Experimental Investigation of Grout Nonlinear Flow Behavior through Rough Fractures

Abstract

:1. Introduction

2. Theoretical Background

2.1. The Cube and Forchheimer’s Law

2.2. Normalized Transmissivity

2.3. Critical Grout Hydraulic Gradient and Reynolds Number

3. Testing Program

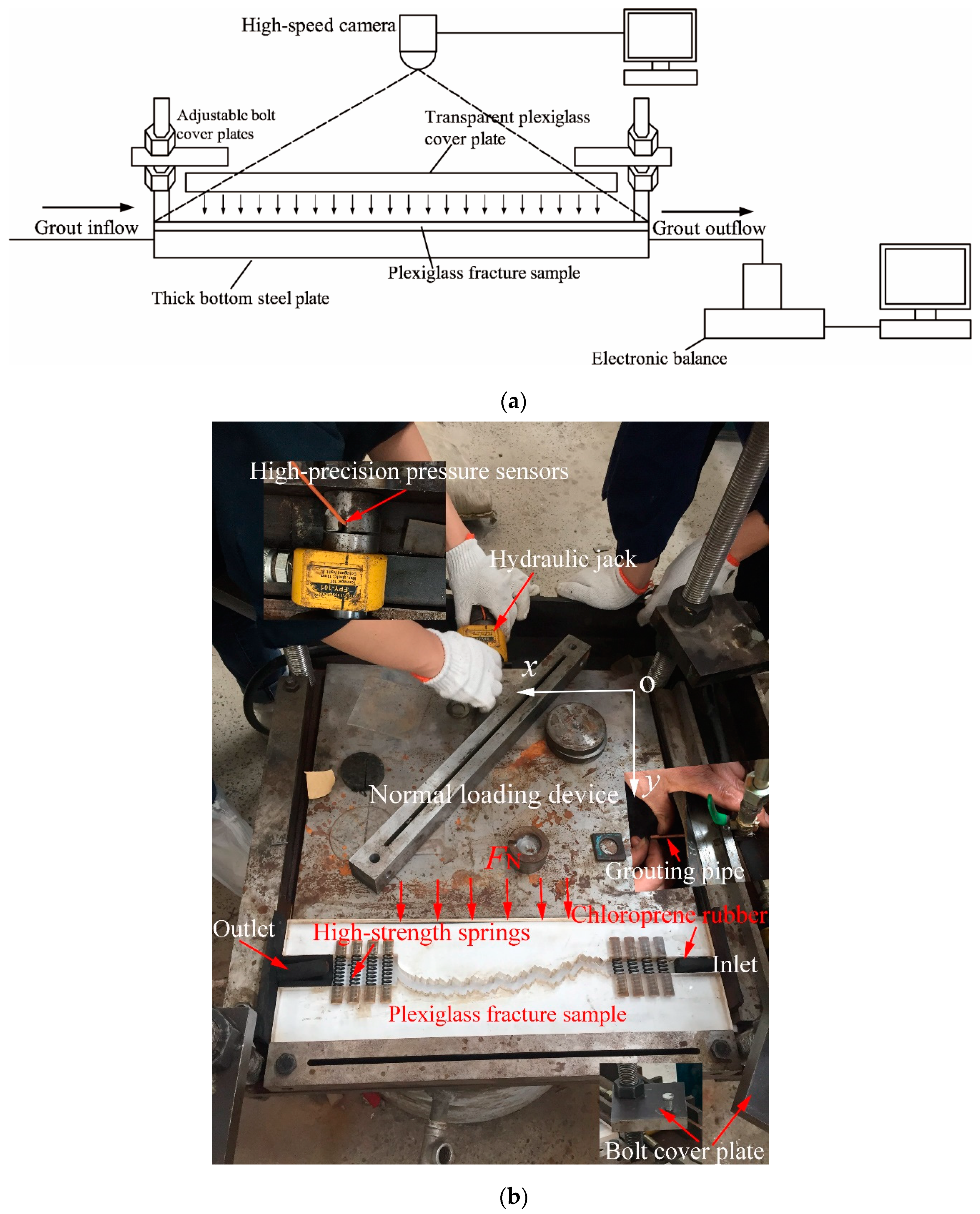

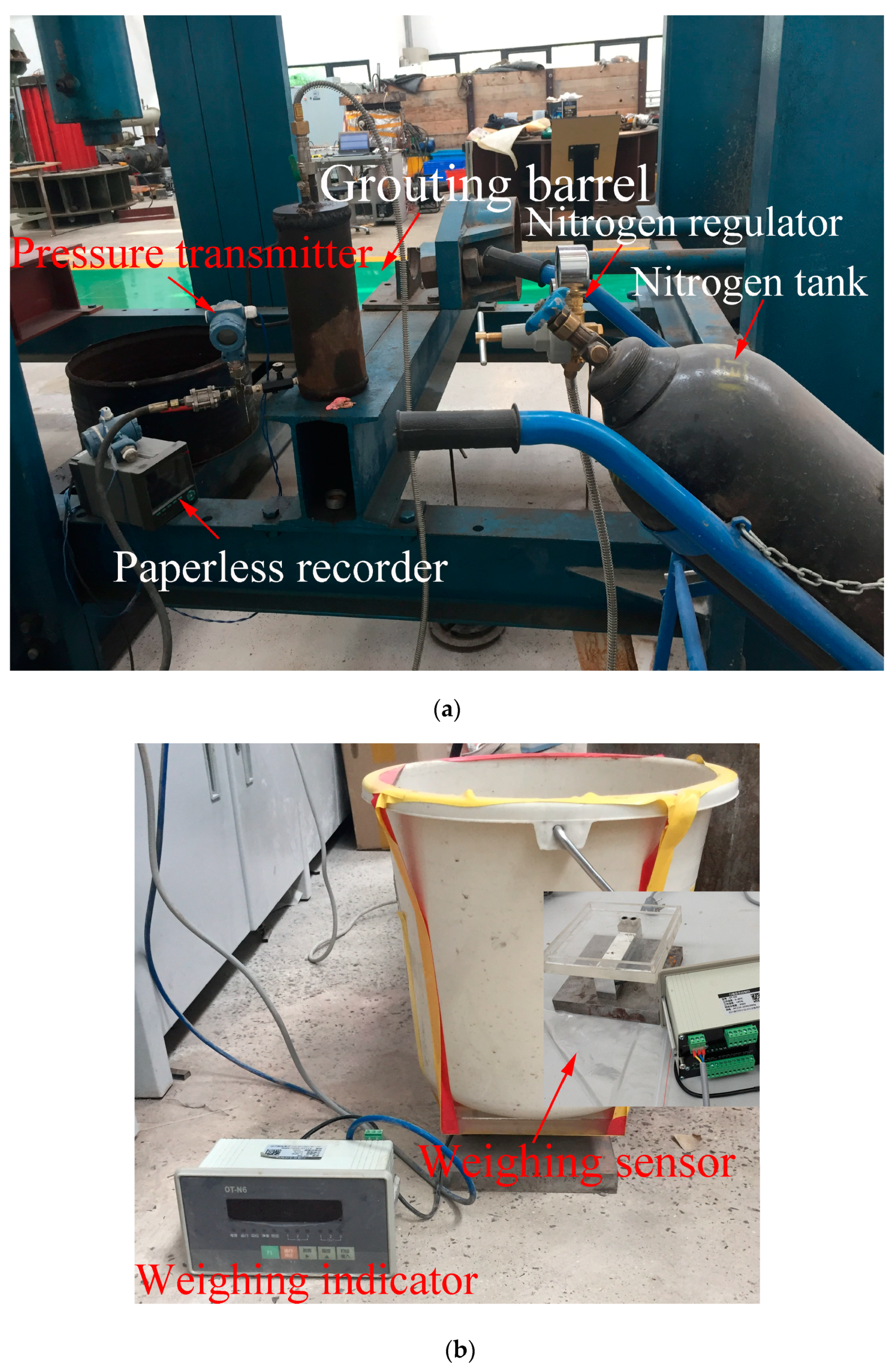

3.1. Grout Flow Testing System

3.2. Grout Material

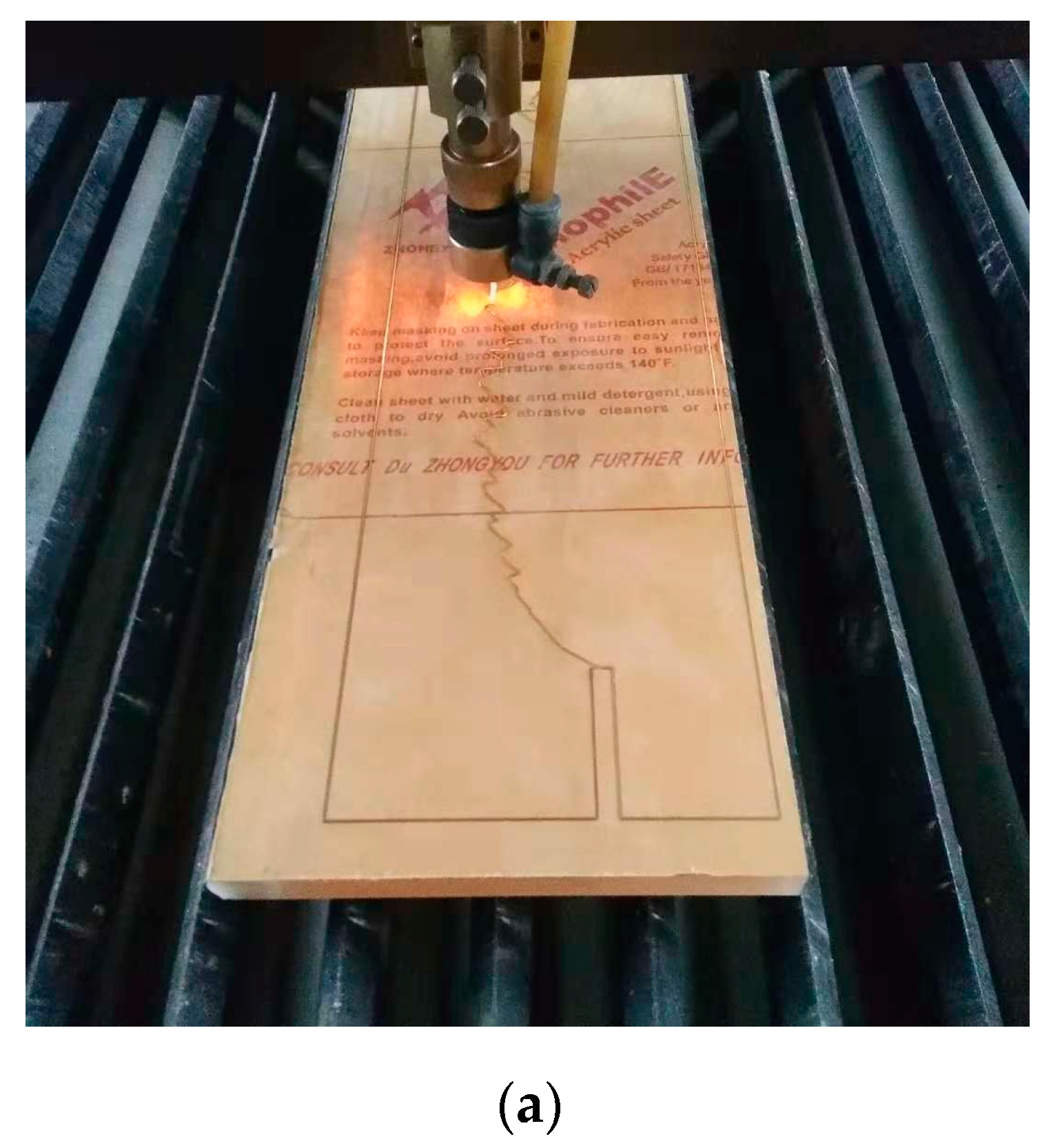

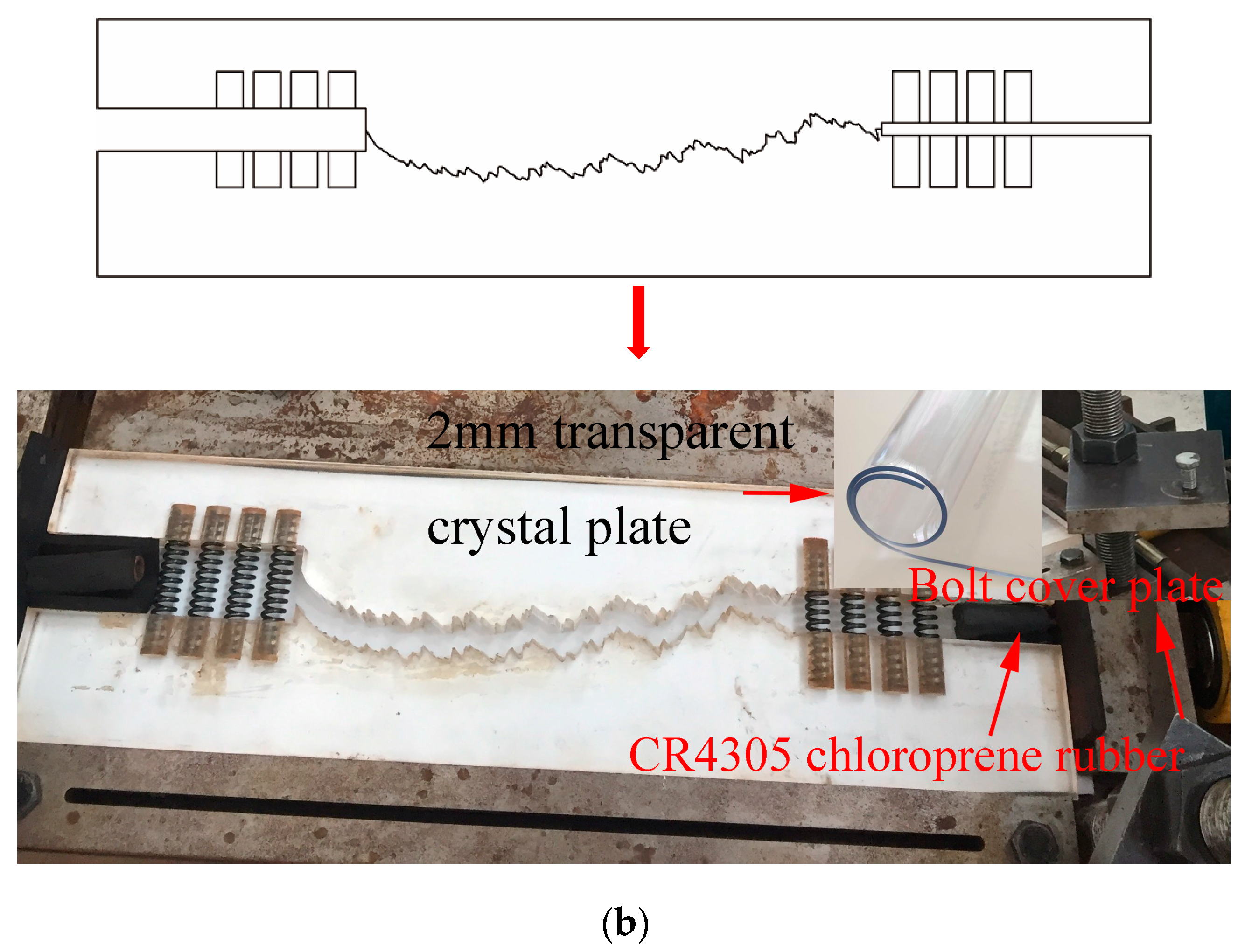

3.3. Fracture Design

3.4. Sealing of the Fractured Sample

3.5. Testing Procedure

4. Results and Analysis

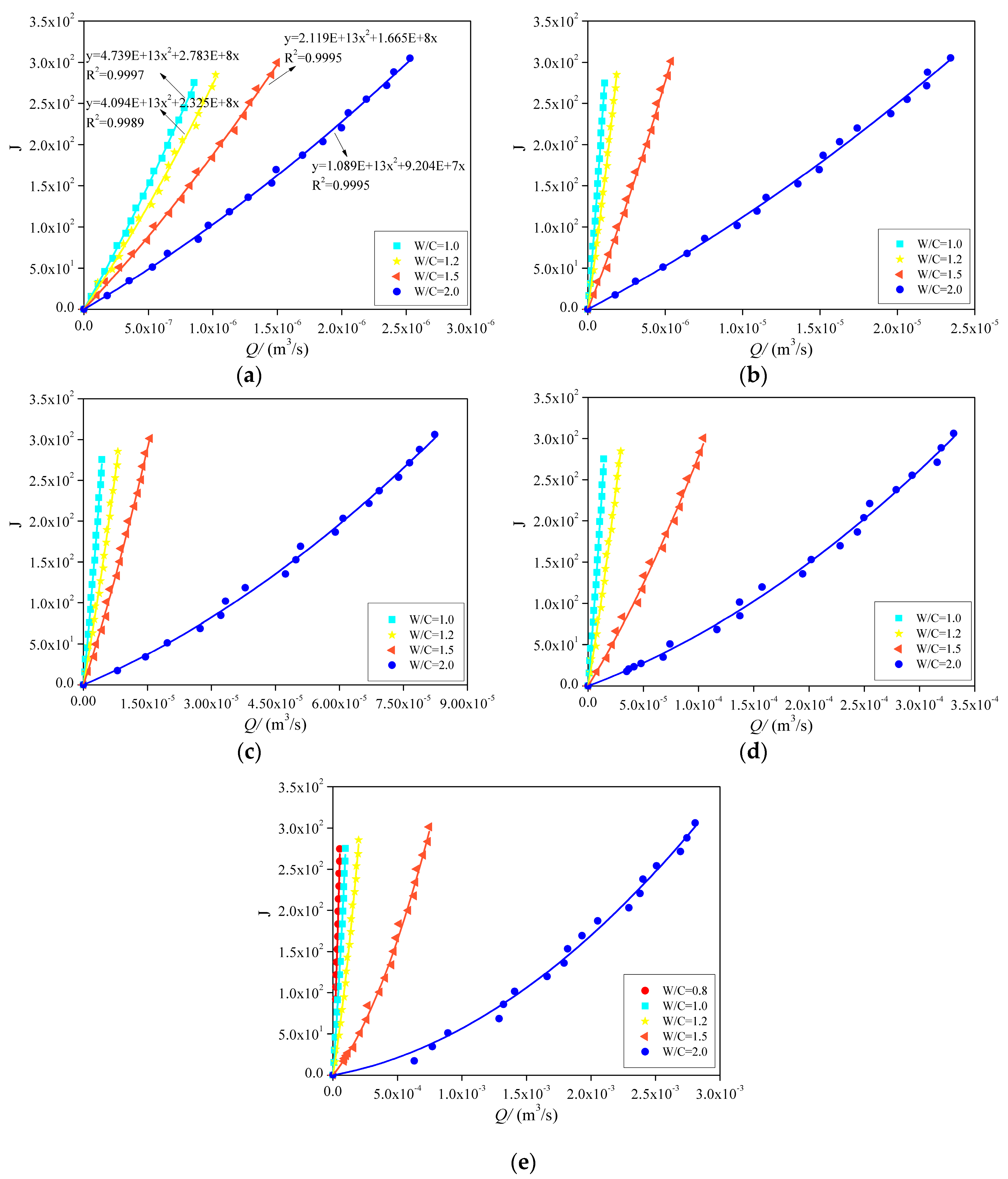

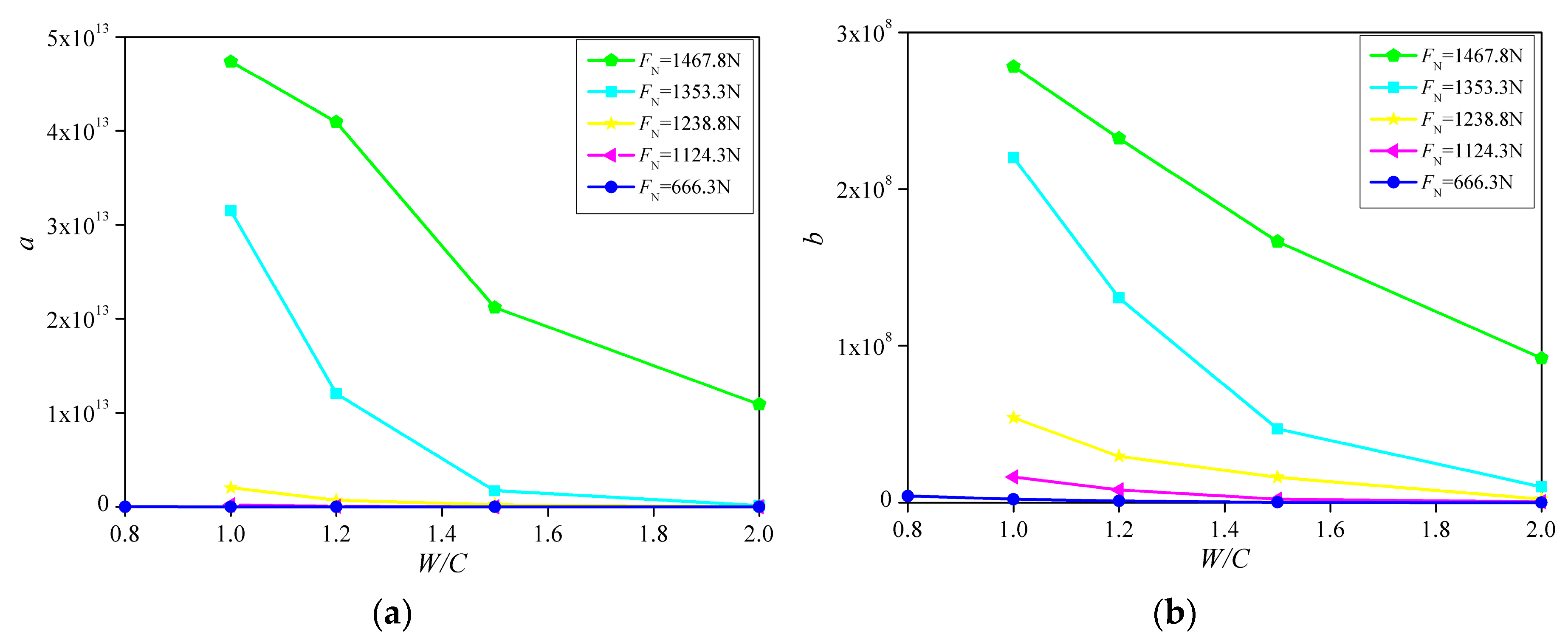

4.1. Stress-Dependent Grout Flow Behavior through Rough Fracture

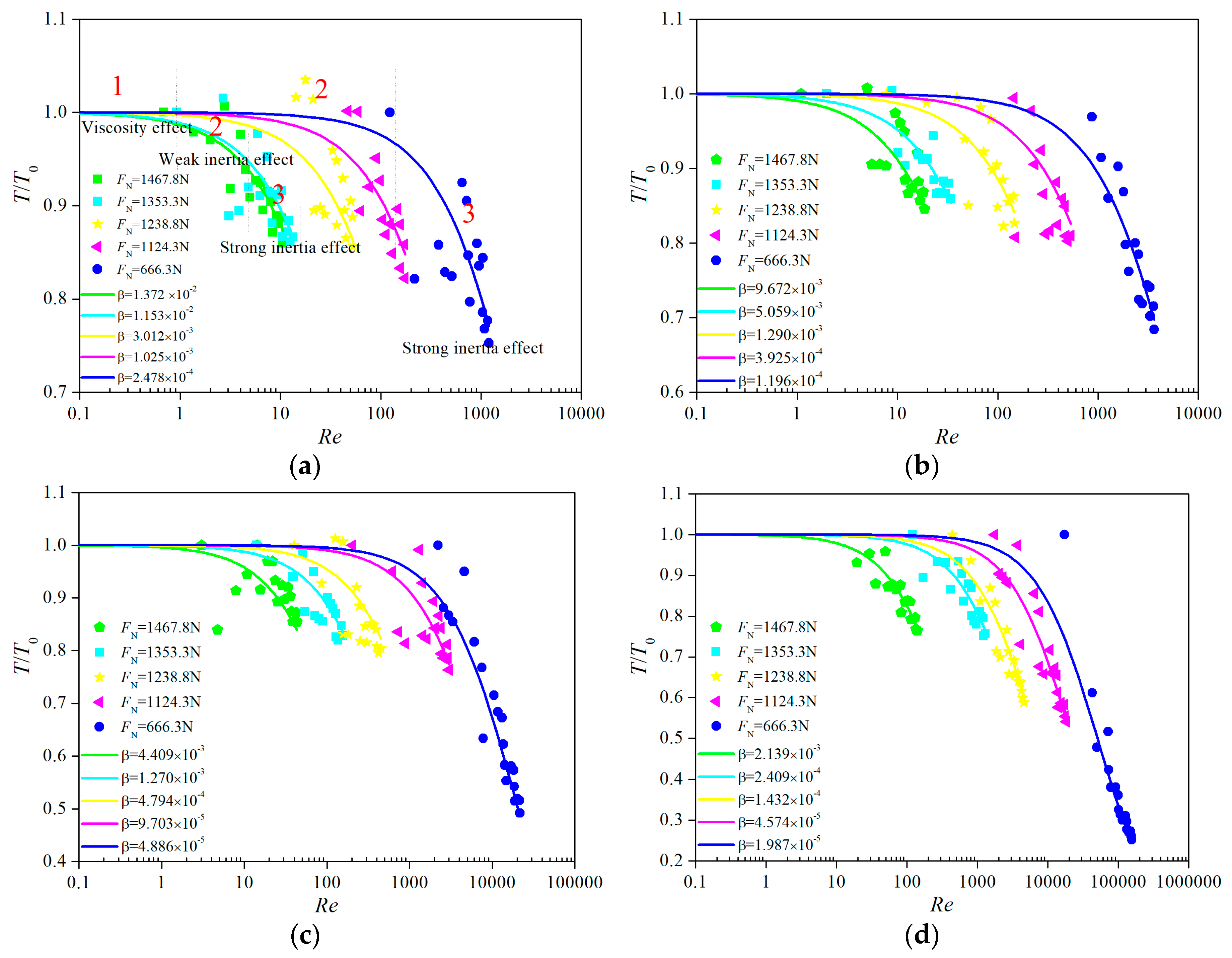

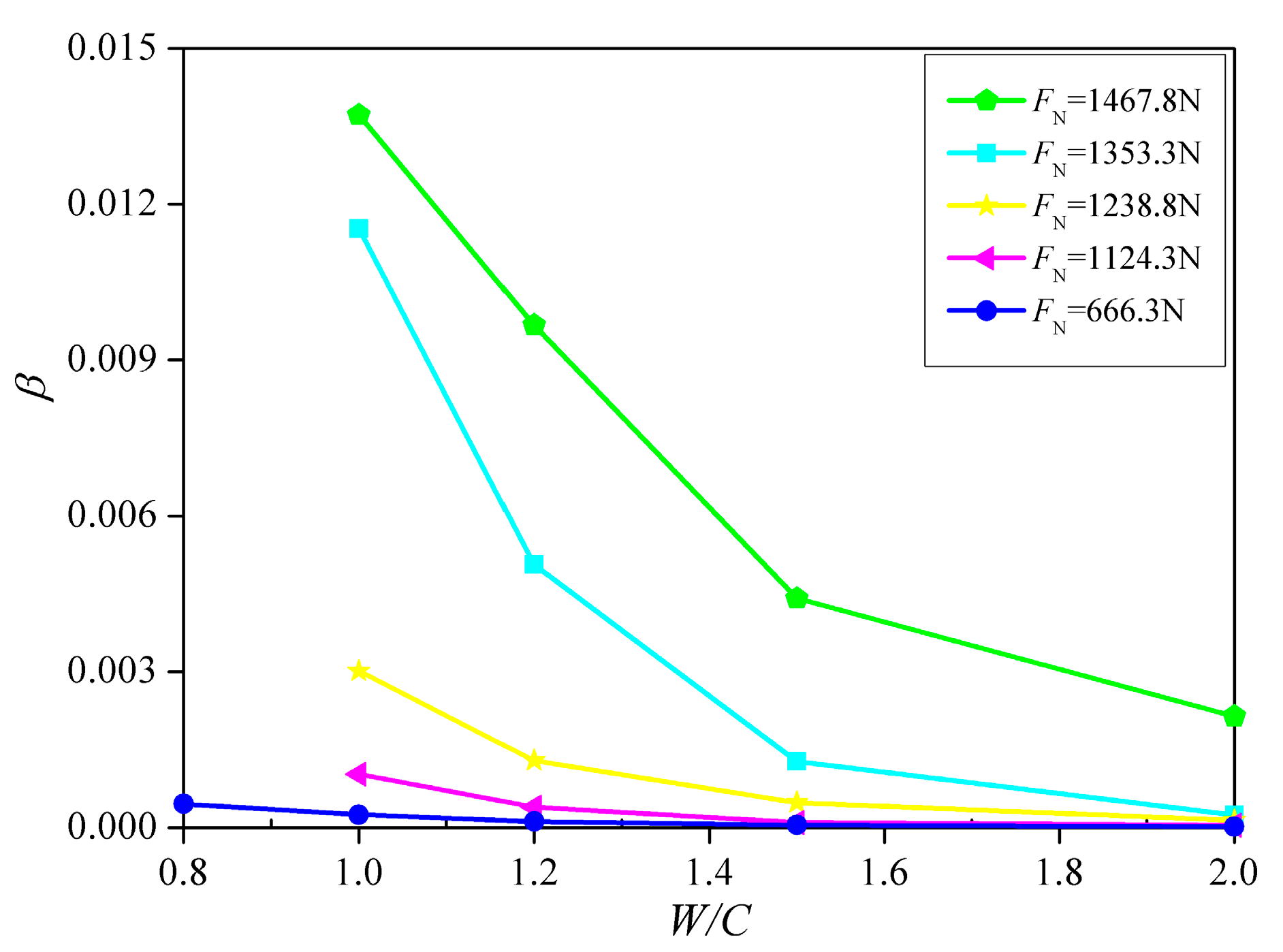

4.2. Normalized Transmissivity Varying with Reynolds Numbers

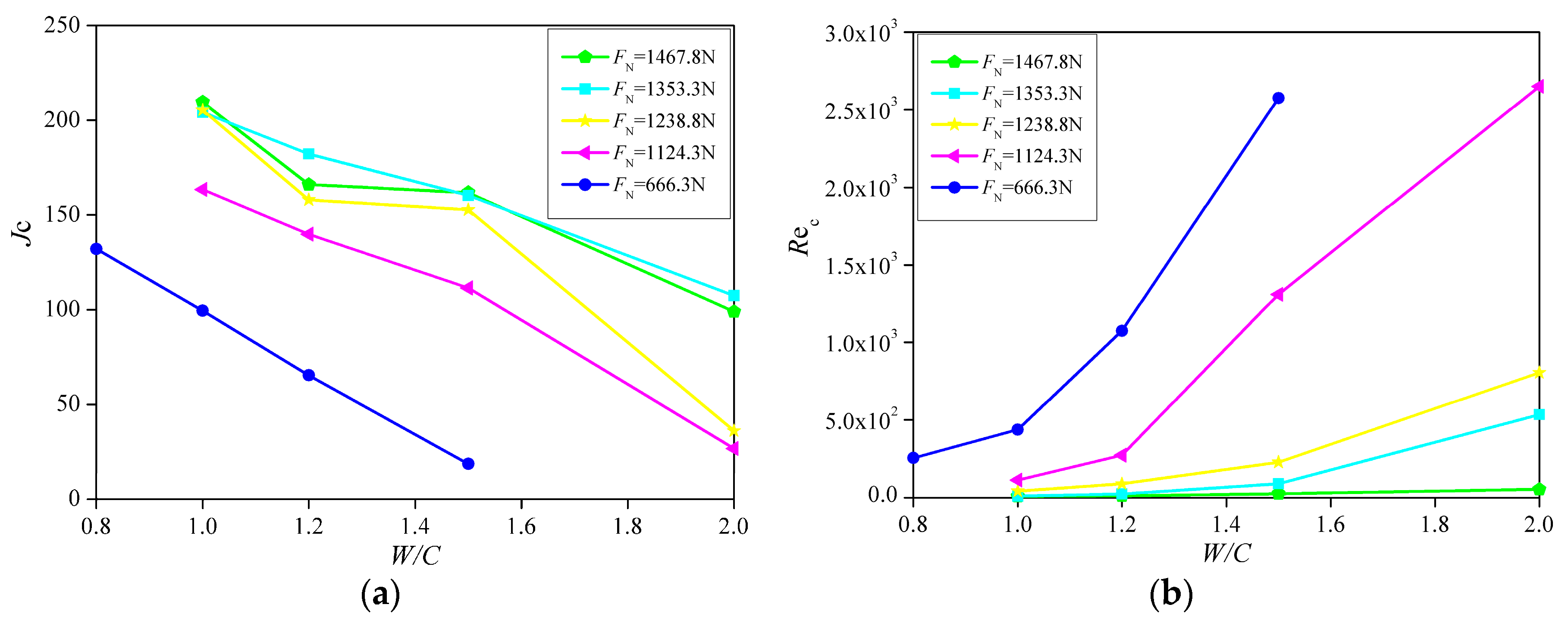

4.3. Critical Grout Hydraulic Gradient and Reynolds Number Analysis

5. Conclusions

- The grout hydraulic gradient J was nonlinear and dependent on the volume flow rate Q based on the grout flow tests, which was fitted by the Forchheimer’s law. With the increase of the W/C ratio, all of the maximum volumetric flow rates, Qmax, showed increasing trends, meaning that the W/C ratio of grout has an important impact on the grout flow through rough fractures. For example, Qmax was increased from 8.534 × 10−7 (W/C ratio = 1.0) to 2.529 × 10−6 (W/C ratio = 2.0), increasing by 1.96 times (FN = 1467.8 N); 1.085 × 10−6 to 2.344 × 10−5 by 20.60 times (FN = 1353.3 N); 4.306 × 10−6 to 8.237 × 10−5 by 18.13 times (FN = 1238.8 N); 1.410 × 10−5 to 3.310 × 10−4 by 22.48 times (FN = 1124.3 N); and 5.355 × 10−5 (W/C ratio = 0.8) to 2.81 × 10−3 by 51.47 times (FN = 666.3 N), respectively. Moreover, both the nonlinear coefficient (a) and linear coefficient (b) with all FN values decreased with the increasing W/C ratio, but increased with the increasing FN values, and the larger the FN was, the larger the amplitude.

- For normalized transmissivity, when the Re value was small, with the increase of Re, the T/T0–Re curves presented a horizontal straight line (close to 1.0), the reason of which was that the viscous effect was dominant in the grout flow behavior through fractures; as the Re continued to increase, the T/T0–Re curves started to bend downward. During this stage, the grout flow behavior was still dominated by the viscous effect, and the inertial effect can be ignored. When Re increased to a certain value, the T/T0–Re curves started to decline linearly. During this stage, the inertial effect can’t be ignored, which became dominant in the grout flow behavior through fractures. The variations in the T/T0–Re curves indicated that when the Reynolds number was small, the grout flow may follow the linear flow law, while as the Reynolds number increased gradually, the grout flow entered the nonlinear flow state. Moreover, for a certain W/C ratio, with an increasing normal load FN, the T/T0–Re curves generally moved downward. The T/T0–Re curve variation trends were in nice agreement with those in the flow behavior study performed by Zimmerman. Moreover, as the W/C ratio increased, the Forchheimer coefficient decreased. However, within larger FN, when the W/C ratios were smaller, as the W/C ratio increased, decreased, and the rate of the decrease was larger. When the W/C ratios were larger, decreased gradually and approached constant values. Within smaller FN values, decreased gradually with increasing W/C ratios and eventually approached constant values.

- The increase of the W/C ratio resulted in the decrease of Jc. Taking FN = 1353.3 N as an example, Jc was 182.179 (W/C ratio = 1.2), 160.361 (1.5), and 107.439 (2.0), respectively, decreasing by 10.78%, 21.47%, and 47.38% over the Jc of 204.194 for W/C ratio of 1.0. Besides, when the W/C ratio was constant, Jc showed increasing trends as the increase of FN. Meanwhile, when FN was constant, as the W/C ratio increased, the critical Reynolds number Rec for all cases showed increasing trends. Taking FN = 1353.3 N as an example, Rec was 22.773 (W/C ratio = 1.2), 88.925 (1.5), and 533.548 (2.0), respectively, increasing by 1.21, 7.64, and 50.84 times over the Rec of 10.292 for W/C ratio of 1.0. Moreover, at a given W/C ratio, Rec showed increasing trends as the FN value decreased.

Author Contributions

Funding

Conflicts of Interest

References

- Chen, M.; Yang, S.; Pathegama-Gamage, R.; Yang, W.; Yin, P.; Zhang, Y.; Zhang, Q. Fracture Processes of Rock-Like Specimens Containing Nonpersistent Fissures under Uniaxial Compression. Energies 2019, 12, 79. [Google Scholar] [CrossRef]

- Yang, S.; Chen, M.; Jing, H.; Chen, K.; Meng, B. A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine, China. Eng. Geol. 2017, 217, 89–101. [Google Scholar] [CrossRef]

- Lei, Q.; Latham, J.; Tsang, C. The use of discrete fracture networks for modelling coupled geomechanical and hydrological behaviour of fractured rocks. Comput. Geotech. 2017, 85, 151–176. [Google Scholar] [CrossRef]

- Jin, Y.; Han, L.; Meng, Q.; Sanda, S.; Zang, H.; Feng, B. Mechanical properties of grouted crushed coal with different grain size mixtures under triaxial compression. Adv. Civ. Eng. 2018, 2018, 9473947. [Google Scholar] [CrossRef]

- Park, D.; Oh, J. Permeation grouting for remediation of dam cores. Eng. Geol. 2018, 233, 63–75. [Google Scholar] [CrossRef]

- Jin, Y.; Han, L.; Meng, Q.; Ma, D.; Han, G.; Gao, F.; Wang, S. Experimental investigation of the mechanical behaviors of grouted sand with UF-OA grouts. Processes 2018, 6, 37. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, S.; Sloan, S.; Sheng, D.; Pakzad, R. Experimental investigation of pressure grouting in sand. Soils Found. 2016, 56, 161–173. [Google Scholar] [CrossRef]

- Wu, K.; Ma, M.; Hao, D. Study on grouting pressure of splitting grouting based on cylindrical expansion considering large strain. Adv. Mater. Res. 2012, 378–379, 288–291. [Google Scholar] [CrossRef]

- Zheng, G.; Zhang, X.; Diao, Y.; Lei, H. Experimental study on grouting in underconsolidated soil to control excessive settlement. Nat. Hazards 2016, 83, 1683–1701. [Google Scholar] [CrossRef]

- Sui, W.; Liu, J.; Hu, W.; Qi, J.; Zhan, K. Experimental investigation on sealing efficiency of chemical grouting in rock fracture with flowing water. Tunn. Undergr. Space Technol. 2015, 50, 239–249. [Google Scholar] [CrossRef]

- Lee, J.; Bang, C.; Mok, Y.; Joh, S. Numerical and experimental analysis of penetration grouting in jointed rock masses. Int. J. Rock Mech. Min. Sci. 2000, 37, 1027–1037. [Google Scholar] [CrossRef]

- Funehag, J.; Fransson, A. Sealing narrow fractures with a Newtonian fluid: Model prediction for grouting verified by field study. Tunn. Undergr. Space Technol. 2006, 21, 492–498. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J.; Yazdani, M.; Tohidi, E.; Nejati, H.; Park, E. Coupled Viscous Fluid Flow and Joint Deformation Analysis for Grout Injection in a Rock Joint. Rock Mech. Rock Eng. 2017, 51, 627–638. [Google Scholar] [CrossRef]

- Hässler, L.; Håkansson, U.; Stille, H. Computer-simulated flow of grouts in jointed rock. Tunn. Undergr. Space Technol. 1992, 7, 441–446. [Google Scholar] [CrossRef]

- Mashayekhizadeh, V.; Kharrat, R.; Ghazanfari, M.; Dejam, M. An experimental investigation of fracture tilt angle effects on frequency and stability of liquid bridges in fractured porous media. Pet. Sci. Technol. 2012, 30, 807–816. [Google Scholar] [CrossRef]

- Zendehboudi, S.; Chatzis, I.; Mohsenipour, A.; Elkamel, A. Dimensional analysis and scale-up of immiscible two-phase flow displacement in fractured porous media under controlled gravity drainage. Energ. Fuel. 2011, 25, 1731–1750. [Google Scholar] [CrossRef]

- Zendehboudi, S.; Chatzis, I.; Shafiei, A.; Dusseault, M. Empirical modeling of gravity drainage in fractured porous media. Energ. Fuel. 2011, 25, 1229–1241. [Google Scholar] [CrossRef]

- Dejam, M.; Hassanzadeh, H. Formation of liquid bridges between porous matrix blocks. AIChE J. 2011, 57, 286–298. [Google Scholar] [CrossRef]

- Mashayekhizadeh, V.; Ghazanfari, M.; Kharrat, R.; Dejam, M. Pore-level observation of free gravity drainage of oil in fractured porous media. Transp. Porous Media 2011, 87, 561–584. [Google Scholar] [CrossRef]

- Dejam, M.; Hassanzadeh, H.; Chen, Z. Reinfiltration through liquid bridges formed between two matrix blocks in fractured rocks. J. Hydrol. 2014, 519, 3520–3530. [Google Scholar] [CrossRef]

- Dejam, M. The role of fracture capillary pressure on the block-to-block interaction process. J. Porous Media 2018, 21, 1121–1136. [Google Scholar] [CrossRef]

- Dejam, M.; Hassanzadeh, H.; Chen, Z. Shear dispersion in a rough-walled fracture. Soc. Pet. Eng. J. 2018, 23, 1669–1688. [Google Scholar] [CrossRef]

- Bear, J. Dynamics of Fluids in Porous Media; American Elsevier Publishing Company: New York, NY, USA, 1972. [Google Scholar]

- Brush, D.; Thomson, N. Fluid flow in synthetic rough-walled fractures: Navier–Stokes, Stokes, and local cubic law simulations. Water Resour. Res. 2003, 39, 1037–1041. [Google Scholar] [CrossRef]

- Yin, Q.; Ma, G.; Jing, H.; Wang, H.; Su, H.; Wang, Y.; Liu, R. Hydraulic properties of 3D rough-walled fractures during shearing: An experimental study. J. Hydrol. 2017, 555, 169–184. [Google Scholar] [CrossRef]

- Rong, G.; Hou, D.; Yang, J.; Cheng, L.; Zhou, C. Experimental study of flow characteristics in non-mated rock fractures considering 3D definition of fracture surfaces. Eng. Geol. 2017, 220, 152–163. [Google Scholar] [CrossRef]

- Zhang, Z.; Nemcik, J. Fluid flow regimes and nonlinear flow characteristics in deformable rock fractures. J. Hydrol. 2013, 477, 139–151. [Google Scholar] [CrossRef]

- Dippenaar, M.; Rooy, J.L.V. On the cubic law and variably saturated flow through discrete open roughwalled discontinuities. Int. J. Rock Mech. Min. Sci. 2016, 89, 200–211. [Google Scholar] [CrossRef]

- Zimmerman, R.; Bodvarsson, G. Hydraulic Conductivity of Rock Fractures. Transp. Porous Media 1996, 23, 1–30. [Google Scholar] [CrossRef]

- Zambrano, M.; Pitts, A.; Salama, A.; Volatili, T.; Giorgioni, M.; Tondi, E. Analysis of Fracture Roughness Control on Permeability Using SfM and Fluid Flow Simulations: Implications for Carbonate Reservoir Characterization. Geofluids 2019, 2019, 4132386. [Google Scholar] [CrossRef]

- Ko, N.; Ji, S.; Koh, Y.; Baik, M. Hydraulic conceptualization of a single fracture using hydraulic interference tests at a deep underground condition. Geosci. J. 2018, 22, 581–588. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Liu, J.; Li, X.; Zhou, Z. The role of gangue on the mitigation of mining-induced hazards and environmental pollution: An experimental investigation. Sci. Total Environ. 2019, 664, 436–448. [Google Scholar] [CrossRef] [PubMed]

- Snow, D. Anisotropic permeability of fractured media. Water Resour. Res. 1969, 5, 1273–1289. [Google Scholar] [CrossRef]

- Ji, S.; Lee, H.; Yeo, I.; Lee, K. Effect of nonlinear flow on DNAPL migration in a rough-walled fracture. Water Resour. Res. 2008, 44, W11431. [Google Scholar] [CrossRef]

- Xia, C.; Qian, X.; Lin, P.; Xiao, W.; Gui, Y. Experimental Investigation of Nonlinear Flow Characteristics of Real Rock Joints under Different Contact Conditions. J. Hydraul. Eng. 2017, 143, 04016090. [Google Scholar] [CrossRef]

- Forchheimer, P. Wasserbewegung durch boden. Z. Ver. Deutsch Ing. 1901, 45, 1782–1788. [Google Scholar]

- Zimmerman, R.; Al-Yaarubi, A.; Pain, C.; Grattoni, C. Non-Linear regimes of fluid flow in rock fractures. Int. J. Rock Mech. Min. Sci. 2004, 41, 163–169. [Google Scholar] [CrossRef]

- Wang, M.; Chen, Y.; Ma, G.; Zhou, J.; Zhou, C. Influence of surface roughness on nonlinear flow behaviors in 3D self-affine rough fractures: Lattice Boltzmann simulations. Adv. Water Resour. 2016, 96, 373–388. [Google Scholar] [CrossRef]

- Zhang, W.; Dai, B.; Liu, Z.; Zhou, C. A pore-scale numerical model for non-Darcy fluid flow through roughwalled fractures. Comput. Geotech. 2017, 87, 139–148. [Google Scholar] [CrossRef]

- Chen, Y.; Lian, H.; Liang, W.; Yang, J.; Nguyen, V.P.; Bordas, S. The influence of fracture geometry variation on non-Darcy flow in fractures under confining stresses. Int. J. Rock Mech. Min. Sci. 2019, 113, 59–71. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Li, X.; Li, Z.; Zhou, Z.; Li, T. Effects of seepage-induced erosion on nonlinear hydraulic properties of broken red sandstones. Tunn. Undergr. Space Technol. 2019, 91, 102993. [Google Scholar] [CrossRef]

- Zeng, Z.; Grigg, R. A Criterion for Non-Darcy Flow in Porous Media. Transp. Porous Media 2006, 63, 57–69. [Google Scholar] [CrossRef]

- Ma, D.; Wang, J.; Li, Z. Effect of particle erosion on mining-induced water inrush hazard of karst collapse pillar. Environ. Sci. Pollut R. 2019, 26, 19719–19728. [Google Scholar] [CrossRef] [PubMed]

- Rong, G.; Yang, J.; Cheng, L.; Zhou, C. Laboratory investigation of nonlinear flow characteristics in rough fractures during shear process. J. Hydrol. 2016, 541, 1385–1394. [Google Scholar] [CrossRef]

- Yang, C.; Shen, S.; Hou, D.; Liao, S.; Yuan, D. Material properties of the seal gasket for shield tunnels: A review. Constr. Build. Mater. 2018, 191, 877–890. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.; Gallardo-Hernández, E.; Pérez-González, J. Compatibility study of common sealing elastomers with a biolubricant (Jatropha oil). Tribol. Int. 2017, 116, 1–8. [Google Scholar] [CrossRef]

- Gillen, K.; Bernstein, R.; Derzon, D. Evidence of non-Arrhenius behaviour from laboratory aging and 24-year field aging of polychloroprene rubber materials. Polym. Degrad. Stab. 2005, 87, 57–67. [Google Scholar] [CrossRef]

- Jin, Y.; Han, L.; Meng, Q.; Ma, D.; Wen, S.; Wang, S. Experimental investigation of the mechanical behaviors of grouted crushed coal rocks under uniaxial compression. Geomech. Eng. 2018, 16. [Google Scholar]

- Xie, H.; Sun, H.; Ju, Y.; Feng, Z. Study on generation of rock fracture surfaces by using fractal interpolation. Int. J. Solids Struct. 2001, 38, 5765–5787. [Google Scholar] [CrossRef]

- Fityus, S.; Giacomini, A.; Buzzi, O. The significance of geology for the morphology of potentially unstable rocks. Eng. Geol. 2013, 162, 43–52. [Google Scholar] [CrossRef]

- Gale, J.; Laubach, S.; Marrett, R.; Olson, J.; Holder, J.; Reed, R. Predicting and characterizing fractures in dolostone reservoirs: Using the link between diagenesis and fracturing. Geol. Soc. Lond. Spec. Publ. 2004, 235, 177–192. [Google Scholar] [CrossRef]

- Wu, J.; Feng, M.; Yu, B.; Han, G. The length of pre-existing fissures effects on the mechanical properties of cracked red sandstone and strength design in engineering. Ultrasonics 2018, 82, 188–199. [Google Scholar] [CrossRef] [PubMed]

- Mandelbrot, B. The Fractal Geometry of Nature; WH Freeman: New York, NY, USA, 1983. [Google Scholar]

| W/C Ratios | 0.8 | 1.0 | 1.2 | 1.5 | 2.0 |

|---|---|---|---|---|---|

| (kg/m3) | 1.660 × 103 | 1.390 × 103 | 1.340 × 103 | 1.270 × 103 | 1.250 × 103 |

| (Pa∙s) | 9.379 × 10−3 | 5.600 × 10−3 | 3.680 × 10−3 | 2.200 × 10−3 | 1.130 × 10−3 |

| W/C Ratio | FN (kN) | a | b | R2 | Jc | Rec |

|---|---|---|---|---|---|---|

| 0.8 | 666.3 | 1.660 × 1010 | 4.125 × 106 | 0.9988 | 132.084 | 254.023 |

| 1.0 | 1467.8 | 4.739 × 1013 | 2.783 × 108 | 0.9997 | 209.498 | 8.379 |

| 1353.3 | 3.150 × 1013 | 2.201 × 108 | 0.9994 | 204.194 | 10.292 | |

| 1238.8 | 2.016 × 1012 | 5.393 × 107 | 0.9987 | 205.337 | 41.952 | |

| 1124.3 | 2.056 × 1011 | 1.616 × 107 | 0.9989 | 163.438 | 112.536 | |

| 666.3 | 6.575 × 109 | 2.138 × 106 | 0.9979 | 99.423 | 512.139 | |

| 1.2 | 1467.8 | 4.094 × 1013 | 2.325 × 108 | 0.9989 | 166.042 | 11.682 |

| 1353.3 | 1.203 × 1013 | 1.306 × 108 | 0.9992 | 182.179 | 22.773 | |

| 1238.8 | 6.884 × 1011 | 2.932 × 107 | 0.9987 | 157.994 | 88.099 | |

| 1124.3 | 5.709 × 1010 | 7.989 × 106 | 0.9981 | 139.855 | 286.505 | |

| 666.3 | 2.135 × 109 | 9.807 × 105 | 0.9987 | 65.263 | 1073.741 | |

| 1.5 | 1467.8 | 2.119 × 1013 | 1.665 × 108 | 0.9995 | 161.746 | 25.232 |

| 1353.3 | 1.714 × 1012 | 4.677 × 107 | 0.9989 | 160.361 | 88.925 | |

| 1238.8 | 2.210 × 1011 | 1.597 × 107 | 0.9987 | 152.714 | 246.806 | |

| 1124.3 | 6.094 × 109 | 2.176 × 106 | 0.9984 | 111.419 | 1311.130 | |

| 666.3 | 2.719 × 108 | 1.928 × 105 | 0.9983 | 18.522 | 2473.841 | |

| 2.0 | 1467.8 | 1.089 × 1013 | 9.204 × 107 | 0.9995 | 98.947 | 53.368 |

| 1353.3 | 1.315 × 1011 | 9.869 × 106 | 0.9990 | 107.439 | 533.548 | |

| 1238.8 | 1.756 × 1010 | 2.217 × 106 | 0.9990 | 36.006 | 805.396 | |

| 1124.3 | 1.254 × 109 | 4.957 × 105 | 0.9983 | 26.653 | 2652.174 | |

| 666.3 | 2.899 × 107 | 2.638 × 104 | 0.9982 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Y.; Han, L.; Xu, C.; Meng, Q.; Liu, Z.; Zong, Y. Experimental Investigation of Grout Nonlinear Flow Behavior through Rough Fractures. Processes 2019, 7, 736. https://doi.org/10.3390/pr7100736

Jin Y, Han L, Xu C, Meng Q, Liu Z, Zong Y. Experimental Investigation of Grout Nonlinear Flow Behavior through Rough Fractures. Processes. 2019; 7(10):736. https://doi.org/10.3390/pr7100736

Chicago/Turabian StyleJin, Yuhao, Lijun Han, Changyu Xu, Qingbin Meng, Zhenjun Liu, and Yijiang Zong. 2019. "Experimental Investigation of Grout Nonlinear Flow Behavior through Rough Fractures" Processes 7, no. 10: 736. https://doi.org/10.3390/pr7100736

APA StyleJin, Y., Han, L., Xu, C., Meng, Q., Liu, Z., & Zong, Y. (2019). Experimental Investigation of Grout Nonlinear Flow Behavior through Rough Fractures. Processes, 7(10), 736. https://doi.org/10.3390/pr7100736