and Shihua Luo. 2020. "Fault Detection and Identification of Blast Furnace Ironmaking Process Using the Gated Recurrent Unit Network" Processes 8, no. 4: 391. https://doi.org/10.3390/pr8040391

APA StyleOuyang, H., Zeng, J., Li, Y., & Luo, S. (2020). Fault Detection and Identification of Blast Furnace Ironmaking Process Using the Gated Recurrent Unit Network. Processes, 8(4), 391. https://doi.org/10.3390/pr8040391