1. Introduction

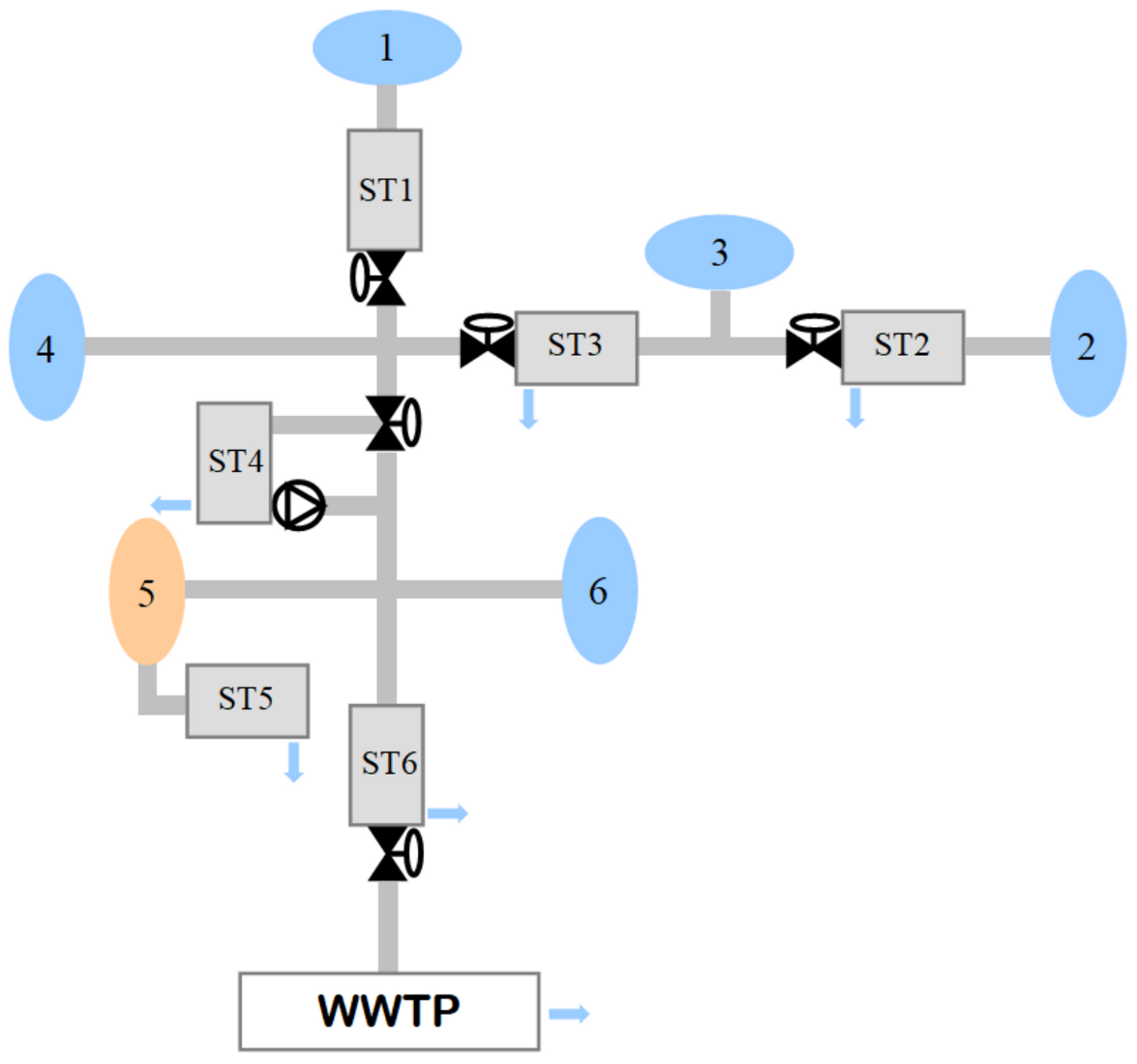

Currently, it is a fact that urban wastewater treatment plants (WWTPs) have a high degree of interconnection with other elements, such as sewers, conduction systems, and storage tanks, which are part of the urban water system. Urban drainage systems (UDS) generally catch and carry both urban wastewater and that which comes from rainfall to WWTPs for treatment before being discharged into the environment, constituting a combined urban drainage system. During periods of heavy rain, the wastewater resulting from the mix can overload the urban system and produce overflows that can be harmful to the environment. Until now, UDS and WWTPs in general have been considered separately to solve their control problems.

In the case of UDS, the research has essentially consisted of the development of detailed process models that facilitate the design and simulation of different control strategies. The operational objectives are basically avoiding wastewater leaks from the collection network before being treated by the treatment plants, due to overflows in the storage tanks and at the entrance of the WWTP, optimizing the degree of use of the station by maximizing the inlet flow, and reducing the economic cost of operation [

1,

2]. Other problems that appear are the “first flush” problems, which occur after a dry season when abundant precipitation occurs, causing a large increase in the concentration of pollutants in the network water.

Some simulation models constitute benchmarks for the control systems of the sewer, such as [

3]. On the one hand, the models try to describe with great precision the processes that take place in a drainage network (hydraulic and chemical processes of degradation of discharged pollutants) and, on the other, they have to be simple enough to be the target of simulations in the long term. In the development of these models, the characteristics of the wastewater collected according to the area (urban and industrial waters with different concentrations of pollutants), the rainwater reaching the network, and the time of year are taken into account, based on a large volume of collected data. As a result, typical patterns that attempt to cover a large number of situations have been developed [

4]. From these models, simpler ones can be obtained to be used in the elaboration of certain types of control algorithms.

Regarding the control systems for UDS [

5], they are usually classified into off-line controllers, which apply static rules, and improved on-line controllers that apply real-time control actions [

3,

6,

7,

8].

Table 1 shows a summary of features for the real-time control systems:

In particular, simple RBC (Rule-Based Control) strategies have been applied in [

9,

10], offering as main disadvantage the increase of rules when the complexity of the system increases. Alternatively, FLC (Fuzzy Logic Control) based control systems that combine simple rules with an expert system and a flexible specification of the output parameters can be used [

9,

11,

12,

13,

14]. An FLC is also used to reduce the volume and number of overflows in the Wilhelmshaven (Germany) UDS achieving both objectives [

15]. The principles of FLC have been used to control the operation of the pumps in the collection network od the city of Taipei, achieving a more efficient drainage of rainwater, and thus preventing flooding [

16]. Another type of algorithm, the LQR regulator, has been applied in [

17] to flow control in a collection network in Bavaria (Germany). In this case, the control objectives were to minimize the overflows in the system by optimally using all the storage capacity of the UDS and emptying the network as soon as possible. Evolutionary Strategies (EA) mimic evolutionary principles to find optimal solutions [

18]. For example, Genetic Algorithms have been applied to water quality management systems in [

19] and to the optimal multiobjective control of UDS [

20]. In [

10], EA combined with self-adaptive algorithms has achieved an improvement in the quality of the water discharged into rivers, with reduced costs. In the control techniques based on Population Dynamics (PD), the designed controller poses a problem of resource location, and its interpretation can be related to biological evolutionary processes, without considering a system model, using game theory concepts. These strategies have been applied in [

21,

22], achieving a better use of network volume and avoiding overflows.

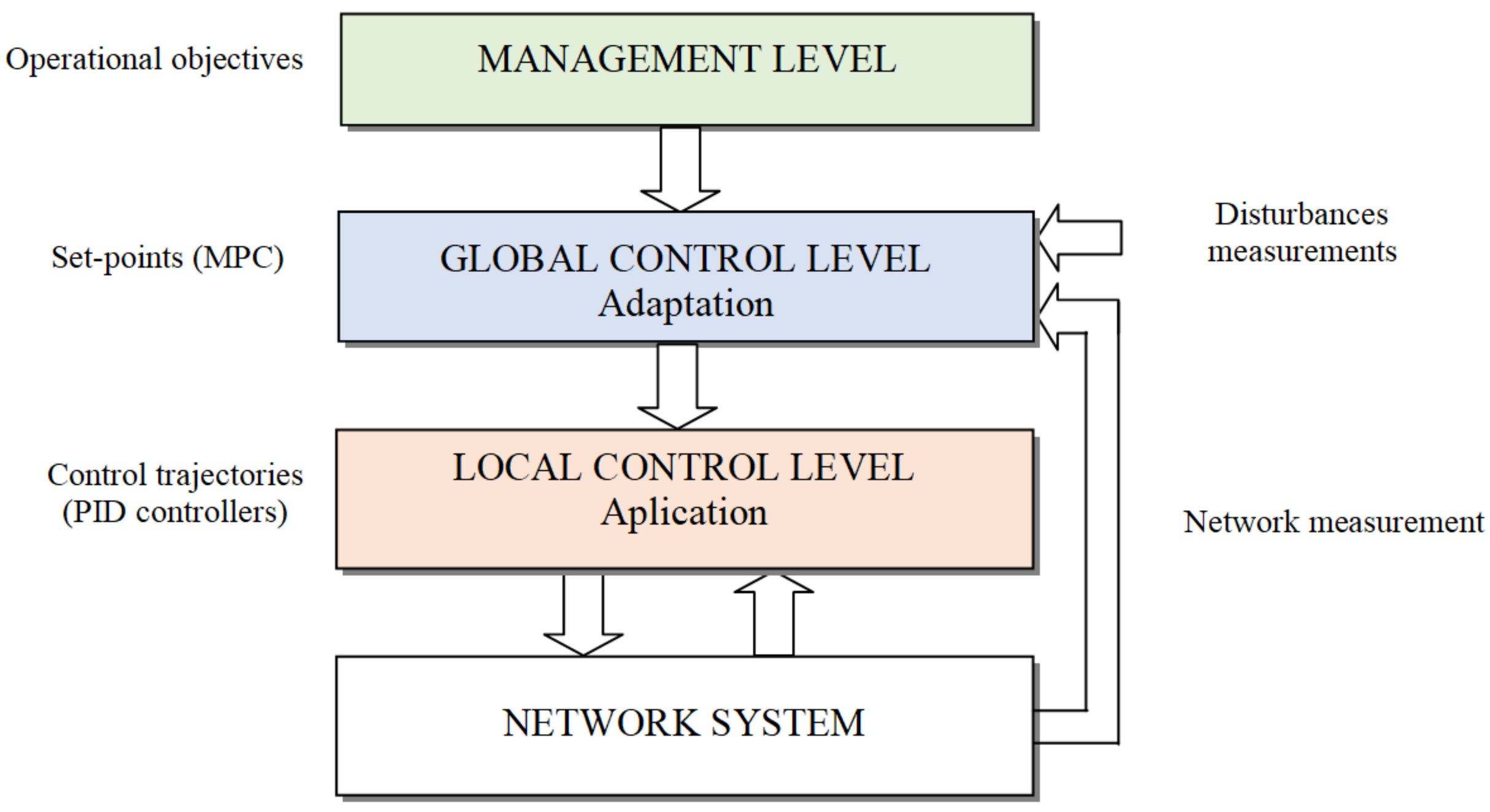

Regarding the architecture of the control systems used in UDS, one of the most common global control configurations is centralized control. However, the local control scheme may be a suitable solution if there are few actuators in the system [

23]. In complex large-scale systems, it is common to have both levels of control (global and local). In this case, there can be up to three levels of control configuring a hierarchical control structure [

24,

25].

In the urban water systems, the interaction between the UDS and the WWTP is clear, since the outflow from the UDS is the inlet of the treatment plants. Consequently, to improve performance, the development and evaluation of control strategies for WWTPs should be addressed from a broader perspective [

26]. However, there are only few works in the literature that take both systems into account in an integrated way and focus on the performance of the WWTP, using simplified models for the sewer networks [

27,

28]. In particular, the consideration of the integrated system allows for a bidirectional coupling of the conceptual models of the subsystems including WWTPs [

29]. Regarding the applied control strategies, in [

30], a heuristic-type control system based on rules that covers both situations of scarcity and abundance of water to be treated is described, also taking into account the operating costs of the entire system. Others, like [

31], present strategies that combine RBC algorithms with Model Predictive Control (MPC).

MPC is a control methodology that uses a process prediction model to calculate the manipulated variables on a future horizon in order to optimize a certain cost function [

32,

33,

34,

35,

36]. An MPC controller has four basic elements: a control-oriented mathematical model of the system, a cost function that expresses the control objective to be achieved, a set of system constraints, and a finite horizon optimization problem that is solved in a receding-horizon way [

33]. In a hierarchical control structure, the MPC is normally used to generate optimal references for local controllers. The characteristics of MPC controllers have certain advantages for their application to UDS, particularly the ability to anticipate the system’s response to future rainfall events and the ability to consider delays and disturbances [

32]. This controller has been applied to the UDS in [

25], where a centralized predictive control has been developed according to a proposed model in which the state variables considered are the volumes of the network tanks, the control or manipulated variables are flow rates in the network pipes, and the measurable disturbances are the flows of rainwater. The restrictions in this case are given by the available volume of tanks and pipes, among others.

A prioritization of multi-objective cost functions is applied by means of the lexicographic technique in the control of a UDS in [

37]. In [

38], an MPC controller has been simulated in a part of Barcelona’s drainage network, in Spain, achieving significant reductions in floods and overflows [

25,

38,

39,

40]. Other cases in which MPC control algorithms have been studied and/or applied to UDS are [

23,

41,

42], where both operation costs and overflows have been reduced using non-linear prediction models.

In large-scale systems, it may be advisable to divide the global process into simpler subsystems to facilitate the application of MPC algorithms [

7]. In this case, prediction models and local cost functions are used, obtaining local solutions to the global control problem. If there is no exchange of information between subsystems, Decentralized Model Predictive Control is a possible solution, but a more efficient alternative is the Distributed Model Predictive Control (DMPC), where local controllers exchange information to calculate their own local solution, as in the cooperative (or Coordinated) Distributed Model Predictive Control [

8,

43,

44,

45]. Although there is a large amount of DMPC strategies applied to different processes [

46,

47,

48], only a few deal with water management, such as the level control in tanks [

49] and the coordination of drinking water supply networks [

50,

51,

52]. To the knowledge of the authors, no applications to sewer systems have been developed.

The main contribution of this work consists in the development and application of a practical cooperative distributed model predictive control to a UDS, based on local linearized models of the system and fuzzy negotiation among subsystems [

53]. Another contribution is the inclusion of the WWTP in the control strategy as an additional objective—more concretely, the optimization of the WWTP inlet flow. The benchmark described in [

3] has been considered, with different disturbances, and the results have been compared with a centralized and decentralized MPC, to assess the suitability of the proposed methodology and its application to this system.

The article is structured as follows. After an introduction, the description of the system under study begins, along with the mathematical model used for the simulation and the model used by the control algorithm. In the following section, its sectorization is detailed. The article continues with the description of the centralized and distributed MPC control algorithms, showing the corresponding results in each case in two representative scenarios. The conclusions are presented at the end.

3. System Sectorization

Applying control techniques to large-scale systems usually involves dividing the global system into simpler subsystems. To this end, a structural analysis of the system has been carried out to determine the best way to sectorize the system, so that the subsystems obtained have a minimum degree of coupling and are controllable [

55]. With this end, the reachability from the entrance of the system has been checked, and the direct graph of the system has been obtained.

Definition: A system S with a direct graph D = (U∪X∪Y, E) is input-reachable if X⊆ℜn is a reachable set of U⊆ℜm, that is, for each node x∈X there is at least one node u∈U with a direct path to it.

Definition: A system S with a direct graph D = (U∪X∪Y, E) is output-reachable if X⊆ℜn is an antecedent set of Y⊆ℜr, that is, for each node x∈X there is at least one node y∈Y with a direct path to it.

Then, a system S is reachable if it is input- and output-reachable. The study of the reachability of the system allows us to determine the possibilities of sectoring while maintaining the reachability of the subsystems obtained. It begins with obtaining the interconnection matrix

E, which is defined from the matrices that determine the dynamic model of the system,

A,

Bp, and

C, as:

Reachability matrix

R can be computed as

, with

, and it has the following form:

where

F,

G,

H, and

θ are binary matrices whose dimensions are consistent with

E.

The system will be input- and output-reachable if and only if the binary matrix

θ has neither zero rows nor zero columns [

55].

For the sewer system considered here, the following matrix

θ has been obtained, resulting in a system that is reachable from the input and the output:

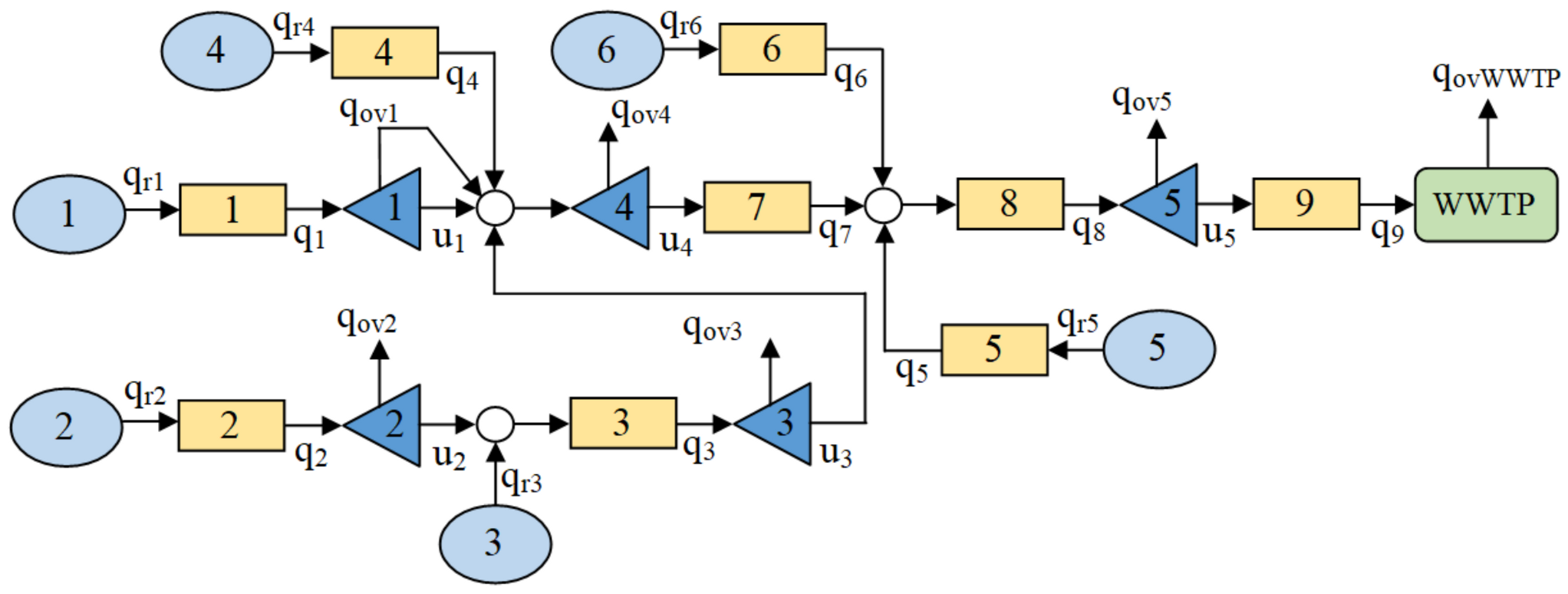

Moreover, obtaining the direct graph of the system (

Figure 3) will allow us to know the interactions between the different variables that are involved in the process and determine the best way to divide the global system into subsystems with minimal interaction [

36], maintaining the reachability of the subsystems obtained.

The graph shows a system coupled by the inputs. The sectoring has been carried out avoiding interactions between states of different subsystems and at the same time ensuring their reachability (

Figure 4). The controllability of each subsystem can be verified. Accordingly, this work considers two subsystems, the first one englobing the tanks 1 to 4 together with link element 3, and the second one tank 5 and link elements 7, 8, and 9.

To apply the distributed MPC developed in

Section 7, the state space local models of each subsystem are expressed as follows, where the coupling input

u4 is considered to belong to subsystem 1.

Matrices A1, Bp11, Bp12, A2, Bp21, and Bp22 are formed by suitably selecting the rows and columns of A and B from the matrices (6). Note that Bp12 and Bd12 are null; Bp21 only has non-zero in the last column, and Bd21 is null, due to the plant’s configuration.

6. Distributed Model Predictive Control (DMPC)

The DMPC algorithm considered in this work is based on [

60], consisting of the minimization of local cost functions that depend on the future evolution of the inputs of each subsystem and the neighbor, using prediction models and local constraints. At each sampling period, agents get an optimal control sequence for their subsystem, keeping the neighbor control sequence constant, and then each agent solves another optimization problem that provides the control sequence for the neighbor, keeping theirs constant.

Due to the particular characteristics of this system, since there is no interaction of the inputs of subsystem 2 in subsystem 1, the procedure is simplified, and some of the optimization problems of the general method are not solved.

Figure 6 gives an overview of the algorithm.

And it consists of several steps:

STEP 1: The state measurements and corresponding to each subsystem are obtained at instant k. Two local predictive control problems (MPC1 and MPC2) are solved, obtaining local solutions and for each subsystem:

The optimization problem is:

, where is the previous optimal control sequence extended to the current instant, keeping constant the last value in the prediction horizon.

The optimization problem is:

, where is the previous optimal control sequence extended to the current instant, as in (25).

STEP 2:

The optimization problem is:

STEP 3: Information exchange: agent 2 sends to agent 1.

STEP 4: Feasibility test: It is necessary to check if the states of subsystem 1 satisfy the constraints of this subsystem, provided that is obtained by the other agent. If the constraints are not fulfilled, this control action will not be considered for negotiation in the following step.

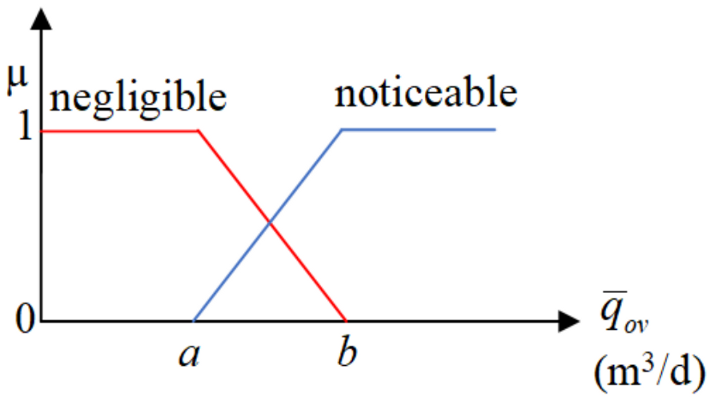

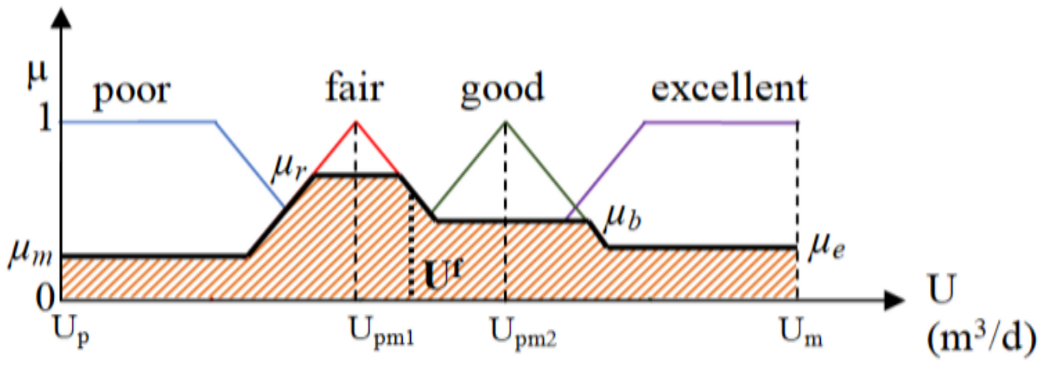

STEP 5: Agent 1 applies a fuzzy negotiation between the two available control signals, which takes into account the average input flow rate to the wastewater treatment plant, , and the average overflow, .

8. Results

In this section, some simulation results considering two different scenarios obtained from the sewer benchmark are presented. In order to reduce the computational time, two periods of 10 days have been taken out from a series that extends to two years, choosing periods where the flows variations are more relevant.

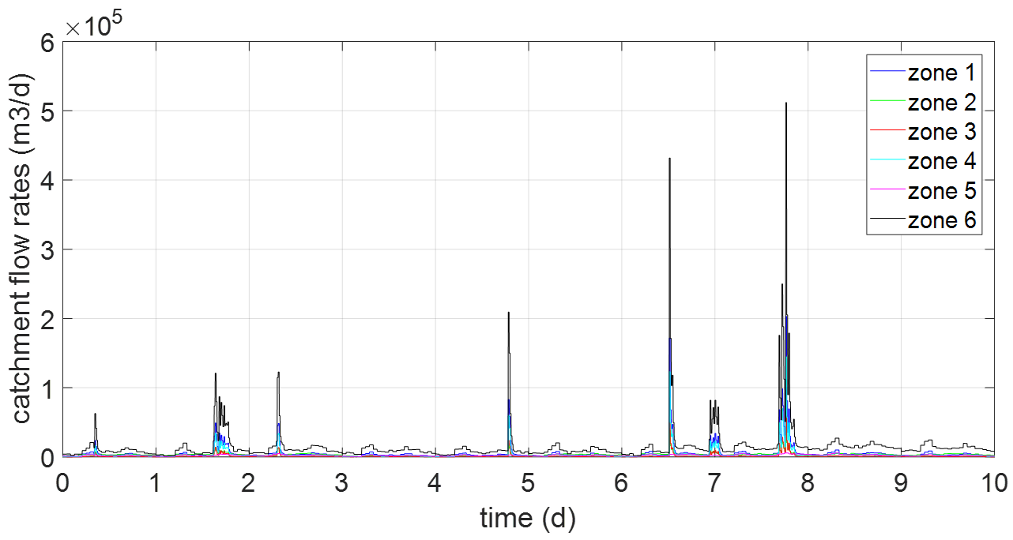

Both scenarios represent specific periods of a humid season with rainfall (

Figure 10), the second one with more rainfall collected (

Figure 11).

For each scenario, to validate the results of the methodology proposed in the paper, four cases have been developed. The first case (without control, CASE 1) is equivalent to keeping all the valves at their maximum opening. The second case (Decentralized MPC, CASE 2) considers two local MPCs according to the models obtained in (15). The third case (DMPC with fuzzy negotiation, CASE 3) is the methodology proposed in the paper, and CASE 4 is a centralized MPC. The received water comes from the normal discharge of urban wastewater and more or less intense rains, depending on the season, which are the ones that mainly cause the overflow in the tanks and at the entrance of the WWTP. For all simulations, the prediction horizon selected is

N = 5, and the weights in the cost function are shown in

Table 3.

The system parameters have been taken from [

3] and are shown in

Table 4.

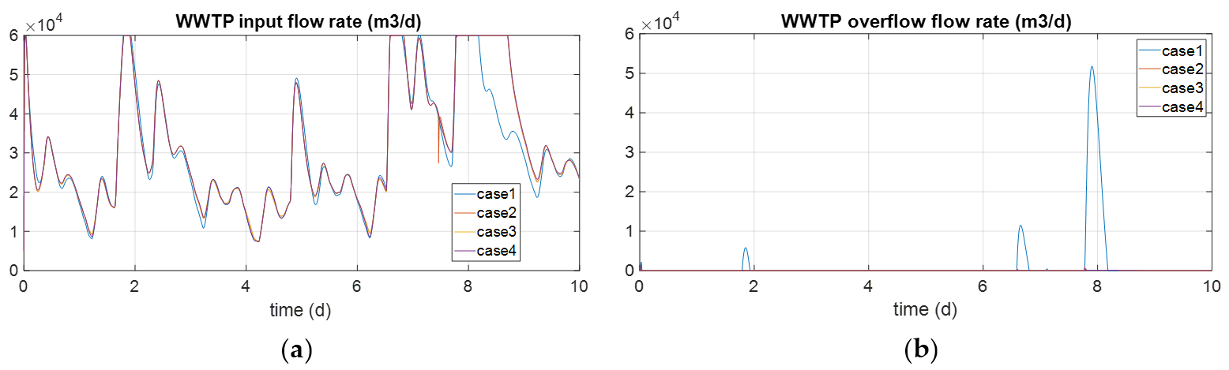

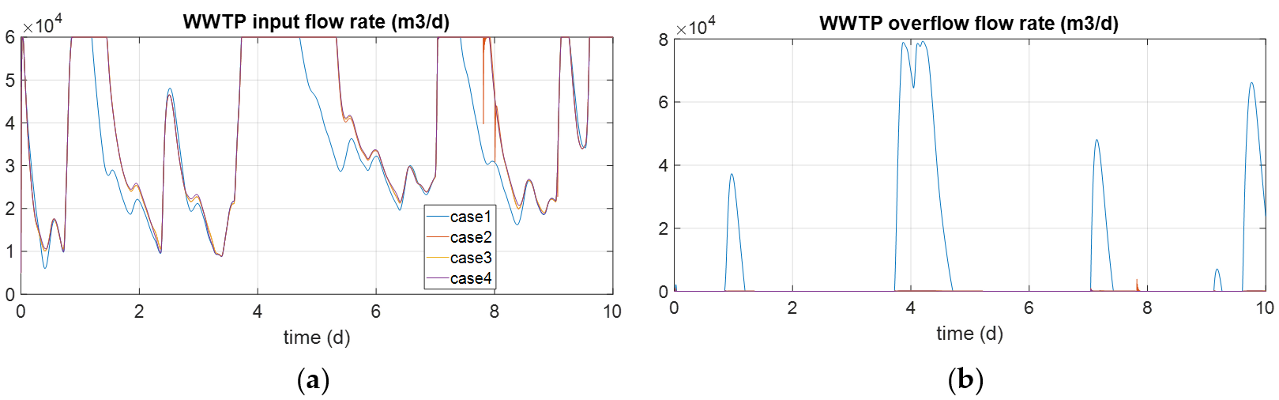

Some simulation graphic results are shown below for scenario 1. As can be seen in

Figure 12, the inflow to WWTP is very similar (b), as well as the overflow flow rate (a), except in the case without control. The differences between the cases considered are better revealed in the numerical results of

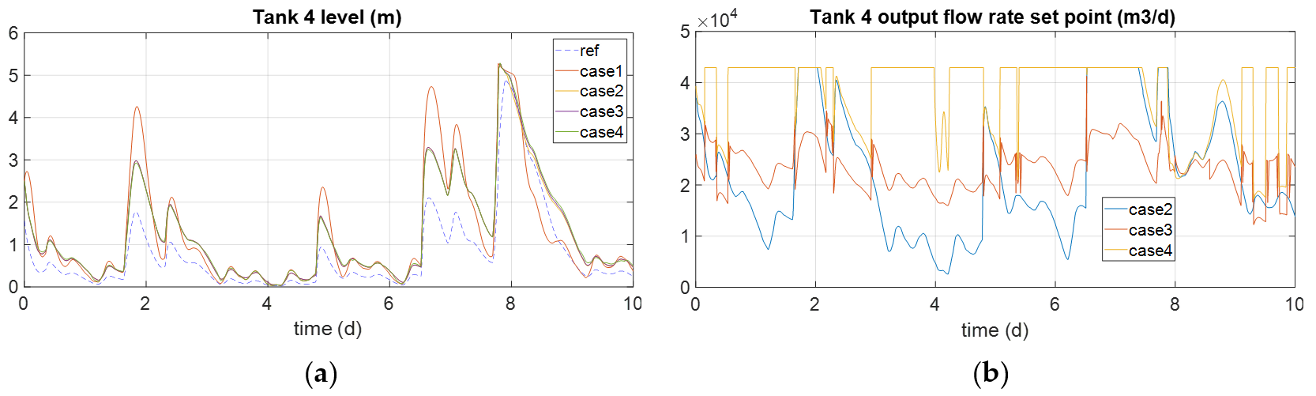

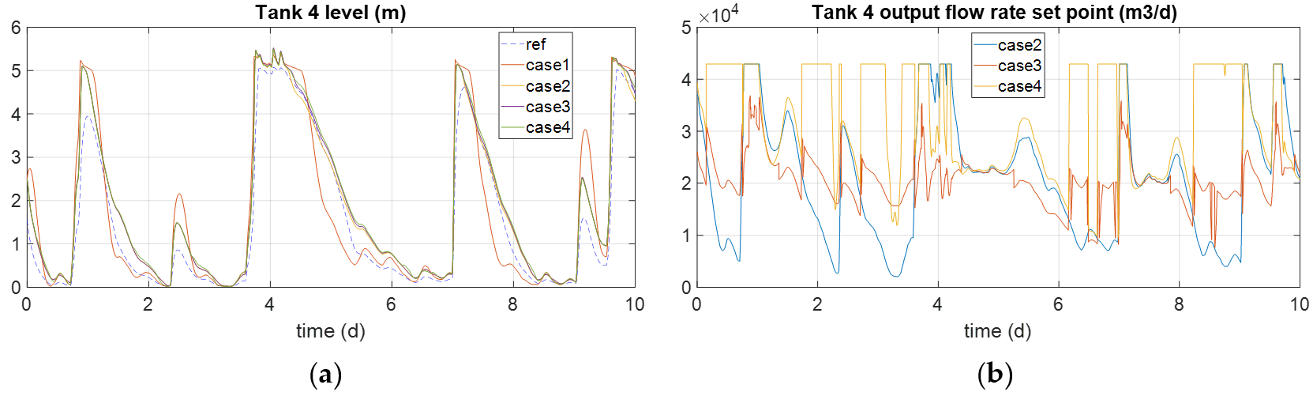

Table 5. For brevity, only tank 4 level (a) and outflow set point (b) in each case are shown in

Figure 13.

The evolution of the water level in tank 4 can be seen together with the reference proposed by the upper layer of the hierarchical controller. The reference tracking is considerably better for cases 2, 3, and 4 than for case 1 (without control). Therefore, if no control is applied, more overflow is produced at the inlet of the WWTP, because not enough water is maintained in the sewer tanks. The controlled cases also improve the total number of overflows at the inlet of the WWTP and the total volume of overflow water (

Table 4). Regarding the inlet flow to the WWTP, it is difficult to keep the nominal value

qWWTPnom, because the water received in the catchments has large variations and most of the time is not enough to reach that value. However, when control is applied, more water is stored in tank 5, allowing for a better regulation of the nominal value of the WWTP inlet flow (

Figure 12a).

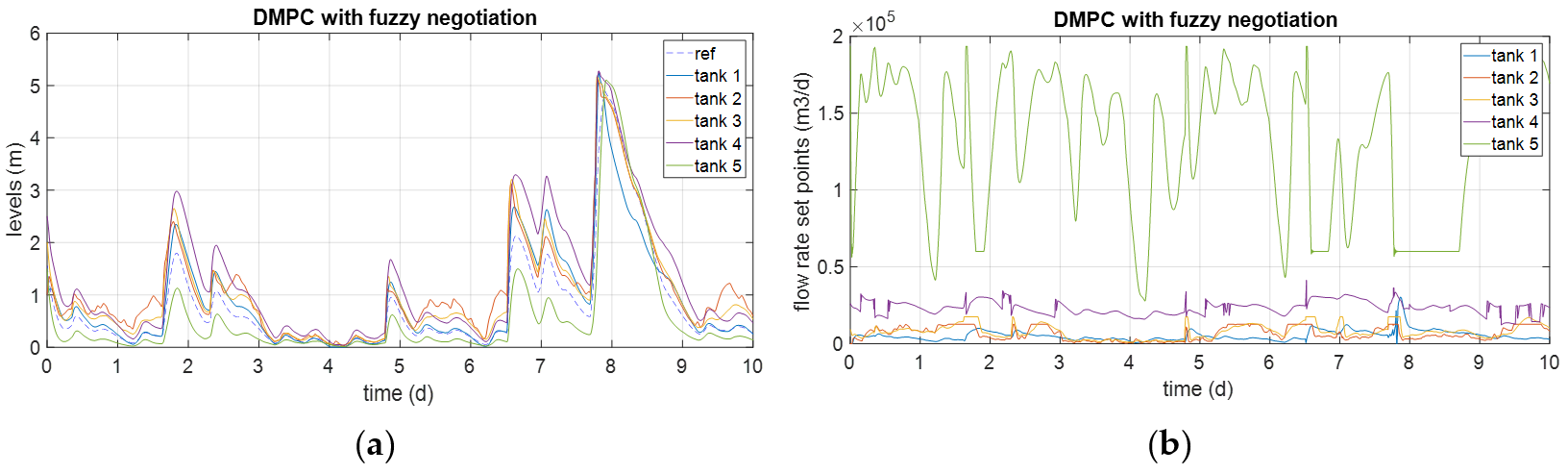

In

Figure 14, level (a) and output flow rate set point (b) can be observed for every tank in case 3, corresponding to a Distributed MPC with fuzzy negotiation. Levels are represented together with the reference level calculated at each instant according to (22). Some of them are closer than others to the reference value to minimize the volume of overflowed water and optimize the inflow to the WWTP.

The results for scenario 2 present a larger number of overflow events (Nov) and a larger overflow (Vov) due to the increase of the water received (disturbances). On the other hand, the usage of the WWTP (Gu) and the QWWTP average are due to the larger availability of water to keep the WWTP working close to the nominal operation point.

In

Table 5 (for scenario 1) and

Table 6 (for scenario 2), the performance indices presented in

Section 2.2 are presented for the four cases. Case 1 (without control) is the worst for all indices, as expected, and the centralized MPC presents the best performance for indices such as the average flow entering the WWTP (

QWWTP), the degree of usage of WWTP (

Gu), and the total volume overflow (

Vov). However, the DMPC with fuzzy negotiation does not show an important decrease of those indices, with the advantage of using local simpler models and optimization problems. Moreover, the use of DMPC provides the smallest

S, due to the smoothing effect of the fuzzy sets considered for negotiation. The case of Decentralized MPC provides the worst performance indices because the local controllers do not exchange information and the existing coupling in the network is not considered.

Finally, to analyze the influence of the fuzzy set design on the performance of the distributed control algorithm, the location of the fuzzy sets has been changed according to

Table 7, but their shape was preserved. Results are presented in

Table 8. The DMPC1 and DMPC2 cases present practically identical results. Therefore, it follows that the influence of the position variation of the fuzzy sets is negligible. By comparing DMPC2 and DMPC3, it can be seen that the degree of usage of the WWTP is slightly smaller in the case of DMPC3 because the center of the fuzzy set has been moved to the WWTP constraint of 60,000 m

3/d. By comparing DMPC3 and DMPC4, the overflow (

Vov) is larger for DMPC4 because the fuzzy set considers as negligible overflows of larger amount. Anyway, the results are very similar because the limits of the fuzzy sets are very next to each other.