Production Process and Optimization of Solid Bioethanol from Empty Fruit Bunches of Palm Oil Using Response Surface Methodology

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Bioethanol

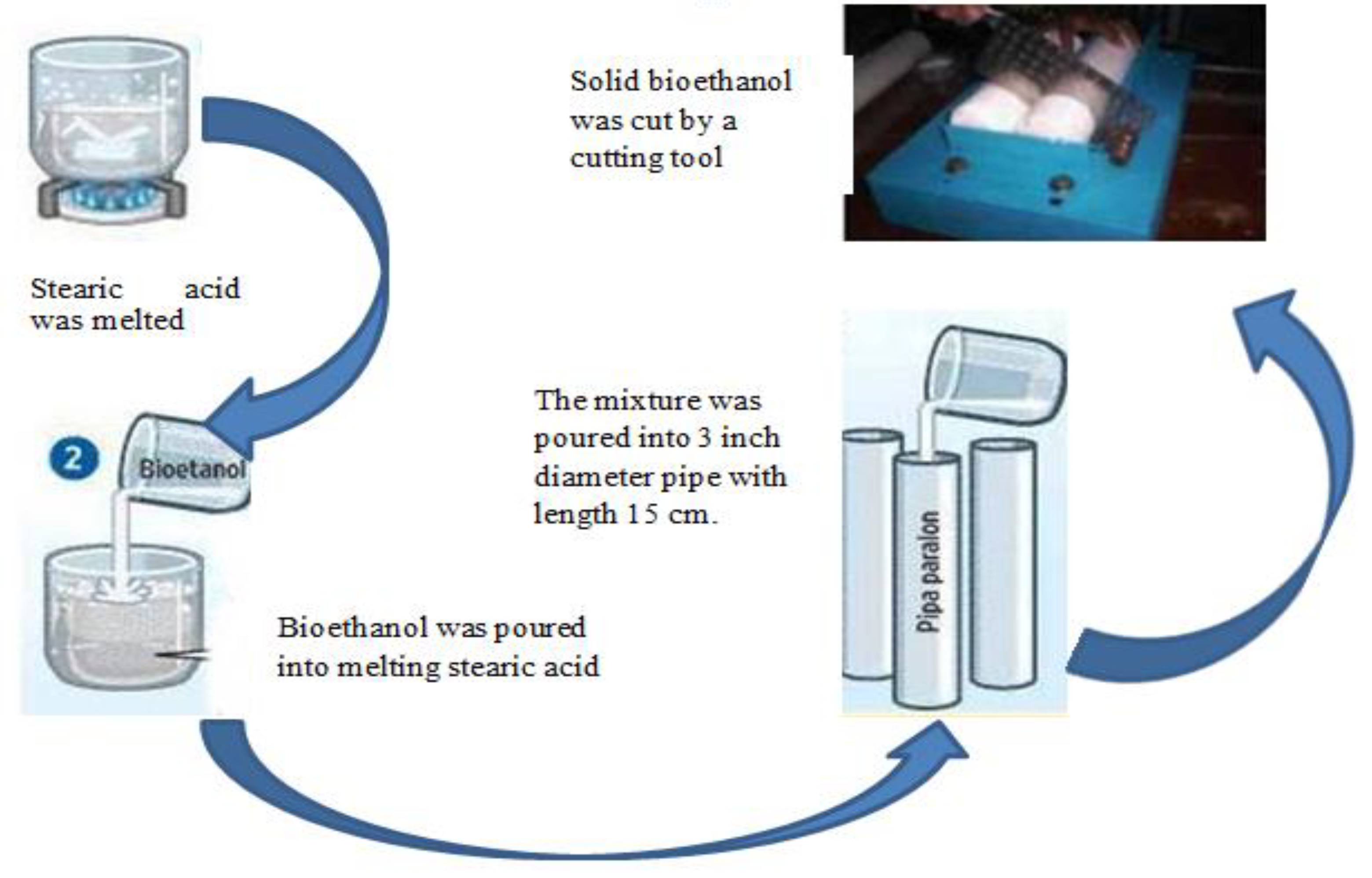

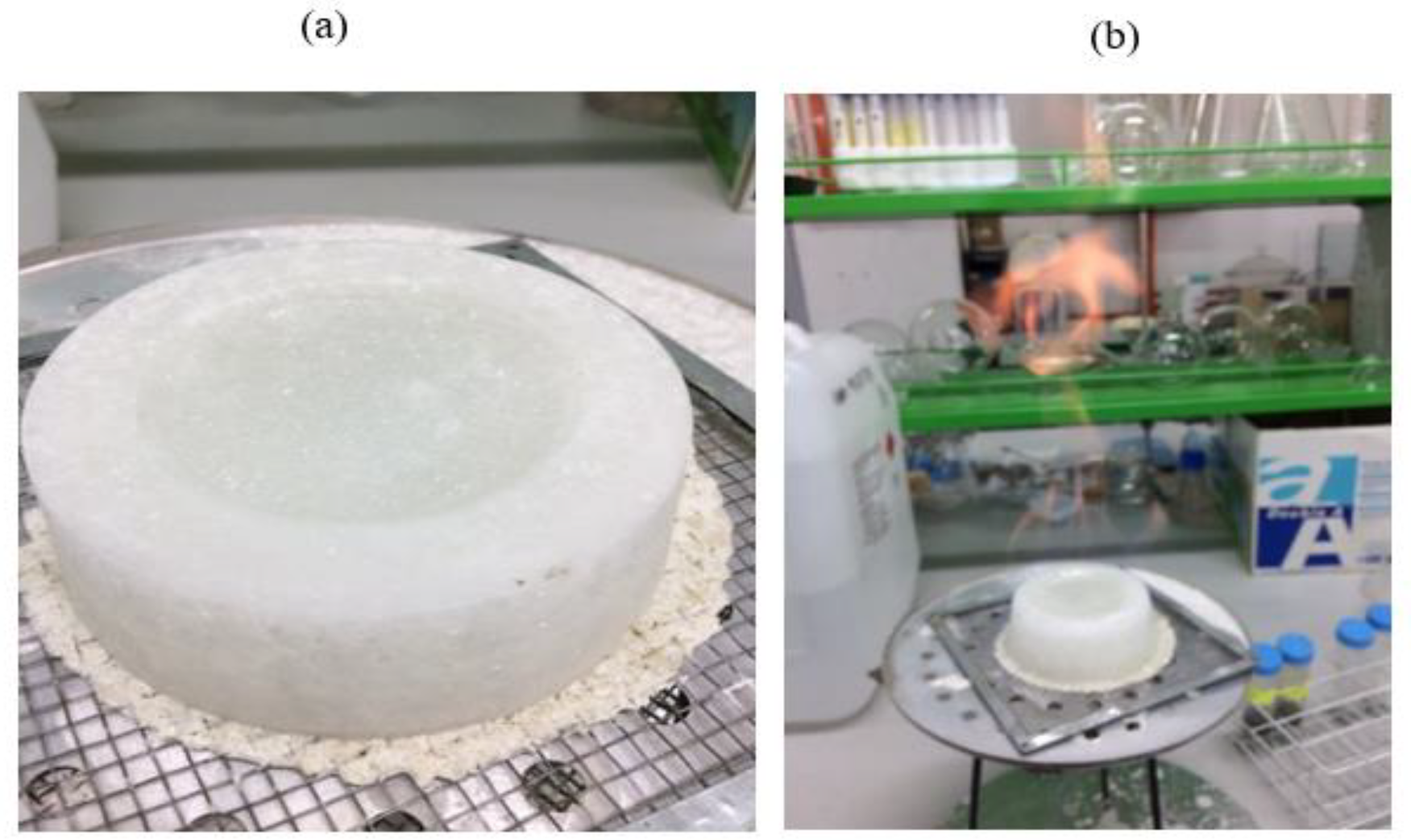

2.3. Solid Ethanol Production and Optimization of Solid Bioethanol Calorific Value

3. Results and Discussion

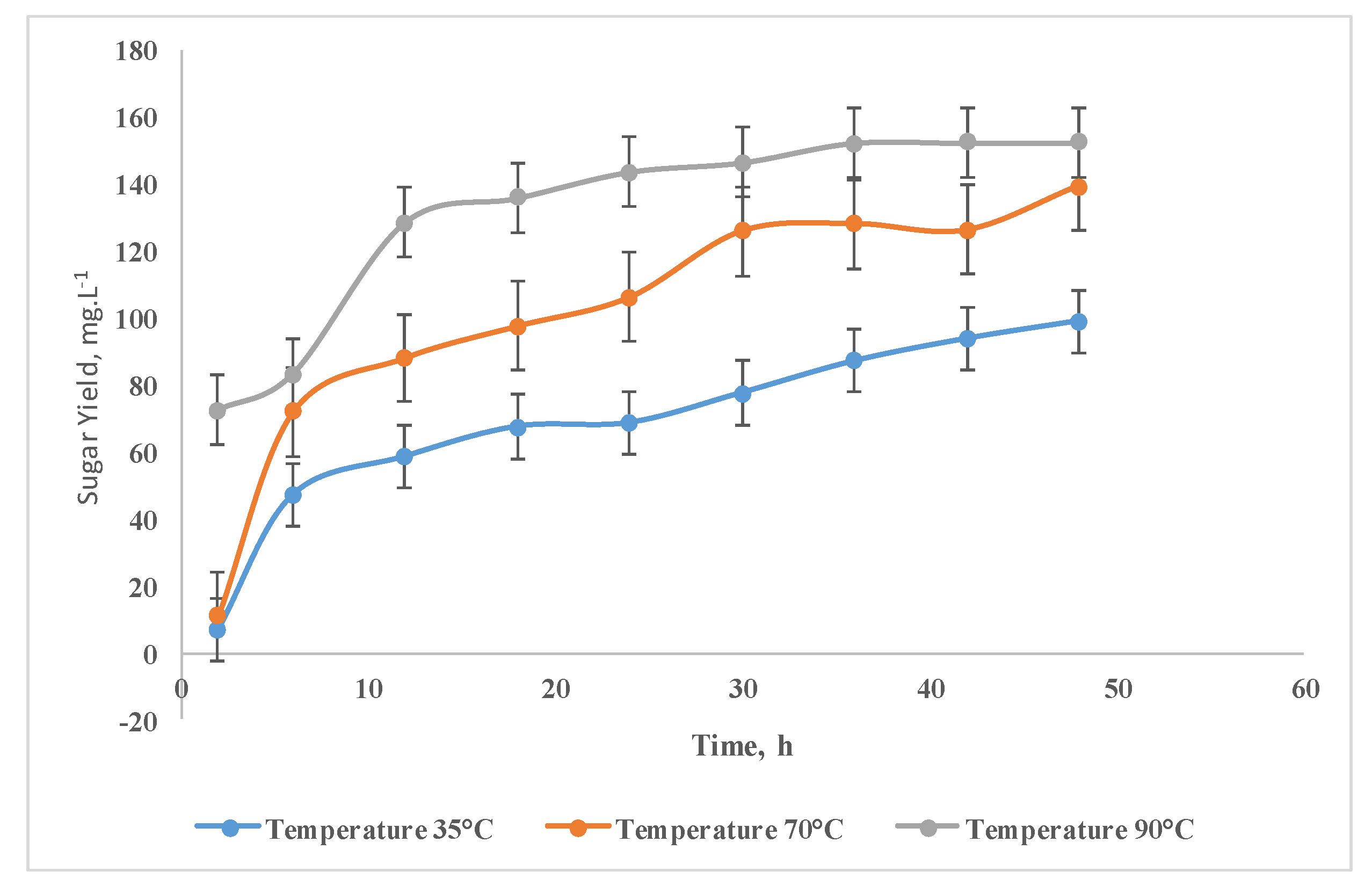

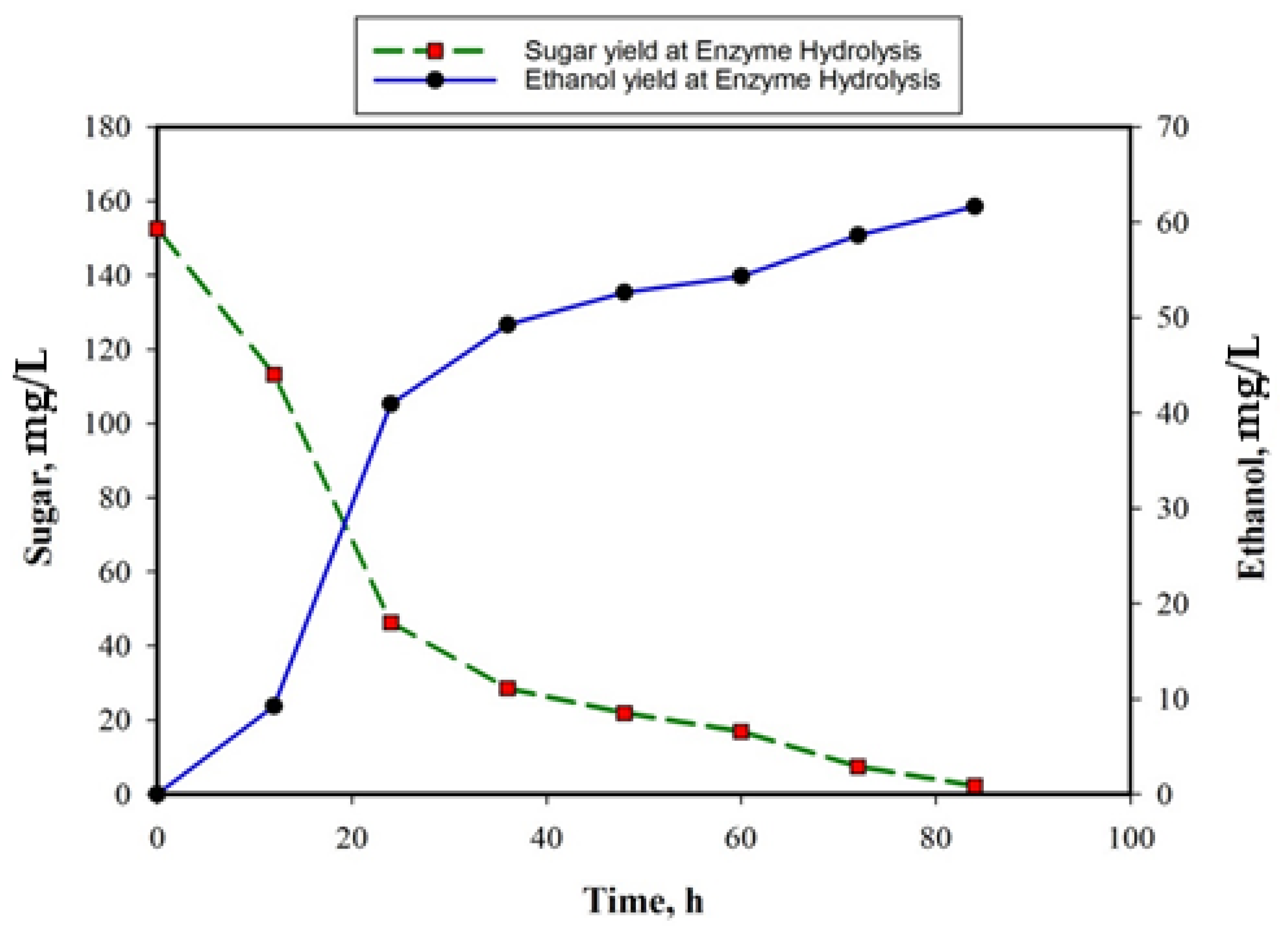

3.1. Sugars and Bioethanol Yield of PEFB

3.2. Optimization of Solid Bioethanol Production

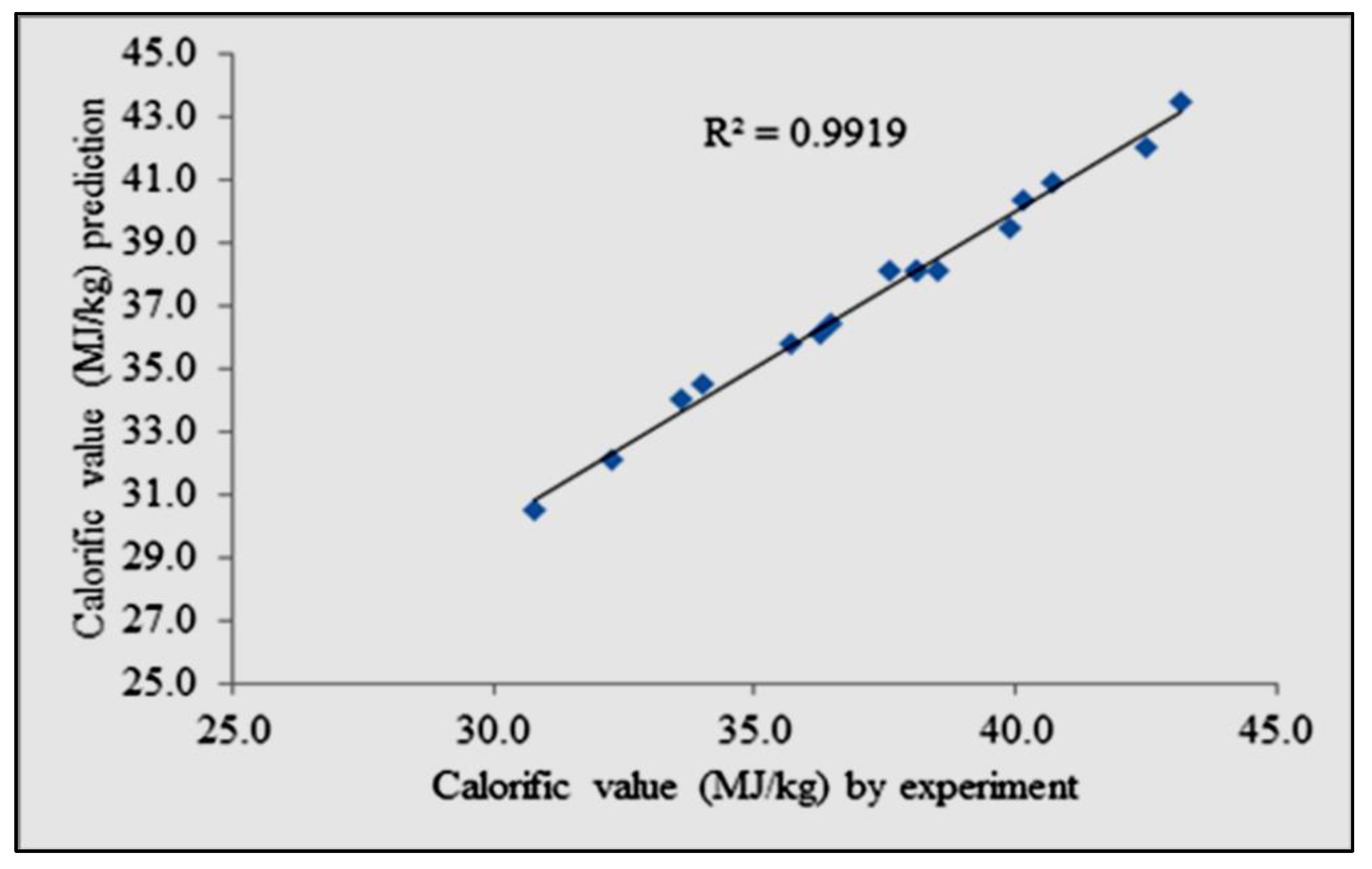

3.2.1. Quadratic Regression Model for Solid Bioethanol Optimization

3.2.2. Effects of Independent Variables on Calorific Value

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Silitonga, A.S.; Masjuki, H.H.; Mahlia, T.M.I.; Ong, H.C.; Chong, W.T. Experimental study on performance and exhaust emissions of a diesel engine fuelled with Ceiba pentandra biodiesel blends. Energy Convers. Manag. 2013, 76, 828–836. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E. Evaluation of biodiesel blending, engine performance and emissions characteristics of Jatropha curcas methyl ester: Malaysian perspective. Energy 2013, 55, 879–887. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Fattah, I.M.R.; Mobarak, H.M. Comparative evaluation of performance and emission characteristics of Moringa oleifera and Palm oil based biodiesel in a diesel engine. Ind. Crops Prod. 2014, 53, 78–84. [Google Scholar] [CrossRef]

- Chia, S.R.; Ong, H.C.; Chew, K.W.; Show, P.L.; Phang, S.M.; Ling, T.C.; Nagarajan, D.; Lee, D.; Chang, J. Sustainable approaches for algae utilisation in bioenergy production. Renew. Energy 2018, 129, 838–852. [Google Scholar] [CrossRef]

- Kusumo, F.; Silitonga, A.S.; Masjuki, H.H.; Ong, H.C.; Siswantoro, J.; Mahlia, T.M.I. Optimization of transesterification process for Ceiba pentandra oil: A comparative study between kernel-based extreme learning machine and artificial neural networks. Energy 2017, 134, 24–34. [Google Scholar] [CrossRef]

- Ong, H.C.; Milano, J.; Silitonga, A.S.; Hassan, M.H.; Shamsuddin, A.H.; Wang, C.T.; Mahlia, T.M.I.; Siswantoro, J.; Kusumo, F.; Sutrisno, J. Biodiesel production from Calophyllum inophyllum-Ceiba pentandra oil mixture: Optimization and characterization. J. Clean. Prod. 2019, 219, 183–198. [Google Scholar] [CrossRef]

- Pathak, G.; Singh, B.; Panigrahi, B.K. Wind-hydro microgrid and its control for rural energy system. IEEE Trans. Ind. Appl. 2019, 55, 3037–3045. [Google Scholar] [CrossRef]

- Ismail, M.S.; Moghavvemi, M.; Mahlia, T.M.I. Techno-economic analysis of an optimized photovoltaic and diesel generator hybrid power system for remote houses in a tropical climate. Energy Convers. Manag. 2013, 69, 163–173. [Google Scholar] [CrossRef]

- Uddin, M.N.; Techato, K.; Taweekun, J.; Rahman, M.M.; Rasul, M.G.; Mahlia, T.M.I.; Ashrafur, S.M. An Overview of Recent Developments in Biomass Pyrolysis Technologies. Energies 2018, 11, 3115. [Google Scholar] [CrossRef]

- Mofijur, M.; Mahlia, T.M.I.; Silitonga, A.S.; Ong, H.C.; Silakhori, M.; Hasan, M.H.; Putra, N.; Rahman, S.M.A. Phase Change Materials (PCM) for Solar Energy Usages and Storage: An Overview. Energies 2019, 12, 3167. [Google Scholar] [CrossRef]

- Amin, M.; Putra, N.; Kosasih, E.A.; Prawiro, E.; Luanto, R.A.; Mahlia, T.M.I. Thermal properties of beeswax/graphene phase change material as energy storage for building applications. Appl. Therm. Eng. 2017, 112, 273–280. [Google Scholar] [CrossRef]

- Mehrali, M.; Latibari, S.T.; Mehrali, M.; Mahlia, T.M.I.; Metselaar, H.S.C.; Naghavi, M.S.; Sadeghinezhad, E.; Akhiani, A.R. Preparation and characterization of palmitic acid/graphene nanoplatelets composite with remarkable thermal conductivity as a novel shape-stabilized phase change material. Appl. Therm. Eng. 2013, 61, 633–640. [Google Scholar] [CrossRef]

- Anwar, M.; Rasul, M.G.; Ashwath, N.; Rahman, M.M. Optimisation of Second-Generation Biodiesel Production from Australian Native Stone Fruit Oil Using Response Surface Method. Energies 2018, 11, 2566. [Google Scholar] [CrossRef]

- Goh, B.H.H.; Ong, H.C.; Cheah, M.Y.; Chen, W.; Yu, K.L.; Mahlia, T.M.I. Sustainability of direct biodiesel synthesis from microalgae biomass: A critical review. Renew. Sustain. Energy Rev. 2019, 107, 59–74. [Google Scholar] [CrossRef]

- Silitonga, A.; Shamsuddin, A.; Mahlia, T.; Milano, J.; Kusumo, F.; Siswantoro, J.; Dharma, S.; Sebayang, A.; Masjuki, H.; Ong, H.C. Biodiesel synthesis from Ceiba pentandra oil by microwave irradiation-assisted transesterification: ELM modeling and optimization. Renew. Energ. 2020, 146, 1278–1291. [Google Scholar] [CrossRef]

- Kusumo, F.; Silitonga, A.S.; Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I. A comparative study of ultrasound and infrared transesterification of Sterculia foetida oil for biodiesel production. Energ. Source. Part A 2017, 39, 1339–1346. [Google Scholar] [CrossRef]

- Ong, H.C.; Masjuki, H.H.; Mahlia, T.M.I.; Silitonga, A.S.; Chong, W.T.; Yusaf, T. Engine performance and emissions using Jatropha curcas, Ceiba pentandra and Calophyllum inophyllum biodiesel in a CI diesel engine. Energy 2014, 69, 427–445. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Mahlia, T.M.I.; Kusumo, F.; Dharma, S.; Sebayang, A.H.; Sembiring, R.W.; Shamsuddin, A.H. Intensification of Reutealis trisperma biodiesel production using infrared radiation: Simulation, optimisation and validation. Renew. Energ. 2019, 133, 520–527. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Mahlia, T.M.I.; Ong, H.C.; Riayatsyah, T.M.I.; Kusumo, F.; Ibrahim, H.; Dharma, S.; Gumilang, D. A comparative study of biodiesel production methods for Reutealis trisperma biodiesel. Energ. Source. Part A 2017, 39, 2006–2014. [Google Scholar] [CrossRef]

- RFA. World Fuel Ethanol Production Renewable Fuel Association; RFA: Washington, DC, USA, 2016. [Google Scholar]

- Lashinky, A.; Schwartz, N. How to beat the high cost of gasoline. Forever 2006. Available online: https://www.energy.gov/sites/prod/files/edg/media/gas_price_fact_sheet.pdf (accessed on 30 May 2019).

- Oktavia, H.T. Pemanfaatan Limbah Air Cucian Beras Sebagai Bahan Baku Pembuatan Bioetanol Padat Secara Fermentasi Oleh Saccharomyces cerevisiae; Diponegoro University: Semarang, Indonesia, 2014. [Google Scholar]

- TN Scientist. Alcohol in Solid Form? 2015. Available online: https://www.thenakedscientists.com/forum/index.php?topic=39961.0 (accessed on 12 December 2016).

- Chou, P.Y.; Fasman, G.D. Conformational parameters for amino acids in helical, β-sheet, and random coil regions calculated from proteins. Biochemistry 1974, 13, 211–222. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.X.; Lim, S.; Ong, H.C.; Pang, Y.L. State of the art review on development of ultrasound-assisted catalytic transesterification process for biodiesel production. Fuel 2019, 235, 886–907. [Google Scholar] [CrossRef]

- Rahman, S.H.A.; Choudhury, J.P.; Ahmad, A.L.; Kamaruddin, A.H. Optimization studies on acid hydrolysis of oil palm empty fruit bunch fiber for production of xylose. Bioresour. Technol. 2007, 98, 554–559. [Google Scholar] [CrossRef] [PubMed]

- Galbe, M.; Zacchi, G. A review of the production of ethanol from softwood. Appl. Microbiol. Biotechnol. 2002, 59, 618–628. [Google Scholar] [CrossRef] [PubMed]

- Jørgensen, H.; Kristensen, J.B.; Felby, C. Enzymatic conversion of lignocellulose into fermentable sugars: Challenges and opportunities. Biofuels Bioprod. Biorefin. 2007, 1, 119–134. [Google Scholar] [CrossRef]

- Chandra, R.P.; Bura, R.; Mabee, W.E.; Berlin, A.; Pan, X.; Saddler, J.N. Substrate Pretreatment: The Key to Effective Enzymatic Hydrolysis of Lignocellulosics? In Biofuels; Olsson, L., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 67–93. [Google Scholar]

- Nurfahmi; Ong, H.C.; Jan, B.M.; Tong, C.W.; Fauzi, H.; Chen, W. Effects of organosolv pretreatment and acid hydrolysis on palm empty fruit bunch (PEFB) as bioethanol feedstock. Biomass Bioenergy 2016, 95, 78–83. [Google Scholar] [CrossRef]

- Chen, H.; Qiu, W. Key technologies for bioethanol production from lignocellulose. Biotechnol. Adv. 2010, 28, 556–562. [Google Scholar] [CrossRef]

- Fernandes, M.C.; Ferro, M.D.; Paulino, A.F.C.; Mendes, J.A.S.; Gravitis, J.; Evtuguin, D.V.; Xavier, A.M.R.B. Enzymatic saccharification and bioethanol production from Cynara cardunculus pretreated by steam explosion. Bioresour. Technol. 2015, 186, 309–315. [Google Scholar] [CrossRef]

- Binod, P.; Sindhu, R.; Singhania, R.R.; Vikram, S.; Devi, L.; Nagalakshmi, S.; Kurien, N.; Sukumaran, R.K.; Pandey, A. Bioethanol production from rice straw: An overview. Bioresour. Technol. 2010, 101, 4767–4774. [Google Scholar] [CrossRef]

- Sharma, A.; Khare, S.K.; Gupta, M.N. Hydrolysis of rice hull by crosslinked Aspergillus niger cellulase. Bioresour. Technol. 2001, 78, 281–284. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, L.; Liu, D. Peracetic acid pretreatment of sugarcane bagasse for enzymatic hydrolysis: A continued work. J. Chem. Technol. Biotechnol. 2008, 83, 950–956. [Google Scholar] [CrossRef]

- Da Silva, A.S.A.; Inoue, H.; Endo, T.; Yano, S.; Bon, E.P.S. Milling pretreatment of sugarcane bagasse and straw for enzymatic hydrolysis and ethanol fermentation. Bioresour. Technol. 2010, 101, 7402–7409. [Google Scholar] [CrossRef] [PubMed]

- Taherzadeh, M.J.; Karimi, K. Acid-based hydrolysis processes for ethanol from lignocellulosic materials: A review. BioResources 2007, 2, 472–499. [Google Scholar]

- Hamzah, F.; Idris, A.; Shuan, T.K. Preliminary study on enzymatic hydrolysis of treated oil palm (Elaeis) empty fruit bunches fibre (EFB) by using combination of cellulase and β 1-4 glucosidase. Biomass Bioenergy 2011, 35, 1055–1059. [Google Scholar] [CrossRef]

- Kamoldeen, A.A.; Lee, C.K.; Abdullah, W.N.W.; Leh, C.P. Enhanced ethanol production from mild alkali-treated oil-palm empty fruit bunches via co-fermentation of glucose and xylose. Renew. Energy 2017, 107, 113–123. [Google Scholar] [CrossRef]

- Fattah, S.S.A.; Mohamed, R.; Jahim, J.M.; Illias, R.M.; Bakar, F.D.A.; Murad, A.M.A. Commercial cellulases and hemicellulase performance towards oil palm empty fruit bunch (OPEFB) hydrolysis. AIP Conf. Proc. 2016, 1784, 020002. [Google Scholar]

- Sebayang, A.H.; Hassan, M.H.; Ong, H.C.; Dharma, S.; Silitonga, A.S.; Kusumo, F.; Mahlia, T.M.I.; Bahar, A.H. Optimization of Reducing Sugar Production from Manihot glaziovii Starch Using Response Surface Methodology. Energies 2017, 10, 35. [Google Scholar] [CrossRef]

- Kim, S.; Park, J.M.; Seo, J.; Kim, C.H. Sequential acid-/alkali-pretreatment of empty palm fruit bunch fiber. Bioresour. Technol. 2012, 109, 229–233. [Google Scholar] [CrossRef]

- Jung, Y.H.; Kim, I.J.; Han, J.; Choi, I.; Kim, K.H. Aqueous ammonia pretreatment of oil palm empty fruit bunches for ethanol production. Bioresour. Technol. 2011, 102, 9806–9809. [Google Scholar] [CrossRef]

- Dharma, S.; Masjuki, H.H.; Ong, H.C.; Sebayang, A.H.; Silitonga, A.S.; Kusumo, F.; Mahlia, T.M.I. Optimization of biodiesel production process for mixed Jatropha curcas–Ceiba pentandra biodiesel using response surface methodology. Energy Convers. Manag. 2016, 115, 178–190. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Masjuki, H.H.; Ong, H.C.; Sebayang, A.H.; Dharma, S.; Kusumo, F.; Siswantoro, J.; Milano, J.; Daud, K.; Mahlia, T.M.I.; et al. Evaluation of the engine performance and exhaust emissions of biodiesel-bioethanol-diesel blends using kernel-based extreme learning machine. Energy 2018, 159, 1075–1087. [Google Scholar] [CrossRef]

- Phwan, C.K.; Chew, K.W.; Sebayang, A.H.; Ong, H.C.; Ling, T.C.; Malek, M.A.; Ho, Y.-C.; Show, P.L. Effects of acids pre-treatment on the microbial fermentation process for bioethanol production from microalgae. Biotechnol. Biofuels 2019, 12, 191. [Google Scholar] [CrossRef] [PubMed]

- Pan, X.; Fan, Z.; Chen, W.; Ding, Y.; Luo, H.; Bao, X. Enhanced ethanol production inside carbon-nanotube reactors containing catalytic particles. Nat. Mater. 2007, 6, 507–511. [Google Scholar] [CrossRef]

- Pan, X.; Gilkes, N.; Kadla, J.; Pye, K.; Saka, S.; Gregg, D.; Ehara, K.; Xie, D.; Lam, D.; Saddler, J. Bioconversion of hybrid poplar to ethanol and co-products using an organosolv fractionation process: Optimization of process yields. Biotechnol. Bioeng. 2006, 94, 851–861. [Google Scholar] [CrossRef] [PubMed]

- Pan, X.; Kadla, J.F.; Ehara, K.; Gilkes, N.; Saddler, J.N. Organosolv Ethanol Lignin from Hybrid Poplar as a Radical Scavenger: Relationship between Lignin Structure, Extraction Conditions, and Antioxidant Activity. J. Agric. Food Chem. 2006, 54, 5806–5813. [Google Scholar] [CrossRef] [PubMed]

- Cai, C.; Qiu, X.; Zeng, M.; Lin, M.; Lin, X.; Lou, H.; Zhan, X.; Pang, Y.; Huang, J.; Xie, L. Using polyvinylpyrrolidone to enhance the enzymatic hydrolysis of lignocelluloses by reducing the cellulase non-productive adsorption on lignin. Bioresour. Technol. 2017, 227, 74–81. [Google Scholar] [CrossRef] [PubMed]

- Nitsos, C.K.; Choli-Papadopoulou, T.; Matis, K.A.; Triantafyllidis, K.S. Optimization of Hydrothermal Pretreatment of Hardwood and Softwood Lignocellulosic Residues for Selective Hemicellulose Recovery and Improved Cellulose Enzymatic Hydrolysis. ACS Sustain. Chem. Eng. 2016, 4, 4529–4544. [Google Scholar] [CrossRef]

- Liu, Z.J.; Lan, T.Q.; Li, H.; Gao, X.; Zhang, H. Effect of bisulfite treatment on composition, structure, enzymatic hydrolysis and cellulase adsorption profiles of sugarcane bagasse. Bioresour. Technol. 2017, 223, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Cheng, K.; Liu, D. Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl. Microbiol. Biotechnol. 2009, 82, 815–827. [Google Scholar] [CrossRef]

- Meryandini, A.; Widosari, W.; Maranatha, B.; Sunarti, T.C.; Rachmania, N.; Satria, H. Isolasi bakteri selulolitik dan karakterisasi enzimnya. Makara Sains 2009, 13, 33–38. [Google Scholar] [CrossRef]

- Volk, W.A.; Wheeler, M.F. Basic Microbiology; Benjamin Cummings: San Francisco, CA, USA, 1997. [Google Scholar]

- Connors, K.A. Chemical Kinetics; VCH Publishers Inc.: New York, NY, USA, 1990. [Google Scholar]

- Pacheco, A.M.; Gondim, D.R.; Gonçalves, L.R.B. Ethanol Production by Fermentation Using Immobilized Cells of Saccharomyces cerevisiae in Cashew Apple Bagasse. Appl. Biochem. Biotechnol. 2010, 161, 209–217. [Google Scholar] [CrossRef]

- Dias, M.O.S.; Modesto, M.; Ensinas, A.V.; Nebra, S.A.; Filho, R.M.; Rossell, C.E.V. Improving bioethanol production from sugarcane: Evaluation of distillation, thermal integration and cogeneration systems. Energy 2011, 36, 3691–3703. [Google Scholar] [CrossRef]

- Mohadesi, M.; Aghel, B.; Khademi, M.H.; Sahraei, S. Optimization of biodiesel production process in a continuous microchannel using response surface methodology. Korean J. Chem. Eng. 2017, 34, 1013–1020. [Google Scholar] [CrossRef]

- Yablonovitch, E. Inhibited Spontaneous Emission in Solid-State Physics and Electronics. Phys. Rev. Lett. 1987, 58, 2059–2062. [Google Scholar] [CrossRef] [PubMed]

- Grimm, H.P.; Helm, P.; Grassi, G.; Lutter, E.; Fjaellstroem, T.; Dong, W. Fostering EU-China cooperation in the development of the biomass fuelled heating and cooking stove market in China. In Proceedings of the 12th European Conference on Biomass Energy Industry and Climate Protection, Amsterdam, The Netherlands, 17–21 June 2002. [Google Scholar]

- Gardoner, J.W.C. Gas Phase Combustion Chemistry; Springer: New York, NY, USA, 2000. [Google Scholar]

| Pretreatment Method | Pros | Cons |

|---|---|---|

| Milling | - Reduces cellulose crystallinity - Reduces polymerization degree - Reduces particle size - Increases specific surface area and pore size | - Significantly increases power and energy consumption |

| Steam explosion | - Improves lignin transformation and hemicellulose solubilization - Reduces cost - Increases glucose and hemicellulose yield in a two-step method | - Increases toxic compound generation - Degrades hemicellulose partially |

| Liquid hot water | The following are not required: - Biomass size reduction - Chemicals - Corrosion-resistant materials | - Increases energy and water consumption - Increases toxic compound generation |

| Ammonia fiber expansion (AFEX) | - Increases available surface area - Reduces inhibitor formation - Reduces use of small biomass particle size | - Not suitable with high lignin content biomass - Increases ammonia cost |

| CO2 explosion | - Increases available surface area - Available at low cost - No inhibitory compound formation - Non-flammability - Ease of recovery after extraction and environmental acceptability | - Requires significantly high pressure |

| Wet oxidation | - Increases hemicellulose and lignin solubilization degree - Reduces degradation compound formation | - Increases oxygen and alkaline catalyst cost |

| Concentrated acid | - Increases glucose yield - Ambient temperatures | - Increases acid cost which needs to be recovered - Requires corrosion-resistant equipment - Toxic and hazardous concentrated acid formation |

| Diluted acid | - Increases sugar yield at the end of the process - Reduces toxic product formation | - Low reducing sugar concentration - Formulation of degradation products |

| Alkali | - Decreases polymerization degree and crystallinity of cellulose - Disruption of lignin structure | - Increases cost significantly - Not suitable for large-scale plant |

| Ozonolysis | - Removes lignin content - Reduces production of toxic residues - Reaction takes place at room temperature and pressure | - Cost significantly increases due to large ozone amount |

| Organosolv | - Causes lignin and hemicellulose hydrolysis | - Requires draining and recycling of solvents - Cost significantly increases |

| Biological | - Reduces energy consumption - Delignification - Reduces cellulose polymerization degree - Partial hydrolysis of hemicelluloses - Requires no chemical - Requires moderate environmental conditions | - Reduces process rate - Significantly lowers treatment rate - Not suitable for commercial application |

| Run | A (Bioethanol Concentrations (%)) | B (Stearic Acid (mg)) | C (Bioethanol (mL)) | Experimental Results of Calorific Value (MJ/kg) | Calorific Value Prediction (MJ/kg) |

|---|---|---|---|---|---|

| 1 | 80 | 5 | 5 | 38.101 | 38.07 |

| 2 | 80 | 3 | 3 | 34.027 | 34.50 |

| 3 | 80 | 7 | 7 | 42.53 | 42.06 |

| 4 | 80 | 5 | 5 | 38.503 | 38.07 |

| 5 | 70 | 7 | 5 | 35.72 | 35.76 |

| 6 | 80 | 5 | 5 | 38.086 | 38.07 |

| 7 | 90 | 3 | 5 | 36.463 | 36.43 |

| 8 | 80 | 7 | 3 | 40.738 | 40.88 |

| 9 | 70 | 5 | 7 | 33.582 | 34.02 |

| 10 | 80 | 5 | 5 | 37.577 | 38.07 |

| 11 | 90 | 7 | 5 | 43.171 | 43.47 |

| 12 | 80 | 5 | 5 | 38.089 | 38.07 |

| 13 | 90 | 5 | 3 | 39.879 | 39.45 |

| 14 | 70 | 5 | 3 | 32.28 | 32.10 |

| 15 | 90 | 5 | 7 | 40.164 | 40.34 |

| 16 | 80 | 3 | 7 | 36.261 | 36.12 |

| 17 | 70 | 3 | 5 | 30.76 | 30.47 |

| Source | Sum of Square | Degree of Freedom | Mean Square | F-Value | p-Value (Prob > F) | Remarks |

|---|---|---|---|---|---|---|

| Model | 186.97 | 9 | 20.77 | 95.50 | <0.0001 | Significant |

| A-bioethanol concentration | 93.40 | 1 | 93.40 | 429.37 | <0.0001 | |

| B-stearic acid | 75.94 | 1 | 75.94 | 349.10 | <0.0001 | |

| C-bioethanol | 3.94 | 1 | 3.94 | 18.10 | 0.0038 | |

| AB | 0.76 | 1 | 0.76 | 3.51 | 0.1031 | |

| AC | 0.26 | 1 | 0.26 | 1.19 | 0.3117 | |

| BC | 0.049 | 1 | 0.049 | 0.22 | 0.65 | |

| A2 | 12.57 | 1 | 12.57 | 57.78 | 0.0001 | |

| B2 | 0.14 | 1 | 0.14 | 0.66 | 0.4424 | |

| C2 | 0.074 | 1 | 0.074 | 0.34 | 0.5775 | |

| Residual | 1.52 | 7 | 0.22 | |||

| Lack of fit | 1.09 | 3 | 0.36 | 3.37 | 0.1358 | Not significant |

| Pure error | 0.43 | 4 | 0.11 | |||

| Cor total | 188.49 | 16 | ||||

| R-squared | 0.9919 | Adjusted R2 | 0.9815 | |||

| Mean | 37.41 | Predicted R2 | 0.9038 | |||

| Coefficient of variation % | 1.25 | Adequate precision | 36.330 |

| Samples | Bioethanol Concentration (%) | Stearic Acid (mg) | Volume Bioethanol (mL) | Calorific Value (MJ/kg) | Burning Time (min) |

|---|---|---|---|---|---|

| 4 | 80 | 5 | 5 | 42.53 | 143 |

| 8 | 80 | 7 | 3 | 40.738 | 25 |

| 11 | 90 | 7 | 5 | 43.171 | 177 |

| 15 | 90 | 5 | 7 | 40.164 | 34 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nurfahmi; Mofijur, M.; Ong, H.C.; Jan, B.M.; Kusumo, F.; Sebayang, A.H.; Husin, H.; Silitonga, A.S.; Mahlia, T.M.I.; Rahman, S.M.A. Production Process and Optimization of Solid Bioethanol from Empty Fruit Bunches of Palm Oil Using Response Surface Methodology. Processes 2019, 7, 715. https://doi.org/10.3390/pr7100715

Nurfahmi, Mofijur M, Ong HC, Jan BM, Kusumo F, Sebayang AH, Husin H, Silitonga AS, Mahlia TMI, Rahman SMA. Production Process and Optimization of Solid Bioethanol from Empty Fruit Bunches of Palm Oil Using Response Surface Methodology. Processes. 2019; 7(10):715. https://doi.org/10.3390/pr7100715

Chicago/Turabian StyleNurfahmi, M. Mofijur, Hwai Chyuan Ong, Badrul Mohamed Jan, Fitranto Kusumo, Abdi Hanra Sebayang, Hazlina Husin, Arridina Susan Silitonga, Teuku Meurah Indra Mahlia, and S. M. Ashrafur Rahman. 2019. "Production Process and Optimization of Solid Bioethanol from Empty Fruit Bunches of Palm Oil Using Response Surface Methodology" Processes 7, no. 10: 715. https://doi.org/10.3390/pr7100715

APA StyleNurfahmi, Mofijur, M., Ong, H. C., Jan, B. M., Kusumo, F., Sebayang, A. H., Husin, H., Silitonga, A. S., Mahlia, T. M. I., & Rahman, S. M. A. (2019). Production Process and Optimization of Solid Bioethanol from Empty Fruit Bunches of Palm Oil Using Response Surface Methodology. Processes, 7(10), 715. https://doi.org/10.3390/pr7100715