Analysis of the Excess Hydrocarbon Gases Output from Refinery Plants

Abstract

:1. Introduction

- Hydrogen production;

- Claus’s process;

- Energy media production processes;

- Wastewater treatment, production of circulating water; and

- Hydrogen recovery processes.

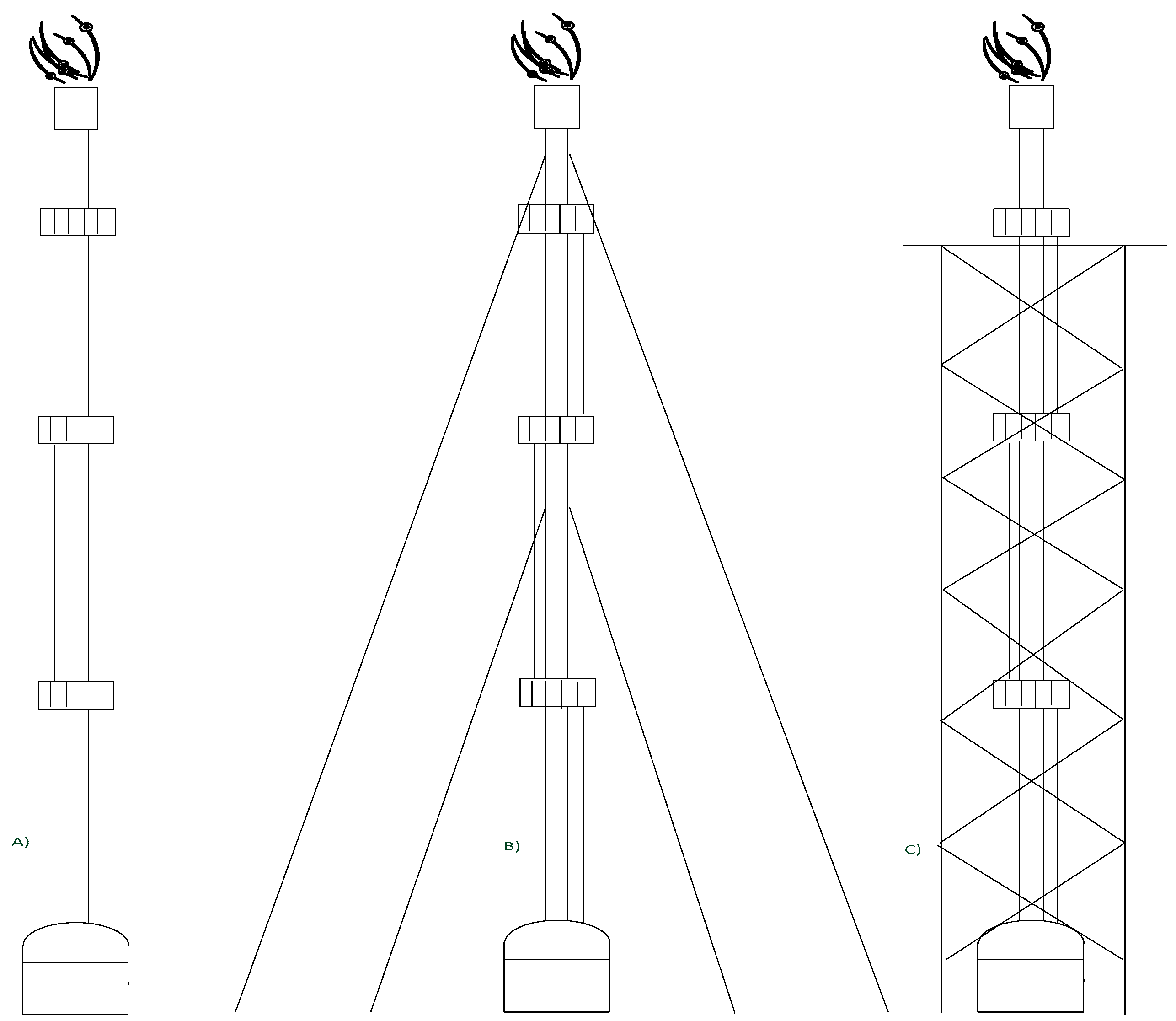

2. Flare Gases in the Industrial Plants

- Protect the surrounding (locally) against the effects of uncontrolled migration of gas, e.g., against explosion, poisoning, and fetor;

- Protect the environment by replacing emissions of more harmful gases by emission of less harmful fumes (e.g., acid gases—hydrogen sulfide, ammonia—occurring primarily as waste gases during the production process; directing acid gases to the flares happens extremely rarely).

3. Results and Discussion

3.1. Existing Solutions for Utilization of Discharge Gases

- When refinery plants are dealing with a large number of conversion processes;

- During implementation of destructive/conversion processes, a larger number of gas streams is created than in the case of conserving processes;

- The amount of processed batch for all installations in total is large.

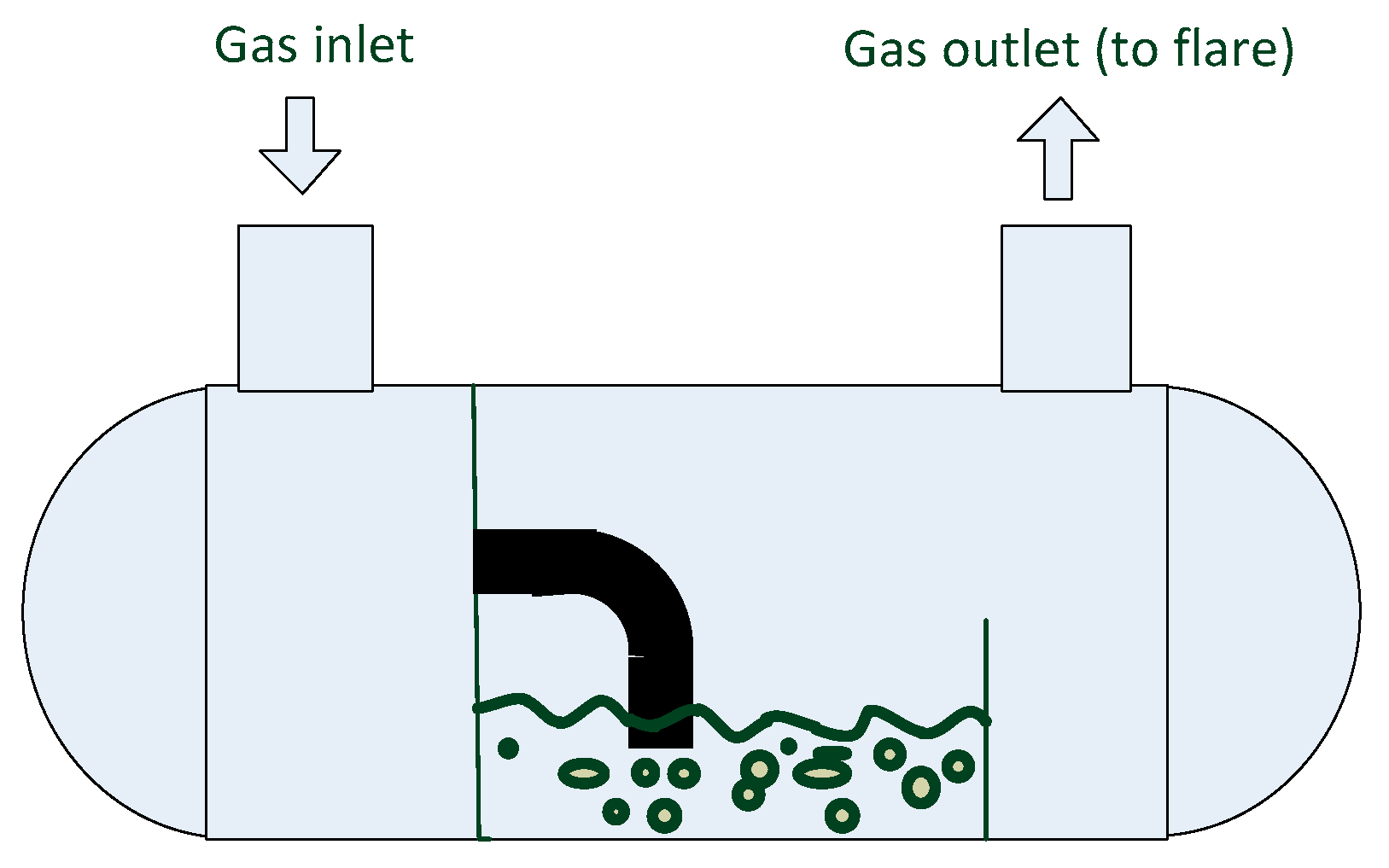

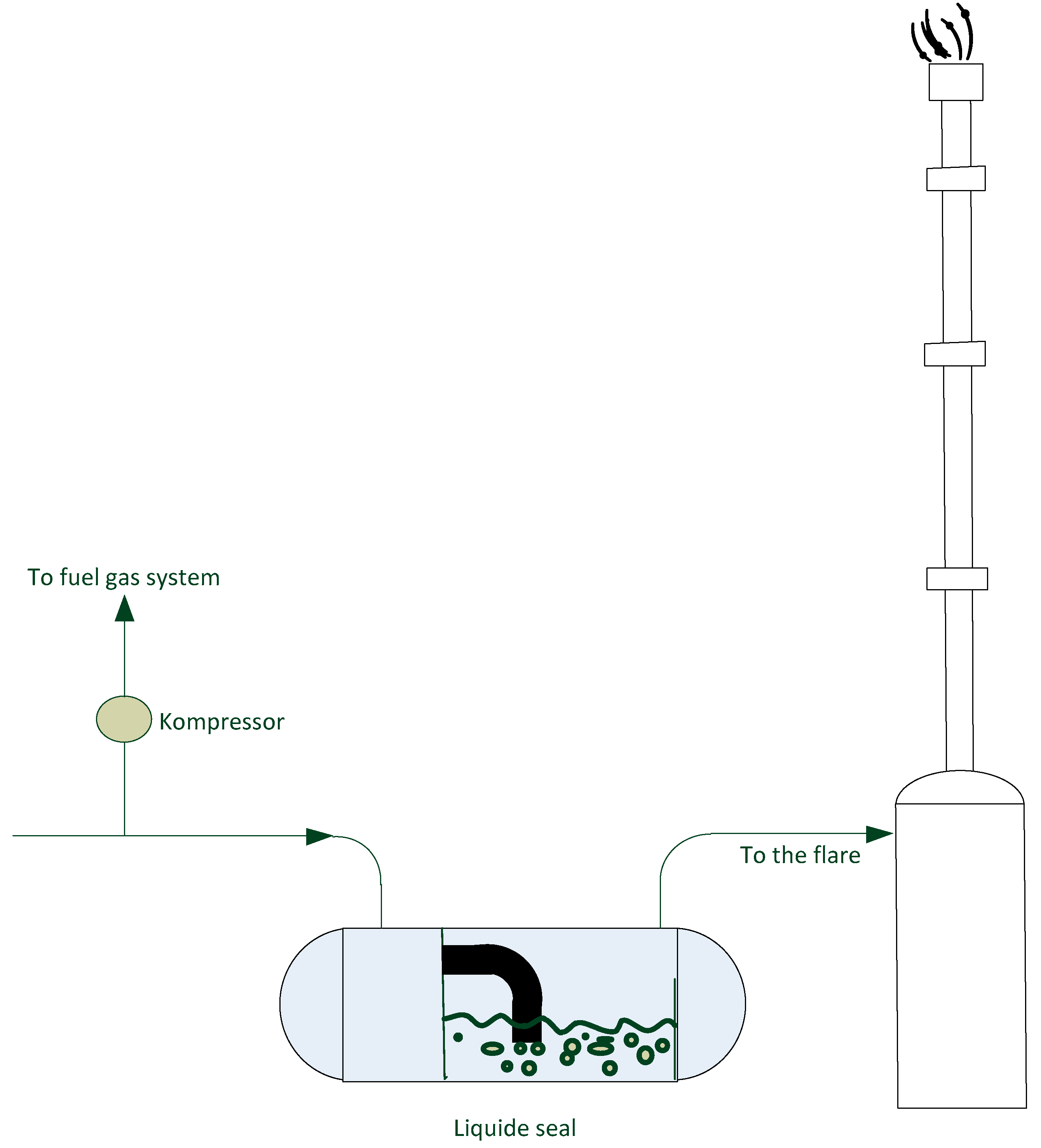

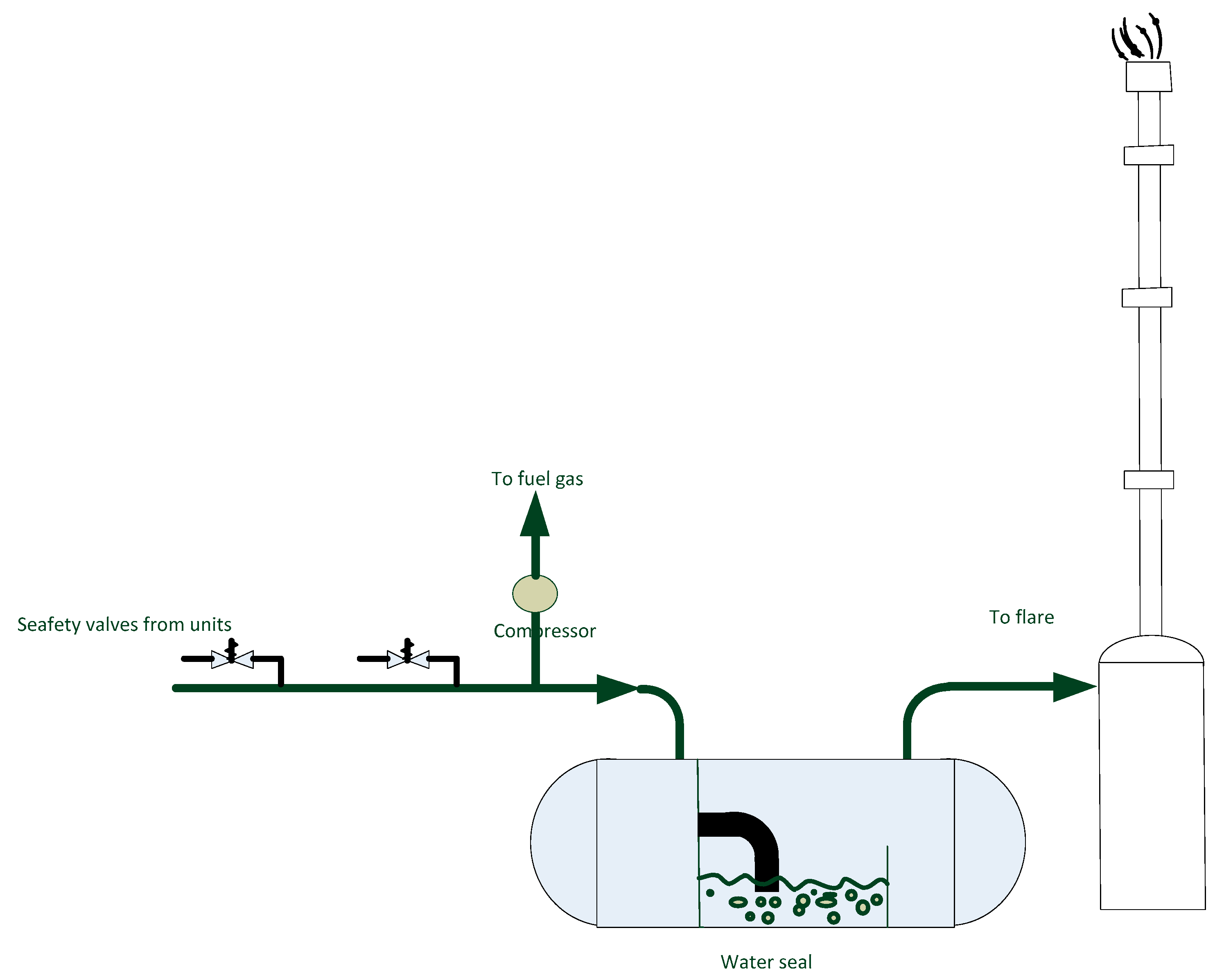

- Gases are discharged from a given installation into a pipeline system and discharge collectors,

- Within a given installation, the liquid phase is separated;

- Gases leave the knockout drum (separator) built into the production plant and are further directed to the collectors cooperating directly with the flare stacks;

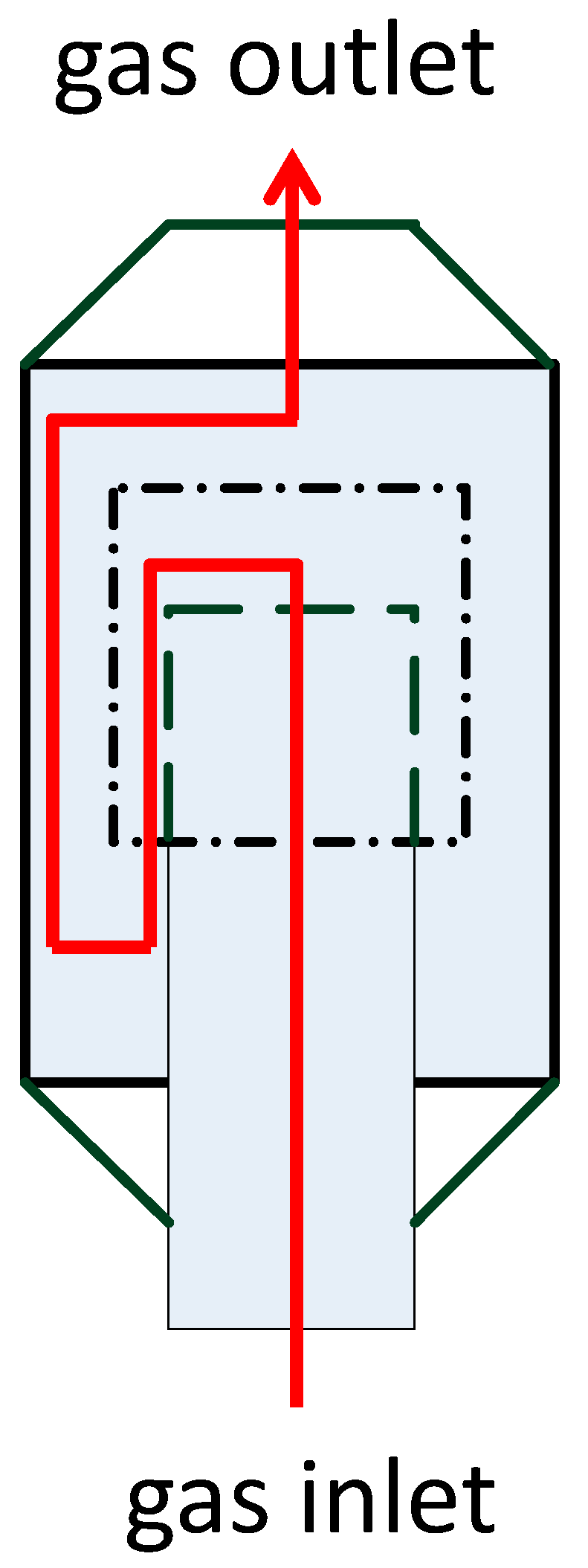

- Flare gas streams pass through a knockout drums (separator), the KO may be integrated with a liquid seal that maintains the pressure of the flare gases at the required level;

- The maintained pressure of the flare gases ensures their influx into the suction of the compressor,

- The compressor the pressure of the gases is increased to the required value,

- Directing gases to the internal fuel gas system.

3.2. The Use of Surplus of Discharge/Flare Gases beyond Manufacturing Plants

- Gas streams that can be found in the flare discharge system, which are dedicated to individual processes/installations;

- Quality of these streams;

- Amount of discharge gas;

- Variability of their composition; and

- Content of impurities.

4. Conclusions

- The quality of the discharge gases generated at individual production installations is known. It is possible to take samples for analysis and have them analyzed in the laboratory. It is also possible to install a chromatograph, which would be used for continuous monitoring and quality control of the selected gas parameters.

- The quality of the natural gas, pumped through the individual transmission pipelines, is known. The technical parameters of transmission pipelines are also known. Also technical requirements for these objects defined in the regulations and technical specifications are known.

- It is possible to determine the impact of the compressed and injected stream of flare gas on the quality of natural gas transported by the selected transmission pipeline, or under the selected system of transit. Knowing the quality and quantity of the discharge gas and natural gas, it is possible to develop a mathematical model by which the gas stream quality can be determined after mixing two streams and then refer the results to the required natural gas quality described in the relevant standards.

- The solution would generate the following beneficial effects on the production plants: Less use and thus consumption of infrastructure.

- Reduced consumption of energy media in the depressurization flare stack systems, thus reducing the consumption of steam-producing fuels, used to atomize the flame on the flare main burner.

Author Contributions

Funding

Conflicts of Interest

References

- Mehraban, M.; Shahraki, B.H. A mathematical model for decoking process of the catalyst in catalytic naphtha reforming radial flow reactor. Fuel Process. Technol. 2019, 188, 172–178. [Google Scholar] [CrossRef]

- Shi, J.; Hou, Y. Practice and Analysis of FCCU Efficient Operation Based on Synergy of Refinery. Petr. Process. Petrochem. 2019, 50, 42–46. [Google Scholar]

- Zhang, J.; Cao, Z.; Wu, Z. Investigation of the technology that can maximize chemical feedstock production by hydrocracking straight-run diesel for Tianjin Petrochemical Company. Petr. Refin. Eng. 2018, 48, 25–27. [Google Scholar]

- Li, R.; Zhang, X.; Li, S.; Li, Z. Analysis of Guo VI gasoline upgrading processes for refineries producing ethanol gasoline blendstocks. Petr. Refin. Eng. 2017, 47, 9–13. [Google Scholar]

- Ozren, O. Oil Refineries in the 21st Century: Energy Efficient, Cost Effective, Environmentally Benign; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005. [Google Scholar]

- He, Y. Analysis and practice of operation optimization of hydrogen system. Petr. Refin. Eng. 2017, 47, 14–17. [Google Scholar]

- Al-Subaie, A.; Maroufmashat, A.; Elkamel, A.; Fowler, M. Presenting the implementation of power-to-gas to an oil refinery as a way to reduce carbon intensity of petroleum fuels. Int. J. Hydrog. Energy 2017, 42, 19376–19388. [Google Scholar] [CrossRef]

- Wu, C.; Li, Y.; Zhou, Y.; Li, Z.; Zhang, S.; Liu, H. Upgrading the Chinese biggest petrochemical wastewater treatment plant: Technologies research and full scale application. Sci. Total Environ. 2018, 633, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Hou, M.; Miao, X. Analysis of factors affecting light olefins’yields of catalytic cracking unit and optimization. Petr. Refin. Eng. 2018, 48, 5–9. [Google Scholar]

- Yang, J.C.; Chang, P.E.; Chie, W.C.; Liu, J.P.; Wu, C.F. Large-scale search method for locating and identifying fugitive emission sources in petrochemical processing areas. Process Saf. Environ. Protect. 2016, 104, 382–394. [Google Scholar] [CrossRef]

- Arendt, J.S.; Casada, M.L.; Rooney, J.J. Reliability and hazards analysis of a cumene hydroperoxide plant. Plant/Oper. prog. 1986, 5, 97–102. [Google Scholar] [CrossRef]

- Franek, L.; Galbfach, R.; Rosciszewski, A.; Urbanski, J.; Zebrowski, M. Cumene Phenol Production—Development of the Technology in Mazovian Refining and Petrochemical Plants in Plock. Przem. Chem. 1985, 64, 522–524. [Google Scholar]

- Kalat Jari, H.R.; Borhani Sazeh, A. Minimize Flaring with Modification to Flare Gas Recovery Unit. Available online: http://gasprocessingnews.com/features/201804/minimize-flaring-with-modifications-to-flare-gas-recovery-unit.aspx (accessed on 8 March 2019).

- Baukal, C.E. Combustion Handbook, Design and Operations; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2013. Available online: http://vr360app.ternium.com/the_john_zink_hamworthy_combustion_handbook_second_edition_volume_2_design_and_operations_industrial_combustion.pdf (accessed on 8 March 2019).

- Environmental Protection Agency (EPA). Installing Vapor Recovery Units on Storage Tanks. 2006. Available online: https://www.epa.gov/sites/production/files/2016-06/documents/ll_final_vap.pdf (accessed on 8 March 2019).

- Mokhatab, S.; Mak, J.Y.; Valappil, J.V.; Wood, D.A. Handbook of Liquefied Natural Gas; Elsevier: Oxford, UK, 2014. [Google Scholar]

- Peterson, J.; Cooper, H.; Baukal, C. Minimize facility flaring. Hydrocarb. Process. 2007, 6, 111–115. [Google Scholar]

- Gas System (GS). 2019. Available online: https://www.gaz-system.pl/ (accessed on 8 March 2019).

| No | Gas Components | Flare Gases, %v/v | Natural Gas, %v/v |

|---|---|---|---|

| 1 | Methane | 43.600 | 96.470 |

| 2 | Ethane | 3.660 | 1.300 |

| 3 | Propane | 20.030 | 0.278 |

| 4 | n-Butane | 2.780 | 0.050 |

| 5 | Isobutane | 14.300 | 0.040 |

| 6 | n-Pentane | 0.266 | 0.010 |

| 7 | Isopentane | 0.530 | 0.020 |

| 8 | neo-Pentane | 0.017 | 0.000 |

| 9 | n-Hexane | 0.635 | 0.000 |

| 10 | Ethylene | 1.050 | 0.000 |

| 11 | Propylene | 2.730 | 0.000 |

| 12 | 1-Butene | 0.696 | 0.000 |

| 13 | Carbon monoxide | 0.186 | 0.000 |

| 14 | Carbon dioxide | 0.713 | 0.000 |

| 15 | Hydrogen sulfide | 0.256 | 0.577 * |

| 16 | Hydrogen | 5.540 | 0.000 |

| 17 | Oxygen | 0.357 | 0.000 |

| 18 | Nitrogen | 1.300 | 1.778 |

| 19 | Water | 1.140 | 0.0095 ** |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szpalerski, J.; Smoliński, A. Analysis of the Excess Hydrocarbon Gases Output from Refinery Plants. Processes 2019, 7, 253. https://doi.org/10.3390/pr7050253

Szpalerski J, Smoliński A. Analysis of the Excess Hydrocarbon Gases Output from Refinery Plants. Processes. 2019; 7(5):253. https://doi.org/10.3390/pr7050253

Chicago/Turabian StyleSzpalerski, Jerzy, and Adam Smoliński. 2019. "Analysis of the Excess Hydrocarbon Gases Output from Refinery Plants" Processes 7, no. 5: 253. https://doi.org/10.3390/pr7050253

APA StyleSzpalerski, J., & Smoliński, A. (2019). Analysis of the Excess Hydrocarbon Gases Output from Refinery Plants. Processes, 7(5), 253. https://doi.org/10.3390/pr7050253