Study on the Effects of Physical Properties of Tenera Palm Kernel during Drying and Its Moisture Sorption Isotherms

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Physical Properties of Palm Kernel

2.2.1. Size and Shape

2.2.2. Surface Area and Specific Surface Area

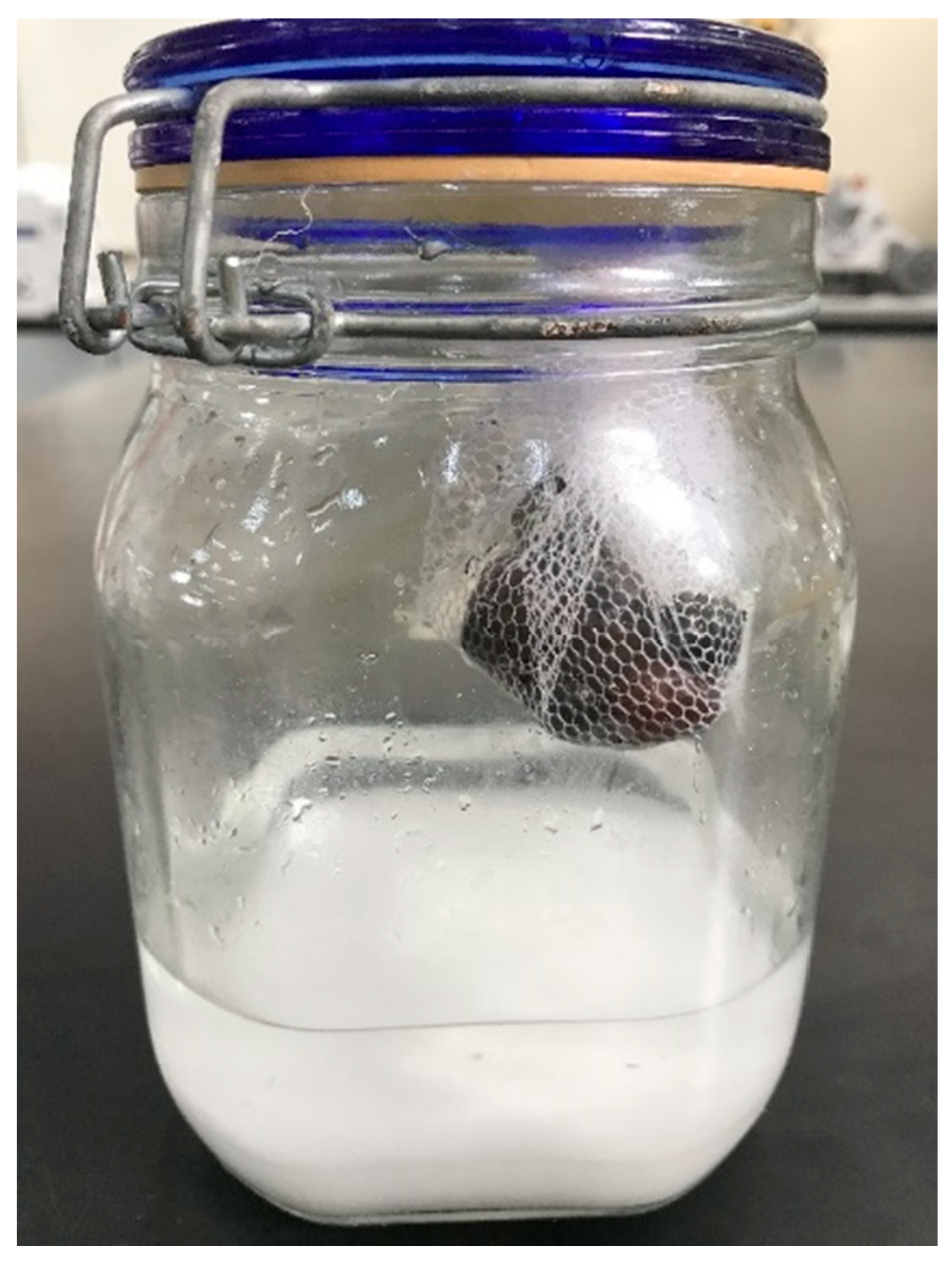

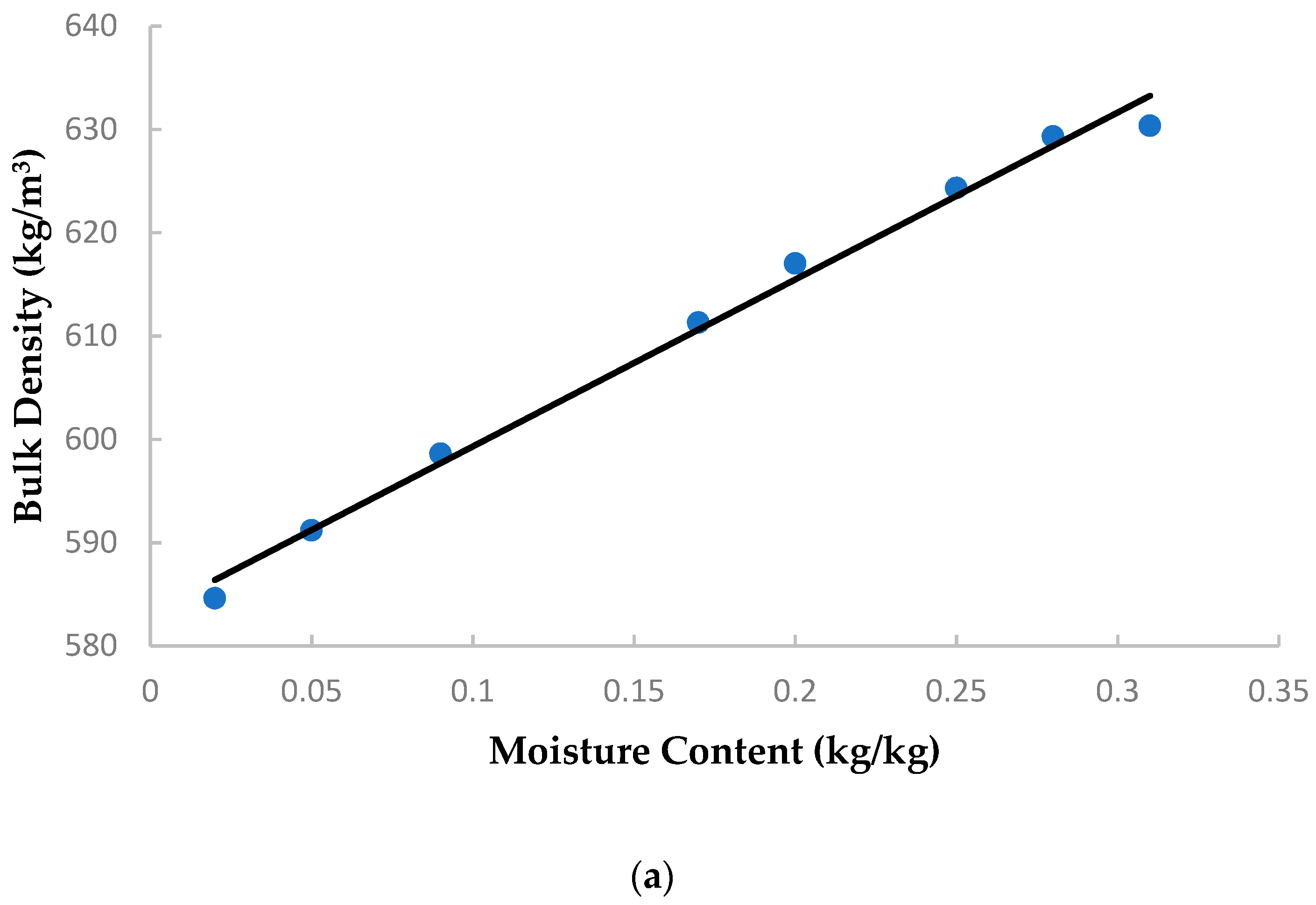

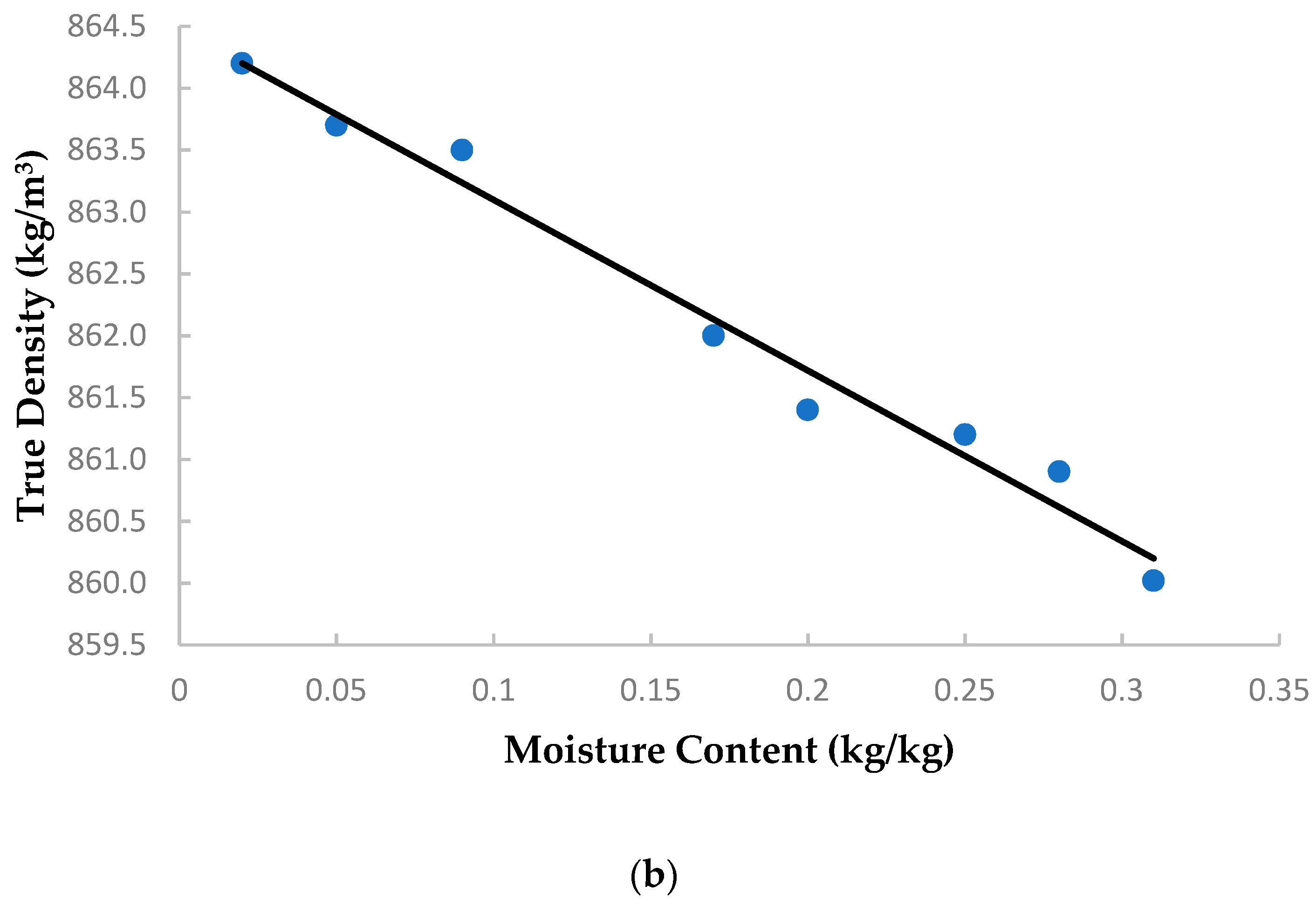

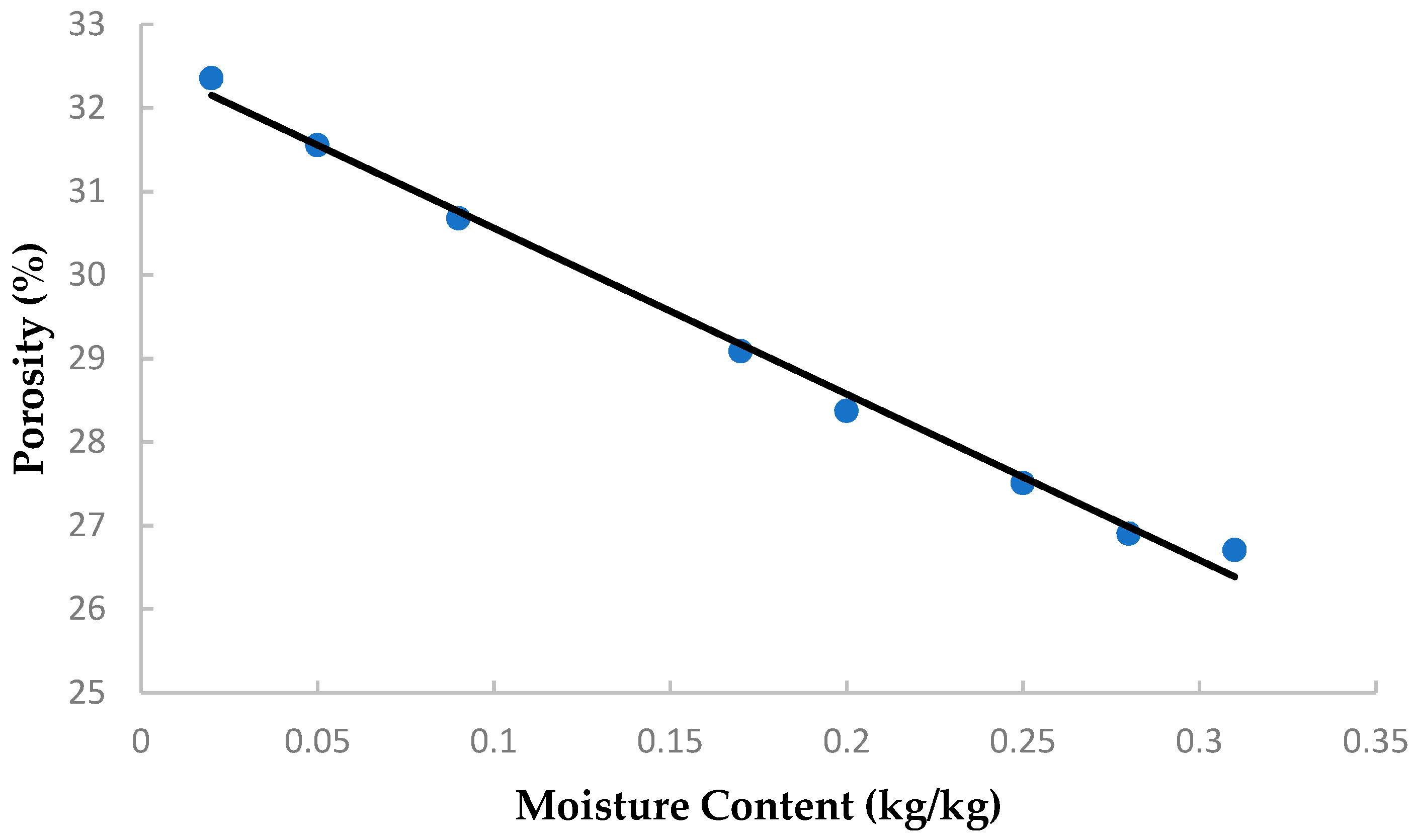

2.2.3. Bulk Density, True Density, and Porosity

2.2.4. Scanning Electron Microscope (SEM)

2.3. Equilibrium Moisture Content

2.3.1. Experimental Procedure

2.3.2. Curve Fitting and Statistical Analysis

3. Results

3.1. Physical Properties

3.1.1. Size and Shape

3.1.2. Surface Area and Specific Surface Area

3.1.3. Bulk Density, True Density, and Porosity

3.1.4. Morphology Structure

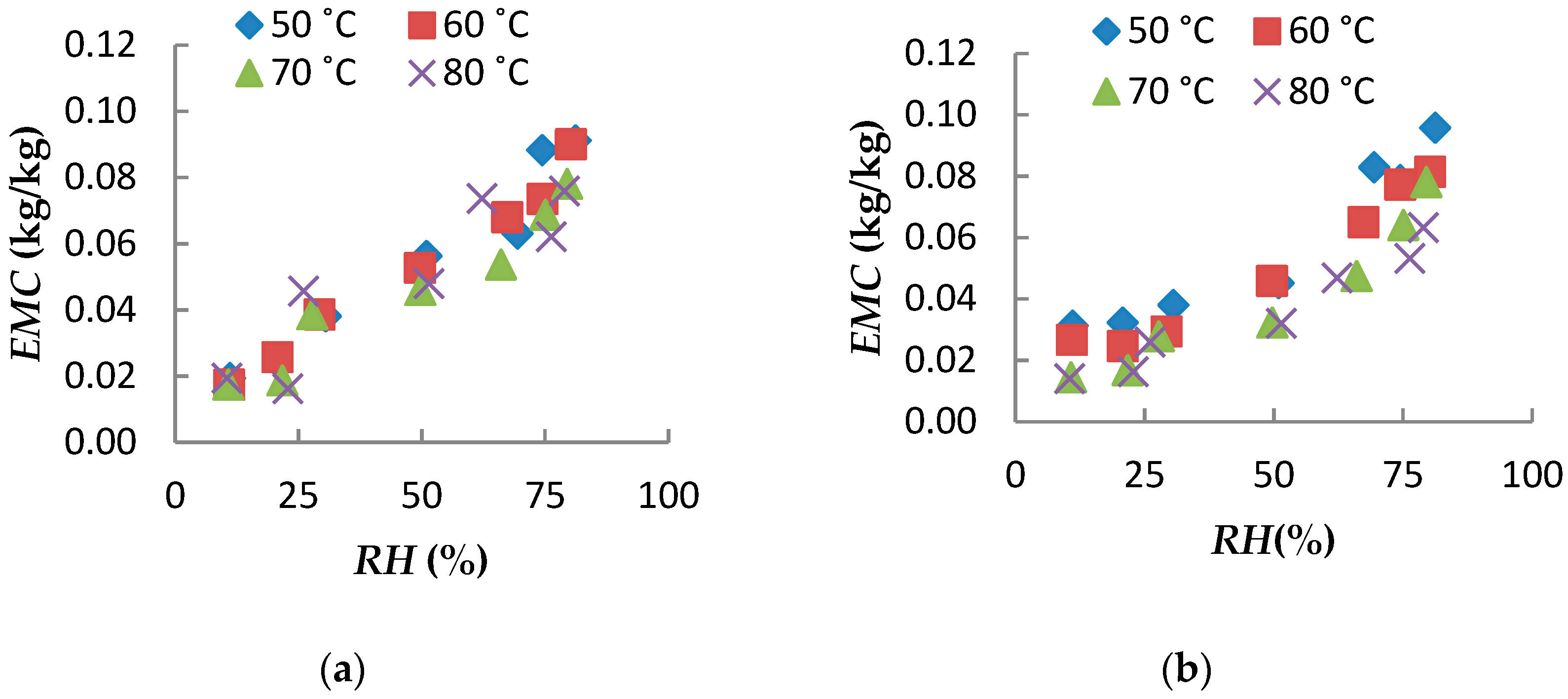

3.2. Desorption Isotherms

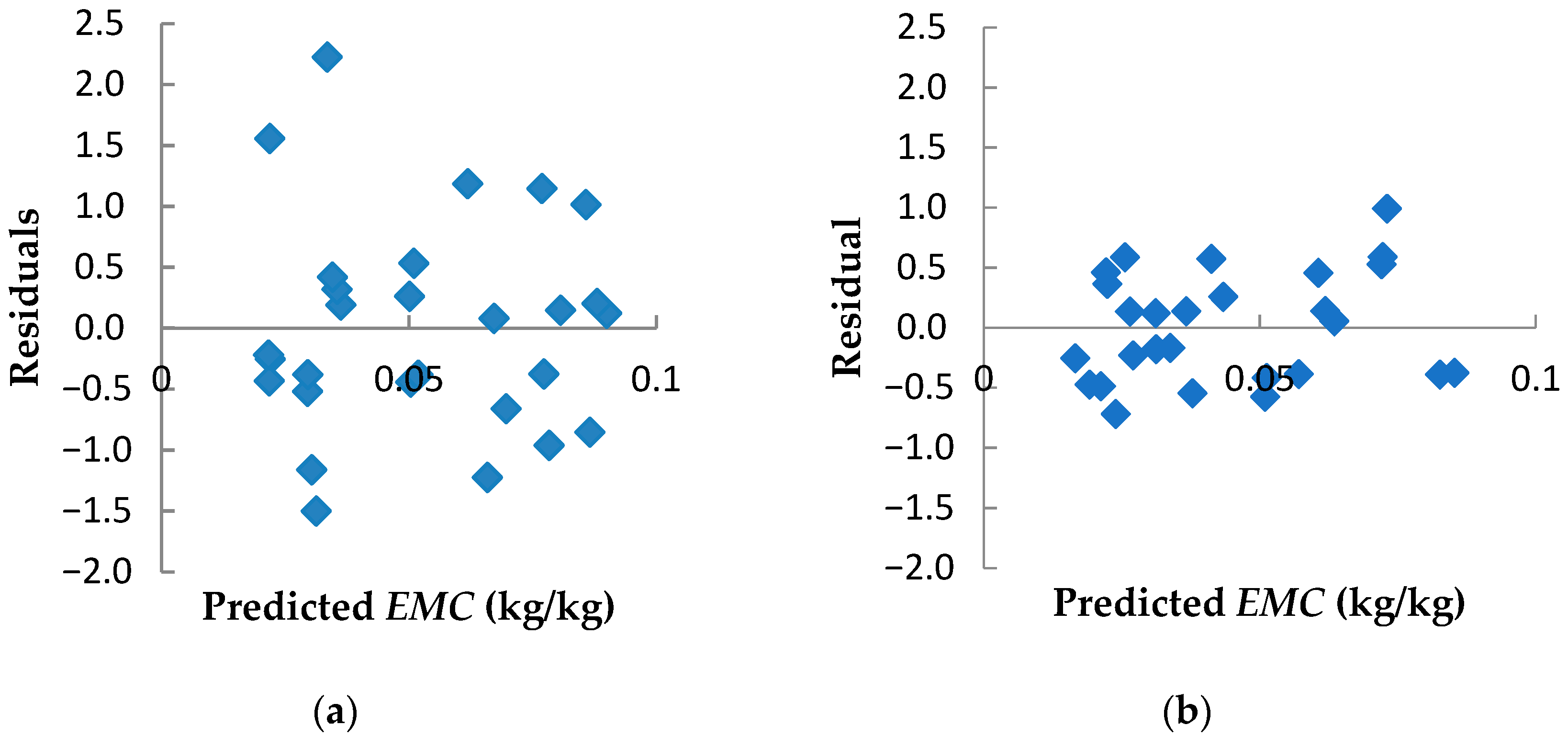

Fitting of Sorption Models

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Macaire, W.H.; Bernard, T.; Noel, T.; Felicite, T.M.; Cesar, K.; Michel, L.; Jacques, F. Extraction of palm kernel oil in Cameroon: Effects of kernels drying on the oil quality. J. Food Technol. 2010, 8, 1–7. [Google Scholar] [CrossRef]

- Hassan, M.N.; Ab Rahman, N.N.; Ibrahim, M.H.; Omar, A.M. Simple fractionation through the supercritical carbon dioxide extraction of palm kernel oil. Sep. Purif. Technol. 2000, 19, 113–120. [Google Scholar] [CrossRef]

- Berger, K.G.; Andaner, W.T.; Applewhite, T.H. The Lauric Oils Medium Chain Fatty Acid Source; American Oil Chemists’ Society: Champaign, IL, USA, 1991. [Google Scholar]

- Pantzaris, T.P.; Ahmad, M.J. Properties and utilization of palm kernel oil. Palm Oil Dev. 2001, 35, 11–23. [Google Scholar]

- Panchariya, P.C.; Popovic, D.; Sharma, A.L. Modeling of desorption isotherm of black tea. Dry. Technol. 2001, 19, 1177–1188. [Google Scholar] [CrossRef]

- Chenarbon, H.A.; Minaei, S.; Bassiri, A.R.; Almassi, M.; Arabhosseini, A. Moisture desorption isotherms of St. John’s wort (Hypericum perforatum L.) leaves at three temperatures. J. Food Agric. Environ. 2010, 8, 188–191. [Google Scholar]

- Zhang, X.W.; Liu, X.; Gu, D.X.; Zhou, W.; Wang, R.L.; Liu, P. Desorption isotherms of some vegetables. J. Sci. Food Agric. 1996, 70, 303–306. [Google Scholar] [CrossRef]

- Ertugay, M.F.; Certel, M.; Gürses, A. Moisture adsorption isotherms of Tarhana at 25 C and 35 C and the investigation of fitness of various isotherm equations to moisture sorption data of Tarhana. J. Sci. Food Agric. 2000, 80, 2001–2004. [Google Scholar] [CrossRef]

- Jamali, A.; Kouhila, M.; Mohamed, L.A.; Jaouhari, J.T.; Idlimam, A.; Abdenouri, N. Sorption isotherms of Chenopodium ambrosioides leaves at three temperatures. J. Food Eng. 2006, 72, 77–84. [Google Scholar] [CrossRef]

- Al-Mahasneh, M.A.; Amer, M.B.; Rababah, T.M. Modeling moisture sorption isotherms in roasted green wheat using least square regression and neural-fuzzy techniques. Food Bioprod. Process. 2012, 90, 165–170. [Google Scholar] [CrossRef]

- Ibrahim, H. Drying of Oil Palm Kernels. Ph.D. Thesis, Universiti Kebangsaan Malaysia (UKM), Bangi, Malaysia, 1994. [Google Scholar]

- Jiménez, R.; Zeledón, M.; Alizaga, R. Relación de equilibrio entre el contenido de humedad de almendras de la palma aceitera (Elaeis guineensis) producida en Costa Rica y la humedad relativa del aire. ASD Oil Pap. 1995, 10, 16–26. [Google Scholar]

- Ajibola, O.O.; Aviara, N.A.; Abodunrin, V.K. Moisture sorption equilibrium and thermodynamic properties of palm kernel. Int. Agrophys. 2005, 19, 273. [Google Scholar]

- Brooker, D.B.; Bakker-Arkema, F.W.; Hall, C.W. Drying and Storage of Grains and Oilseeds; The Avi Publishing Company: Westport, CT, USA, 1992. [Google Scholar]

- Kuntom, A. MPOB Test Methods: A Compendium of Test on Palm Oil Products, Palm Kernel Products, Fatty Acids, Food Related Products and Others; Malaysian Palm Oil Board: Bandar Baru Bangi, Malaysia, 2005.

- Gbadam, E.K.; Anthony, S.; Asiam, E.K. The determination of some design parameters for palm nut crackers. Eur. J. Sci. Res. 2009, 38, 315–327. [Google Scholar]

- Mohsenin, N.N. Physical Properties of Plant and Animal Materials, 2nd ed.; Gordon and Breach Science Publishers: London, UK, 1986. [Google Scholar]

- Tunde-Akintunde, T.Y.; Akintunde, B.O. Some physical properties of sesame seed. Biosyst. Eng. 2004, 88, 127–129. [Google Scholar] [CrossRef]

- Sirisomboon, P.; Kitchaiya, P.; Pholpho, T.; Mahuttanyavanitch, W. Physical and mechanical properties of Jatropha curcas L. fruits, nuts and kernels. Biosyst. Eng. 2007, 97, 201–207. [Google Scholar] [CrossRef]

- Garnayak, D.K.; Pradhan, R.C.; Naik, S.N.; Bhatnagar, N. Moisture-dependent physical properties of jatropha seed (Jatropha curcas L.). Ind. Crops Prod. 2008, 27, 123–129. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 13th ed.; Association of Official Analytical Chemists, AOAC International: Rockville, MD, USA, 1980. [Google Scholar]

- Vasquez, V.R.; Braganza, A.; Coronella, C.J. Molecular thermodynamics modeling of equilibrium moisture in foods. J. Food Eng. 2011, 103, 103–114. [Google Scholar] [CrossRef]

- Greenspan, L. Humidity fixed points of binary saturated aqueous solutions. J. Res. Natl. Bur. Stand. 1977, 81, 89–96. [Google Scholar] [CrossRef]

- Quirijns, E.J.; van Boxtel, A.J.; van Loon, W.K.; van Straten, G. An improved experimental and regression methodology for sorption isotherms. J. Sci. Food Agric. 2005, 85, 175–185. [Google Scholar] [CrossRef]

- Hadjikinova, M.; Menkov, N.; Hadjikinov, D. Sorption characteristics of dietary hard candy. Czech J. Food Sci. 2003, 21, 97–99. [Google Scholar] [CrossRef]

- Thompson, T.L.; Peart, R.M.; Foster, G.H. Mathematical simulation of corn drying—A new model. Trans. ASAE 1968, 11, 582–586. [Google Scholar] [CrossRef]

- Chen, C. A Study of Equilibrium Relative Humidity for Yellow-Dent Corn Kernels. Ph.D. Thesis, University of Minnesota, Minneapolis, MN, USA, 1988. [Google Scholar]

- Iglesias, H.A.; Chirife, J. Prediction of the effect of temperature on water sorption isotherms of food material. Int. J. Food Sci. Tech. 1976, 11, 109–116. [Google Scholar] [CrossRef]

- Pfost, H.B.; Maurer, S.G.; Chung, D.S.; Milliken, G.A. Summarizing and reporting equilibrium moisture data for grains. ASAE 1976, 76, 3520. [Google Scholar]

- Ghodake, H.M.; Goswami, T.K.; Chakraverty, A. Moisture sorption isotherms, heat of sorption and vaporization of withered leaves, black and green tea. J. Food Eng. 2007, 78, 827–835. [Google Scholar] [CrossRef]

- Hafezi, N.; Sheikhdavoodi, M.J.; Sajadiye, S.M. The Effect of drying kinetic on shrinkage of potato slices. Int. J. Adv. Biol. Biomed. Res. 2014, 2, 2779–2782. [Google Scholar]

- Visvanathan, R.; Palanisamy, P.T.; Gothandapani, L.; Sreenarayanan, V.V. Physical properties of neem nut. J. Agric. Eng. Res. 1996, 63, 19–25. [Google Scholar] [CrossRef]

- Kibar, H.; Öztürk, T. Physical and mechanical properties of soybean. Int. Agrophys. 2008, 22, 239–244. [Google Scholar]

- Chandrasekar, V.; Viswanathan, R. Physical and thermal properties of coffee. J. Agric. Eng. Res. 1999, 73, 227–234. [Google Scholar] [CrossRef]

- Baryeh, E.A. Physical properties of bambara groundnuts. J. Food Eng. 2001, 47, 321–326. [Google Scholar] [CrossRef]

- Dutta, S.K.; Nema, V.K.; Bhardwaj, R.K. Physical properties of gram. J. Agric. Eng. Res. 1988, 39, 259–268. [Google Scholar] [CrossRef]

- Akubuo, C.O.; Eje, B.E. PH—Postharvest technology: Palm kernel and shell separator. Biosyst. Eng. 2002, 81, 193–199. [Google Scholar] [CrossRef]

- Akinoso, R.; Raji, A.O. Physical properties of fruit, nut and kernel of oil palm. Int. Agrophys. 2011, 25, 85–88. [Google Scholar]

- Davier, R.M. Physical and mechanical properties of palm fruit, kernel and nut. J. Agric. Technol. 2012, 8, 2147–2156. [Google Scholar]

- Gbadamosi, L. Some engineering properties of palm kernel seeds (PKS). J. Agric. Eng. Tech. 2006, 14, 58–66. [Google Scholar]

- Baryeh, E.A.; Mangope, B.K. Some physical properties of QP-38 variety pigeon pea. J. Food Eng. 2003, 56, 59–65. [Google Scholar] [CrossRef]

- Ezeoha, S.L.; Akubuo, C.O. Classification and engineering properties of unknown variety of oil palm kernel from Nigeria. IOSR J. Eng. 2014, 4, 51–58. [Google Scholar] [CrossRef]

- Altuntas, E.; Özgöz, E.; Taşer, Ö.F. Some physical properties of fenugreek (Trigonella foenum-graceum L.) seeds. J. Food Eng. 2005, 71, 37–43. [Google Scholar] [CrossRef]

- Ozturk, I.; Kara, M. Physico-chemical grain properties of new common bean cv. ‘Elkoca-05’. Sci. Res. Essays 2009, 4, 88–93. [Google Scholar]

- Kibar, H.; Öztürk, T.; Esen, E. The effect of moisture content on physical and mechanical properties of rice (Oryza sativa L.). Span. J. Agric. Res. 2010, 8, 741–749. [Google Scholar] [CrossRef]

- Baryeh, E.A. Physical properties of millet. J. Food Eng. 2002, 51, 39–46. [Google Scholar] [CrossRef]

- Dursun, E.; Dursun, I. Some physical properties of caper seed. Biosyst. Eng. 2005, 92, 237–245. [Google Scholar] [CrossRef]

- Razavi, S.M.; Emadzadeh, B.; Rafe, A.; Amini, A.M. The physical properties of pistachio nut and its kernel as a function of moisture content and variety: Part I. Geometrical properties. J. Food Eng. 2007, 81, 209–217. [Google Scholar] [CrossRef]

- Sangamithra, A.; John, S.G.; Sorna Prema, R.; Nandini, K.; Kannan, K.; Sasikala, S.; Suganya, P. Moisture dependent physical properties of maize kernels. Int. Food Res. J. 2016, 23, 109–115. [Google Scholar]

- Hsu, M.H.; Mannapperuma, J.D.; Singh, R.P. Physical and thermal properties of pistachios. J. Agric. Eng. Res. 1991, 49, 311–321. [Google Scholar] [CrossRef]

- Gupta, R.K.; Das, S.K. Physical properties of sunflower seeds. J. Agric. Eng. Res. 1997, 66, 1–8. [Google Scholar] [CrossRef]

- Araújo, W.D.; Goneli, A.L.; Souza, C.D.; Gonçalves, A.A.; Vilhasanti, H.C. Propriedades físicas dos grãos de amendoim durante a secagem. Rev. Bras. Eng. Agric. Am. 2014, 18, 279–286. [Google Scholar] [CrossRef]

- De Souza Smaniotto, T.A.; Resende, O.; de Sousa, K.A.; Campos, R.C.; Guimarães, D.N.; Rodrigues, G.B. Physical properties of sunflower seeds during drying. Semina Ciências Agrárias 2017, 38, 157–164. [Google Scholar] [CrossRef]

- Paksoy, M.; Aydin, C. Some physical properties of edible squash (Cucurbita pepo L.) seeds. J. Food Eng. 2004, 65, 225–231. [Google Scholar] [CrossRef]

- Altuntas, E.; Erkol, M. Physical properties of shelled and kernel walnuts as affected by the moisture content. Czech J. Food Sci. 2010, 28, 547–556. [Google Scholar] [CrossRef]

- Martins, E.A.; Goneli, A.L.; Hartmann Filho, C.P.; Mauad, M.; Siqueira, V.C.; Gonçalves, A.A. Physical properties of safflower grains. Part I: Geometric and gravimetric characteristics. Rev. Bras. Eng. Agric. Ambient. 2017, 21, 344–349. [Google Scholar] [CrossRef][Green Version]

- Deshpande, S.D.; Bal, S.; Ojha, T.P. Physical properties of soybean. J. Agric. Eng. Res. 1993, 56, 89–98. [Google Scholar] [CrossRef]

- Nimkar, P.M.; Chattopadhyay, P.K. PH—Postharvest Technology: Some physical properties of green gram. J. Agric. Eng. Res. 2001, 80, 183–189. [Google Scholar] [CrossRef]

- Aydin, C. Ph—postharvest technology: Physical properties of hazel nuts. Biosyst. Eng. 2002, 82, 297–303. [Google Scholar] [CrossRef]

- Kaleemullah, S.; Gunasekar, J.J. PH—Postharvest Technology: Moisture-dependent physical properties of Arecanut kernels. Biosyst. Eng. 2002, 82, 331–338. [Google Scholar] [CrossRef]

- Baümler, E.; Cuniberti, A.; Nolasco, S.M.; Riccobene, I.C. Moisture dependent physical and compression properties of safflower seed. J. Food Eng. 2006, 72, 134–140. [Google Scholar] [CrossRef]

- Koya, O.A.; Idowu, A.; Faborode, M.O. Some properties of palm kernel and shell relevant in nut cracking and product separation. J. Agric. Eng. Tech. 2004, 12, 33–44. [Google Scholar]

- Mijinyawa, Y.; Omoikhoje, S. Determination of some physical properties of palm kernel. Proc. Niger. Inst. Agric. Eng. 2005, 27, 157–160. [Google Scholar]

- Ezeoha, S.L. Determination of Some Physical Properties of Palm Kernels Relevant in Rational Design of Processing and Storage Systems; Technical Paper Submitted in Fulfillment of the Requirement for the Course AGE: 702 (Special Problems in Agricultural Engineering); Department of Agricultural and Bioresources Engineering, University of Nigeria: Nsukka, Nigeria, 2011. [Google Scholar]

- Kingsly, A.R.P.; Singh, D.B.; Manikantan, M.R.; Jain, R.K. Moisture dependent physical properties of dried pomegranate seeds (Anardana). J. Food Eng. 2006, 75, 492–496. [Google Scholar] [CrossRef]

- Sacilik, K.; Öztürk, R.; Keskin, R. Some physical properties of hemp seed. Bios. Eng. 2003, 86, 191–198. [Google Scholar] [CrossRef]

- Kabas, O.; Ozmerzi, A.; Akinci, I. Physical properties of cactus pear (Opuntia ficus india L.) grown wild in Turkey. J. Food Eng. 2006, 73, 198–202. [Google Scholar] [CrossRef]

- Simonyan, K.J.; Yiljep, Y.D.; Oyatoyan, O.B.; Bawa, G.S. Effects of moisture content on some physical properties of Lablab purpureus (L.) sweet seeds. Agric. Eng. Int. CIGR J. 2009, 11, 1279. [Google Scholar]

- Balasubramanian, S.; Viswanathan, R. Influence of moisture content on physical properties of minor millets. Int. J. Food Sci. Technol. 2010, 47, 279–284. [Google Scholar] [CrossRef] [PubMed]

- Akar, R.; Aydin, C. Some physical properties of gumbo fruit varieties. J. Food Eng. 2005, 66, 387–393. [Google Scholar] [CrossRef]

- Aprajeeta, J.; Gopirajah, R.; Anandharamakrishnan, C. Shrinkage and porosity effects on heat and mass transfer during potato drying. J. Food Eng. 2015, 144, 119–128. [Google Scholar] [CrossRef]

- Gazor, H.R.; Chaji, H. Equilibrium moisture content and heat of desorption of saffron. Int. J. Food Sci. Technol. 2010, 45, 1703–1709. [Google Scholar] [CrossRef]

- Basunia, M.A.; Abe, T. Moisture desorption isotherms of medium-grain rough rice. J. Stored Prod. Res. 2001, 37, 205–219. [Google Scholar] [CrossRef]

- Somade, B. Moisture equilibrium of palm kernels. J. Sci. Food Agric. 1955, 6, 425–427. [Google Scholar] [CrossRef]

| Salt Solution | Chemical Formula | RH (%) | |||

|---|---|---|---|---|---|

| 50 °C | 60 °C | 70 °C | 80 °C | ||

| Lithium chloride | LiCl | 11.10 | 10.95 | 10.75 | 10.51 |

| Potassium fluoride | KF | 20.80 | 20.77 | 21.74 | 22.85 |

| Magnesium chloride | MgCl2 | 30.54 | 29.26 | 27.77 | 26.05 |

| Sodium bromide | NaBr | 50.93 | 49.66 | 49.70 | 51.43 |

| Sodium nitrate | NaNO3 | 69.04 | 67.35 | 66.04 | 62.22 |

| Sodium chloride | NaCl | 74.43 | 74.50 | 75.06 | 76.29 |

| Potassium chloride | KCl | 81.20 | 80.25 | 79.49 | 78.90 |

| Model Name | Model | Equation No. | Reference |

|---|---|---|---|

| Modified Henderson | EMC | (9) | [26] |

| Modified Oswin | EMC | (10) | [27] |

| Modified Halsey | EMC | (11) | [28] |

| Modified Chung–Pfost | EMC | (12) | [29] |

| MC (kg/kg) | L (mm) | W (mm) | Th (mm) | GMD (mm) |

|---|---|---|---|---|

| 0.31 ± 0.76 | 16.08 a ± 2.09 | 12.06 a ± 1.40 | 10.01 a ± 1.27 | 12.88 ± 1.33 a |

| 0.28 ± 0.78 | 16.63 a ± 2.11 | 12.49 a ± 1.56 | 9.02 b ± 1.42 | 12.07 ± 1.20 a |

| 0.25 ± 1.41 | 14.63 b ± 2.67 | 11.55 b ± 1.52 | 9.21 b ± 1.27 | 11.76 ± 1.23 b |

| 0.20 ± 1.77 | 14.58 b ± 2.64 | 11.49 b ± 1.37 | 9.34 b ± 1.21 | 11.56 ± 1.21 b |

| 0.17 ± 1.35 | 14.68 b ± 2.39 | 11.45 b ± 1.52 | 9.34 b ± 1.21 | 11.43 ± 1.28 b |

| 0.09 ± 2.01 | 14.22 b ± 2.04 | 11.40 b ± 1.59 | 9.19 b ± 1.75 | 11.43 ± 0.98 b |

| 0.05 ± 0.59 | 14.20 b ± 2.44 | 11.37 b ± 1.08 | 9.18 b ± 1.38 | 11.36 ± 1.26 b |

| 0.02 ± 1.42 | 14.17 b ± 2.30 | 11.24 b ± 1.08 | 9.18 b ± 1.04 | 11.31 ± 0.97 b |

| Parameters | Modified | Modified | Modified | Modified |

|---|---|---|---|---|

| Henderson | Chung–Pfost | Halsey | Oswin | |

| a | 6.70 × 10−8 | 6.08 × 109 | 2.42 | 4.94 |

| b | 5.34 × 105 | 1.37 × 109 | 8.4 × 10−4 | 1.59 × 10−3 |

| c | 1.77 | 0.35 | 1.81 | 2.51 |

| R2 | 0.98 | 0.878 | 0.977 | 0.978 |

| Adjusted R2 | 0.88 | 0.77 | 0.878 | 0.884 |

| SEE | 2.67 | 2.65 | 2.66 | 2.59 |

| RSS | 21.4 | 21.2 | 21.25 | 20.26 |

| χ2 | 0.82 | 0.815 | 0.817 | 0.77 |

| Residual plot | random | random | random | random |

| Parameters | Modified | Modified | Modified | Modified |

|---|---|---|---|---|

| Henderson | Chung–Pfost | Halsey | Oswin | |

| a | 0 | 151.456 | 3.58 | 8.31 |

| b | −19 | −26.031 | −0.024 | −0.061 |

| c | 1.64 | 0.38 | 1.7 | 2.35 |

| R2 | 0.99 | 0.938 | 0.992 | 0.991 |

| Adjusted R2 | 0.94 | 0.8 | 0.964 | 0.96 |

| SEE | 1.71 | 1.79 | 1.37 | 1.45 |

| RSS | 8.82 | 9.61 | 5.68 | 6.32 |

| χ2 | 0.33 | 0.36 | 0.21 | 0.24 |

| Residual plot | random | random | random | random |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habibiasr, M.; Mokhtar, M.N.; Ibrahim, M.N.; Md Yunos, K.F.; Ibrahim, N.A. Study on the Effects of Physical Properties of Tenera Palm Kernel during Drying and Its Moisture Sorption Isotherms. Processes 2020, 8, 1658. https://doi.org/10.3390/pr8121658

Habibiasr M, Mokhtar MN, Ibrahim MN, Md Yunos KF, Ibrahim NA. Study on the Effects of Physical Properties of Tenera Palm Kernel during Drying and Its Moisture Sorption Isotherms. Processes. 2020; 8(12):1658. https://doi.org/10.3390/pr8121658

Chicago/Turabian StyleHabibiasr, Mina, Mohd Noriznan Mokhtar, Mohd Nordin Ibrahim, Khairul Faezah Md Yunos, and Nuzul Amri Ibrahim. 2020. "Study on the Effects of Physical Properties of Tenera Palm Kernel during Drying and Its Moisture Sorption Isotherms" Processes 8, no. 12: 1658. https://doi.org/10.3390/pr8121658

APA StyleHabibiasr, M., Mokhtar, M. N., Ibrahim, M. N., Md Yunos, K. F., & Ibrahim, N. A. (2020). Study on the Effects of Physical Properties of Tenera Palm Kernel during Drying and Its Moisture Sorption Isotherms. Processes, 8(12), 1658. https://doi.org/10.3390/pr8121658