Installation time (

IT) represents the time period required for construction and start-up of a new milk drying unit. Usually, such a process may take up to two years. In our study,

IT was equal to one year. Required investment (

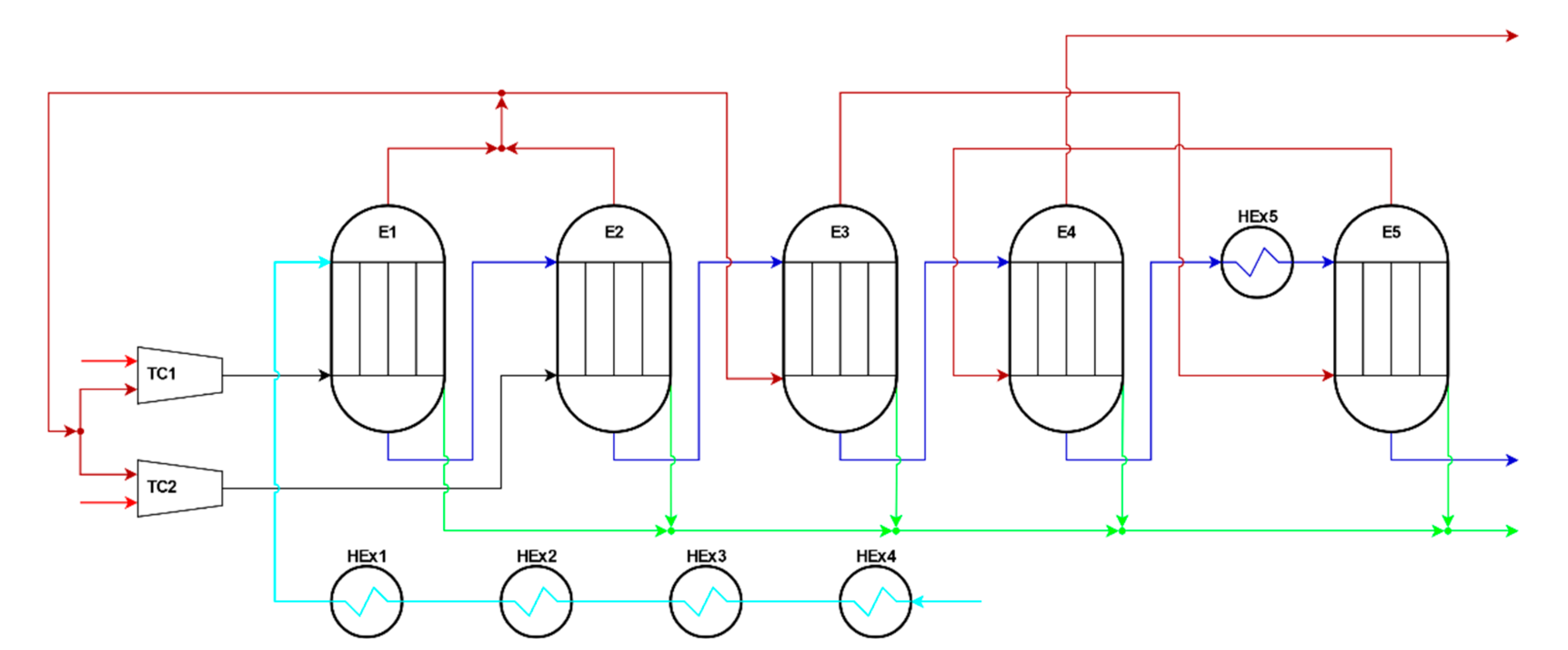

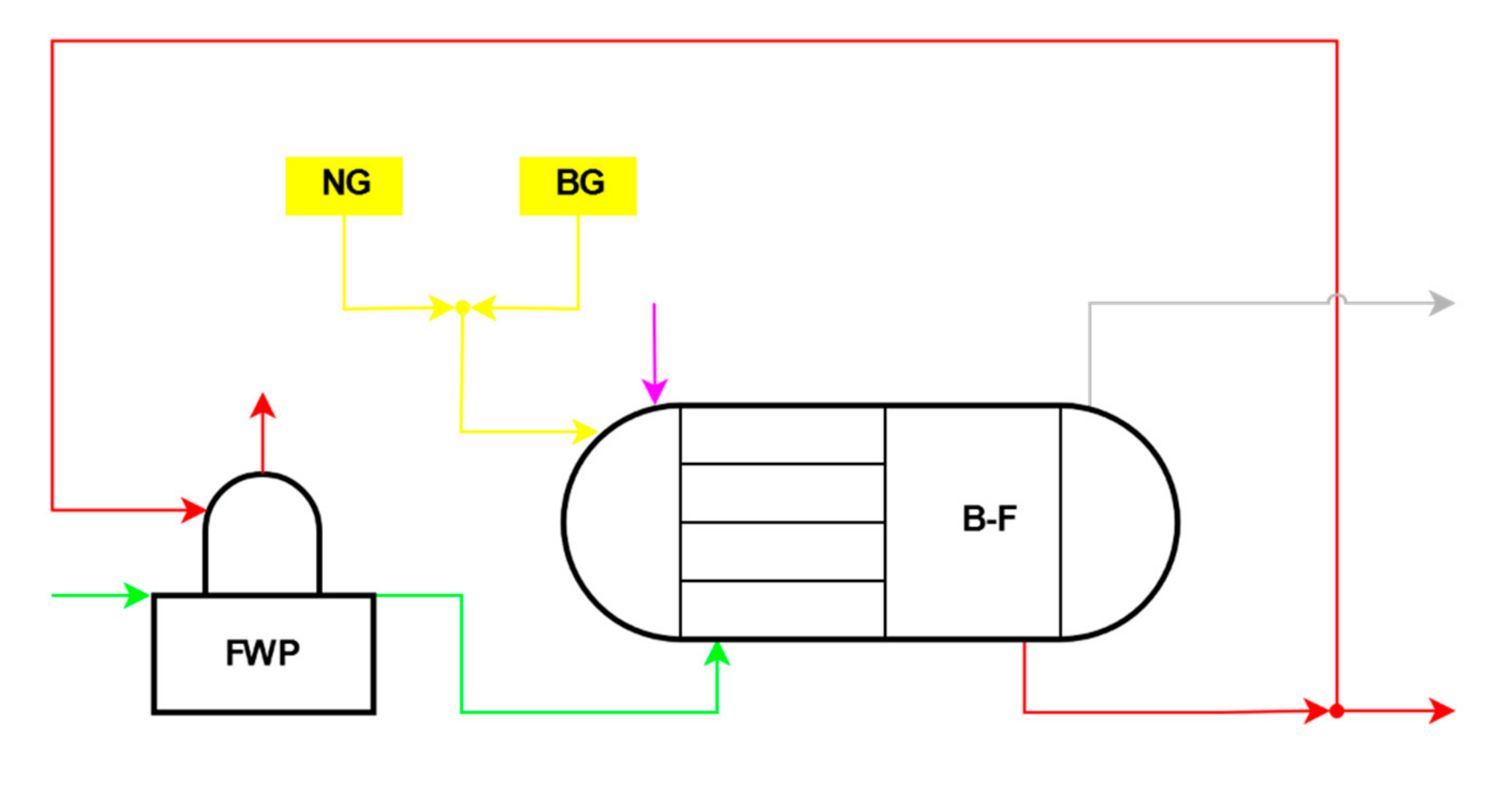

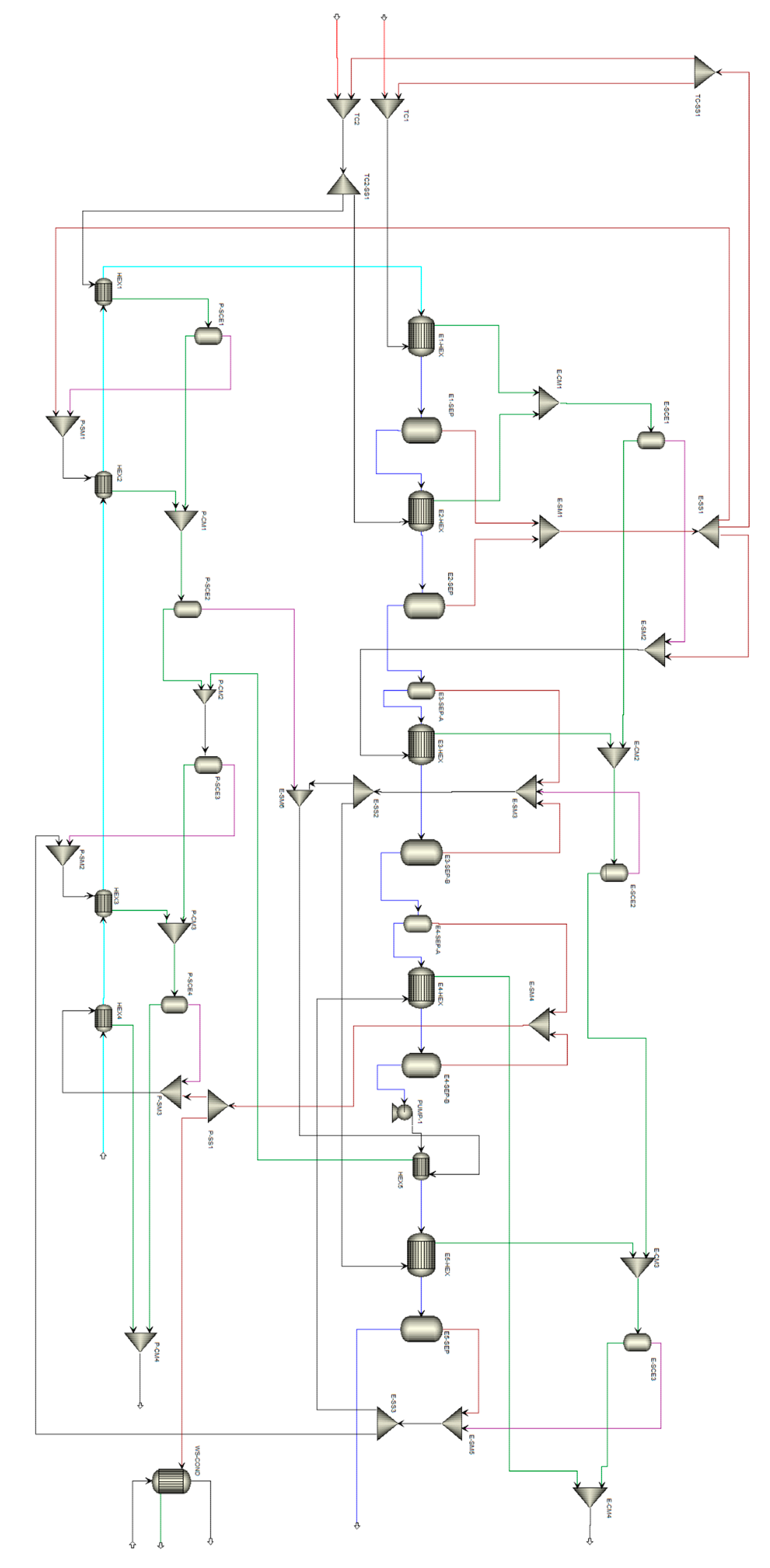

RI) was calculated taking into account all new equipment required for the milk drying (as simulated in

Figure 3 and

Figure 4)—multieffect evaporator, spray dryer, boiler, heat exchangers, pumps, fans, and thermocompressors. For the purposes of the presented economic analysis, the sum of costs for purchase, taxation, delivery, and installation of these units was considered constant and equal to 1.12 mil. EUR based on literature guidance [

35]. More detailed RI breakdown is presented in

Table 6. Annual cash inflow (

CI) and cash outflow (

CO) are variables in this analysis.

CI represented profit from sales of milk powder, that is, the difference between selling prices of powdered milk and fresh pasteurized milk. Due to the local and global regulations in the milk market, prices of fresh milk and powdered milk are very volatile and country-specific (

Figure 9) [

36]. The effect of the fresh milk selling price was in the range from 260 to 400 EUR/t and powdered milk selling price in the range from 2200 to 3700 EUR/t.

CO comprised operating costs related to energy consumption. The main energy media considered in our study were water, natural gas, biogas, and electricity. Prices of water, natural gas, and electricity can be considered constant, thus, water price of 0.35 EUR/m

3 for boiler feed water and 0.05 EUR/m

3 for cooling water in the waste steam condenser, natural gas price of 0.35 EUR/m

3, and electricity price of 115 EUR/MWh were considered. Costs related to biogas production, desulphurization, and transfer were subject to our study. These costs strongly depend on the quality of substrate and process conditions. Because of the unknown effect of cattle manure co-digestion, the range of biogas prices was based on technical publications’ reviews [

37,

38]. Palm [

37] analyzed costs for biogas production, upgrade, distribution, and sale in Sweden. After conversion from SEK to EUR and recalculation from kWh to m

3, raw biogas price varied from 0.163 EUR/m

3 to 0.380 EUR/m

3. Beddoes et al. [

38] listed biogas production costs with different sources of biomass in the USA. After conversion from USD to EUR and recalculation from ft

3 to m

3, raw biogas price varied from 0.046 EUR/m

3 to 0.105 EUR/m

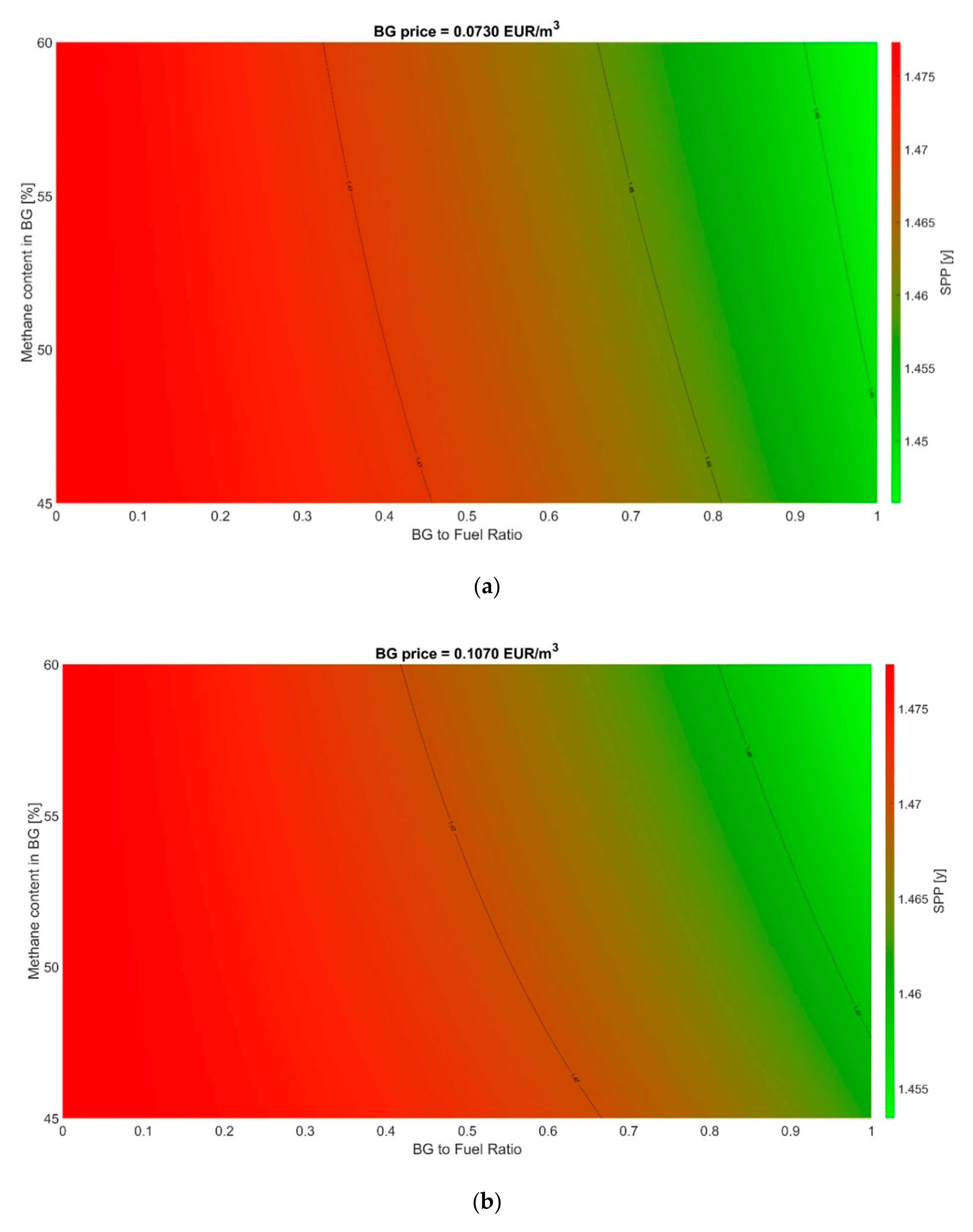

3 for dairy-origin biomass. In the presented economic analysis, biogas price varied from 0.073 EUR/m

3 to 0.243 EUR/m

3 with a step of 0.034 EUR/m

3.

CO was increased by 3% to cover maintenance costs and potential increase in wage costs. Annual operating time of the dairy plant of 8400 h was considered.

Economic analysis was split into three scenarios to represent very positive, very negative, and neutral market situations. Scenario A represents conservative circumstances with moderate powdered milk selling price of 3320 EUR/t and moderate fresh milk selling price of 280 EUR/t. Such a scenario should be closest to reality. Scenario B is the best-case scenario in which the highest value of powdered milk selling price and the lowest value of fresh milk selling price were considered. This combination favors further processing of raw milk into milk powder, thus leading to generally shorter payback periods. Scenario C is the worst-case scenario, where fresh milk selling price was the highest and powdered milk selling price was the lowest. Considering such market status can lead to very long payback periods or even to higher

CO than

CI (i.e., negative cashflow). In such a scenario, the project of a new milk drying unit is unfeasible. All milk prices considered in the scenarios are summarized in

Table 7. Similar complex figures as

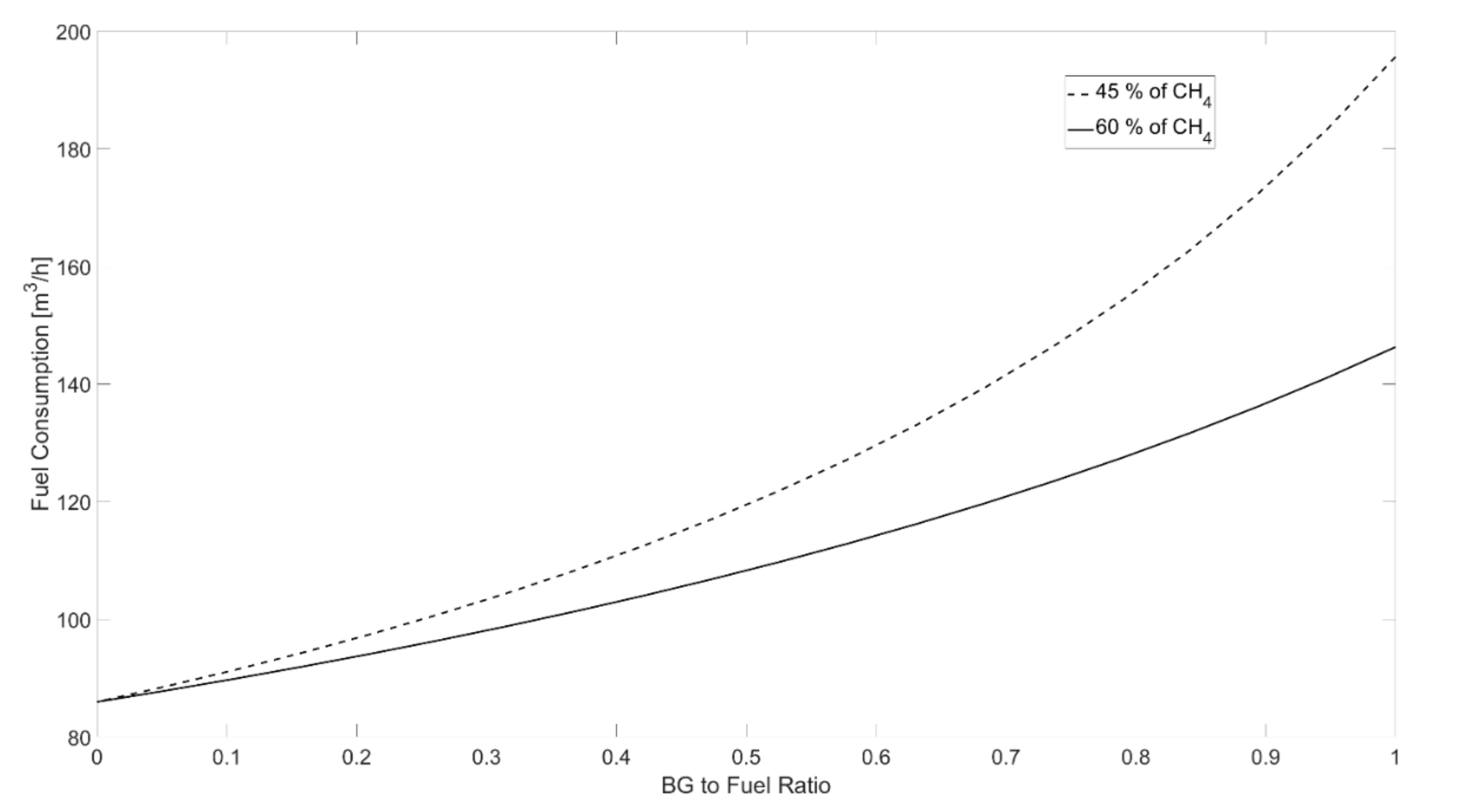

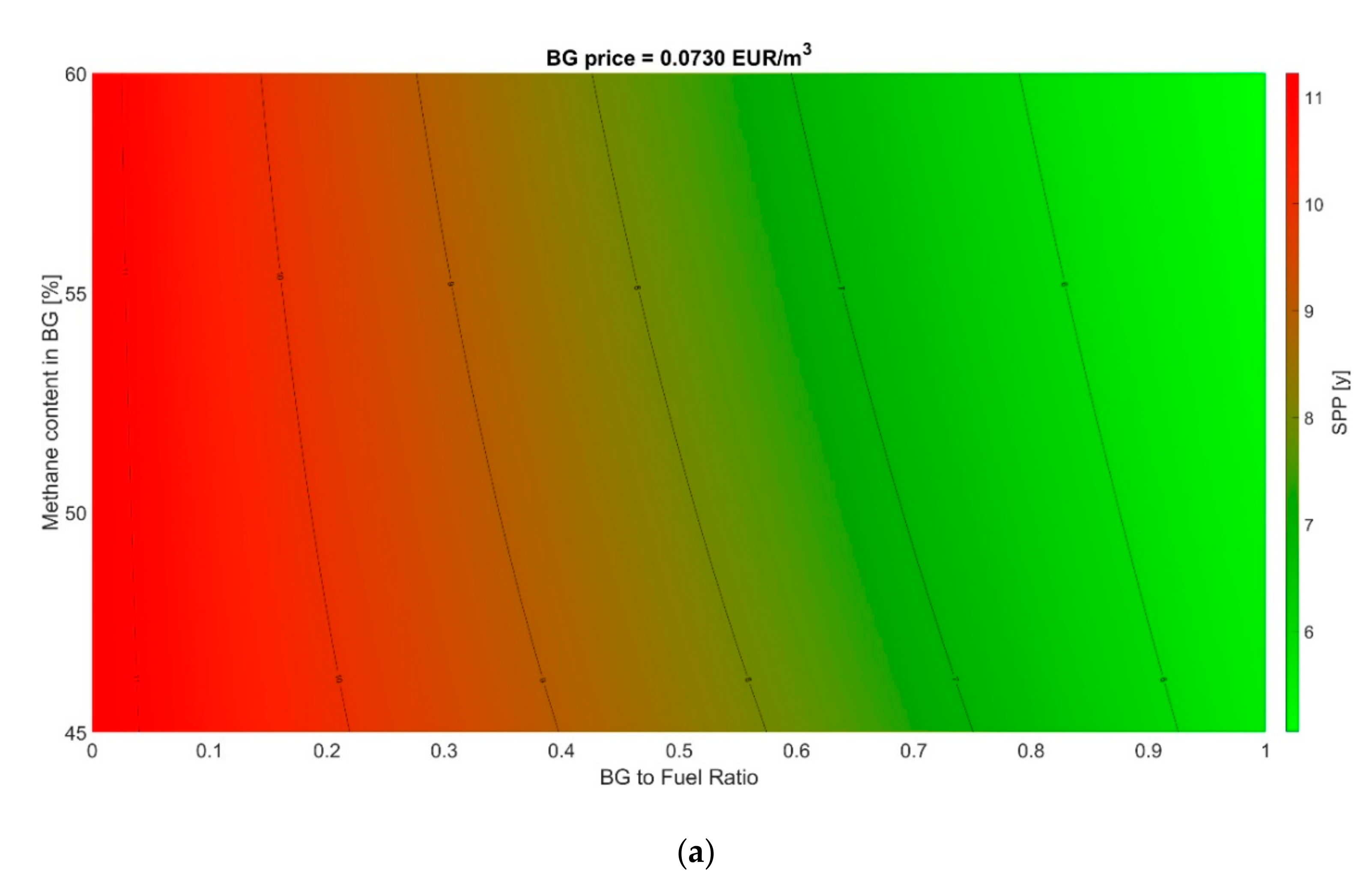

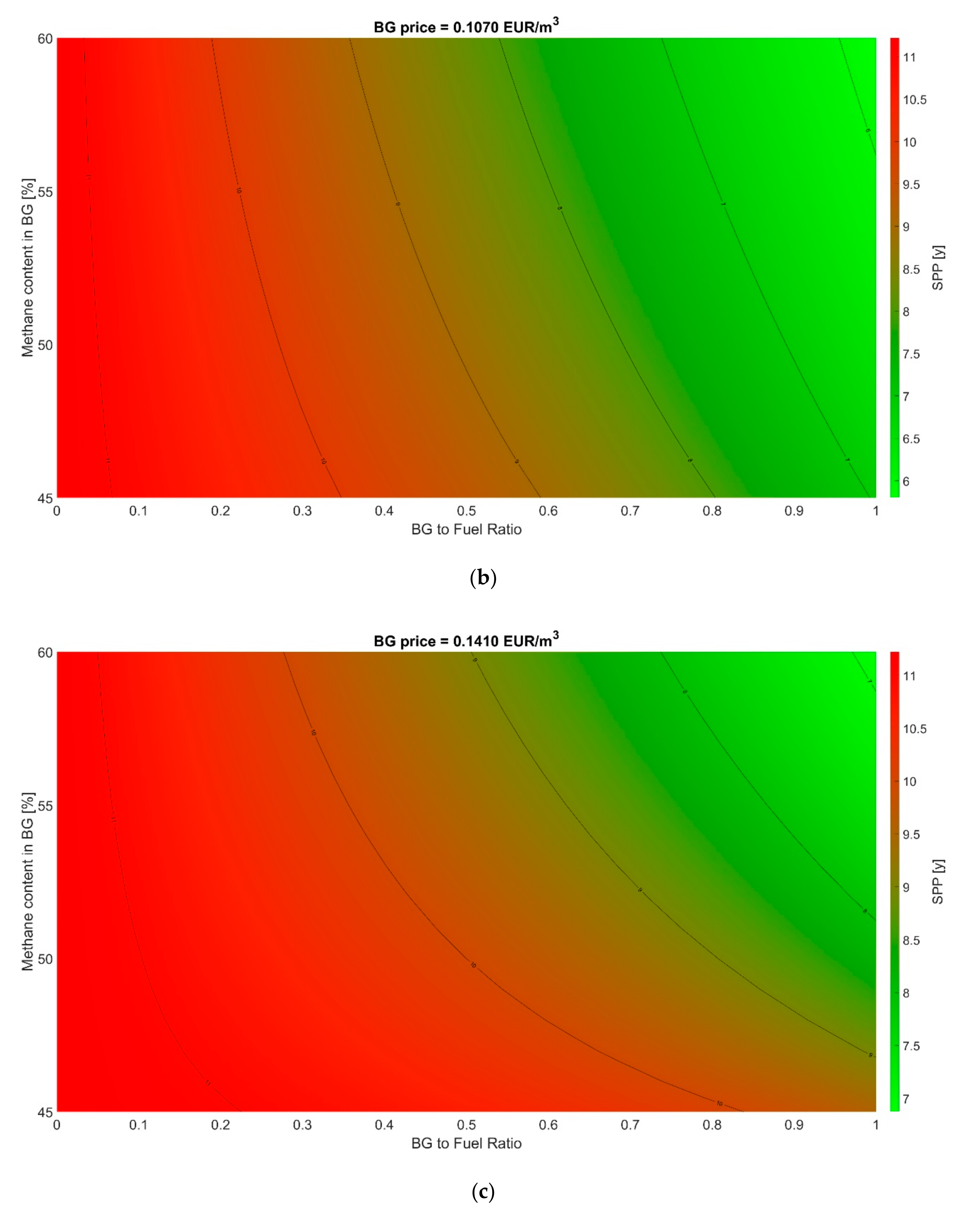

Figure 7 were constructed to grasp the dependency of the project’s profitability on biogas price. Biogas-to-fuel ratio and methane content in biogas remained as analyzed process variables. Instead of fuel consumption, SPP as defined by Equation (1) was evaluated as a function of these two parameters and biogas price.

3.2.1. Scenario A

In this scenario, SPP varied from 5.1 to over 60 years. If no biogas is used as boiler fuel, SPP value is 11.2 years.

Figure 10 demonstrates the effect of the biogas portion in fuel and biogas digestion conditions (methane content and purification costs) on the project’s economics. Five 3D figures were constructed to represent five different biogas prices. Three different states can be recognized. In the first state (

Figure 10a–c), addition of biogas to fuel had always a positive effect on the project’s profitability (i.e., it led to a decrease of SPP). However, with the increasing biogas price, this effect was reduced, which is logical. The minimum achievable SPP in the case of lowest biogas price (0.073 EUR/m

3) was 5.1 years and in the case of highest biogas price (0.141 EUR/m

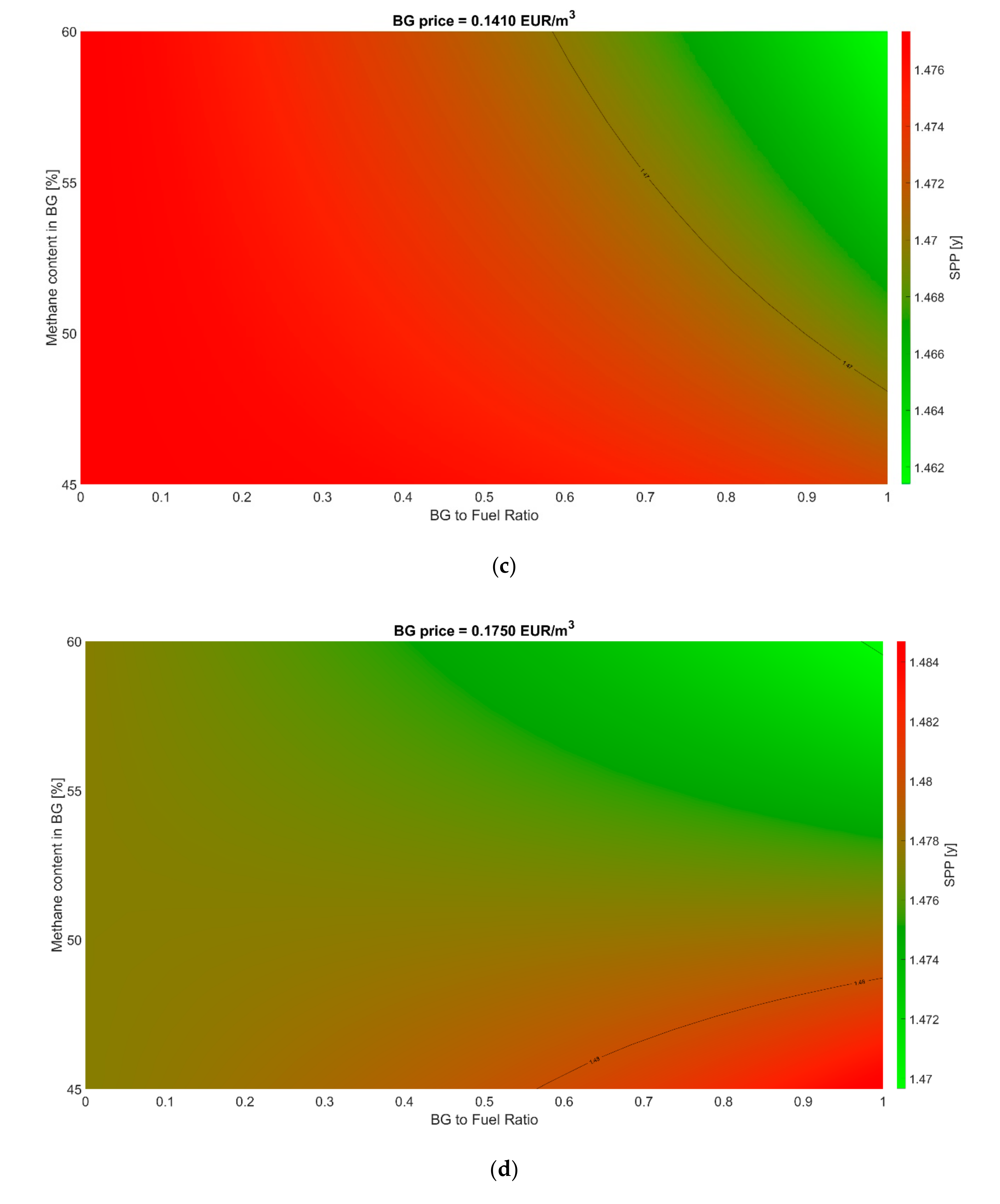

3), it was 6.9 years. The second state (

Figure 10d) corresponds to the situation in which biogas addition has positive or negative effect depending on its methane content. In this region, higher methane content led to desired SPP decrease because of higher calorific value of biogas and thus lower required biogas flow for steam generation. Vice versa, if methane content was insufficient, biogas calorific value was too low and consequent increase in biogas flow led to increase in SPP. For methane-rich biogas (over ca. 53 mol.%), adding biogas to boiler fuel led to the desired decrease in SPP from 11.2 years down to 8.6 years. If methane content in biogas was between 53 and 50 mol.%, addition of biogas had negligible effect and SPP remained almost the same. Mixing biogas with methane content below 50 mol.% into boiler fuel had a negative effect on SPP. In the worst case, adding biogas led to an increase of SPP from 11.2 years to 16.1 years, thus disfavoring cattle manure co-digestion as a solution to improve the proposed milk drying unit profitability.

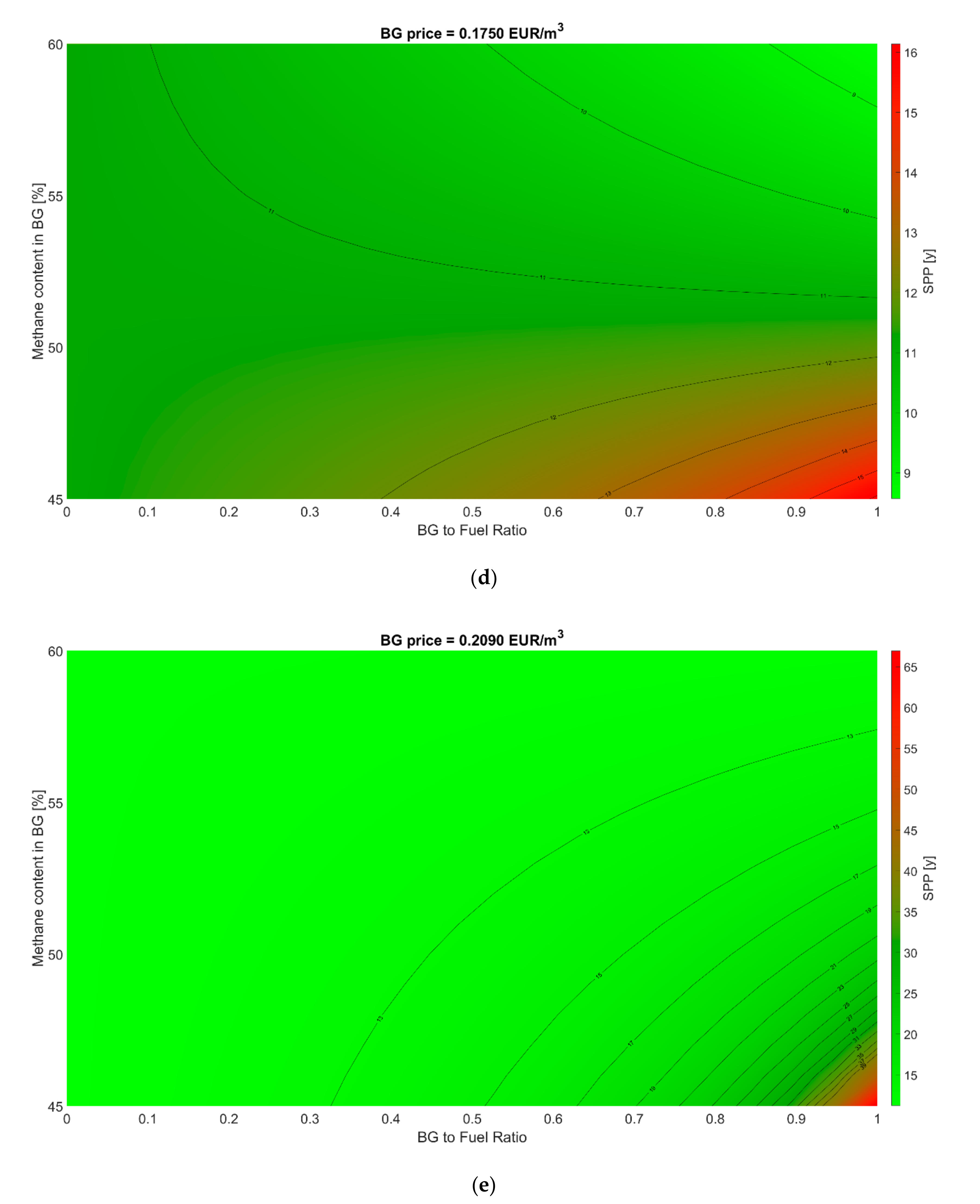

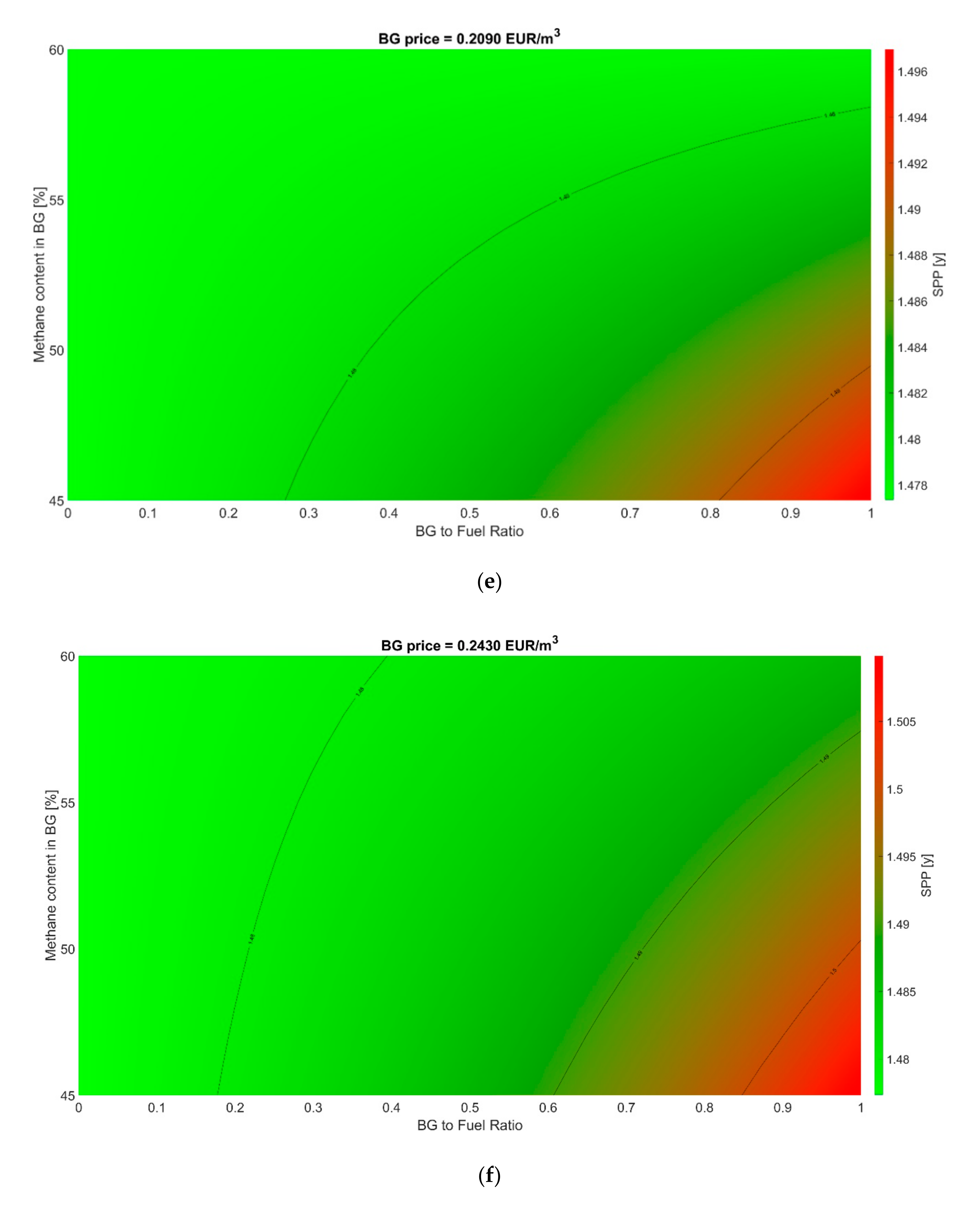

The third state (

Figure 10e) represents an adverse situation in which adding biogas has always a negative effect on the project’s economics. For biogas with the lowest methane content, 45 mol.%, SPP increased from 11.2 years up to 66.4 years, making the project completely unfeasible. In this situation, biogas addition is not recommended. A similar plot (with significantly worse SPP increase to unreasonable values over 100 years) was modeled also for the highest considered biogas price of 0.243 EUR/m

3, which is not presented in this paper.