Improving the Inner Surface State of Thick-Walled Tubes by Heat Treatments with Internal Quenching Considering a Simulation Based Optimization

Abstract

1. Introduction

1.1. State of the Art

1.2. Internal Quenching

1.3. This Work

2. Materials and Methods

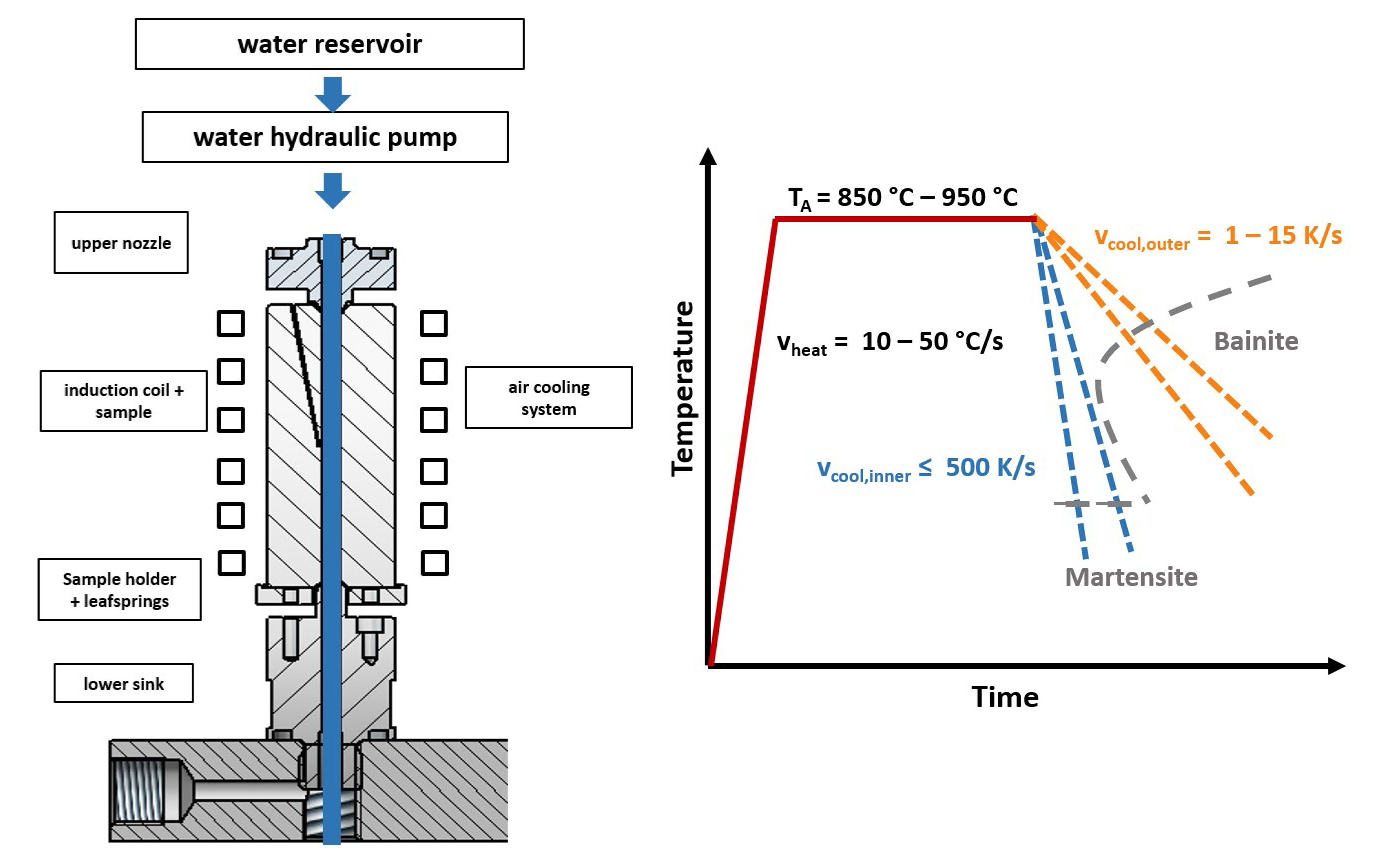

2.1. Samples

2.2. Internal Quenching Heat Treatment

2.3. Metallographic Characterization

2.4. Residual Stress Measurement

2.4.1. X-ray Diffraction Analysis

2.4.2. Sachs Boring/EDM

3. FE-Simulation

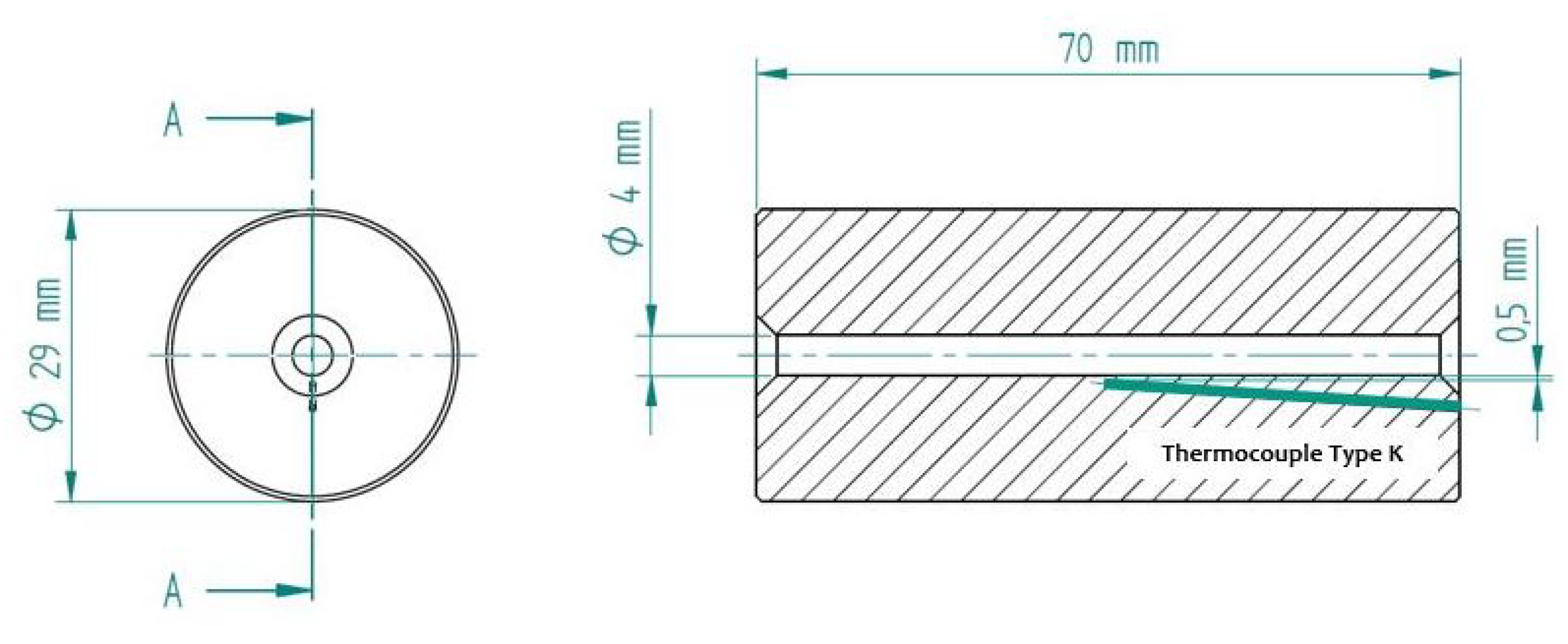

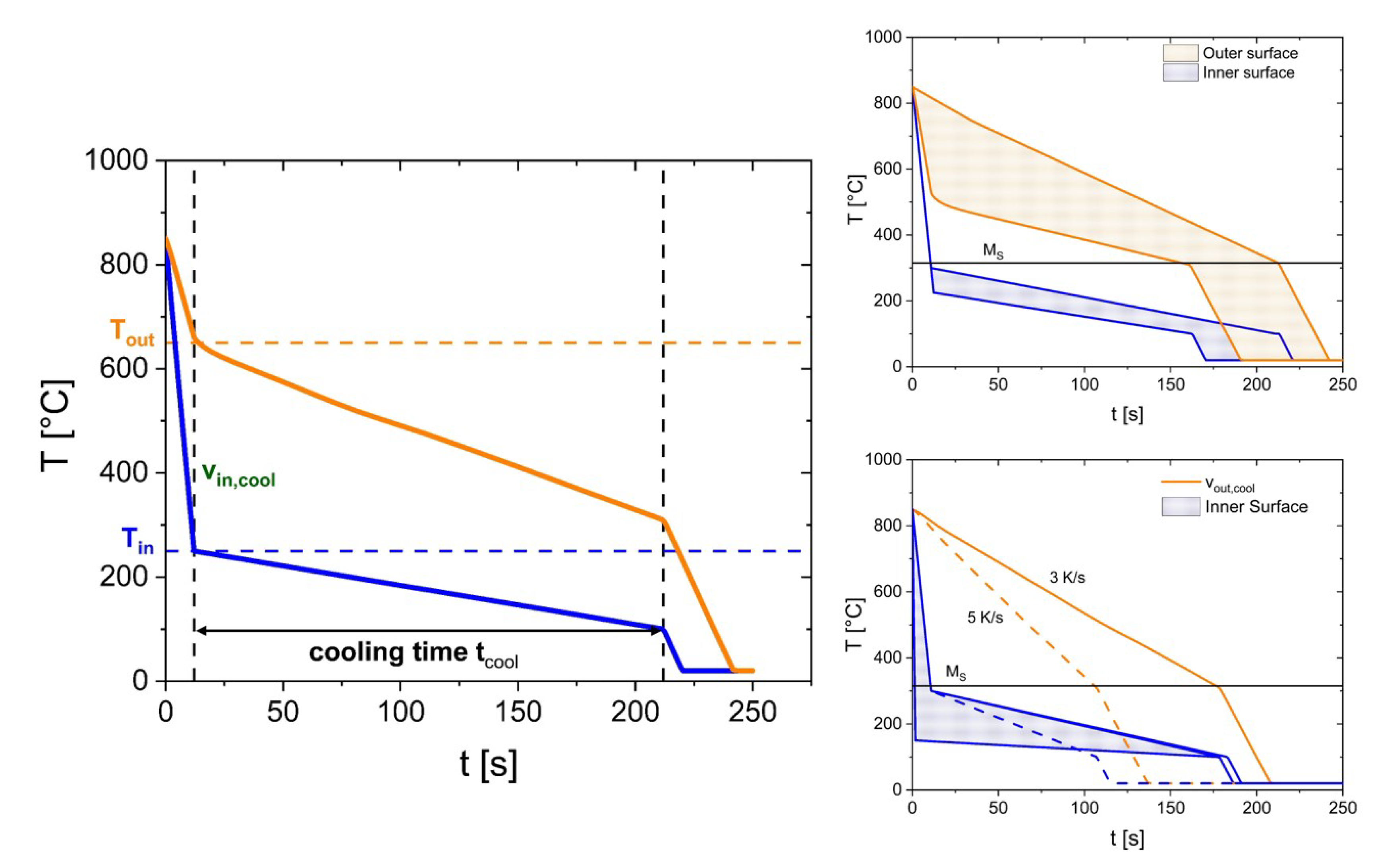

3.1. Model

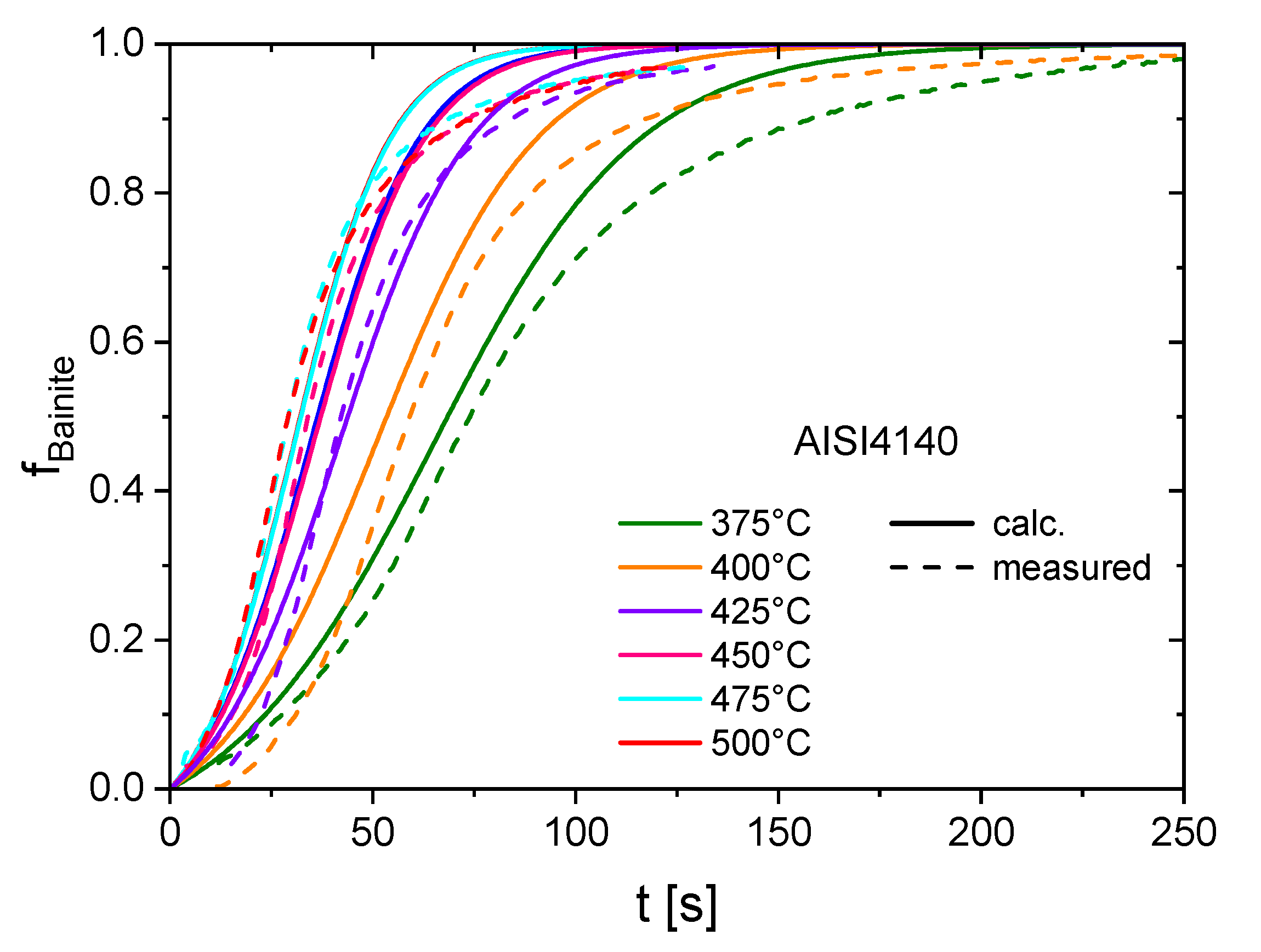

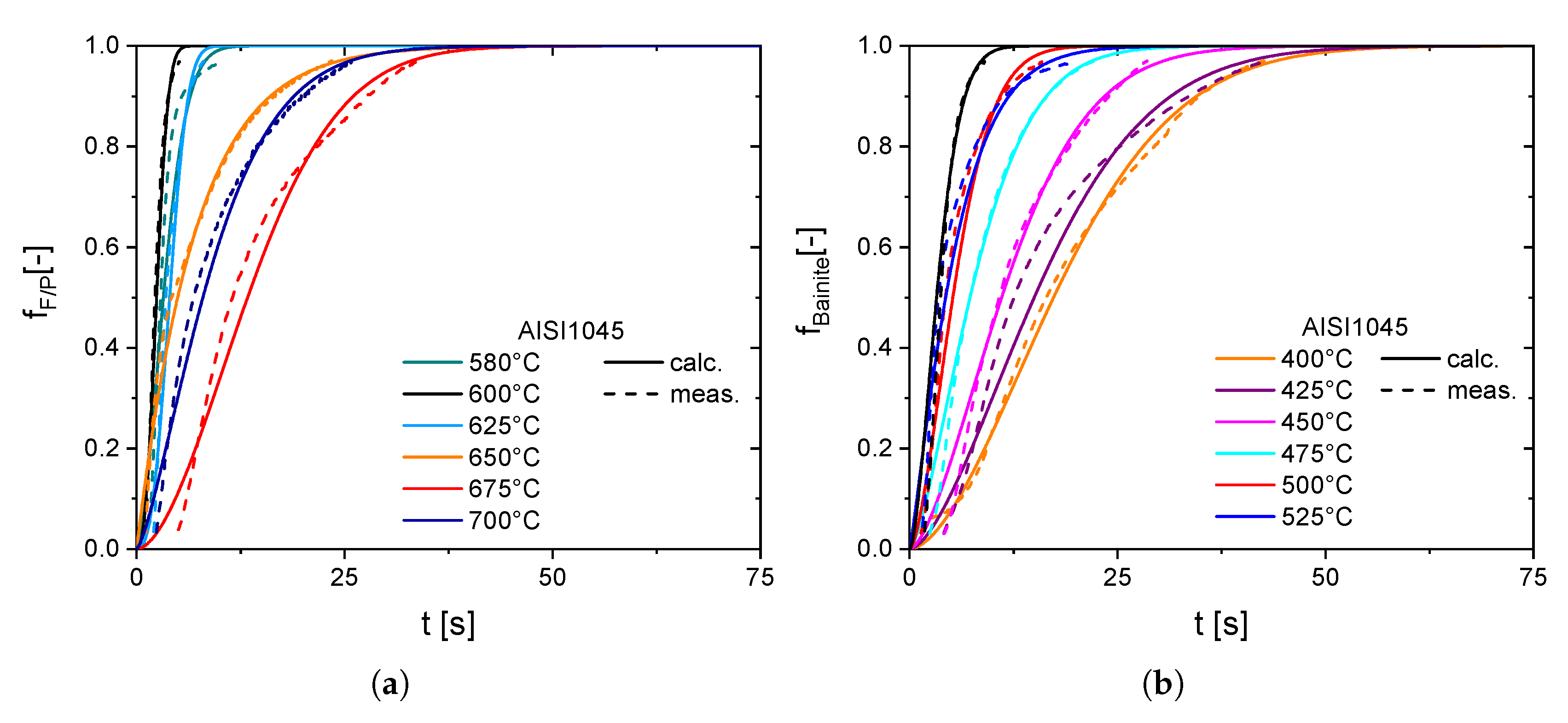

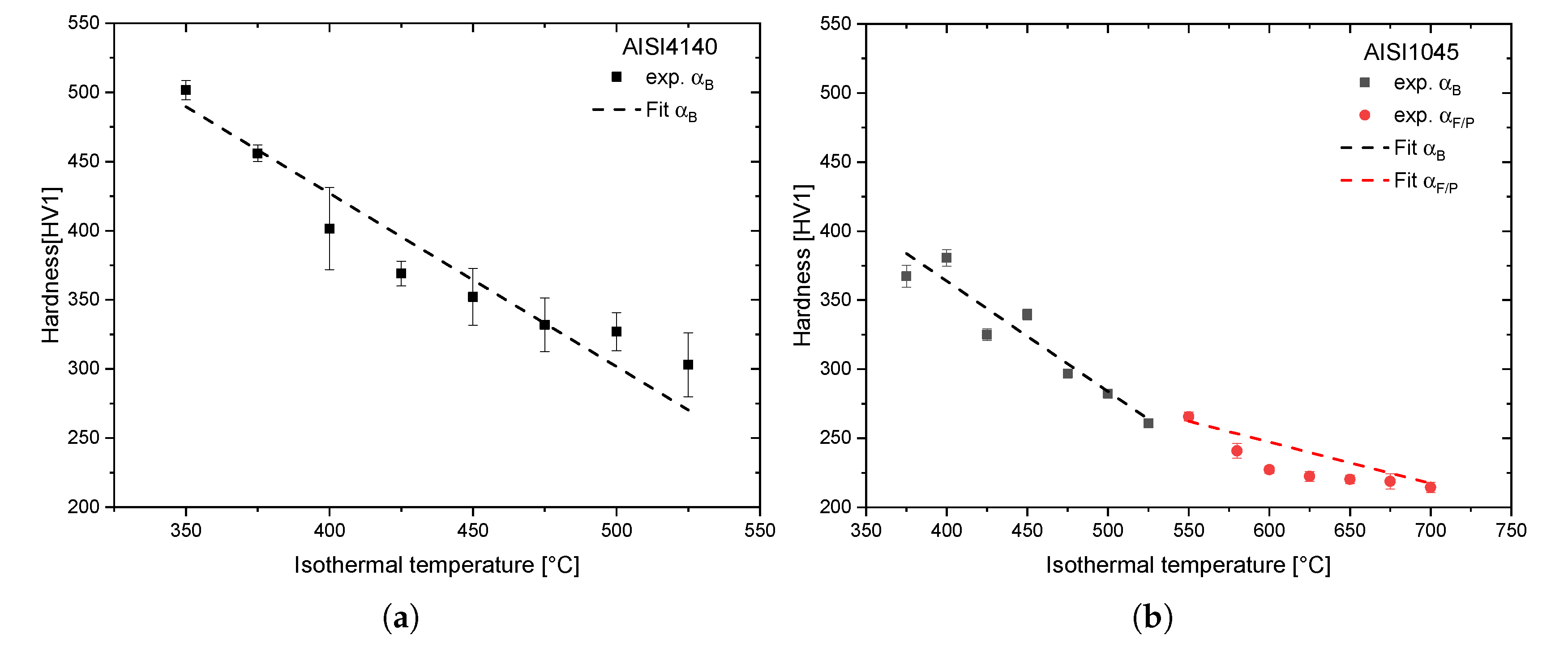

3.2. Material Parameters

4. Simulative Optimization Study

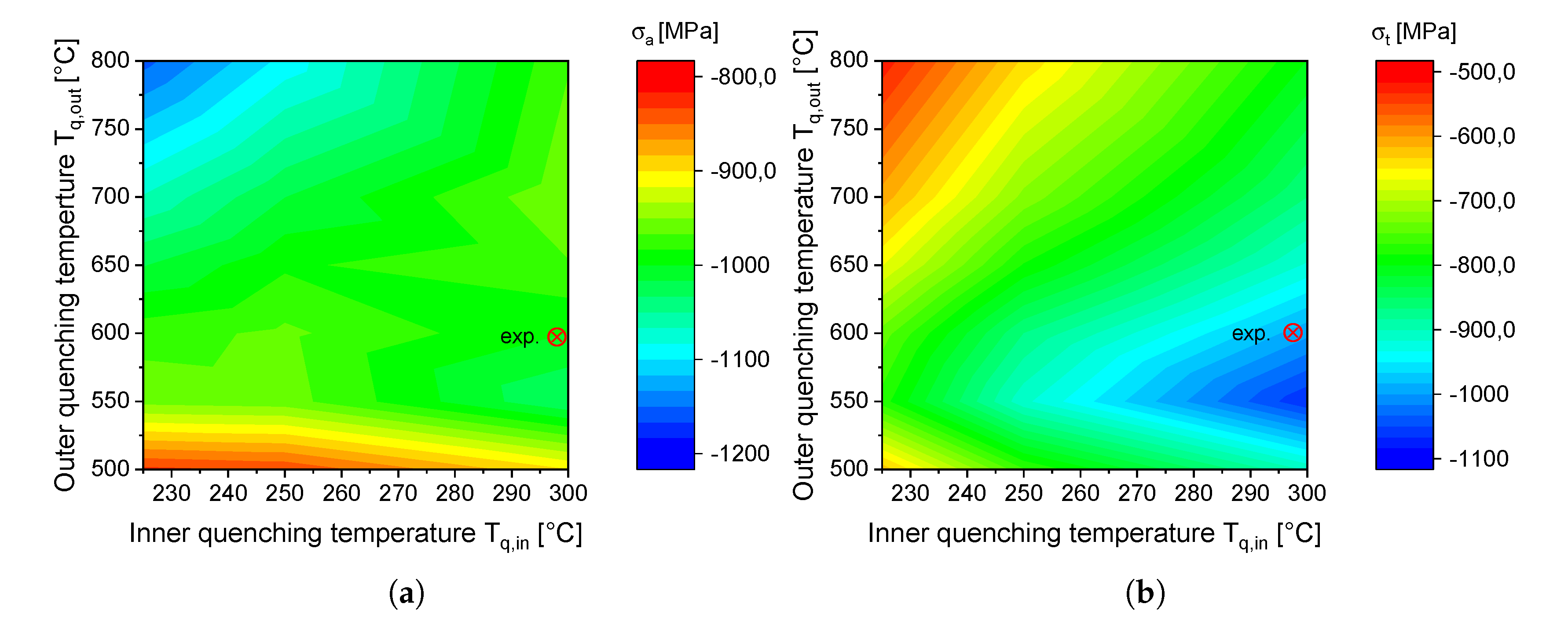

4.1. Parameter Field for AISI 4140

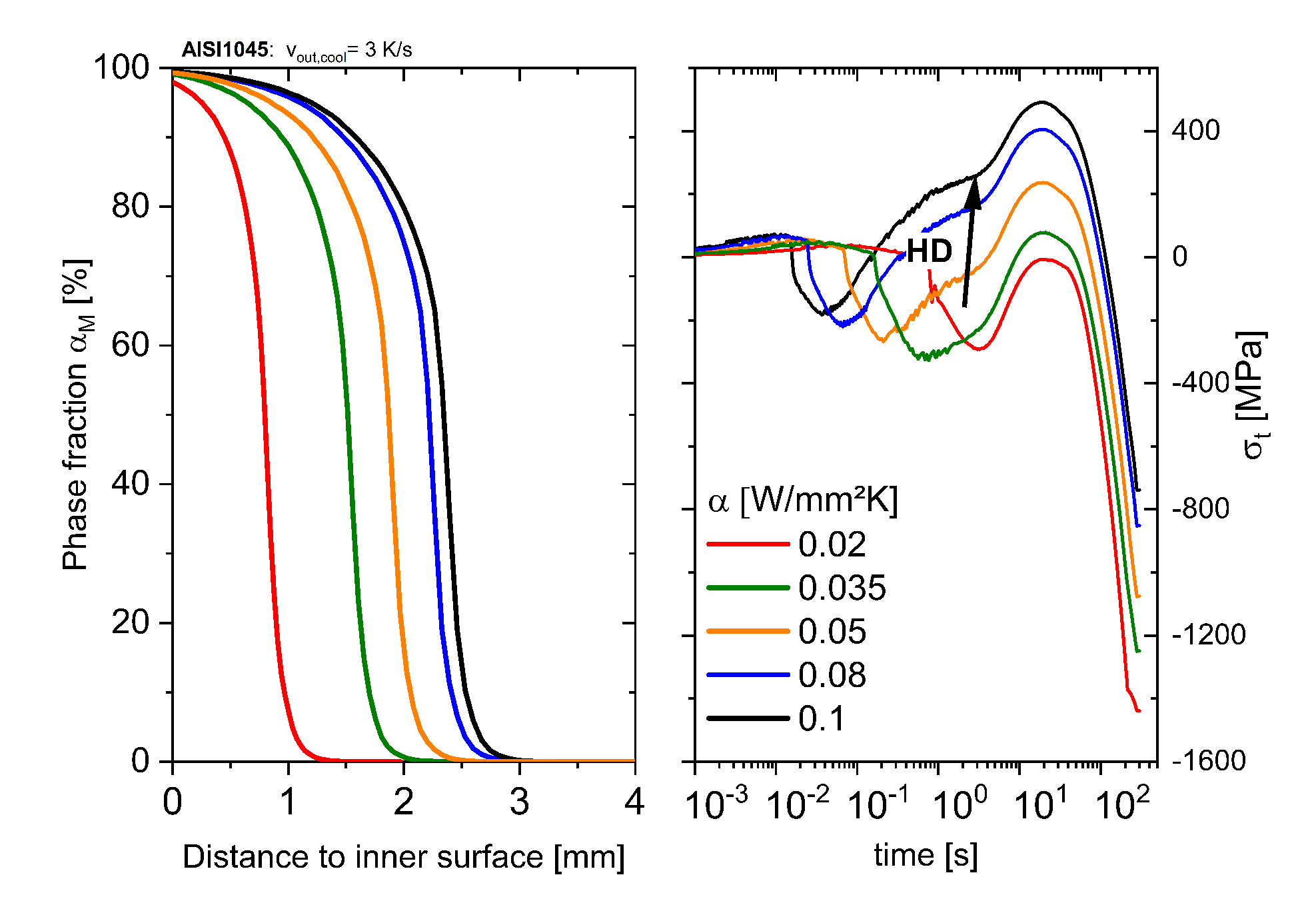

4.2. Parameter Field for AISI 1045

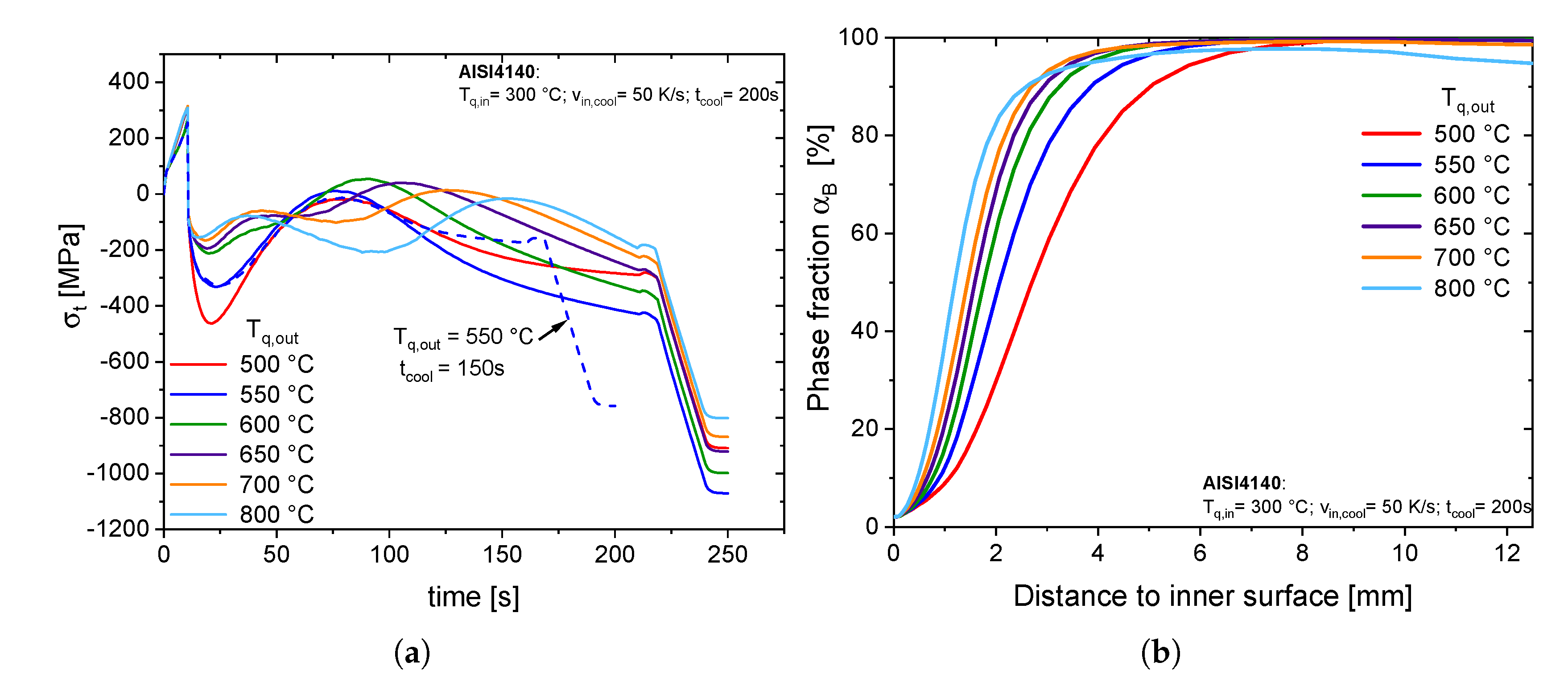

4.3. AISI 4140, Discontinuous Cooling

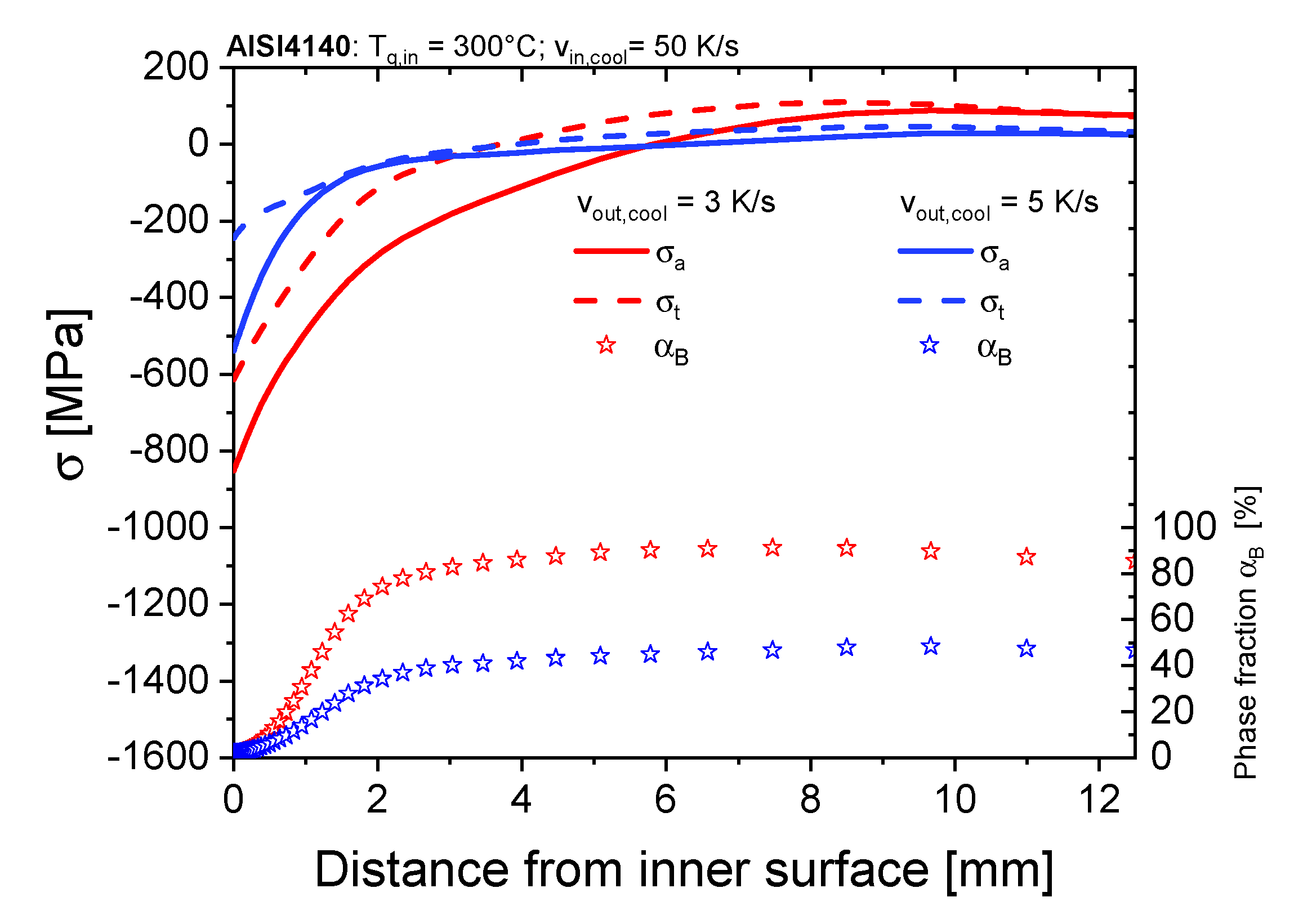

4.4. AISI 4140, Continuous Cooling

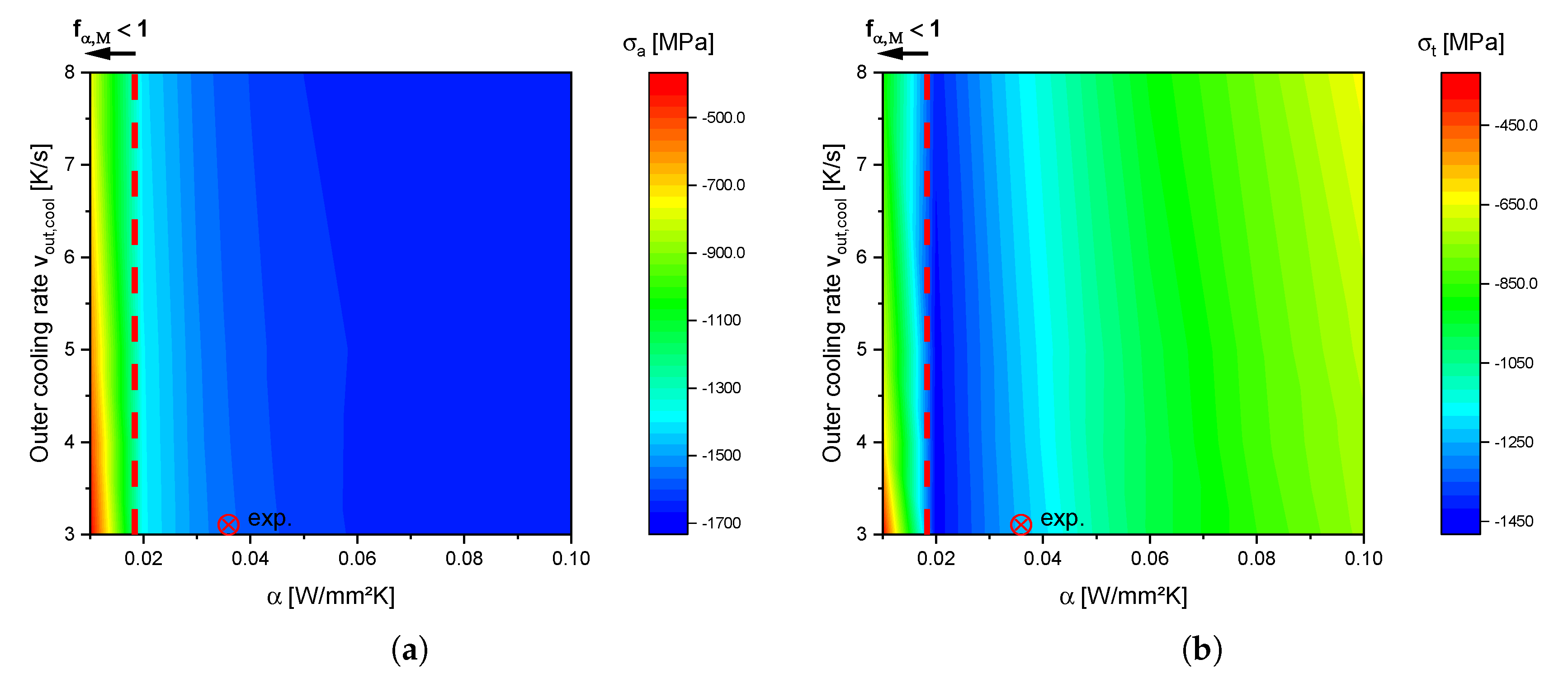

4.5. AISI 1045, Continuous Cooling

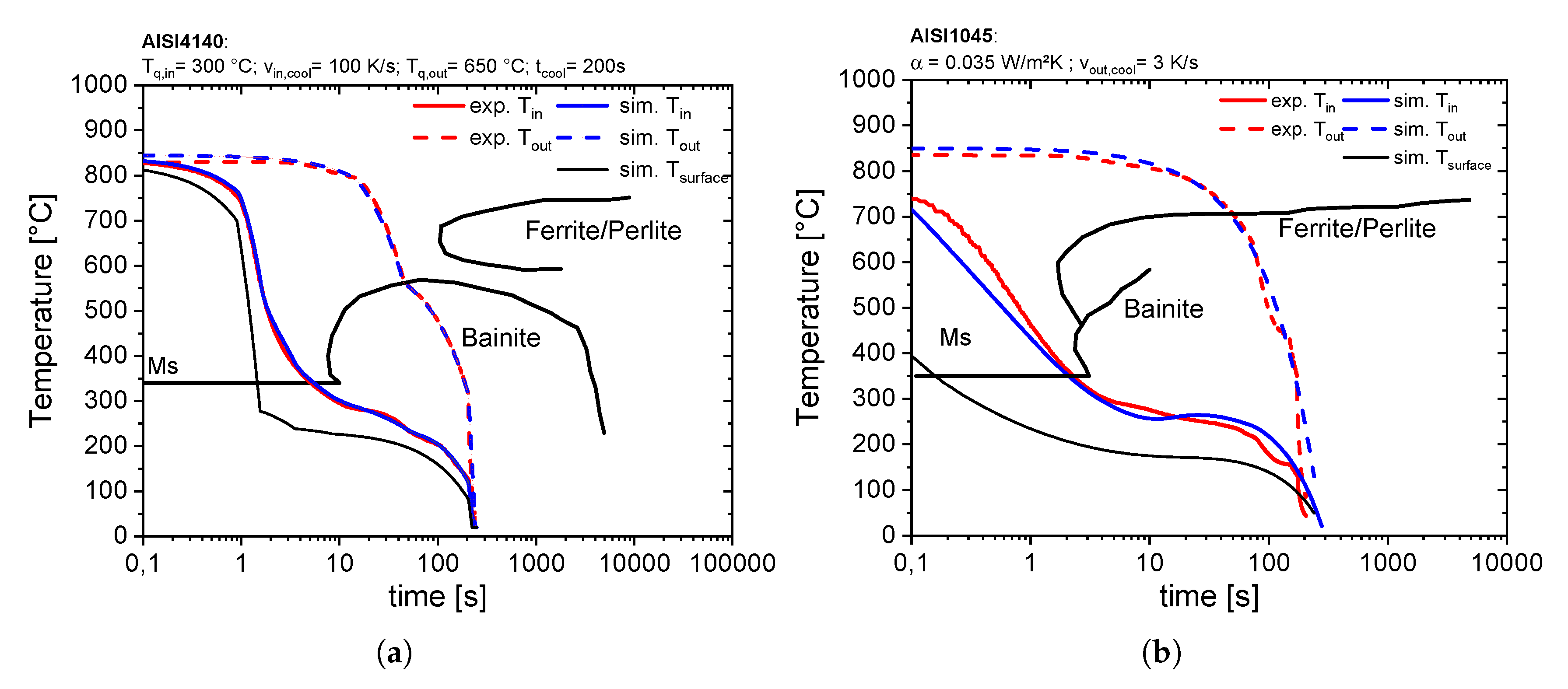

5. Results and Discussion of Experiments and Validation

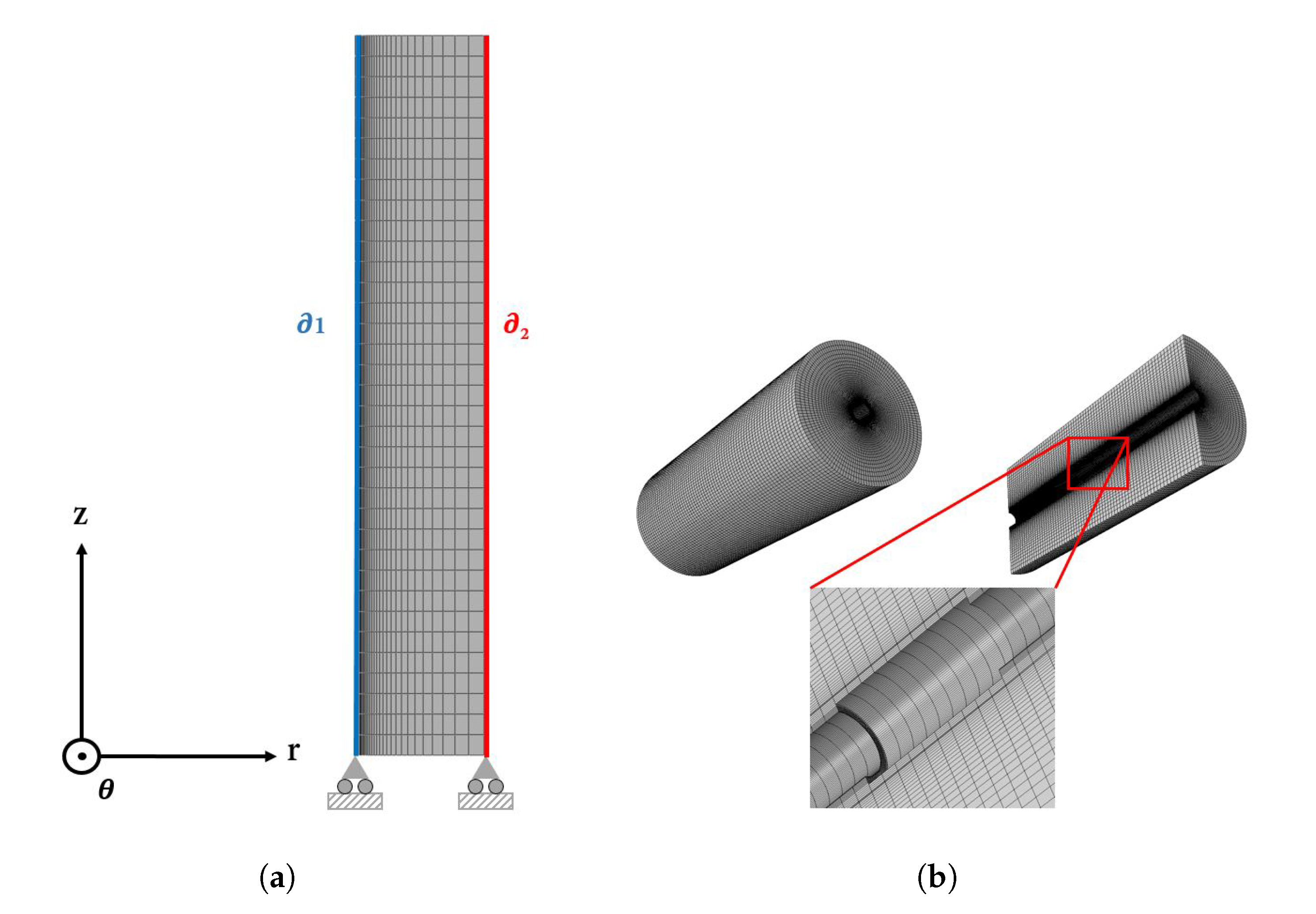

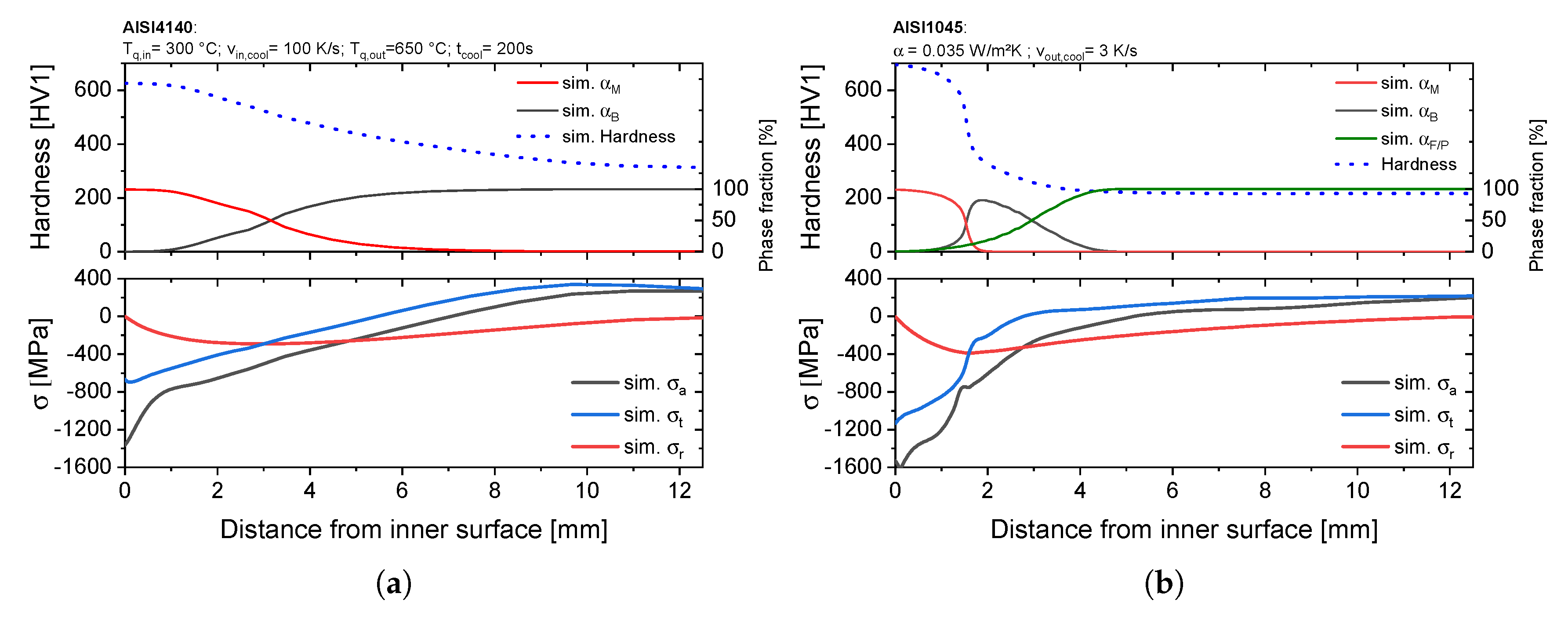

5.1. Microstructure and Hardness

5.2. Residual Stresses

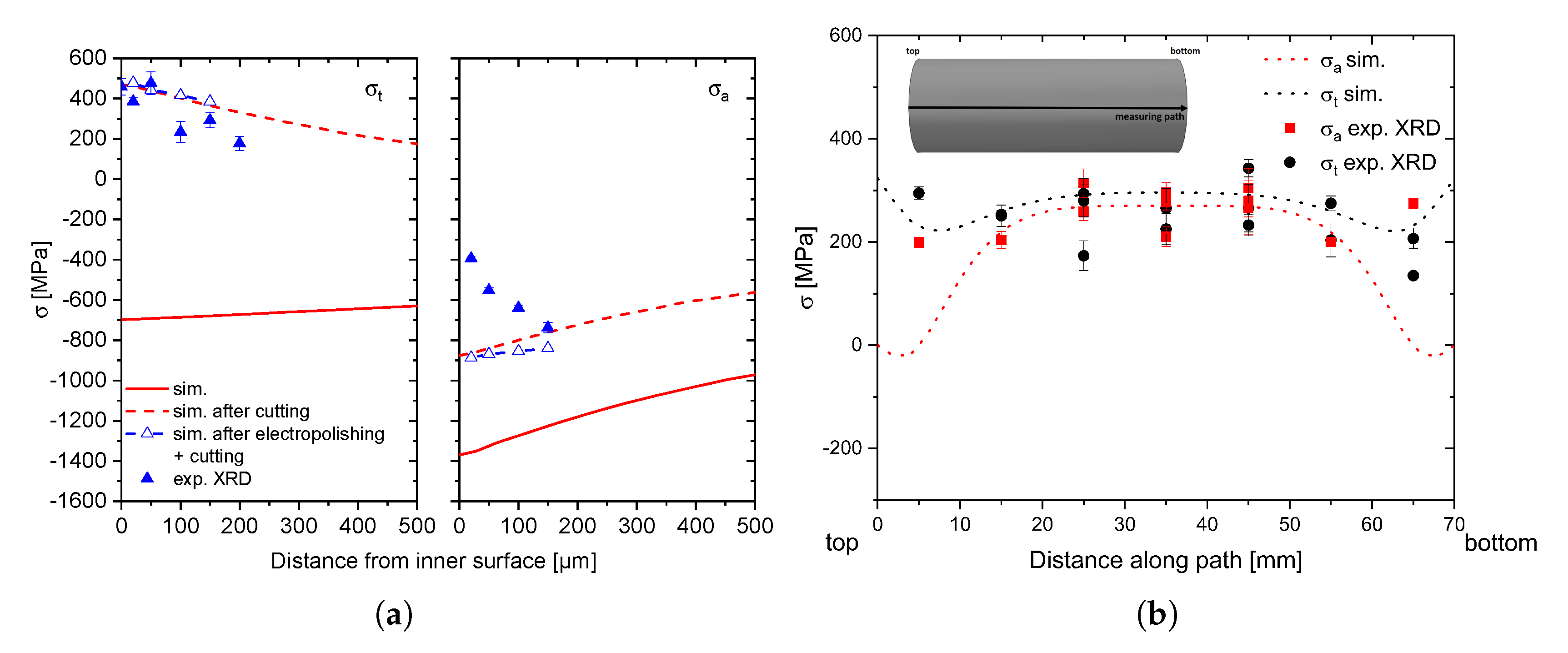

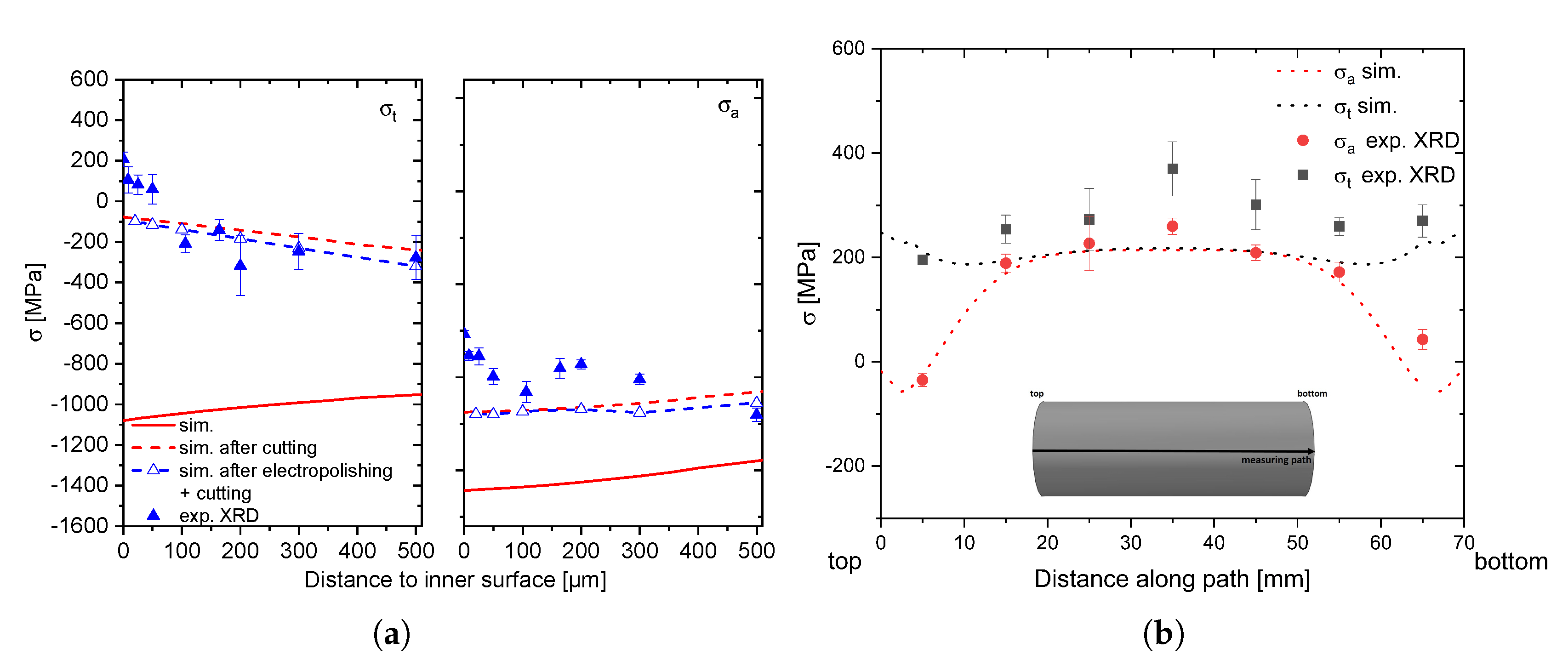

5.2.1. X-ray Diffraction Analysis

5.2.2. Sachs EDM Measurements

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Input Parameters

| Quantity | Unit | Phase | Source | ||||

|---|---|---|---|---|---|---|---|

| 0 | [32] | ||||||

| , , | 0 | [32] | |||||

| 476 | 0 | 0 | [32] | ||||

| , , | 233 | 0 | 0 | [32] | |||

| - | 0 | 0 | 0 | this work | |||

| - | 0 | 0 | 0 | this work | |||

| E | 0 | 0 | [33] | ||||

| E | , , | [20] | |||||

| 0 | 0 | 0 | [32] | ||||

| 0 | 0 | this work | |||||

| 0 | 0 | this work | |||||

| - | 0 | 0 | 0 | this work | |||

| - | 0 | 0 | 0 | this work | |||

| - | - | - | - | this work | |||

| - | - | - | - | this work | |||

| - | - | 0 | 0 | 0 | this work | ||

| - | - | 0 | 0 | 0 | this work | ||

| - | - | 0 | 0 | 0 | this work | ||

| - | - | 0 | 0 | 0 | this work | ||

| 0 | [32] | ||||||

| 0 | [32] | ||||||

| 0 | 0 | [32] | |||||

| - | 0 | 0 | [32] | ||||

| [21] | |||||||

| 0 | 0 | 0 | [21] | ||||

| 300 | 0 | 0 | 0 | [21] | |||

| - | 250 | 0 | 0 | 0 | [21] | ||

| 0 | 0 | [21] | |||||

| 0 | 0 | 0 | 0 | [21] | |||

| 0 | 0 | 0 | 0 | [21] | |||

| - | 0 | 0 | 0 | 0 | [21] |

| Quantity | Unit | Phase | Source | ||||

|---|---|---|---|---|---|---|---|

| 0 | 0 | [22] | |||||

| , , | 0 | 0 | [22] | ||||

| 491 | 0 | 0 | [22] | ||||

| , , | 0 | 0 | [22] | ||||

| - | 0 | 0 | 0 | [22] | |||

| - | 0 | 0 | 0 | [22] | |||

| E | 0 | 0 | [33] | ||||

| E | , , | [20] | |||||

| 0 | 0 | 0 | this work | ||||

| 0 | 0 | this work | |||||

| 0 | 0 | 0 | this work | ||||

| - | 0 | 0 | 0 | this work | |||

| - | 0 | 0 | 0 | this work | |||

| - | 0 | 0 | 0 | this work | |||

| - | - | 0 | 0 | this work | |||

| - | - | this work | |||||

| - | - | 0 | 0 | this work | |||

| - | - | this work | |||||

| - | - | 0 | this work | ||||

| - | - | 0 | this work | ||||

| - | - | 0 | 0 | 0 | this work | ||

| - | - | 0 | 0 | 0 | this work | ||

| - | - | 0 | 0 | 0 | this work | ||

| 0 | 0 | [22] | |||||

| 0 | [21] | ||||||

| 0 | 0 | [21] | |||||

| - | 0 | 0 | [21] | ||||

| 0 | 0 | [22] | |||||

| 2000 | 0 | 0 | 0 | [21] | |||

| 300 | 0 | 0 | 0 | [21] | |||

| - | 0 | 0 | 0 | [21] | |||

| 0 | 0 | [22] | |||||

| 2000 | 0 | 0 | 0 | [21] | |||

| 300 | 0 | 0 | 0 | [21] | |||

| - | 250 | 0 | 0 | 0 | [21] | ||

| 1598 | 0 | 0 | [22] | ||||

| 0 | 0 | 0 | 0 | [21] | |||

| 0 | 0 | 0 | 0 | [21] | |||

| - | 0 | 0 | 0 | 0 | [21] |

References

- Vormwald, M.; Schlitzer, T.; Panic, D.; Beier, H.T. Fatigue strength of autofrettaged Diesel injection system components under elevated temperature. Int. J. Fatigue 2018, 113, 428–437. [Google Scholar] [CrossRef]

- Dewangan, M.K.; Panigrahi, S.K. Residual stress analysis of swage autofrettaged gun barrel via finite element method. J. Mech. Sci. Technol. 2015, 29, 2933–2938. [Google Scholar] [CrossRef]

- Perl, M.; Saley, T. Swage and hydraulic autofrettage impact on fracture endurance and fatigue life of an internally cracked smooth gun barrel Part I – The effect of overstraining. Eng. Fract. Mech. 2017, 182, 372–385. [Google Scholar] [CrossRef]

- Krug, T.; Lang, K.H.; Fett, T.; Löhe, D. Influence of residual stresses and mean load on the fatigue strength of case-hardened notched specimens. Mater. Sci. Eng. A 2007, 468–470, 158–163. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Bocher, P.; Zhu, C.; Sun, Z. Effects of case hardening properties on the contact fatigue of a wind turbine gear pair. Int. J. Mech. Sci. 2018, 141, 520–527. [Google Scholar] [CrossRef]

- Bepari, M. 2.3 Carburizing: A Method of Case Hardening of Steel. In Comprehensive Materials Finishing; Hashmi, S., Ed.; Elsevier: Oxford, UK; Waltham, MA, USA, 2017; pp. 71–106. [Google Scholar] [CrossRef]

- Kiefer, D.; Schüssler, P.; Mühl, F.; Gibmeier, J. Experimental and Simulative Studies on Residual Stress Formation for Laser-Beam Surface Hardening. HTM J. Heat Treat. Mater. 2019, 74, 23–35. [Google Scholar] [CrossRef]

- Areitioaurtena, M.; Segurajauregi, U.; Urresti, I.; Fisk, M.; Ukar, E. Predicting the induction hardened case in 42CrMo4 cylinders. Procedia CIRP 2020, 87, 545–550. [Google Scholar] [CrossRef]

- Kobasko, N.I.; Aronov, M.A. 12.07—Intensive Quenching. In Comprehensive Materials Processing; Hashmi, S., Ed.; Elsevier: Oxford, UK, 2014; pp. 253–269. [Google Scholar] [CrossRef]

- Kobasko, N.I. Intensive Quenching Systems: Engineering and Design; ASTM MNL; ASTM International: West Conshohocken, PA, USA, 2010; Volume 64. [Google Scholar]

- Rath, J. Maximierung der Randnahen Druckeigenspannung von Stählen mit Hilfe einer Hochgeschwindigkeits-Abschreckanlage. Ph.D. Thesis, Universität Bremen, Bremen, Germany, 2012. [Google Scholar]

- Kobasko, N. Intensive Steel Quenching Methods. In Theory and Technology of Quenching—A Handbook; Springer: New York, NY, USA, 1992; pp. 367–389. [Google Scholar]

- Habschied, M.; de Graaff, B.; Klumpp, A.; Schulze, V. Fertigung und Eigenspannungen. HTM J. Heat Treat. Mater. 2015, 70, 111–121. [Google Scholar] [CrossRef]

- Muehl, F.; Dietrich, S.; Schulze, V. Internal Quenching: Ideal Heat Treatment for Difficult to Access Component Sections. HTM J. Heat Treat. Mater. 2019, 74, 191–201. [Google Scholar] [CrossRef]

- Eigenmann, B.; Macherauch, E. Röntgenographische Untersuchung von Spannungszuständen in Werkstoffen. Tl. 3. Mater. Wiss. u. Werkstofftech. 1996, 27, 426–437. [Google Scholar] [CrossRef]

- Peiter, A. Eigenspannungen 1. Art: Ermittlung und Bewertung; Triltsch: Düsseldorf, Germany, 1966. [Google Scholar]

- Kaiser, D.; Damon, J.; Mühl, F.; de Graaff, B.; Dietrich, S.; Schulze, V. Experimental investigation and finite-element modeling of the short-time inductive quench-and-temper process. J. Mater. Process. Technol. 2019, 279, 116485. [Google Scholar]

- Liščić, B. (Ed.) Quenching Theory and Technology, 2nd ed.; CRC Press: Boca Raton, FL, USA; IFHTSE: Zurich, Switzerland, 2010. [Google Scholar]

- Desalos, Y. Comportement Dilatométrique et Mécanique de L’austénite Métastable d’un Acier A 533; Rapport Technique N • 95349401; IRSID: Saint-Germainen-Lay, France, 1981. [Google Scholar]

- Kaiser, D. Experimentelle Untersuchung und Simulation des Kurzzeitanlassens unter Berücksichtigung Thermisch randschichtgehärteter Zustände am Beispiel von 42CrMo4. Ph.D. Thesis, Karlsruhe Institute of Technology, Karlsruhe, Germany, 2019. [Google Scholar]

- Mioković, T. Analyse des Umwandlungsverhaltens bei ein- und mehrfacher Kurzzeithärtung bzw. Laserstrahlhärtung des Stahls 42CrMo4. In Schriftenreihe Werkstoffwissenschaft und Werkstofftechnik; Vol. Band 25/2005; Shaker Verlag: Aachen, Germany, 2005. [Google Scholar]

- Graja, P. Rechnerische und Experimentelle Untersuchungen zum Einfluß Kontinuierlicher und Diskontinuierlicher Wärmebehandlungsverfahren auf die Wärme- und Umwandlungseigenspannungen und Verzüge von un- und Niedriglegierten Stählen. Ph.D. Thesis, Karlsruhe Institute of Technology, Karlsruhe, Germany, 1987. [Google Scholar]

- Majorek, A. Der Einfluärmeübergangs auf die Eigenspannungs- und Verzugsausbildung beim Abschrecken von Stahlzylindern in Verdampfenden Flüssigkeiten. Ph.D. Thesis, Karlsruhe Institute of Technology, Karlsruhe, Germany, 1996. [Google Scholar]

- Van Bohemen, S.M.C.; Sietsma, J. Modeling of isothermal bainite formation based on the nucleation kinetics. Int. J. Mater. Res. 2008, 99, 739–747. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change. I General Theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar] [CrossRef]

- De Graaff, B.; Autenrieth, H.; Hoffmeister, J.; Schulze, V. Investigation on Short Time Tempering by Induction Heating of the low alloyed AISI 4140 steel. In Proceedings of the European Conference on Heat Treatment, Munich, Germany, 12–15 May 2014. [Google Scholar]

- Wever, F.; Rose, A. (Eds.) Atlas zur Wärmebehandlung der Stähle; Verl. Stahleisen: Düsseldorf, Germany, 1961. [Google Scholar]

- Denis, S.; Gautier, E.; Simon, A.; Beck, G. Stress–phase-transformation interactions—basic principles, modelling and calculation of internal stresses. Mater. Sci. Technol. 1985, 1, 805–814. [Google Scholar] [CrossRef]

- Said Schicchi, D.; Hunkel, M. Effect of Pre-strain and High Stresses on the Bainitic Transformation of Manganese-boron Steel 22MnB5. Metall. Mater. Trans. A 2018, 49, 2011–2025. [Google Scholar] [CrossRef]

- Van Bohemen, S.M.C.; Hanlon, D.N. A physically based approach to model the incomplete bainitic transformation in high-Si steels. Int. J. Mater. Res. 2012, 103, 987–991. [Google Scholar] [CrossRef]

- Ravi, A.M.; Sietsma, J.; Santofimia, M.J. Exploring bainite formation kinetics distinguishing grain-boundary and autocatalytic nucleation in high and low-Si steels. Acta Mater. 2016, 105, 155–164. [Google Scholar] [CrossRef]

- Schwenk, M. Numerische Modellierung der Induktiven Ein- und Zweifrequenzrandschichthärtung. Ph.D. Thesis, Karlsruhe Institute of Technology, Karlsruhe, Germany, 2012. [Google Scholar]

- Ahrens, U. Beanspruchungsabhängiges Umwandlungsverhalten und Umwandlungsplastizität Niedrig Legierter Stähle mit Unterschiedlich Hohen Kohlenstoffgehalten. Ph.D. Thesis, Universität Paderborn, Paderborn, Germany, 2003. [Google Scholar]

| C | Si | Mn | Cr | Mo | Fe | |

|---|---|---|---|---|---|---|

| AISI 4140 | 0.43 ± 0.01 | 0.21 ± 0.003 | 0.82 ± 0.014 | 1.13 ± 0.015 | 0.18 ± 0.002 | bal. |

| AISI 1045 | 0.48 ± 0.02 | 0.25 ± 0.003 | 0.612 ± 0.011 | 0.162 ± 0.018 | 0.01 ± 0.001 | bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mühl, F.; Klug, M.; Dietrich, S.; Schulze, V. Improving the Inner Surface State of Thick-Walled Tubes by Heat Treatments with Internal Quenching Considering a Simulation Based Optimization. Processes 2020, 8, 1303. https://doi.org/10.3390/pr8101303

Mühl F, Klug M, Dietrich S, Schulze V. Improving the Inner Surface State of Thick-Walled Tubes by Heat Treatments with Internal Quenching Considering a Simulation Based Optimization. Processes. 2020; 8(10):1303. https://doi.org/10.3390/pr8101303

Chicago/Turabian StyleMühl, Fabian, Moritz Klug, Stefan Dietrich, and Volker Schulze. 2020. "Improving the Inner Surface State of Thick-Walled Tubes by Heat Treatments with Internal Quenching Considering a Simulation Based Optimization" Processes 8, no. 10: 1303. https://doi.org/10.3390/pr8101303

APA StyleMühl, F., Klug, M., Dietrich, S., & Schulze, V. (2020). Improving the Inner Surface State of Thick-Walled Tubes by Heat Treatments with Internal Quenching Considering a Simulation Based Optimization. Processes, 8(10), 1303. https://doi.org/10.3390/pr8101303