CFD Hydrodynamics Investigations for Optimum Biomass Gasifier Design

Abstract

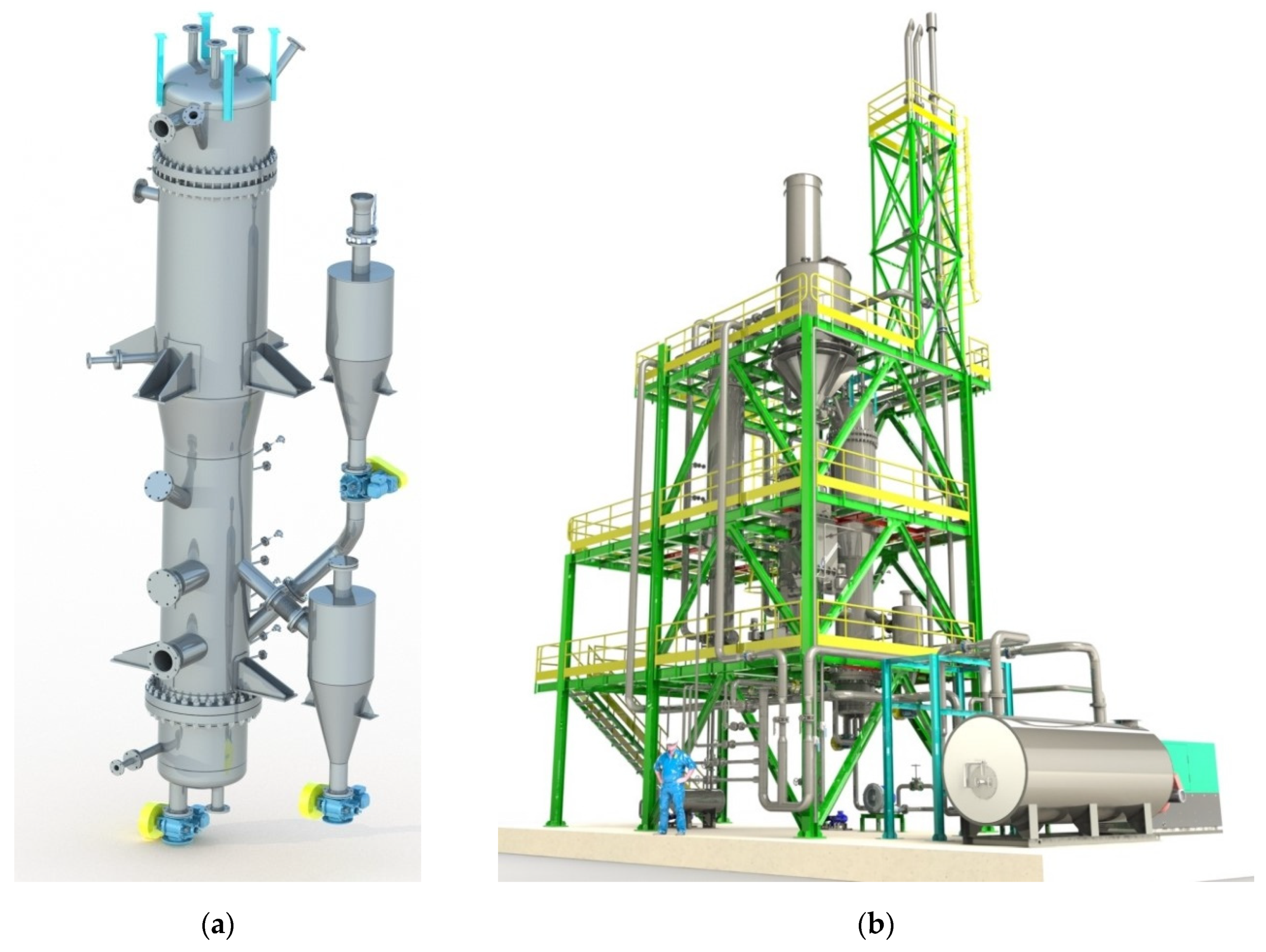

1. Introduction

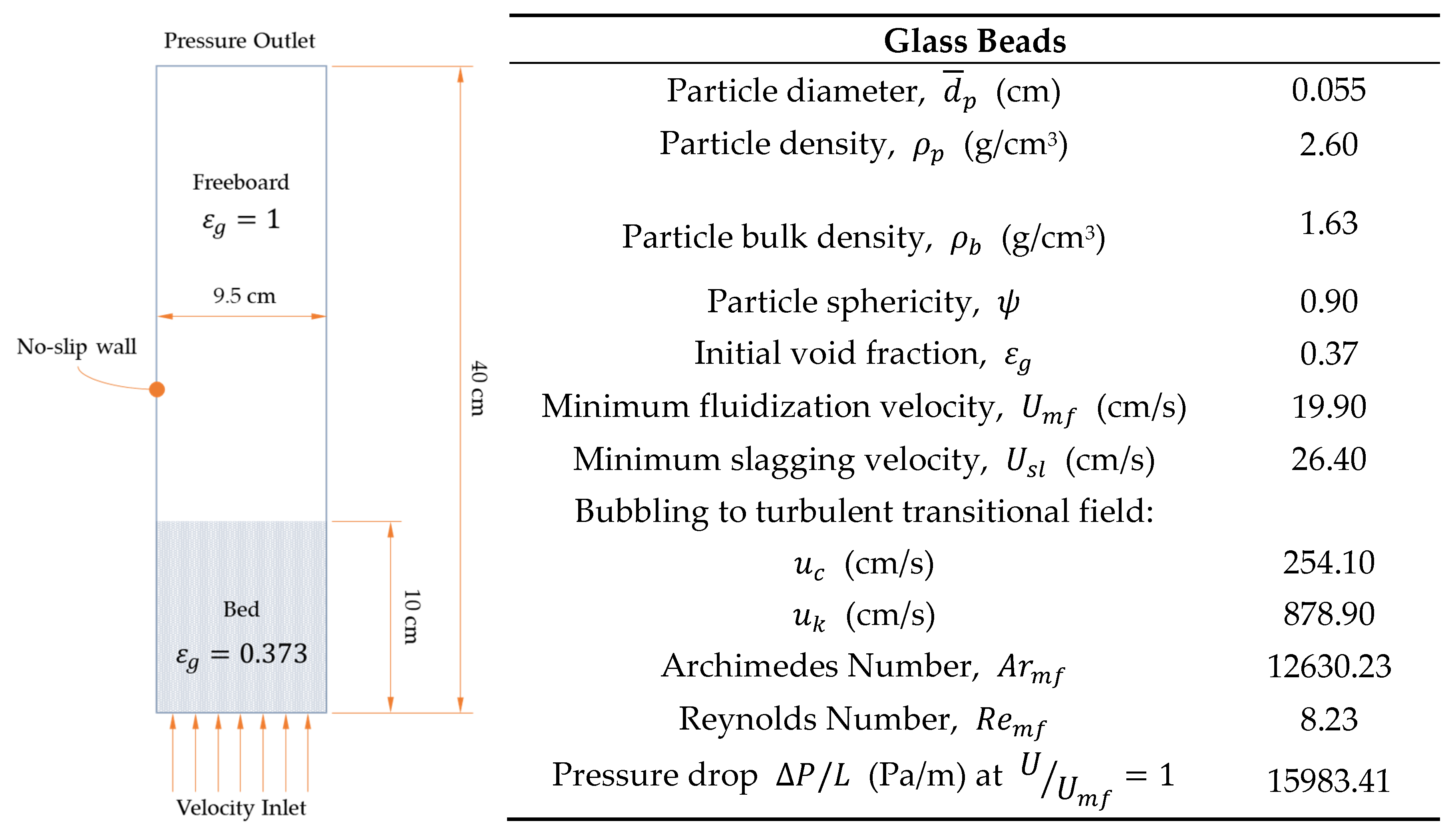

2. Materials and Methods

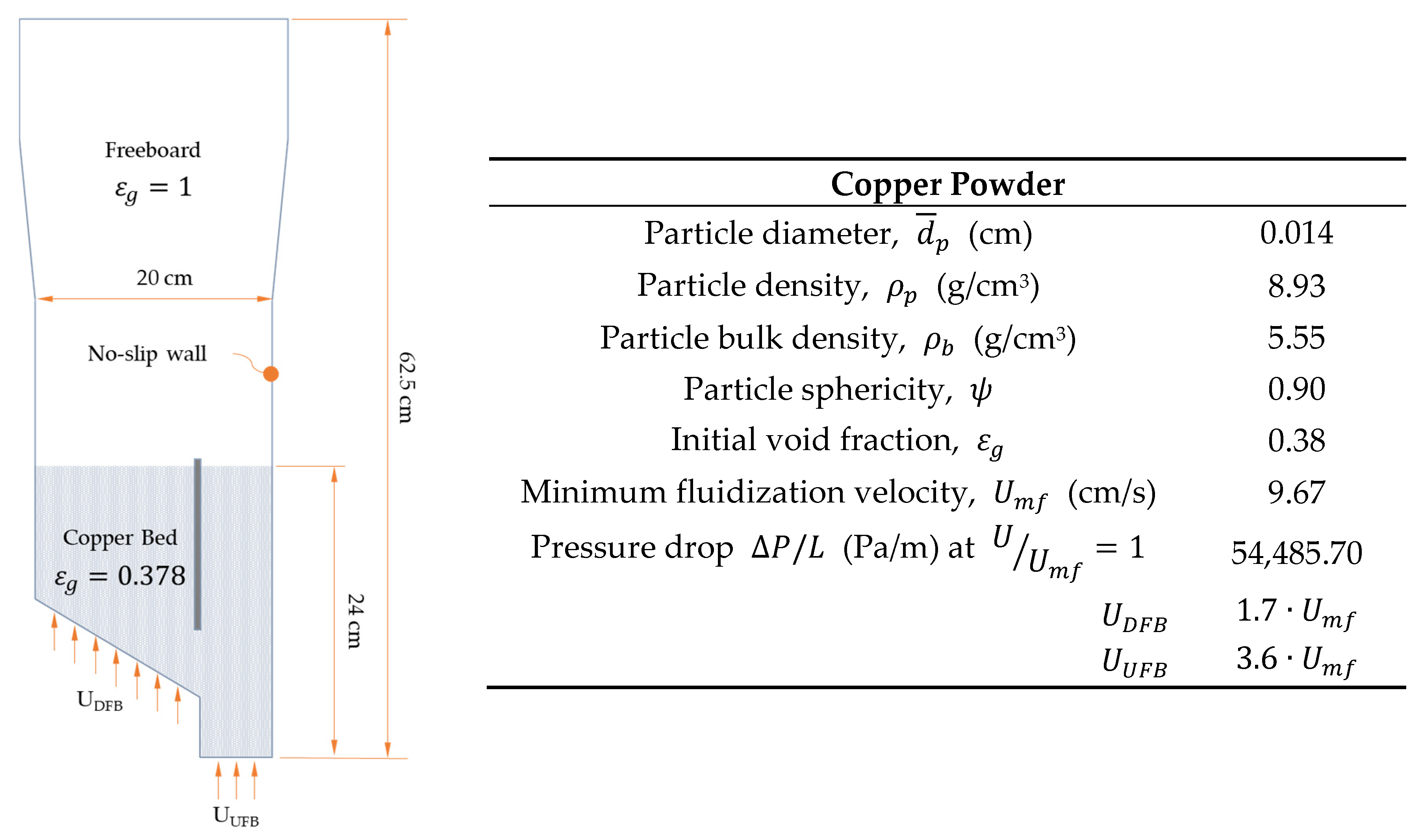

2.1. Cold Model Definition

2.2. Mathematical Model

2.3. Computational Methodology

3. Results and Discussion

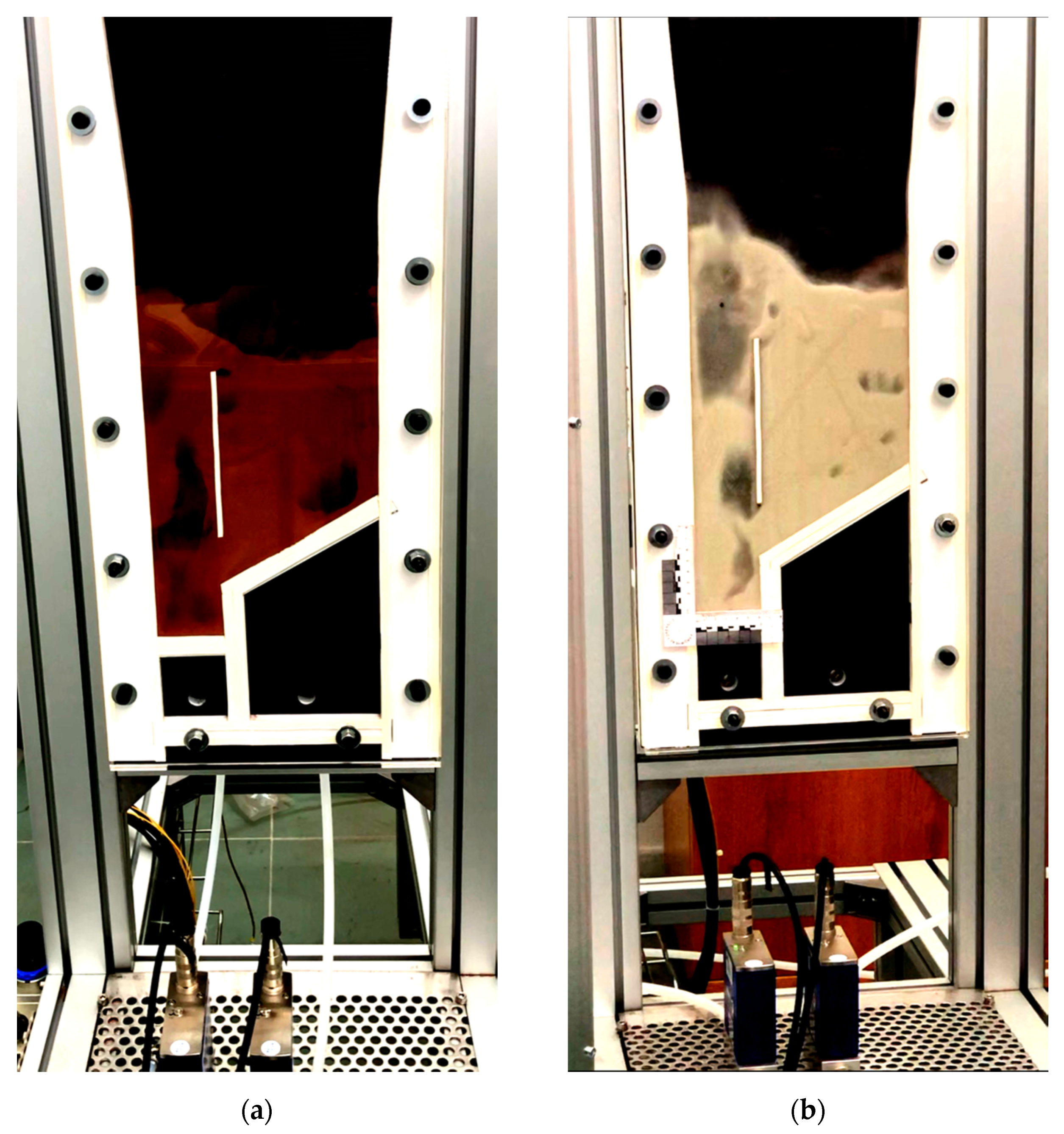

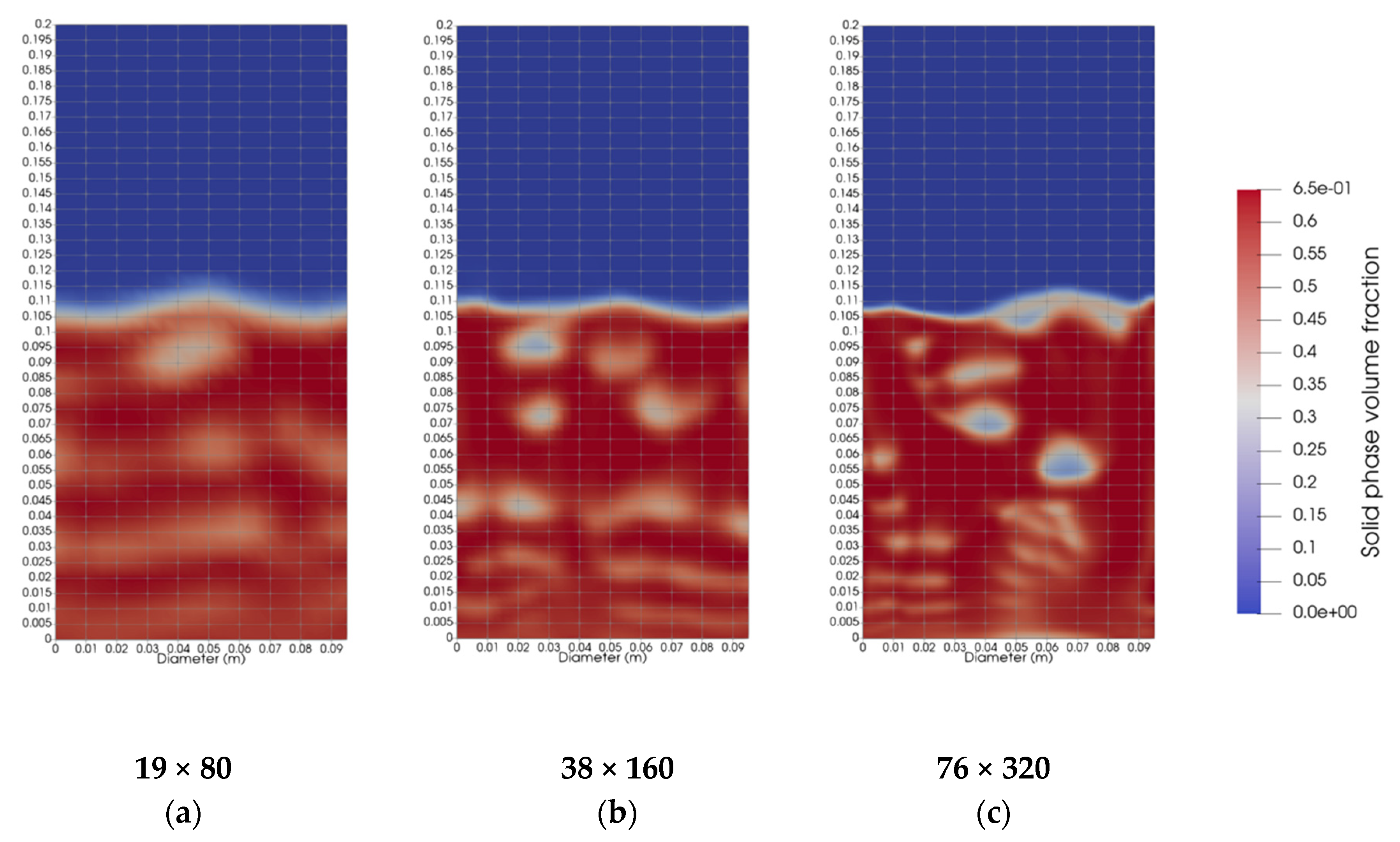

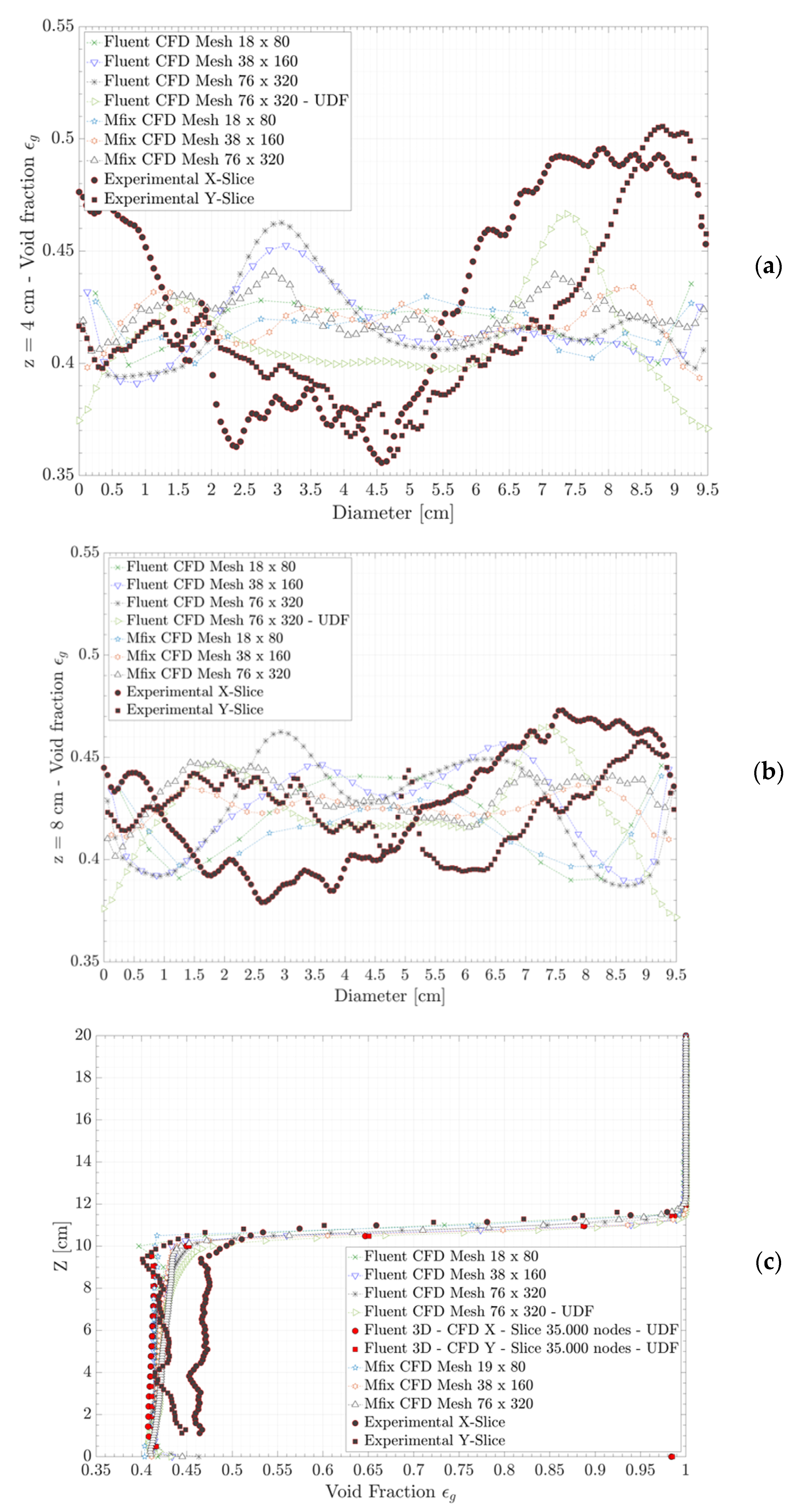

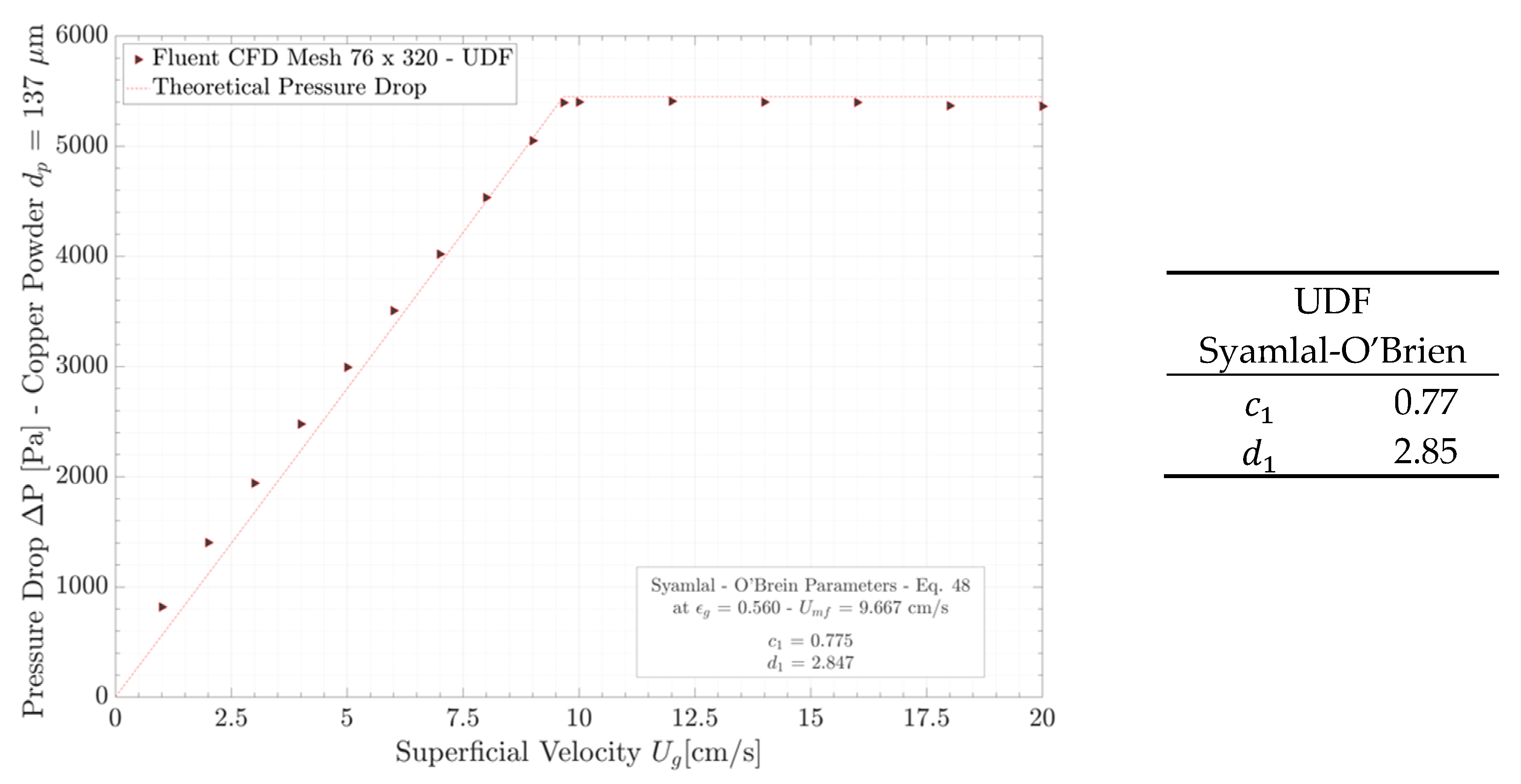

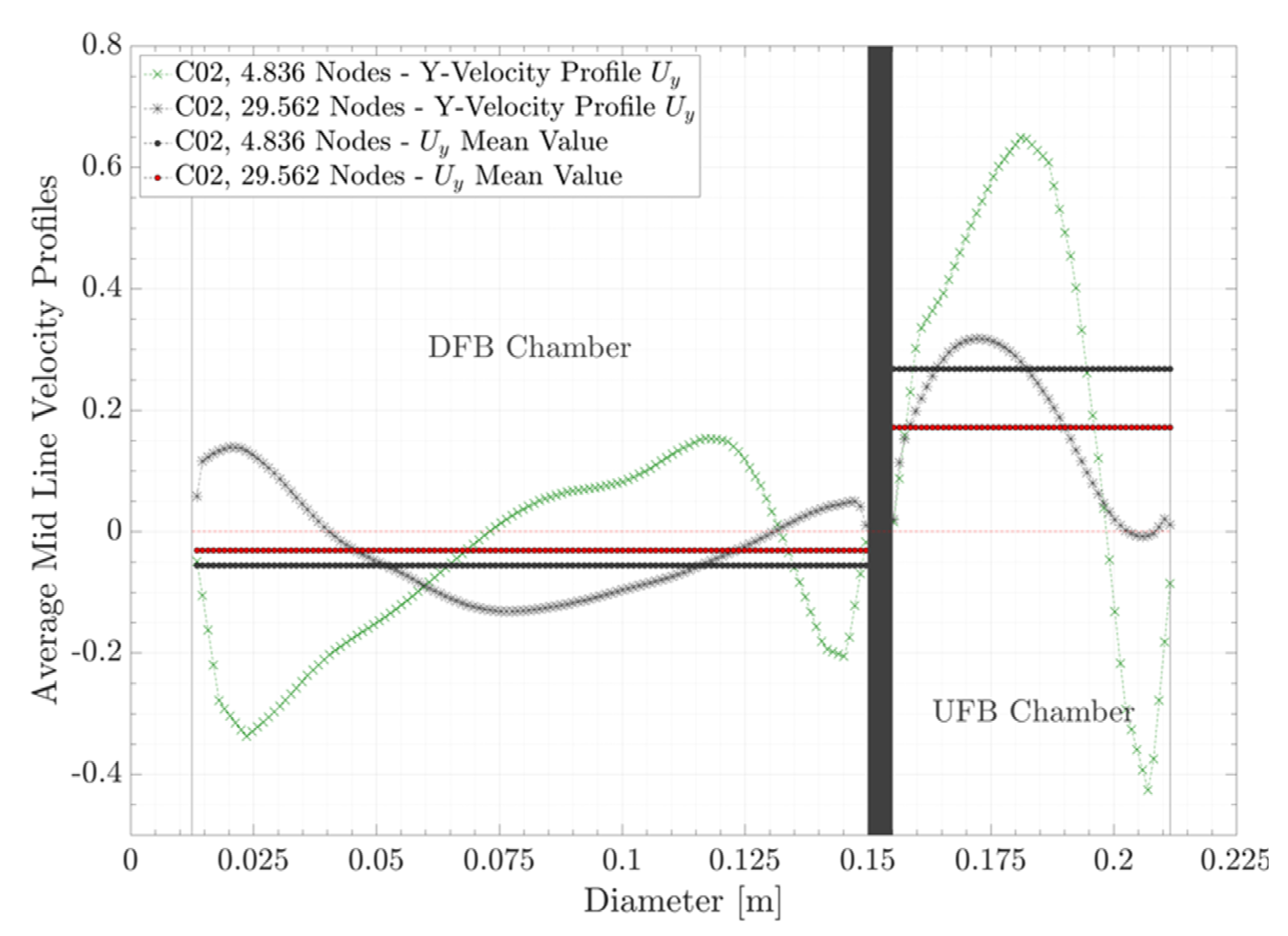

3.1. Numerical Benchmark

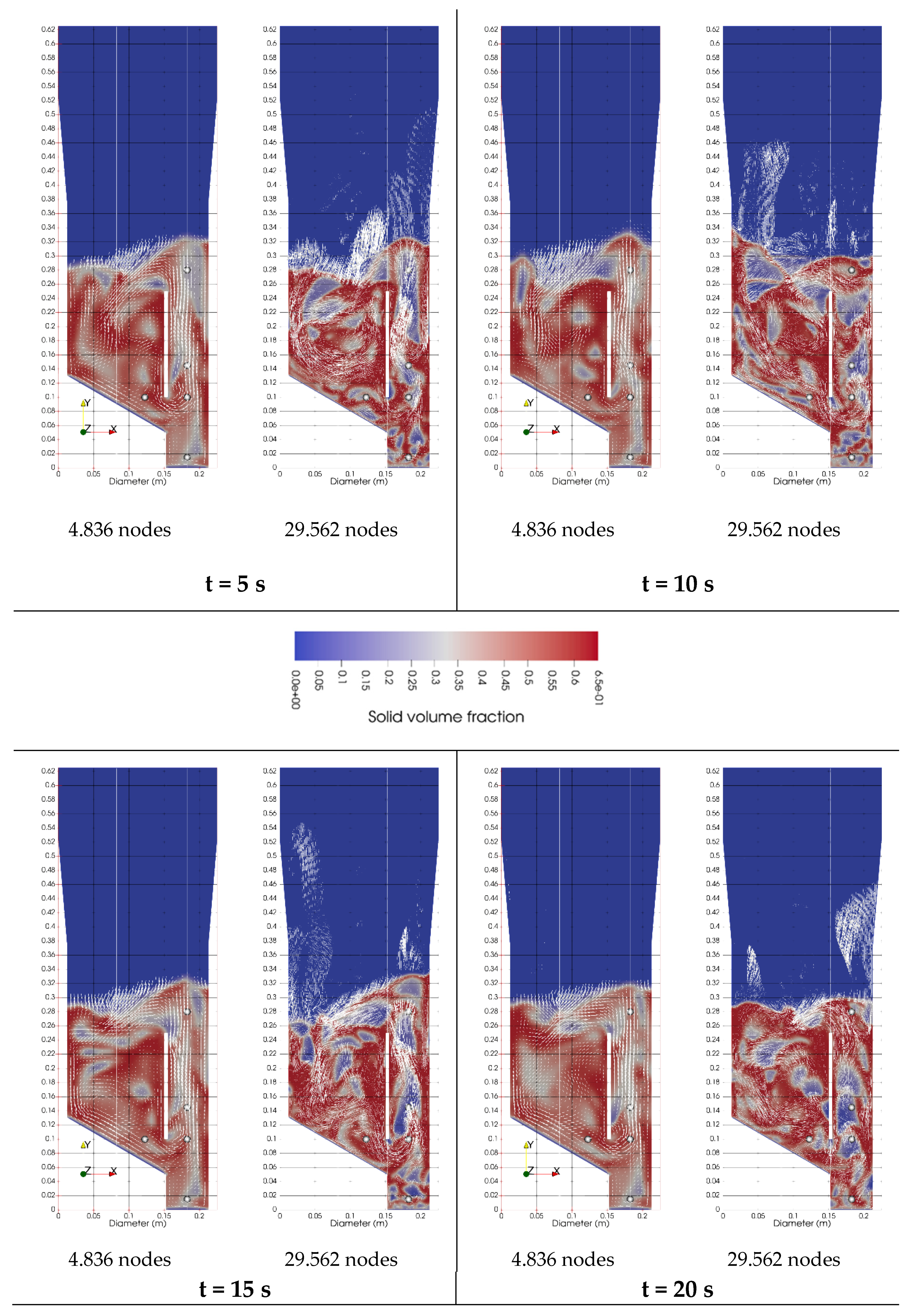

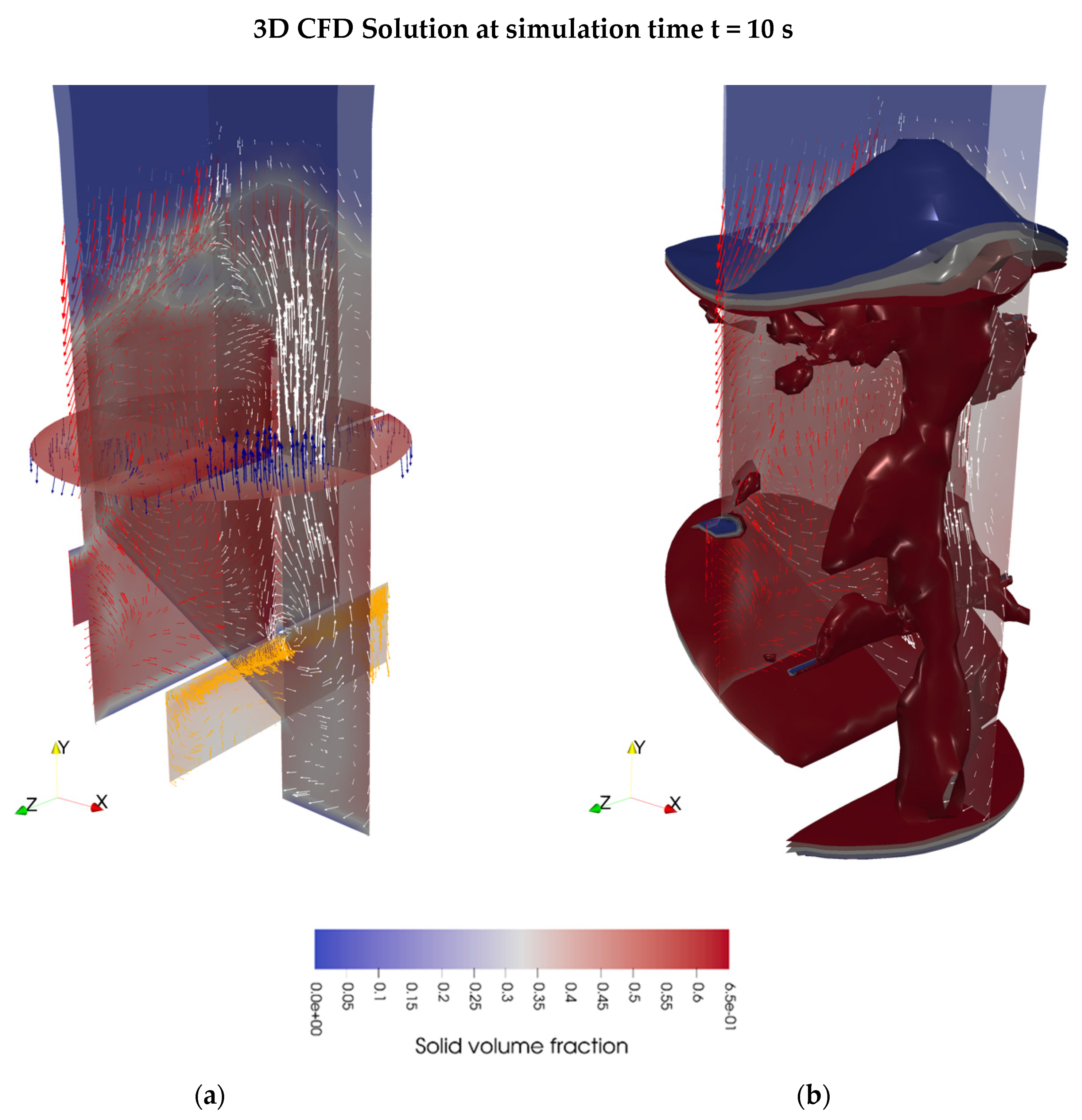

3.2. ENEA’s ICBFB Cold Model Analysis

4. Conclusions

5. Patents

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| List of symbols | |

| cross-sectional area, (m2) | |

| Archimedes number | |

| drag coefficient | |

| particle discharge coefficient | |

| diameter, (m) | |

| average char particle size | |

| Density number | |

| initial fuel size, (m) | |

| coefficient of restitution | |

| drag factor | |

| Flow number | |

| Froude number | |

| virtual mass forces | |

| gravitational acceleration, (m/s2) | |

| mass flow rate through opening, (kg/s) | |

| radial distribution function | |

| instantaneous bed height, (m) | |

| initial bed height, (m) | |

| identity tensor | |

| interphase exchange coefficient | |

| bed height, (m) | |

| Length number | |

| mass transfer rate between phases and , (kg/m3 s) | |

| Reynolds number | |

| pressure drop, (Pa) | |

| pressure drop across the opening, (Pa) | |

| pressure, (Pa) | |

| solid pressure, (Pa) | |

| gas flow rate, (m3/s) | |

| interacting forces term | |

| down flowing chamber cross sectional area, (m2) | |

| opening section, (m2) | |

| source term for phase , (kg/ m3 s) | |

| time, (s) | |

| superficial velocity, (m/s) | |

| velocity vector, (m/s) | |

| terminal velocity for the solid phase, (m/s) | |

| mass flux at down flowing chamber, (kg/m2 s) | |

| Greek | |

| δ | bubbles fraction |

| volume fraction | |

| granular temperature | |

| bulk viscosity, (Pa s) | |

| cinematic viscosity, (Pa s) | |

| granular viscosity, (Pa s) | |

| density, (kg/m3) | |

| multiplication factors | |

| response time parameter | |

| stress tensor | |

| shrinkage factor | |

| particle sphericity | |

| Subscripts | |

| computational fluid dynamics | |

| at cold model length scale | |

| collisional | |

| droplet | |

| frictional | |

| gas phase | |

| at real gasifier length scale | |

| kinetic | |

| mean values | |

| minimum fluidization conditions | |

| opening | |

| particles | |

| solid phase | |

| slagging | |

| theoretical | |

| x-axis direction | |

| Abbreviations | |

| DDPM | Discrete Dense Phase Model |

| DIA | Digital Image Analysis |

| DFB | Down-Flowing Bed |

| E-E | Eulerian–Eulerian approach |

| E-L | Eulerian–Lagrange approach |

| EMMS | Energy Minimization Multi-Scale approach |

| MM | macro-motion |

| PIV | Particle Image Velocimetry |

| SM | sub-motion |

| UFB | Up-Flowing Bed |

References

- IEA. Bioenergy Power Generation; IEA: Paris, France, 2020. [Google Scholar]

- Demirbas, A. Biofuels sources, biofuel policy, biofuel economy and global biofuel projections. Energy Convers. Manag. 2008, 49, 2106–2116. [Google Scholar] [CrossRef]

- Devi, L.; Ptasinski, K.J.; Janssen, F.J.J.G. A review of the primary measures for tar elimination in biomass gasification processes. Biomass Bioenergy 2003, 24, 125–140. [Google Scholar] [CrossRef]

- Santos, R.G.D.; Alencar, A.C. Biomass-derived syngas production via gasification process and its catalytic conversion into fuels by Fischer Tropsch synthesis: A review. Int. J. Hydrogen Energy 2019. [Google Scholar] [CrossRef]

- Jiang, G.; Wei, L.; Chen, Z.; Peng, L.; He, N.; Wu, C. Experimental Investigation of Particle Circulation in an Internally Circulating Clapboard-Type Fluidized Bed. Chem. Eng. Technol. 2020, 43, 253–262. [Google Scholar] [CrossRef]

- Basu, P. Combustion and Gasification in Fluidized Beds; CRC Press: Boca Raton, FL, USA, 2006; ISBN 9780429075018. [Google Scholar]

- Abba, I.A.; Grace, J.R.; Bi, H.T.; Thompson, M.L. Spanning the flow regimes: Generic fluidized-bed reactor model. AIChE J. 2003, 49, 1838–1848. [Google Scholar] [CrossRef]

- Alauddin, Z.A.B.Z.; Lahijani, P.; Mohammadi, M.; Mohamed, A.R. Gasification of lignocellulosic biomass in fluidized beds for renewable energy development: A review. Renew. Sustain. Energy Rev. 2010, 14, 2852–2862. [Google Scholar] [CrossRef]

- Hofbauer, H. Biomass CHP plant Guessing—A success story. Pyrolysis Gasif. Biomass Waste 2003, 371–383. [Google Scholar]

- Bolhar-Nordenkampf, M.; Hofbauer, H.; Rauch, R.; Tremmel, H.; Aichernig, C. Biomass CHP Plant Güssing–Using Gasification for Power Generation. In Proceedings of the 2nd regional Conference on Energy Technology Towards a Clean Envionnment, Phuket, Thailand, 12–14 February 2003. [Google Scholar]

- Kern, S.; Pfeifer, C.; Hofbauer, H. Gasification of wood in a dual fluidized bed gasifier: Influence of fuel feeding on process performance. Chem. Eng. Sci. 2013, 90, 284–298. [Google Scholar] [CrossRef]

- Karl, J.; Pröll, T. Steam gasification of biomass in dual fluidized bed gasifiers: A review. Renew. Sustain. Energy Rev. 2018, 98, 64–78. [Google Scholar] [CrossRef]

- Woolcock, P.J.; Brown, R.C. A review of cleaning technologies for biomass-derived syngas. Biomass Bioenergy 2013, 52, 54–84. [Google Scholar] [CrossRef]

- Valderrama Rios, M.L.; González, A.M.; Lora, E.E.S.; Almazán del Olmo, O.A. Reduction of tar generated during biomass gasification: A review. Biomass Bioenergy 2018, 108, 345–370. [Google Scholar] [CrossRef]

- Guan, G.; Kaewpanha, M.; Hao, X.; Abudula, A. Catalytic steam reforming of biomass tar: Prospects and challenges. Renew. Sustain. Energy Rev. 2016, 58, 450–461. [Google Scholar] [CrossRef]

- Singh, R.I.; Brink, A.; Hupa, M. CFD modeling to study fluidized bed combustion and gasification. Appl. Eng. 2013, 52, 585–614. [Google Scholar] [CrossRef]

- Ariyaratne, W.K.H.; Manjula, E.V.P.J.; Ratnayake, C.; Melaaen, M.C. CFD Approaches for Modeling Gas-Solids Multiphase Flows–A Review. In Proceedings of the 9th EUROSIM Congress on Modelling and Simulation, EUROSIM 2016, The 57th SIMS Conference on Simulation and Modelling SIMS 2016, Oulu, Finland, 12–16 September 2016; 2016. [Google Scholar] [CrossRef]

- Kuramoto, M.; Furusawa, T.; Kunii, D. Development of a new system for circulating fluidized particles within a single vessel. Powder Technol. 1985, 44, 77–84. [Google Scholar] [CrossRef]

- Kuramoto, M.; Kunii, D.; Furusawa, T. Flow of dense fluidized particles through an opening in a circulation system. Powder Technol. 1986, 47, 141–149. [Google Scholar] [CrossRef]

- Felice, R.D.I.; Rapagna, S.; Foscolo, P.U. Cold modelling studies of fluidized bed reactors. Chem. Eng. Sci. 1992, 47, 2233–2238. [Google Scholar] [CrossRef]

- Niewland, J.J.; Huizenga, P.; Kuipers, J.A.M.; van Swaaij, W.P.M. Hydrodynamic modelling of circulating fluidised beds. Chem. Eng. Sci. 1994, 49, 5803–5811. [Google Scholar] [CrossRef]

- Zimmermann, S.; Taghipour, F. CFD Modeling of the Hydrodynamics and Reaction Kinetics of FCC Fluidized-Bed Reactors. Ind. Eng. Chem. Res. 2005, 44, 9818–9827. [Google Scholar] [CrossRef]

- Foscolo, P.U.; Germanà, A.; Jand, N.; Rapagnà, S. Design and cold model testing of a biomass gasifier consisting of two interconnected fluidized beds. Powder Technol. 2007, 173, 179–188. [Google Scholar] [CrossRef]

- Papadikis, K.; Bridgwater, A.V.; Gu, S. CFD modelling of the fast pyrolysis of biomass in fluidised bed reactors, Part A: Eulerian computation of momentum transport in bubbling fluidised beds. Chem. Eng. Sci. 2008, 63, 4218–4227. [Google Scholar] [CrossRef]

- Papadikis, K.; Gu, S.; Bridgwater, A.V. CFD modelling of the fast pyrolysis of biomass in fluidised bed reactors. Part B. Heat, momentum and mass transport in bubbling fluidised beds. Chem. Eng. Sci. 2009, 64, 1036–1045. [Google Scholar] [CrossRef]

- Papadikis, K.; Gu, S.; Bridgwater, A.V. A CFD approach on the effect of particle size on char entrainment in bubbling fluidised bed reactors. Biomass Bioenergy 2010, 34, 21–29. [Google Scholar] [CrossRef]

- Pecate, S.; Morin, M.; Kessas, S.A.; Hemati, M.; Kara, Y.; Valin, S. Hydrodynamic study of a circulating fluidized bed at high temperatures: Application to biomass gasification. Kona Powder Part. J. 2019, 36, 271–293. [Google Scholar] [CrossRef]

- Armstrong, L.M.; Luo, K.H.; Gu, S. Two-dimensional and three-dimensional computational studies of hydrodynamics in the transition from bubbling to circulating fluidised bed. Chem. Eng. J. 2010, 160, 239–248. [Google Scholar] [CrossRef]

- Gerber, S.; Behrendt, F.; Oevermann, M. An Eulerian modeling approach of wood gasification in a bubbling fluidized bed reactor using char as bed material. Fuel 2010, 89, 2903–2917. [Google Scholar] [CrossRef]

- Liu, H.; Elkamel, A.; Lohi, A.; Biglari, M. Computational fluid dynamics modeling of biomass gasification in circulating fluidized-bed reactor using the eulerian-eulerian approach. Ind. Eng. Chem. Res. 2013, 52, 18162–18174. [Google Scholar] [CrossRef]

- Canneto, G.; Freda, C.; Braccio, G. Numerical simulation of gas-solid flow in an interconnected fluidized bed. Science 2015, 19, 317–328. [Google Scholar] [CrossRef]

- Barisano, D.; Canneto, G.; Nanna, F.; Alvino, E.; Pinto, G.; Villone, A.; Carnevale, M.; Valerio, V.; Battafarano, A.; Braccio, G. Steam/oxygen biomass gasification at pilot scale in an internally circulating bubbling fluidized bed reactor. Fuel Process. Technol. 2016, 141, 74–81. [Google Scholar] [CrossRef]

- Barisano, D.; Canneto, G.; Nanna, F.; Villone, A.; Alvino, E.; Carnevale, M.; Pinto, G. Production of Gaseous Carriers Via Biomass Gasification for Energy Purposes. Energy Procedia 2014, 45, 2–11. [Google Scholar] [CrossRef][Green Version]

- Glicksman, L.R.; Hyre, M.; Woloshun, K. Simplified scaling relationships for fluidized beds. Powder Technol. 1993, 77, 177–199. [Google Scholar] [CrossRef]

- Kolar, A.K.; Leckner, B. Scaling of CFB boiler hydrodynamics. In Proceedings of the 1st National Con-ference on Advances in Energy Research (AER 2006), Mumbai, India, 4–5 December 2006; pp. 34–40. [Google Scholar]

- Wen, C.Y.; Yu, Y.H. A generalized method for predicting the minimum fluidization velocity. AIChE J. 1966, 12, 610–612. [Google Scholar] [CrossRef]

- Syamlal, M.; O’Brien, T.J. Computer Simulation of Bubbles in a Fluidized Bed. AIChE Symp. Ser. 1989, 85, 22–31. [Google Scholar]

- Gidaspow, D. Continuum and kinetic theory descriptions. In Multiphase Flow and Fluidization; Academic Press: Cambridge, MA, USA, 1994; ISBN 9780080512266. [Google Scholar]

- Taghipour, F.; Ellis, N.; Wong, C. Experimental and computationa l study of gas-solid fluidized bed hydrodynamics. Chem. Eng. Sci. 2005. [Google Scholar] [CrossRef]

- Syamlal, M.; Brien, T.O. The Derivation of a Drag Coefficient Formula from Velocity-Voidage Correlations; Technical Note; US Department of energy, Office of Fossil Energy, NETL: Morgantown, WV, USA, 1994.

- Lun, C.K.K.; Savage, S.B.; Jeffrey, D.J.; Chepurniy, N. Kinetic theories for granular flow: Inelastic particles in Couette flow and slightly inelastic particles in a general flowfield. J. Fluid Mech. 1984. [Google Scholar] [CrossRef]

- Theory Guide: Ansys Fluent 15.0; ANSYS-INC.: Canonsburg, PA, USA, 2013.

- Ponti, G.; Palombi, F.; Abate, D.; Ambrosino, F.; Aprea, G.; Bastianelli, T.; Beone, F.; Bertini, R.; Bracco, G.; Caporicci, M.; et al. The role of medium size facilities in the HPC ecosystem: The case of the new CRESCO4 cluster integrated in the ENEAGRID infrastructure. In Proceedings of the 2014 International Conference on High Performance Computing and Simulation, Bologna, Italy, 21–25 July 2014; pp. 1030–1033. [Google Scholar]

- Deza, M.; Franka, N.P.; Heindel, T.J.; Battaglia, F. CFD modeling and X-ray imaging of biomass in a fluidized bed. J. Fluids Eng. Trans. Asme 2009, 131, 1113031–11130311. [Google Scholar] [CrossRef]

- Division, F.E.; Statement, E.P.; Accuracy, N.; Eng, A.J.F.; Engineering, F.; Policy, E.; Accuracy, N.; Eng, A.J.F. Procedure for Estimation and Reporting of Uncertainty Due to Discretization in CFD Applications. J. Fluids Eng. Trans. ASME 2008, 130, 2008–2011. [Google Scholar] [CrossRef]

- Coltters, R.; Rivas, A.L. Minimum fluidation velocity correlations in particulate systems. Powder Technol. 2004, 147, 34–48. [Google Scholar] [CrossRef]

- Chiba, S.; Chiba, T.; Nienow, A.W.; Kobayashi, H. The minimum fluidisation velocity, bed expansion and pressure-drop profile of binary particle mixtures. Powder Technol. 1979, 22, 255–269. [Google Scholar] [CrossRef]

- Gómez-Barea, A.; Leckner, B. Modeling of biomass gasification in fluidized bed. Prog. Energy Combust. Sci. 2010, 36, 444–509. [Google Scholar] [CrossRef]

| Parameters | Gasifier Reactor 1 | Cold Model 2 |

|---|---|---|

| Fluidizing flow density, (kg/m3) | 0.33 | 0.99 |

| Fluidizing flow viscosity, (Pa s) | 4.38 × 10−5 | 1.89 × 10−5 |

| Particle density, (kg/m3) | 2965 | 8930 |

| Archimedes number, | 6.22 × 102 | |

| Reynolds number, | 6.24 × 10−1 | |

| Froude number, | 2.38 × 10−4 | |

| Density number, | 1.11 × 10−4 | |

| Particle diameter, (mm) | 0.50 | 0.14 |

| Minimum fluidization velocity, Umf (cm/s) | 16.64 | 8.71 |

| Length scale ratio, | 3.65 | |

| Gas flow velocity ratio, -() | 1.91 | |

| Gas flow rate ratio, () | 25.45 | |

| Time ratio, () | 1.91 | |

| Parameters | Value |

|---|---|

| (kg/m3) | 4109.48 |

| (kg/m3) | 3550.60 |

| 0.47 | |

| 0.52 | |

| 0.49 | |

| 0.60 | |

| 0.49 | |

| 0.56 | |

| 0.18 | |

| 0.29 | |

| 1.13 | |

| 1.34 | |

| (m/s) | −0.039 |

| (m/s) | 0.19 |

| (Pa) | 22.390 |

| (kg/s) | 5.80 |

| Th. (Equation (6), Kuramoto et al. [19] (kg/s) | 6.86 |

| Th. (Equation (14b), Kuramoto et al. [19] (kg/s) | 4.29 |

| Particles | ||||

|---|---|---|---|---|

| Char Real | Cold Model | Char Real | Cold Model | |

| (kg/m3) | 0.33 | 0.99 | 0.33 | 0.99 |

| Fluidizing flow viscosity, µ (Pa s) | 4.38 × 10−5 | 1.89 × 10−5 | 4.38 × 10−5 | 1.89 × 10−5 |

| (kg/m3) | 975 | 2937 | 975 | 2937 |

| 8.38 × 102 | 1.64 × 103 | |||

| 1.19 | 2.21 | |||

| 2.23 × 104 | 2.98 × 104 | |||

| 3.37 × 10−4 | 3.37 × 10−4 | |||

| (cm/s) | 19.80 | 10.36 | 29.49 | 15.43 |

| (m/s) | 0.64 | 0.33 | 1.13 | 0.59 |

| (mm) | 0.80 | 0.22 | 1.00 | 0.27 |

| 3.65 | ||||

| ) | 1.91 | |||

| ) | 25.49 | |||

| ) | 1.91 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fanelli, E. CFD Hydrodynamics Investigations for Optimum Biomass Gasifier Design. Processes 2020, 8, 1323. https://doi.org/10.3390/pr8101323

Fanelli E. CFD Hydrodynamics Investigations for Optimum Biomass Gasifier Design. Processes. 2020; 8(10):1323. https://doi.org/10.3390/pr8101323

Chicago/Turabian StyleFanelli, Emanuele. 2020. "CFD Hydrodynamics Investigations for Optimum Biomass Gasifier Design" Processes 8, no. 10: 1323. https://doi.org/10.3390/pr8101323

APA StyleFanelli, E. (2020). CFD Hydrodynamics Investigations for Optimum Biomass Gasifier Design. Processes, 8(10), 1323. https://doi.org/10.3390/pr8101323