Evolutionary Observer Ensemble for Leak Diagnosis in Water Pipelines

Abstract

:1. Introduction

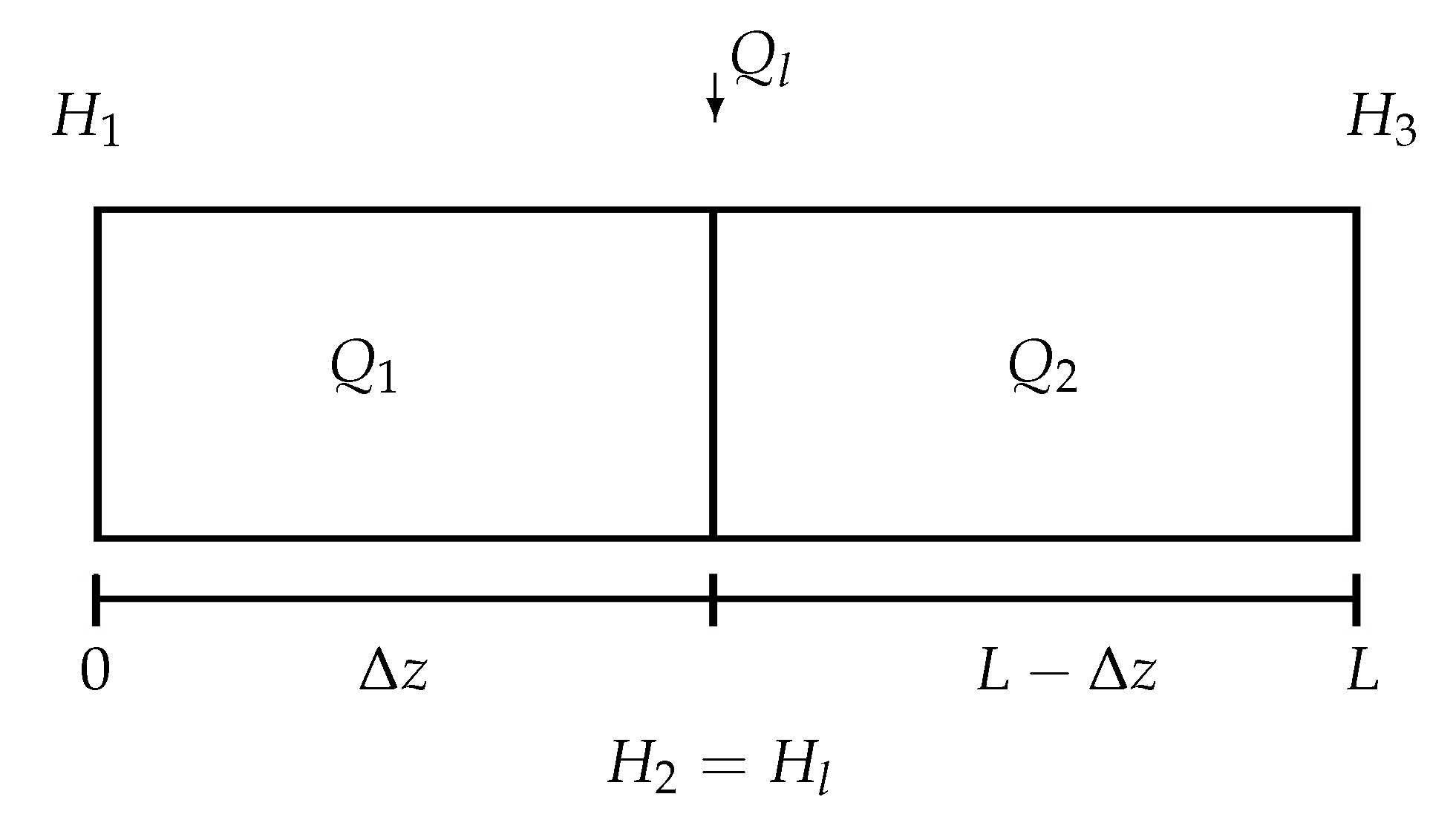

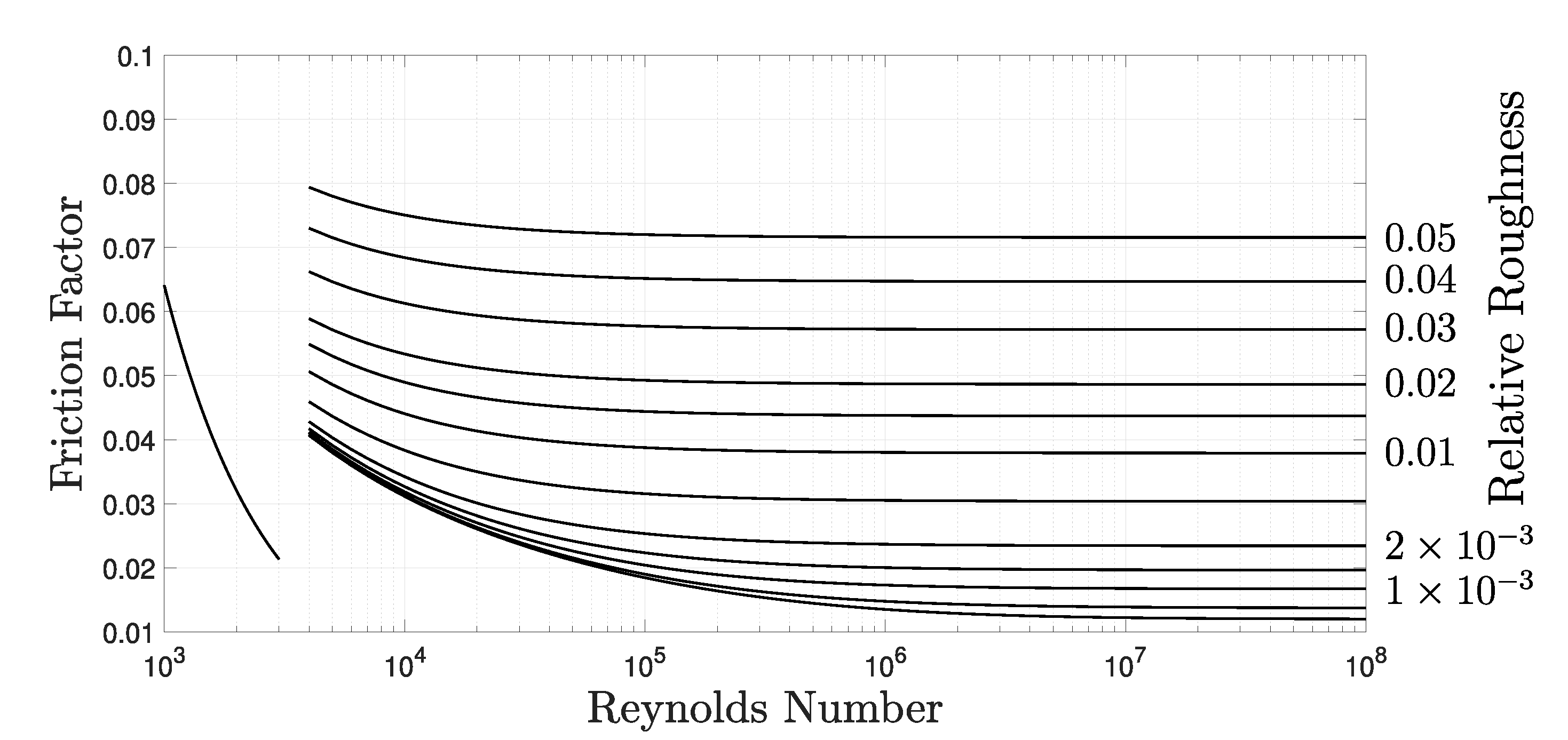

2. Pipeline Mathematical Model

Spatial Discretization of the Modeling Equations

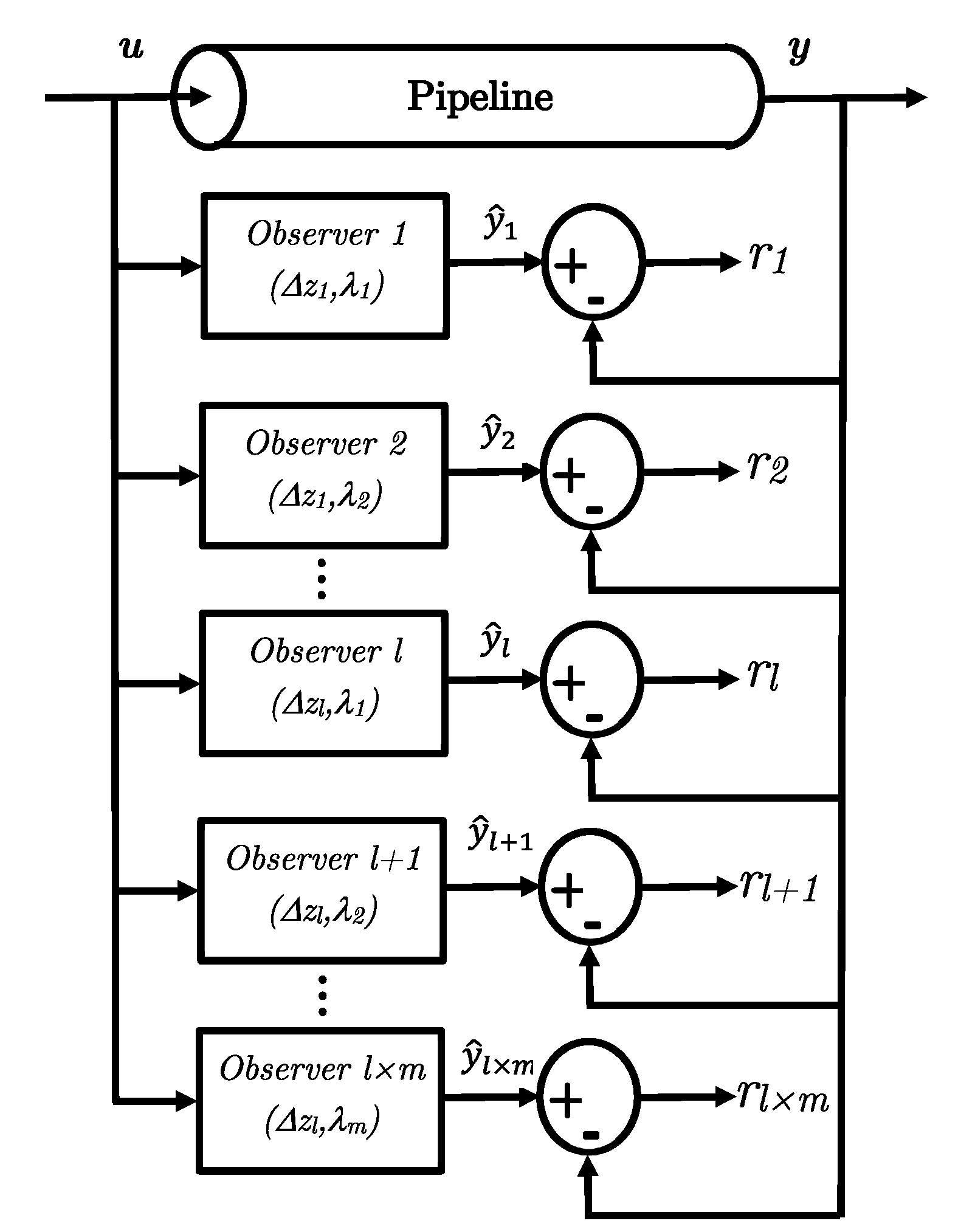

3. LDI Scheme Approach

3.1. Extended Luenberger Observer for MIMO Systems

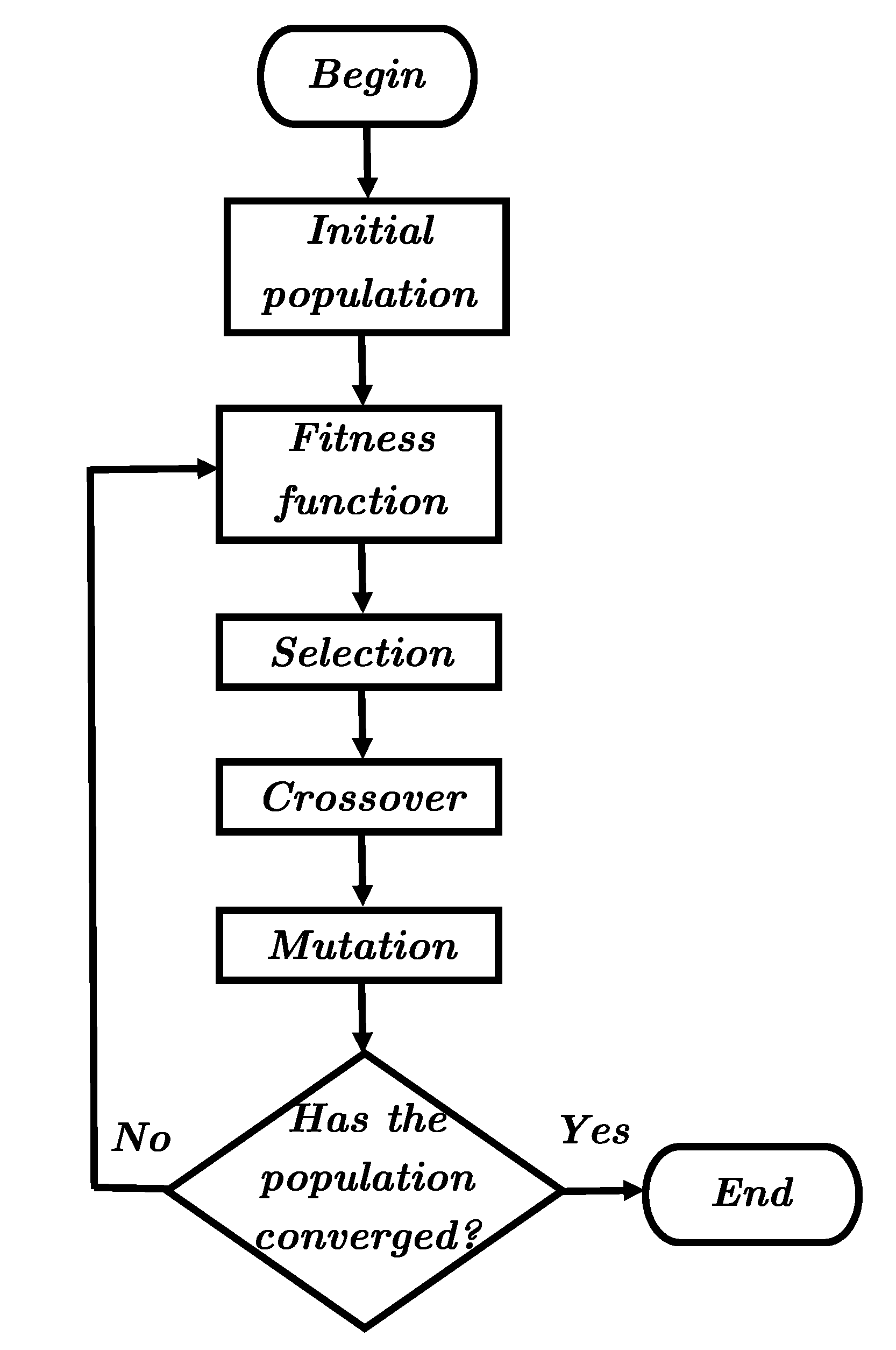

3.2. Genetic Algorithm

- Initial population. The first step of the process is to obtain a set of individuals randomly generated (initial population) in which each such individual is a candidate solution to a problem.As in the natural selection process, an individual is characterized by a set of parameters called genes. The solutions, known as chromosomes, are genes joined into a string.In a genetic algorithm, the chromosome is represented using a string in terms of an alphabet. Binary encoding (a string of ones and zeros) is the most common procedure to encode the genes in a chromosome.

- Fitness function. The fitness function defines how close an individual fits a solution and, in this way, determines which will reproduce and survive into the next generation. The fitness function provides a “fitness score” to each individual. Such “fitness score” settles the probability that an individual will be selected for reproduction.

- Selection. In this phase, the chromosomes in the population that more closely match the fitness function are selected. The solution (chromosome) that fits better during iteration is more likely to be selected to reproduce.

- Crossover. After the selection process, a recombination of the chromosomes is carried out in order to generate a new population for the next iteration. Crossover is applied to randomly pair strings and exchanges the sub-sequences before and after to create two offspring.

- Mutation. To preserve diversity within the population and prevent premature convergence, a mutation process is done. The mutation operation is applied after the crossover process is achieved. For each bit in a subset of the new offspring, some of their genes can be mutated with a low probability. This is done by flipping some bits in the chromosome bit string.

- Termination. If the algorithm does not produce new populations that are sufficiently different from the previous generation, the algorithm has converged. Then, the genetic algorithm has found a set of solutions to the problem, and it is terminated. Such a criteria is predefined by the designer according to specific constraints. In particular, for the proposed scheme, the algorithm is kept in operation during the entire experiment since a permanent pipeline monitoring is assumed no matter if a leak is occurring or not.

3.3. Evolutionary Ensemble of Observers

4. Experimental Results

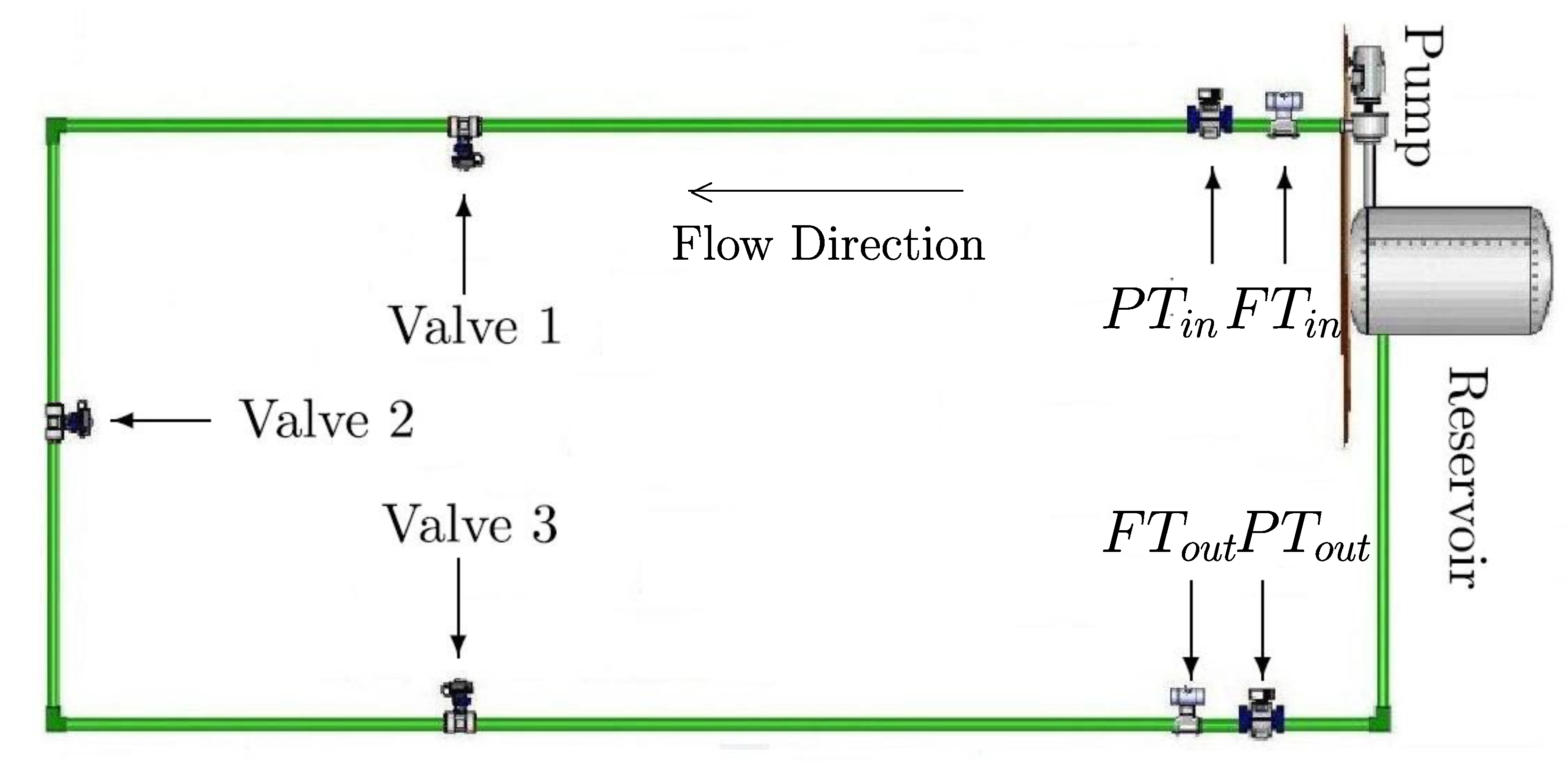

4.1. Experimental Setup

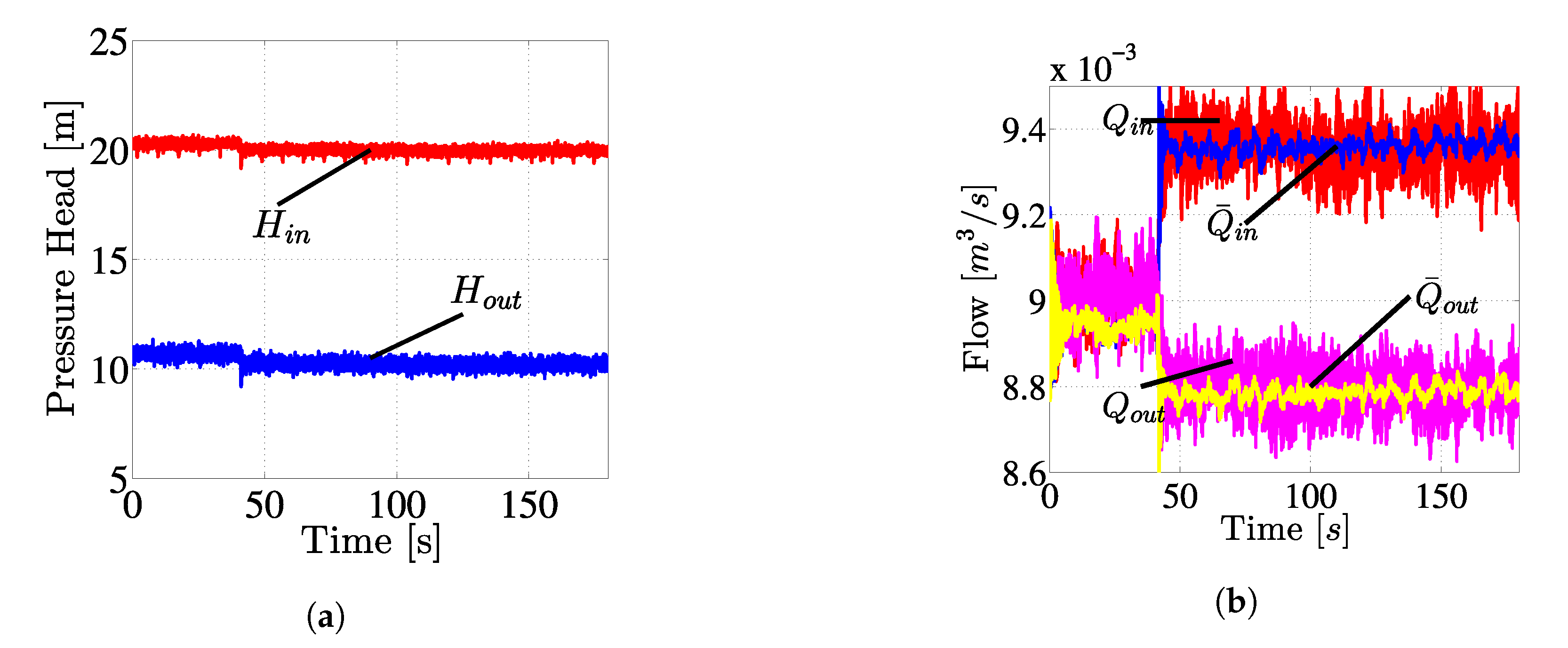

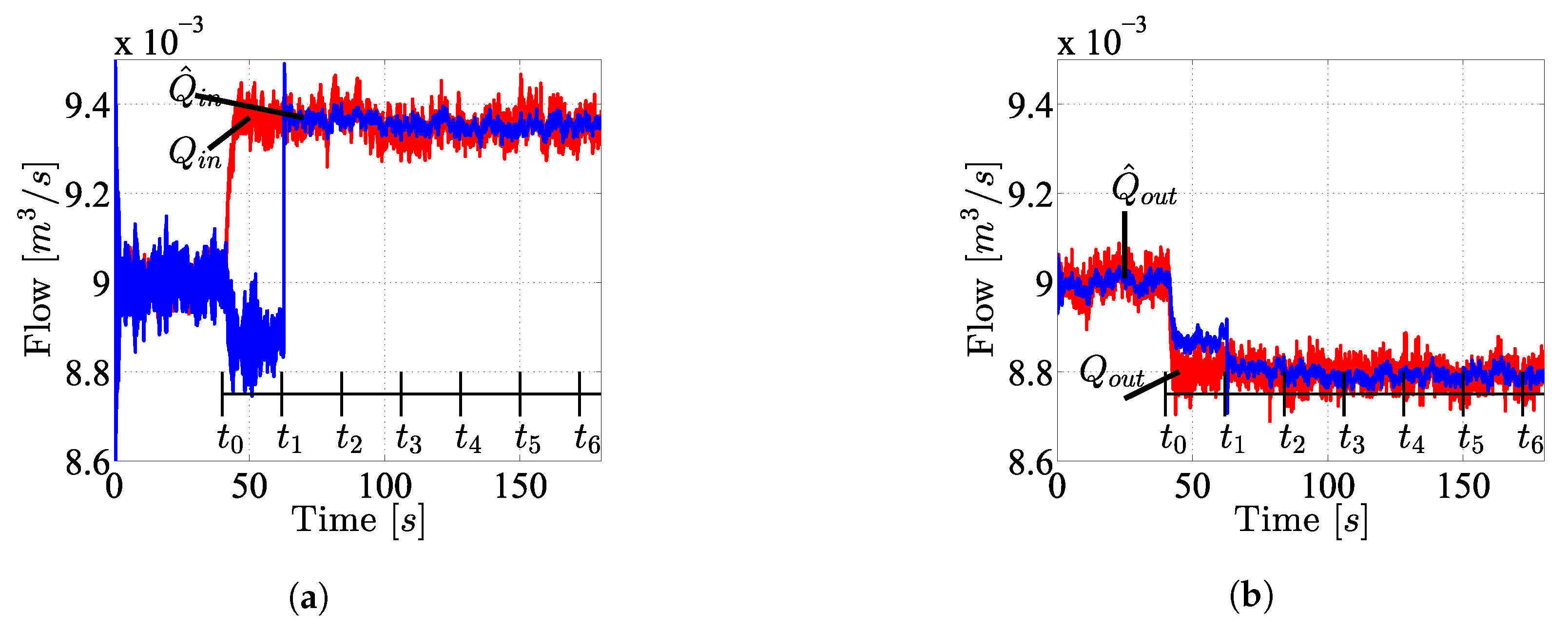

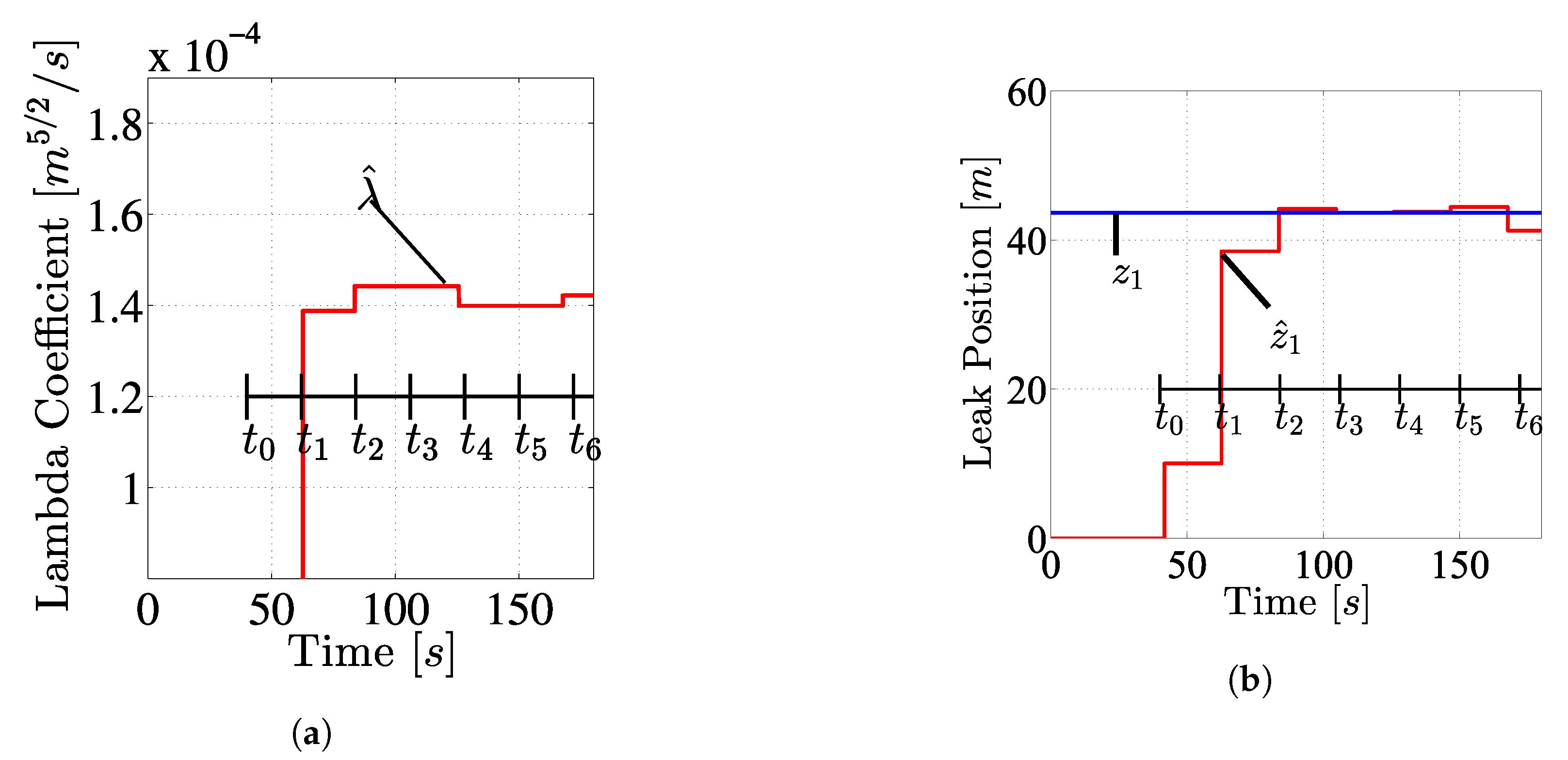

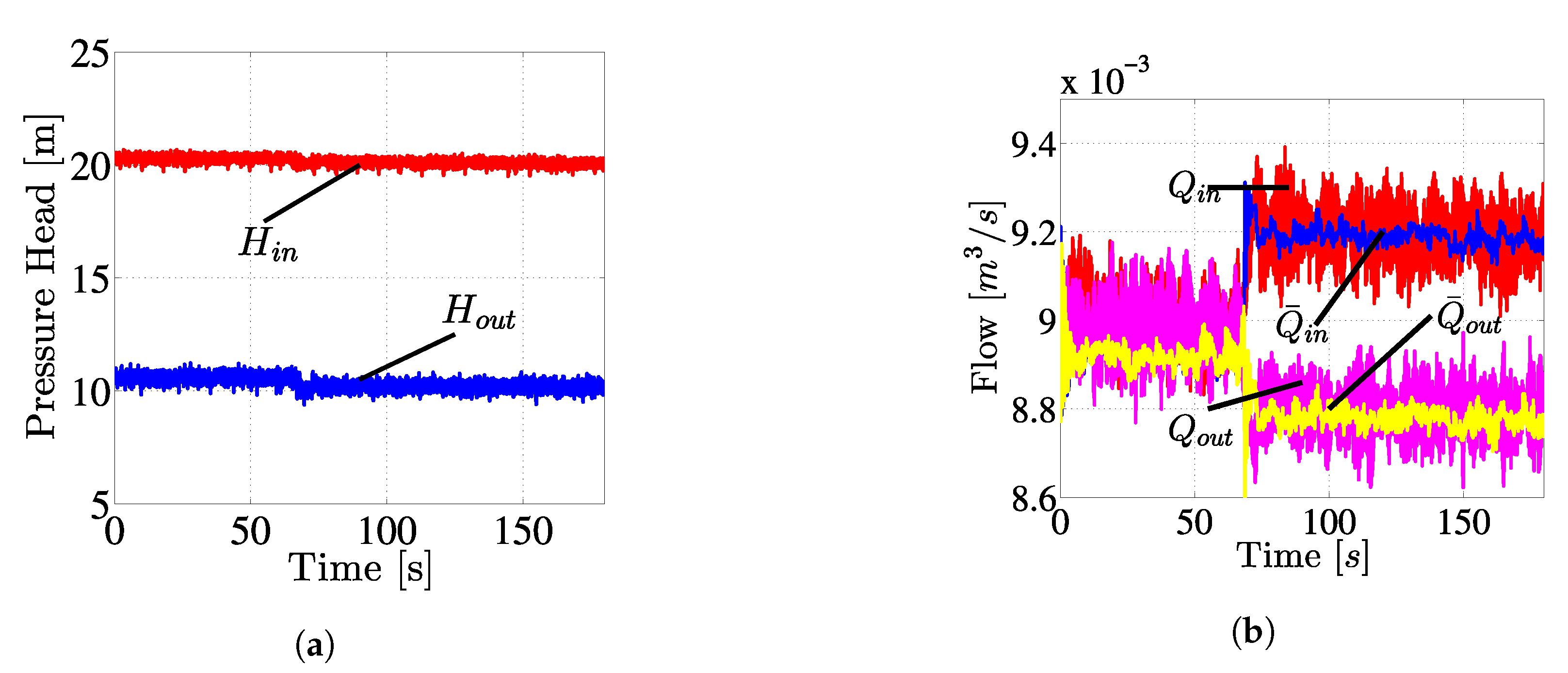

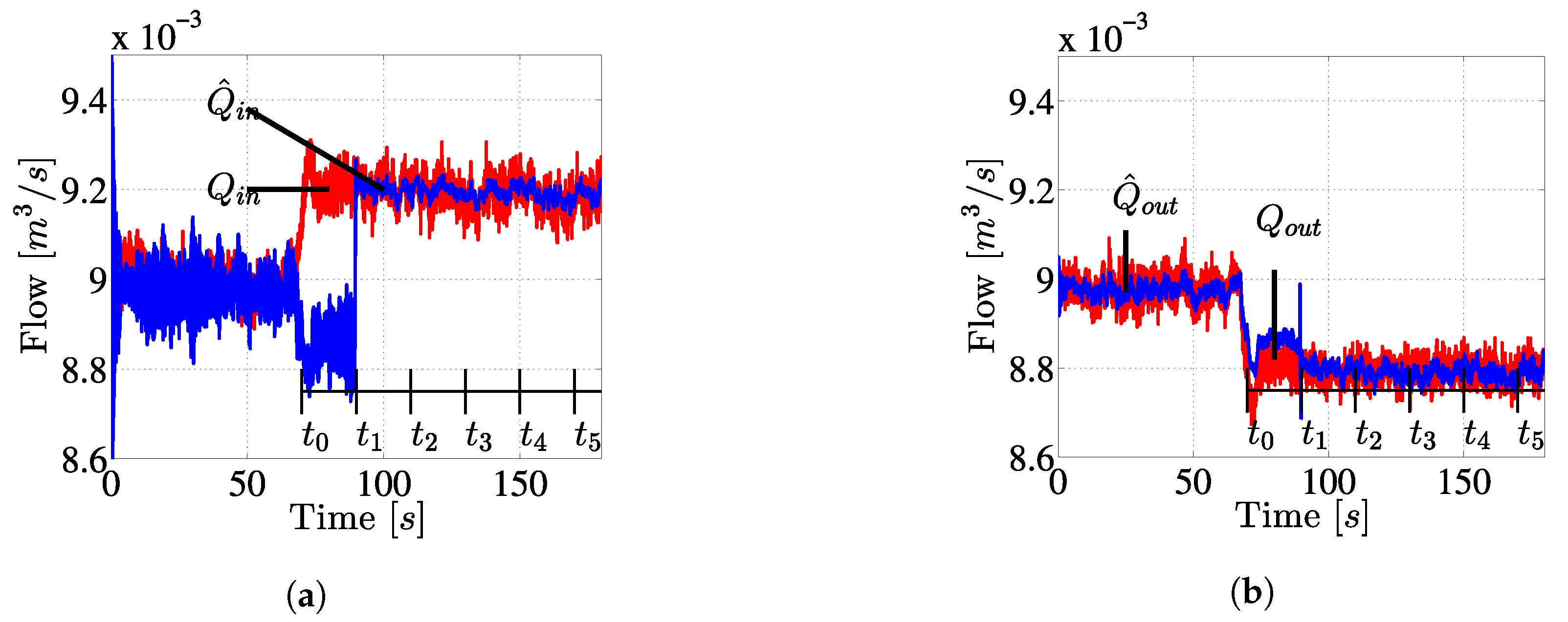

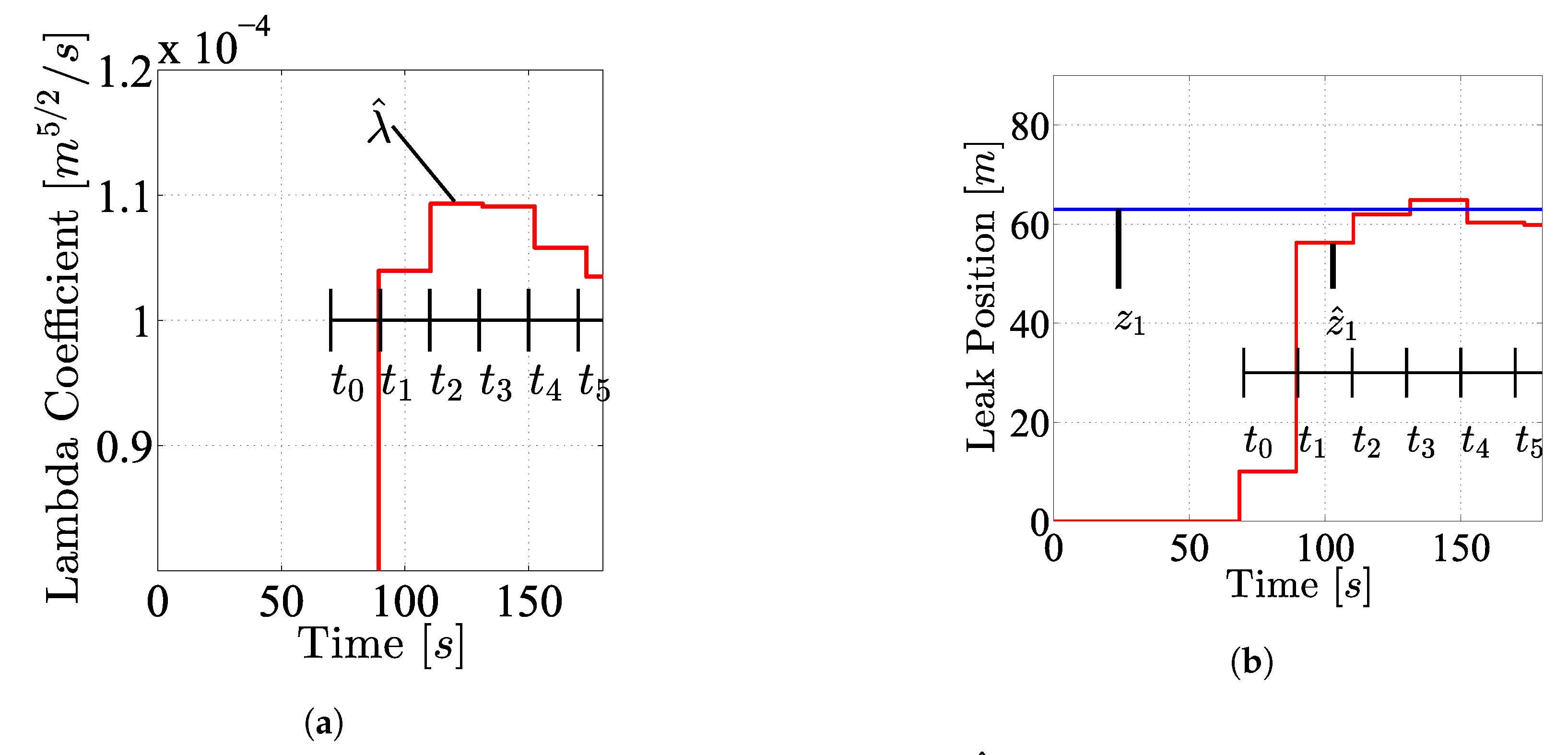

4.2. Leak Isolation Scheme Results

4.2.1. Leak Case in Valve 1

4.2.2. Leak Case in Valve 2

4.2.3. Leak Case in Valve 3

5. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- CONAGUA. Sectorización en Redes de Agua Potable; Technical report; Semarnat: Mexico City, Mexico, 2007.

- Begovich, O.; Pizano, A.; Besançon, G. Online implementation of a leak isolation algorithm in a plastic pipeline prototype. Lat. Am. Appl. Res. 2012, 57, 131–140. [Google Scholar]

- Billman, L.; Isermann, R. Leak Detection Methods for Pipelines. Automatica 1987, 23, 381–385. [Google Scholar] [CrossRef]

- Delgado-Aguiñaga, J.; Besançon, G.; Begovich, O.; Carvajal, J. Multi-leak diagnosis in pipelines based on Extended Kalman Filter. Control Eng. Pract. 2016, 49, 139–148. [Google Scholar] [CrossRef]

- Verde, C.; Molina, L.; Torres, L. Parameterized transient model of a pipeline for multiple leaks location. J. Loss Prev. Process. Ind. 2014, 29, 177–185. [Google Scholar] [CrossRef]

- Ostapkowicz, P. Leakage detection from liquid transmission pipelines using improved pressure wave technique. Eksploatacja i Niezawodność Maintenance Reliability 2014, 16, 9–16. [Google Scholar]

- Zhang, T.; Tan, Y.; Zhang, X.; Zhao, J. A novel hybrid technique for leak detection and location in straight pipelines. J. Loss Prev. Process. Ind. 2015, 35, 157–168. [Google Scholar] [CrossRef]

- Tian, S.; Du, J.; Shao, S.; Xu, H.; Tian, C. A study on a real-time leak detection method for pressurized liquid refrigerant pipeline based on pressure and flow rate. Appl. Therm. Eng. 2016, 95, 462–470. [Google Scholar] [CrossRef]

- Santos-Ruiz, I.; Bermúdez, J.; López-Estrada, F.; Puig, V.; Torres, L.; Delgado-Aguiñaga, J. Online leak diagnosis in pipelines using an EKF-based and steady-state mixed approach. Control Eng. Pract. 2018, 81, 55–64. [Google Scholar] [CrossRef]

- Delgado-Aguiñaga, J.A.; Begovich, O. Water Leak Diagnosis in Pressurized Pipelines: A Real Case Study. In Modeling and Monitoring of Pipelines and Networks; Verde, C., Torres, L., Eds.; Springer International Publishing: Cham, Switzerland, 2017; Volume 7, pp. 235–262. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.; Fang, L.; Xu, M. New leak-localization approaches for gas pipelines using acoustic waves. Measurement 2019, 134, 54–65. [Google Scholar] [CrossRef]

- Rubio Scola, I.; Besancon, G.; Georges, D.; Guillén, M.; Dulhoste, J.F.; Santos, R. On the design of a nonlinear state observer for the location of a blockage in a pipeline. In Proceedings of the XII International Congress on Numerical Methods in Engineering and Applied Sciences, Pampatar, Magarita Island, Venezuela, 24–26 March 2014. [Google Scholar]

- Lyu, P.; Liu, S.; Lai, J.; Liu, J. An analytical fault diagnosis method for yaw estimation of quadrotors. Control Eng. Pract. 2019, 86, 118–128. [Google Scholar] [CrossRef]

- Chouchane, A.; Khedher, A.; Nasri, O.; Kamoun, A. Diagnosis of Partially Observed Petri Net Based on Analytical Redundancy Relationships. Asian J. Control 2019. [Google Scholar] [CrossRef]

- Lunze, J. A method to get analytical redundancy relations for fault diagnosis. IFAC-PapersOnLine 2017, 50, 1006–1012. [Google Scholar] [CrossRef]

- Witczak, M. Advances in model-based fault diagnosis with evolutionary algorithms and neural networks. Int. J. Appl. Math. Comput. Sci. 2006, 16, 85–99. [Google Scholar]

- Vitkovsky, J.P.; Simpson, A.R.; Lambert, M.F. Leak Detection and Calibration Using Transients and Genetic Algorithms. J. Water Resour. Plan. Manag. 2000, 126, 262–265. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.Y.; Sage, P. Water Loss Detection via Genetic Algorithm Optimization-based Model Calibration. In Proceedings of the Water Distribution Systems Analysis Symposium 2006, Cincinnati, OH, USA, 27–30 August 2006; pp. 1–11. [Google Scholar] [CrossRef] [Green Version]

- Roberson, J.A.; Cassidy, J.J.; Chaudhry, M.H. Hydraulic Engineering; Wiley: Hoboken, NJ, USA, 1998. [Google Scholar]

- Delgado-Aguiñaga, J.; Begovich, O.; Besançon, G. Exact-differentiation-based leak detection and isolation in a plastic pipeline under temperature variations. J. Process. Control 2016, 42, 114–124. [Google Scholar] [CrossRef]

- Navarro, A.; Begovich, O.; Sánchez Torres, J.D.; Besancon, G. Real-Time Leak Isolation Based on State Estimation with Fitting Loss Coefficient Calibration in a Plastic Pipeline: Real-Time Leak Isolation based on State Estimation. Asian J. Control 2016. [Google Scholar] [CrossRef]

- Brkić, D. Review of explicit approximations to the Colebrook relation for flow friction. J. Pet. Sci. Eng. 2011, 77, 34–48. [Google Scholar] [CrossRef] [Green Version]

- Swamee, P.K.; Jain, A.K. Explicit equations for pipe-flow problems. J. Hydraul. Div. 1976, 102, 657–664. [Google Scholar]

- Verde, C. Accommodation of multi-leak location in a pipeline. Control Eng. Pract. 2005, 13, 1071–1078. [Google Scholar] [CrossRef]

- Besançon, G.; Georges, D.; Begovich, O.; Verde, C.; Aldana, C. Direct observer design for leak detection and estimation in pipelines. In Proceedings of the European Control Conference, ECC’07, Kos, Greece, 2–5 July 2007; pp. 5666–5670. [Google Scholar]

- Mott, R.L. Applied Fluid Mechanics, 6th ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Birk, J.; Zeitz, M. Extended Luenberger observer for non-linear multivariable systems. Int. J. Control 1988, 47, 1823–1836. [Google Scholar] [CrossRef]

- Krener, A.J.; Isidori, A. Linearization by output injection and nonlinear observers. Syst. Control Lett. 1983, 3, 47–52. [Google Scholar] [CrossRef]

- J. Krener, A.; Respondek, W. Nonlinear Observer with Linearizable Error Dynamics. SIAM J. Control Optim. 1985, 23. [Google Scholar] [CrossRef]

- Khalil, H.K. Nonlinear Systems, 2nd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- Schmitt, L.M. Theory of Genetic Algorithms. Theor. Comput. Sci. 2001, 259, 1–61. [Google Scholar] [CrossRef] [Green Version]

- Mitchell, M. An Introduction to Genetic Algorithms; MIT Press: Cambridge, MA, USA, 1998. [Google Scholar]

- Whitley, D. A genetic algorithm tutorial. Stat. Comput. 1994, 4, 65–85. [Google Scholar] [CrossRef]

- Navarro, A.; Begovich, O.; Besançon, G.; Dulhoste, J. Real-time leak isolation based on state estimation in a plastic pipeline. In Proceedings of the IEEE International Conference on Control Applications (CCA), Denver, CO, USA, 28–30 September 2011; pp. 953–957. [Google Scholar] [CrossRef]

- Torres, L.; Besançon, G.; Georges, D.; Navarro, A.; Begovich, O. Examples of pipeline monitoring with nonlinear observers and real-data validation. In Proceedings of the 8th International Multi-Conference on Systems, Signals and Devices, Sousse, Tunisia, 22–25 March 2011. [Google Scholar]

- Isermann, R. Fault Diagnosis Systems an Introduction from Fault Detection to Fault Tolerance; Springer: Heidelberg/Berlin, Germany, 2006. [Google Scholar]

- Papoulis, A.; Pillai, S.U. Probability, Random Variables, and Stochastic Processes, 4th ed.; McGraw Hill: Boston, MA, USA, 2002. [Google Scholar]

| Parameter | Symbol | Value |

|---|---|---|

| Length between PT sensors | 68.84 m | |

| Internal diameter | m | |

| Friction factor | f | |

| Gravity acceleration | g | 9.81 m/s |

| Pressure wave speed | b | 341 m/s |

| Fitting loss coefficient sum | [-] |

| Estimated in ESL Terms | Symbol | Value |

|---|---|---|

| Between PT sensors | L | 105.1 m |

| Upstream to Valve 1 | 30.92 m | |

| Upstream to Valve 2 | 43.64 m | |

| Upstream to Valve 3 | 62.99 m |

| Estimated | Symbol | Value |

|---|---|---|

| [m/s] | ||

| 12 [m] | ||

| [m/s] |

| Variable | SNR |

|---|---|

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navarro, A.; Delgado-Aguiñaga, J.A.; Sánchez-Torres, J.D.; Begovich, O.; Besançon, G. Evolutionary Observer Ensemble for Leak Diagnosis in Water Pipelines. Processes 2019, 7, 913. https://doi.org/10.3390/pr7120913

Navarro A, Delgado-Aguiñaga JA, Sánchez-Torres JD, Begovich O, Besançon G. Evolutionary Observer Ensemble for Leak Diagnosis in Water Pipelines. Processes. 2019; 7(12):913. https://doi.org/10.3390/pr7120913

Chicago/Turabian StyleNavarro, A., J. A. Delgado-Aguiñaga, J. D. Sánchez-Torres, O. Begovich, and G. Besançon. 2019. "Evolutionary Observer Ensemble for Leak Diagnosis in Water Pipelines" Processes 7, no. 12: 913. https://doi.org/10.3390/pr7120913

APA StyleNavarro, A., Delgado-Aguiñaga, J. A., Sánchez-Torres, J. D., Begovich, O., & Besançon, G. (2019). Evolutionary Observer Ensemble for Leak Diagnosis in Water Pipelines. Processes, 7(12), 913. https://doi.org/10.3390/pr7120913