Development of Environmental Friendly Dust Suppressant Based on the Modification of Soybean Protein Isolate

Abstract

1. Introduction

2. Experiments

2.1. Main Equipment and Raw Materials

2.2. Preparation of SDS-SPI Cementing Dust Suppressant

2.3. Application of SDS-SPI Cementing Dust Suppressant

3. Characterization of Properties

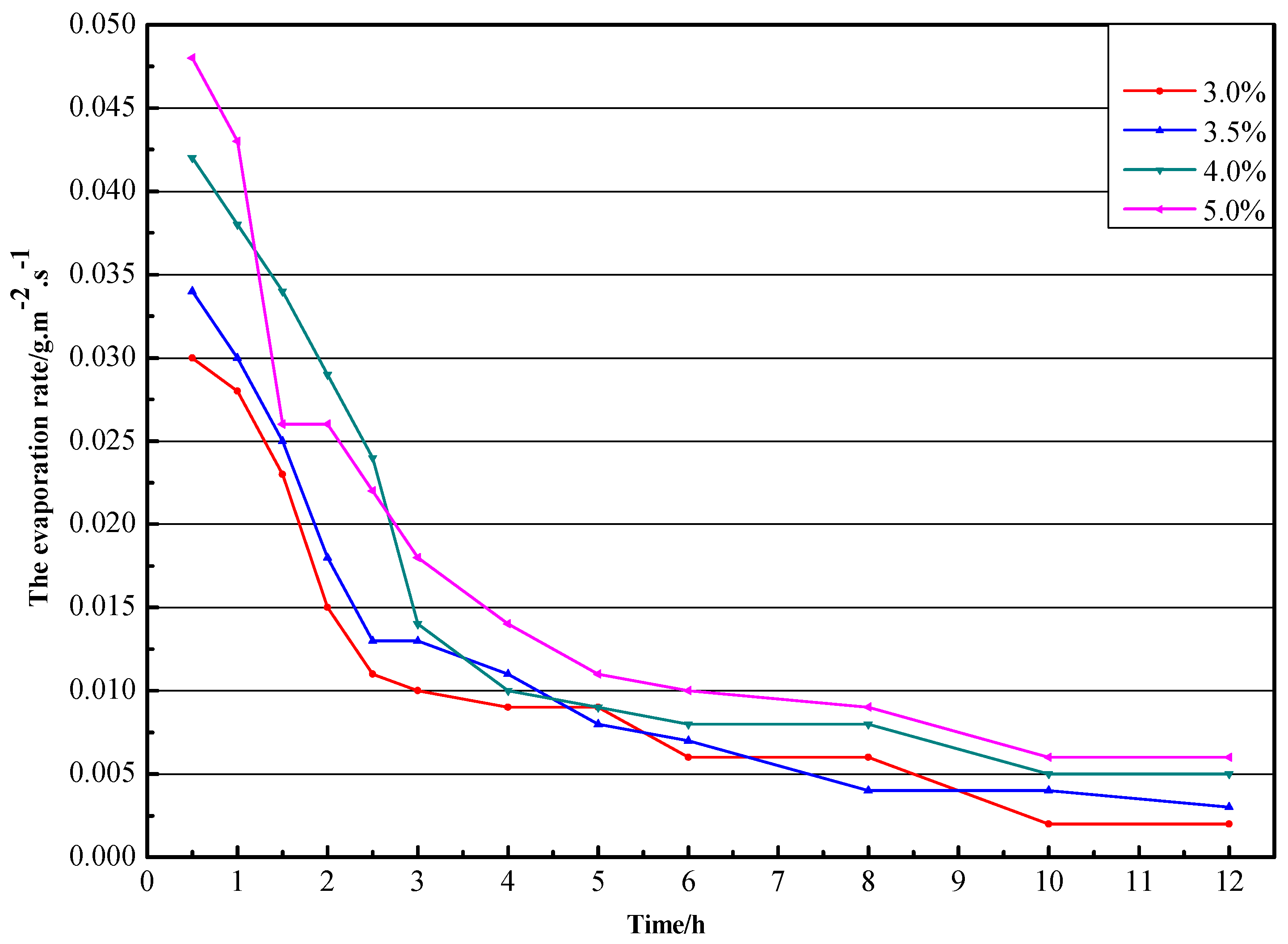

3.1. Experimental Characterization of Water Retention Performance of Dust Suppressant

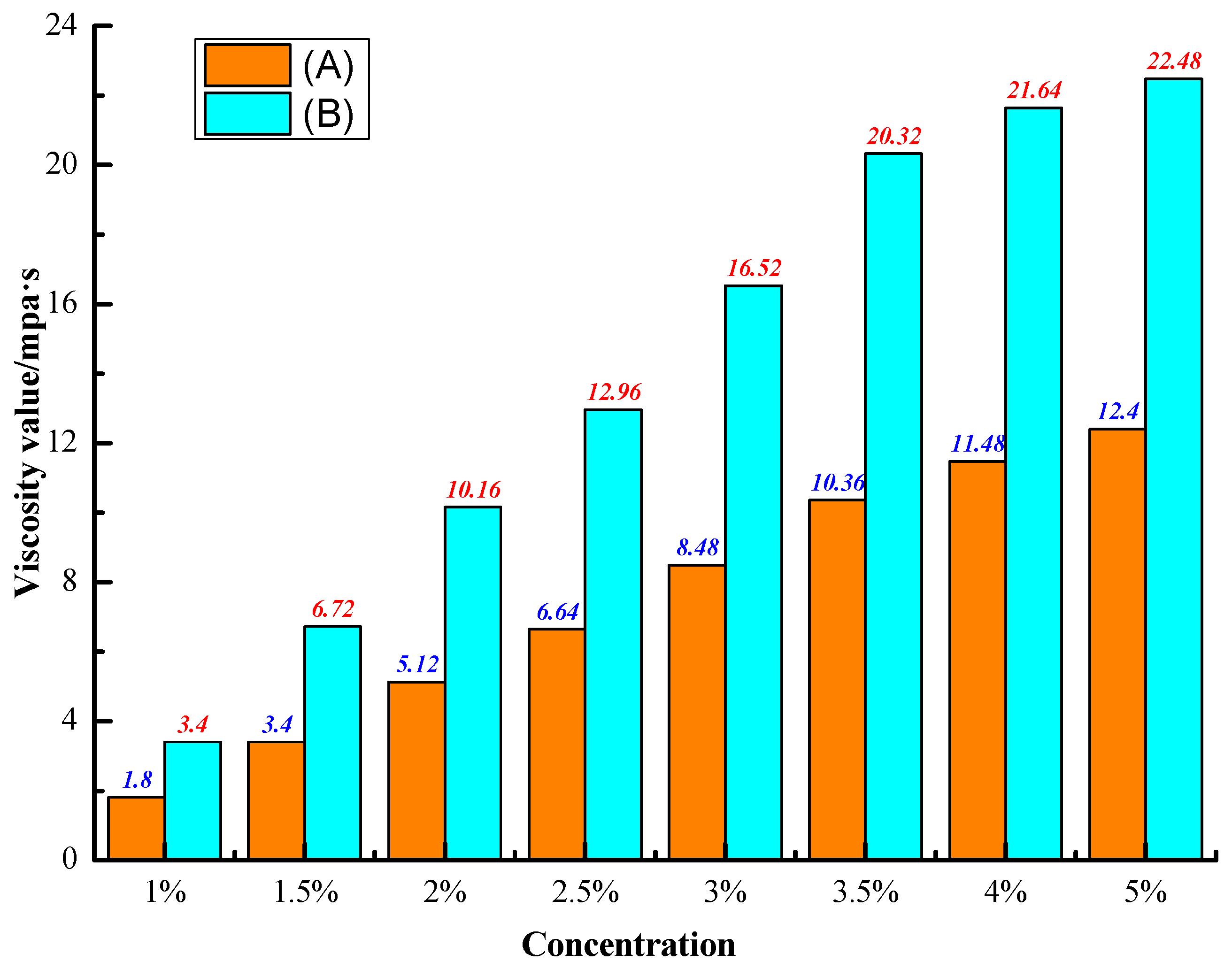

3.2. Viscosity Testing Experiments

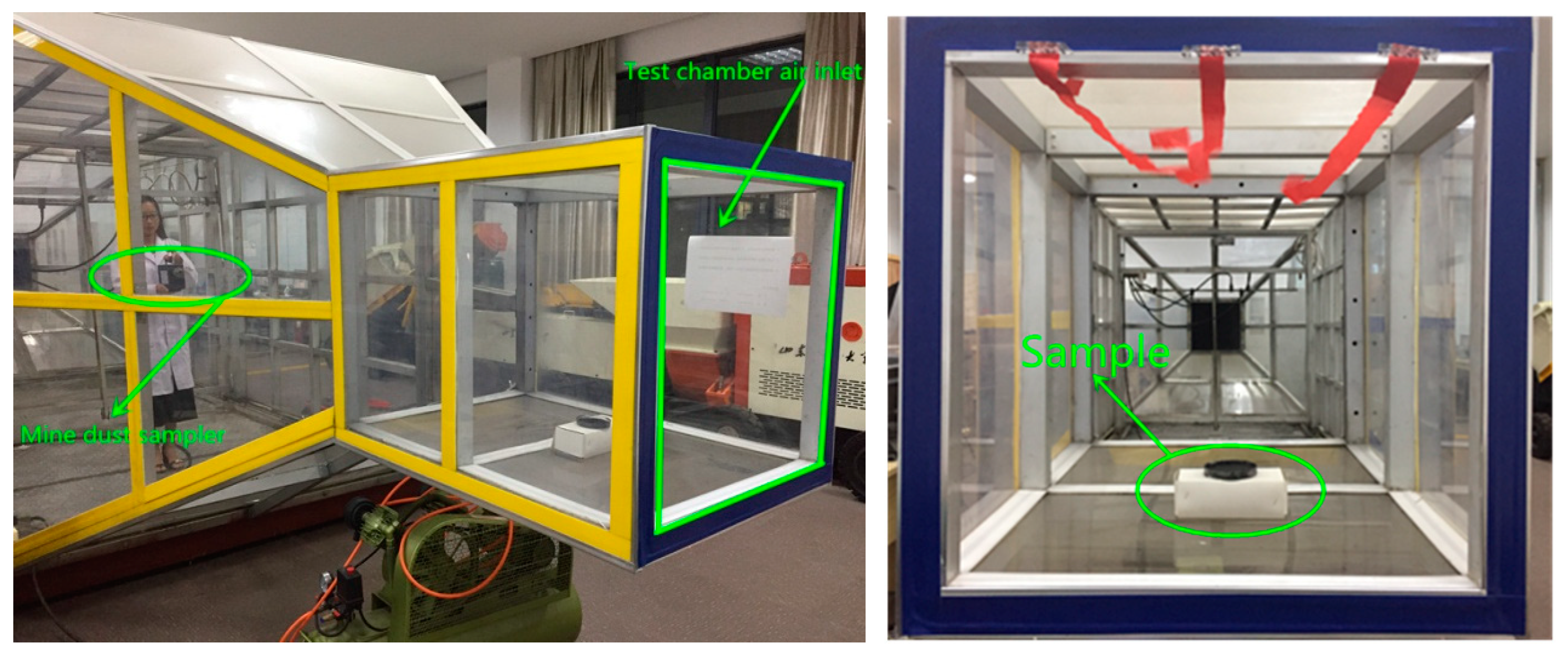

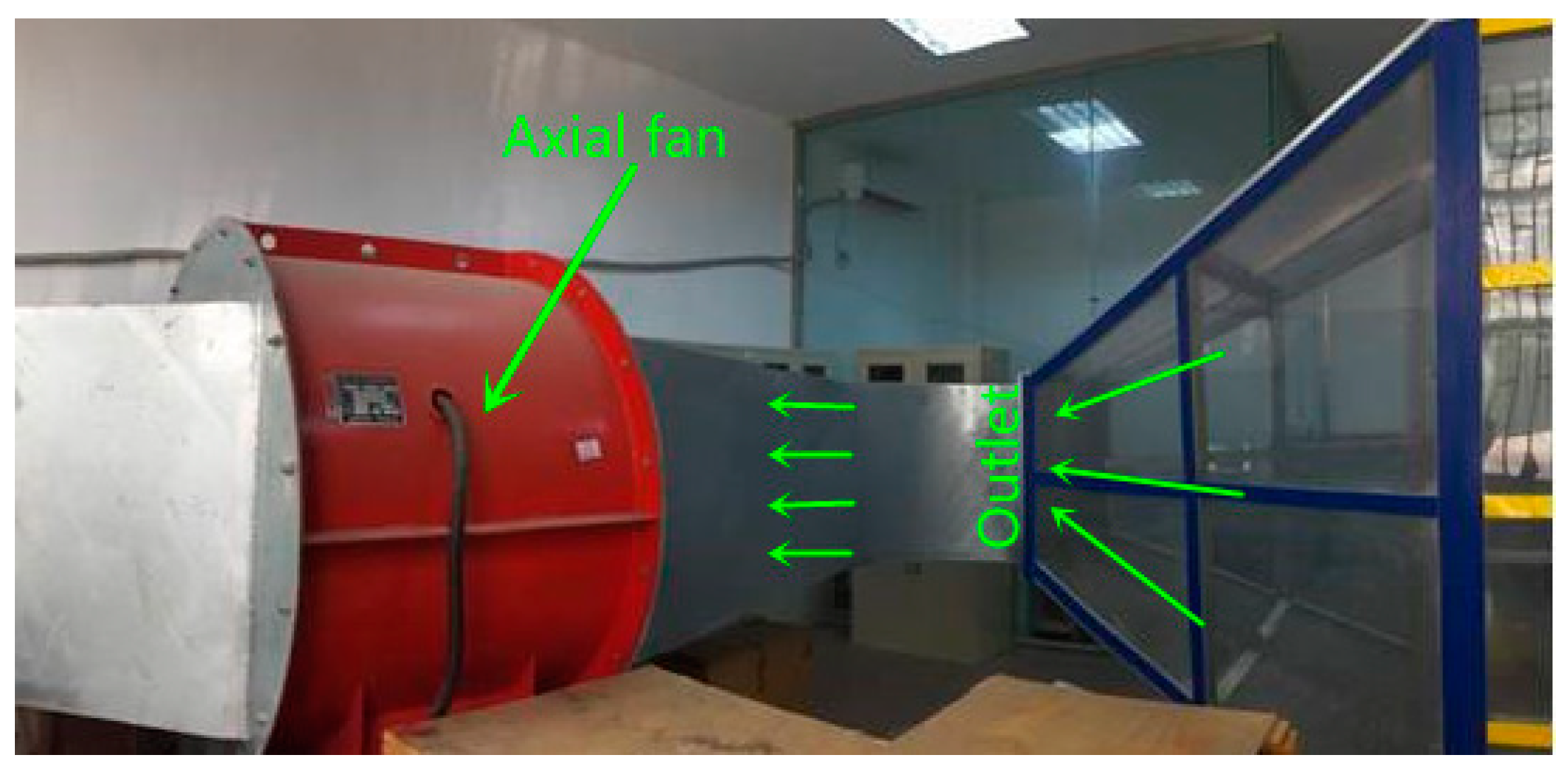

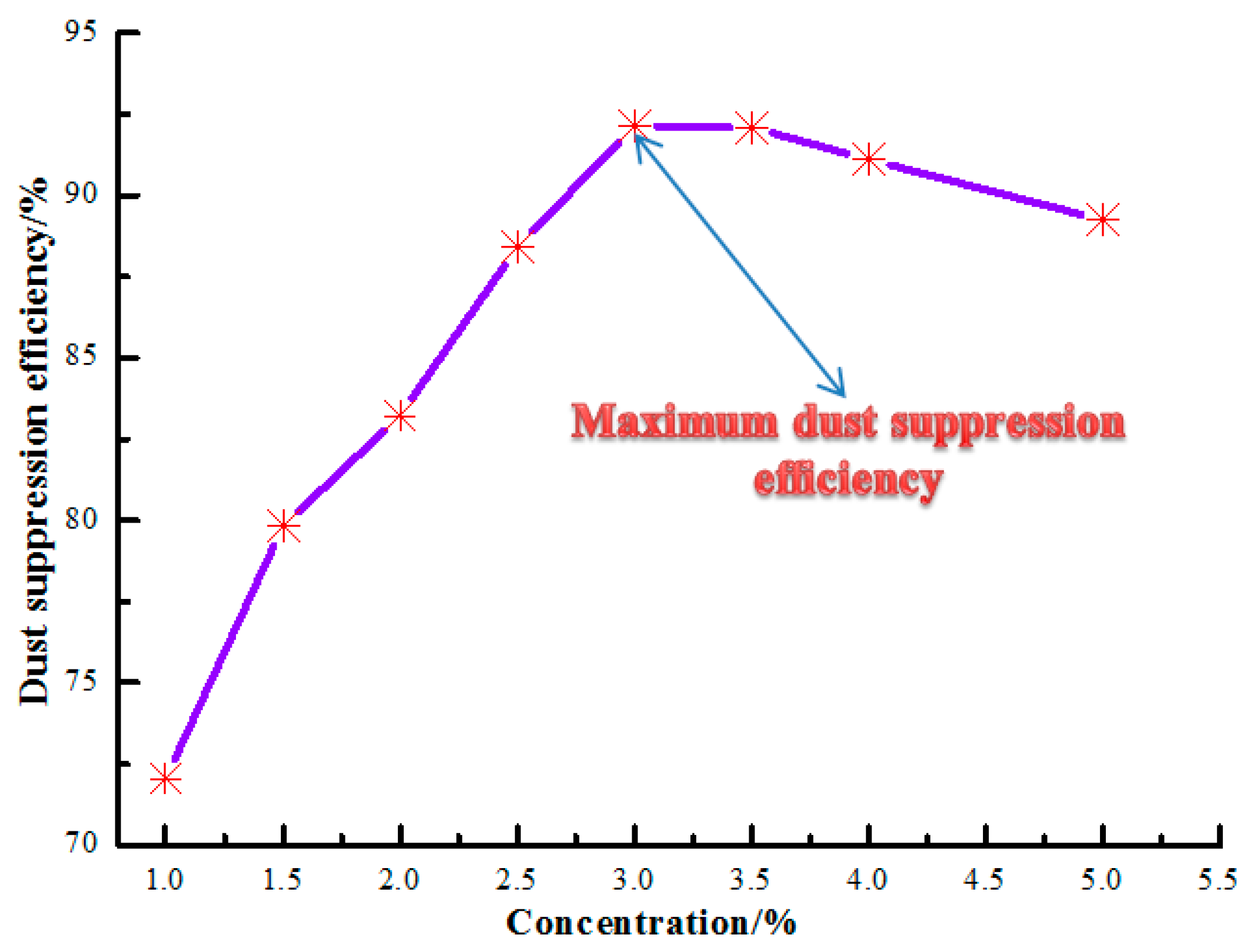

3.3. Measurement of Dust Suppression Efficiency

4. Analysis of Dust Suppression Mechanism

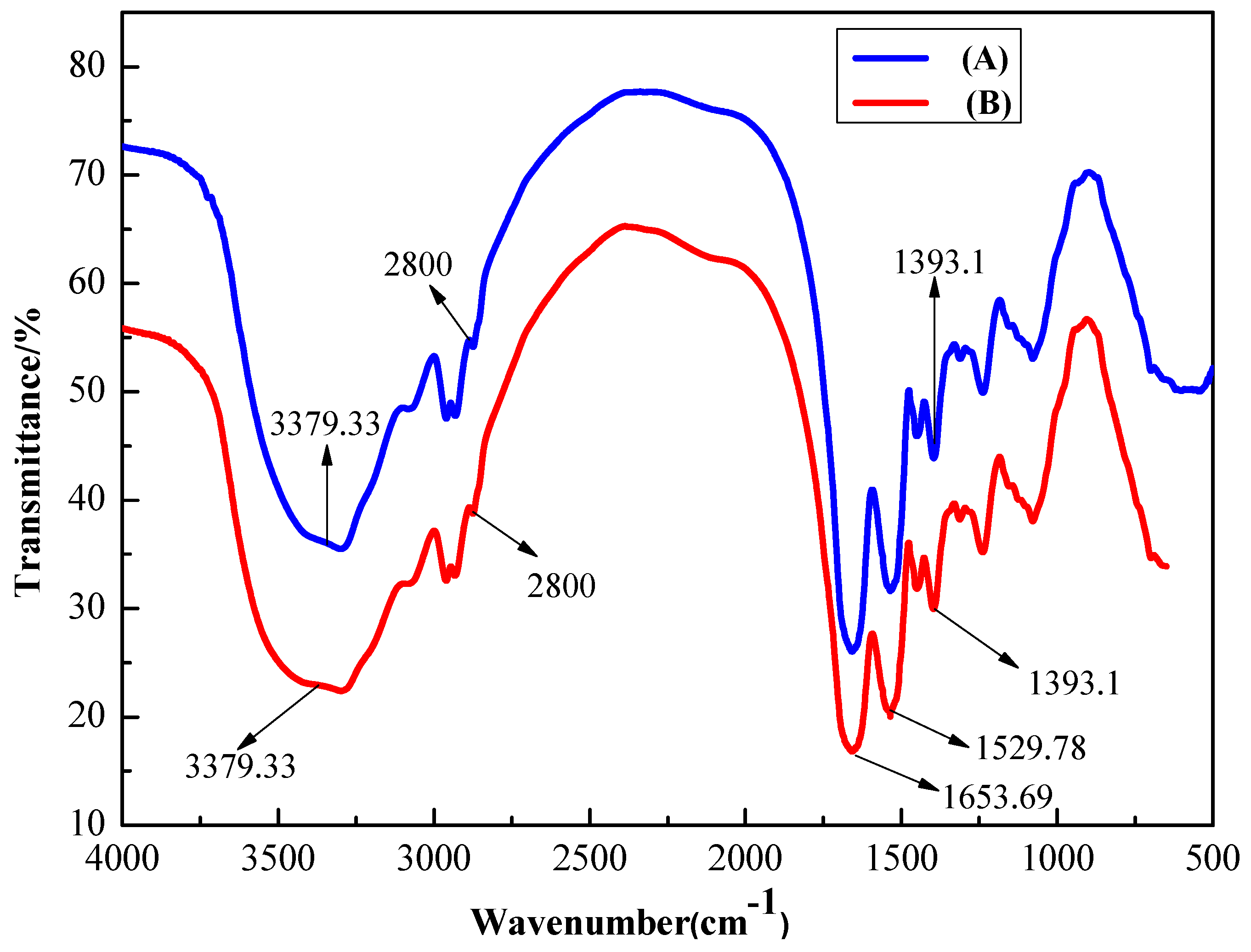

4.1. Infrared Spectra Tests

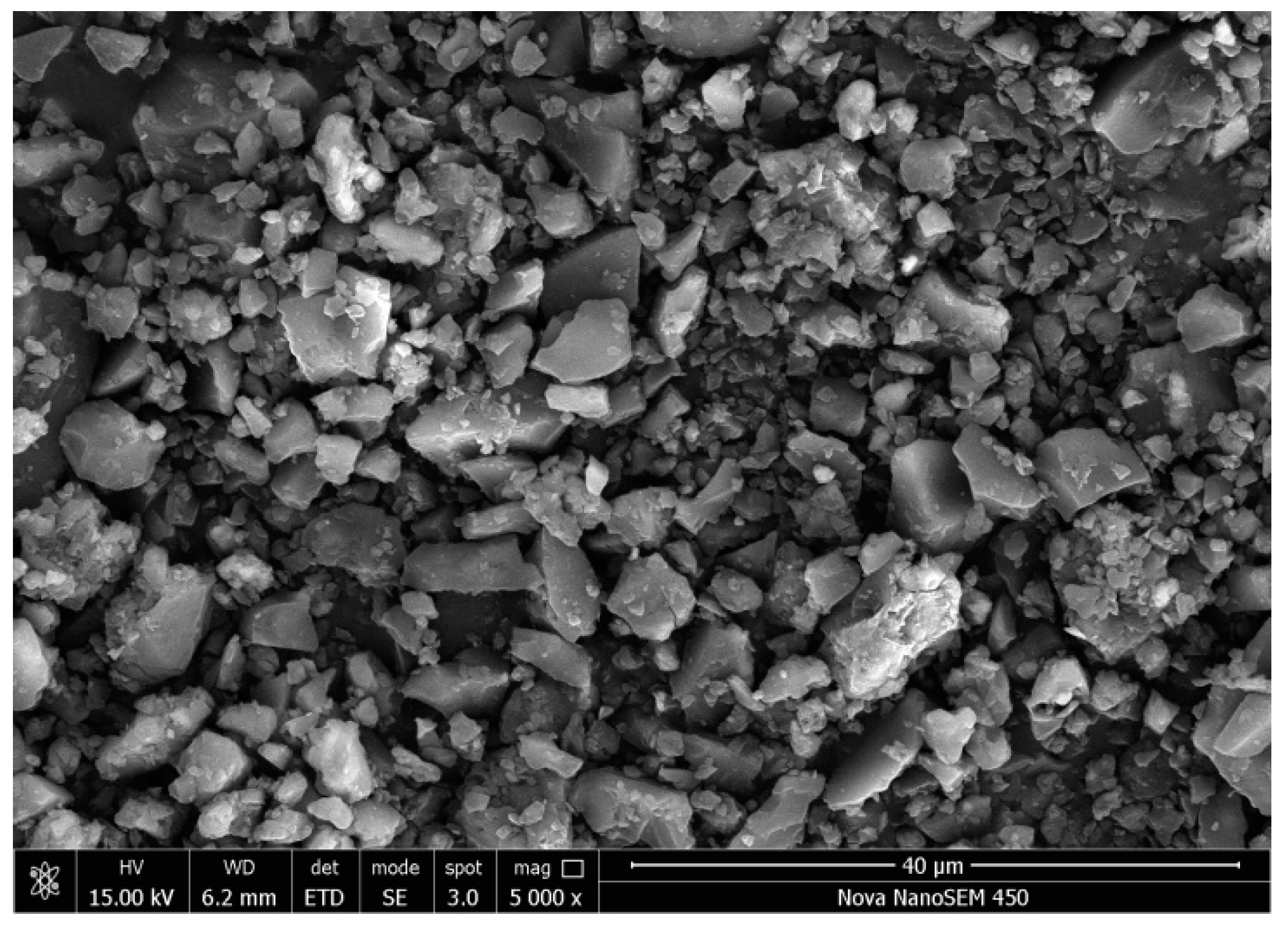

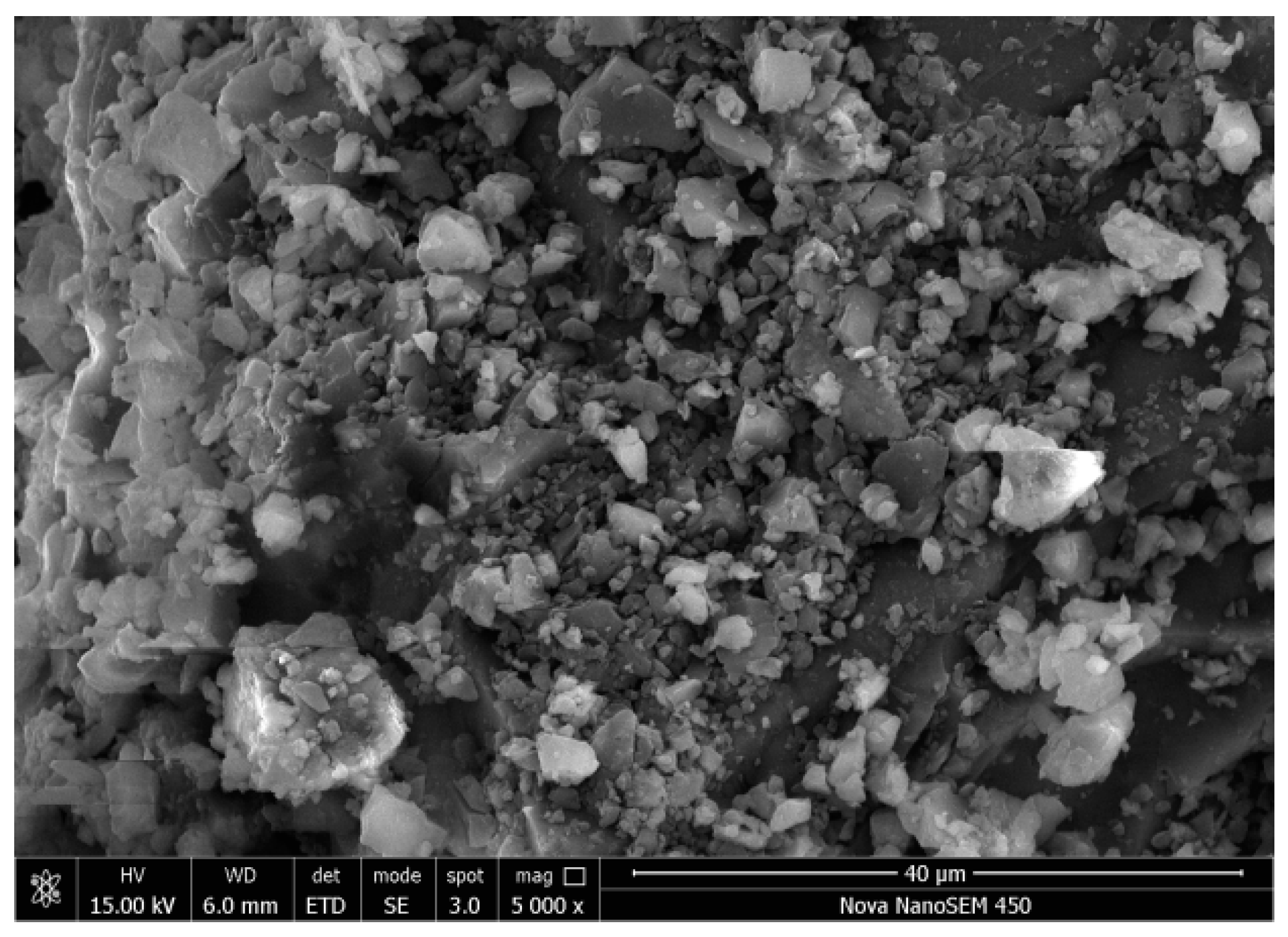

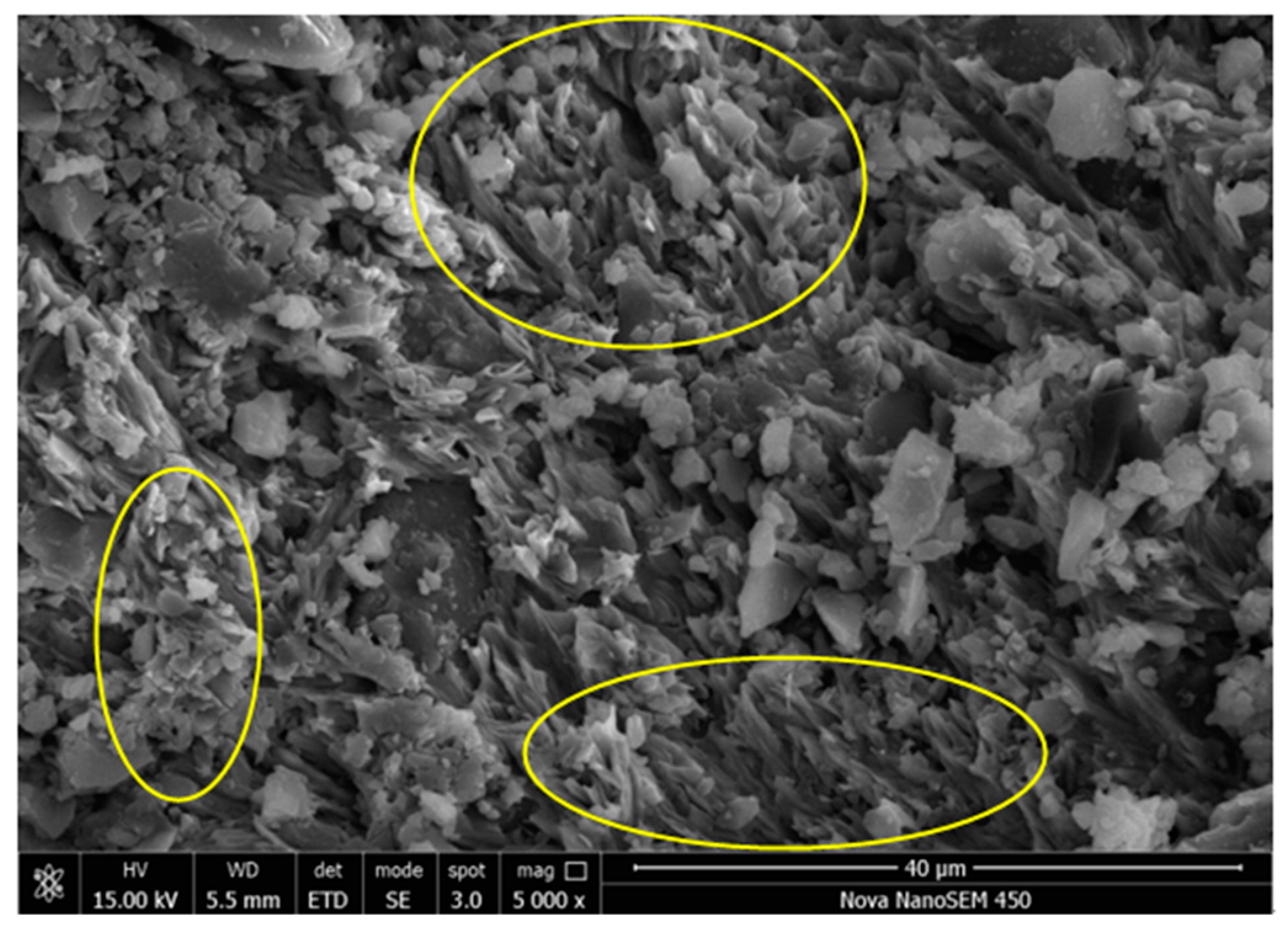

4.2. Scanning Electron Microscope (SEM) Experiments

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hattori, T.; Matsuda, M.; Miyake, M. Resource recovery of cupola dust: Study on sorptive property and mechanism for hydrogen sulfide. J. Mater. Sci. 2006, 12, 3701–3706. [Google Scholar] [CrossRef]

- Wang, Y.X.; Guo, P.P.; Dai, F.; Li, X.; Zhao, Y.L.; Liu, Y. Behavior and modeling of fiber-reinforced clay under triaxial compression by combining the superposition method with the energy-based homogenization technique. Int. J. Geomech. 2018, 18. [Google Scholar] [CrossRef]

- Cheng, W.M.; Nie, W.; Zhou, G.; Yu, Y.B.; Ma, Y.Y.; Xue, J. Research and practice on fluctuation water injection technology at low permeability coal seam. Saf. Sci. 2012, 50, 851–856. [Google Scholar] [CrossRef]

- Cai, P.; Nie, W.; Chen, D.W.; Yang, S.B.; Liu, Z.Q. Effect of air flowrate on pollutant dispersion pattern of coal dust particles at fully mechanized mining face based on numerical simulation. Fuel 2019, 239, 623–635. [Google Scholar] [CrossRef]

- Wang, Y.X.; Guo, P.P.; Li, X.; Lin, H.; Liu, Y.; Yuan, H.P. Behavior of Fiber-Reinforced and Lime-Stabilized Clayey Soil in Triaxial Tests. Appl. Sci. 2019, 9, 900. [Google Scholar] [CrossRef]

- Peng, X.L.; Wu, C. New advances in chemical dust suppressants. J. Saf. Sci. Technol. 2005, 5, 44–47. [Google Scholar]

- Cai, J.X.; Dong, B.; Li, Y.Q. New Experimental Research dust suppressants in Bulk coal yard Applicability. Mine Environ. Prot. 2011, 21, 71–73. [Google Scholar]

- Wang, Y.X.; Guo, P.P.; Ren, W.X.; Yuan, B.X.; Yuan, H.P.; Zhao, Y.L.; Shan, S.B.; Cao, P. Laboratory investigation on strength characteristics of expansive soil treated with jute fiber reinforcement. Int. J. Geomech. 2017, 17. [Google Scholar] [CrossRef]

- Yang, S.B.; Nie, W.; Liu, Z.Q.; Peng, H.T.; Cai, P. Effects of spraying pressure and installation angle of nozzles on atomization characteristics of external spraying system at a fully-mechanized mining face. Powder Technol. 2019, 343, 754–764. [Google Scholar] [CrossRef]

- Yuan, B.X.; Sun, M.; Wang, Y.X.; Zhai, L.H.; Luo, Q.; Zhang, X. Full 3D displacement measuring system for 3D displacement field of soil around a laterally loaded pile in transparent soil. Int. J. Geomech. 2019, 19, 04019028. [Google Scholar] [CrossRef]

- Zhang, H.H.; Nie, W.; Liu, Y.H.; Wang, H.K.; Jin, H.; Bao, Q. Synthesis and performance measurement of environment-friendly solidified dust suppressant for open pit coalmine. J. Appl. Polym. Sci. 2018, 135, 46505. [Google Scholar] [CrossRef]

- Nie, W.; Ma, X.; Cheng, W.M.; Liu, Y.H.; Xin, L.; Peng, H.T.; Wei, W.L. A novel spraying/negative-pressure secondary dust suppression device used in fully mechanized mining face: A case study. Saf. Environ. 2016, 103, 126–135. [Google Scholar] [CrossRef]

- Cheng, W.M.; Liu, W.; Nie, W.; Zhou, G.; Cui, X.F.; Sun, X. The Prevention and Control Technology of Dusts in Heading and Winning Faces and Its Development Tendency. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2010, 4, 77–82. [Google Scholar]

- Cai, P.; Nie, W.; Hua, Y.; Wei, W.L.; Jin, H. Diffusion and pollution of multi-source dusts in a fully mechanized coal face. Process. Saf. Environ. 2018, 118, 93–105. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.Y.; Qi, C.C.; Zhang, B.; Guo, L.J.; Song, K.-I. Numerical study on the pipe flow characteristics of the cemented paste backfill slurry considering hydration effects. Powder Technol. 2019, 343, 454–464. [Google Scholar] [CrossRef]

- Wang, M.; Liu, L.; Zhang, X.Y.; Liu, C.; Wang, S.Q.; Jia, Y.H. Experimental and numerical investigations of heat transfer and phase change characteristics of cemented paste backfill with PCM. Appl. Therm. Eng. 2019, 150, 121–131. [Google Scholar] [CrossRef]

- Liu, X.S.; Tan, Y.L.; Ning, J.G.; Lu, Y.W.; Gu, Q.H. Mechanical properties and damage constitutive model of coal in coal-rock combined body. Int. J. Rock Mech. Min. 2018, 110, 140–150. [Google Scholar] [CrossRef]

- Wang, H.T.; Wang, D.M.; Wang, Q.G.; Jia, Z.Q. Novel Approach for Suppressing Cutting Dust Using Foam on a Fully Mechanized Face with Hard Parting. J. Occup. Environ. Hyg. 2013, 3, 154–164. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.Y.; Feng, R.; Ren, X.Y.; Xu, G.; Chang, P.; Wang, Z.; Zhang, Y.T.; Li, Z.; Gao, Q. Numerical study of gas-solid two-phase flow in a coal roadway after blasting. Adv. Powder Technol. 2016, 4, 1607–1617. [Google Scholar] [CrossRef]

- Wang, H.T.; Wang, D.M.; Ren, W.X.; Lu, X.; Han, F.W.; Zhang, Y.K. Application of foam to suppress rock dust in a large cross-section rock roadway driven with roadheader. Adv. Powder Technol. 2012, 1, 257–262. [Google Scholar] [CrossRef]

- Hu, S.Y.; Wang, Z.; Feng, G.R. Temporal and Spatial Distribution of Respirable Dust After Blasting of Coal Roadway Driving Faces: A Case Study. Minerals 2015, 4, 679–692. [Google Scholar] [CrossRef]

- Wang, H.; Nie, W.; Cheng, W.M.; Liu, Q.; Jin, H. Effects of air volume ratio parameters on air curtain dust suppression in a rock tunnel’s fully-mechanized working face. Adv. Powder Technol. 2018, 29, 230–244. [Google Scholar] [CrossRef]

- Wang, Y.X.; Guo, P.P.; Lin, H.; Li, X.; Zhao, Y.L.; Yuan, B.X.; Liu, Y.; Cao, P. Numerical Analysis of Fiber-Reinforced Soils based on the Equivalent Additional Stress Concept. Int. J. Geomech. 2019, in press. [Google Scholar]

- Liu, Q.; Nie, W.; Hua, Y.; Peng, H.T.; Liu, C.Q.; Wei, C.H. Research on tunnel ventilation systems: Dust diffusion and pollution behaviour by air curtains based on CFD technology and field measurement. Build. Environ. 2019, 147, 444–460. [Google Scholar] [CrossRef]

- Wang, Q.G.; Wang, D.M.; Wang, H.T.; Han, F.W.; Zhu, X.L.; Tang, Y.; Si, W.B. Optimization and implementation of a foam system to suppress dust in coal mine excavation face. Process Saf. Environ. 2015, 96, 184–190. [Google Scholar] [CrossRef]

- Han, F.W.; Liu, J. Flow field characteristics and coal dust removal performance of an arc fan nozzle used for water spray. PLoS ONE 2018, 13, 0203875. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Gao, W.; Zhang, P.; Yan, H.J.; Ren, C.S. Study of the Characteristics of DC and ICP Hybrid Discharge Plasmas. Plasma Sci. Technol. 2015, 3, 191–195. [Google Scholar] [CrossRef]

- Lyu, X.J.; You, X.F.; He, M.; Zhang, W.; Wei, H.B.; Li, L.; He, Q. Adsorption and molecular dynamics simulations of nonionic surfactant on the low rank coal surface. Fuel 2018, 211, 529–534. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.Y.; Wu, Y.P.; Lai, X.P.; Wang, P.; Song, K.-I. Experimental investigation of solid-liquid two-phase flow in cemented rock-tailings backfill using Electrical Resistance Tomography. Constr. Build. Mater. 2018, 175, 267–276. [Google Scholar] [CrossRef]

- Nie, W.; Peng, H.T.; Jin, H.; Liu, Y.H.; Wei, W.L. The effect of spray pressure on atomization characteristics of external spray nozzle on coal mining machine. J. Chin. Univ. Min. Technol. 2017, 46, 41–47. [Google Scholar]

- Wang, H.T.; He, S.; Xie, G.R.; Chen, X.Y.; Qin, B.T. Study of the mechanism by which magnetization reduces dust suppressant usage. Colloids Surf. A 2018, 558, 16–22. [Google Scholar] [CrossRef]

- Liu, Y.H.; Nie, W.; Jin, H.; Ma, H.; Hua, Y.; Cai, P.; Wei, W.L. Solidifying dust suppressant based on modified chitosan and experimental study on its dust suppression performance. Adsorpt. Sci. Technol. 2018, 36, 640–654. [Google Scholar] [CrossRef]

- Yuan, Q.H.; Xu, X.J.; Liu, Q.; Zhang, X.J. Medium Consumption Control in Dense Medium Coal Preparation Plant Based on Response Surface Methodology. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2018, 37, 11–21. [Google Scholar] [CrossRef]

- Kong, B.; Li, Z.H.; Wang, E.Y.; Liu, W.; Chen, L.; Qi, G.S. An experimental study for characterization the process of coal oxidation and spontaneous combustion by electromagnetic radiation technique. Process Saf. Environ. 2018, 119, 285–294. [Google Scholar] [CrossRef]

- Ding, Y.M.; Ezekoye, O.A.; Zhang, J.Q.; Wang, C.J.; Lu, S.X. The effect of chemical reaction kinetic parameters on the bench-scale pyrolysis of lignocellulosic biomass. Fuel 2018, 232, 147–153. [Google Scholar] [CrossRef]

- Cheng, W.M.; Liu, Z.; Yang, H.; Wang, W.Y. Non-linear Seepage Characteristics and Influential Factors of Water Injection in Gassy Seams. Exp. Therm. Fluid Sci. 2018, 91, 41–53. [Google Scholar] [CrossRef]

- Yang, J.; Liu, D.D.; Zhu, X.L.; Fang, X.M. Research progress of chemical dust suppression agent. Chemistry 2013, 4, 346–353. [Google Scholar]

- Sa, Z.Y.; Liu, J.; Liu, J.Z.; Zhang, Y.J. Research on effect of gas pressure in the development process of gassy coal extrusion. Saf. Sci. 2019, 115, 28–35. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, M.Y.; Zhao, S.S.; Liu, Y.Y.; Yang, J. Synthesis and Modification of Hyperbranched Polyester Dust Suppressant. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2018, 37, 26–34. [Google Scholar] [CrossRef]

- Nie, W.; Peng, H.T.; Liu, Y.H.; Ma, X.; Wei, W.L. Experimental Research on the Coupling and Settlement of Droplets and Dust Particles Influenced by Airflow. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2016, 35, 30–36. [Google Scholar] [CrossRef]

- Kong, B.; Wang, E.Y.; Li, Z.H. The effect of high temperature environment on rock properties—An example of electromagnetic radiation characterization. Environ. Sci. Pollut. R. 2018, 25, 29104–29114. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Yang, H.; Wang, W.Y.; Cheng, W.M.; Xin, L. Experimental Study on the Pore Structure Fractals and Seepage Characteristics of a Coal Sample Around a Borehole in Coal Seam Water Infusion. Transp. Porous Med. 2018, 125, 289–309. [Google Scholar] [CrossRef]

- Bao, Q.; Nie, W.; Liu, C.Q.; Liu, Y.H.; Zhang, H.H.; Wang, H.K.; Jin, H. Preparation and characterization of a binary-graft-based, water-absorbing dust suppressant for coal transportation. J. Appl. Polym. Sci. 2018, 136, 47065. [Google Scholar] [CrossRef]

- Grogan, R. Mixtures, Compositions, and Methods of Using and Preparing Same. Patent US 20090269499, 29 October 2009. [Google Scholar]

- Zhang, L.B.; Jiao, J.; Zhao, X.Y.; Zhang, J.; Zou, D.; Ji, Y.; Shan, C. Study on preparation and properties of eco-friendly dust suppressant. Trans. Chin. Soc. Agric. Eng. 2013, 18, 218–225. [Google Scholar]

- Zhang, H.H.; Nie, W.; Wang, H.K.; Bao, Q.; Jin, H.; Liu, Y.H. Preparation and experimental dust suppression performance characterization of a novel guar gum-modification-based environmentally-friendly degradable dust suppressant. Powder Technol. 2018, 339, 314–325. [Google Scholar] [CrossRef]

- Yang, J.; Wang, K.; Fang, X.M. The Preparation and Performance Test of a New Coal Dust Depressor. Saf. Coal Mines 2009, 5, 21–24. [Google Scholar]

- Polat, H.; Chander, S. Adsorption of PEO/PPO Triblock Co-polymers and Wetting of Coal. Colloids Surf. A Physicochem. Eng. Asp. 1999, 1, 199–212. [Google Scholar] [CrossRef]

- Zhou, Q.; Qin, B.T.; Wang, J.; Wang, H.T.; Wang, F. Experimental investigation on the changes of the wettability and surface characteristics of coal dust with different fractal dimensions. Colloids Surf. A 2018, 551, 148–157. [Google Scholar] [CrossRef]

- Liu, Q.; Nie, W.; Hua, Y.; Peng, H.T.; Liu, Z.Q. The effects of the installation position of a multi-radial swirling air-curtain generator on dust diffusion and pollution rules in a fully-mechanized excavation face: A case study. Powder Technol. 2018, 329, 371–385. [Google Scholar] [CrossRef]

- Liu, Y.H.; Nie, W.; Mu, Y.B.; Zhang, H.H.; Wang, H.K.; Jin, H.; Liu, Z.Q. A synthesis and performance evaluation of a highly efficient ecological dust depressor based on the sodium lignosulfonate–acrylic acid graft copolymer. RSC Adv. 2018, 8, 11498–11508. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhang, L.Y.; Wang, W.J.; Wan, W.; Li, S.Q.; Ma, W.H.; Wang, Y.X. Creep behavior of intact and cracked limestone under multi-level loading and unloading cycles. Rock Mech. Rock Eng. 2017, 50, 1409–1424. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.Y.; Qi, C.C.; Zhang, B.; Guo, L.J.; Song, K.-I. Experimental investigation on the relationship between pore characteristics and unconfined compressive strength of cemented paste backfill. Constr. Build. Mater. 2018, 179, 254–264. [Google Scholar] [CrossRef]

- Qin, B.T.; Dou, G.L.; Zhong, X.X. Effect of stannous chloride on low-temperature oxidation reaction of coal. Fuel Process. Technol. 2018, 176, 59–63. [Google Scholar] [CrossRef]

- Li, L.; Qin, B.T.; Ma, D.; Zhuo, H.; Liang, H.J.; Gao, A. Unique spatial methane distribution caused by spontaneous coal combustion in coal mine goafs: An experimental study. Process Saf. Environ. 2018, 116, 199–207. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Li, R.Y.; Ji, C.F.; Huan, C.; Zhang, B.; Liu, L. Parametric study and design of an earth air heat exchanger using model experiment for memorial heating and cooling. Appl. Therm. Eng. 2019, 148, 838–845. [Google Scholar] [CrossRef]

- Liu, X.S.; Gu, Q.H.; Tan, Y.L.; Ning, J.G.; Jia, Z.C. Mechanical Characteristics and Failure Prediction of Cement Mortar with a Sandwich Structure. Minerals 2019, 9, 143. [Google Scholar] [CrossRef]

- Nie, W.; Liu, Y.H.; Wang, H.; Wei, W.L.; Peng, H.T.; Cai, P.; Hua, Y.; Jin, H. The development and testing of a novel external-spraying injection dedusting device for the heading machine in a fully-mechanized excavation face. Process Saf. Environ. 2017, 109, 716–731. [Google Scholar] [CrossRef]

- Nie, W.; Wei, W.L.; Ma, X.; Liu, Y.H.; Peng, H.T.; Liu, Q. The effects of ventilation parameters on the migration behaviors of head-on dusts in the heading face. Tunn. Undergr. Space Technol. 2017, 70, 400–408. [Google Scholar] [CrossRef]

- Hua, Y.; Nie, W.; Wei, W.L.; Liu, Q.; Liu, Y.H.; Peng, H.T. Research on multi-radial swirling flow for optimal control of dust dispersion and pollution at a fully mechanized tunnelling face. Tunn. Undergr. Space Technol. 2018, 79, 293–303. [Google Scholar] [CrossRef]

- Dimech, C.C.; Cheeseman, R.; Cook, S.; Simon, J.; Boccaccini, A.R. Production of sintered materials from air pollution control residues from waste incineration. J. Mater. Sci. 2008, 12, 4143–4151. [Google Scholar] [CrossRef]

- Li, T.Y.; Wang, N.; Fang, Q.H. Incorporation of modified soy protein isolate as filier in BR/SBR blends. J. Mater. Sci. 2010, 7, 1904–1911. [Google Scholar] [CrossRef]

- Zhong, X.X.; Qin, B.T.; Dou, G.L.; Xia, C.; Wang, F. A chelated calcium-procyanidine-attapulgite composite inhibitor for the suppression of coal oxidation. Fuel 2017, 217, 680–688. [Google Scholar] [CrossRef]

- Nie, W.; Wei, W.L.; Cai, P.; Liu, Z.Q.; Liu, Q.; Ma, H.; Liu, H.J. Simulation experiments on the controllability of dust diffusion by means of multi-radial vortex airflow. Adv. Powder Technol. 2018, 29, 835–847. [Google Scholar] [CrossRef]

- Wang, Y.X.; Lin, H.; Zhao, Y.L.; Li, X.; Guo, P.P.; Liu, Y. Analysis of fracturing characteristics of unconfined rock plate under edge on impact loading. Eur. J. Environ Civ. Eng. 2019. [Google Scholar] [CrossRef]

- Peng, H.T.; Nie, W.; Cai, P.; Liu, Q.; Liu, Z.Q.; Yang, S.B. Development of a novel wind-assisted centralized spraying dedusting device for dust suppression in a fully mechanized mining face. Environ. Sci. Pollut. Res. 2018. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.W.; Nie, W.; Cai, P.; Liu, Z.Q. The diffusion of dust in a fully-mechanized mining face with a mining height of 7 m and the application of wet dust-collecting nets. J. Clean. Prod. 2018, 205, 463–476. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Luo, S.L.; Wang, Y.X.; Wang, W.J.; Zhang, L.Y.; Wan, W. Numerical Analysis of Karst Water Inrush and a Criterion for Establishing the Width of Water-resistant Rock Pillars. Mine Water Environ. 2017, 36, 508–519. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, C.; Qi, C.C.; Zhang, B.; Song, K.-I. A microstructural hydration model for cemented paste backfill considering internal sulfate attacks. Constr. Build. Mater. 2019, in press. [Google Scholar]

- Kim, J.R.; Netravali, A.N. Parametric study of protein-encapsulated microcapsule formation and effect on self-healing efficiency of ‘green’ soy protein resin. J. Mater. Sci. 2017, 6, 3028–3047. [Google Scholar] [CrossRef]

- Jin, H.; Nie, W.; Zhang, H.H.; Liu, Y.H.; Bao, Q.; Wang, H.K. The Preparation and Characterization of a Novel Environmentally-Friendly Coal Dust Suppressant. J. Appl. Polym. Sci. 2018, 136, 47354. [Google Scholar] [CrossRef]

- Liu, C.Q.; Nie, W.; Bao, Q.; Liu, Q.; Wei, C.H.; Hua, Y. The effects of the pressure outlet’s position on the diffusion and pollution of dust in tunnel using a shield tunneling machine. Energy Build. 2018, 176, 232–245. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Tang, J.Z.; Chen, Y.; Zhang, L.Y.; Wang, W.J.; Liao, J.P. Hydromechanical coupling tests for mechanical and permeability characteristics of fractured limestone in complete stress–strain process. Environ. Earth Sci. 2017, 76, 1–18. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Zhang, Z.H.; Ji, C.F.; Liu, L.; Zhang, B.; Huan, C. Characterization of particulate matter from heating and cooling several edible oils. Build. Environ. 2019, 152, 204–213. [Google Scholar] [CrossRef]

- Ding, Y.M.; Zhou, R.; Wang, C.J.; Lu, K.H.; Lu, S.X. Modeling and analysis of bench-scale pyrolysis of lignocellulosic biomass based on merge thickness. Bioresour. Technol. 2018, 268, 77–80. [Google Scholar] [CrossRef] [PubMed]

- Luo, R.D.; Lin, M.S.; Luo, Y.B.; Dong, J.F. Preparation and properties of a new type of coal dust suppressant. J. Chin. Coal Soc. 2016, 41, 454. [Google Scholar] [CrossRef]

- Wei, Q.H.; Tong, L.; Chen, N.L.; Lin, Q.J. Adhesive properties of a soy-based wood adhesive using sodium dodecyl sulfate. J. Zhejiang For. Coll. 2008, 6, 772–776. [Google Scholar]

- Hua, Y.; Nie, W.; Cai, P.; Liu, Y.H.; Peng, H.T.; Liu, Q. Pattern characterization concerning spatial and temporal evolution of dust pollution associated with two typical ventilation methods at fully mechanized excavation faces in rock tunnels. Powder Technol. 2018, 334, 117–131. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Wang, Y.X.; Wang, W.; Tang, L.; Liu, Q.; Cheng, G. Modeling of rheological fracture behavior of rock cracks subjected to hydraulic pressure and far field stresses. Theor. Appl. Fract. Mech. 2019. [Google Scholar] [CrossRef]

- Qi, C.C.; Chen, Q.S.; Fourie, A.; Tang, X.L.; Zhang, Q.L.; Dong, X.J.; Feng, Y. Constitutive modelling of cemented paste backfill: A data-mining approach. Constr. Build. Mater. 2019, 197, 262–270. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Nie, W.; Peng, H.T.; Yang, S.B.; Chen, D.W.; Liu, Q. The effects of the spraying pressure and nozzle orifice diameter on the atomizing rules and dust suppression performances of an external spraying system in a fully-mechanized excavation face. Powder Technol. 2019, in press. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, R.; Song, D.Z.; Wang, Z.Q. Experimental investigation on occurrence of gassy coal extrusion in coalmine. Saf. Sci. 2019, 113, 362–371. [Google Scholar] [CrossRef]

| Chemical Name | Chemical Formula | Purity | Manufacturer |

|---|---|---|---|

| Soybean protein isolate | C13H10N2 | BR | Sinopharm Chemical Reagent Co., Ltd., Beijing, China |

| Carboxymethylcellulose sodium | C8H11O7Na | CP | Xiya Reagent Co., Ltd., Chengdu, China |

| Methanesiliconic acid sodium | CH5SiO3Na | CP | Shandong Yousuo Chemical Technology Co., Ltd., Qingdao, China |

| Sodium dodecyl sulfonate | C12H25OSO3Na | Tech | Shandong Yousuo Chemical Technology Co., Ltd., Qingdao, China |

| Experimental Equipment | Specifications | Manufacturer |

|---|---|---|

| Rotary viscometer | NDI-79 | Shanghai Precision Instrument Co., Ltd. Shanghai, China |

| High-Resolution Scanning Electron Microscope | Nova Nano SEM | Shanghai Casting Gold Analytical Instruments and Equipment Co., Ltd. Shanghai, China |

| Fourier-transform infrared spectroscope | Nicolet (iS10) | Beijing Kaifeng Fengyuan Technology Co., Ltd. Beijing, China |

| Coal mine dust sampler | AKFC-92 | Qingdao Lubo Weiye Environmental Protection Technology Co., Ltd. Qingdao, China |

| Mine energy-saving axialfan | ASZ-11.2 | Zibo Jinhe Fan Co., Ltd. Zibo, China |

| Sample (%) | Time (h) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | |

| water | 0.062 | 0.055 | 0.051 | 0.042 | 0.038 | 0.023 | 0.015 | 0.012 | 0.008 | 0.008 | 0.005 | 0.005 |

| 1 | 0.058 | 0.052 | 0.047 | 0.039 | 0.035 | 0.021 | 0.013 | 0.013 | 0.008 | 0.007 | 0.003 | 0.003 |

| 1.5 | 0.045 | 0.042 | 0.036 | 0.034 | 0.028 | 0.021 | 0.012 | 0.009 | 0.009 | 0.007 | 0.007 | 0.004 |

| 2 | 0.043 | 0.040 | 0.035 | 0.031 | 0.025 | 0.019 | 0.011 | 0.008 | 0.008 | 0.006 | 0.006 | 0.004 |

| 2.5 | 0.031 | 0.029 | 0.023 | 0.017 | 0.015 | 0.015 | 0.010 | 0.005 | 0.005 | 0.003 | 0.003 | 0.002 |

| 3 | 0.030 | 0.028 | 0.023 | 0.016 | 0.012 | 0.010 | 0.009 | 0.006 | 0.004 | 0.004 | 0.002 | 0.002 |

| 3.5 | 0.034 | 0.030 | 0.025 | 0.018 | 0.013 | 0.013 | 0.011 | 0.008 | 0.007 | 0.004 | 0.004 | 0.003 |

| 4 | 0.042 | 0.038 | 0.034 | 0.029 | 0.024 | 0.014 | 0.010 | 0.009 | 0.008 | 0.008 | 0.005 | 0.005 |

| 5 | 0.048 | 0.043 | 0.035 | 0.026 | 0.022 | 0.018 | 0.014 | 0.011 | 0.010 | 0.009 | 0.006 | 0.006 |

| Number | Concentration | |||||||

|---|---|---|---|---|---|---|---|---|

| 1% | 1.5% | 2% | 2.5% | 3% | 3.5% | 4% | 5% | |

| 1# | 3.68 | 6.20 | 10.20 | 13.28 | 16.20 | 19.40 | 22.48 | 21.84 |

| 2# | 3.48 | 6.76 | 10.72 | 12.84 | 16.76 | 20.84 | 21.80 | 22.72 |

| 3# | 3.04 | 7.20 | 9.56 | 12.76 | 16.60 | 20.72 | 20.64 | 22.88 |

| Average Viscosity (mPa·s) | 3.40 | 6.72 | 10.16 | 12.96 | 16.52 | 20.32 | 21.64 | 22.48 |

| Number | Concentration | |||||||

|---|---|---|---|---|---|---|---|---|

| 1% | 1.5% | 2% | 2.5% | 3% | 3.5% | 4% | 5% | |

| 1# | 1.80 | 3.40 | 5.01 | 6.32 | 8.52 | 10.29 | 11.36 | 12.21 |

| 2# | 1.92 | 3.48 | 5.27 | 6.59 | 8.31 | 10.35 | 11.44 | 12.38 |

| 3# | 1.64 | 3.32 | 5.08 | 7.01 | 8.61 | 10.44 | 11.64 | 12.61 |

| Average Viscosity (mPa·s) | 1.80 | 3.40 | 5.12 | 6.64 | 8.48 | 10.36 | 11.48 | 12.40 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, H.; Nie, W.; Zhang, Y.; Wang, H.; Zhang, H.; Bao, Q.; Yan, J. Development of Environmental Friendly Dust Suppressant Based on the Modification of Soybean Protein Isolate. Processes 2019, 7, 165. https://doi.org/10.3390/pr7030165

Jin H, Nie W, Zhang Y, Wang H, Zhang H, Bao Q, Yan J. Development of Environmental Friendly Dust Suppressant Based on the Modification of Soybean Protein Isolate. Processes. 2019; 7(3):165. https://doi.org/10.3390/pr7030165

Chicago/Turabian StyleJin, Hu, Wen Nie, Yansong Zhang, Hongkun Wang, Haihan Zhang, Qiu Bao, and Jiayi Yan. 2019. "Development of Environmental Friendly Dust Suppressant Based on the Modification of Soybean Protein Isolate" Processes 7, no. 3: 165. https://doi.org/10.3390/pr7030165

APA StyleJin, H., Nie, W., Zhang, Y., Wang, H., Zhang, H., Bao, Q., & Yan, J. (2019). Development of Environmental Friendly Dust Suppressant Based on the Modification of Soybean Protein Isolate. Processes, 7(3), 165. https://doi.org/10.3390/pr7030165