Methodology for Concurrent Multi-Parametric Physical Modeling of a Target Natural Unfractured Homogeneous Sandstone

Abstract

1. Introduction

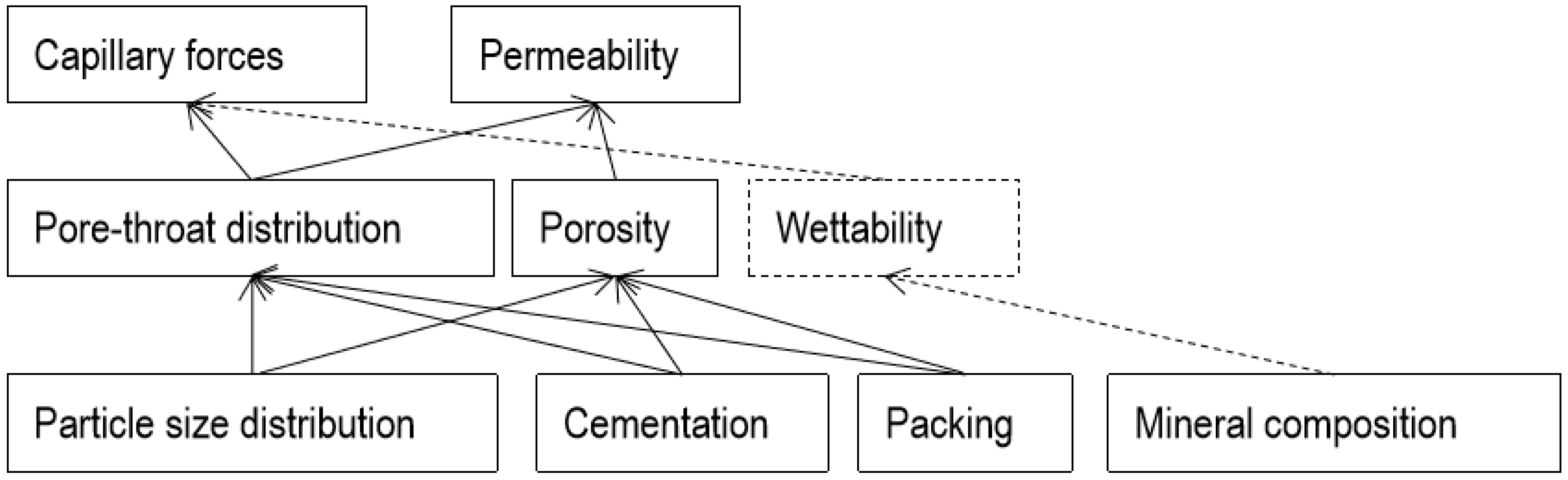

The Theoretical Physical Pathway Governing Interactions of Pore-Network Related Physical Parameters in a Natural Sandstone

2. Materials and Methods

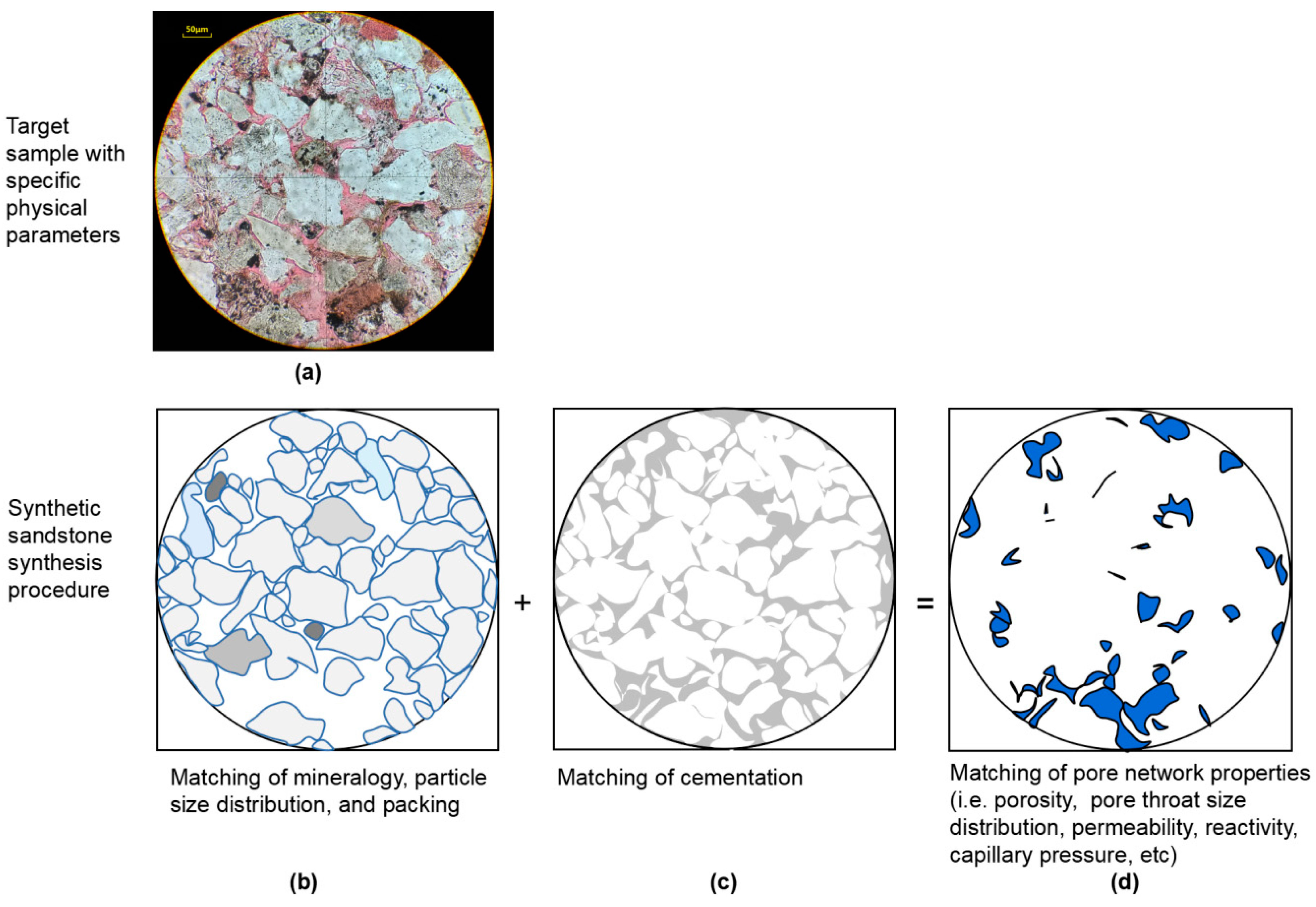

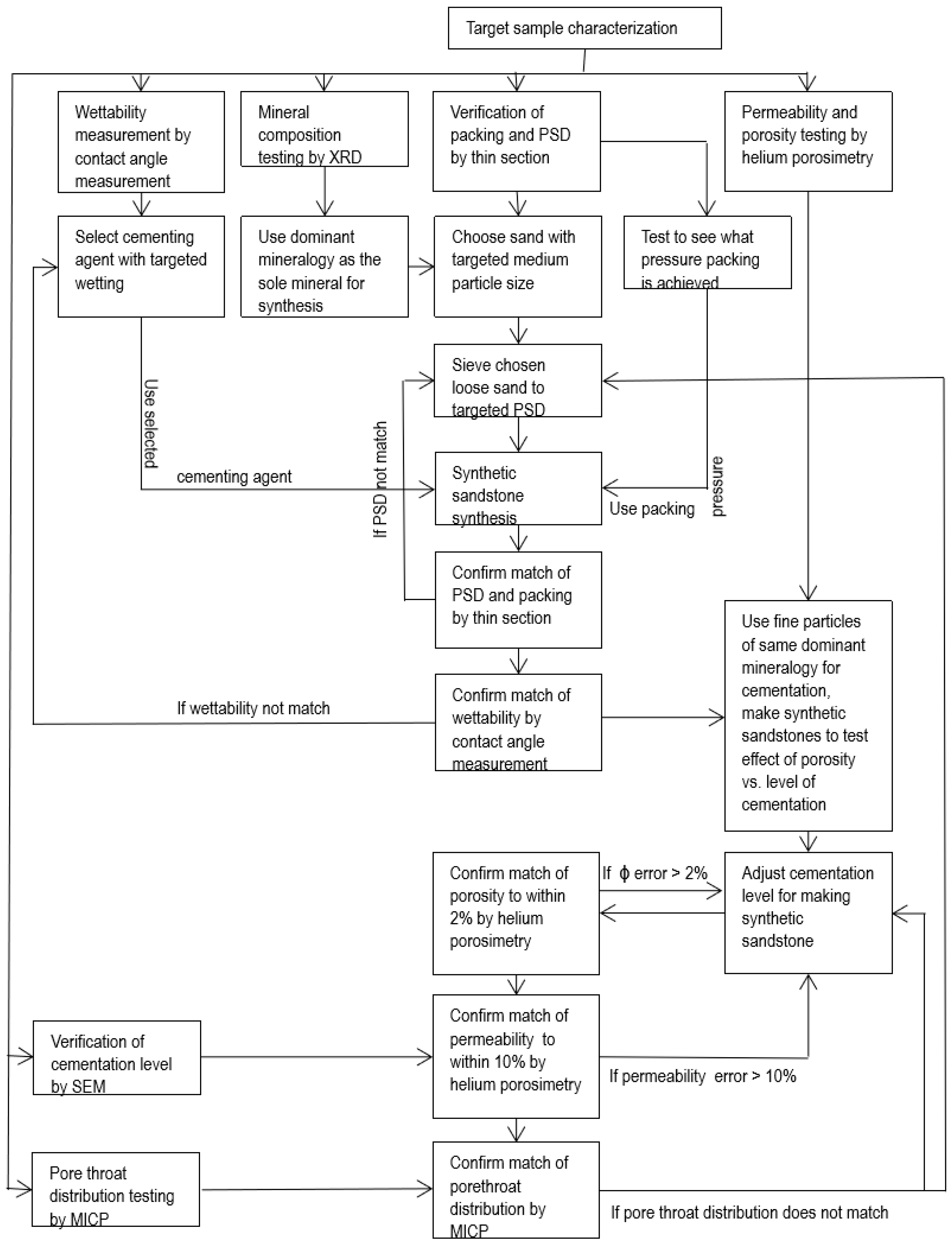

2.1. Methodology

2.2. Materials

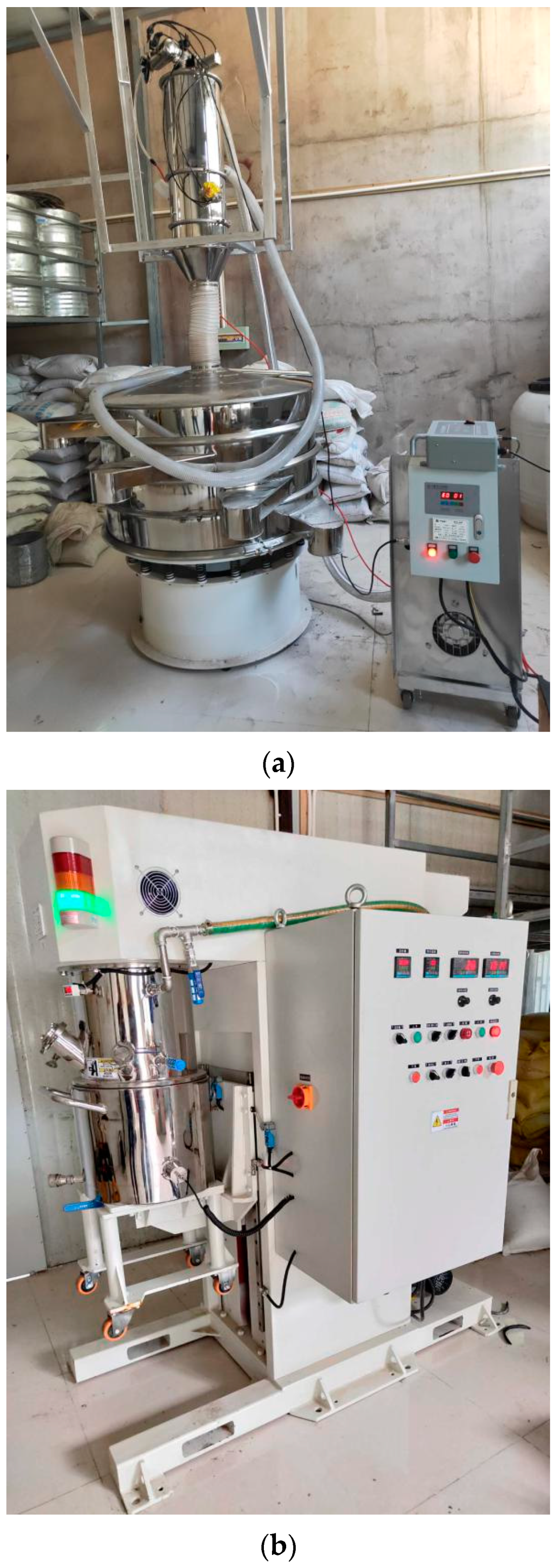

2.3. Equipment

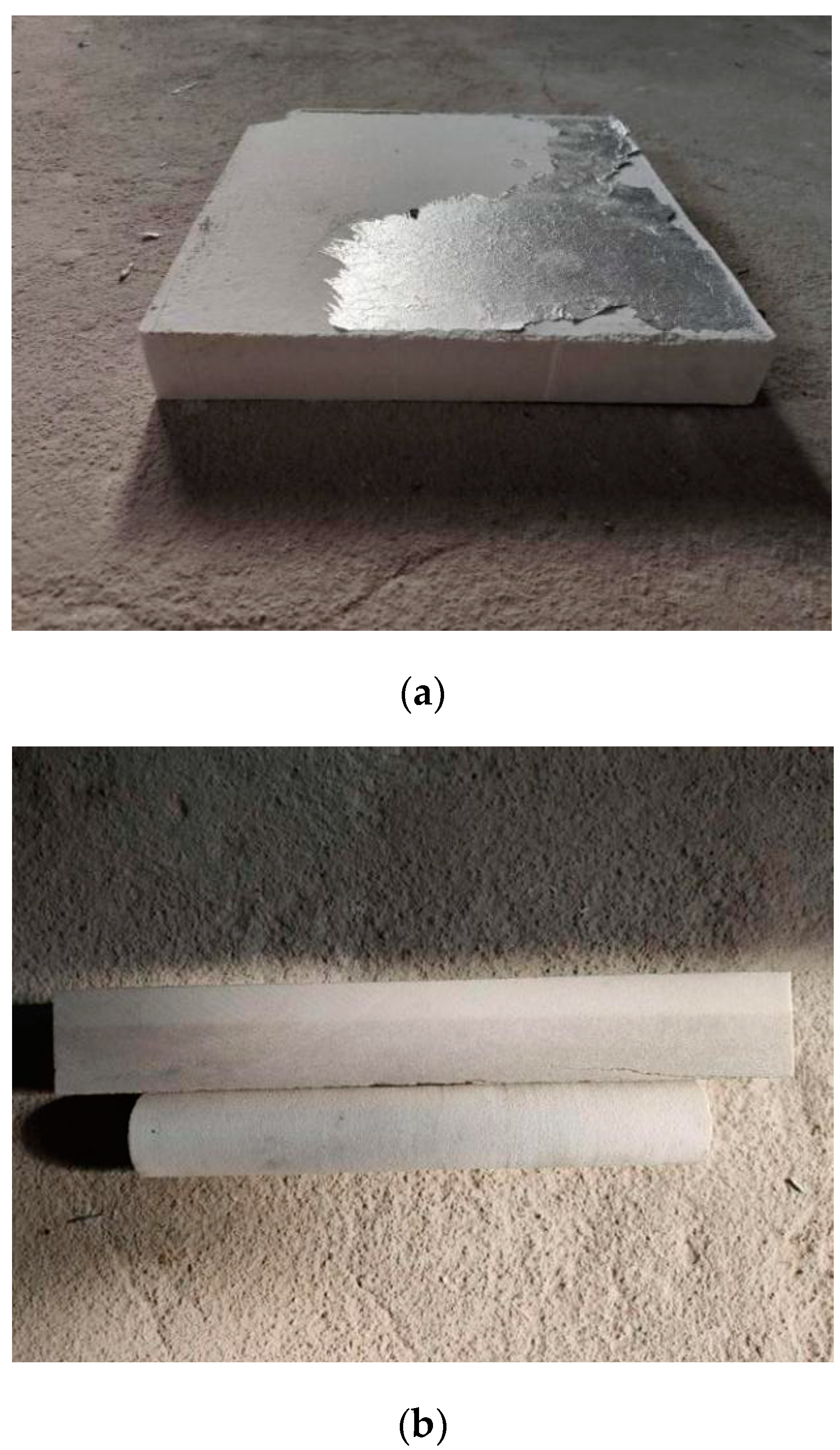

2.4. Synthetic Sandstone Synthesis

3. Results

3.1. Target Sample Characterization

3.2. Match of the Mineral Composition

3.3. The Matching of the Particle Size Distribution

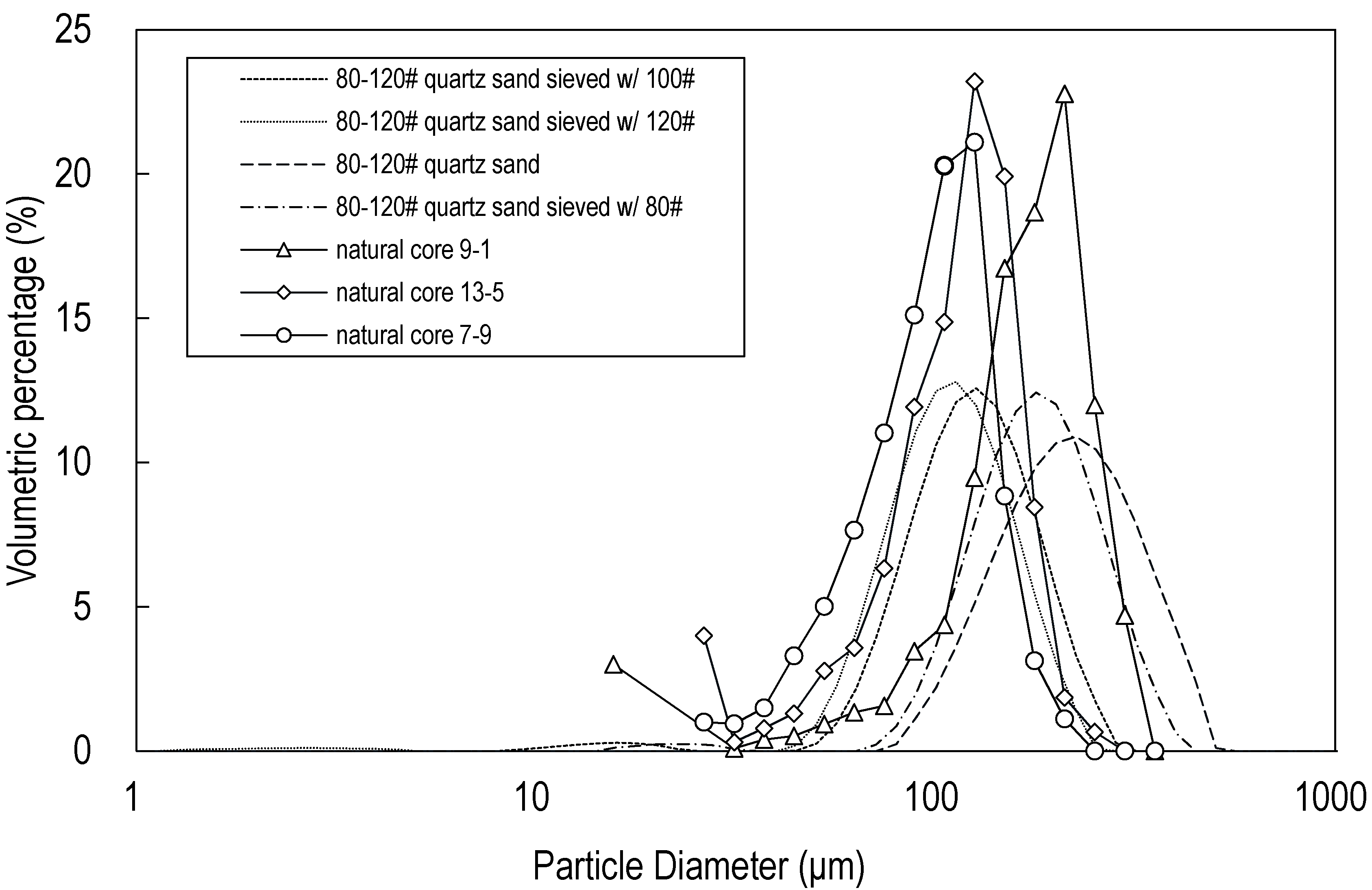

3.3.1. The Loose sand Selection

3.3.2. The Trimming of the Loose Sand to Match the Particle Size Distribution of Target Prior to Synthetic Sandstone Synthesis

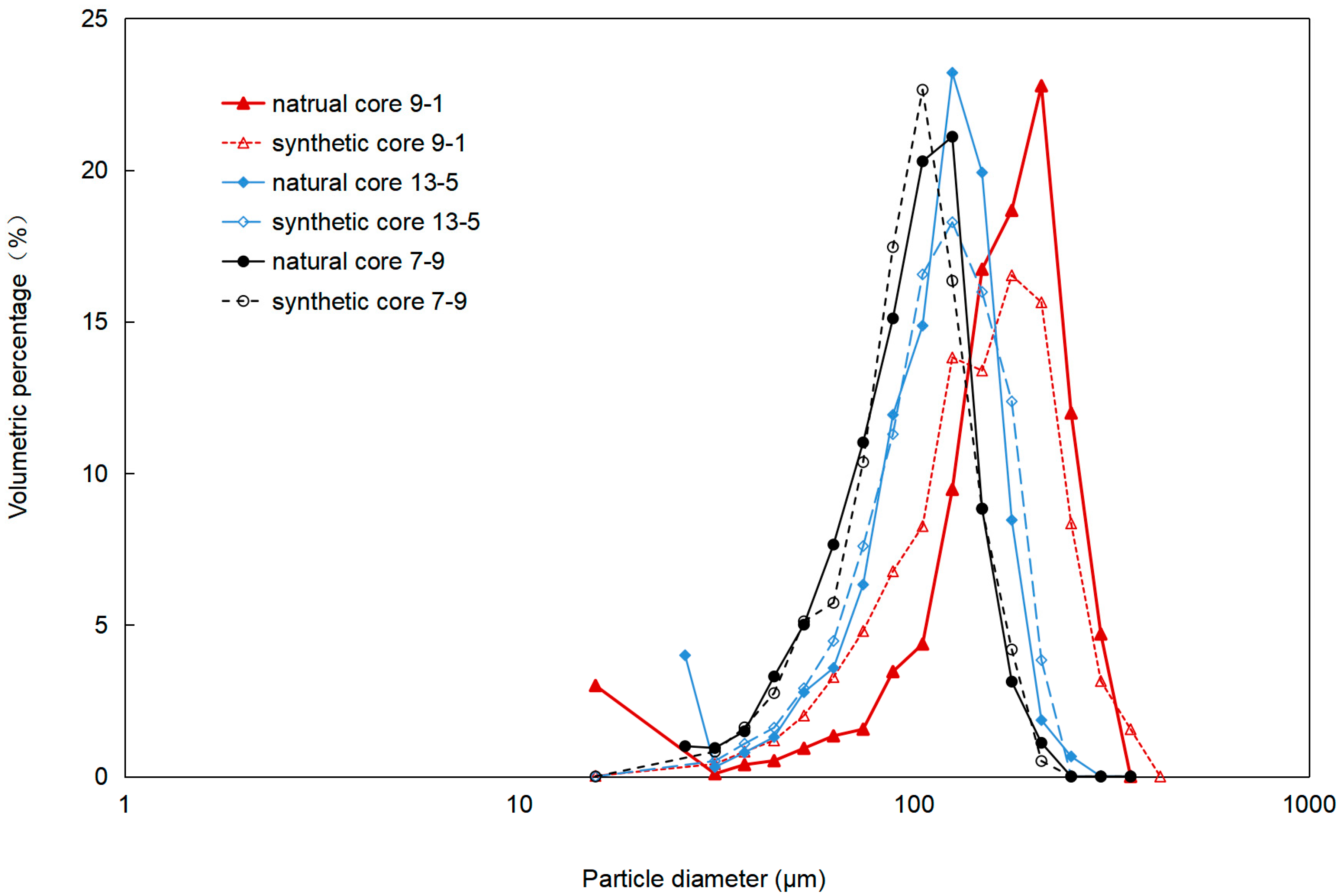

3.3.3. Match of Particle Size Distribution to Targets in Synthetic Sandstone by Thin Section Analysis

3.4. The Match of Wettability

3.5. Match of Packing

3.6. The Match of Porosity: Rough Adjustment Phase of Cementation Level

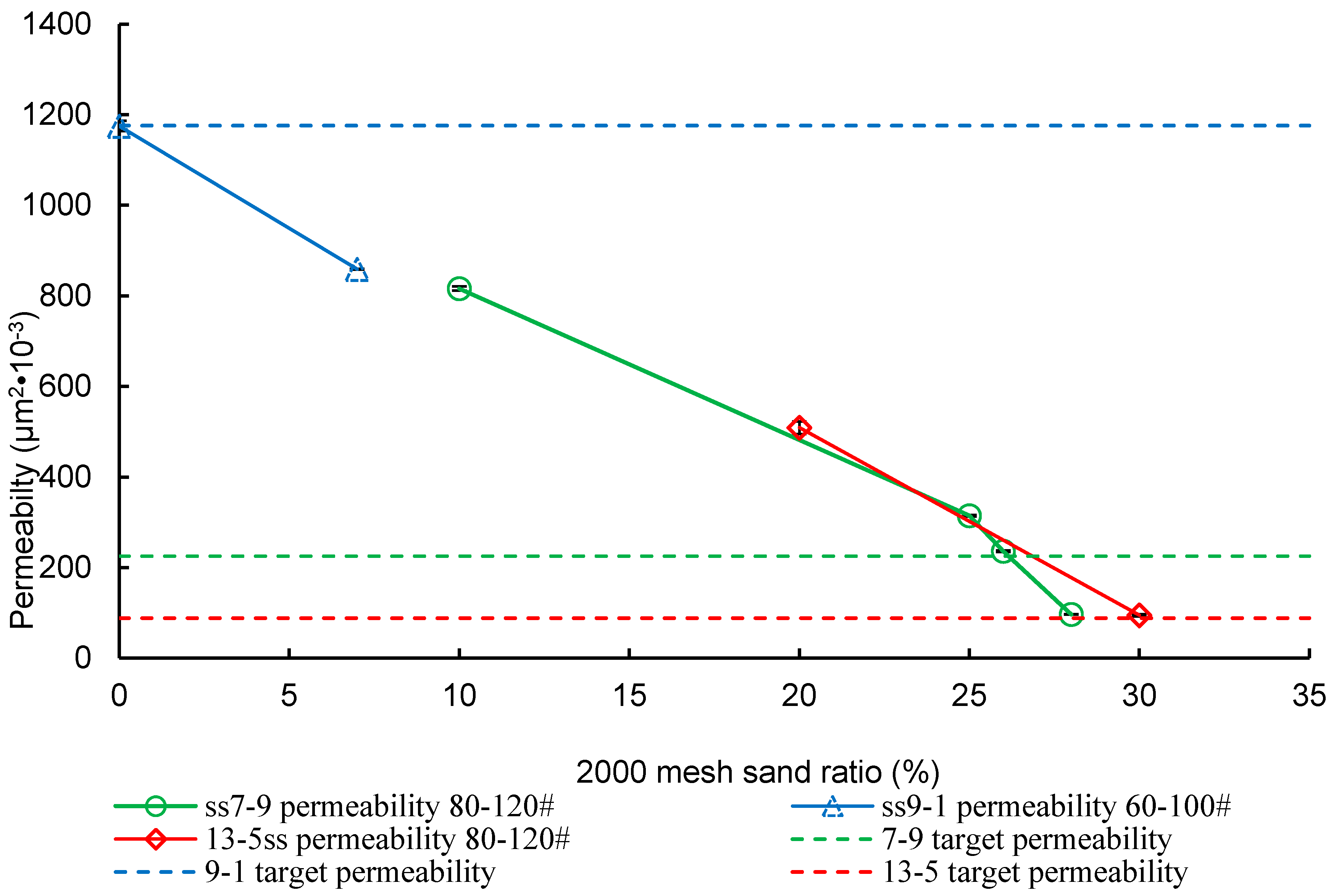

3.7. The Match of Permeability: Fine Adjustment Phase of Cementation Level

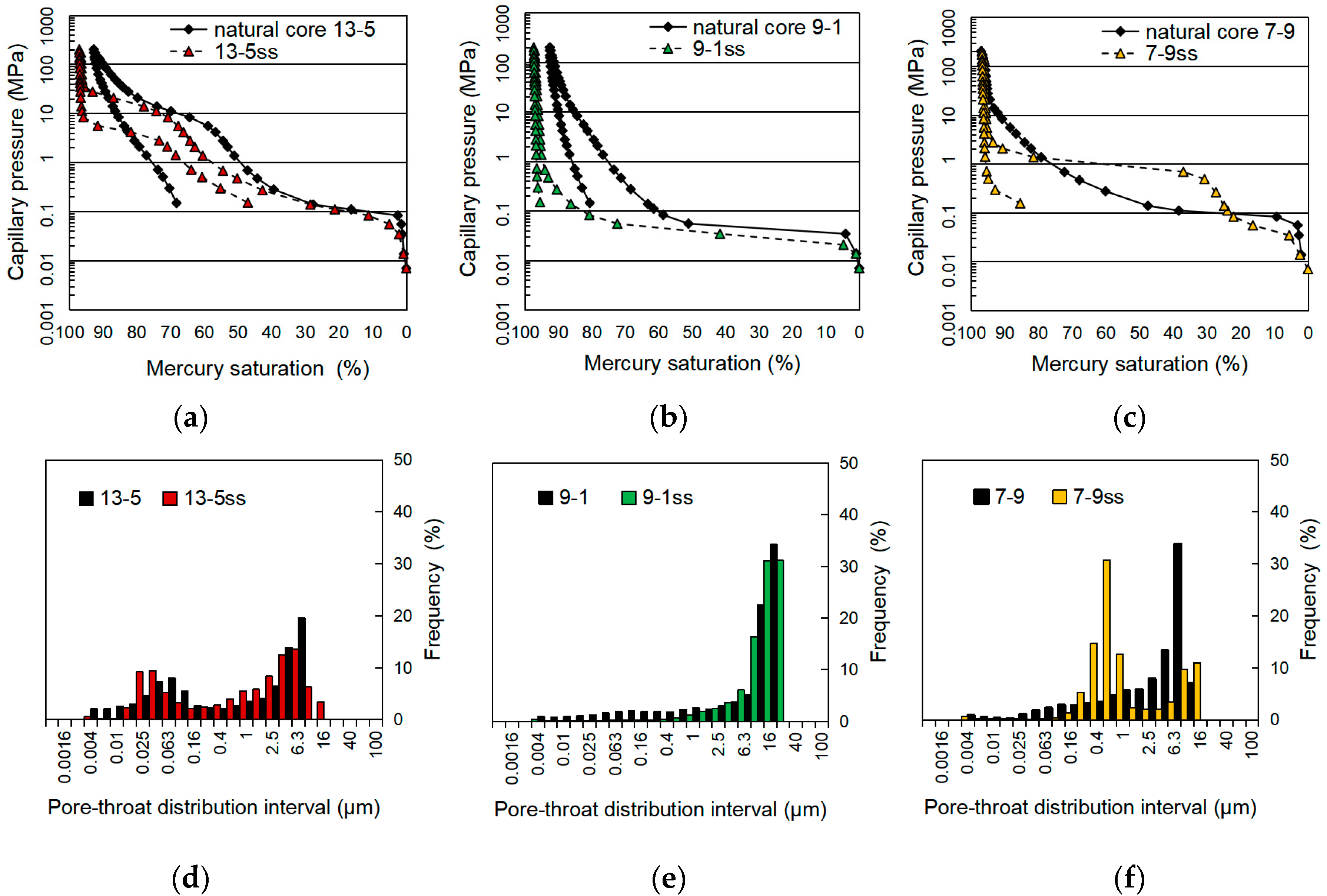

3.8. The Match of the Pore Throat Size Distribution: Fine Adjustment of Cementation Level and PSD

3.9. The Match of the Cementation Level: Validation by SEM

4. Summary and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ghosh, J.; Geoffrey, R.T.; Akyol, N.H.; Zhang, Y. A pore-scale investigation of heavy crude oil trapping and removal during surfactant-enhanced remediation. J. Contam. Hydrol. 2019, 223, 10347. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P.; Kostarelos, K.; Lenschow, S.; Christensen, A.; de Blanc, P.C. Surfactant flooding makes a comeback: Results of a full-scale, field implementation to recover mobilized NAPL. J. Contam. Hydrol. 2020, 230, 103602. [Google Scholar] [CrossRef] [PubMed]

- Bai, M.; Liu, L.; Li, C.; Song, K. Relative Permeability Characteristics During Carbon Capture and Sequestration Process in Low-Permeable Reservoirs. Materials 2020, 13, 990. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Q.; Yang, D.; Liu, X. Laboratory core flooding experimental systems for CO2 geosequestration: An updated review over the past decade. J. Rock Mech. Geotech. Eng. 2016, 8, 113–126. [Google Scholar] [CrossRef]

- Aadland, R.C.; Jakobsen, T.D.; Heggset, E.B.; Long-Sanouiller, H.; Simon, S.; Paso, K.G.; Syverud, K.; Torsæter, O. High-Temperature Core Flood Investigation of Nanocellulose as a Green Additive for Enhanced Oil Recovery. Nanomaterials 2019, 9, 665. [Google Scholar] [CrossRef]

- Vorhauer, N.; Altaf, H.; Tsotsas, E.; Vidakovic-Koch, T. Pore Network Simulation of Gas-Liquid Distribution in Porous Transport Layers. Processes 2019, 7, 558. [Google Scholar] [CrossRef]

- Vorhauer-Huget, N.; Altaf, H.; Dürr, R.; Tsotsas, E.; Vidaković-Koch, T. Computational Optimization of Porous Structures for Electrochemical Processes. Processes 2020, 8, 1205. [Google Scholar] [CrossRef]

- Keshmiri, K.; Mozaffari, S.; Tchoukov, P.; Huang, H.; Nazemifard, N. Using Microfluidic Device to Study Rheological Properties of Heavy Oil. In Proceedings of the 2016 AIChE Annual Meeting, San Francisco, CA, USA, 14 November 2016. [Google Scholar]

- Mozaffari, S.; Tchoukov, P.; Mozaffari, A.; Atias, J.; Czarnecki, J.; Nazemifard, N. Capillary driven flow in nanochannels–Application to heavy oil rheology studies. Colloids Surf. A Physicochem. Eng. Asp. 2017, 513, 178–187. [Google Scholar] [CrossRef]

- Churcher, P.L.; French, P.R.; Shaw, J.C.; Schramm, L.L. Rock Properties of Berea Sandstone, Baker Dolomite, and Indiana Limestone. In Proceedings of the SPE International Symposium on Oilfield Chemistry, Anaheim, CA, USA, 1 January 1991. [Google Scholar] [CrossRef]

- Abdelgawad, K.Z.; Mahmoud, M.; Elkatatny, S.; Abdulraheem, A.; Patil, S. Reaction Kinetics and Coreflooding Study of High-Temperature Carbonate Reservoir Stimulation Using GLDA in Seawater. Energies 2019, 12, 3407. [Google Scholar] [CrossRef]

- Brattekås, B.; Føyen, T.L.; Vabø, T.; Haugland, H.; Reite, S.I.; Saunes, A.S.; Fernø, M.A. Dos and don’ts when developing a system to investigate spontaneous imbibition in unconsolidated porous media. In Proceedings of the International Symposium of the Society of Core Analysts, Trondheim, Norway, 27–30 August 2018. [Google Scholar]

- Ronan, L. An NMR Investigation to Pore Size and Paramagnetic Effect in Synthetic Sandstone. Ph.D. Thesis, University of Western Australia, Perth, Australia, 2006. [Google Scholar]

- Shi, L.; Zhu, S.; Guo, Z.; Zhao, W.; Xue, X.; Wang, X.; Ye, Z. Experimental Study on the Effect of Polymer Injection Timing on Oil Displacement in Porous Media. Processes 2020, 8, 93. [Google Scholar] [CrossRef]

- Shi, J.Q.; Xue, Z.; Durucan, S. Supercritical CO2 core flooding and imbibition in Tako sandstone—Influence of sub-core scale heterogeneity. Int. J. Greenh. Gas Control 2011, 5, 75–87. [Google Scholar] [CrossRef]

- Al-Homadhi, E.S. Artificial Sandstone Cores Production with a Wide Range of Petrophysical Properties. J. King Saud Univ. Eng. Sci. 2002, 14, 95–117. [Google Scholar] [CrossRef]

- Fedrizzi, R.M.; Rodrigues de Ceia, M.A.; Misságia, R.M.; Santos, V.H.; Neto, I.L. Artificial carbonate rocks: Synthesis and petrophysical characterization. J. Pet. Sci. Eng. 2018, 163, 303–310. [Google Scholar] [CrossRef]

- den Brok, S.W.J.; David, C.; Bernabé, Y. Preparation of synthetic sandstones with variable cementation for studying the physical properties of granular rocks. C. R. Acad. Sci. Ser. IIa Sci. Terre Planetes 1997, 325, 487–492. [Google Scholar] [CrossRef]

- Kozhagulova, A.A.; Shabdirova, A.D.; Tokazhanov, G.; Minh, N.H. Bond Characteristics of Artificial Sandstones with sodium silicate cement. In Proceedings of the 52nd U.S. Rock Mechanics/Geomechanics Symposium, Seattle, WA, USA, 17–20 June 2018. [Google Scholar]

- Klimentos, T.; Parker, A. The preparation (by an epoxy-resin method) and physical properties of artificial sandstones. Sediment. Geol. 1988, 59, 307–312. [Google Scholar] [CrossRef]

- Holt, R.M.; Unander, T.E.; Kenter, C.J. Constitutive mechanical behaviour of synthetic sandstone formed under stress. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 719–722. [Google Scholar] [CrossRef]

- Mozaffari, S.; Li, W.; Dixit, M.; Seifert, S.; Lee, B.; Kovarik, L.; Mpourmpakis, G.; Karim, A.M. The role of nanoparticle size and ligand coverage in size focusing of colloidal metal nanoparticles. Nanoscale Adv. 2019, 1, 4052–4066. [Google Scholar] [CrossRef]

- Ghasemi, H.; Aghabarari, B.; Alizadeh, M.; Khanlarkhani, A.; Abu-Zahra, N. High efficiency decolorization of wastewater by Fenton catalyst: Magnetic iron-copper hybrid oxides. J. Water Process. Eng. 2020, 37, 101540. [Google Scholar] [CrossRef]

- Guo, W.; Xiao, H.; Yao, X.; Liu, J.; Liang, J.; Gao, P.; Zeng, G. Tuning pore structure of corrosion resistant solid-state-sintered SiC porous ceramics by particle size distribution and phase transformation. Mater. Des. 2016, 100, 1–7. [Google Scholar] [CrossRef]

- Rashidi, S.; Kashefi, M.H.; Kim, K.C.; Samimi-Abianeh, O. Potentials of porous materials for energy management in heat exchangers—A comprehensive review. Appl. Energy 2019, 243, 206–232. [Google Scholar] [CrossRef]

- Rashidi, S.; Esfahani, J.A.; Karimi, N. Porous materials in building energy technologies—A review of the applications, modelling and experiments. Renew. Sustain. Energy Rev. 2018, 91, 229–247. [Google Scholar] [CrossRef]

- Yang, K.; Li, J.; Zhou, L.; Zhang, T.; Fu, L. Synthetic strategies of two-dimensional porous materials towards highly effective catalysts. FlatChem 2019, 15, 100109. [Google Scholar] [CrossRef]

- Su, J.; Chen, J.S. Synthetic porous materials applied in hydrogenation reactions. Microporous Mesoporous Mater. 2017, 237, 246–259. [Google Scholar] [CrossRef]

- Costa, S.E.D.; Barros Neto, E.L.; Oliveira, M.C.A.; Santos, J.S.C. Mechanical and petrophysical analysis of synthetic sandstone for enhanced oil recovery applications. Braz. J. Pet. Gas 2017, 11, 131–140. [Google Scholar] [CrossRef][Green Version]

- Schäfer, A.; Teyssen, T. Size, shape and orientation in sands and sandstones-image analysis applied to rocks in thin sections. Sediment. Geol. 1987, 52, 3. [Google Scholar] [CrossRef]

- Deng, Y.; Hao, W.H.; Lu, W.L. The contact angle of water on feldspar in a reservoir rock. Chin. Sci. Bull. 2018, 63, 3137–3145. [Google Scholar] [CrossRef]

- Deng, Y.; Xu, L.; Lu, H.; Wang, H.; Shi, Y. Direct Measurement of the Contact Angle of Water Droplet on Quartz in a Reservoir Rock with Atomic Force Microscopy. Chem. Eng. Sci. 2017, 177. [Google Scholar] [CrossRef]

- Sharifipour, M.; Pourafshary, P.; Nakhaee, A. Study of the effect of clay swelling on the oil recovery factor in porous media using a glass micromodel. Appl. Clay Sci. 2017, 141, 125–131. [Google Scholar] [CrossRef]

- Kamal, M.S.; Mahmoud, M.; Hanfi, M.; Elkatatny, S.; Hussein, I. Clay minerals damage quantification in sandstone rocks using core flooding and NMR. J. Pet. Explor. Prod. Technol. 2019, 9, 593. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Determination of Pore Volume and Pore Volume Distribution of Soil and Rock by Mercury Intrusion Porosimetry; ASTM (American society for Testing and Materials): West Conshohocken, PA, USA, 1984; pp. 4404–4484, reapproved 1998. [Google Scholar]

- Shafer, J.; Neashman, J. Mercury porosimetry protocol for rapid determination of petrophysical and reservoir quality properties. In Proceedings of the Society of Core Analysts, Abu Dhabi, UAE, 18–20 October 2000. [Google Scholar]

- Fu, J.Y.; Yue, X.A.; Li, L.; Zhang, L. Method of Predicting the Location of Water Cresting for Horizontal Wells in a Water-Drive Reservoir for Early Prevention. ACS Omega 2020, 5, 26153–26168. [Google Scholar] [CrossRef]

| Sample | Mineral Composition (%) | ||||||

|---|---|---|---|---|---|---|---|

| Quartz | Potassium-Feldspar | Plagioclase-Feldspar | Calcite | Dolomite | Rock Salt | Clay | |

| 9-1 | 51.7 | 11.4 | 27.7 | / | / | 2.8 | 6.4 |

| 13-5 | 55.4 | 10.1 | 22.1 | / | / | / | 12.4 |

| 7-9 | 51.1 | 8.4 | 30 | 0 | 2.4 | 0.7 | 7.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, J.Y.; Yue, X.; Zhang, B. Methodology for Concurrent Multi-Parametric Physical Modeling of a Target Natural Unfractured Homogeneous Sandstone. Processes 2020, 8, 1448. https://doi.org/10.3390/pr8111448

Fu JY, Yue X, Zhang B. Methodology for Concurrent Multi-Parametric Physical Modeling of a Target Natural Unfractured Homogeneous Sandstone. Processes. 2020; 8(11):1448. https://doi.org/10.3390/pr8111448

Chicago/Turabian StyleFu, Joseph Y., Xiang’an Yue, and Bo Zhang. 2020. "Methodology for Concurrent Multi-Parametric Physical Modeling of a Target Natural Unfractured Homogeneous Sandstone" Processes 8, no. 11: 1448. https://doi.org/10.3390/pr8111448

APA StyleFu, J. Y., Yue, X., & Zhang, B. (2020). Methodology for Concurrent Multi-Parametric Physical Modeling of a Target Natural Unfractured Homogeneous Sandstone. Processes, 8(11), 1448. https://doi.org/10.3390/pr8111448