Comparison of a Novel Miniaturized Screening Device with Büchi B290 Mini Spray-Dryer for the Development of Spray-Dried Solid Dispersions (SDSDs)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

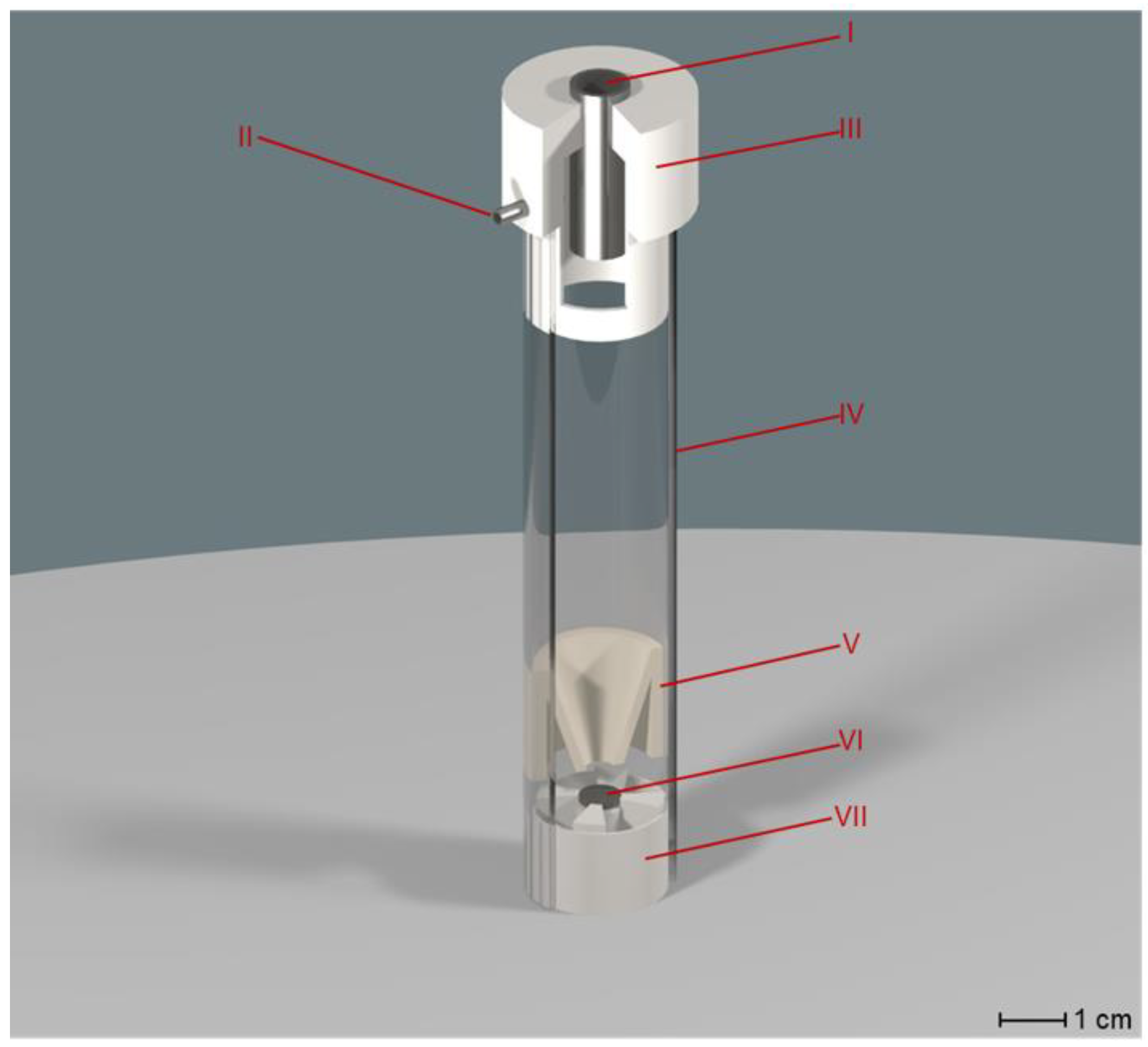

2.2.1. Design of the Novel Miniaturized Atomization Device

2.2.2. Performance Qualification of the Novel Device

2.2.3. Manufacturing Method of Reference—Spray-Dryer

2.2.4. Operational and Performance Equipment Parameters

Yield

Equipment Parameters Including Dimensionless Parameter

- Atomizing-airflow-to-liquid-feed-flow-rate ratio was calculated using both our miniaturized device and laboratory-scale Büchi B290 mini spray-dryer. Density (ρ) values of DCM (ρDCM(25 °C) = 1.33 g/mL), air (ρair(25 °C-1013.25 mbar) = 1.184 kg/m3), and nitrogen (ρN2 (25 °C-1013.25 mbar) = 1.145 kg/m3) were used to convert the volumetric flow rate of feed solution and atomizing airflow (mL/min and L/min, respectively) into mass flow rate (g/min). This dimensionless parameter allows correlating the atomization conditions to the droplet size and comparing the process atomization characteristics of spray-drying operating at different scales [23,24].

- The ratio of the equipment volume to the minimum amount of API used when processing was calculated at both scales, respectively. Such a calculation allows estimation of the material loss on the glass wall’s drying chamber for different manufacturing processes. The volume of the equipment was approximated by considering the geometry of the drying chamber equivalent to a cylinder.

Residence Time

2.2.5. Powder Characterization

Modulated Differential Scanning Calorimetry

Thermogravimetric Analysis

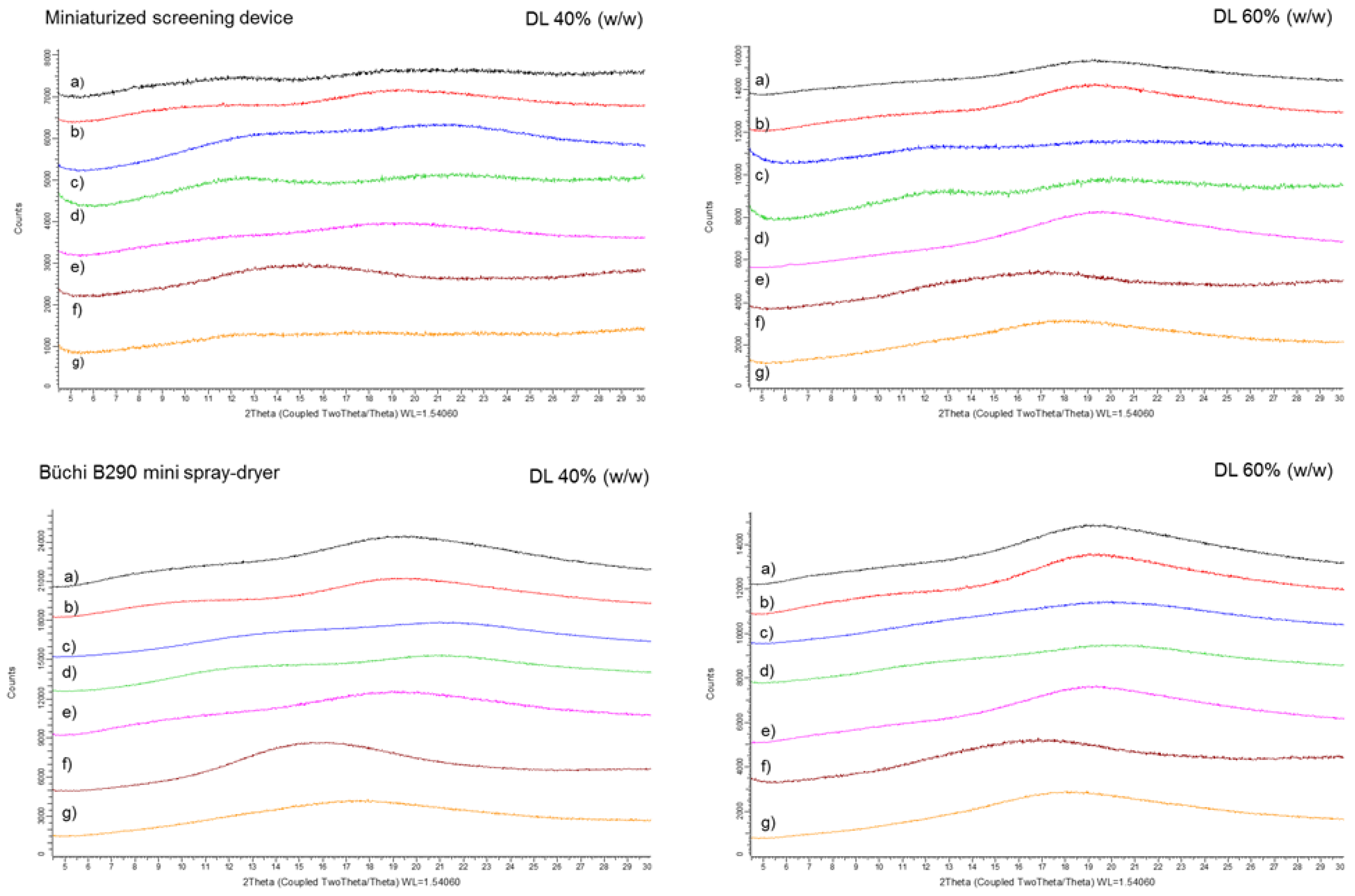

X-Ray Powder Diffraction

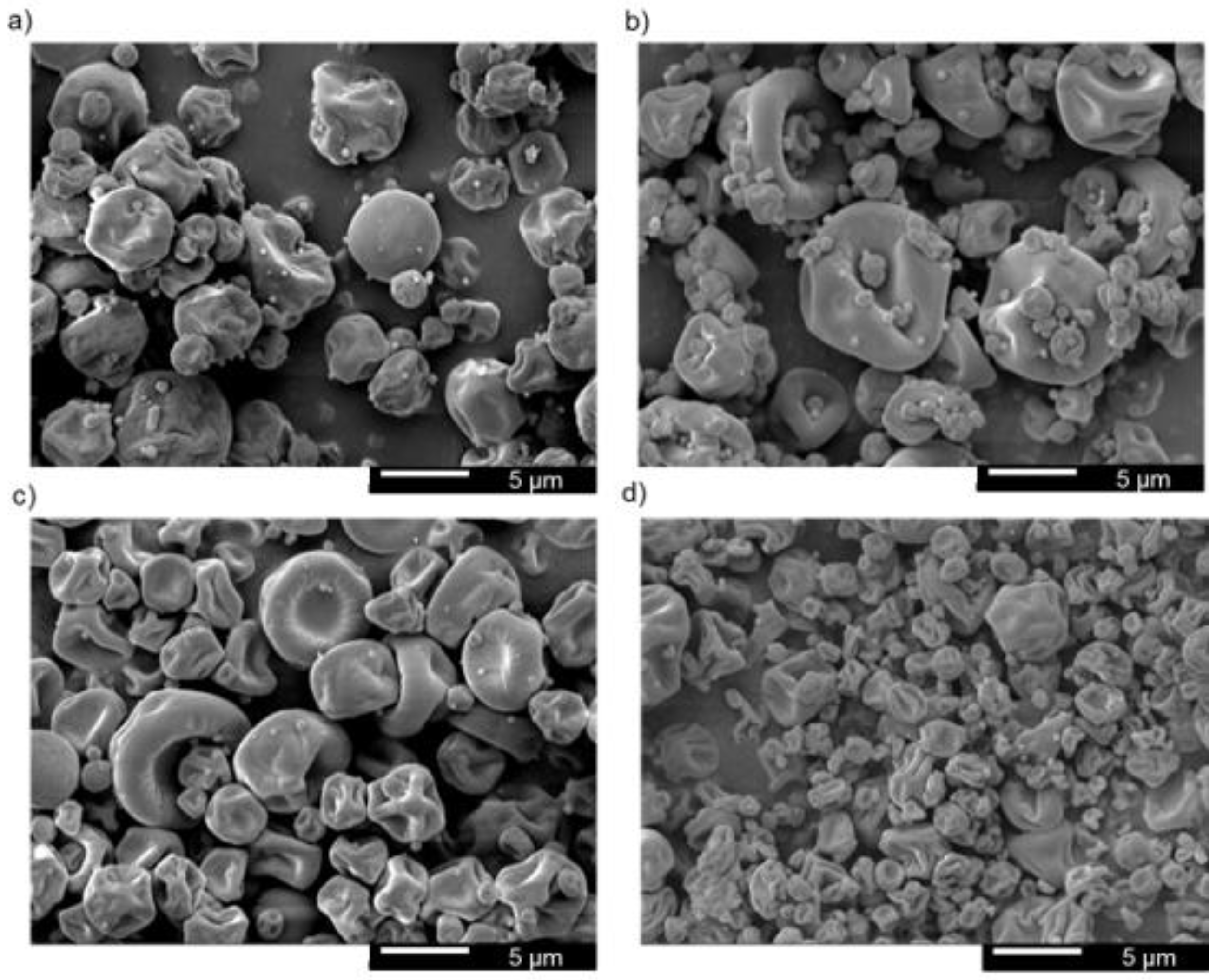

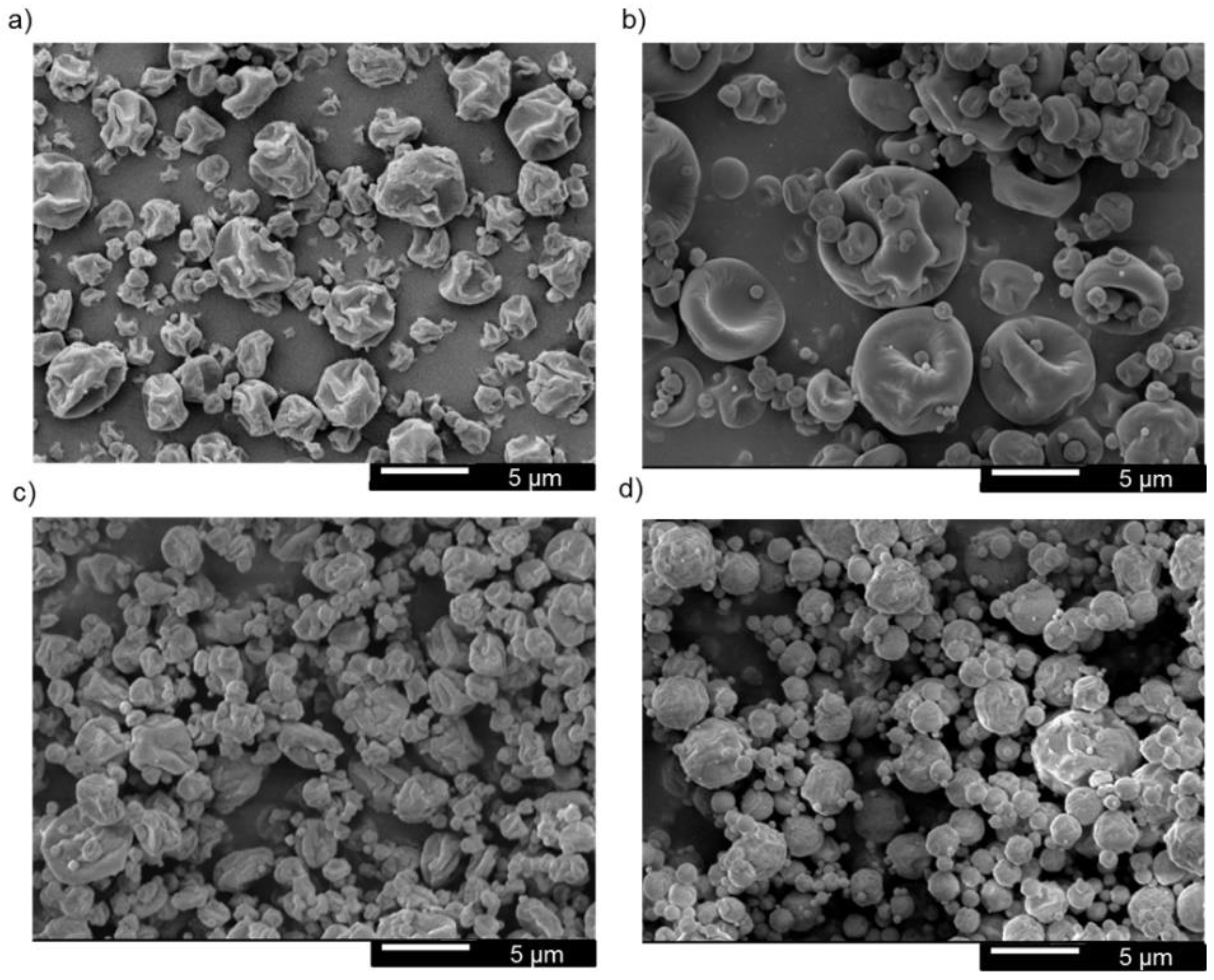

Scanning Electron Microscopy

3. Results and Discussion

3.1. Operational Equipment Parameters and Its Comparison to Laboratory-Scale Büchi B290 Mini Spray-Dryer

3.2. Equipment Performance and Comparison to a Büchi B290 Mini Spray-Dryer

3.2.1. API Consumption, Production Rate, and Yield Obtained

3.2.2. Outlet Temperature Monitoring

3.3. Equipment Qualification: Comparison of Particle/Powder Attributes of SDSDs Generated from the Two Scale Manufacturing Processes

3.3.1. Particles’ Morphology

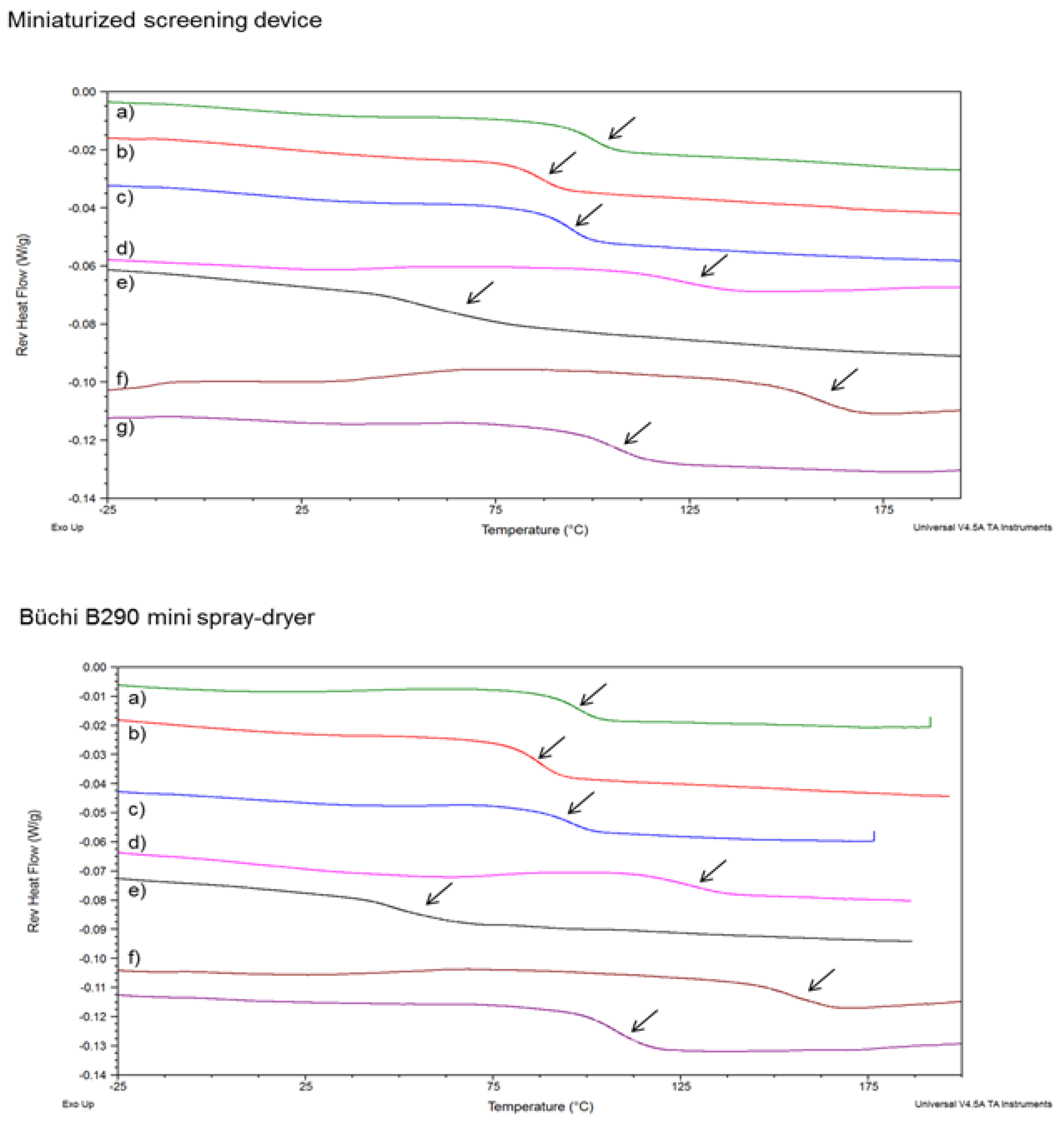

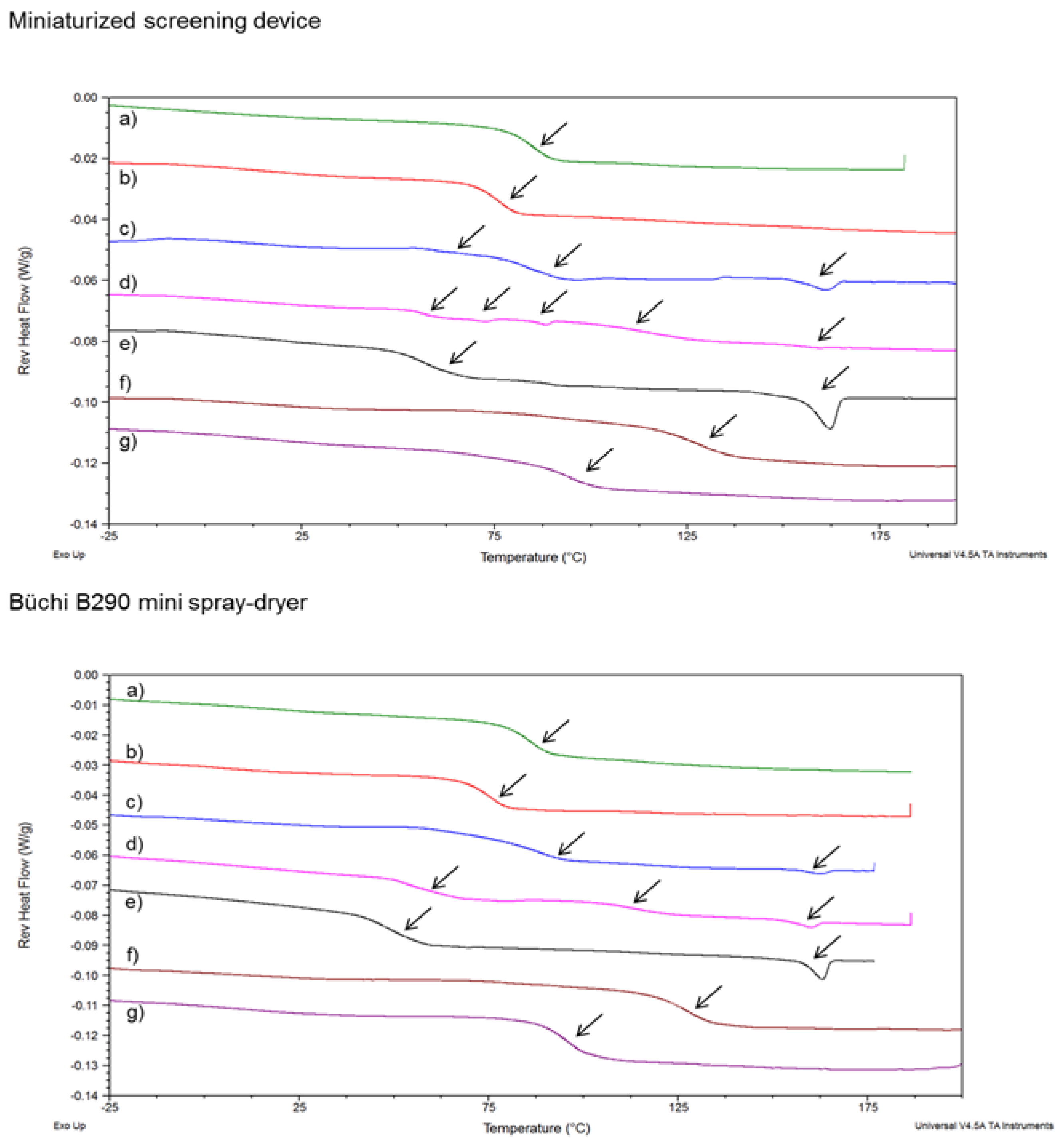

3.3.2. Miscibility and Solid State Properties of SDSDs

3.3.3. Moisture and Residual Solvent Content of SDSDs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Singh, A.; Van den Mooter, G. Spray drying formulation of amorphous solid dispersions. Adv. Drug Deliv. Rev. 2016, 100, 27–50. [Google Scholar] [CrossRef] [PubMed]

- Broadhead, J.; Edmond Rouan, S.K.; Rhodes, C.T. The spray drying of pharmaceuticals. Drug Dev. Ind. Pharm. 1992, 18, 1169–1206. [Google Scholar] [CrossRef]

- Tontul, I.; Topuz, A. Spray-drying of fruit and vegetable juices: Effect of drying conditions on the product yield and physical properties. Trends Food Sci. Technol. 2017, 63, 91–102. [Google Scholar] [CrossRef]

- Wisniewski, R. Spray drying technology review. In Proceedings of the 45th International Conference on Environmental Systems, Bellevue, WA, USA, 12–16 July 2015; pp. 1–46. [Google Scholar]

- Maltesen, M.J.; Bjerregaard, S.; Hovgaard, L.; Havelund, S.; van de Weert, M. Quality by design-spray drying of insulin intended for inhalation. Eur. J. Pharm. Biopharm. 2008, 70, 828–838. [Google Scholar] [CrossRef] [PubMed]

- Vicente, J.; Pinto, J.; Menezes, J.; Gaspar, F. Fundamental analysis of particle formation in spray drying. Powder Technol. 2013, 247, 1–7. [Google Scholar] [CrossRef]

- Vasconcelos, T.; Marques, S.; das Neves, J.; Sarmento, B. Amorphous solid dispersions: Rational selection of a manufacturing process. Adv. Drug Deliv. Rev. 2016, 100, 85–101. [Google Scholar] [CrossRef] [PubMed]

- Haser, A.; Cao, T.; Lubach, J.; Listro, T.; Acquarulo, L.; Zhang, F. Melt extrusion vs. Spray drying: The effect of processing methods on crystalline content of naproxen-povidone formulations. Eur. J. Pharm. Sci. 2017, 102, 115–125. [Google Scholar] [CrossRef] [PubMed]

- Vo, C.L.N.; Park, C.; Lee, B.J. Current trends and future perspectives of solid dispersions containing poorly water-soluble drugs. Eur. J. Pharm. Biopharm. 2013, 85, 799–813. [Google Scholar] [CrossRef] [PubMed]

- Vasconcelos, T.; Sarmento, B.; Costa, P. Solid dispersions as strategy to improve oral bioavailability of poor water soluble drugs. Drug Discov. Today 2007, 12, 1068–1075. [Google Scholar] [CrossRef] [PubMed]

- Vialpando, M.; Smulders, S.; Bone, S.; Jager, C.; Vodak, D.; Van Speybroeck, M.; Verheyen, L.; Backx, K.; Boeykens, P.; Brewster, M.E.; et al. Evaluation of three amorphous drug delivery technologies to improve the oral absorption of flubendazole. J. Pharm. Sci. 2016, 105, 2782–2793. [Google Scholar] [CrossRef] [PubMed]

- Janssens, S.; De Zeure, A.; Paudel, A.; Van Humbeeck, J.; Rombaut, P.; Van den Mooter, G. Influence of preparation methods on solid state supersaturation of amorphous solid dispersions: A case study with itraconazole and eudragit e100. Pharm. Res. 2010, 27, 775–785. [Google Scholar] [CrossRef] [PubMed]

- Janssens, S.; Van den Mooter, G. Review: Physical chemistry of solid dispersions. J. Pharm. Pharmacol. 2009, 61, 1571–1586. [Google Scholar] [CrossRef] [PubMed]

- Chiang, P.C.; Ran, Y.; Chou, K.J.; Cui, Y.; Sambrone, A.; Chan, C.; Hart, R. Evaluation of drug load and polymer by using a 96-well plate vacuum dry system for amorphous solid dispersion drug delivery. AAPS PharmSciTech 2012, 13, 713–722. [Google Scholar] [CrossRef] [PubMed]

- Konno, H.; Taylor, L.S. Influence of different polymers on the crystallization tendency of molecularly dispersed amorphous felodipine. J. Pharm. Sci. 2006, 95, 2692–2705. [Google Scholar] [CrossRef] [PubMed]

- Ousset, A.; Chavez, P.F.; Meeus, J.; Robin, F.; Schubert, M.A.; Somville, P.; Dodou, K. Prediction of phase behavior of spray-dried amorphous solid dispersions: Assessment of thermodynamic models, standard screening methods and a novel atomization screening device with regard to prediction accuracy. Pharmaceutics 2018, 10, 1–29. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Williams, R.O. Effects of the preparation process on the properties of amorphous solid dispersions. AAPS PharmSciTech 2018, 19, 1971–1984. [Google Scholar] [CrossRef] [PubMed]

- Ormes, J.D.; Zhang, D.; Chen, A.M.; Hou, S.; Krueger, D.; Nelson, T.; Templeton, A. Design of experiments utilization to map the processing capabilities of a micro-spray dryer: Particle design and throughput optimization in support of drug discovery. Pharm. Dev. Technol. 2013, 18, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Paudel, A.; Worku, Z.A.; Meeus, J.; Guns, S.; Van den Mooter, G. Manufacturing of solid dispersions of poorly water soluble drugs by spray drying: Formulation and process considerations. Int. J. Pharm. 2013, 453, 253–284. [Google Scholar] [CrossRef] [PubMed]

- Baldinger, A.; Clerdent, L.; Rantanen, J.; Yang, M.; Grohganz, H. Quality by design approach in the optimization of the spray-drying process. Pharm. Dev. Technol. 2012, 17, 389–397. [Google Scholar] [CrossRef] [PubMed]

- Paudel, A.; Loyson, Y.; Van den Mooter, G. An investigation into the effect of spray drying temperature and atomizing conditions on miscibility, physical stability, and performance of naproxen–pvp k 25 solid dispersions. J. Pharm. Sci. 2013, 102, 1249–1267. [Google Scholar] [CrossRef] [PubMed]

- Lauer, M.E.; Maurer, R.; Paepe, A.T.; Stillhart, C.; Jacob, L.; James, R.; Kojima, Y.; Rietmann, R.; Kissling, T.; van den Ende, J.A.; et al. A miniaturized extruder to prototype amorphous solid dispersions: Selection of plasticizers for hot melt extrusion. Pharmaceutics 2018, 10, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Schmitz-Schug, I.; Foerst, P.; Kulozik, U. Impact of the spray drying conditions and residence time distribution on lysine loss in spray dried infant formula. Dairy Sci. Technol. 2013, 93, 443–462. [Google Scholar] [CrossRef]

- Petit, J.; Méjean, S.; Accart, P.; Galet, L.; Schuck, P.; Le Floch-Fouéré, C.; Delaplace, G.; Jeantet, R. A dimensional analysis approach for modelling the size of droplets formed by bi-fluid atomisation. J. Food Eng. 2015, 149, 237–247. [Google Scholar] [CrossRef]

- Kemp, I.C.; Wadley, R.; Hartwig, T.; Cocchini, U.; See-Toh, Y.; Gorringe, L.; Fordham, K.; Ricard, F. Experimental study of spray drying and atomization with a two-fluid nozzle to produce inhalable particles. Dry. Technol. 2013, 31, 930–941. [Google Scholar] [CrossRef]

- Kemp, I.C.; Hartwig, T.; Herdman, R.; Hamilton, P.; Bisten, A.; Bermingham, S. Spray drying with a two-fluid nozzle to produce fine particles: Atomization, scale-up, and modeling. Dry. Technol. 2015, 34, 1243–1252. [Google Scholar] [CrossRef]

- Patel, B.B.; Patel, J.K.; Chakraborty, S.; Shukla, D. Revealing facts behind spray dried solid dispersion technology used for solubility enhancement. Saudi Pharm. J. 2015, 23, 352–365. [Google Scholar] [CrossRef] [PubMed]

- Arpagaus, C.; Schwartzbach, H. Scale-Up from Bench-Top Research to Laboratory Production; Buchi: Flawil, Switzerland, 2018. [Google Scholar]

- Dobry, D.E.; Settell, D.M.; Baumann, J.M.; Ray, R.J.; Graham, L.J.; Beyerinck, R.A. A model-based methodology for spray-drying process development. J. Pharm. Innov. 2009, 4, 133–142. [Google Scholar] [CrossRef] [PubMed]

- Elsayed, K.; Lacor, C. The effect of cyclone inlet dimensions on the flow pattern and performance. Appl. Math. Model. 2011, 35, 1952–1968. [Google Scholar] [CrossRef]

- Handscomb, C.S.; Kraft, M. Simulating the structural evolution of droplets following shell formation. Chem. Eng. Sci. 2010, 65, 713–725. [Google Scholar] [CrossRef]

- Grasmeijer, N.; de Waard, H.; Hinrichs, W.L.; Frijlink, H.W. A user-friendly model for spray drying to aid pharmaceutical product development. PLoS ONE 2013, 8, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Al-Khattawi, A.; Bayly, A.; Phillips, A.; Wilson, D. The design and scale-up of spray dried particle delivery systems. Expert Opin. Drug Deliv. 2017, 15, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Conder, E.W.; Cosbie, A.S.; Gaertner, J.; Hicks, W.; Huggins, S.; MacLeod, C.S.; Remy, B.; Yang, B.S.; Engstrom, J.D.; Lamberto, D.J.; et al. The pharmaceutical drying unit operation: An industry perspective on advancing the science and development approach for scale-up and technology transfer. Org. Process Res. Dev. 2017, 21, 420–429. [Google Scholar] [CrossRef]

- Paterson, A.H.J.; Brooks, G.F.; Bronlund, J.E.; Foster, K.D. Development of stickiness in amorphous lactose at constant t − tg levels. Int. Dairy J. 2005, 15, 513–519. [Google Scholar] [CrossRef]

- Weuts, I.; Kempen, D.; Verreck, G.; Decorte, A.; Heymans, K.; Peeters, J.; Brewster, M.; Van den Mooter, G. Study of the physicochemical properties and stability of solid dispersions of loperamide and peg6000 prepared by spray drying. Eur. J. Pharm. Biopharm. 2005, 59, 119–126. [Google Scholar] [CrossRef] [PubMed]

- Lowinger, M.; Baumann, J.; Vodak, D.T.; Moser, J. Practical considerations for spray dried formulation and process development. In Discovering and Developing Molecules with Optimal Drug-Like Properties, 1st ed.; Templeton, A.C., Byrn, S.R., Haskell, R.J., Prisinzano, T.E., Eds.; Springer: New York, NY, USA, 2015; Volume 15, pp. 383–435. [Google Scholar]

- Ozmen, L.; Langrish, T.A.G. Comparison of glass transition temperature and sticky point temperature for skim milk powder. Dry. Technol. 2002, 20, 1177–1192. [Google Scholar] [CrossRef]

- Walton, D.E. Spray-dried particle morphologies. Dev. Chem. Eng. Miner. Process 2002, 10, 323–348. [Google Scholar] [CrossRef]

- Maas, S.G.; Schaldach, G.; Littringer, E.M.; Mescher, A.; Griesser, U.J.; Braun, D.E.; Walzel, P.E.; Urbanetz, N.A. The impact of spray drying outlet temperature on the particle morphology of mannitol. Powder Technol. 2011, 213, 27–35. [Google Scholar] [CrossRef]

- Nuzzo, M.; Sloth Overgaard, J.; Bergenståhl, B.; Millqvist-Fureby, A. The morphology and internal composition of dried particles from whole milk—From single droplet to full scale drying. Food Struct. 2017, 13, 35–44. [Google Scholar] [CrossRef]

- Walton, D.E. The morphology of spray-dried particles a qualitative view. Dry. Technol. 2000, 18, 1943–1986. [Google Scholar] [CrossRef]

- Cal, K.; Sollohub, K. Spray drying technique. I: Hardware and process parameters. J. Pharm. Sci. 2010, 99, 575–586. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Hu, Y.; Liu, L.; Su, L.; Li, N.; Yu, J.; Tang, B.; Yang, Z. Physical stability of amorphous solid dispersions: A physicochemical perspective with thermodynamic, kinetic and environmental aspects. Pharm. Res. 2018, 35, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Six, K.; Verreck, G.; Peeters, J.; Binnemans, K.; Berghmans, H.; Augustijns, P.; Kinget, R.; Van den Mooter, G. Investigation of thermal properties of glassy itraconazole: Identification of a monotropic mesophase. Thermochim. Acta 2001, 376, 175–181. [Google Scholar] [CrossRef]

- Huang, Y.; Dai, W.G. Fundamental aspects of solid dispersion technology for poorly soluble drugs. Acta Pharm. Sin. B 2014, 4, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Worku, Z.A.; Aarts, J.; Singh, A.; Van den Mooter, G. Drug-polymer miscibility across a spray dryer: A case study of naproxen and miconazole solid dispersions. Mol. Pharm. 2014, 11, 1094–1101. [Google Scholar] [CrossRef] [PubMed]

- Mehta, M.; Kothari, K.; Ragoonanan, V.; Suryanarayanan, R. Effect of water on molecular mobility and physical stability of amorphous pharmaceuticals. Mol. Pharm. 2016, 13, 1339–1346. [Google Scholar] [CrossRef] [PubMed]

- Prudic, A.; Ji, Y.; Luebbert, C.; Sadowski, G. Influence of humidity on the phase behavior of api/polymer formulations. Eur. J. Pharm. Biopharm. 2015, 94, 352–362. [Google Scholar] [CrossRef] [PubMed]

- Weuts, I.; Van Dycke, F.; Voorspoels, J.; De Cort, S.; Stokbroekx, S.; Leemans, R.; Brewster, M.E.; Xu, D.; Segmuller, B.; Turner, Y.T.; et al. Physicochemical properties of the amorphous drug, cast films, and spray dried powders to predict formulation probability of success for solid dispersions: Etravirine. J. Pharm. Sci. 2011, 100, 260–274. [Google Scholar] [CrossRef] [PubMed]

- Shanbhag, A.; Rabel, S.; Nauka, E.; Casadevall, G.; Shivanand, P.; Eichenbaum, G.; Mansky, P. Method for screening of solid dispersion formulations of low-solubility compounds–miniaturization and automation of solvent casting and dissolution testing. Int. J. Pharm. 2008, 351, 209–218. [Google Scholar] [CrossRef] [PubMed]

| Miniaturized Atomization Device | Büchi B290 Mini Spray-Dryer | |

|---|---|---|

| Feed solution | ||

| Solvent | DCM/EtOH 2:1 (v/v) | DCM/EtOH 2:1 (v/v) |

| Concentration of solutes | 5% (w/v) | 5% (w/v) |

| DL | 20%–80% (w/w) | 20%–80% (w/w) |

| Volume of feed solution | 0.25–1 mL | 100 mL |

| Feed flow rate | 2 mL/min | 4 mL/min |

| Equipment configuration | ||

| Drying chamber dimension (length × diameter) | 15 × 2 cm | 47 × 15.9 cm a |

| Drying chamber surface area | 94.2 cm2 b | 2.3.103 cm2 b |

| Drying chamber volume | 5.0.10−2 L b | 9.3 L b |

| Recycling loop configuration | open | closed |

| Drying gas | ||

| Drying gas flow rate | 20 L/min | 580 L/min |

| Drying gas | Air | N2 |

| Heating power | 500 W | 2300 W a |

| Inlet temperature | 100 °C | 65 °C |

| Residence time | 0.14 s c | 0.96 s c |

| Atomization | ||

| Nozzle selection | bifluid | bifluid |

| Nozzle diameter | 0.15 mm | 0.7 mm |

| Atomization gas flow rate | 18 L/min | 9 L/min |

| Atomization gas | Air | N2 |

| Atomization gas flow rate/Feed flow rate | 8.0 c | 1.9 c |

| Particle separation system and powder properties | ||

| Particle separation principle | DSC pan | cyclone |

| Particle separation selectivity | - | 2 μm a |

| Typical PSD obtained | ≤10 μm d | ≤10 μm d |

| Equipment performance and output parameters | ||

| Minimum sample volume per batch | 0.25 mL | 30 mL a |

| Corresponding minimum materials needs per batch | 12.5 mg e | 1.5 g e |

| Production rate per hour | 4 f | 1 f |

| Typical yield value | 15%–50% | 65%–90% |

| Outlet temperature | 40 ± 5 °C | 45 ± 2 °C |

| Drying chamber surface area/min. API used | 7.5 × 103 cm2/g b,e | 1.5 × 103 cm2/g b,e |

| 40:60 (w/w) ASDs | Miniaturized Atomization Device | Büchi B290 Mini Spray-Dryer | ||

|---|---|---|---|---|

| Tga (°C) | % Weight Loss b | Tga (°C) | % Weight Loss b | |

| itraconazole/HPMCP HP50 | 100.5 ± 0.1 | 1.8 | 99.7 ± 0.9 | 1.8 |

| itraconazole/HPMCAS-LF | 85.4 ± 1.8 | 1.7 | 87.4 ± 0.6 | 1.2 |

| itraconazole/PVPVA | 94.2 ± 0.3 | 4.3 | 95.9 ± 0.3 | 4.0 |

| itraconazole/PVPK30 | 128.6 ± 0.7 | 9.0 | 128.7 ± 1.0 | 8.6 |

| itraconazole/Soluplus | 53.9 ± 1.6 | 2.8 | 50.2 ± 1.6 | 2.3 |

| itraconazole/Eudragit L100 | 158.8 ± 2.1 | 3.4 | 160.2 ± 1.5 | 3.6 |

| itraconazole/Eudragit L100-55 | 107.3 ± 1.5 | 1.9 | 106.7 ± 0.4 | 1.5 |

| ASDs | HPMCP HP50 | HPMCAS-LF | PVPVA | PVPK30 | Soluplus | Eudragit L100 | Eudragit L100-55 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DLScale | Lab | Min | Lab | Min | Lab | Min | Lab | Min | Lab | Min | Lab | Min | Lab | Min |

| 20:40 (w/w) | Glass solution | Glass solution | Glass solution | Glass solution | Glass solution | Glass solution | Glass solution | |||||||

| 40:60 (w/w) | ||||||||||||||

| 60:40 (w/w) | Drug melting/recryst. | Drug melting/recryst. | Drug melting/recryst. | |||||||||||

| 80:20 (w/w) | Drug melting/recryst. | Drug melting/recryst. | Drug melt/recryst. | GS. | Drug melting/recryst. | |||||||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ousset, A.; Meeus, J.; Robin, F.; Schubert, M.A.; Somville, P.; Dodou, K. Comparison of a Novel Miniaturized Screening Device with Büchi B290 Mini Spray-Dryer for the Development of Spray-Dried Solid Dispersions (SDSDs). Processes 2018, 6, 129. https://doi.org/10.3390/pr6080129

Ousset A, Meeus J, Robin F, Schubert MA, Somville P, Dodou K. Comparison of a Novel Miniaturized Screening Device with Büchi B290 Mini Spray-Dryer for the Development of Spray-Dried Solid Dispersions (SDSDs). Processes. 2018; 6(8):129. https://doi.org/10.3390/pr6080129

Chicago/Turabian StyleOusset, Aymeric, Joke Meeus, Florent Robin, Martin Alexander Schubert, Pascal Somville, and Kalliopi Dodou. 2018. "Comparison of a Novel Miniaturized Screening Device with Büchi B290 Mini Spray-Dryer for the Development of Spray-Dried Solid Dispersions (SDSDs)" Processes 6, no. 8: 129. https://doi.org/10.3390/pr6080129

APA StyleOusset, A., Meeus, J., Robin, F., Schubert, M. A., Somville, P., & Dodou, K. (2018). Comparison of a Novel Miniaturized Screening Device with Büchi B290 Mini Spray-Dryer for the Development of Spray-Dried Solid Dispersions (SDSDs). Processes, 6(8), 129. https://doi.org/10.3390/pr6080129