1. Introduction

High specific speed centrifugal pumps with low head and large flow are generally used in rural irrigation, urban drainage, fish pond aquaculture, aerospace engineering, etc. As the internal flow during the operation of centrifugal pump is extremely complicated, especially under off-design working conditions, it is often accompanied by unstable phenomena, such as overload operation, cavitation, and vibration, which will affect the normal operation. Therefore, it is particularly important to optimize the performance to improve their stability and reliability (Zhang et al. [

1]). Numerical simulation has become a common research method with the development of computational fluid dynamics (CFD) (Wei et al. [

2]; Zhou et al. [

3]; Han et al. [

4]).

Generally, there are two ways to optimize the performance of centrifugal pump. One is to study the effect of a single parameter or structure on the performance of centrifugal pump. Skrzypacz and Bieganowski [

5] studied the influence of micro grooves on centrifugal pump performance by numerical simulation and experiment. The results illustrated that micro-blades can make the velocity distribution in the impeller passage more uniform, which thus improves the head and efficiency of the pump. Chen, He and Liu [

6] put forward the concept of twisted vice blade, and verified that the use of twisted vice blades can effectively improve the comprehensive performance of centrifugal pumps. Nishi, Fukutomi, and Fujiwara [

7] found the influence of blade outlet angle on radial thrust and modeled components is obvious by experiments and CFD analysis. Fu, Zhu, Jiang, and Li [

8] uncovered how the diffuser vane height affects the pump performance. They concluded that reducing the diffuser vane height could improve the output work of impeller. Cui, Wang, Zhu, and Jin [

9] found that a larger blade outlet angle could improve the internal flow of low-specific-speed centrifugal pump and improve its working efficiency.

The other common optimization method is to use some mathematical models or algorithms to study the comprehensive effects of several parameters on the performance of centrifugal pumps, such as DOE (Design of Experiments), approximation models, genetic algorithm, etc. (Zhou et al. [

10]; Lyn et al. [

11]; Nasruddin et al. [

12]). Wang, Feng, Ye, and Luo, Liu [

13] selected blade inlet angle, outlet angle, and blade wrap angle as the optimization variables. The multi-objective optimization was carried out based on NSGA-II genetic algorithm. The optimization results show that the algorithm can effectively improve the performance of centrifugal slurry pump. Derakhshan, Pourmahdavi, Abdolahnejad, Reihani, and Ojaghi [

14] adopted the ABC (artificial bee colony) and ANNs (artificial neural networks) algorithm to design a new flow passage shape of centrifugal pump. Zhang, Hu, Wu, Zhang, and Chen [

15] used Kriging metamodels to optimize double suction centrifugal pump based on four different parameters. Lomakin, Chaburk, and Kuleshova [

16] chose six parameters of impeller and guide vane as optimization parameters, and used LP-tau algorithm to optimize the centrifugal pump to improve its comprehensive performance, including increasing head, reducing cavitation, and vibration phenomenon. Koor, Vassiljev and Koppel [

17] used the LMA (Levenberg-Marquardt algorithm) to maximize the total efficiency of the pump system and thereby minimize energy consumption.

Among these optimization methods, the orthogonal design experiment in DOE is a more efficient and economical method. Pei, Yin, Yuan, and Wang [

18] used the orthogonal design experiment to study the influence of impeller geometric parameters on the cavitation of the pump, and found that the optimum combination of parameters had a better anti-cavitation and hydraulic performance than the original one. Huang and Liu [

19] studied the influence of four parameters on centrifugal pump by orthogonal experiment, which provided reference for the design of rotor and volute. Wang and Huo [

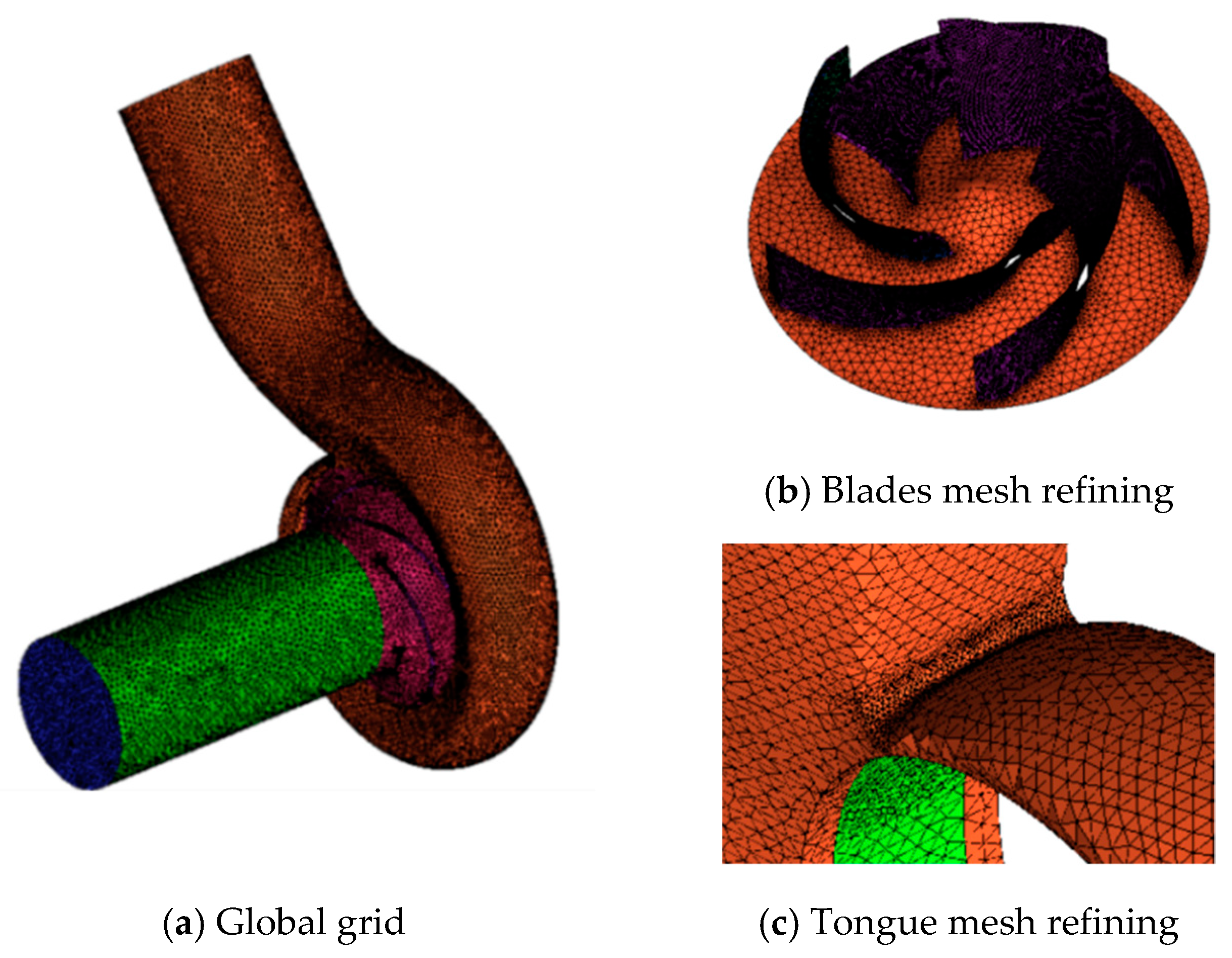

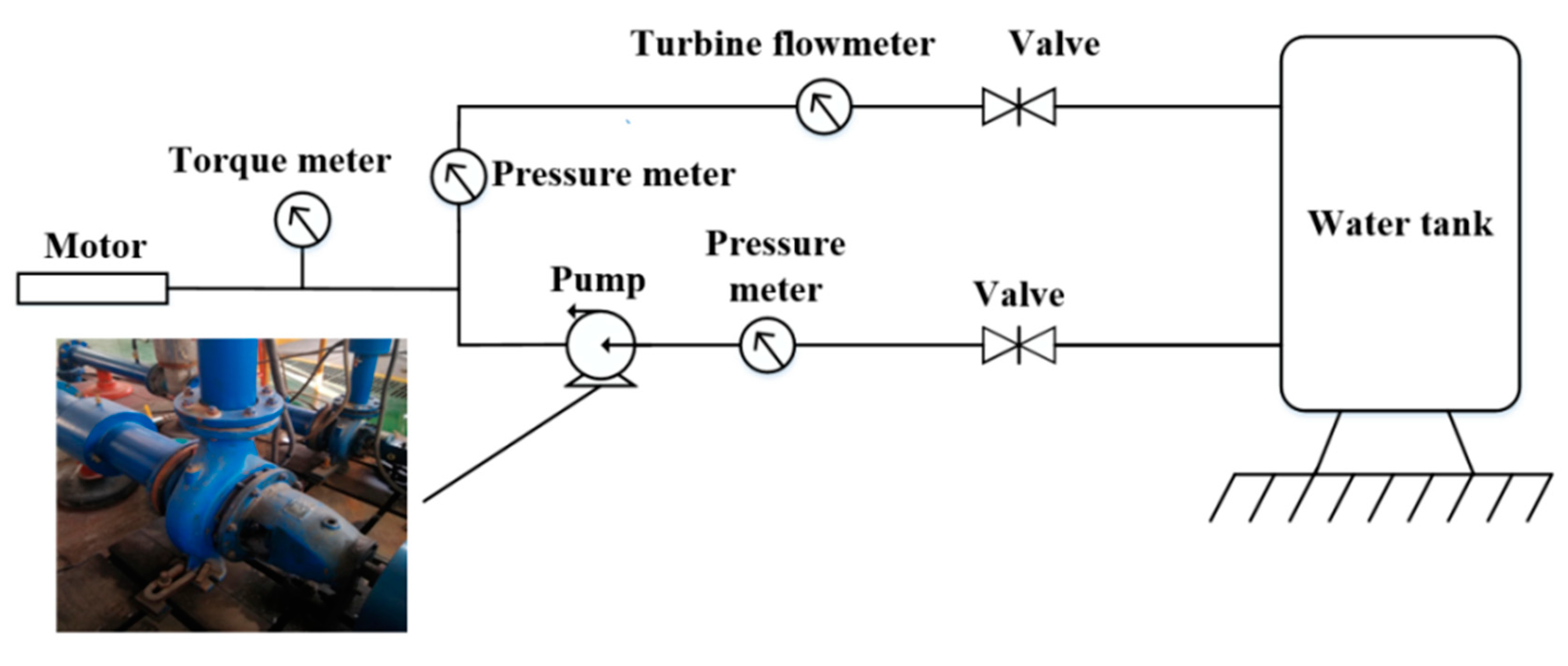

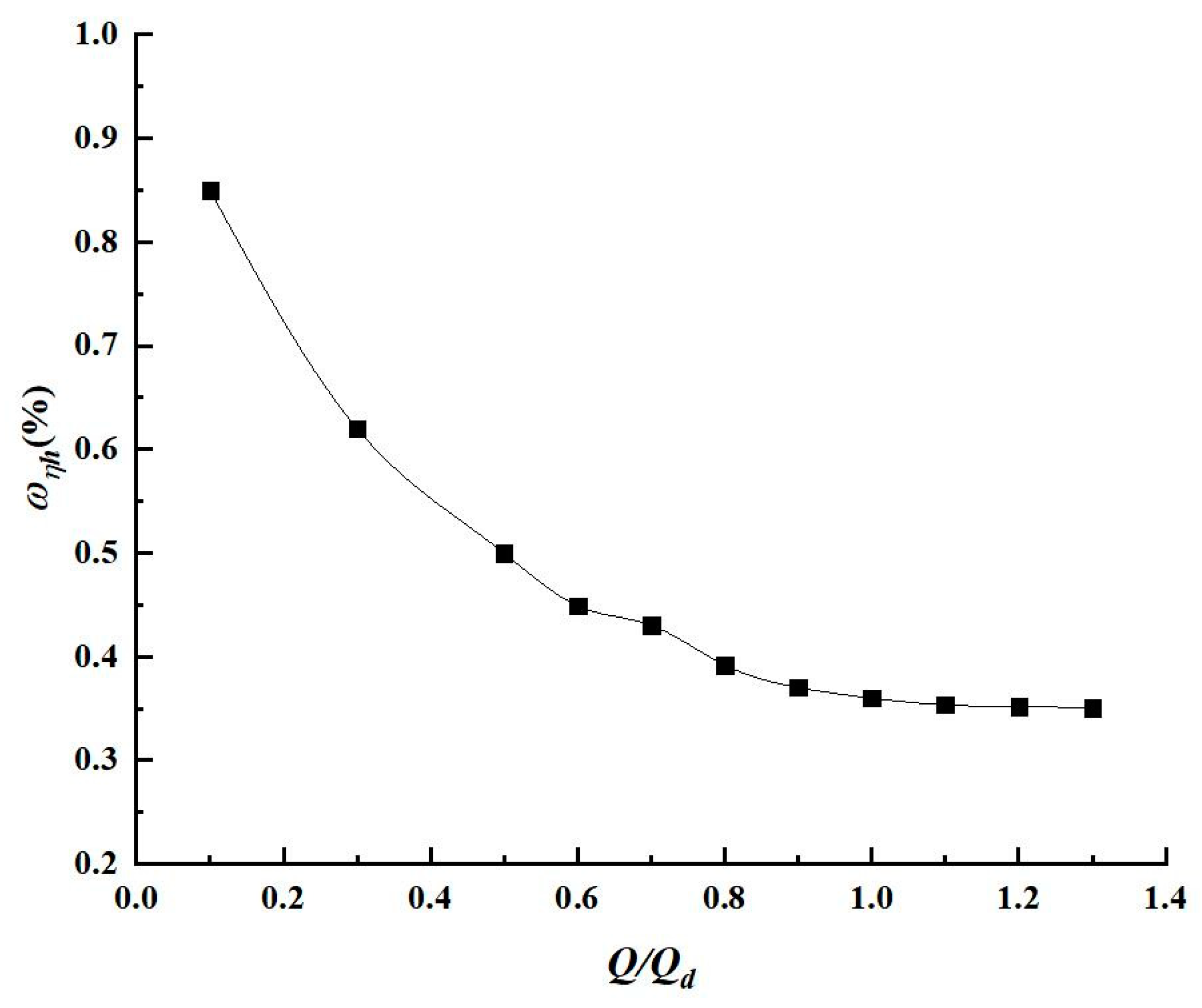

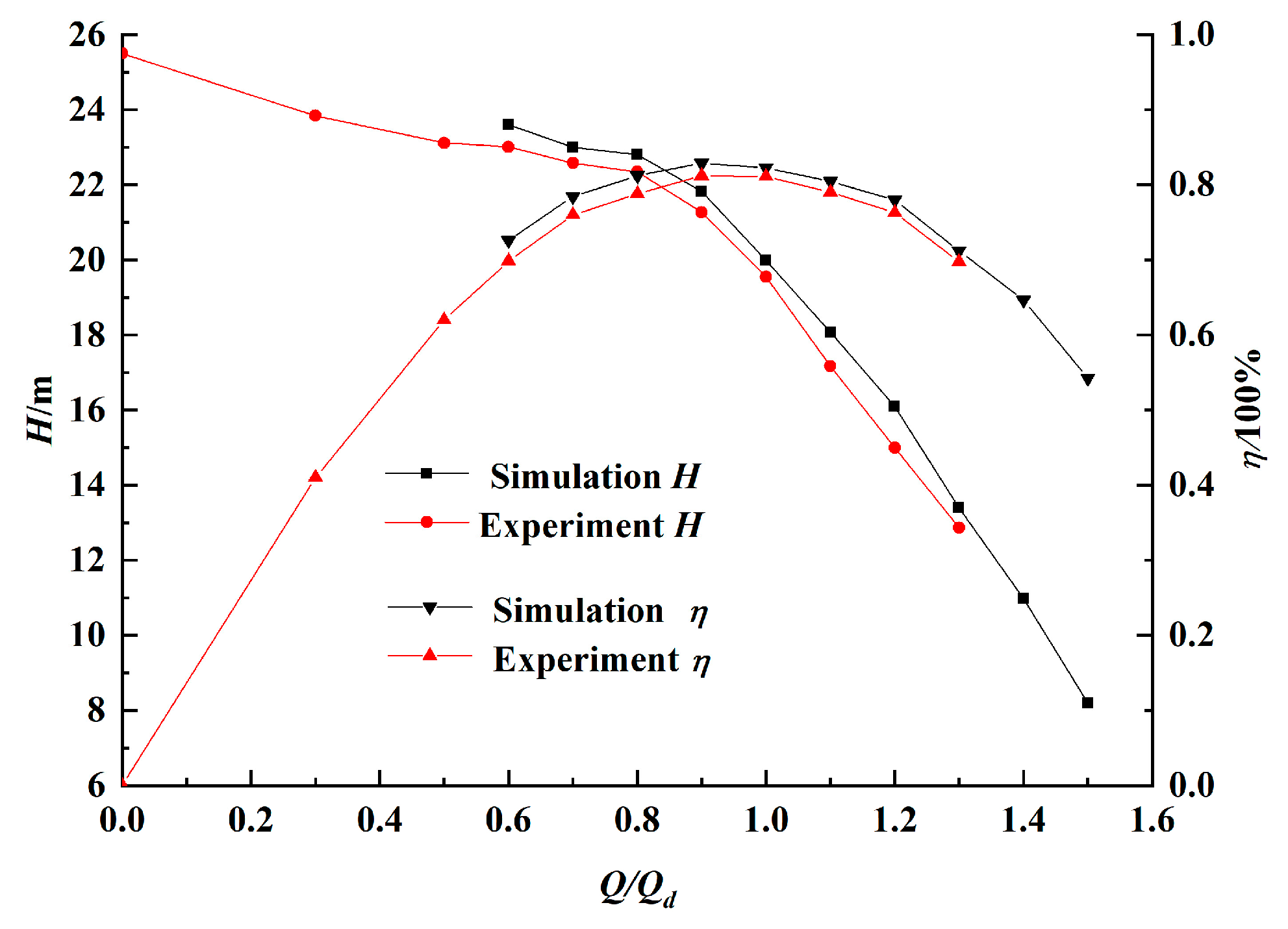

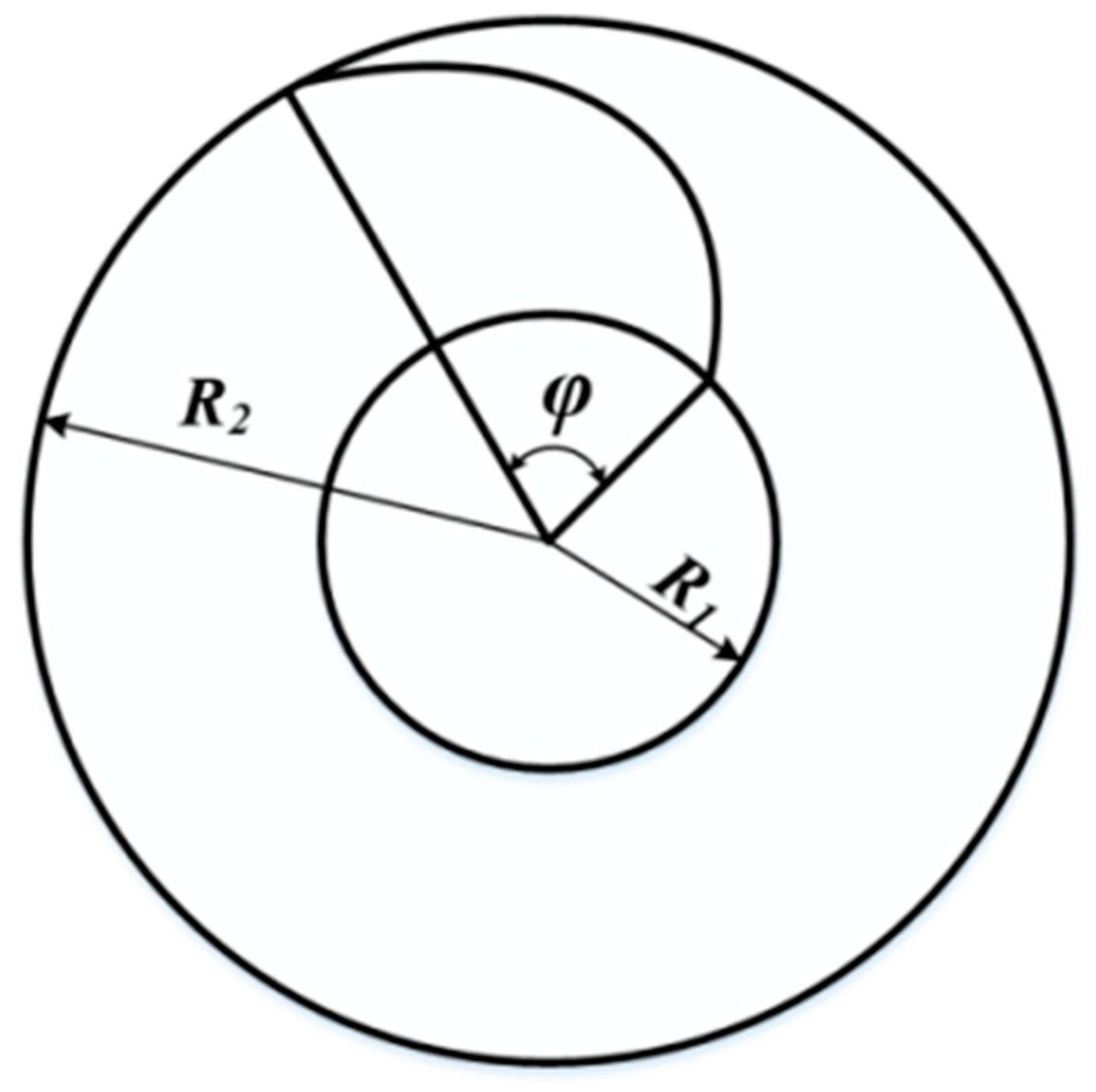

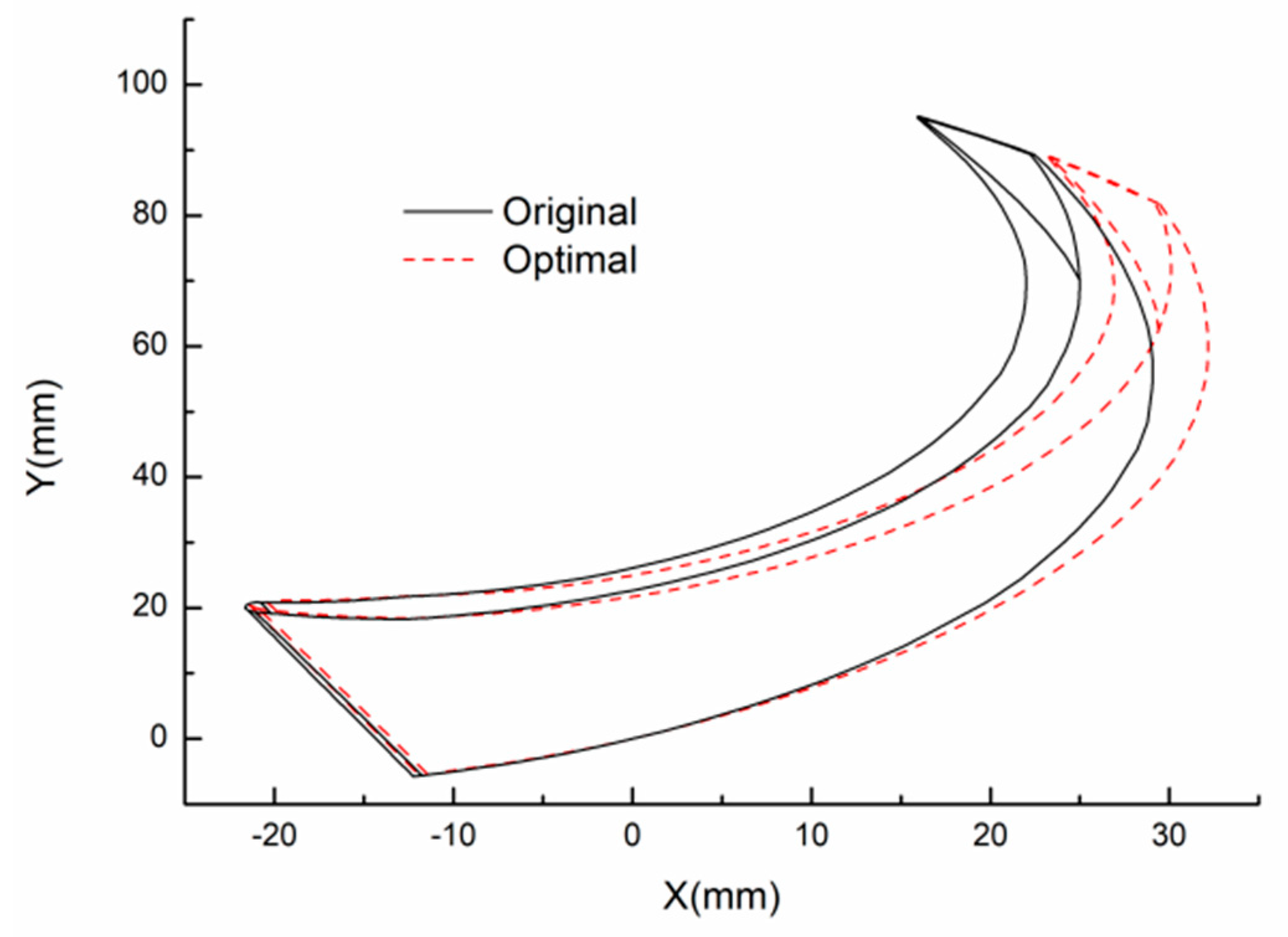

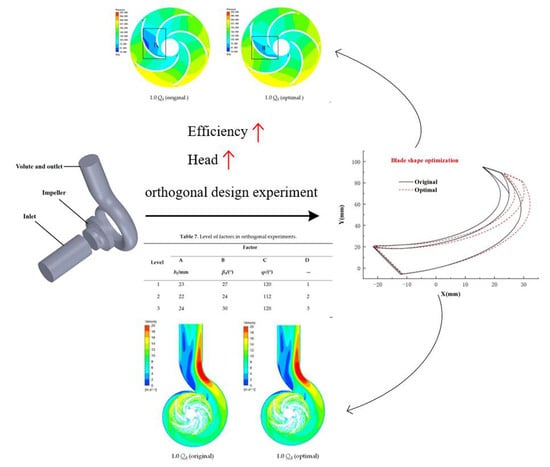

20] concluded that the optimized pump had no obvious “jet-wake” phenomenon by an orthogonal test. The blade outlet angle and blade leading edge position of impeller are critical factors affecting efficiency and anti-cavitation performance. Although orthogonal design experiments have been used to optimize centrifugal pumps in some references, few references have been made to optimize cavitation performance, and there is basically no research regarding centrifugal pumps with high specific speed. In this paper, the orthogonal design method is adopted to optimize the performance of high specific speed centrifugal pump basing on three parameters, namely, the blade outlet width b

2, the blade outlet angle β

2, and the blade wrap angle φ. First, the hydraulic experiment of the prototype pump is carried out to verify that the three-dimensional (3D) model can be simulated. Subsequently, nine groups of representative parameter combinations are obtained according to the orthogonal table. The number of simulations are greatly reduced. Finally, the best combination of parameters is obtained through numerical simulation results. For the high specific speed centrifugal pump that was studied in this paper, the hydraulic performance and anti-cavitation performance can be improved by properly increasing the blade outlet width, reducing the blade outlet angel, and blade wrap angle.

5. Conclusions

In this paper, three impeller parameters are selected for orthogonal design experiments, and the optimal combination of parameters is obtained according to the results of numerical simulation. The main conclusions are as follows:

(1) Orthogonal design experiments can be used to study the influence of impeller parameters on the head and efficiency of centrifugal pumps. Among the three parameters studied, the wrap angle φ has the greatest impact on the head, while the blade outlet angle β2 has the greatest impact on the efficiency.

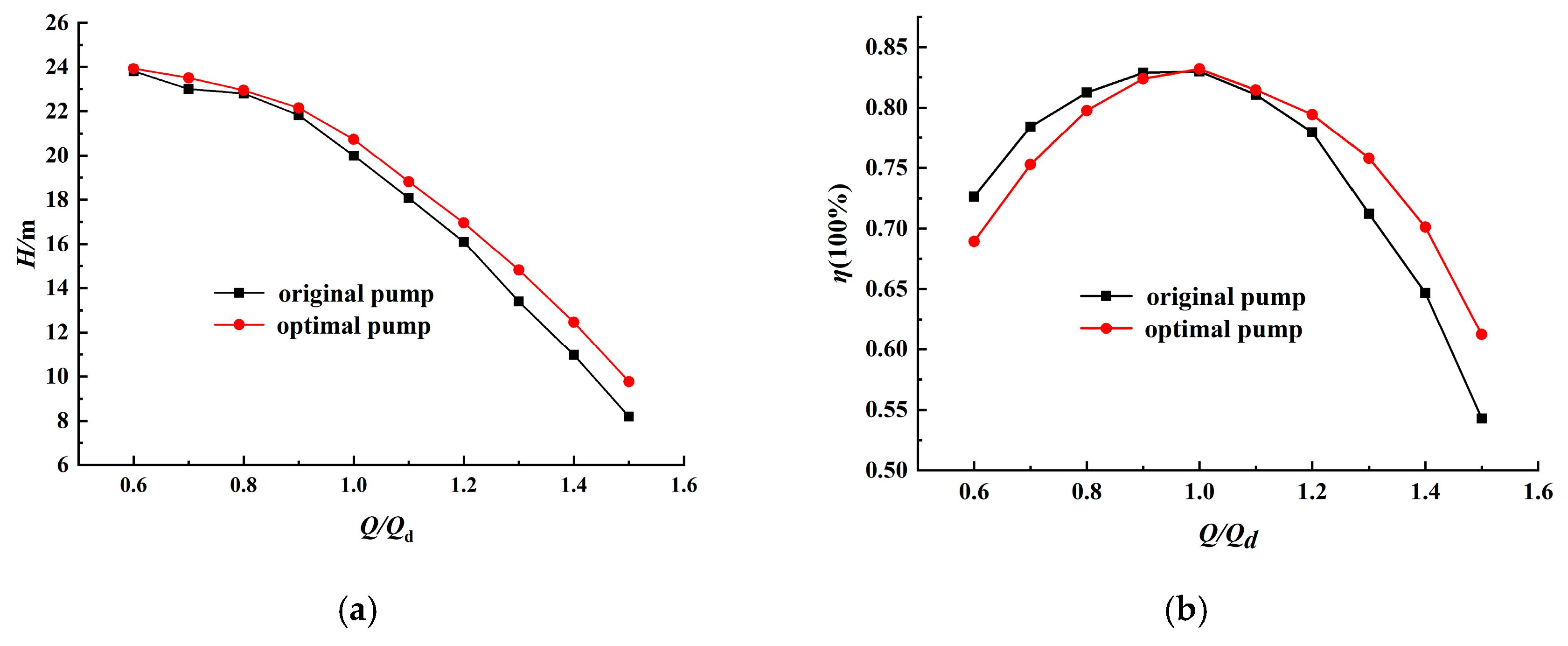

(2) The head of optimal pump is obviously higher than that of the original pump, which increases by 0.74 m under the design flow rate and 1.58 m under 1.5 Qd. However, the optimal pump’s efficiency is lower than the original pump when the flow rate is less than 1.0 Qd. When the flow rate is greater than 1.0 Qd, the efficiency significantly increases; its value increases by 6.9% at 1.5 Qd.

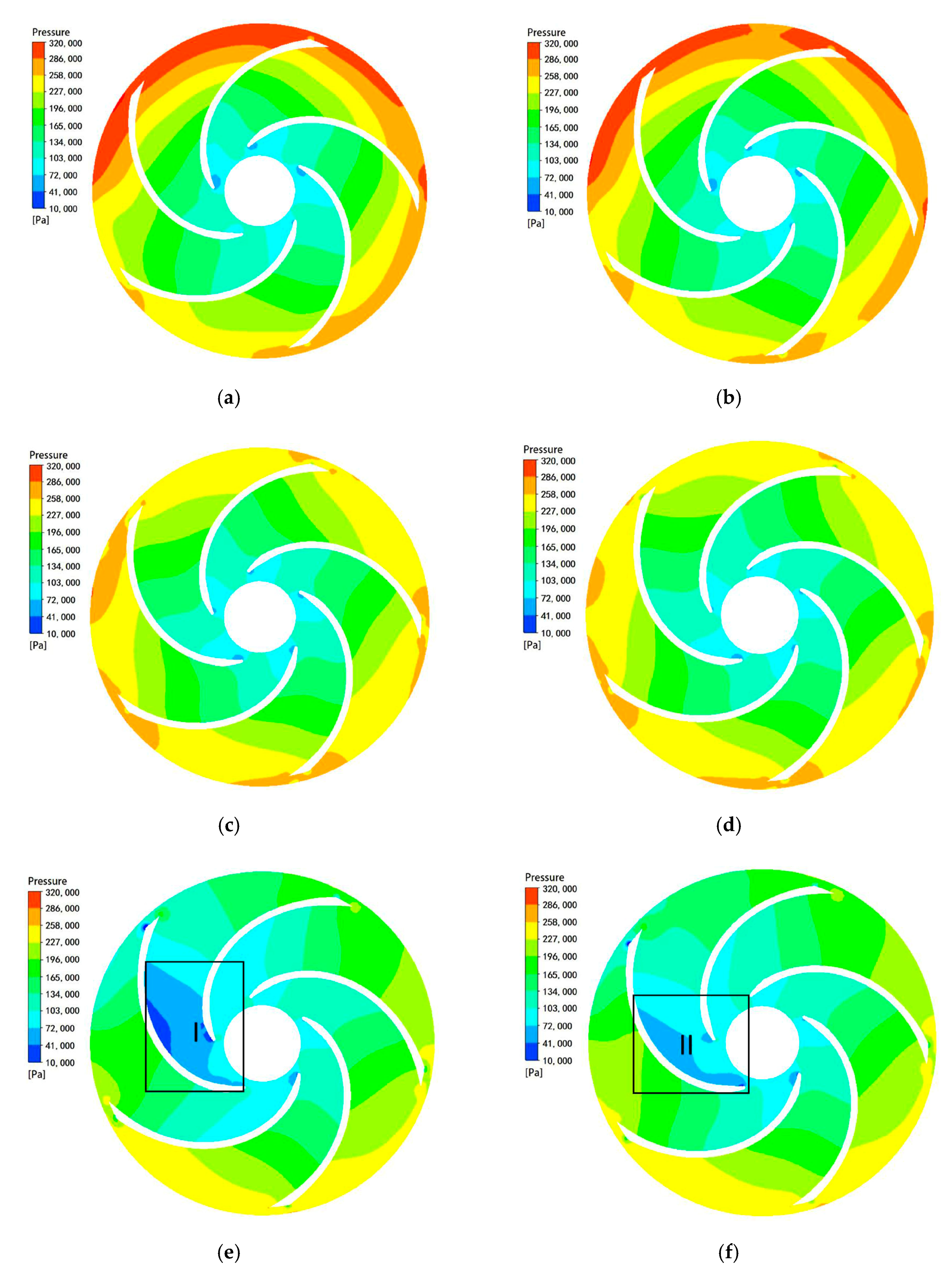

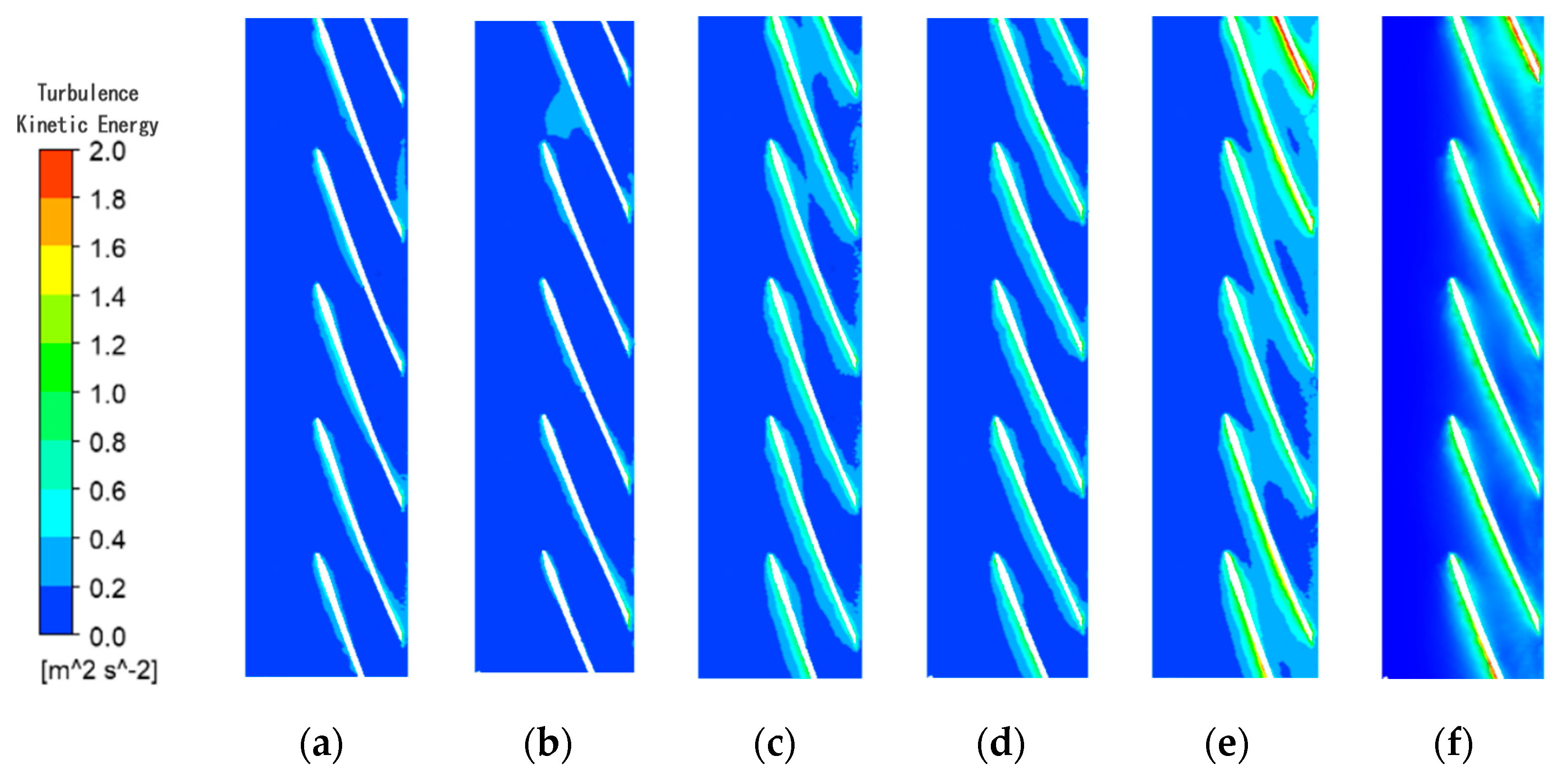

(3) The total pressure distribution of optimal pump is improved under the three operation points, especially at 1.5 Qd. At the same time, the low velocity area of optimal pump is reduced, which will cause less hydraulic loss and increase efficiency. Additionally, the optimized pump has less turbulent kinetic energy loss and better flow characteristics.

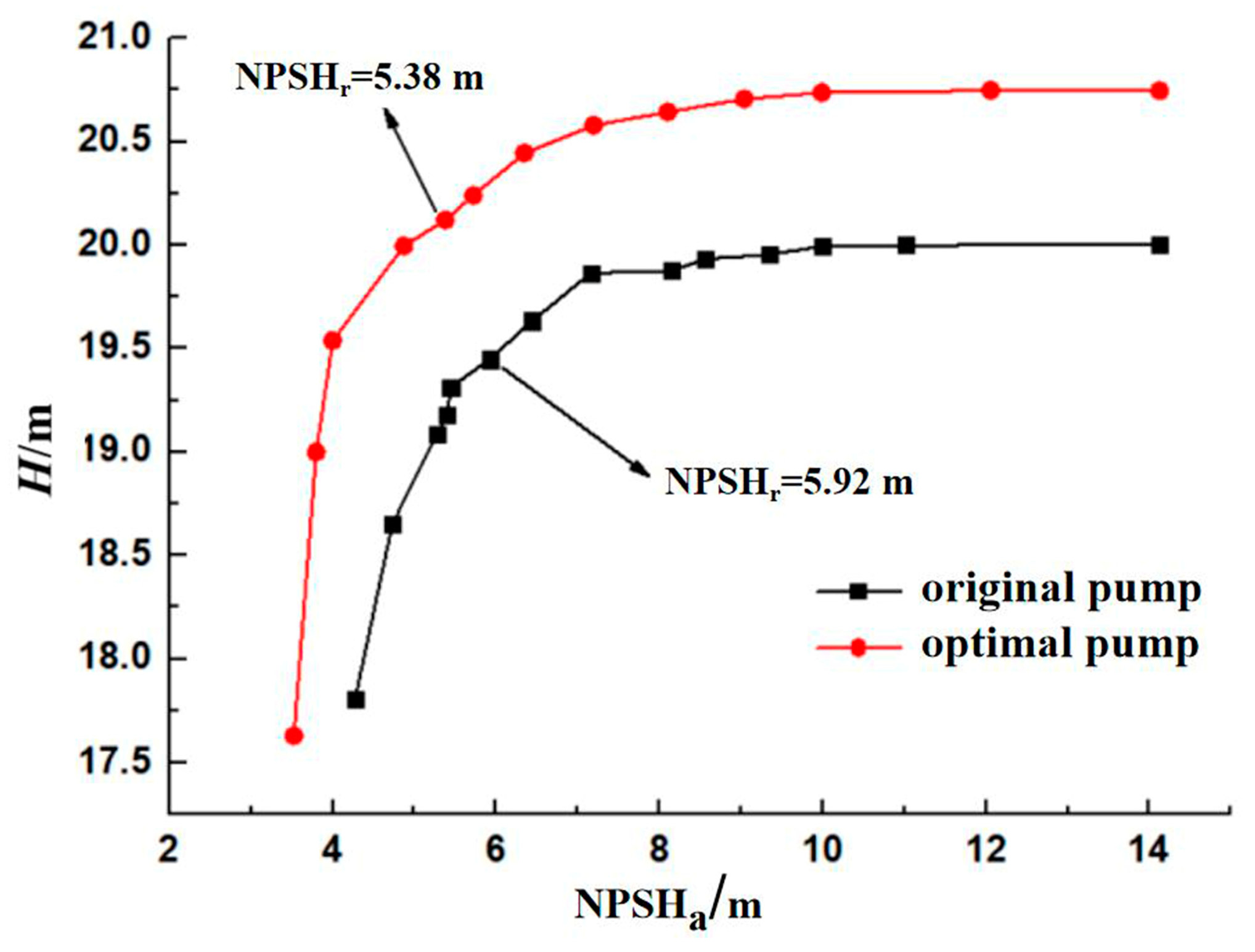

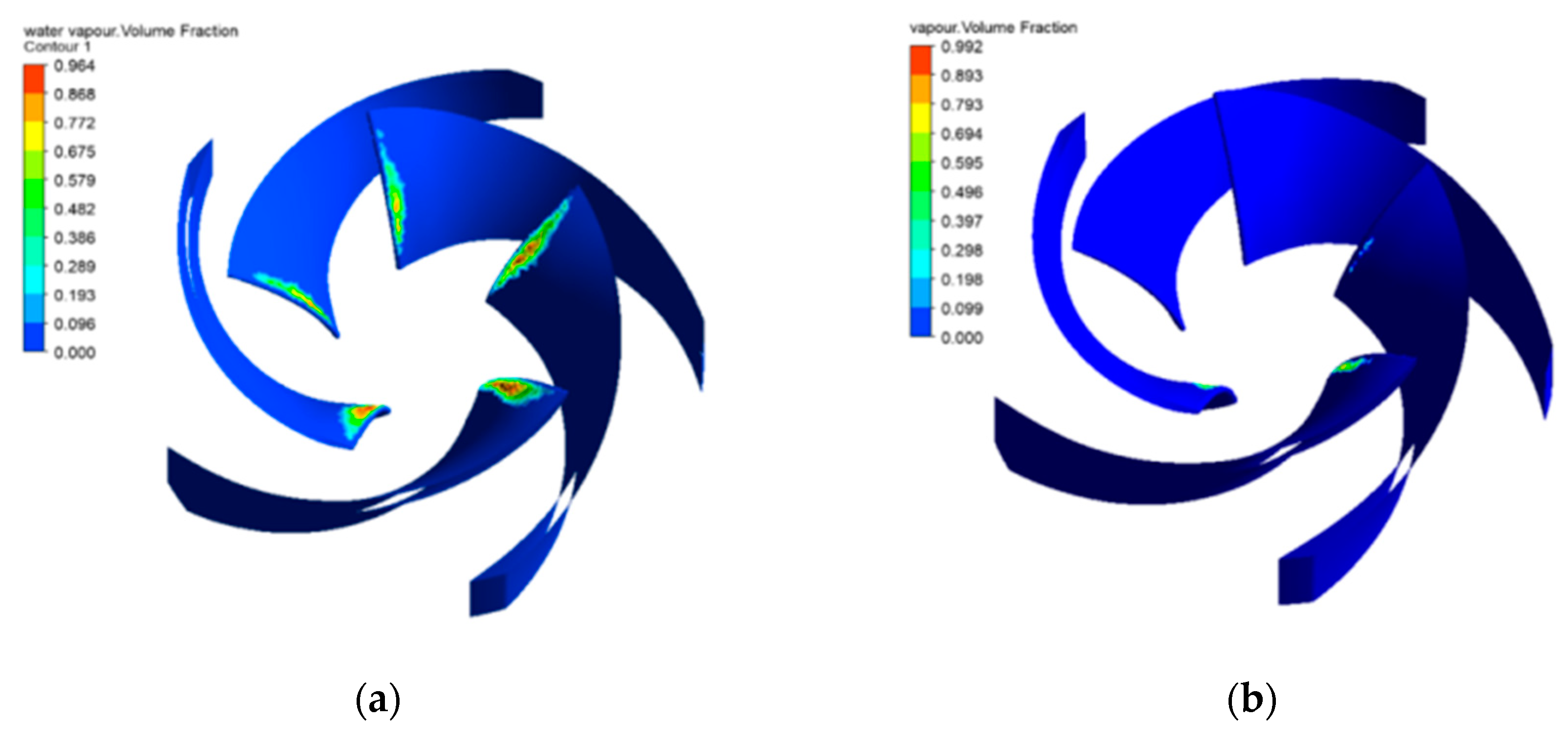

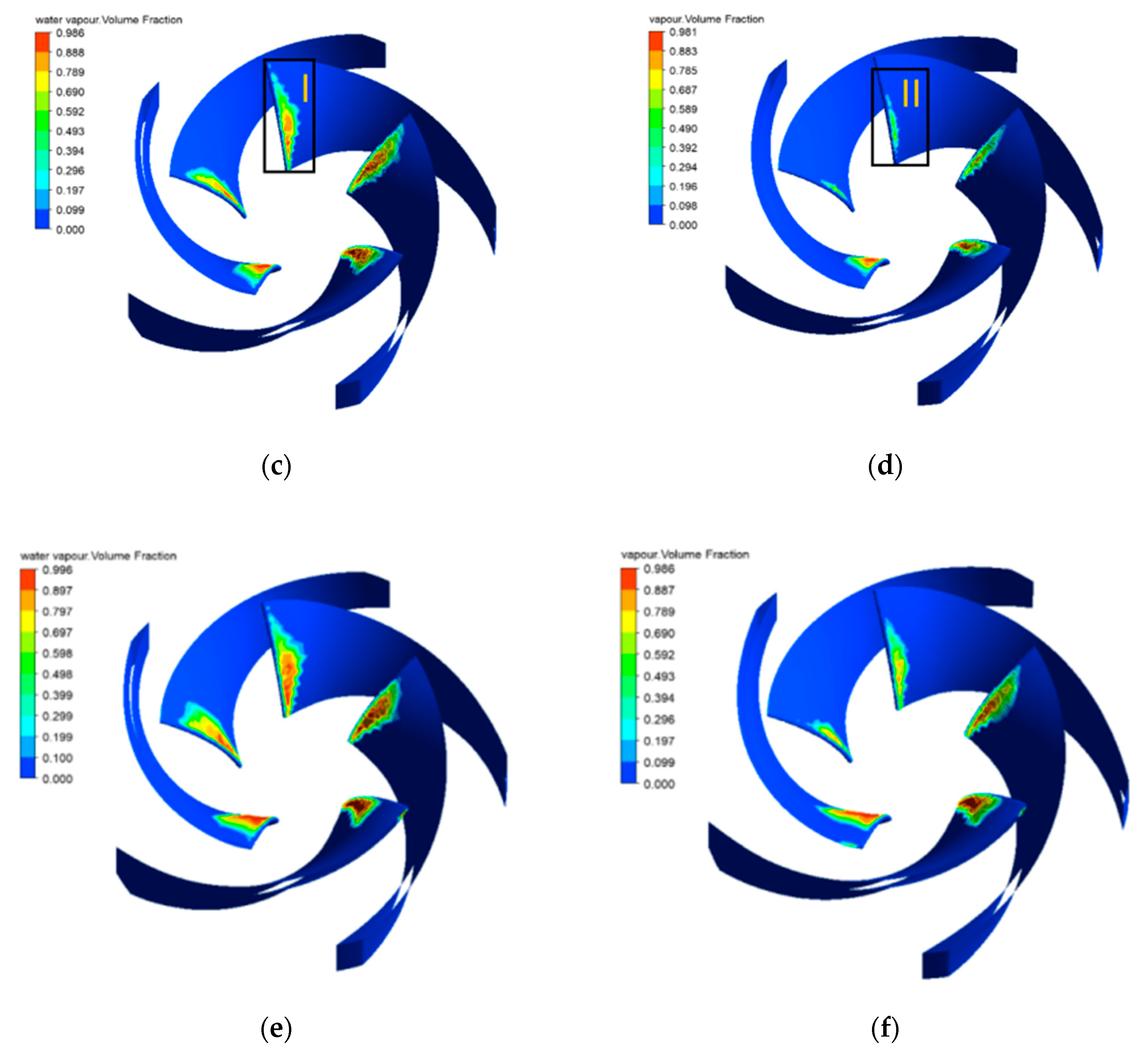

(4) The NPSHr value of optimized centrifugal pump is 0.54 m lower than the original model and its anti-cavitation performance is better.

The major optimizing objective in this paper is to improve efficiency. On this basis, the cavitation performance is also compared. However, the selected parameters are not enough to improve the cavitation performance, and some inlet parameters should be selected. In future work, the influence of volute parameters on the unsteady performance of centrifugal pump can also be studied. The optimization method can also adopt more advanced methods, such as Optimal Latin hypercube design.