Energetic and Exergetic Investigations of Hybrid Configurations in an Absorption Refrigeration Chiller by Aspen Plus

Abstract

:1. Introduction

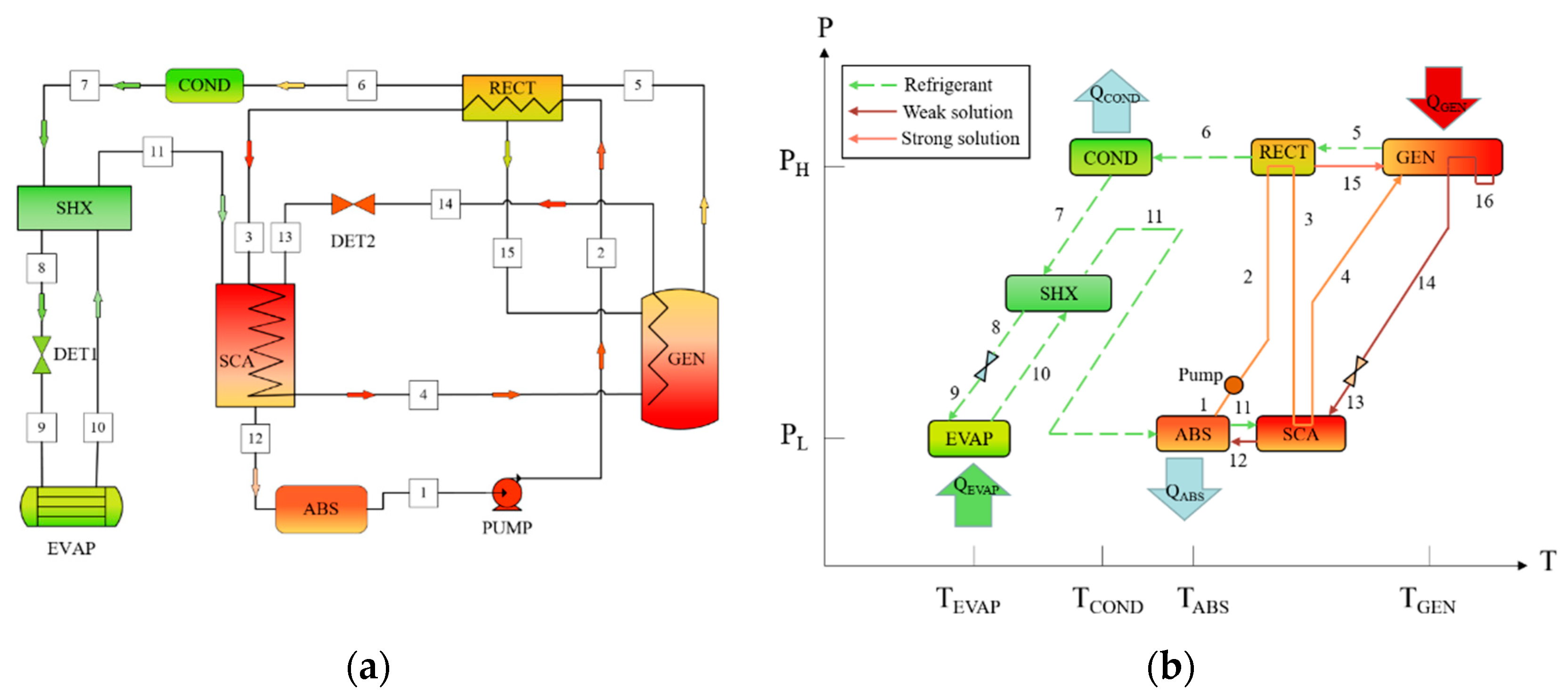

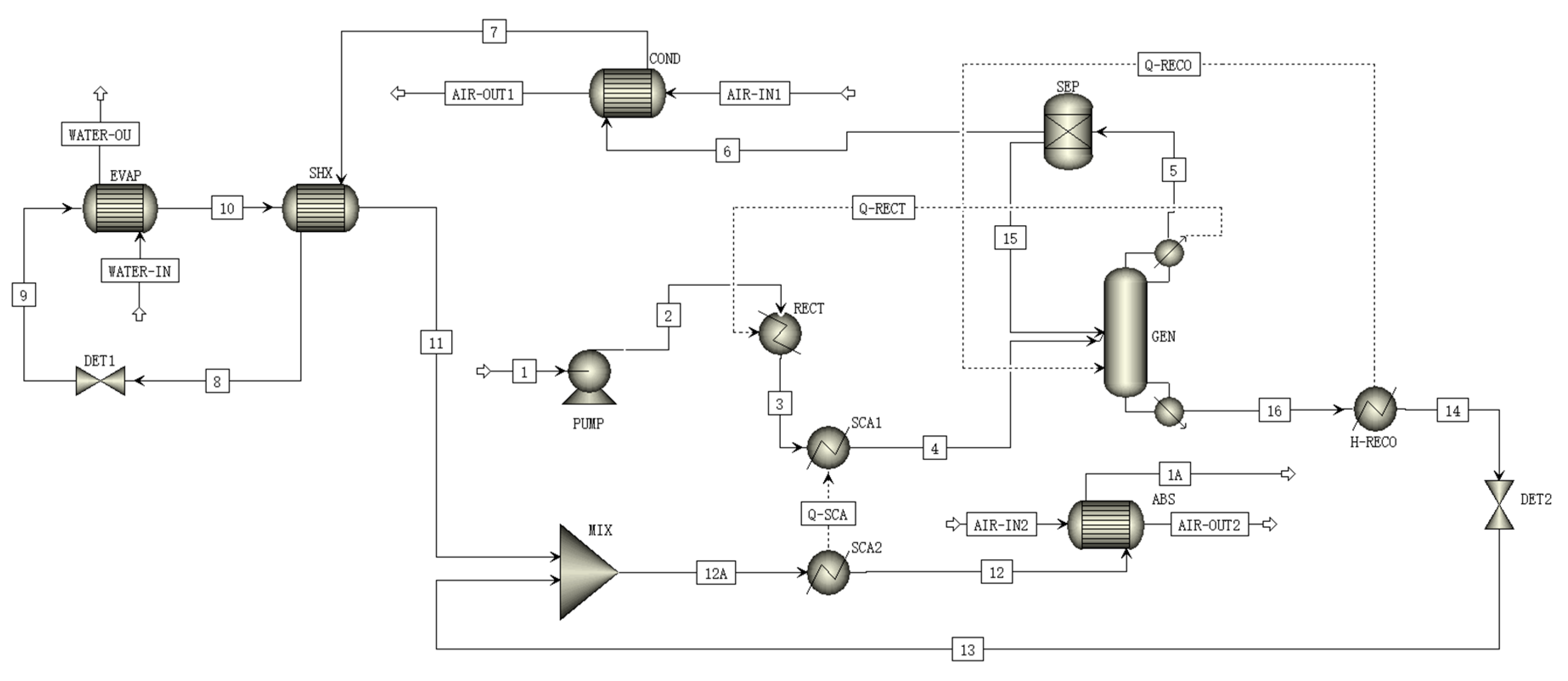

2. Unit Description and Working Principles

3. Establishment of Simulation Model

3.1. Setting Parameters

3.2. Assumptions and Simplification

- Because of the lack of relevant experimental information, the processes of the vapor leaving the RECT towards the COND and the condensate returning to the GEN were supposed to be in equilibrium. Given this, to simply the device, the rectifier was integrated into the generator module with the top stage of the distillation column as a rectifier for which the heat transferred to the strong solution could be considered in its regenerating process. This was a rough but effective simplification [29].

- As the wide concentration change existed between strong and weak solutions (suggesting their huge temperature differences in the solution loop), there was a process of internal heat recovery happening in the GEN, where inlet solutions (Stream 4, 15) were heated by the sensible heat of the high-temperature outlet solution (Stream 14). For simplification, the exit temperature of Stream 14 was almost equal to that of stage 2 in the GEN, i.e., it was equivalent to the temperature of the condensate leaving the rectifier (RECT) [31].

- The treatment of complex structures of the solution cooling absorber (SCA) was also effectively simplified by introducing a new parameter to define its unique heat exchanger effectiveness:According to its definition, T13 and T3 represent the highest temperature of the incoming weak solution (Stream 13) and the lowest temperature of the incoming strong solution (Stream 3) in the SCA respectively. Also, T12 denotes the outlet strong solution’s temperature (Stream 12). Therefore, the denominator and the numerator represent the theoretical maximum heat transfer rate and the actual heat recovery of the exothermic reaction that could be achieved for liquid, respectively. To be specific, describes the ratio of possible heat for liquid that could be recovered from the coupled heat/mass transfer processes in the SCA.

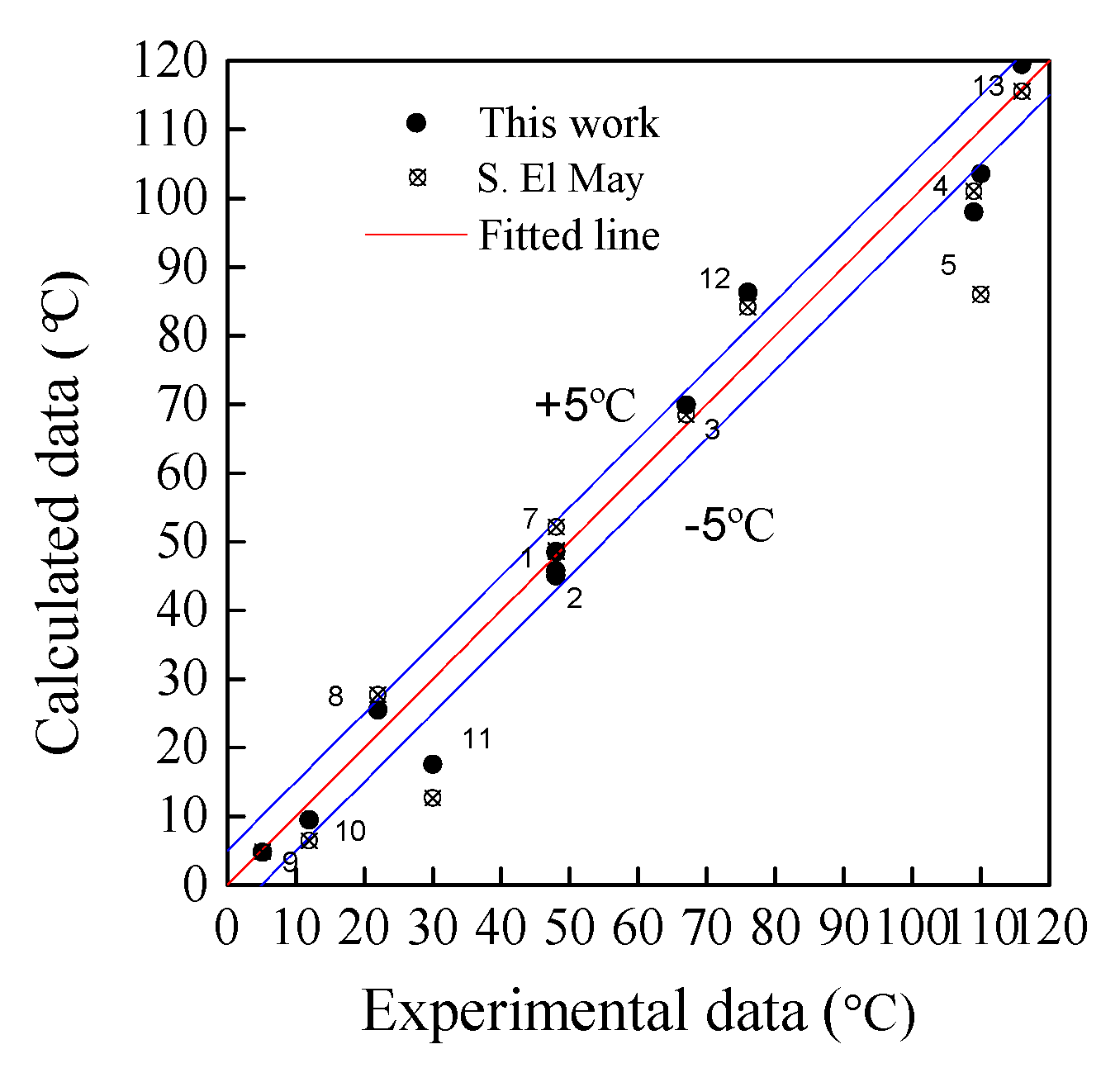

3.3. Validation of the Model

4. Exergy Balance

- All investigations are in steady-state;

- Pressure drop and heat losses within the device can be neglected except the throttling process;

- The temperature of each heat exchanger is its logarithmic mean temperature difference;

- The exergy destruction of the virtual block SEP is ignored;

- Reference states of the ambient environment are 1.01325 bar and 25 °C.

5. Hybrid Cycles

6. Results and Discussion

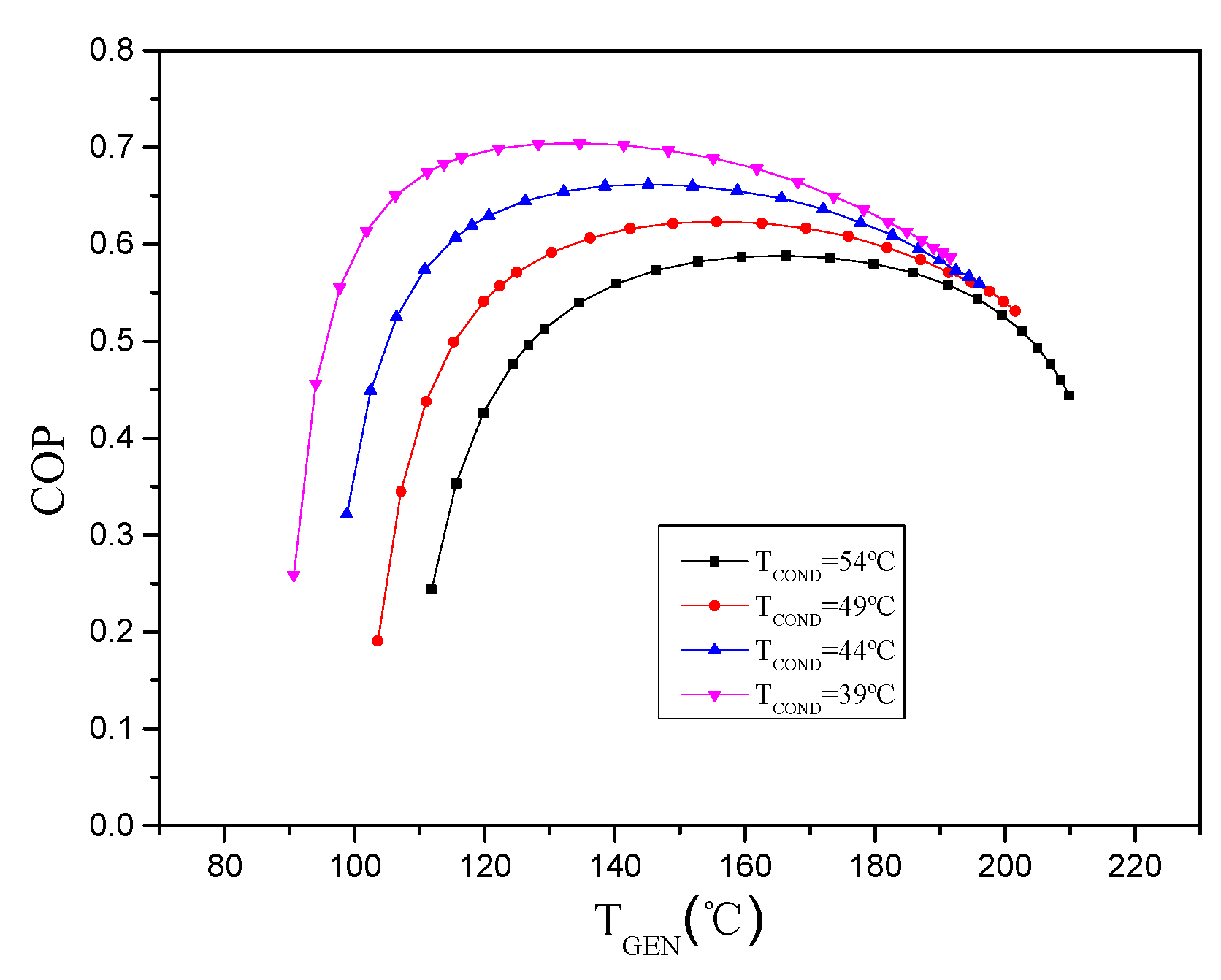

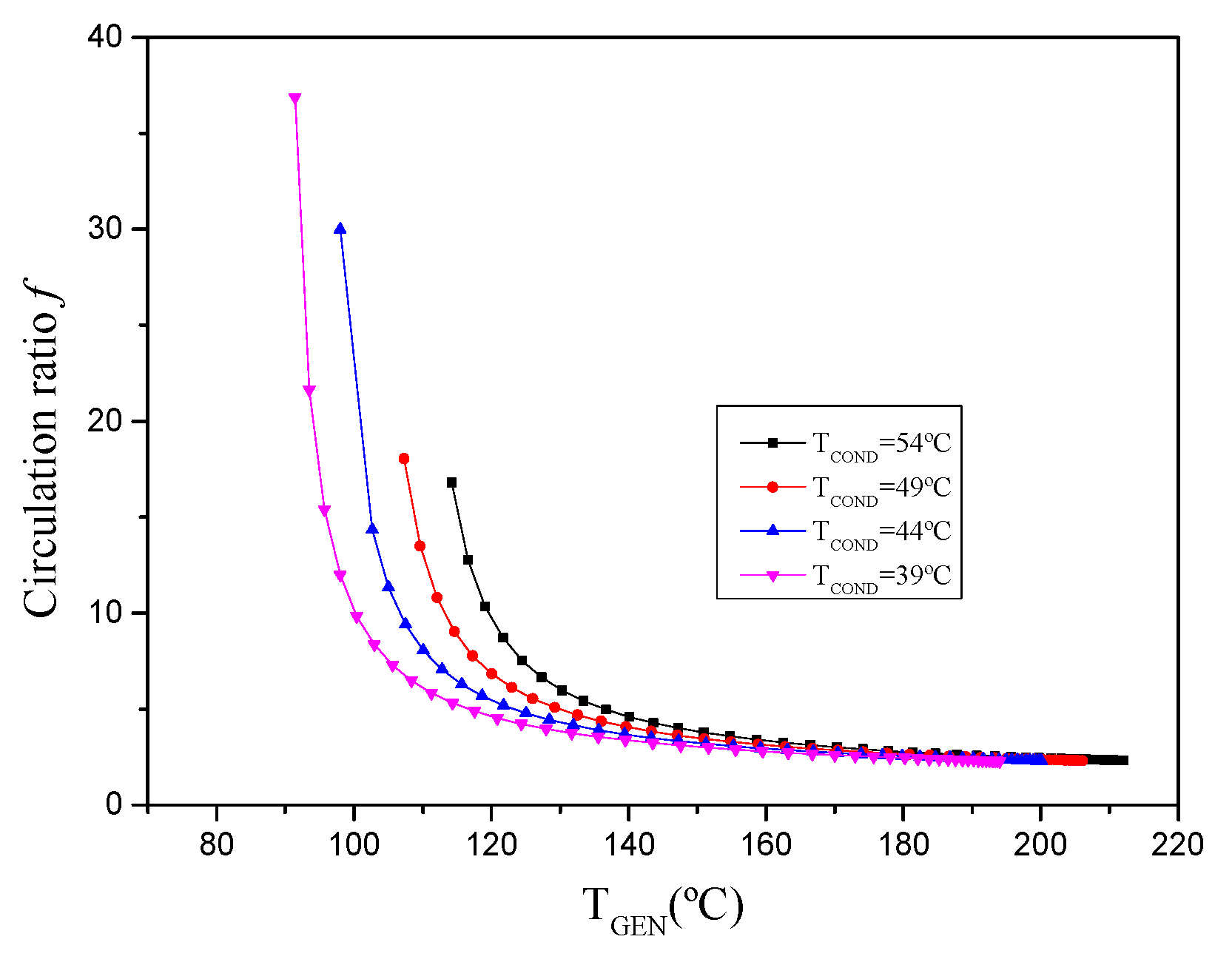

6.1. Performance of Basic Cycle

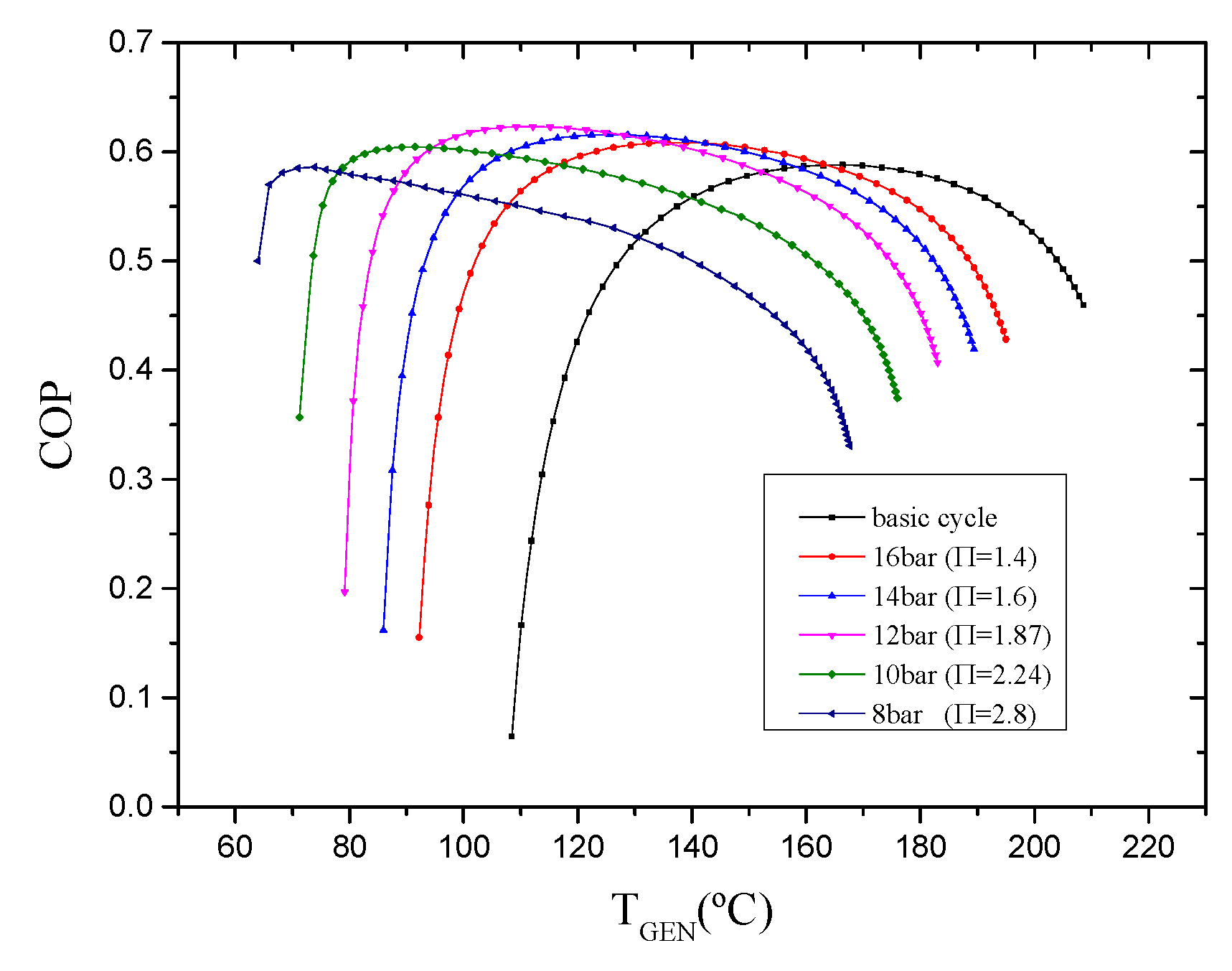

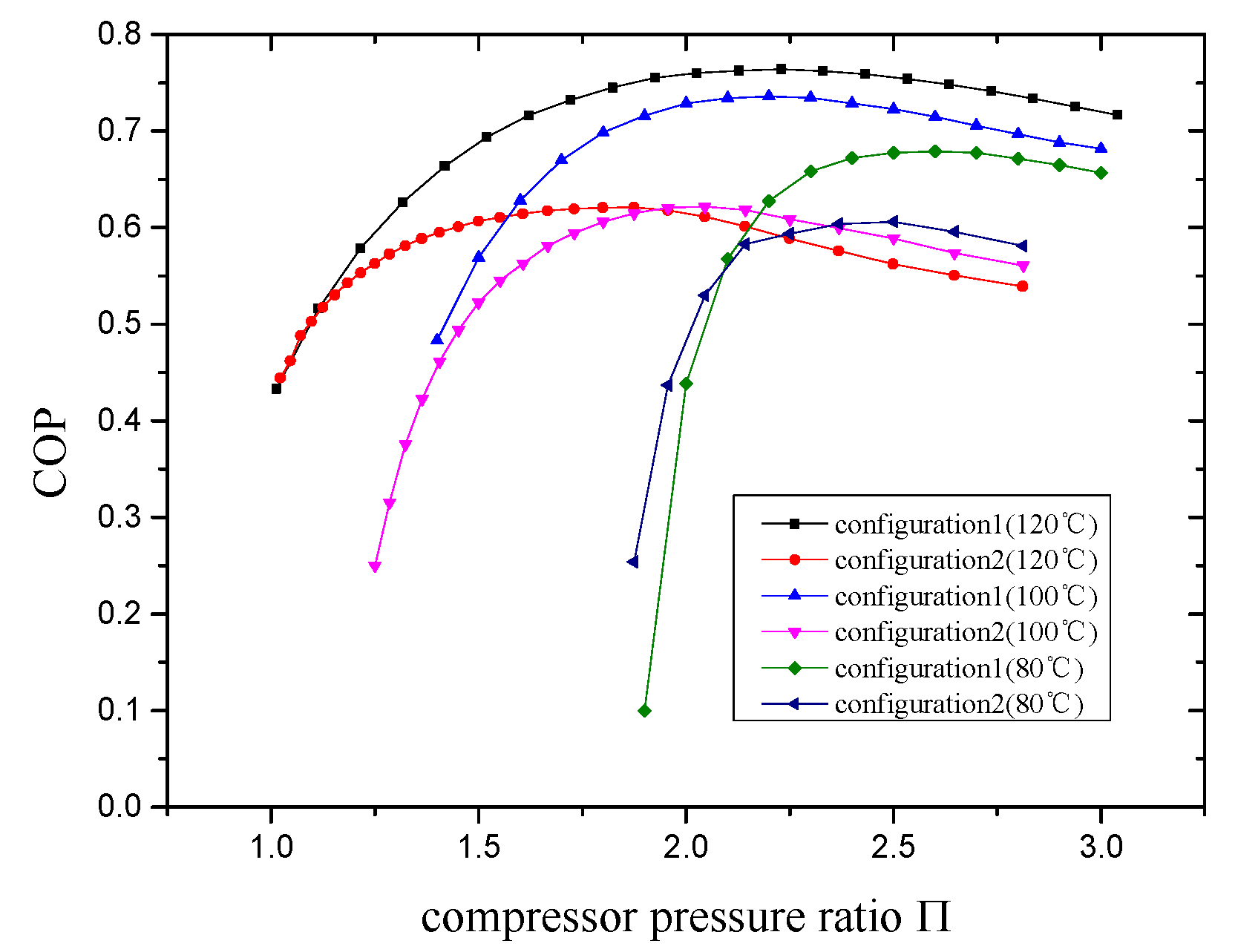

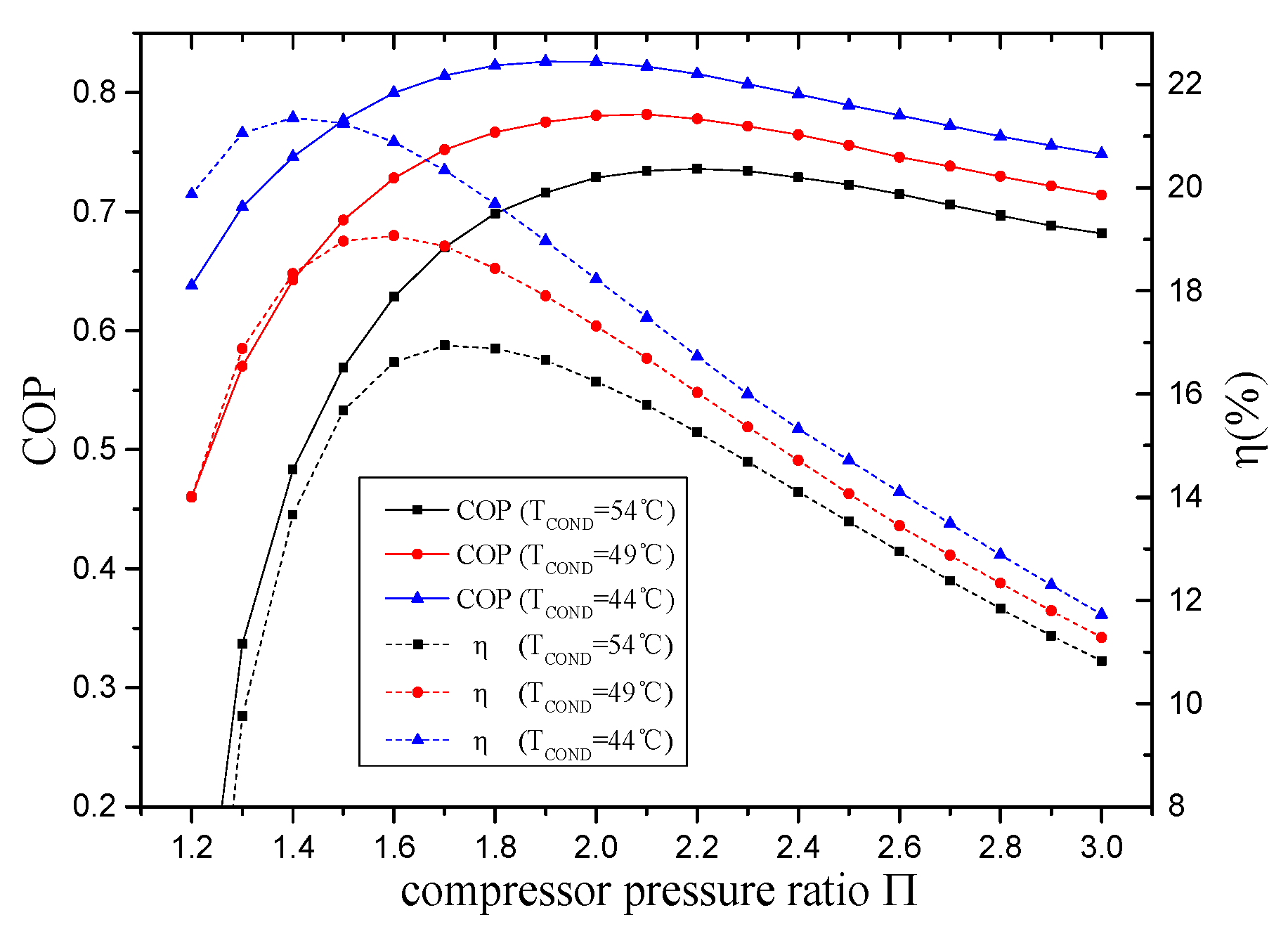

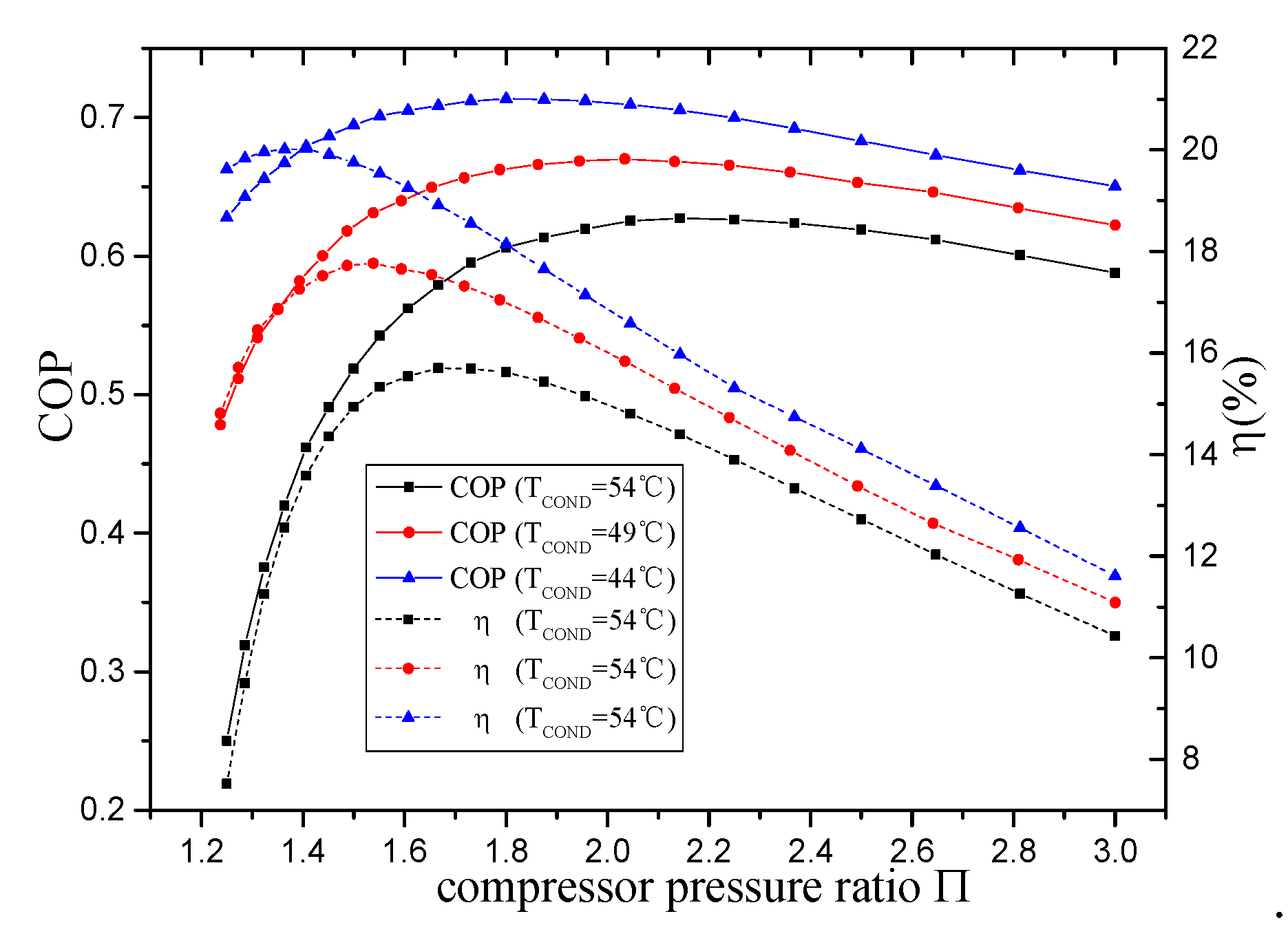

6.2. Variations of COP for Hybrid Cycles

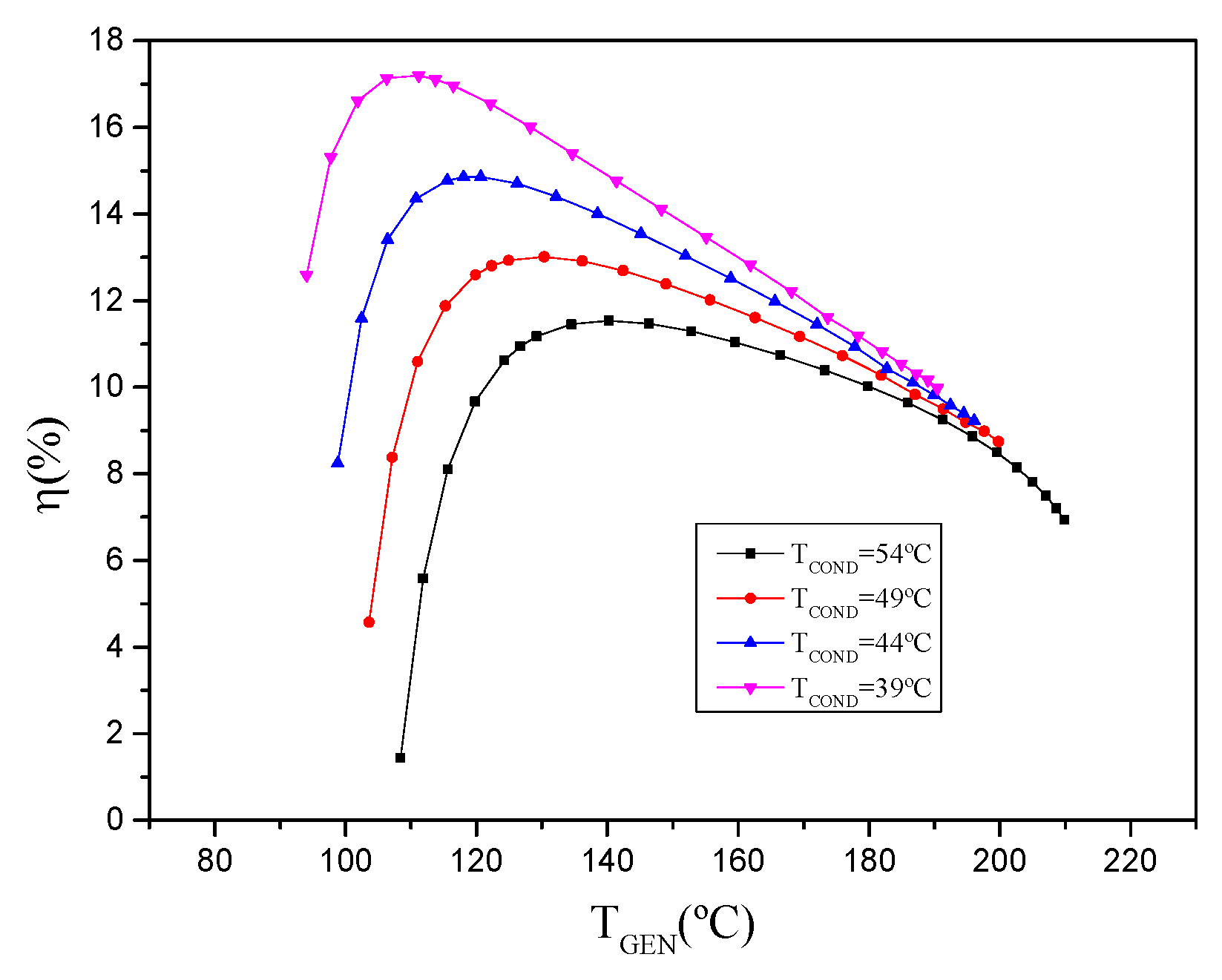

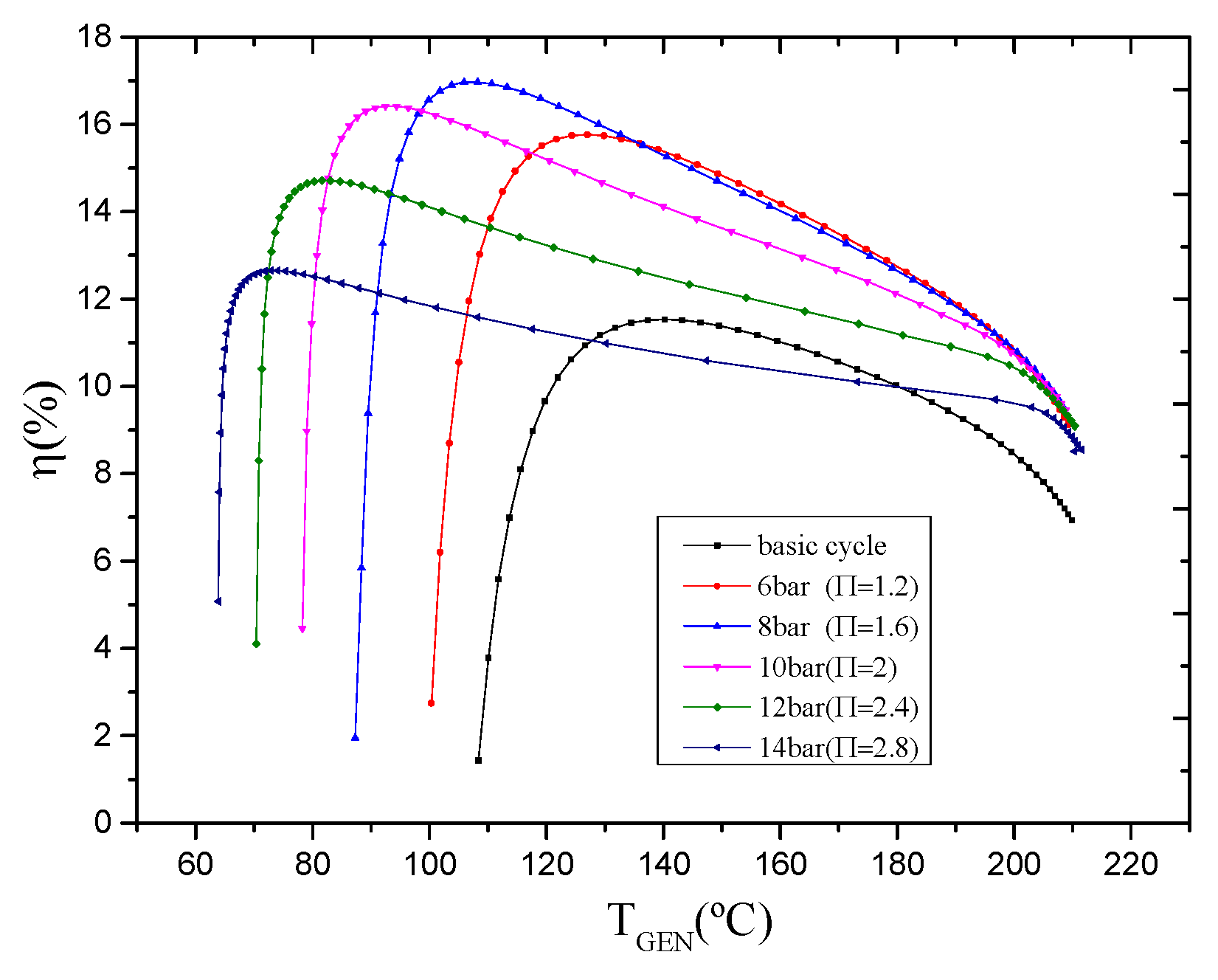

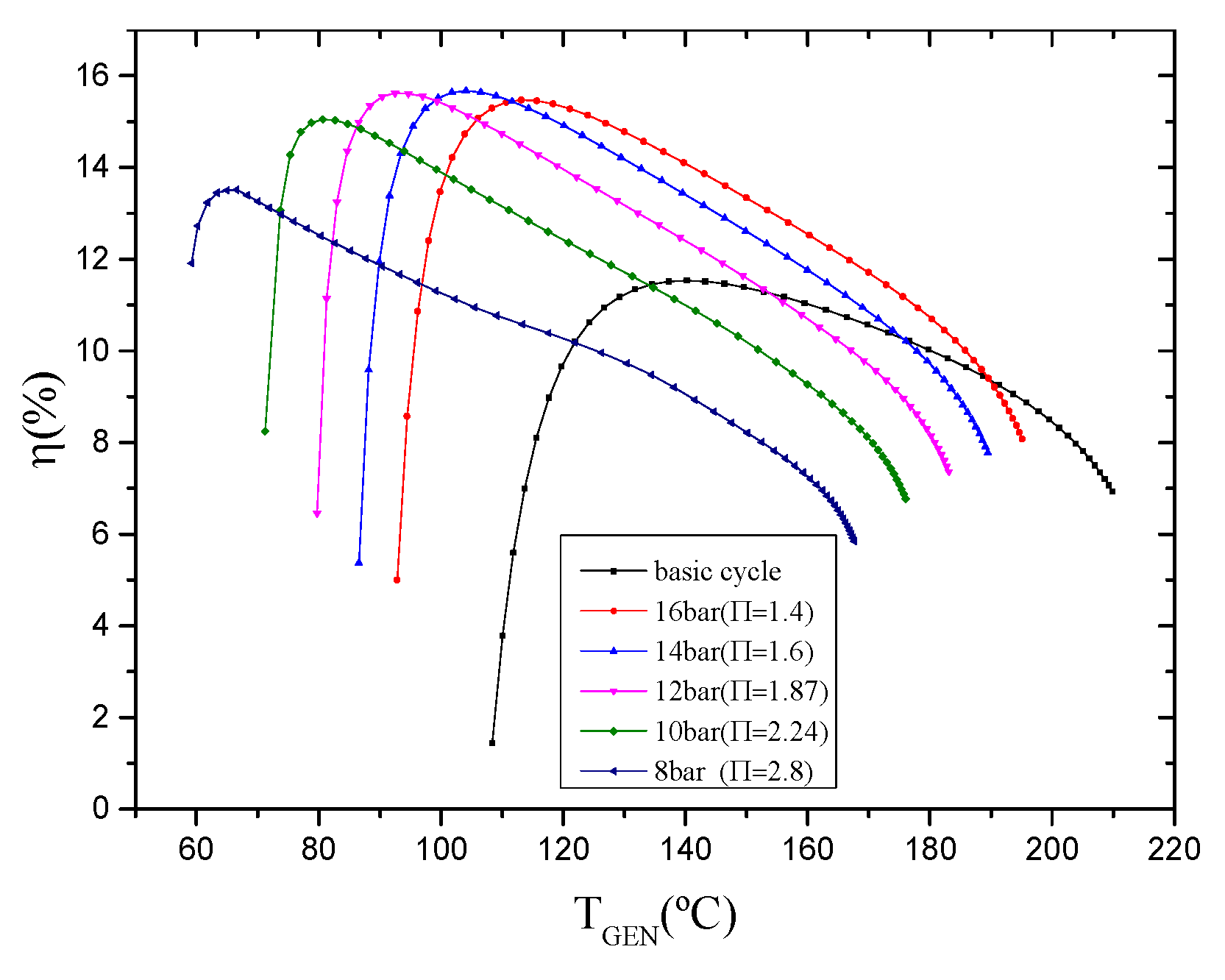

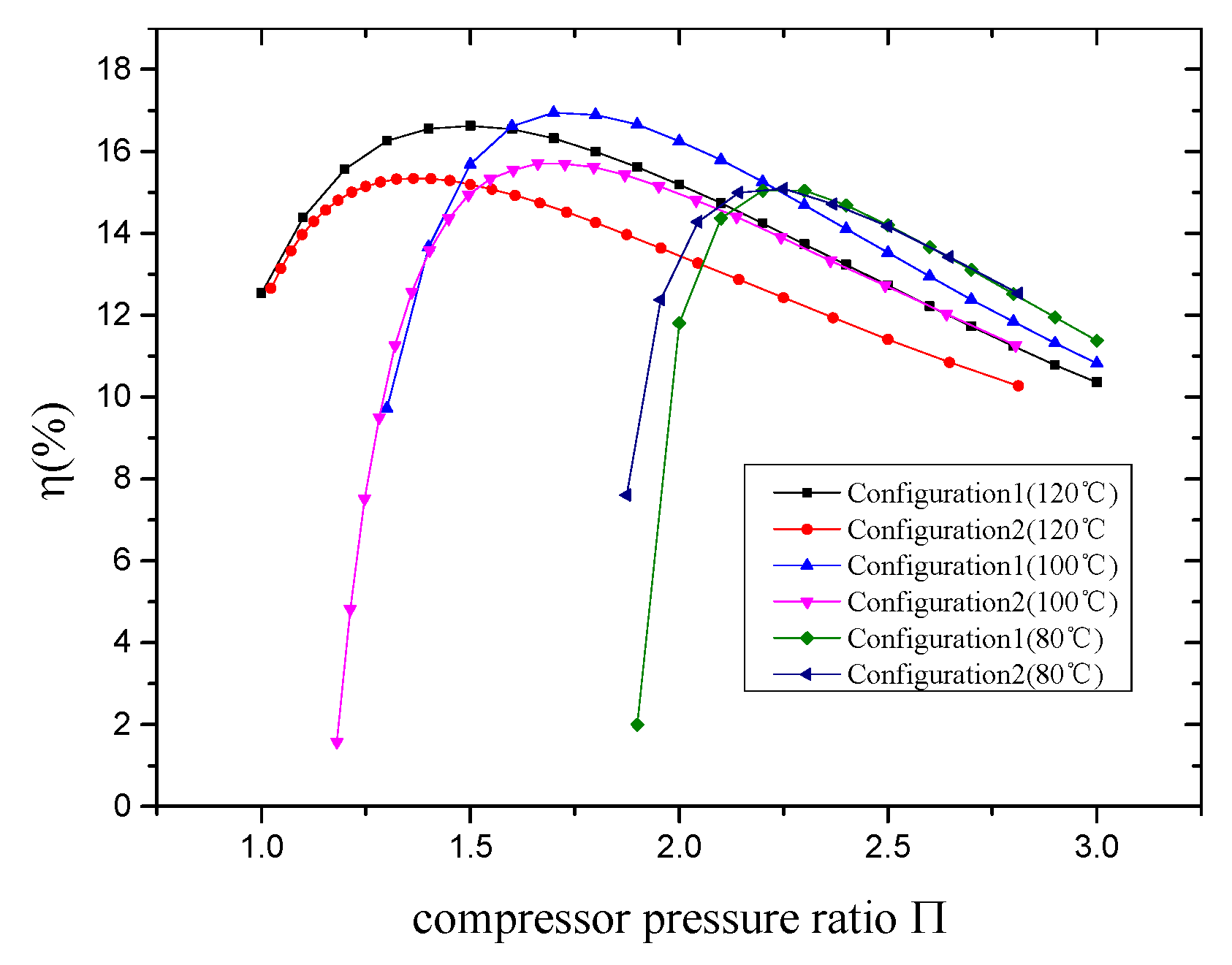

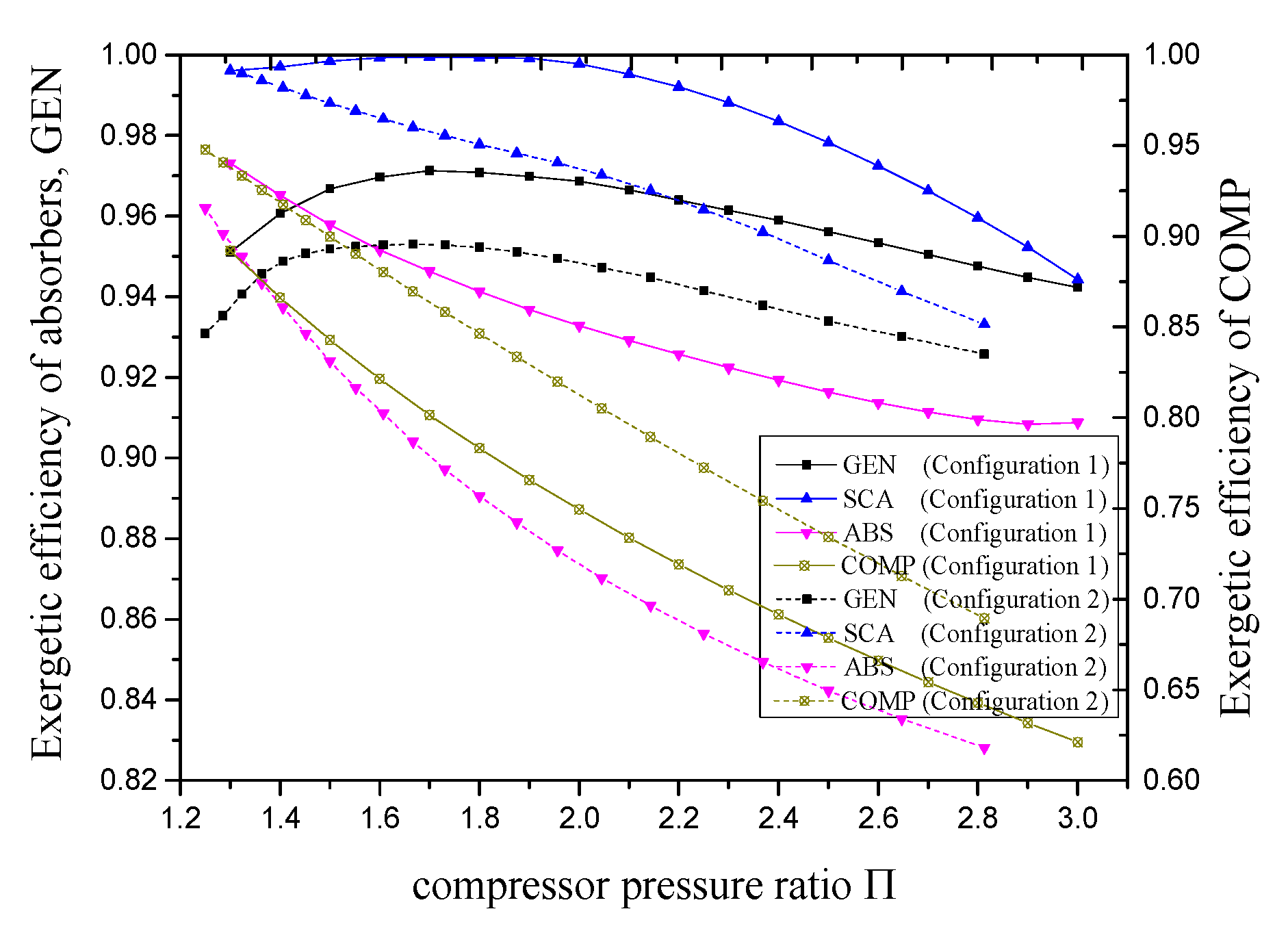

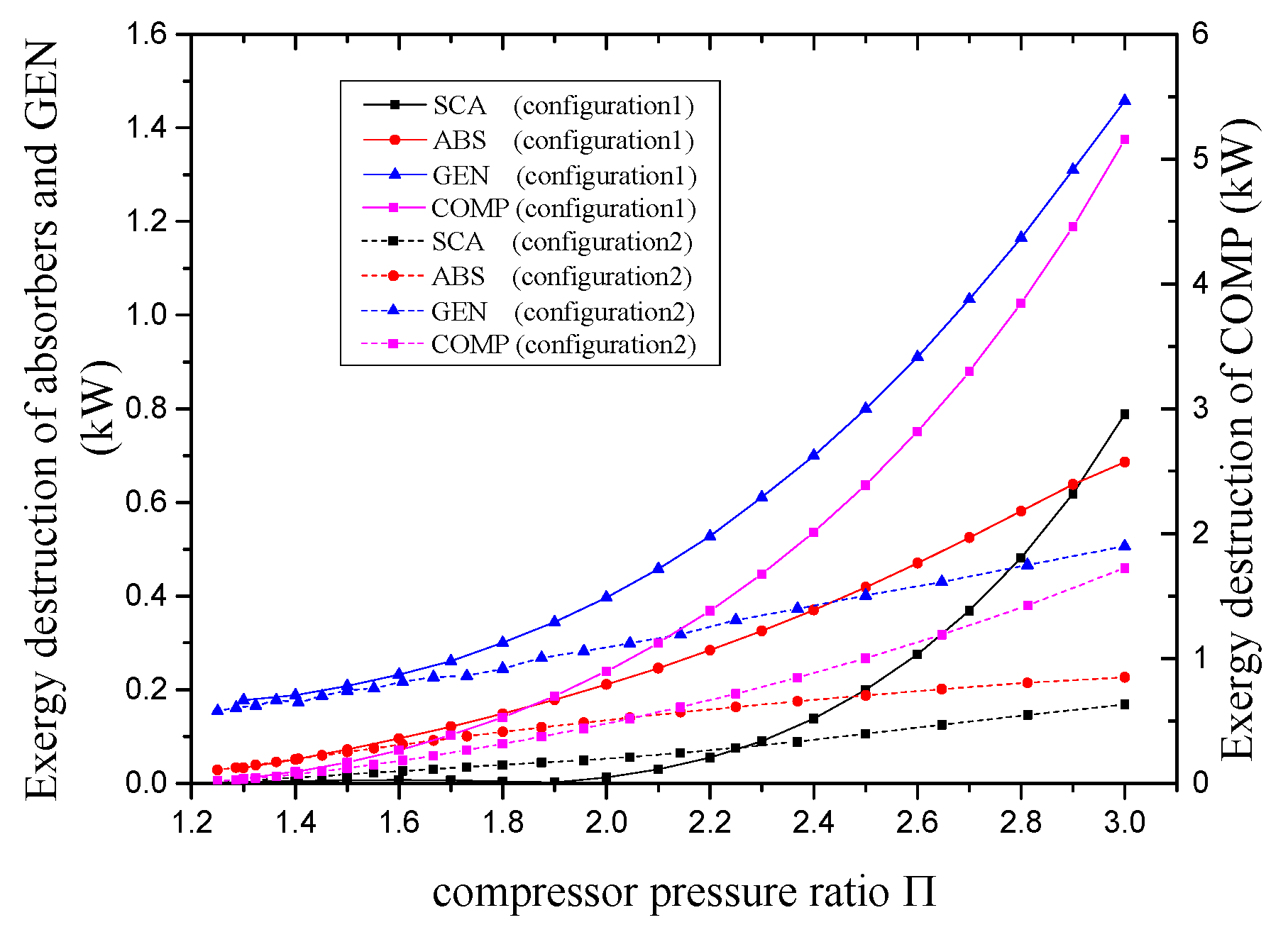

6.3. Variations of Overall Exergetic Efficiency for Hybrid Cycles

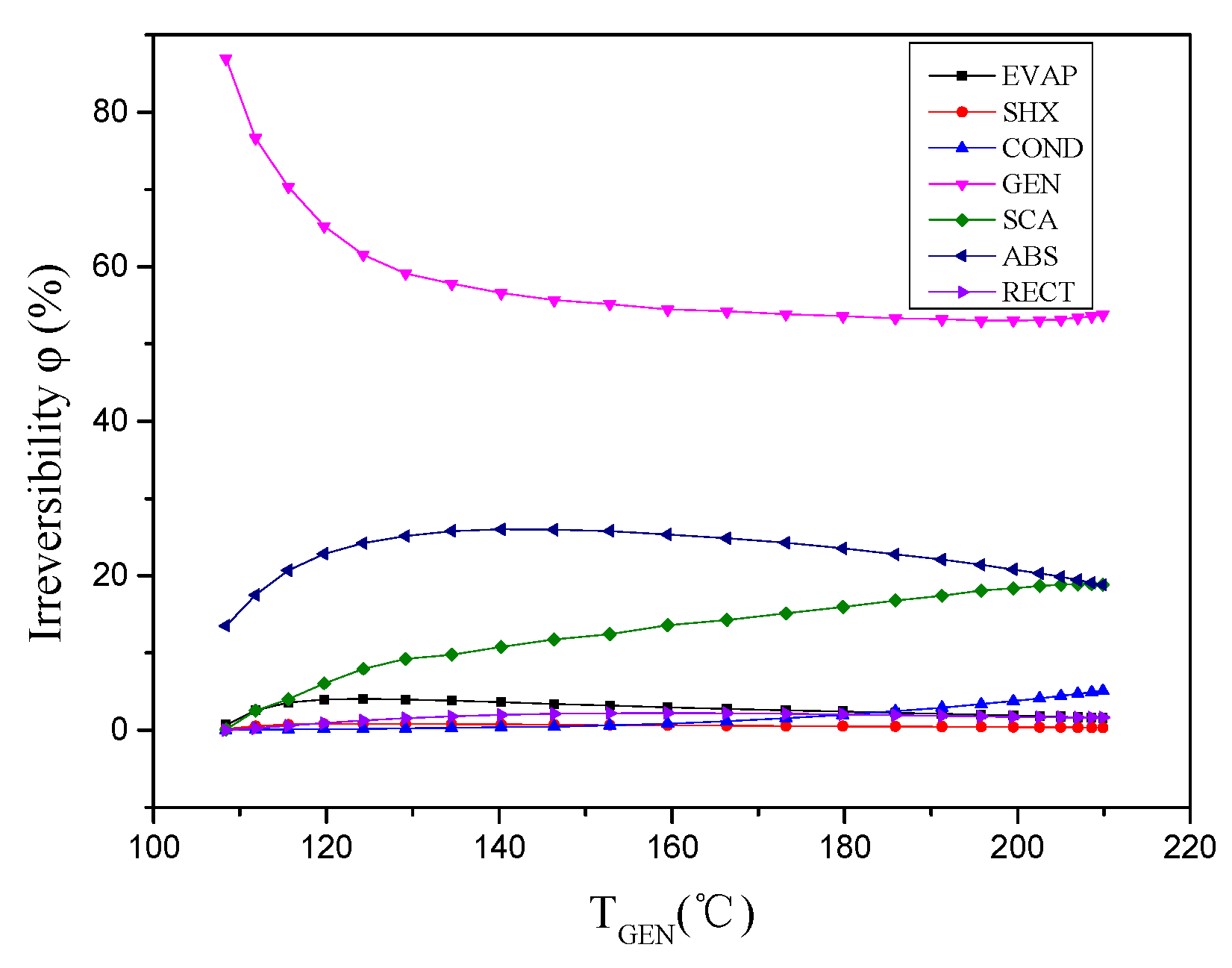

6.4. Detailed Information of Optimal State for Hybrid Cycles

7. Conclusions

- Both configurations could improve the basic cycle because the maximum COP and η of configuration 1 increased by 15% and 5.5%, respectively, and those of configuration 2 were also upregulated by 5% and 4%. The driving generator temperatures of both configurations also decreased, which verified their feasibility in waste heat sources.

- Both configurations had the optimal corresponding to COP and η, and the optimal of η was reflected faster than COP, which proved the exergetic analysis to be more sensitive. The rise in merely expanded the operating range of configuration 1, suggesting its wider range of waste heat utilization, while a corrosion of the high-temperature solution in the generator could be avoided by configuration 2.

- Detailed information at common optimal TGEN = 100 °C was also illustrated. The results confirmed that the main irreversible components (except the absorber) both had improvements. Moreover, with the rise in , the compressor gradually played a major role in exergy losses. The results at the optimal TGEN affected by condensation temperatures were also displayed.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| COND | Condenser |

| SHX | Solution heat exchanger |

| DET1 | Expansion valve 1 |

| DET2 | Expansion valve 2 |

| EVAP | Evaporator |

| SCA | Solution cooling absorber |

| ABS | Absorber |

| GEN | Generator |

| PUMP | Pump |

| RECT | Rectifier |

| SEP | Virtual component separator |

| H-RECO | Heat-recovery block |

| MIX | Mixer |

| COP | Coefficients of Performance, COP = /() |

| COMP | Compressor |

| UA | Product of heat transfer coefficient and area |

| T | Temperature [°C] |

| P | Pressure [bar] |

| x | Mole fraction |

| Heat duty [kW] | |

| Mole flow [kmol/h] | |

| Isentropic efficiency | |

| hy | Mole enthalpy [kJ/mol] |

| s | Mole entropy [kJ/mol·K] |

| Ex | Specific exergy [kW] |

| Subscripts | |

| liq | Liquid |

| cal | Calculated |

| exp | Experimental |

| D | Destroyed exergy |

| T | Total |

| 0 | Reference |

| is | Isentropic |

| k | Specific component |

| I | Intermediate-pressure |

| L | Lowest-pressure |

| H | Highest-pressure |

References

- Sim, J.; Kim, C.S. The value of renewable energy research and development investments with default consideration. Renew. Energy 2019, 143, 530–539. [Google Scholar] [CrossRef]

- Li, J.; Xu, S. The performance of absorption–compression hybrid refrigeration driven by waste heat and power from coach engine. Appl. Therm. Eng. 2013, 61, 747–755. [Google Scholar] [CrossRef]

- Jung, C.W.; Song, J.Y.; Kang, Y.T. Study on ammonia/water hybrid absorption/compression heat pump cycle to produce high temperature process water. Energy 2018, 145, 458–467. [Google Scholar] [CrossRef]

- Dixit, M.; Arora, A.; Kaushik, S. Thermodynamic and thermoeconomic analyses of two stage hybrid absorption compression refrigeration system. Appl. Therm. Eng. 2017, 113, 120–131. [Google Scholar] [CrossRef]

- Chen, W.; Sun, Q.; Bai, Y.; Zhang, B. Numerical investigation of the thermal performance of compressor-assisted double-effect absorption refrigeration using [mmim]DMP/CH3OH as working fluid. Energy Convers. Manag. 2018, 166, 433–444. [Google Scholar] [CrossRef]

- Seyfouri, Z.; Ameri, M.; Mehrabian, M.A. A Totally Heat-Driven Refrigeration System Using Low-Temperature Heat Sources for Low-Temperature Applications. Int. J. Air Cond. Refrig. 2019, 27, 1950012. [Google Scholar] [CrossRef]

- Meng, X.; Zheng, D.; Wang, J.; Li, X. Energy saving mechanism analysis of the absorption–compression hybrid refrigeration cycle. Renew. Energy 2013, 57, 43–50. [Google Scholar] [CrossRef]

- Lounissi, D.; Bouaziz, N. Exergetic analysis of an absorption/compression refrigeration unit based on R124/DMAC mixture for solar cooling. Int. J. Hydrog. Energy 2017, 42, 8940–8947. [Google Scholar] [CrossRef]

- Wu, W. Novel ionic-liquid-based low-GWP working fluids used for hybrid low-temperature absorption cooling. Energy Procedia 2019, 158, 1620–1625. [Google Scholar] [CrossRef]

- Rostamzadeh, H.; Namin, A.S.; Ghaebi, H.; Amidpour, M. Performance assessment and optimization of a humidification dehumidification (HDH) system driven by absorption-compression heat pump cycle. Desalination 2018, 447, 84–101. [Google Scholar] [CrossRef]

- Liu, C.; Jiang, Y.; Han, W.; Kang, Q. A high-temperature hybrid absorption-compression heat pump for waste heat recovery. Energy Convers. Manag. 2018, 172, 391–401. [Google Scholar] [CrossRef]

- Schweigler, C.; Helm, M.; Eckert, T. Flexible heat pump or chiller with hybrid water/LiBr absorption/compression cycle. Int. J. Refrig. 2018. [Google Scholar] [CrossRef]

- Liu, X.; Ye, Z.; Bai, L.; He, M. Performance comparison of two absorption-compression hybrid refrigeration systems using R1234yf/ionic liquid as working pair. Energy Convers. Manag. 2019, 181, 319–330. [Google Scholar] [CrossRef]

- Morosuk, T.; Tsatsaronis, G.; Schult, M. Conventional and Advanced Exergetic Analyses: Theory and Application. Arab. J. Sci. Eng. 2013, 38, 395–404. [Google Scholar] [CrossRef]

- Yildiz, A.; Ersöz, M.A. Energy and exergy analyses of the diffusion absorption refrigeration system. Energy 2013, 60, 407–415. [Google Scholar] [CrossRef]

- Kairouani, D.L.N.B. An exergetic study of a new hybrid heat pump based on R124/DMAC mixture for solar cooling. Int. J. Exergy 2015, 17, 513–531. [Google Scholar]

- Wu, W.; Wang, B.; You, T.; Wang, J.; Shi, W.; Li, X. Compression-assisted absorption cycles using ammonia and various ionic liquids for cleaner heating. J. Clean. Prod. 2018, 195, 890–907. [Google Scholar] [CrossRef]

- Razmi, A.; Soltani, M.; Kashkooli, F.M.; Farshi, L.G. Energy and exergy analysis of an environmentally-friendly hybrid absorption/recompression refrigeration system. Energy Convers. Manag. 2018, 164, 59–69. [Google Scholar] [CrossRef]

- Dixit, M.; Arora, A.; Kaushik, S. Thermodynamic analysis of GAX and hybrid GAX aqua-ammonia vapor absorption refrigeration systems. Int. J. Hydrog. Energy 2015, 40, 16256–16265. [Google Scholar] [CrossRef]

- Yari, M.; Zarin, A.; Mahmoudi, S. Energy and exergy analyses of GAX and GAX hybrid absorption refrigeration cycles. Renew. Energy 2011, 36, 2011–2020. [Google Scholar] [CrossRef]

- Kholghi, S.A.; Mahmoudi, S.M.S. Energy and exergy analysis of a modified absorption cycle: A comparative study. Sustain. Energy Technol. Assess. 2019, 32, 19–28. [Google Scholar] [CrossRef]

- Seyfouri, Z.; Ameri, M.; Mehrabian, M.A. Exergo-economic analysis of a low-temperature geothermal-fed combined cooling and power system. Appl. Therm. Eng. 2018, 145, 528–540. [Google Scholar] [CrossRef]

- Bian, Y.; Pan, J.; Liu, Y.; Zhang, F.; Yang, Y.; Arima, H. Performance analysis of a combined power and refrigeration cycle. Energy Convers. Manag. 2019, 185, 259–270. [Google Scholar] [CrossRef]

- Mansouri, R.; Boukholda, I.; Bourouis, M.; Bellagi, A. Modelling and testing the performance of a commercial ammonia/water absorption chiller using Aspen-Plus platform. Energy 2015, 93, 2374–2383. [Google Scholar] [CrossRef]

- Sun, L.; Ding, X.; Yu, N.; Yu, S.M. Chemical Process Simulation Training, 2nd ed.; Chemical Industry Press: Beijing, China, 2017. [Google Scholar]

- Mejbri, K.; Bellagi, A. Modelling of the thermodynamic properties of the water–ammonia mixture by three different approaches. Int. J. Refrig. 2006, 29, 211–218. [Google Scholar] [CrossRef]

- Klein, S.A. A Model of the Steady-State Performance of an Absorption Heat Pump, US Department of Commerce; NBS National Engineering Laboratory Center for Building Technology: Washington, DC, USA, 1982. [Google Scholar]

- El May, S.; Boukholda, I.; Bellagi, A. Energetic and exergetic analysis of a commercial ammonia water absorption chiller. Int. J. Exergy 2011, 8, 33–50. [Google Scholar] [CrossRef]

- Yue, X.Y.; Li, S.H.; Xu, M.K.; Li, Y.J.; Du, K.; Yang, L. Experimental study of ternary NH3-H2O-LiBr absorption cycle combined with membrane separation technique. Sustain. Cities Soc. 2018, 40, 728–734. [Google Scholar]

- Fitó, J.; Coronas, A.; Mauran, S.; Mazet, N.; Stitou, D. Definition and performance simulations of a novel solar-driven hybrid absorption-thermochemical refrigeration system. Energy Convers. Manag. 2018, 175, 298–312. [Google Scholar] [CrossRef]

- Keith, E.H.; Radermacher, R.; Klein, S.A. Absorption Chillers, and Heat Pumps, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Salehi, S.; Yari, M. Exergoeconomic assessment of two novel absorption-ejection heat pumps for the purposes of supermarkets simultaneous heating and refrigeration using NaSCN/NH3, LiNO3/NH3 and H2O/NH3 as working pairs. Int. J. Refrig. 2019, 101, 178–195. [Google Scholar] [CrossRef]

- Jain, V.; Sachdeva, G.; Kachhwaha, S. Comparative performance study and advanced exergy analysis of novel vapor compression-absorption integrated refrigeration system. Energy Convers. Manag. 2018, 172, 81–97. [Google Scholar] [CrossRef]

- Razmi, A.; Soltani, M.; Aghanajafi, C.; Torabi, M. Thermodynamic and economic investigation of a novel integration of the absorption-recompression refrigeration system with compressed air energy storage (CAES). Energy Convers. Manag. 2019, 187, 262–273. [Google Scholar] [CrossRef]

- Elakhdar, M.; Tashtoush, B.; Nehdi, E.; Kairouani, L. Thermodynamic analysis of a novel Ejector Enhanced Vapor Compression Refrigeration (EEVCR) cycle. Energy 2018, 163, 1217–1230. [Google Scholar] [CrossRef]

| Parameters | Values | Units |

|---|---|---|

| Inlet temperature of chilled water | 20 | °C |

| Chilled water flow rate | 35 | kmol/h |

| Inlet air temperature | 35 | °C |

| Inlet air flow rate | 70–150 | kmol/h |

| Condensation pressure | 22.4 | bar |

| Evaporation pressure | 4.94 | bar |

| Strong solution flow rate | 5.165 | kmol/h |

| Ammonia mole fraction in strong solution | 0.458 | |

| Distillate mole flow rate of vapor mixture | 2.091 | kmol/h |

| Components | Aspen Modules | Input Data |

|---|---|---|

| Evaporator (EVAP) | Two-stream countercurrent heat exchanger HeatX | Pinch temperature difference: Hot inlet-cold outlet difference: 10.5 °C |

| Solution heat exchanger (SHX) | Two-stream countercurrent heat exchanger HeatX | Pinch temperature difference: Hot inlet-cold outlet difference: 22.5 °C |

| Condenser (COND) | Two-stream countercurrent heat exchanger HeatX | Pinch temperature difference: Hot outlet-cold inlet difference: 13.5 °C |

| Absorber (ABS) | Two-stream countercurrent heat exchanger HeatX | Pinch temperature difference: Hot outlet-cold inlet difference: 10 °C |

| Expansion valve 1/2 (DET1/2) | Valve | Outlet pressure: 4.936 bar |

| Solution cooling absorber (SCA1/2 and MIX) | Two heater modules and mixer | Pressure drop: 0 bar Exit temperature based on calculator block of εliq Pressure drop: 0 bar |

| Generator (GEN) | Rigorous distillation tower module RadFrac | Number of stages: 5; feed stage: 3; distillate total mole flow rate: 2.091 kmol/h Reflux mass ratio: 0.09 |

| Heater | Pressure drop: 0 bar Exit temperature equal to stage 2 in RadFrac | |

| Rectifier (RECT) | Heater | Pressure drop: 0 bar Duty comes from condensation load of RadFrac |

| Pump | Pump | Discharge pressure: 22.4 bar Isentropic efficiency: 100% |

| Virtual component separator (SEP)-only used in analysis | Component separator SEP | Split fraction of ammonia: 0.999 |

| States | Temperature (°C) | Pressure (bar) | h (kJ/mol) | s (kJ/mol·K) | Ex (kW) | ||

|---|---|---|---|---|---|---|---|

| 1 | 45 | 4.936 | 0.458 | 5.165 | −187.88 | −0.1715 | 0.536 |

| 2 | 45.8 | 22.4 | 0.458 | 5.165 | −187.77 | −0.1712 | 0.604 |

| 3 | 69.9 | 22.4 | 0.458 | 3.074 | −186.24 | −0.1667 | 0.829 |

| 4 | 98 | 22.4 | 0.458 | 5.165 | −184.37 | −0.1615 | 1.271 |

| 6 | 103.6 | 22.4 | 0.976 | 2.091 | −486.85 | −0.1157 | 4.395 |

| 7 | 48.5 | 22.4 | 0.976 | 2.091 | −705.19 | −0.1809 | 3.006 |

| 8 | 25.5 | 22.4 | 0.976 | 2.091 | −724.74 | −0.1872 | 2.962 |

| 9 | 4.8 | 4.936 | 0.976 | 2.091 | −724.74 | −0.1868 | 2.893 |

| 10 | 9.5 | 4.936 | 0.976 | 2.091 | −554.65 | −0.1258 | 2.21 |

| 11 | 17.6 | 4.936 | 0.976 | 2.091 | −535.1 | −0.1190 | 2.161 |

| 12 | 86.4 | 4.936 | 0.458 | 5.165 | −176.92 | −0.1390 | 2.373 |

| 13 | 122.7 | 4.936 | 0.106 | 3.074 | −257.73 | −0.1465 | 0.911 |

| 14 | 124.1 | 22.4 | 0.106 | 3.074 | −257.73 | −0.1466 | 0.938 |

| 12A | 93.8 | 4.936 | 0.458 | 5.165 | −175.06 | −0.1339 | 2.855 |

| 16 | 187.7 | 22.4 | 0.106 | 3.074 | −252.22 | −0.1338 | 2.372 |

| Parameters | Experimental Data | Simulated Data |

|---|---|---|

| (kW) | 9.64 | 9.84 |

| (kW) | 17 | 18.25 |

| - | 15.46 | |

| COND (kW) | - | 12.7 |

| (kW) | - | 0.07 |

| COP | 0.567 | 0.537 |

| Components | Exergy Destruction (kW) | Irreversibility (%) | Exergetic Efficiency |

|---|---|---|---|

| GEN | 2.01 | 53.13 | 0.82 |

| EVAP | 0.079 | 2.08 | 0.948 |

| COND | 0.114 | 3.025 | 0.974 |

| ABS | 0.829 | 21.9 | 0.645 |

| SCA | 0.665 | 17.59 | 0.981 |

| RECT | 0.069 | 1.84 | 0.923 |

| SHX | 0.016 | 0.43 | 0.99 |

| = 3.785 | = 100% | = 9.15% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Cai, L.; Chen, T. Energetic and Exergetic Investigations of Hybrid Configurations in an Absorption Refrigeration Chiller by Aspen Plus. Processes 2019, 7, 609. https://doi.org/10.3390/pr7090609

Zhang X, Cai L, Chen T. Energetic and Exergetic Investigations of Hybrid Configurations in an Absorption Refrigeration Chiller by Aspen Plus. Processes. 2019; 7(9):609. https://doi.org/10.3390/pr7090609

Chicago/Turabian StyleZhang, Xiao, Liang Cai, and Tao Chen. 2019. "Energetic and Exergetic Investigations of Hybrid Configurations in an Absorption Refrigeration Chiller by Aspen Plus" Processes 7, no. 9: 609. https://doi.org/10.3390/pr7090609

APA StyleZhang, X., Cai, L., & Chen, T. (2019). Energetic and Exergetic Investigations of Hybrid Configurations in an Absorption Refrigeration Chiller by Aspen Plus. Processes, 7(9), 609. https://doi.org/10.3390/pr7090609