Anthropogenic greenhouse gas (GHG) emissions in 2010 reached 49 ± 4.5 GtCO

2-eq/year, emissions of CO

2 from fossil fuel combustion and industrial processes contributed approximately 80% of the total GHG emissions increase from 1970–2010 [

1]. The mitigation of climate change and increasing global temperatures requires a combination of new, renewable technology and an improvement of the existing infrastructure to move towards a low and ideally zero-carbon society; in line with the Climate Change Act requirements of an 80% reduction in total emissions by 2050 [

2]. The use of fossil-fueled power stations continues to grow due to their ability to respond to changes in demand [

3] and offset the intermittency of current renewable technology. Coal and gas are the predominant fuels used in power generation; however, since the UK’s 2016 consultation to end the use of unabated coal, its usage in power generation has declined from 22% in 2015 to 1.6% in the second quarter of 2018 [

4]. Natural gas sees its share of generation at 42% and although often perceived as a much cleaner fuel at the point of use than coal [

5], producing around 350 kgCO

2/MWh [

6], reducing the carbon intensity of this growing sector is vital for stabilizing global temperature increase to below 2 °C. Amine-based carbon capture and storage (CCS) is seen as one of the best CO

2 abatement approaches [

7]; the solvent monoethanolamine (MEA) is most commonly used due to its low material costs [

8]; however, due to the energy requirements of solvent regeneration, there is a large energy penalty incurred on the power plant. To make post combustion CCS a viable option in mitigating the GHG emissions from power generation, optimization of such a plant is paramount.

The techno-economic analysis of a post combustion capture (PCC) and compression plant using MEA coupled to a 400 MW NG-CCGT conducted by Alhaja et al. [

9] found that by studying the effect of the PCC unit’s key operating parameters on the power plant’s key performance indicators, an optimum lean loading of 0.31 molCO

2/molMEA, which minimized the specific reboiler duty (SRD), could be found. This represents a balance between the sensible heat required to raise the temperature of the solvent to that of the reboiler and the latent heat to vaporize water and provide the stripping steam. By increasing the pressure within the stripping column within the limits of solvent degradation, a reduction in SRD was also seen. The inclusion of packing volume as a studied parameter illustrates the importance of studying the capture process as a whole system, especially due to the capital costs associated with such plants. An optimum lean loading of the solvent that minimized the SRD was also found by Masoudi Soltani et al. [

10]; the MEA-based unit demonstrated that the SRD was dependent on the concentration of MEA within the solution. The 3.98 GJ/tonneCO

2 SRD occurred with a 30 wt% MEA solution and a lean loading in the range of 0.19–0.21 molCO

2/molMEA. The SRD was also seen to vary secondly as a function of EGR, owing to the change in CO

2 partial pressure within the flue gas stream; employing a greater percentage EGR reduced SRD further. Another optimization of an MEA-based PCC system [

11] determined strong links between the L/G ratio, lean loading, and reboiler duty. The lean solvent flow rate was determined by varying the lean CO

2 loading to achieve 90% capture; with a lower L/G ratio, the requirement in the reboiler is primarily for stripping steam, whereas with a higher L/G ratio, there is a larger requirement for heat to increase the temperature of the rich stream; once more corroborating the balance of sensible and latent heats in the reboiler [

9,

10]. A 30 wt% MEA-employing model validated against the UK CCS research centre pilot plant was used to evaluate and optimize the performance of a PCC unit [

12]; a lean loading of 0.23 gave a 15% reduction in SRD from 7.1 Mj/kgCO

2 to 5.13 MJ/kgCO

2. An increase in stripper pressure from 1.25–2.50 bar added a further 17% reduction in SRD, but in order to avoid thermal degradation of the solvent, a pressure of 1.80 bar was found to be most suitable, a similar phenomenon to that found by Lindqvist et al. [

13]. With an optimum lean loading of 0.21 in line with the findings of Masoudi Soltani et al. [

10], the SRD was 4.4 MJ/kgCO

2. Packing material and heat exchanger logarithmic mean temperature difference (LMTD) were also studied, optimization of which could give SRD reductions of 40% and 5%, respectively. Xiaobo Luo [

14] investigated the optimal operation of an MEA-based capture unit and found that for a 90% capture rate, a 9.58% net power efficiency decrease was seen in the NGCC using an optimum lean loading of 0.26–0.28, slightly higher than in the previous studies. The reason for this is that in the other studies, column sizing is minimized to reduce capital expenditure by reducing the L/G ratio, thus requiring a lower lean loading, whereas with this study [

14], column sizing is fixed and the optimal operation is to reduce the operating expenditure, hence a higher lean loading can be exploited. The comparison between MEA and CESAR-1 (an aqueous solution of 2-amino-2-methyl-propanal and piperazine) [

15] found that using MEA reduced the NGCC plant efficiency by 8.4%, with an energy requirement in the PCC unit of 3.36 GJ/tonneCO

2. A parametric evaluation carried out by Kothandaraman et al. [

16] on a 30 wt% MEA PCC system identified that for a DOC above 95%, there was a disproportionate increase in SRD. The temperature of the solvent was shown to have little effect on the system’s performance; decreasing absorption temperature increases the driving force for reaction but the rate of reaction and diffusivity decreased, effectively cancelling each other out. For the lean loading used (0.22), the SRD was 4.5 GJ/tCO

2 with a flue gas CO

2 content of 4 vol%, i.e., without the use of EGR. An MEA-based PCC unit modelled by Arachchige et al. [

17] concluded that the removal efficiency was proportional to the solvent concentration and temperature whilst being inversely effected by lean loading thanks to the reduction in MEA capacity; a similar phenomenon to that found by Kothandaraman et al. [

16] was observed with respect to solvent temperature. Variation of absorber pressure saw a decrease in SRD due to the increased partial pressure of the CO

2; 4.56 GJ/tCO

2 to 4.38 GJ/tCO

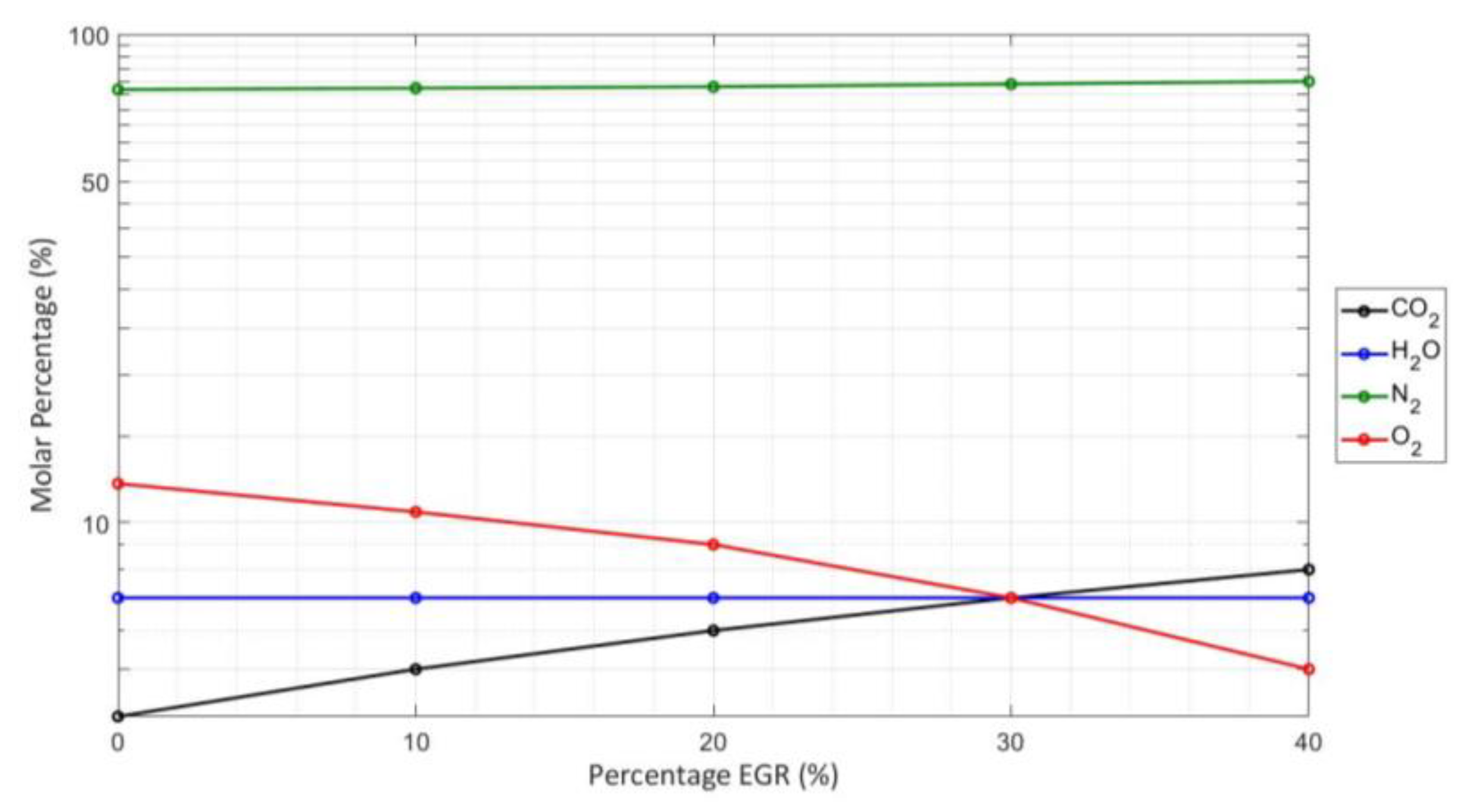

2 with an increase in absorber pressure of 0.9 to 1.2 bar. The effect of implementing EGR on the integrated MEA-based CO

2 capture plant when coupled to an 800 MW NGCC was studied exclusively by Ali et al. [

18], something not considered comprehensively in other studies [

12,

13,

15]. The use of EGR resulted in a 57% increase in CO

2 molar composition in the flue gas stream (4.16–6.53 mol%), resulting in a 2.3% reduction in SRD; they also identified that the NGCC case with EGR is the most attractive for use with CCS due to its lowest reduction in plant net efficiency. Lars Erik Øi [

19] simulated the operation of a simplified MEA-based PCC coupled to a 400 MW CCGT; he found that for a removal of 85% of the emitted CO

2, the heat consumption was 3.7 GJ/tCO

2. He identified that an increased solvent circulation rate would increase the removal grade of the CO

2; an increase in the temperatures of the inlet streams to the absorber would improve CO

2 absorption due to an increase in reaction rates and; operating the stripper close to the degradation limits of the solvent would give better removal efficiency and thus lower CO

2 loading in the lean stream. Afkhamipour and Mofarahi [

20] employed the methods of Taguchi to maximize the CO

2 removal efficiency using a sophisticated multilayer-perceptual-neural-network model. Focusing on the controllable inlet conditions to the absorber, they identified that CO

2 loading, amine flow rate, and amine concentration were the major factors in increasing the capture efficiency. The degree of capture (DOC), however, was not kept constant; this is dependent on amine flow rate. Instead, the response value used in the Taguchi analysis was the CO

2 removal efficiency; the optimization of removal efficiency does not inherently mean a less intensive energy requirement for the system.

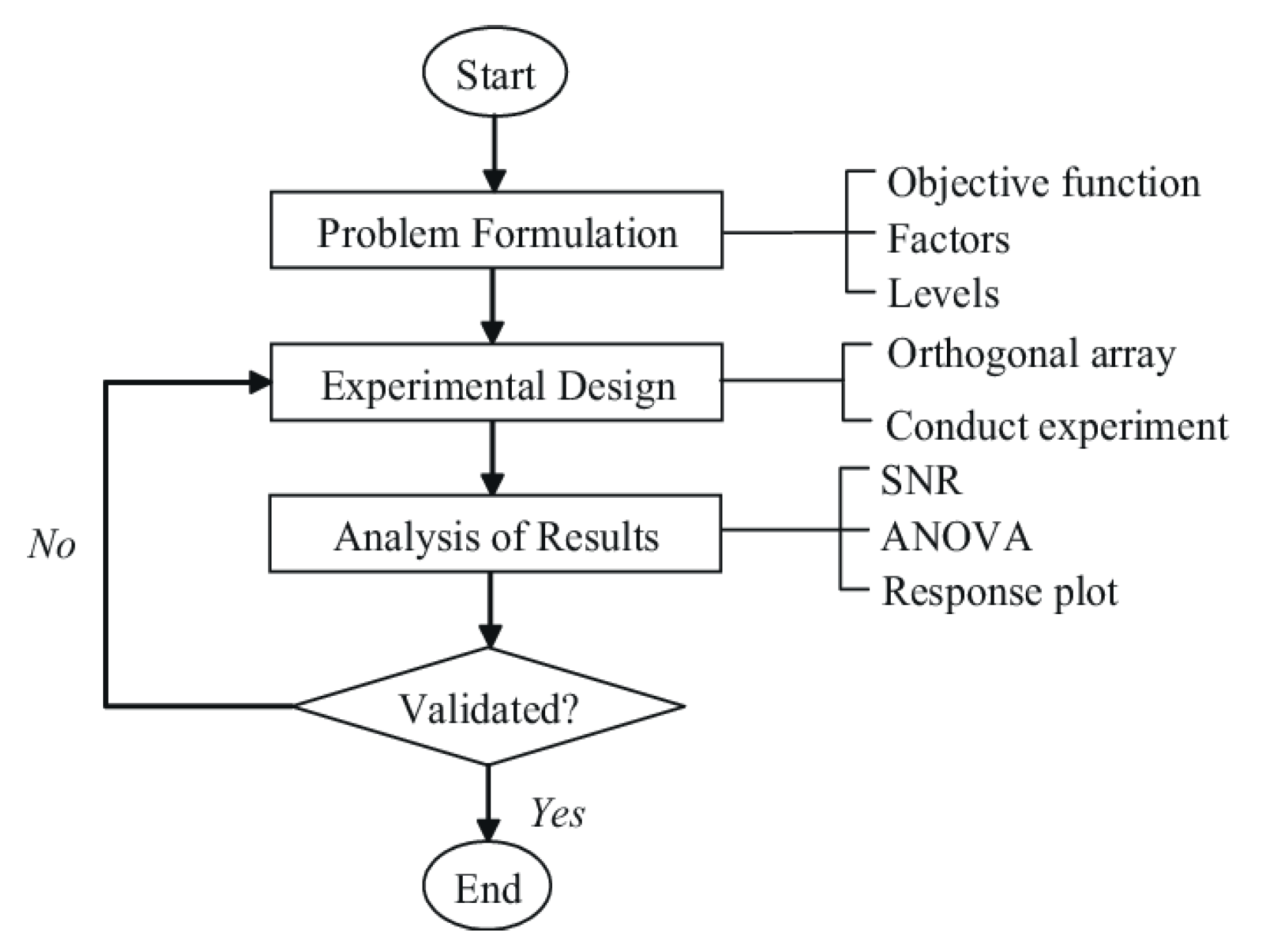

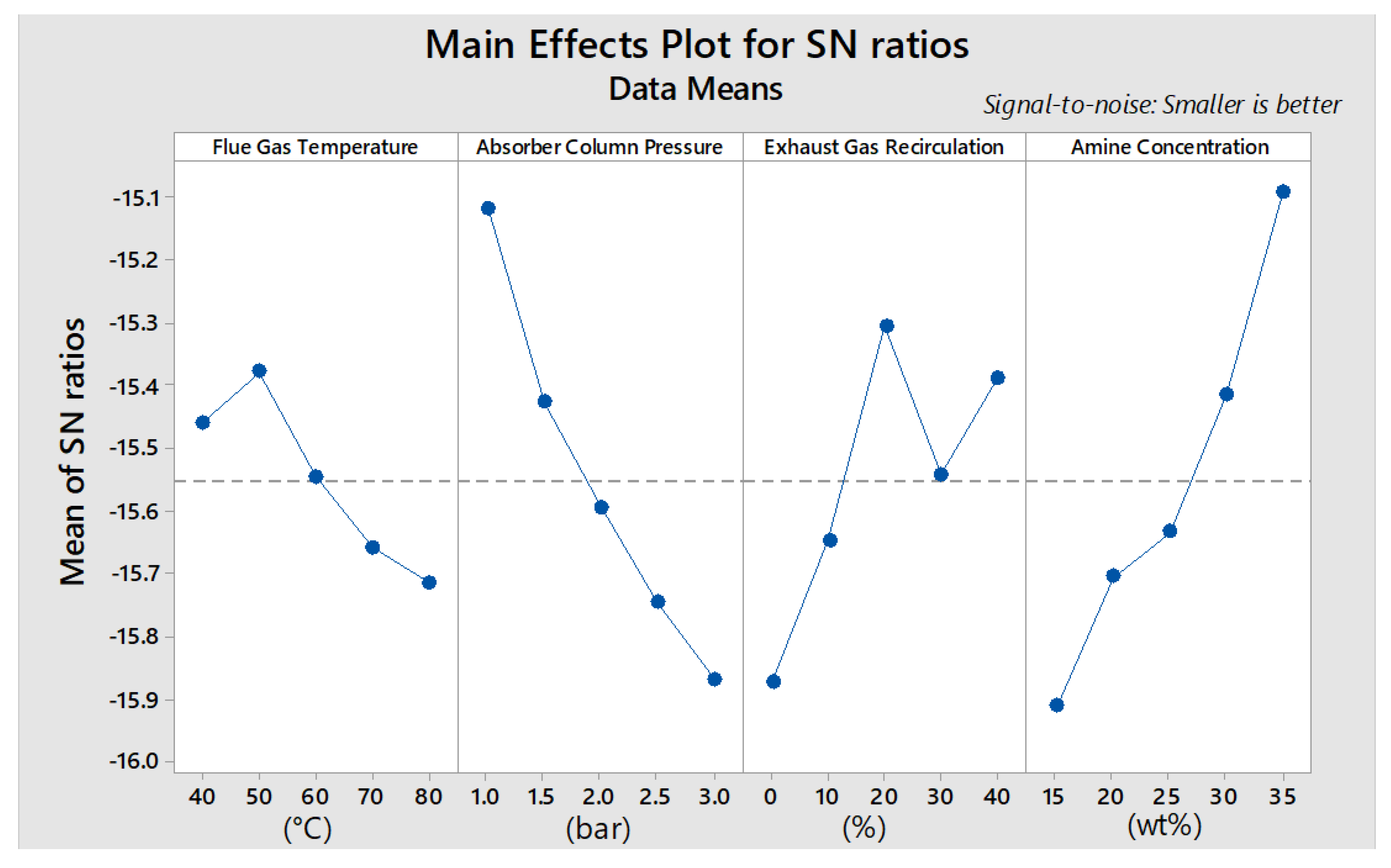

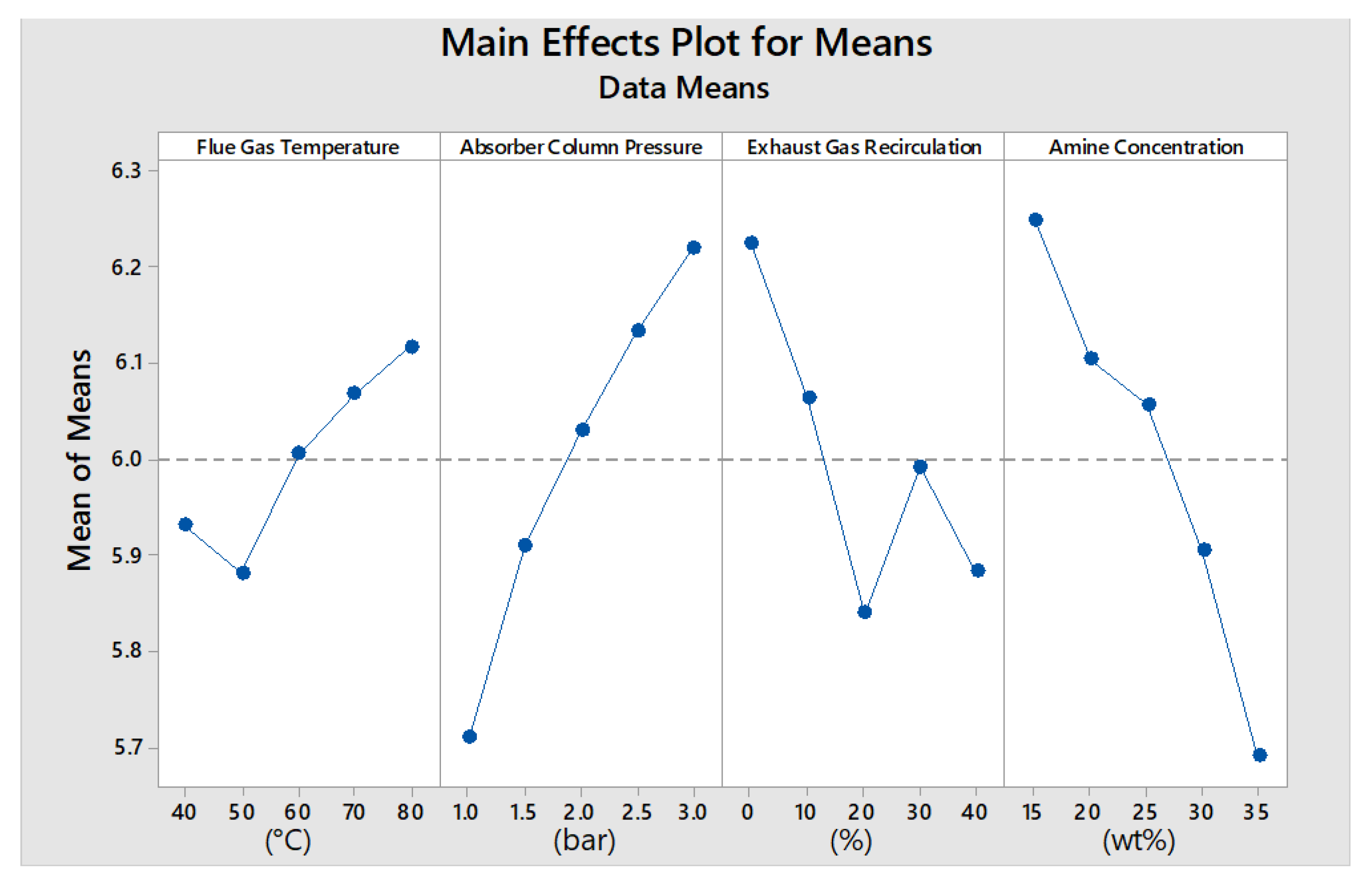

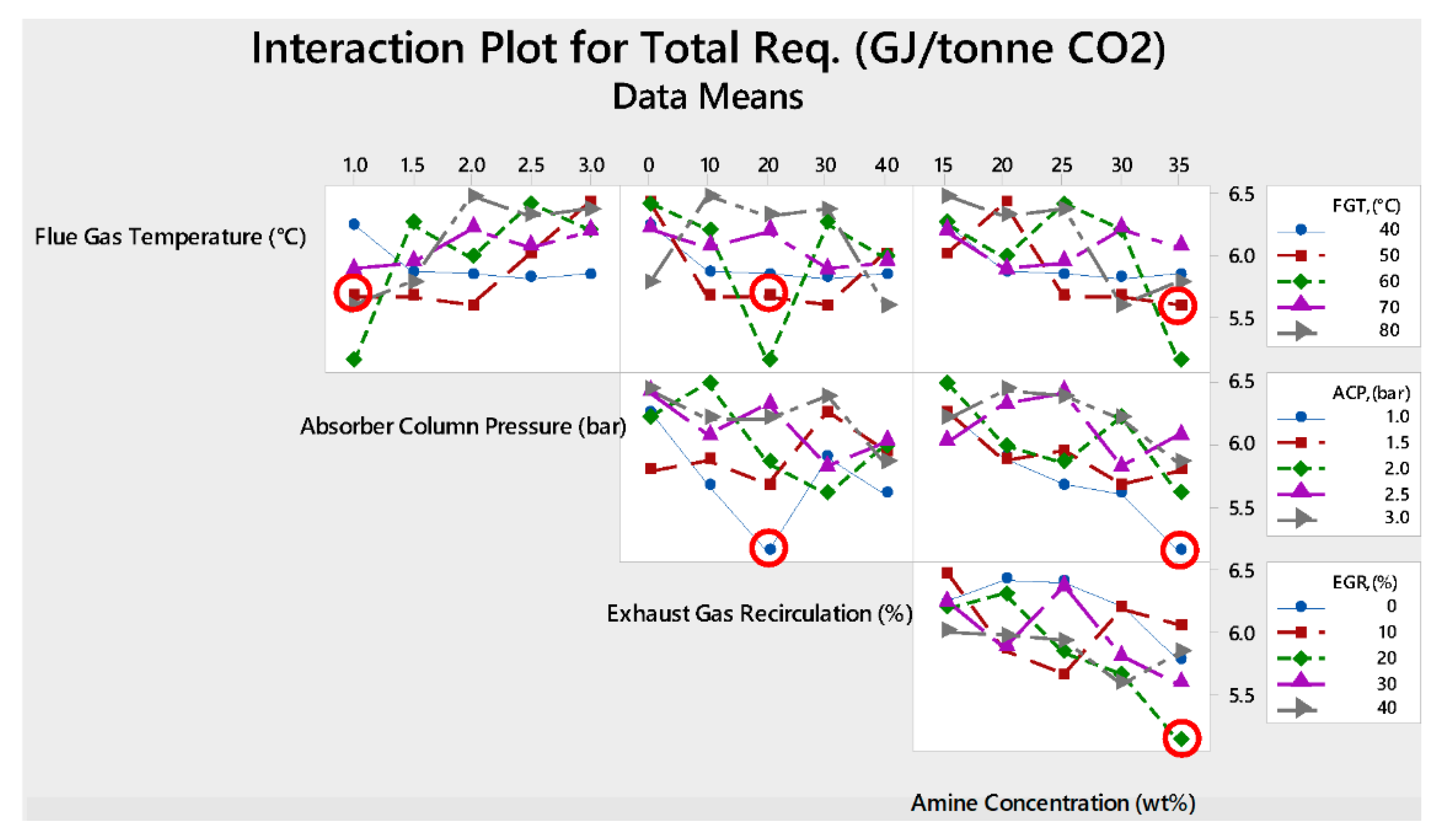

In this work, the optimization of an MEA-based PCC system is carried out using a Taguchi design of experiment. The PCC system is modelled in Aspen Plus to process the flue gas from a 600 MW CCGT power plant and capture 90% of the emitted CO2. The optimization parameters were: the inlet temperature of the flue gas to the absorber (FGT); the operating pressure of the absorber column (ACP); the amount of exhaust gas recirculation (EGR) so as to model the capture process using different molar CO2 concentrations in the flue gas; and the concentration of the amine (CONC) in the lean stream inlet to the absorber.