The Investigation of Optimizing Leaching Efficiency of Al in Secondary Aluminum Dross via Pretreatment Operations

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. SAD

2.1.2. Chemical Reagents

2.2. Methods

2.2.1. Grinding operation

2.2.2. Leaching Operation

2.3. Detection and Analysis Methods

3. Results and Discussion

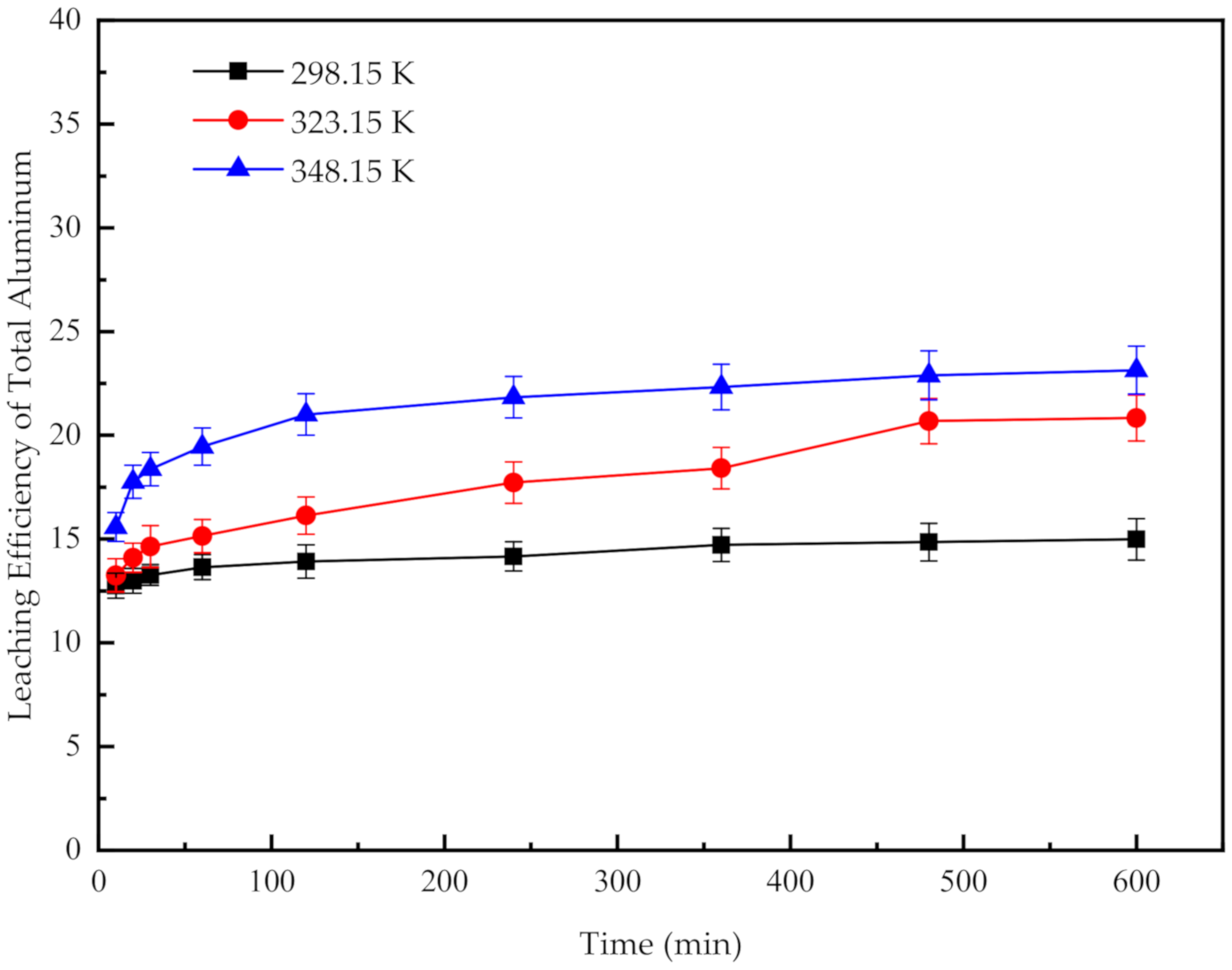

3.1. Direct Acid Leaching Process

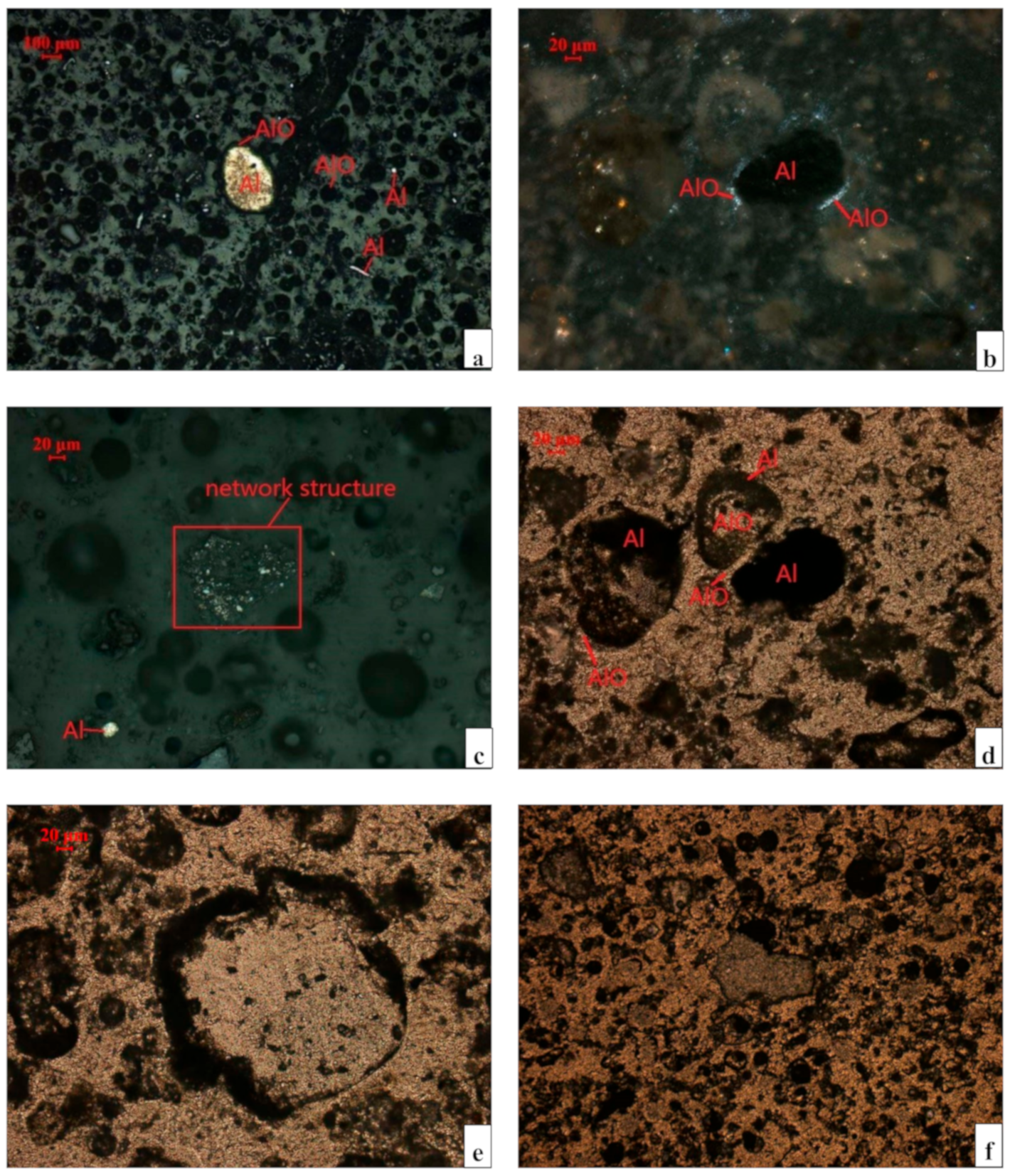

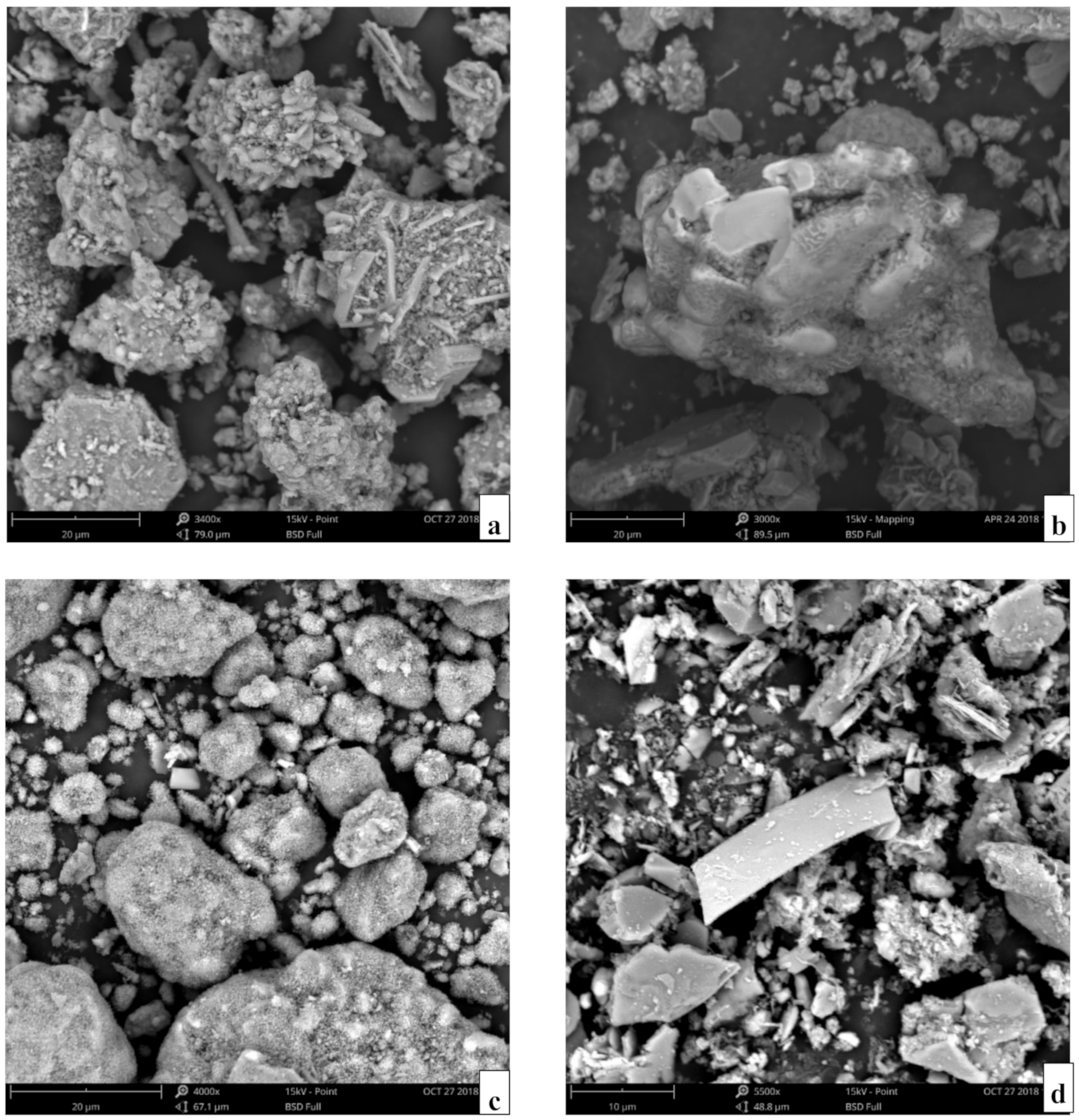

3.2. Investigation of the Process Mineralogy of the SAD

3.3. Effects of the Pretreatment Operation on Acid Leaching

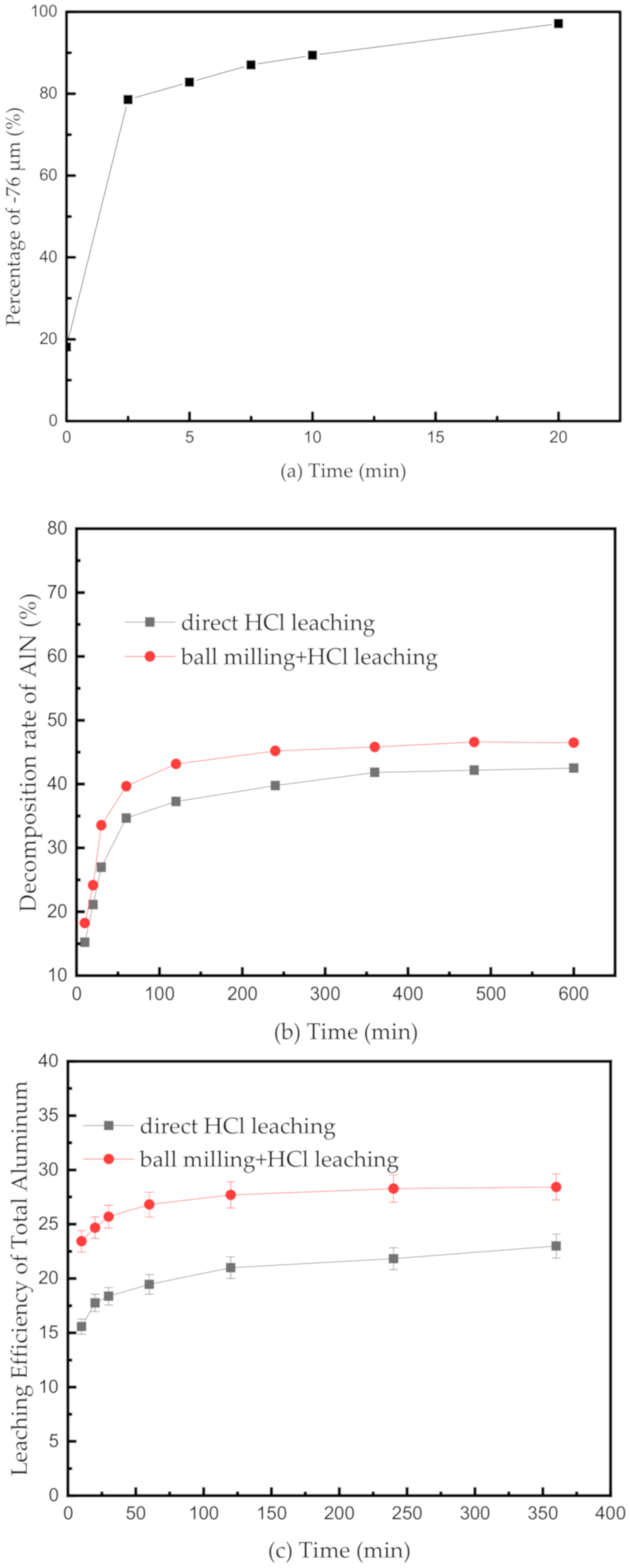

3.3.1. Effect of Ball-Grinding Operation

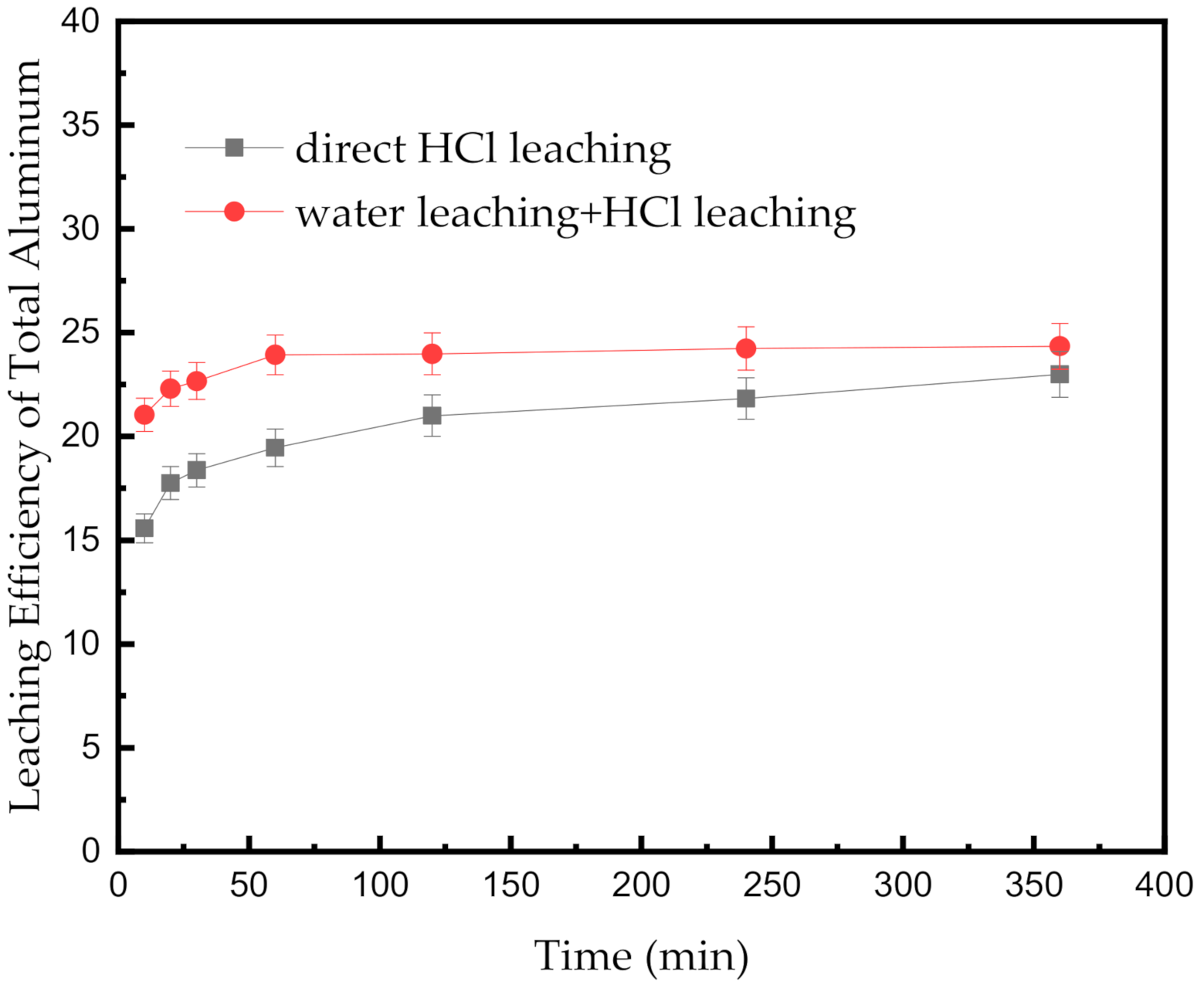

3.3.2. Effect of Water Leaching Operation

3.3.3. Comparison of Different Leaching Operations

3.4. Analysis of the Evolution of Phases and Morphology

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Hagelstein, K. Globally sustainable manganese metal production and use. J. Environ. Manag. 2009, 90, 3736–3740. [Google Scholar] [CrossRef]

- Green, J.A.S. Aluminum Recycling Processing for Energy Conservation and Sustainability; ASM International: Materials Park, OH, USA, 2007; p. 288. [Google Scholar]

- Institute, I.A. Global Aluminium Recycling: A Cornerstone of Sustainable Development; International Aluminium Institute: London, UK, 2009; p. 36. [Google Scholar]

- Aluminum Association. Aluminum—The Element of Sustainability; The Aluminum Association: Washington, DC, USA, 2011; p. 70. [Google Scholar]

- Mahinroosta, M.; Allahverdi, A. A promising green process for synthesis of high purity activated-alumina nanopowder from secondary aluminum dross. J. Clean. Prod. 2018, 179, 93–102. [Google Scholar] [CrossRef]

- Tsakiridis, P.E. Aluminium salt slag characterization and utilization—A review. J. Hazard. Mater. 2012, 217–218, 1–10. [Google Scholar] [CrossRef]

- Xiao, Y.P.; Reuter, M.A.; Boin, U. Aluminium recycling and environmental issues of salt slag treatment. J. Environ. Sci. Health Part A 2005, 40, 1861–1875. [Google Scholar] [CrossRef]

- Das, B.R.; Dash, B.; Tripathy, B.C.; Bhattacharya, I.N.; Das, S.C. Production of η-alumina from waste aluminium dross. Miner. Eng. 2007, 20, 252–258. [Google Scholar] [CrossRef]

- Calder, G.V.; Timothy, D.S. Aluminum Reactions and Problems in Municipal Solid Waste Landfills. Waste Manag. 2010, 14, 258–265. [Google Scholar] [CrossRef]

- Gil, A. Management of the salt cake from secondary aluminum fusion processes. Ind. Eng. Chem. Res. 2005, 44, 8852–8857. [Google Scholar] [CrossRef]

- Tenorio, J.A.S.; Espinosa, D.C.R. Effect of salt/oxide interaction on the process of aluminum recycling. J. Light Met. 2002, 2, 89–93. [Google Scholar] [CrossRef]

- Gil, A.; Korili, S.A. Management and valorization of aluminum saline slags: Current status and future trends. Chem. Eng. J. 2016, 289, 74–84. [Google Scholar] [CrossRef]

- Meshram, A.; Singh, K.K. Recovery of valuable products from hazardous aluminum dross: A review. Resour. Conserv. Recycl. 2018, 130, 95–108. [Google Scholar] [CrossRef]

- Peterson, R.D.; Newton, L. Review of aluminum dross processing. In Light Metals 2002; Schneider, W.A., Ed.; John Wiley & Sons, Inc: San Antonio, TX, USA, 2002; pp. 1029–1037. [Google Scholar]

- Zhang, L. State of the Art in Aluminum Recycling from Aluminum Dross. In Light Metals: Proceedings of Sessions: TMS Annual Meeting; John Wiley & Sons, Inc.: San Antonio, TX, USA, 2006; pp. 931–936. [Google Scholar]

- Hiraki, T.; Nagasaka, T. An easier upgrading process of aluminum dross residue by screening technique. J. Mater. Cycles Waste Manag. 2014, 17, 566–573. [Google Scholar] [CrossRef]

- Türk, M.; Altıner, M.; Top, S.; Karaca, S.; Bouchekrit, C. Production of Alpha-Alumina from Black Aluminum Dross Using NaOH Leaching Followed by Calcination. JOM 2020. [Google Scholar] [CrossRef]

- David, E.; Kopac, J. Hydrolysis of aluminum dross material to achieve zero hazardous waste. J. Hazard Mater. 2012, 209–210, 501–509. [Google Scholar] [CrossRef] [PubMed]

- Nhi, T.T.N.; Lee, M.S.; Thi Hong, N. Ball Milling Treatment of Black Dross for Selective Dissolution of Alumina in Sodium Hydroxide Leaching. Processes 2018, 6. [Google Scholar] [CrossRef]

- Bruckard, W.J.; Woodcock, J.T. Characterisation and treatment of Australian salt cakes by aqueous leaching. Miner. Eng. 2007, 20, 1376–1390. [Google Scholar] [CrossRef]

- Tsakiridis, P.E.; Oustadakis, P.; Agatzini-Leonardou, S. Aluminium recovery during black dross hydrothermal treatment. J. Environ. Chem. Eng. 2013, 1, 23–32. [Google Scholar] [CrossRef]

- Li, Q.; Yang, Q.; Zhang, G.; Shi, Q. Investigations on the hydrolysis behavior of AlN in the leaching process of secondary aluminum dross. Hydrometallurgy 2018, 182, 121–127. [Google Scholar] [CrossRef]

- Yang, Q.; Li, Q.; Zhang, G.; Shi, Q.; Feng, H. Investigation of leaching kinetics of aluminum extraction from secondary aluminum dross with use of hydrochloric acid. Hydrometallurgy 2019, 187, 158–167. [Google Scholar] [CrossRef]

- Dash, B.; Das, B.R.; Tripathy, B.C.; Bhattacharya, I.N.; Das, S.C. Acid dissolution of alumina from waste aluminium dross. Hydrometallurgy 2008, 92, 48–53. [Google Scholar] [CrossRef]

- Sarker, M.S.R.; Alam, M.Z.; Qadir, M.R.; Gafur, M.A.; Moniruzzaman, M. Extraction and characterization of alumina nanopowders from aluminum dross by acid dissolution process. Int. J. Miner. Metall. Mater. 2015, 22, 429–436. [Google Scholar] [CrossRef]

- Nhi, T.T.N.; Song, S.J.; Lee, M.S. Development of a hydrometallurgical process for the recovery of pure alumina from black dross and synthesis of magnesium spinel. J. Mater. Res. Technol. 2020, 9, 2568–2577. [Google Scholar] [CrossRef]

| Grain-Size (mm) | Yield (%) | Aluminum Grade (%) | Aluminum Distribution (%) |

|---|---|---|---|

| 0.25–0.45 | 6.65 | 15.26 | 26.63 |

| 0.15−0.25 | 21.50 | 5.72 | 35.18 |

| 0.10−0.15 | 29.71 | 2.23 | 18.95 |

| 0.076−0.10 | 24.05 | 1.81 | 12.45 |

| 0−0.076 | 18.08 | 1.31 | 6.78 |

| Initial SAD | 100.00 | 3.58 | 100.00 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, H.; Zhang, G.; Yang, Q.; Xun, L.; Zhen, S.; Liu, D. The Investigation of Optimizing Leaching Efficiency of Al in Secondary Aluminum Dross via Pretreatment Operations. Processes 2020, 8, 1269. https://doi.org/10.3390/pr8101269

Feng H, Zhang G, Yang Q, Xun L, Zhen S, Liu D. The Investigation of Optimizing Leaching Efficiency of Al in Secondary Aluminum Dross via Pretreatment Operations. Processes. 2020; 8(10):1269. https://doi.org/10.3390/pr8101269

Chicago/Turabian StyleFeng, Haigang, Guofan Zhang, Qun Yang, Luobing Xun, Siyuan Zhen, and Dezhi Liu. 2020. "The Investigation of Optimizing Leaching Efficiency of Al in Secondary Aluminum Dross via Pretreatment Operations" Processes 8, no. 10: 1269. https://doi.org/10.3390/pr8101269

APA StyleFeng, H., Zhang, G., Yang, Q., Xun, L., Zhen, S., & Liu, D. (2020). The Investigation of Optimizing Leaching Efficiency of Al in Secondary Aluminum Dross via Pretreatment Operations. Processes, 8(10), 1269. https://doi.org/10.3390/pr8101269