A Novel Multiphase Methodology Simulating Three Phase Flows in a Steel Ladle

Abstract

1. Introduction

2. Numerical Method

2.1. Eulerian Model Using IPSA Algorithm

2.2. Volume of Fluid Model

2.3. Coupling between IPSA and VOF Algorithms

| DO ISTEP = 1, LSTEP |

| DO ISWEEP = 1, LSWEEP |

| DO IZ = 1, NZ |

| Apply previous sweep’s pressure & velocity corrections |

| DO IC = 1, LITC |

| Solve scalars in order |

| KE, EP, C1, C3 |

| ENDDO |

| Solve velocities in order V1, U1, W1, U2, V2, W2 |

| Construct and store Pressure correction sources and coefficients |

| ENDDO |

| Solve and store pressure corrections whole-field |

| ENDDO |

2.4. Initial and Boundary Conditions

2.4.1. Initial Conditions

2.4.2. Boundary Conditions

2.5. Solution Technique

3. Experimental Work

4. Results

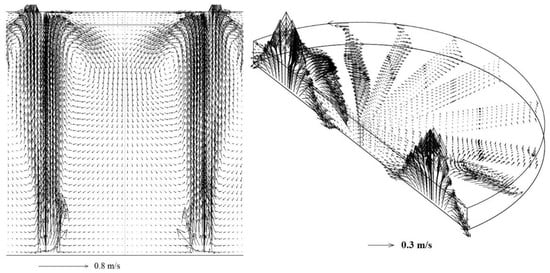

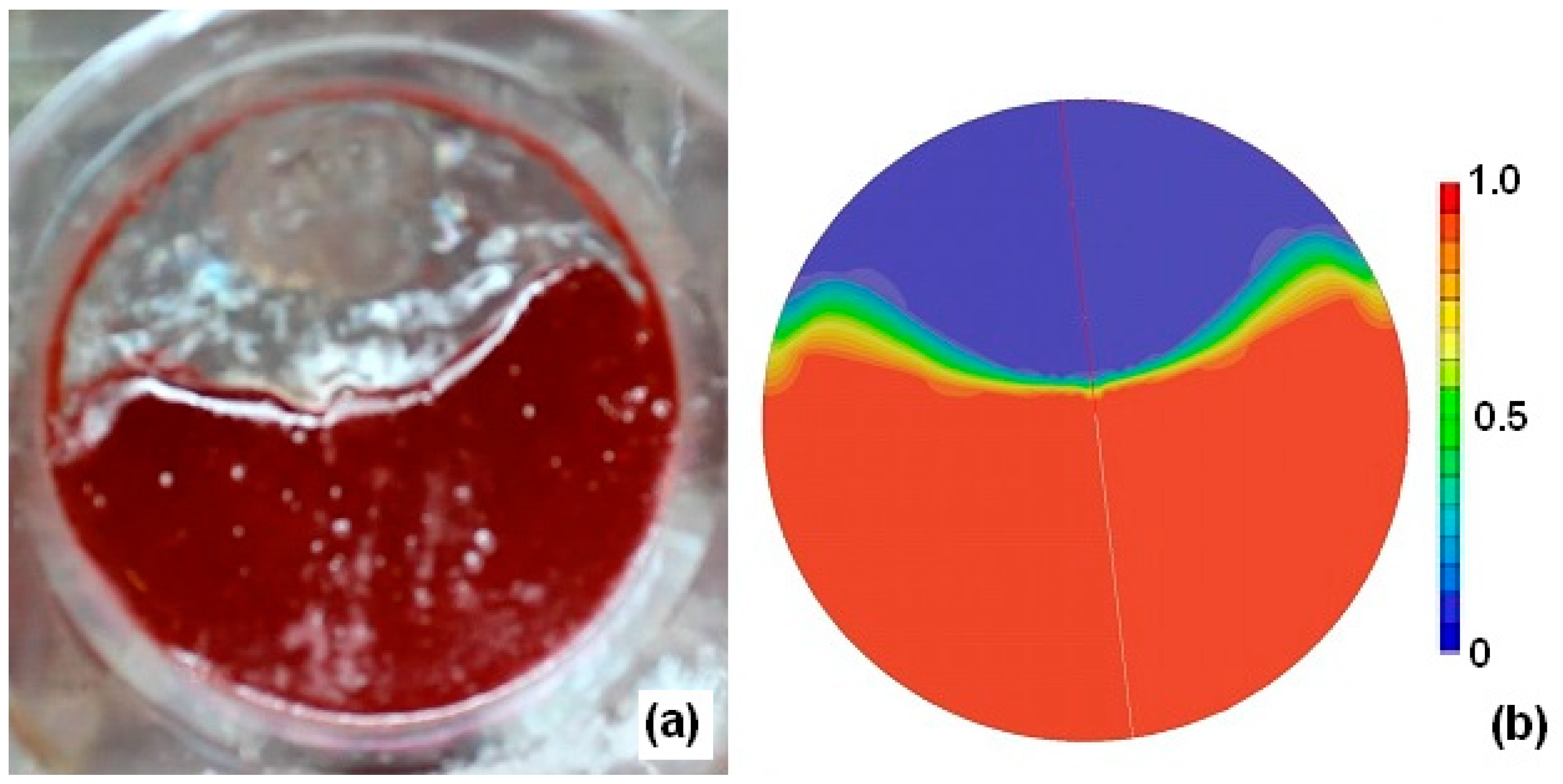

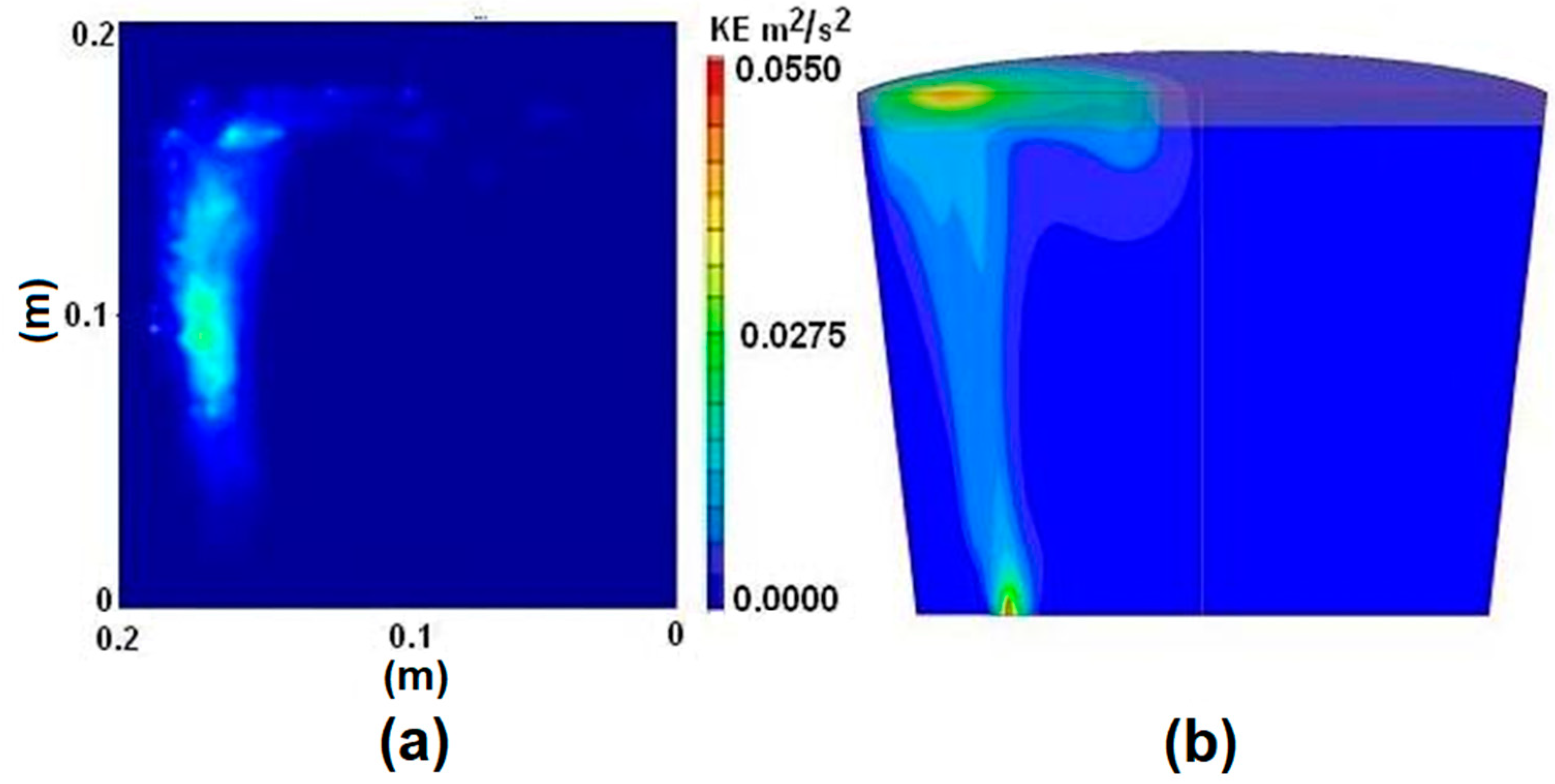

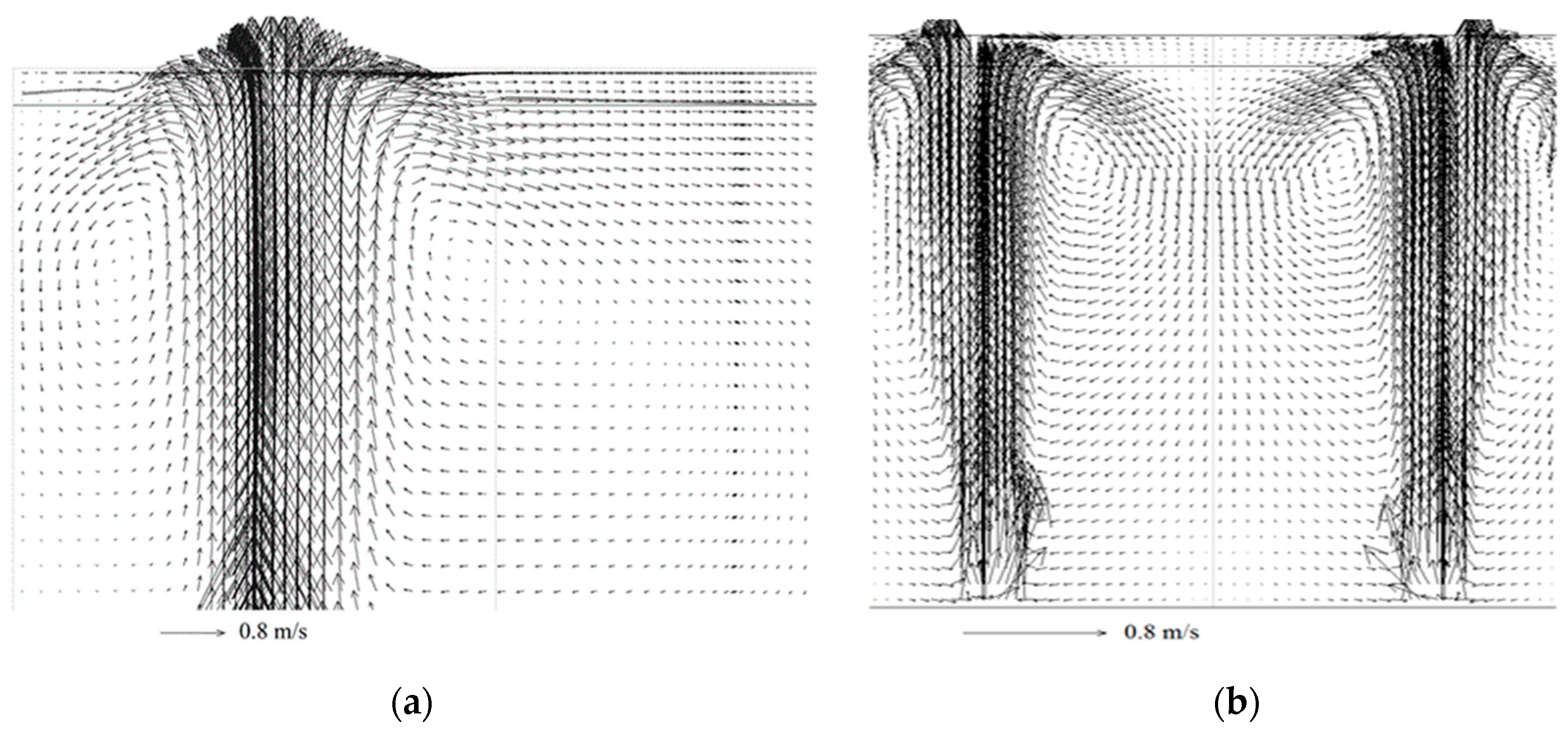

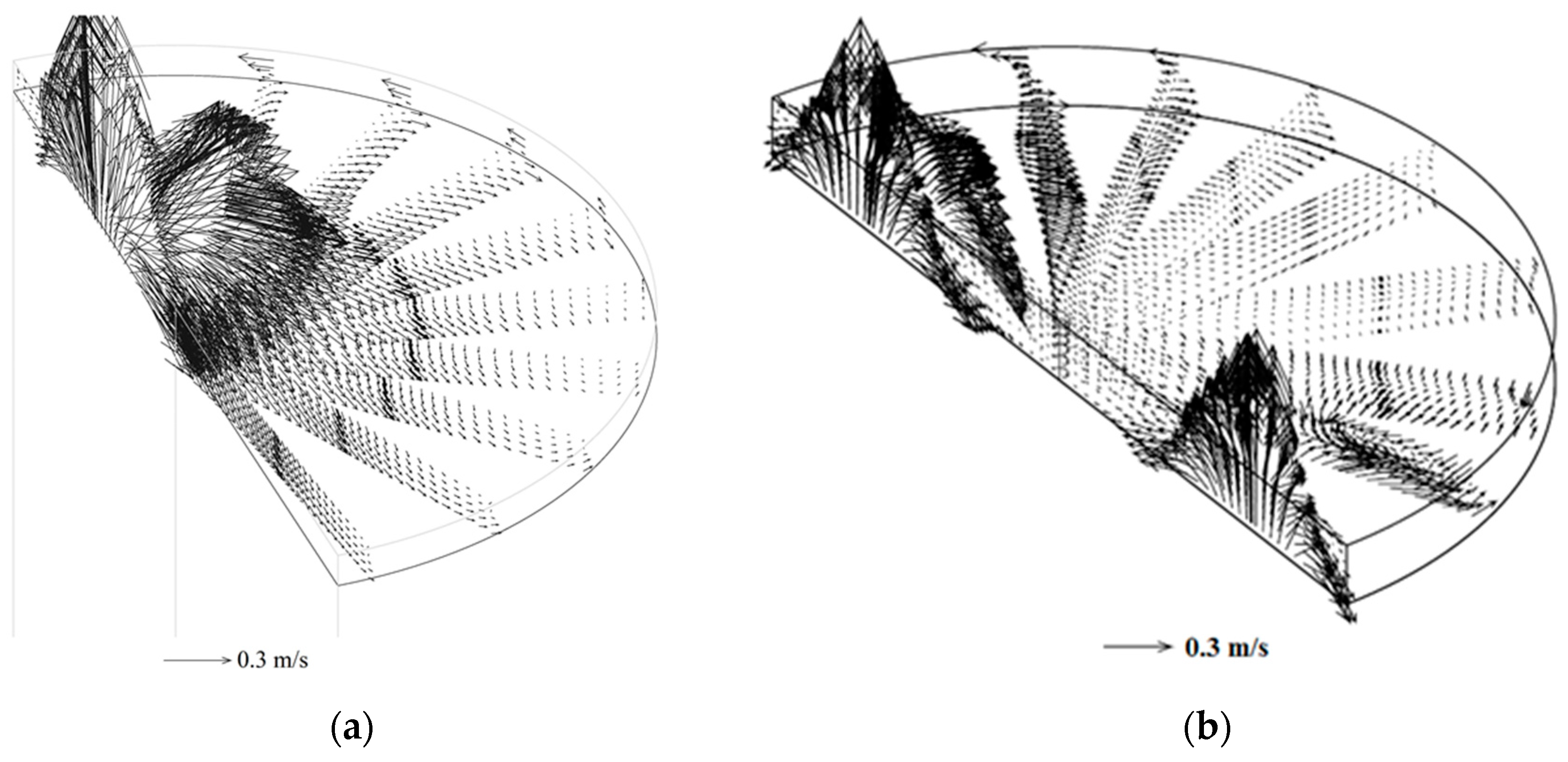

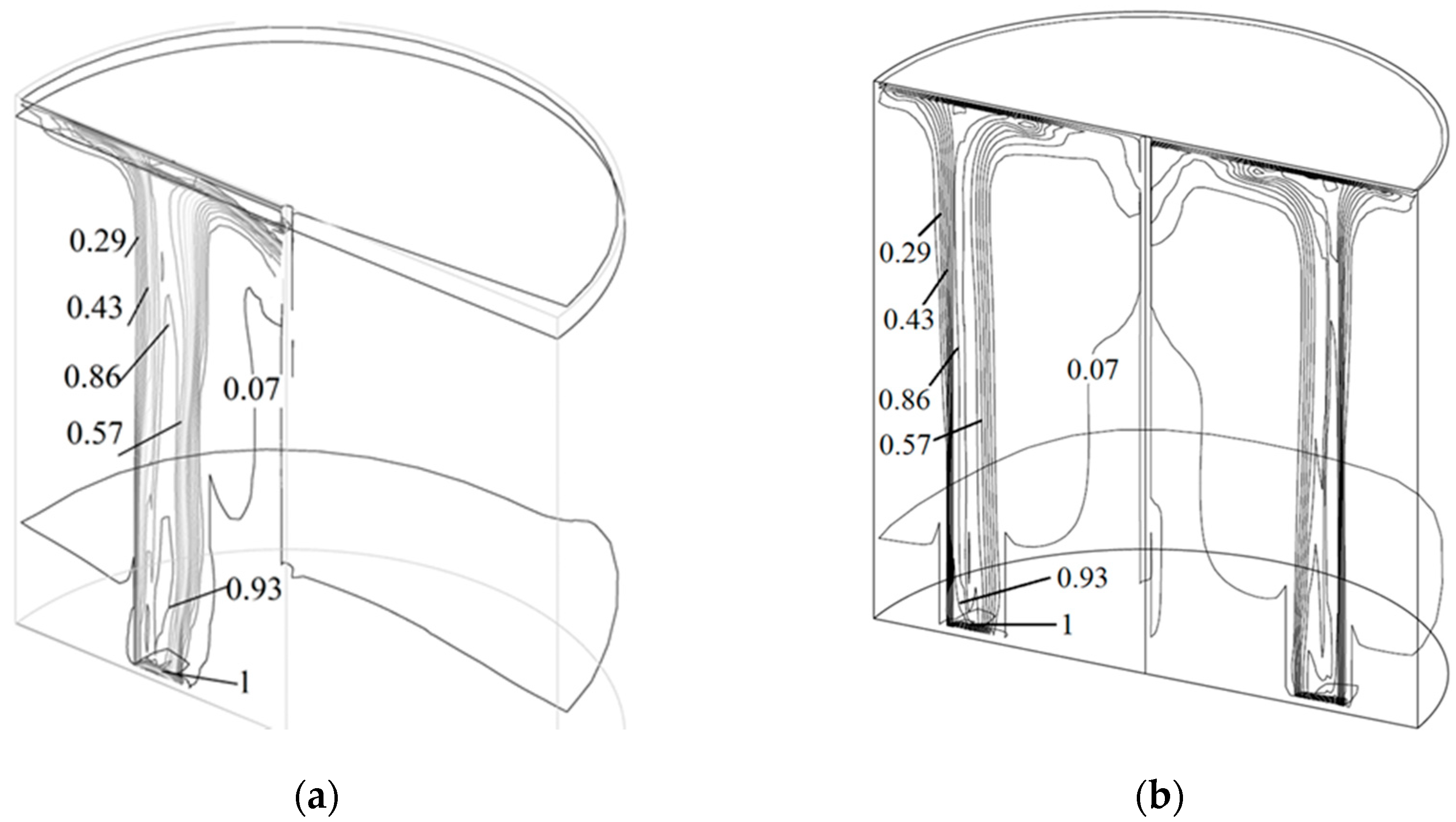

4.1. Model Validation

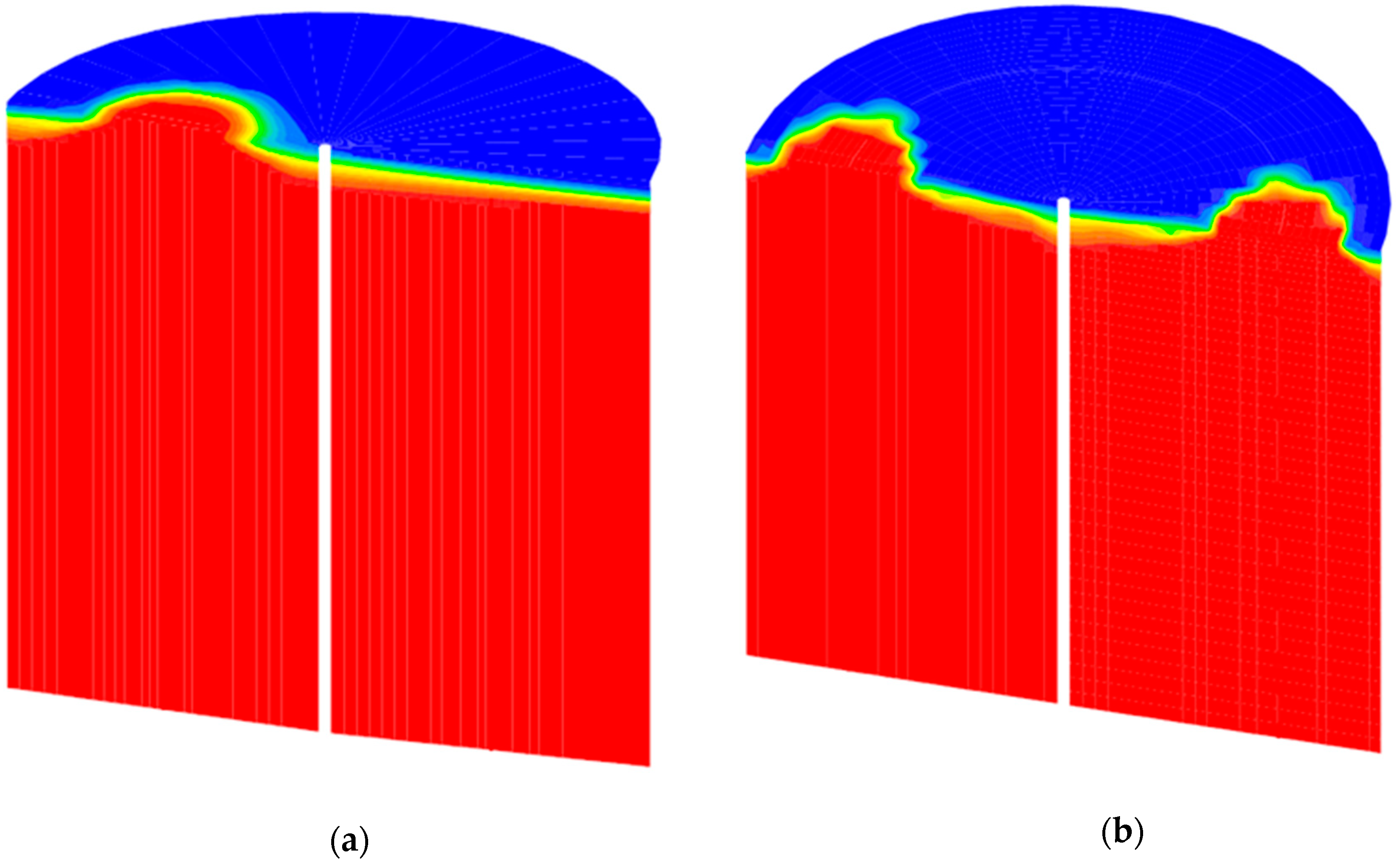

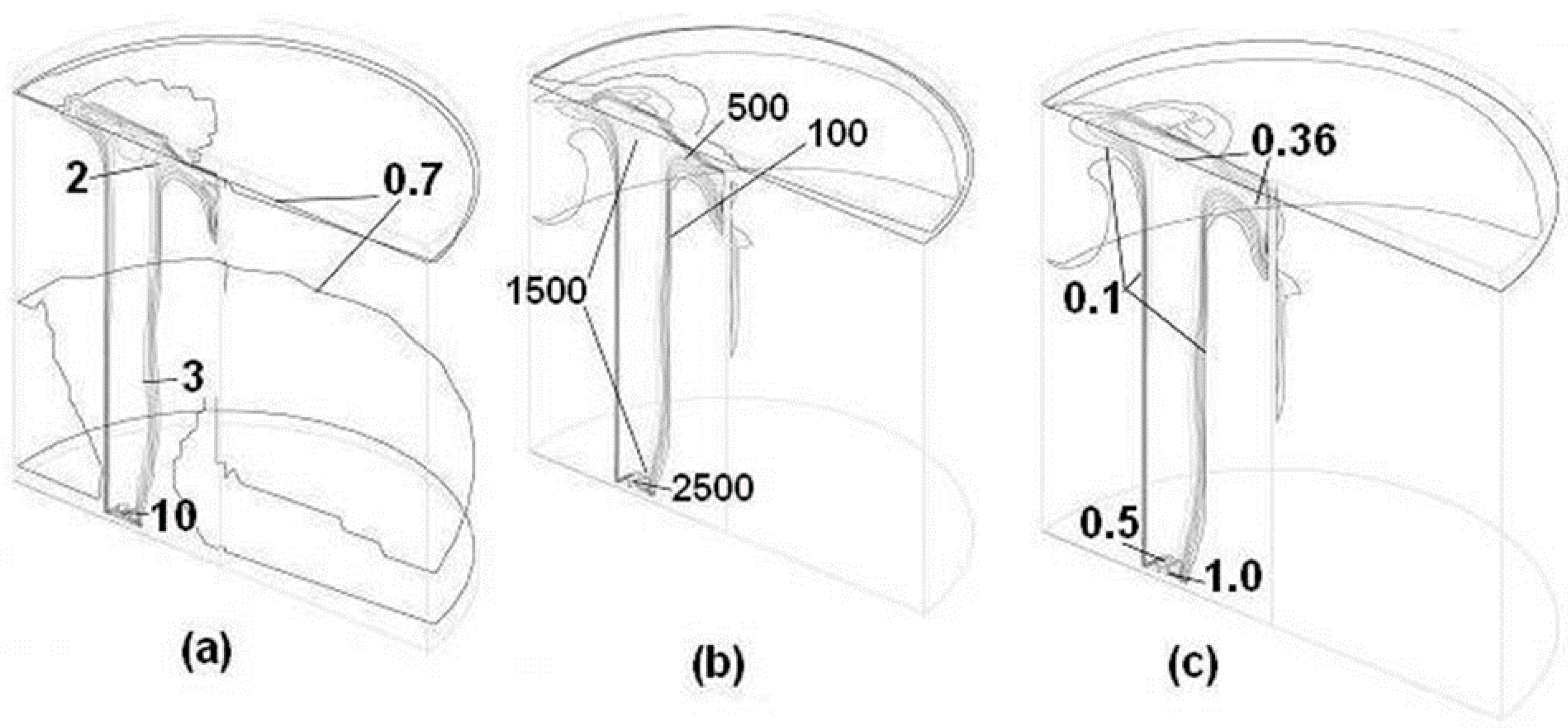

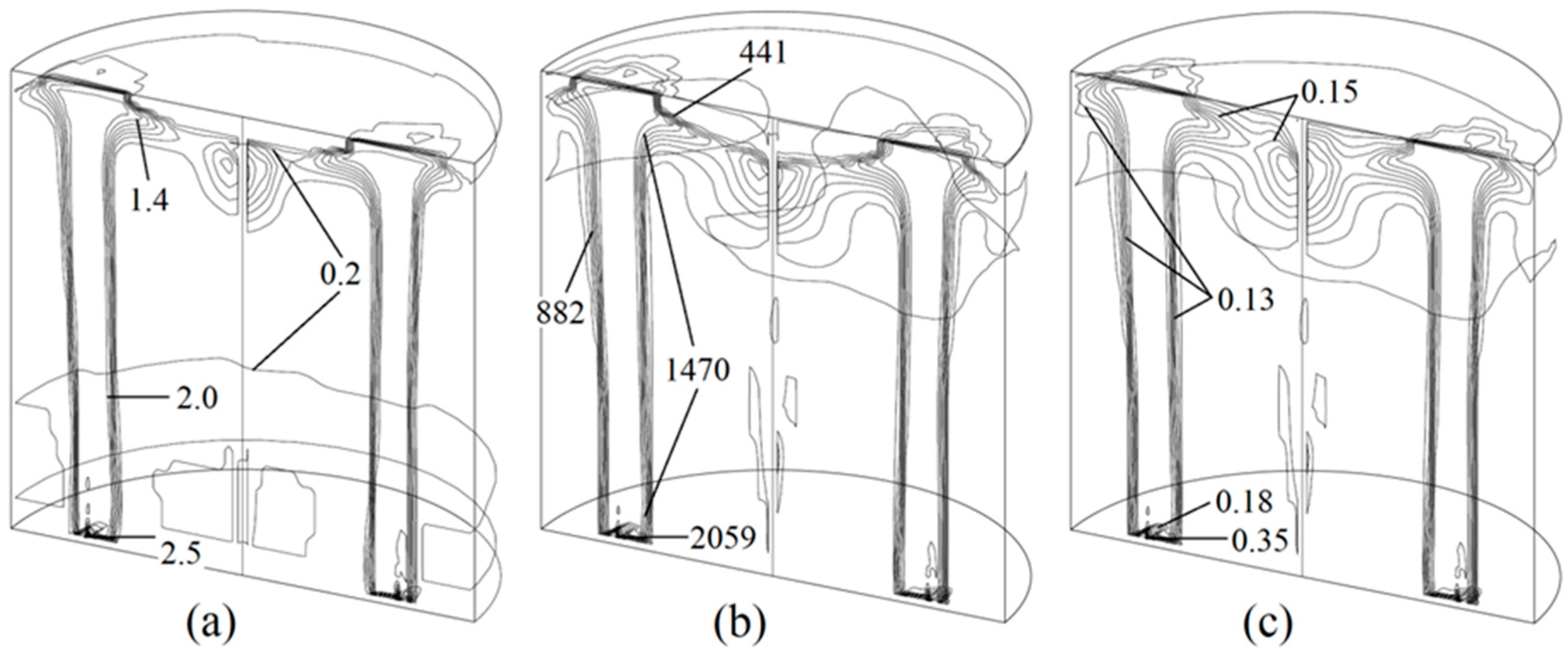

4.2. Flow Patterns of an Industrial Ladle

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mazumdar, D.; Guthrie, R.I.L. The Physical and Mathematical Modelling of Gas Stirred Ladle Systems. ISIJ Int. 1995, 35, 1–20. [Google Scholar] [CrossRef]

- Liu, Y.; Ersson, M.; Liu, H.; Jönsson, P.G.; Gan, Y. A review of physical and numerical approaches for the study of gas stirring in ladle metallurgy. Metall. Matls. Trans. B 2019, 501, 555–577. [Google Scholar] [CrossRef]

- Joo, V.; Guthrie, R.I.L. Modeling flows and mixing in steelmaking ladles designed for single- and dual-plug bubbling operations. Met. Trans. B 1992, 23, 765–778. [Google Scholar] [CrossRef]

- Goldschmit, M.B.; Owen, A.H.C. Numerical modelling of gas stirred ladles. Ironmak. Steelmak. 2001, 28, 337–341. [Google Scholar] [CrossRef]

- Markatos, N.C. The mathematical modelling of turbulent flows. Appl. Math. Model. 1986, 10, 190–220. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Mazumdar, D.; Guthrie, R.I.L. A comparison of three mathematical modeling procedures for simulating fluid flow phenomena in bubble-stirred ladles. Metall. Mater. Trans. B 1994, 251, 308–312. [Google Scholar] [CrossRef]

- Mazumdar, D.; Guthrie, R.I.L. On mathematical models and numerical solutions of gas stirred ladle systems. Appl. Math. Model. 1993, 17, 255–262. [Google Scholar] [CrossRef]

- Sheng, Y.Y.; Irons, G.A. Measurement and modeling of turbulence in the gas/liquid two-phase zone during gas injection. Metall. Mater. Trans. B 1993, 24, 695–705. [Google Scholar] [CrossRef]

- Sichen, D. Modeling Related to Secondary Steel Making. Steel Res. Int. 2012, 83, 825–841. [Google Scholar] [CrossRef]

- Jonsson, L.; Jönsson, P. Modeling of Fluid Flow Conditions around the Slag/Metal Interface in a Gas-stirred Ladle. ISIJ Int. 1996, 36, 1127–1134. [Google Scholar] [CrossRef]

- Méndez, C.G.; Nigro, N.; Cardona, A.; Begnis, S.S.; Chiapparoli, W.P. Physical and Numerical Modelling of a Gas Stirred Ladle. Mecánica Computacional 2002, 21, 2646–2654. [Google Scholar]

- Han, J.W.; Heo, S.W.; Kam, D.H.; You, B.D.; Pak, J.J.; Song, H.S. Transient Fluid Flow Phenomena in a Gas Stirred Liquid Bath with Top Oil Layer—Approach by Numerical Simulation and Water Model Experiments. ISIJ Int. 2001, 41, 1165–1172. [Google Scholar] [CrossRef]

- Olsen, J.E.; Cloete, S. Coupled DPM and VOF model for analyses of gas stirred ladles at higher gas rates. In Proceedings of the 7th International Conference on CFD in the Minerals and Process Industries, CSIRO, Melbourne, Australia, 9–11 December 2009; pp. 1–6. [Google Scholar]

- Hoang, Q.N.; Ramírez-Argáez, M.A.; Conejo, A.N.; Blanpain, B.; Dutta, A. Numerical Modeling of Liquid-Liquid Mass Transfer and the Influence of Mixing in Gas-Stirred Ladles. J. Met. 2018, 70, 2109–2118. [Google Scholar] [CrossRef]

- Li, B.; Yin, H.; Zhou, C.-Q.; Tsukihashi, F. Modeling of three-phase flows and behavior of slag/steel interface in an argon gas stirred ladle. ISIJ Int. 2008, 48, 1704–1711. [Google Scholar] [CrossRef]

- Sulasalmi, P.; Visuri, V.V.; Kärnä, A.; Fabritius, T. Simulation of the Effect of Steel Flow Velocity on Slag Droplet Distribution and Interfacial Area Between Steel and Slag. Steel Res. Int. 2015, 86, 212–222. [Google Scholar] [CrossRef]

- Huang, A.; Harmuth, H.; Doletschek, M.; Vollmann, S.; Feng, X. Toward CFD Modeling of Slag Entrainment in Gas Stirred Ladles. Steel Res. Int. 2015, 86, 1447–1454. [Google Scholar] [CrossRef]

- Li, L.; Liu, Z.; Li, B.; Matsuura, H.; Tsukihashi, F. Water Model and CFD-PBM Coupled Model of Gas-Liquid-Slag Three-Phase Flow in Ladle Metallurgy. ISIJ Int. 2015, 55, 1337–1346. [Google Scholar] [CrossRef]

- Singh, U.; Anapagaddi, R.; Mangal, S.; Padmanabhan, K.A.; Singh, A.K. Multiphase Modeling of Bottom-Stirred Ladle for Prediction of Slag–Steel Interface and Estimation of Desulfurization Behavior. Metall. Mater. Trans. B 2016, 47, 1804–1816. [Google Scholar] [CrossRef]

- Haiyan, T.; Xiaochen, G.; Guanghui, W.; Yong, W. Effect of Gas Blown Modes on Mixing Phenomena in a Bottom Stirring Ladle with Dual Plugs. ISIJ Int. 2016, 56, 2161–2170. [Google Scholar] [CrossRef]

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Spalding, D.B. IPSA 1981: New Developments and Computed Results; Imperial College, CFDU Report HTS/81/2; Concentration, Heat & Momentum Limited: London, UK.

- Schwarz, M.P. Simulation of gas injection into liquid melts. Appl. Math. Model. 1996, 20, 41–51. [Google Scholar] [CrossRef]

- Davis, M.P.; Pericleous, K.; Cross, M.; Schwarz, M.P. Mathematical Modelling Tools for the Optimization of Direct Smelting Processes. Appl. Math. Model. 1998, 22, 921–940. [Google Scholar] [CrossRef]

- Stephens, D.; Tabib, M.; Davis, M.; Schwarz, M.P. CFD Simulation of bath dynamics in the HIsmelt smelt reduction vessel for iron production. Prog. Comput. Fluid Dyn. 2012, 12, 196–206. [Google Scholar] [CrossRef]

- Davidson, J.F.; Harrison, D. Fluidized Particles; Cambridge University Press: London, UK; New York, NY, USA, 1963. [Google Scholar]

- Kuo, J.T.; Wallis, G.B. Flow of bubbles through nozzles. Int. J. Multiphase Flow 1998, 14, 547–564. [Google Scholar] [CrossRef]

- Lopez de Bertodano, M. Turbulent Bubbly Flow in a Triangular Duct. Ph.D. Thesis, Rensselaer Polytechnic Institute, Troy, NY, USA, 1991. [Google Scholar]

- Ramshaw, J.D.; Trapp, J.A. A numerical technique for low-speed homogeneous two-phase flow with sharp interfaces. J. Comput. Phys. 1976, 21, 438–453. [Google Scholar] [CrossRef]

- Roe, P.L. Characteristic-Based Schemes for the Euler Equations. Ann. Rev. Fluid Mech. 1986, 18, 337–365. [Google Scholar] [CrossRef]

- El Gharbi, N.; Absi, R.; Benzaoui, A.; Amara, E.H. Effect of near-wall treatments on airflow simulations. In Proceedings of the International Conference on Computational Methods for Energy Engineering and Environment: ICCM3E, Sousse, Tunisia, 20–22 November 2009; pp. 185–189. [Google Scholar]

- Ramírez-Argáez, M.; González-Rivera, C. Modeling of Metal-Slag Mass and Momentum Exchanges in Gas-Stirred Ladles. In Proceedings of the 3rd Pan American Materials Congress; Springer: Berlin/Heidelberg, Germany, 2017; pp. 771–781. [Google Scholar]

- Schwarz, M.P.; Taylor, I.F. CFD and Physical Modelling of Slag-Metal Contacting in a Smelter. In Proceedings of the 4th World Conference on Applied Fluid Mechanics, Freiburg, Germany, 7–11 June 1998; Volume 4, pp. 1–15. [Google Scholar]

- Ramírez-Argáez, M.A. Mathematical Modeling of DC Electric Arc Furnace Operations. Ph.D. Thesis, MIT, Cambridge, MA, USA, 2000; pp. 165–174. [Google Scholar]

- Conejo, A.; Kitamura, S.; Maruoka, N.; Kim, S. Effects of Top Layer, Nozzle Arrangement, and Gas Flow Rate on Mixing Time in Agitated Ladles by Bottom Gas Injection. Metall. Mater. Trans. B 2013, 44, 914–923. [Google Scholar] [CrossRef]

| Variable/Boundary | Bottom Wall | Lateral Wall | Free Surface | Two Symmetry Planes (θ = 0° and θ = 180°) | Symmetry Axis at r = 0 | Plug (Inlet or Inlets for both Single and Dual Gas Injection) |

|---|---|---|---|---|---|---|

| αg | ||||||

| αl | ||||||

| ug | ||||||

| vg | ||||||

| wg | But | according to the gas flow rate and if the injection is single or dual | ||||

| ul | standard wall functions | standard wall functions | ||||

| vl | standard wall functions | standard wall functions | ||||

| wl | standard wall functions | standard wall functions | ||||

| k | k = 0.0 | k = 0.0 | k = 0.0 | |||

| ε | ε = 0.0 | ε = 0.0 | ε = 0.0 | |||

| C1 | ||||||

| C3 |

| Height of Liquid | Symbol | Value |

|---|---|---|

| Ladle | ||

| Diameter | D | 0.21 m |

| Height of liquid | H | 0.21 m |

| Nozzle | ||

| Diameter | D | 0.005 m |

| Position | 1/2 R for single injection | |

| 2/3 R for dual injection | ||

| Air properties (room temperature) | ||

| Density | ρg | 1.205 kg/m3 |

| Viscosity | μg | 1.74 × 10−5 kg/m·s |

| Bubble diameter | Dp | 0.005 m |

| Gas flow rate | Q | 13.8 × 10−5 m3/s |

| Water properties | ||

| Density | ρa | 1000 kg/m3 |

| Viscosity | μa | 1 × 10−3 kg/m·s |

| Surface tension (water-air) | σ | 728 mN/m |

| Engine oil properties | ||

| Density | ρe | 800 kg/m3 |

| Viscosity | μe | 0.08 kg/m·s |

| Thickness | Δ | 0.84 cm (4% in height) |

| Parameter | Symbol | Value |

|---|---|---|

| Ladle | ||

| Diameter | D | 3.58 m |

| Height | H | 3.57 m |

| Nozzle | ||

| Diameter | D | 0.013 m |

| Position | 1/2 R, 2/3 R | |

| Argon properties | ||

| Density | ρg | 0.933 kg/m3 |

| Viscosity | μg | 2.2501 × 10−5 kg/m·s |

| Heat capacity | Cpg | 520 J/kg K |

| Thermal conductivity | kg | 0.01723 W/m·K |

| Bubble diameter | Dp | 0.005 m |

| Gas flow rate | Q | 9.72 × 10−3 m3/s |

| Argon temperature at inlet | 311 K | |

| Steel properties | ||

| Density | ρa | 7200 kg/m3 |

| Viscosity | μa | 6.2 × 10−3 kg/m·s |

| Surface tension (argon-steel) | σ | 1.8 N/m |

| Heat capacity | Cpa | 789.9 J/kg·K |

| Thermal conductivity | ka | 32.7 W/m·K |

| Emissivity | E | 0.8 |

| Initial Steel temperature | 1875 K | |

| Slag properties | ||

| Density | ρe | 2690 kg/m3 |

| Viscosity | μe | 0.266 kg/m·s |

| Heat capacity | Cpe | 964.8 J/kg·K |

| Thermal conductivity | ke | 1.5 W/m·K |

| Initial slag temperature | 1873 K | |

| Slag layer | Δ | 14.28 cm (4% thickness) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramírez-Argáez, M.A.; Dutta, A.; Amaro-Villeda, A.; González-Rivera, C.; Conejo, A.N. A Novel Multiphase Methodology Simulating Three Phase Flows in a Steel Ladle. Processes 2019, 7, 175. https://doi.org/10.3390/pr7030175

Ramírez-Argáez MA, Dutta A, Amaro-Villeda A, González-Rivera C, Conejo AN. A Novel Multiphase Methodology Simulating Three Phase Flows in a Steel Ladle. Processes. 2019; 7(3):175. https://doi.org/10.3390/pr7030175

Chicago/Turabian StyleRamírez-Argáez, Marco A., Abhishek Dutta, A. Amaro-Villeda, C. González-Rivera, and A. N. Conejo. 2019. "A Novel Multiphase Methodology Simulating Three Phase Flows in a Steel Ladle" Processes 7, no. 3: 175. https://doi.org/10.3390/pr7030175

APA StyleRamírez-Argáez, M. A., Dutta, A., Amaro-Villeda, A., González-Rivera, C., & Conejo, A. N. (2019). A Novel Multiphase Methodology Simulating Three Phase Flows in a Steel Ladle. Processes, 7(3), 175. https://doi.org/10.3390/pr7030175