Abstract

The aim of the study was to examine the effect of fresh vegetable addition on processing efficiency, and to ascertain the energy and water consumption during production of potato-based snack pellets. The extrusion-cooking process with a modified single screw extruder was applied at variable screw speeds and amounts of vegetable additives. A mixture of potato flakes, potato grits and starch was used as a basic recipe. The potato composition was supplemented with fresh pulp of onion, leek, kale and carrot in amounts of 2.5–30.0% as replacement of a related amount of potato starch. The water consumption, as well as processing indicators: the production efficiency, the specific mechanical energy (SME), and the total SME requirements during snack pellets processing at the laboratory scale were evaluated. As a result of this work, we found that the amount of applied vegetable additives had little impact on both processing efficiency and SME depending on the screw speeds applied. Moreover, we saw increased processing efficiency with increased screw speed during extrusion. Of particular note, maximum value of processing efficiency was observed if fresh onion was used as an additive at the highest speed screw. Furthermore, the lowest specific mechanical energy consumption was noted for extrudates supplemented with fresh onion addition processed at the lowest screw speed. The most important limiting of water consumption during processing without negative effects on processing efficiency and quality of the final snack pellets was observed if 20% to 30% of fresh vegetables were used in the recipe. We believe that application of fresh vegetable pulp limited the energy requirements by mitigating the drying process of additives.

1. Introduction

The food industry is one of the greatest consumers of energy and water. Therefore, a thorough superintendence of energy and water flows in this sector is required in order to achieve sustainable development, and this can be achieved through tasks aimed at saving energy and water consumption. This is especially important in an era of growing demands for food and an increasing world population [1]. Moreover, reduction of water consumption to save the freshwater resources is particularly desirable in those parts of the world where such water resources are limited due to ongoing climate changes [2].

One of the most widely used food processing methods is extrusion-cooking. This is commonly applied for the production of inexpensive products, i.e., snacks, breakfast cereals or animal feed [3]. Energy and water consumption during the extrusion-cooking depends on the raw materials, their moisture content, additives used, the type and configuration of the equipment and processing conditions. However, energy consumption occurs even before the extrusion stage [4,5]. Indeed, some extrudates require additional treatment because of conditioning needs, as heating and moisturizing before the extrusion is necessary to achieve proper product quality. For example, for the production of a wide variety of extruded products supplemented with fruits, vegetables or herbs, some thermal treatment is necessitated in order to achieve dry or lyophilized additives, e.g., when tomatoes, apple pomace and vegetable by-products are added to increase nutritional value of extrudates [6,7,8,9,10,11,12].

For many centuries, food and agricultural products have been preserved through air drying. Currently, many fruits and vegetables are still prepared this way to maintain high-quality and enhance shelf-life stability. Drying equipment and operating conditions must comply with raw materials characteristics, quality requirements for final dry product, and economic criteria [13]. Various types of drying processes are used to preserve foodstuffs or additives and can be applied as i.e., convective, microwave, infrared, vacuum or osmotic drying.

In order to prevent moisture congestion and to increase moisture conveyance capacity around the drying product, it is necessary to use hot air [14]. These methods are also associated with various degrees of energy consumption and changes in bioactive food ingredients [15]. For example, a freeze-drying application to vegetables or fruits allows obtaining high quality products, however, it is a time consuming and high-energy process [16].

Extruded snacks are very popular on the market due to the wide variety of applicable raw materials, additives, shapes, colors or tastes. A specific type is that of snacks prepared in a two-stage process: as snacks pellets via extrusion-cooking and expansion by way of further thermal treatment. The snack pellets market is still growing (by 2023, at a CAGR of 5.3%) due to increasing changes in consumer demands. New ingredients, new variants and processing techniques have high impact on innovations in this sector, especially when looking at the new savory snacks manufacturing market [17]. By type, the potato snack pellets segment is estimated to be the largest in the market. Potato-based snack pellets have a lot of advantages, including high bulk density, long shelf-life, low-cost transport, storage convenience, as well as being of various flavors and holding popularity across the spectrum of age and life-style.

The basic raw materials are usually starchy ingredients like potato derivatives such as starch powder or flakes, as well as cereals and pseudo-cereals as corn, rice, wheat, barley, buckwheat and many others. Snack pellet processing utilizes extrusion-cooking technology and include several phases as mixing, extrusion-cooking, cutting, pre-drying and final drying to about 10–12% of moisture content. In brief, raw materials are mixed in a mixing tank equipped with blades, together with cold or warm water according to specific recipes to form the dough, which is transferred inside the extruder. The moisture content of blends should range from 25% to 36% [18]. The dry or liquid ingredients may be applied as a spray in the batch mixer or injected into the extruder. During extrusion-cooking, raw materials are completely cooked under a temperature range from 80 °C to 150 °C in the cooking zone at 120–250 bars and from 65 °C to 90 °C in the forming zone at 60–90 bars, with a residence time of 30–90 s. These conditions are minimal for starch gelatinization and have influence on the expansion. Snack pellets are formed at low pressure to prevent expansion and dried to form a glassy pellet. The drying procedure of pellets is the longest step and takes an average of 4–8 h to reach stable product [17,18,19,20]. These are non-expanded and semi-finished products that are converted into finished snacks after expansion, either through exposure to hot air puffing, deep oil frying or microwave heating. In directly expanded snacks, as crisps or breakfast cereals, the pressure during the extrusion-cooking should be high (30–110 bars) and treatment intensity, temperature, screw speed, shear forces and pressure are more intensive to achieve directly expanded product what is connected with a dramatic pressure drop when material is coming out from the forming die. In snack pellets processing the shear forces and thus pressure should be minimal due to limiting pressure difference before and after the forming die, so the high moisture, low temperature and low screw speed applied led to the avoidance of overheating of water present in the treated blend and limiting expansion of snack pellets. The total energy requirements for producing of third-generation snacks may be quite low when using tuber starches or pre-gelled starches in a formula [5,20].

From the nutritional point of view, starchy raw materials are poor in several components, especially proteins, flavonoids and vitamins, so additional components can be used to improve the nutritional balance of snack foods. Fresh, not processed fruits and vegetables are the richest sources of bioactive components and health-improving ingredients. Carrots include dietary fiber and carotenoids [21]. Kale is primarily a source of phytochemicals, such as polyphenols and vitamins. Moreover, it has high antioxidant capacity [22]. Leek includes bioactive compounds such as flavonoids, polysaccharides and glucosinolates, as well as numerous organosulfur compounds [23]. Onion is characterized by quercetin and quercetin derivatives content in its composition. It is also the most popular sources of dietary flavonoids in human diet [24]. Application of additives not only affects the nutritional value, but also has influence on processing requirements and quality of supplemented foods, especially in terms of the energy or water consumption needed not only for processing, but also for ingredient preparation.

Therefore, the purpose of the work was to investigate potato-based snack pellets with the addition of fresh pulp from selected vegetables to determine the effects of fresh additives on process efficiency, specific energy requirements, as well as on water and energy consumption at the laboratory scale.

2. Materials and Methods

2.1. Raw Material and Processing

The basic raw material composition used for the production of snack pellets was a mixture consisting of 25% potato flakes, 25% potato grits and 50% potato starch (kindly supplied by Pol-Foods Sp. z o. o., Prostki, Poland) as a control sample. During the study, the starch of the basic mixture was replaced to the extent of 2.5–30.0% by fresh vegetable pulp from carrot (C), kale (K), onion (O) and leek (L; purchased on the local market) prepared using a laboratory grinder Retsch GM 200 (Düsseldorf, Germany) with installed power 0.9 kW. The obtained blends before processing were crumbled on a laboratory knife mill LMN-100 (TestChem, Radlin, Poland), installed power 2.2 kW, to particle size below 1 mm. The prepared blends were moistened to 33% of moisture content by adding the appropriate amount of water calculated based on the initial moisture content of the raw materials including water derived from the fresh vegetables. Moistened samples were mixed for 6 min by means of a laboratory mixer (installed power 0.37 kW) to make uniform the water distribution and consistency of each blend. The prepared mixtures were extruded by way of a modified single-screw extruder TS-45 type (ZMCh Metalchem, Gliwice, Poland) with installed power of 10 kW to obtain the flat form of snack pellets. The extrusion was carried out using a L/D = 18 plasticizing unit with an intensive glycol cooling system in the last barrel section [25]. The temperature range in individual extruder sections was as follows: dosing section 80–85 °C, plasticizing section 90–105 °C, cooling section 50–65 °C and forming die 60–75 °C. The pellets were shaped to a flat strip form using a 30 mm × 0.4 mm die head and were cut to the final dimensions of about 30 mm × 30 mm. The snack pellets were then dried in a laboratory shelf air-dryer with installed power 3 kW, at a temperature of 40 °C, for about 10 h to obtain a final moisture content that did not exceed 11%.

2.2. Calculation of Water Consumption

Calculation of water amount was based on the following Formula (1):

where: W—demand of water (kg kg−1), ms—mass of sample (kg), Mf—final moisture content of blend (%) and Mi—initial moisture content of blend (%).

For the snack pellet processing, the moisture content needed to achieve the proper dough consistency and product quality had to range from 25% to 36% (25–36 kg of water for 100 kg of materials) [18,19,20]. The moisture content of blends used in the experiment was set at 33% and the proper amount of water needed was calculated for a basic recipe (control) showing 10.93% of initial moisture content, as well as for the tested blends with fresh pulp addition. Moisture content of ingredients was tested utilizing an air-oven by following AACC 44-15.02 standard procedure [26]. Simulation was also made if dry vegetable components had been added instead of fresh. The difference between water amount needed to moisten dry components and that needed for blends with fresh vegetable addition was calculated.

2.3. Processing Efficiency and Energy Consumption

The processing efficiency (Q) was determined as a ratio of the obtained pellets mass at the defined time. The following formula was used [5]:

where: Q—processing efficiency (kg h−1) m—mass of the obtained snacks (kg), and t—measurement time (h).

The specific mechanical energy (SME) consumption during the extrusion-cooking of snack pellets was calculated according to the Formula (3) [4]:

where: SME—specific mechanical energy (kWh kg−1), n—screw rotations (rpm), P—electric power (kW), L—engine load (%), nmax—maximum screw rotations (rpm) and Q—process efficiency (kg h−1).

The calculation of total specific mechanical energy consumption in a laboratory conditions was done as a sum of specific mechanical energy per kg needed for grinding raw materials, mixing, extrusion and drying of pellets, and was compared with the theoretical simulation of specific mechanical energy consumption during the processing of pellets if the additional drying process of vegetable components would be applied. The following Equation (4) was applied:

Total SMEpellets processing = SME grinding + SME mixing + SME extrusion + SME pellets drying +SME vegetables drying (kWh kg−1),

2.4. Statistical Analysis

The obtained results of extrusion process characteristics were subjected to statistical analysis using Statistica 13.3 software (StatSoft, Tulsa, OK, USA). The data were analyzed utilizing response surface method (RSM) and three-dimensional plots were created to show the effects of independent variables: level of the added vegetables (X1; CA) and screw speed (X2; SS). In the experiment seven levels of X1 were used: 0, 2.5%, 5%, 7.5%, 10%, 20% and 30% and three levels of screw speed (X2): 60, 80 and 100 rpm. The final number of experiments came out to be 21 for single vegetable (84 runs in total). Measured responses were the value of process output (Y1) and SME (Y2). Regression equations and determination coefficients of the process efficiency and specific mechanical energy consumption models for the obtained results were then determined. A second-order polynomial model (Equation (5)) was defined to fit the responses:

where: Y is the response obtained by the fitted model and β0 is the model intercept, β1 and β2 are the linear coefficients, β12 is the interaction coefficient and β11 and β22 are the quadratic coefficients. Moreover, analysis of variance of the effects of processing conditions on studied factors and significance of differences by a Tukey test were performed at the level of confidence α = 0.05.

Y = β0 + β1X1 + β2X2 + β11(X1)2 + β12X1X2 + β22(X2)2,

3. Results and Discussion

3.1. Water Requirements

Consumption of energy, water and other resources should be calculated to enhance efficiency, cost savings and minimize negative environmental impacts [27]. The food industry when compared to other processing sectors needs various amounts of water for each ton of processed product, and there are considerable differences in water consumption amongst the various food sectors. Meat, dairy and fruit and vegetable processors use high amounts of water as compared to bakeries or grain producers involved in dry processes. The treatment of fruits and vegetables needs, for example, especially huge amounts of water for washing and cleaning [28,29]. Consumption of water may, however, be decreased by 30–50% with the application of water efficiency management systems or wastewater re-use after treatment [29]. This water saving strategy is confirmed by the European Commission (EC) Council Directive 96/61/EC on Integrated Pollution Prevention and Control (IPPC), as well as by local rules, i.e., the Food Industry Sustainability Strategy (FISS) of the Department of Environment, Food and Rural Affairs (DEFRA, London, UK), which mandate a 10–15% reduction of water in food industry by 2020 [30]. To meet these goals, there are some technological possibilities indicated as suitable to reduce fresh water use of up to 90%, for example, dry peeling instead of wet peeling, optimization of water flow by flow restrictors, high pressure low volume cleanup systems or dry pre-cleaning prior to washing [28].

The extrusion-cooking technology is a low water consumption process because the initial moisture content of raw material ranges from 12% to 14% for crisps production, up to 35–40% for animal feed or texturized proteins extrusion [18]. For snack pellets, water addition is needed to enable the gelatinization of starch to the amount of 25–36% moisture content in the processed blends. If dry components are used in the recipe, water must be supplied to reach the desired moisture level. In our research, fresh vegetables with their natural water content were used, so significant reduction was seen in amount of water needed for snack pellet processing.

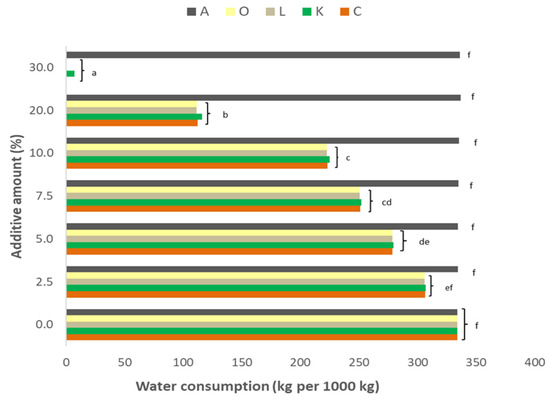

Figure 1 presents the effect of additive levels on water consumption during the extrusion-cooking of potato extrudates with the addition of fresh vegetables. The initial moisture of processed blends was affected by the additive type and amount, so during water calculations, each additive was analyzed separately. The moisture content of potato components was as follows: potato starch 12.87%, potato grits 7.51% and potato flakes 9.26%, so the total blend showed 10.93% of initial moisture content. The amount of water needed for moisturizing the potato blend up to predicted desired moisture of 33% was 0.334 kg per kg of raw materials.

Figure 1.

The effect of the additive level on water consumption during the extrusion-cooking of potato snack pellets with addition of fresh vegetables: A—Control without additives, O—Onion, L—Leek, K—Kale, C—Carrot; a–f Means followed by the same letters do not differ significantly at α = 0.05.

Vegetable additives used in the experiment were characterized by holding the following content of water: carrot—87.10%, kale—85.89%, leek—88.62% and onion—87.35%. Application of fresh vegetable pulp decreased water consumption mostly depending on the amount of additive. Consumption of water needed to prepare proper blends differed even if the additive level was low at 5% in the recipe and significant differences were observed especially if vegetable pulp was more than 10% (significant differences indicated by different letters in Figure 1).

The amount of water was lowered to almost zero value if the vegetable content was around 30%, because the water delivered from the vegetables was sufficient to reach the recommended level. The exception was kale. This characterized the lowest amount of water in fresh material (Figure 1). The use of vegetable additive in the amount of 30% reduced the amount of water consumed in the range from 97.92% (kale) to 99.5% (leek). The amount of water saved during snack pellet processing by extrusion-cooking was 0.33 kg of water per kg of the final product at the laboratory scale and could reach 10 kg if the processing capacity would be at 30 kg h−1. At the industrial scale, production capacity was much higher—up to 1 ton per hour, so it is possible to save 330 kg of fresh water in one processing line. Daily production in an industrial scale with 2-shifts operation could save 5280 kg of water per day and achieve a monthly (28 day) saving of about 147,840 kg (over 147 m3) of water in one high-capacity (1 t h−1) processing line just for the extrusion step. The water needed for washing and peeling of vegetables is necessary to use in all kinds of cleaning steps, both for fresh and dried vegetables, so we could not save it.

The proposed solution could, therefore, minimize the water consumption during the extrusion-cooking of specific types of snack pellets supplemented with fresh vegetable pulp. It should also be pointed out that the quality of pellets remained almost unchanged due to sufficient water content and proper processing conditions that enabled the starch present in the potato components to gelatinize. The only visible effect was the color of pellets due to the natural pigments present in the fresh vegetables used in the experiment.

3.2. Energy Requirements

Extrusion-cooking seems to be considered as an energy consuming process, but this mostly depends on the type and processing capacity of the extruders. Mechanical energy input influences the degree of starch gelatinization and thus the product quality, and is dependent upon the energy input. Small capacity single-screw extruders may require electrical engines support supplying mechanical energy that can vary from 10 to 50 kW, with a production up to 500 kg h−1, and up to 300–400 kW when the production capacity reaches 8–10 tons per hour [18]. Twin-screw extruders offer more intensive treatment of multiple materials, but the energy input is much higher with a similar capacity (i.e., 450 kW at 10 tons per hour) and even up to 900 kW with production capacity of 20 t h−1. Thus, the energy consumption has to be calculated per mass of product, taking into account specific processing conditions and equipment.

Processing output in a laboratory scale was evaluated as the amount of product collected in a specific time. Figure 2 presents the response surface of the extrusion-cooking process efficiency during processing under various screw speeds of potato-based snacks that were supplemented with various fresh vegetables. High values of determination coefficients (Table 1) indicated very good fitting the model of response and the predicted values are similar to the obtained results. Herein, increased rotational screw speed generated increased process efficiency for extrudates supplemented with onion (Figure 2a), leek (Figure 2b), kale (Figure 2c) and carrot (Figure 2d) in a range that was dependent upon the level of additive used. The authors who had previously studied corn extrudates produced at a screw rotational speed that ranged from 60 to 120 rpm noticed that the efficiency of the process increased along with the increased screw speed [4]. Corn-rice instant grits produced at 80–120 rpm also showed the same tendency [31]. Screw speed had, therefore, a significant effect of all the tested snack pellets (p = 0.000; Table 2).

Figure 2.

Response plots of processing efficiency results during the extrusion-cooking of potato-based snack pellets supplemented with addition of various vegetables: (a) onion, (b) leek, (c) kale and (d) carrot.

Table 1.

Multiple regression equations and determination coefficients of process efficiency and specific energy consumption models for various additives in extruded blends.

Table 2.

Results of analysis of variance of the effects of processing conditions on process efficiency and specific energy consumption during the extrusion-cooking.

Matysiak et al. [5] also observed the lowest process efficiency of potato and cereal snack pellets produced with single-screw extruder using the minimum speed of 20 rpm. Moreover, they considered that the initial moisture had a greater impact on process efficiency than the screw speed. They associated this with viscosity reduction of the processed materials, because added water acts as a lubricant. Similar dependencies were found in our research. We saw that with the increased amount of extra vegetable ingredients, a processing efficiency decrease was noticed for snack pellets supplemented with carrot addition up to 20%, with kale in the whole range applied, with onion up to 10%, and with leek up to 2.5% as compared to control potato pellets (Figure 2). Of note, addition of various levels of leek did not affect the processing output.

The maximum value of process efficiency (31.92 kg h−1) was observed for potato pellets with the addition of 30% fresh onion when processed at 100 rpm screw speed, while the lowest (15.6 kg h−1) was obtained if 10% of onion was added while using a screw speed of 60 rpm during processing. Analysis of variance (Table 2) showed that the level of the vegetable additive had a significant effect only for snack pellets supplemented with onion (p = 0.011).

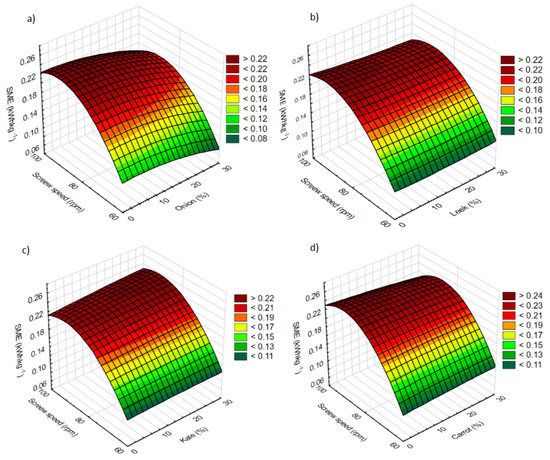

According to Meng et al. [32], high SME is connected with a better degree of starch gelatinization and extrudate expansion. Generally speaking, by promoting the rupture of intermolecular hydrogen bonds, mechanical energy leads to gelatinization of starch [33]. In our experiment, SME results ranged from 0.08 to 0.25 kWh kg−1 for snack pellets processed at various screw speeds depending on the type and amount of vegetable additives applied (Figure 3). The minimum SME value was noted for snack pellets with 30% of onion in the recipe and produced at 60 rpm. The maximum SME was observed for a snack with 10% of carrot when 80 rpm was used during extrusion. The content of the vegetable additives had an insignificant effect on SME for all the tested samples. However, it was noted that speed screw significantly affected the SME values for all extrudates (Table 2). As expected, increasing screw speed during processing increased the mechanical energy requirements.

Figure 3.

Response plots of the effect of processing variables on specific mechanical energy during the extrusion-cooking of potato-based snack pellets with addition of fresh vegetables: (a) carrot, (b) kale, (c) leek and (d) onion.

Some authors have observed, however, that SME depends on other factors. Altan et al. [7] found SME decreasing with increasing temperature and decreasing screw speed during the extrusion-cooking of barley flour and tomato pomace blends at screws speed ranging from 150 to 200 rpm. They concluded that probably a higher temperature reduced the viscosity of material that eventually led to reduced SME. This can be the end-effect of the transformation from solid flow into viscoelastic flow inside the extruder barrel [34]. The increase in SME is accompanied by an increase in rotational speed, because higher screw speed results in higher shearing and friction [35]. Increased SME is also connected with changes in energy input to the screw and the decrease in torque associated with the decrease in apparent viscosity due to the shear thinning behavior of the non-Newtonian materials [8]. Previous researchers have observed that viscosity decreases, which ultimately leads to reduced SME with increase in feed moisture content [36]. We found similar observations because when fresh vegetables were added to the test blends, the moisture content significantly increased and a lowering of SME was observed, especially when carrot and onion were used as additives (Figure 3a,d, respectively).

The total energy requirements for producing snack pellets may be quite low when using tuber starches or pre-gelled starches in the formula [19]. Still, whole cereal grains or high-protein wheat flours compel the need for increased mechanical energy so as to complete the gelatinization of the starch present in the recipe and lower the molecular weight of the starch granules [5]. It must be remembered, however, in snack pellet processing, the energy needs of other technological steps have to be taken into account. These include grinding, mixing or drying of the final products. So, in our research we prepared a simulation of the energy consumption needed to create acceptable snack pellets when supplemented with fresh vegetables in laboratory conditions.

We calculated SME per kg of material for each processing step in regard to the material output, equipment capacity and according to the equipment used and its installed power. SME, herein, was calculated by applying Equation (4), and inputting process time and amount of raw material. The results of this endeavor indicate that the energy consumed by the fresh vegetables at the grinding stage (5000 rpm speed) was 0.019 kWh kg−1, in the mixing process, we found the SME for a laboratory mixer to be 0.012 kWh kg−1. After mixing, the samples were ground again to afford uniform distribution of vegetables within the potato component matrix. For the aforementioned, energy consumption came to be 0.22 kWh kg−1.

SME values calculated for the extrusion of snack pellets varied from 0.08 to 0.25 kWh kg−1 as described previously. Cutting of pellets was done manually, so this step was skipped in a laboratory situation, but in an industrial setting, it must be taken for calculations. A further step was the drying process of pellets. This takes about 10 h in a laboratory air dryer, and the energy consumption was 30 kW during the drying cycle, separately for each type of vegetable additive. So, the electrical energy needed for drying was calculated as 1.67 kWh kg−1 of pellets. Calculated mechanical energy requirements for the processing of snack pellets supplemented with fresh vegetables at laboratory scale varied from 2.001 to 2.17 kWh kg−1 of the product. If we transfer this result into high capacity production with efficiency of 1 ton per hour, our simulation shows the SME to be at 2170 kWh per ton of pellets. If drying of fresh vegetable is applied, an additional 3.89 kWh kg−1 must be added, so the total energy consumption is increased by 5.89–6.06 kWh kg−1. Hence, calculation for 1 ton of material gives 6060 kWh per 1 ton of pellets. This gives three times more energy consumption if dried additives will be used.

The removal of moisture from solids is an integral part of food processing. Almost every food product is dried at least once at one point within its preparation. In Canada, USA, France and UK, the drying process consumes 10–15% of the total national industrial energy demand, in Denmark and Germany, about 20–25%, and about 12% in developing countries [37]. Additional energy needed for the drying process of vegetables was omitted in our research, so no energy was spent for the vegetable drying stage. Theoretically, depending on the type of dryer and raw materials, a great quantity of energy is often applied during the conversion of raw substances into higher-value dry food products. For example, to evaporate 1 kg of water from products, an average of 1.8 kW (6 MJ) of heat is needed during the drying process; however, to reduce the temperature of products under −20 °C, 0.3 kWh (or 1 MJ) of electricity is required during the freezing process [16,38]. Dehydration processes are often the most energy-intensive types of operation met within the food industry, and the most common drying method is convection drying using hot air systems. Of note, some modern drying methods have been developed to decrease the energy consumption or shorten the time of the process.

There are several reports of variation in energy consumption during the drying process as applied within various methods. Some research [39] has indicated that the specific moisture extraction ratio is the most useful indicator for energy efficiency (SMER). This is expressed in kg kW−1 h−1 as the amount of water evaporated divided by energy used. Ananias et al. [40] found fan power consumption from 30 to 122 kWh m−3 when applying accelerated (ACT) and high-temperature (HT) drying schedules for drying of radiata pine, and that this depended on air velocity and stock thickness. Motevali and coworkers [41] found that the specific energy requirement decreased with increasing temperature at all air velocities. Furthermore, the specific energy required for drying pomegranate arils was found to be 50.78 kWh kg−1, with the minimum value being observed at 70 °C at 0.5 m s−1 air velocity and the maximum value of 252.33 kWh kg−1 being seen at 45 °C at 1.5 m s−1 air velocity. For vacuum drying of pomegranate, the found SME ranged from 75 to 325 kWh kg−1.

Beigi et al. [42] reported that the energy consumption for drying apple slices at different air temperatures and flow rates was between 13.89 and 23.94 kWh. Assessment of the specific energy requirement in various dryers used for apple slices drying showed that the highest and lowest values were found for the vacuum and microwave methods, these at 85.45 and 1.2 kWh kg−1 (318.42 and 4.32 MJ/kgw), respectively, being the sum of mechanical energy consumption (kJ) and thermal energy consumption (kJ) per weight of loss water (kg) [41]. So, calculation of the energy needed for the drying process is difficult due to variable techniques and conditions. However, generally, if the drying process is omitted and fresh components are used, a significant energy saving can be achieved. Additionally, vegetables are indispensable sources of vitamins and mineral components, biologically active components, flavoring substances and have a specific color. Drying processes are not indifferent towards inclusion of these nutritionally valuable components, some damage and some severe changes in the physicochemical and organoleptic properties can be observed. It must be remembered that incorporation of fresh vegetable also gives some nutritional benefits [22,43]. Moreover, dried products often have a longer shelf-life. This can reduce the cost of storage and transport, due to the loss of the weight and original shape. If fresh vegetables are used, a higher storage surface is needed, as well as climate control during storage. So, the total energy requirements can be calculated only particularly to the processing operational conditions and equipment.

4. Conclusions

The presented results confirmed the possibility of utilizing fresh vegetables as additives in the extrusion-cooking processing of snack pellets. According to the obtained results, the most efficient production method due to the high process output and low specific energy consumption was extrusion-cooking of snack pellets with the addition of 30% fresh onion and at the 100 and 60 rpm speed of the screw, respectively. For all snack pellets obtained by extrusion of potato components with the addition of fresh vegetables, the screw speed had a significant effect on both process efficiency and SME values, higher screw speed increased processing output as well as specific mechanical energy during extrusion. What is of greater importance, was that the addition of more than 5% of fresh vegetables significantly reduced water consumption during snack pellet extrusion step, and lessened total energy consumption due to the need to not dry the vegetables prior to the extrusion process.

Author Contributions

Conceptualization, K.L.; methodology, K.L., A.W.; validation, K.L.; formal analysis, K.L.; investigation, K.L.; resources, K.L., A.W.; data curation, K.L.; writing—Original draft preparation, K.L.; writing—Review and editing, A.W.; visualization, K.L., A.W.; supervision, A.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Martzopoulou, A.; Komninos, N. The effect of solar energy on the environmental impacts and sustainability of food industry. J. Environ. Manag. 2019, 7, 303–321. [Google Scholar] [CrossRef]

- Nemati-Amirkolaii, K.; Romdhana, H.; Lameloise, M.L. Pinch methods for efficient use of water in food industry: A survey review. Sustainability 2019, 11, 4492. [Google Scholar] [CrossRef]

- Benhur, D.R.; Bhargavi, A.; Kalpana, K.; Vishala, A.D.; Ganapathy, K.N.; Patil, J.V. Development and standardization of sorghum pasta using extrusion technology. J. Food Sci. Technol. 2015, 52, 6828–6833. [Google Scholar] [CrossRef]

- Kręcisz, M. Energy consumption during production of corn extrudates in relation to the process parameters. Agric. Eng. 2016, 20, 125–131. [Google Scholar] [CrossRef]

- Matysiak, A.; Wójtowicz, A.; Oniszczuk, T. Process efficiency and energy consumption during the extrusion of potato and multigrain formulations. Agric. Eng. 2018, 22, 49–57. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Zalewska-Korona, M.; Jabłońska-Ryś, E.; Skalicka-Woźniak, K.; Oniszczuk, A. Chemical characteristics and physical properties of functional snacks enriched with powdered tomato. Pol. J. Food Nutr. Sci. 2018, 68, 251–261. [Google Scholar] [CrossRef]

- Altan, A.; McCarthy, M.L.; Maskan, M. Evaluation of snack foods from barley–tomato pomace blends by extrusion processing. J. Food Eng. 2008, 84, 231–242. [Google Scholar] [CrossRef]

- Singha, P.; Muthukumarappan, K. Effects of processing conditions on the system parameters during single screw extrusion of blend containing apple pomace. J. Food Process Eng. 2017, 40, 1–11. [Google Scholar] [CrossRef]

- Correia, F.K.; Loro, A.C.; Zanatta, S.; Spoto, M.H.F.; Vieira, T.M.F.S. Effect of temperature, time, and material thickness on the dehydration process of tomato. Int. J. Food Sci. 2015, 970724. [Google Scholar] [CrossRef]

- Stojceska, V.; Ainsworth, P.; Plunkett, A.; İbanoğlu, E.; İbanoğlu, S. Cauliflower by-products as a new source of dietary fibre, antioxidants and proteins in cereal based ready-to-eat expanded snacks. J. Food Eng. 2008, 87, 554–563. [Google Scholar] [CrossRef]

- Stojceska, V.; Ainswirth, P.; Plunkett, A.; Ibanoglu, S. The effect of extrusion cooking using different water feed rates on quality of ready-to-eat snacks made from food by-products. Food Chem. 2009, 114, 226–232. [Google Scholar] [CrossRef]

- Makowska, A.; Mildner-Szkudlarz, S.; Obuchowski, W. Effect of brewer’s spent grain addition on properties of corn extrudates with an increased dietary fibre content. Pol. J. Food Nutr. Sci. 2013, 63, 19–24. [Google Scholar] [CrossRef]

- Ratti, C. Advances in Food Dehydration, 1st ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar] [CrossRef]

- Holtz, E.; Ahrné, L.; Rittenauer, M.; Rasmuson, A. Influence of dielectric and sorption properties on drying behaviour and energy efficiency during microwave convective drying of selected food and non-food inorganic materials. J. Food Eng. 2010, 97, 144–153. [Google Scholar] [CrossRef]

- Alibas, I. Energy consumption and colour characteristics of nettle leaves during microwave, vacuum and convective drying. Biosyst. Eng. 2007, 96, 495–502. [Google Scholar] [CrossRef]

- Lue-lue, H.; Min, Z.; ArunS, M.; Dong-feng, S.; Guan-wei, T.; Shameel, T. Studies on decreasing energy consumption for a freeze-drying process of apple slices. Dry. Technol. 2009, 27, 938–946. [Google Scholar] [CrossRef]

- Snack Pellets Market by Type (Potato, Corn, Rice, Tapioca, Multigrain), Form (Laminated, Tridimensional, Die-face, Gelatinized), Technique (Twin-screw extruder, Single-screw extruder), Flavor (Plain, Flavored, Nutritional), and Region–Global Forecast to 2023. 2018. Available online: https://www.marketsandmarkets.com/Market-Reports/snack-pellets-market-34540077.html (accessed on 2 December 2019).

- Moscicki, L. Extrusion-Cooking Techniques: Applications, Theory and Sustainability; WILEY-VCH Verlag GmbH& Co. KGaA: Weinheim, Germany, 2011. [Google Scholar]

- Gandhi, N.; Kaur, K.; Kaur, A.; Singh, B.; Singh, P. Technological innovations in third generation snack foods. Progress. Res. Int. J. 2016, 11, 4948–4959. [Google Scholar]

- Panak Balentić, J.; Babić, J.; Jozinović, A.; Ačkar, Đ.; Miličević, B.; Muhamedbegović, B.; Šubarić, D. Production of third-generation snacks. Croat. J. Food Sci. Technol. 2018, 10, 98–105. [Google Scholar] [CrossRef][Green Version]

- Tiwari, S.; Upadhyay, N.; Singh, A.K.; Meena, G.S.; Arora, S. Organic solvent-free extraction of carotenoids from carrot biowaste and its physico-chemical properties. J. Food Sci. Technol. 2019, 56, 1–10. [Google Scholar] [CrossRef]

- Kasprzak, K.; Oniszczuk, T.; Wójtowicz, A.; Waksmundzka-Hajnos, M.; Olech, M.; Nowak, R.; Polak, R.; Oniszczuk, A. Phenolic acid content and antioxidant properties of extruded corn snacks enriched with kale. J. Anal. Methods. Chem. 2018, 2, 1–7. [Google Scholar] [CrossRef]

- Kratchanova, M.; Nikolova, M.; Pavlova, E.; Yanakieva, I.; Kussovski, V. Composition and properties of biologically active pectic polysaccharides from leek (Allium porrum). J. Sci. Food Agric. 2010, 90, 2046–2051. [Google Scholar] [CrossRef]

- Gawlik-Dziki, U.; Świeca, M.; Dziki, D.; Baraniak, B.; Tomiło, J.; Czyż, J. Quality and antioxidant properties of breads enriched with dry onion (Allium cepa L.) skin. Food Chem. 2013, 138, 1621–1628. [Google Scholar] [CrossRef] [PubMed]

- Bouasla, A.; Wójtowicz, A. Rice-buckwheat gluten-free pasta: Effect of processing parameters on quality characteristics and optimization of extrusion-cooking process. Foods 2019, 8, 496. [Google Scholar] [CrossRef] [PubMed]

- AACC Approved Methods of the AACC, 10th ed.; American Association of Cereal Chemists: St. Paul, MI, USA, 2000.

- Nikmaram, R.; Rosentrater, K.A. Overview of some recent advances in improving water and energy efficiencies in food processing factories. Front. Nutr. 2019, 6. [Google Scholar] [CrossRef] [PubMed]

- Ölmez, H. Minimizing water consumption in the fresh-cut processing industry. Stewart Postharvest Rev. 2013, 9, 1–6. [Google Scholar] [CrossRef]

- Letho, M.; Sipilä, I.; Alakukku, L.; Kymäläinen, H.R. Water consumption and wastewaters in fresh-cut vegetable production. Agric. Food Sci. 2014, 23, 246–256. [Google Scholar] [CrossRef]

- FISS. DEFRA (United Kingdom-Department for Environment, Food and Rural Affairs) Food Industry Sustainability Strategy (FISS). 2006. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/69283/pb11649-fiss2006-060411.pdf (accessed on 2 December 2019).

- Kręcisz, M.; Wójtowicz, A.; Oniszczuk, A. Effect of selected parameters on process efficiency and energy consumption during the extrusion-cooking of corn-rice instant grits. Agric. Sci. Procedia 2015, 7, 139–145. [Google Scholar] [CrossRef][Green Version]

- Meng, X.; Threinen, D.; Hansen, M.; Driedger, D. Effects of extrusion conditions on system parameters and physical properties of a chickpea flour-based snack. Food Res. Int. 2010, 43, 650–658. [Google Scholar] [CrossRef]

- Pardhi, S.D.; Singh, B.; Nayik, G.A.; Dar, B.N. Evaluation of functional properties of extruded snacks developed from brown rice grits by using response surface methodology. J. Saudi Soc. Agric. Sci. 2019, 18, 7–16. [Google Scholar] [CrossRef]

- Ali, S.; Singh, B.; Sharma, S. Response surface analysis and extrusion process optimization of maize-mungbean based instant weaning food. Int. J. Food Sci. Technol. 2016, 51, 2301–2312. [Google Scholar] [CrossRef]

- Zhuang, H.; An, H.; Chen, H.; Xie, Z.; Zhao, J.; Xu, X.; Jin, Z. Effect of extrusion parameters on physicochemical properties of hybrid indica rice (type 9718) extrudates. J. Food Process Pres. 2010, 34, 1080–1102. [Google Scholar] [CrossRef]

- Chang, Y.K.; Martinez-Bustos, F.; Park, T.S.; Kokini, J.L. The influence of specific mechanical energy on cornmeal viscosity measured by an on-line system during twin-screw extrusion. Braz. J. Chem. Eng. 1999, 16, 285–295. [Google Scholar] [CrossRef]

- Mujumdar, A.S. Handbook of Industrial Drying, 4th ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Banakar, A.; Ghobadian, B.; Khoshtaghaza, M.H. Comparison of energy parameters in various dryers. Energ. Convers. Manag. 2014, 87, 711–725. [Google Scholar] [CrossRef]

- Raghavan, G.S.V.; Rennie, T.J.; Sunjka, P.S.; Orsat, V.; Phaphuangwittayakul, W.; Terdtoon, P. Overview of new techniques for drying biological materials with emphasis on energy aspects. Braz. J. Chem. Eng. 2005, 22, 195–201. [Google Scholar] [CrossRef]

- Ananias, R.A.; Ulloa, J.; Elustondo, D.M.; Salinas, C.; Rebolledo, P.; Fuentes, C. Energy consumption in industrial drying of radiata pine. Dry. Technol. 2012, 30, 774–779. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Khoshtagaza, M.H. Evaluation of energy consumption in different drying methods. Energ. Convers. Manag. 2011, 52, 1192–1199. [Google Scholar] [CrossRef]

- Beigi, M. Energy efficiency and moisture diffusivity of apple slices during convective drying. Food Sci. Technol. Camp. 2016, 36, 145–150. [Google Scholar] [CrossRef]

- Lisiecka, K.; Wójtowicz, A. The production efficiency and specific energy consumption during processing of corn extrudates with fresh vegetables addition. Agric. Eng. 2019, 23, 15–23. [Google Scholar] [CrossRef][Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).