1. Introduction

The vast majority of industrial processes require a tailored control architecture to fulfill the system requirements. In such a scheme, the control system should keep the controlled variable as close as possible to its desired value acting against external phenomena (disturbances) that affect process variables. Therefore, disturbances should be considered in the control problem design [

1]. Due to their origin, disturbances can be classified as measurable and unmeasurable. The measurable disturbances are an important issue that must be considered in control schemes, especially for process control [

2]. A typical industrial process is formed by several subsystems that interact with each other and influence the control loops. Moreover, there are many systems, especially bioprocesses, where the control system has to compensate for the external disturbances [

3,

4]. In industrial processes, the basic control structure consists of a feedback controller, since it is capable of providing reference tracking, while reducing the influence of plant-model mismatch and compensating for process disturbances [

1,

5]. It is usual that the control system only focuses on one of the listed problems, providing weak performance for the other issues [

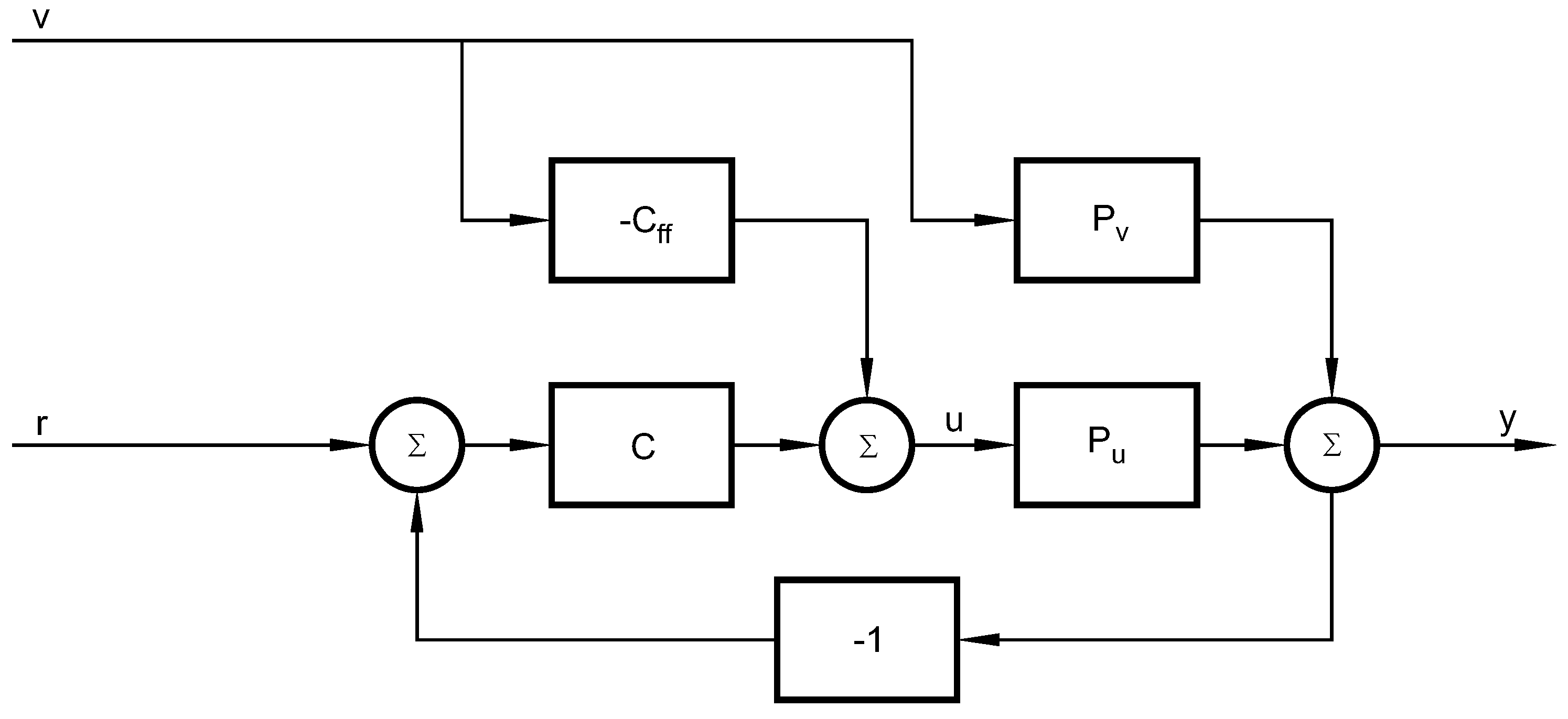

6]. The feedback controller can be implemented using numerous techniques and approaches; however, to improve the rejection of measurable disturbances, a feedforward scheme is usually introduced.

Feedforward from measurable disturbances was first used for drum-level control of tanks connected in series in 1925 [

7]. Many of the other early applications were related to distillation columns’ control [

8,

9]. Nowadays, feedforward control is widely used as a complement to feedback to improve measurable disturbance compensation. In fact, this mechanism is implemented in most distributed control systems [

1].

The ideal feedforward controller is computed as the quotient between the disturbance and the plant dynamics. However, this compensation is seldom realizable, e.g., a dead time may not be inverted. This drawback moved some authors to develop more sophisticated tuning rules during the past few decades. In [

8], an open-loop design procedure for lead-lag feedforward filters was proposed. First, the static gain of the filter is obtained from pure static models. After that, the time constants are computed to reduce the integral error of the open-loop response without taking into account the effect of the feedback controller. Similar open-loop design strategies were also proposed by [

7,

10].

Successive works dealt with the drawback of not taking into account the feedback controller at the design stage. In [

11], an additional feedforward control signal is also added to the feedback control error for decoupling purposes. In contrast, a least-squares procedure was introduced in [

12] to obtain the parameters of the feedforward controller that minimize the norm of the disturbance residual output for a given feedback controller. Recently, robust feedforward control was also introduced. The interested reader is referred to [

13,

14] and [

15,

16] for the standard and internal model control approach, respectively, and to [

17] for a quantitative feedback theory approach.

The so far commented design strategies rely on an optimization procedure to obtain the feedforward controller parameters. Nevertheless, as occurs with PID (Proportional-Integral-Derivative) control, most industrial controllers are implemented within a fixed structure [

1], thus leading to a need for analytical tuning rules to deal with typically low-order processes. Portable simple tuning rules for lead-lag feedforward filters were introduced in [

2,

6,

18] assuming that the plant dynamics are modeled with first-order plus dead time systems and considering step-like disturbances.

In industrial practice, PID controllers are widely used. This is due to their efficacy, relatively low complexity and numerous tuning methods [

1]. In such a scheme, the feedback control loop is extended with classical feedforward to provide an anticipated action to provide the measurable disturbance compensation. This classical scheme can provide significant improvements in the overall control performance. However, this is possible only in very limited situations, since the feedforward compensator must result in an implementable structure. When a feedforward compensator results in a non-realizable structure, a special tuning procedure is required to take full advantage of this technique. This is especially visible in processes that are characterized by input-output and disturbance-output time delays. As previously mentioned, the feedforward tuning methodology attracts the attention of many researches, since important advantages can be obtained when the proper set up of feedforward action is used. In this work, the tuning guidelines provided in [

14,

18,

19] are used, since they introduce a methodology that significantly improves the feedforward control performance.

On the other hand, the MPC (Model Predictive Control) approach is frequently used in process control, since it provides a unified solution for feedback and feedforward control, where most of the problems discussed above are solved intrinsically thanks to the form of the control approach. Moreover, the MPC techniques can consider many process constraints in an intrinsic way, since the control signal is computed through an optimization procedure. All of these features and possibilities to deal with multivariable systems makes MPC a powerful tool in industrial applications. From the disturbance compensation point of view, the most important advantages of MPC controllers are related to the incorporation of future disturbance information [

20,

21]. The MPC feedback and feedforward co-design procedure results in a tradeoff, where the controller tuning procedure is carried out taking into account the most important aspects. There exist several MPC formulations that can be used for disturbance compensation analysis providing the specific methodology in accordance with the analyzed features [

17,

22,

23]. In [

3,

22,

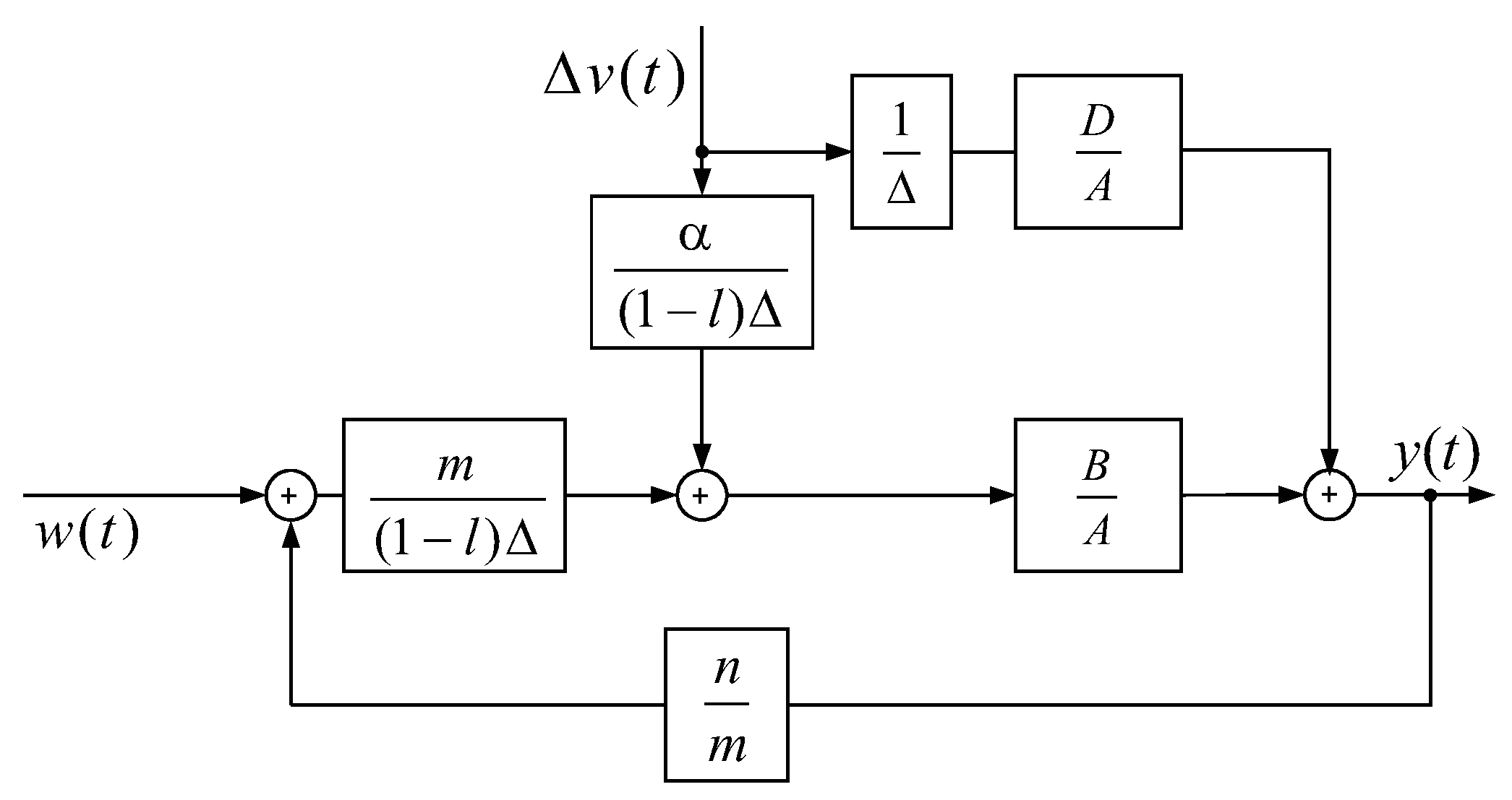

24], it was shown that the optimal MPC controller setup for disturbance attenuation results in high bandwidths in the feedback loop, and it is necessary to compensate this issue. Considering the aforementioned feature of the MPC feedforward compensator, in this work, we use the modified GPC (Generalized Predictive Control) scheme and tuning provided in [

3]. Such a configuration provides a two-degree-of-freedom control scheme within the Filtered Smith Predictor (FSP)-based GPC [

25], that improves the robustness capabilities of the resulting controller.

Taking into account the importance of the disturbance compensation problem and previous aspects, in this work, we focus on the processes, the dynamics of which involves the time delays. The analyzed configurations are focused on control problems related to process input-output and disturbance-output time delays. It is well known that time delays are a natural part of numerous processes. From the classical feedforward approach point of view, the presence of time delays may lead to a sluggish response, non-implementable structures and even result in unstable control. The typical solution for such systems is able to compensate the disturbance in an ineffective way (usually, only the invertible part is implemented). Despite this, the feedforward control schemes for dead time processes have not attracted much attention [

26]. For this reason, in this work, the feedforward control problem for those processes is analyzed, and as a result, the control problem is reduced to a few configurations that can arise for such systems. Once the possible configurations are isolated, the feedforward compensators are evaluated for control schemes where PID and MPC approaches are used as feedback controllers. To this end, improved tuning methods are used for each approach. Several simulations are provided to highlight the main features, and a comparison using some performance indexes is performed [

27].

The paper is organized as follows. The feedforward control problem is presented in

Section 2, where a traditional feedback plus feedforward control loop and implicit disturbance compensation mechanisms of GPC are shown.

Section 3 is devoted to explain the tuning rules for each approach considering different process configurations. Simulation examples to illustrate the responses of PID plus feedforward and the implicit GPC compensator are shown in

Section 4. Additionally, several control performance indexes are computed for different process configurations and compared in this section. Finally, the paper ends with some conclusions on the analyzed structures [

23].

4. Results and Discussion

This section presents the simulation results of the analyzed feedforward strategies for both approaches that consider PID and GPC algorithms. Firstly, the process configuration with the realizable feedforward compensator is introduced. This example is used to show the classical approach and to highlight the limitations of the GPC implicit feedforward action based on the classic scheme. Secondly, the non-realizable feedforward compensator is studied to analyze the advantages and drawbacks for the feedforward compensator design in PID and GPC approaches. Additionally, a third example is considered to test the studied techniques against process constraints. In this case, the process is set to result in a non-realizable compensator, and the control system is limited by the control signal saturation. Finally, several control system performance indexes are computed to show the individual properties of each configuration.

In all of the presented simulations, the PID and GPC controllers keep the same parameters, and only those released to the disturbance compensation are modified to obtain the desired performance. As previously mentioned, the analyzed process is represented by the first-order systems (see Equation (

27)), which are used to setup the feedback controller. Consider that the PID feedback controller is designed according to the SIMCtuning rule [

30], such that

and

. Moreover, the GPC controller with implicit feedforward action was implemented with the following parameters: prediction and control horizons were set to

,

and

, respectively. The reference filter value has been set to zero, since it has no influence over the analyzed implicit disturbance compensation mechanism. The GPC control scheme has been implemented with a sampling time

seconds to obtain the discrete time polynomials

,

and

from the transfer functions

and

.

To determine the control performance for each analyzed configuration, the following indexes have been considered:

where

represents the Integrated Absolute Error between reference and controlled variable, the

refers to the Integrated Absolute Control signal and

stands for the Control System Effort (computed as the normalized value of the discrete/discretized controls’ signal increments

).

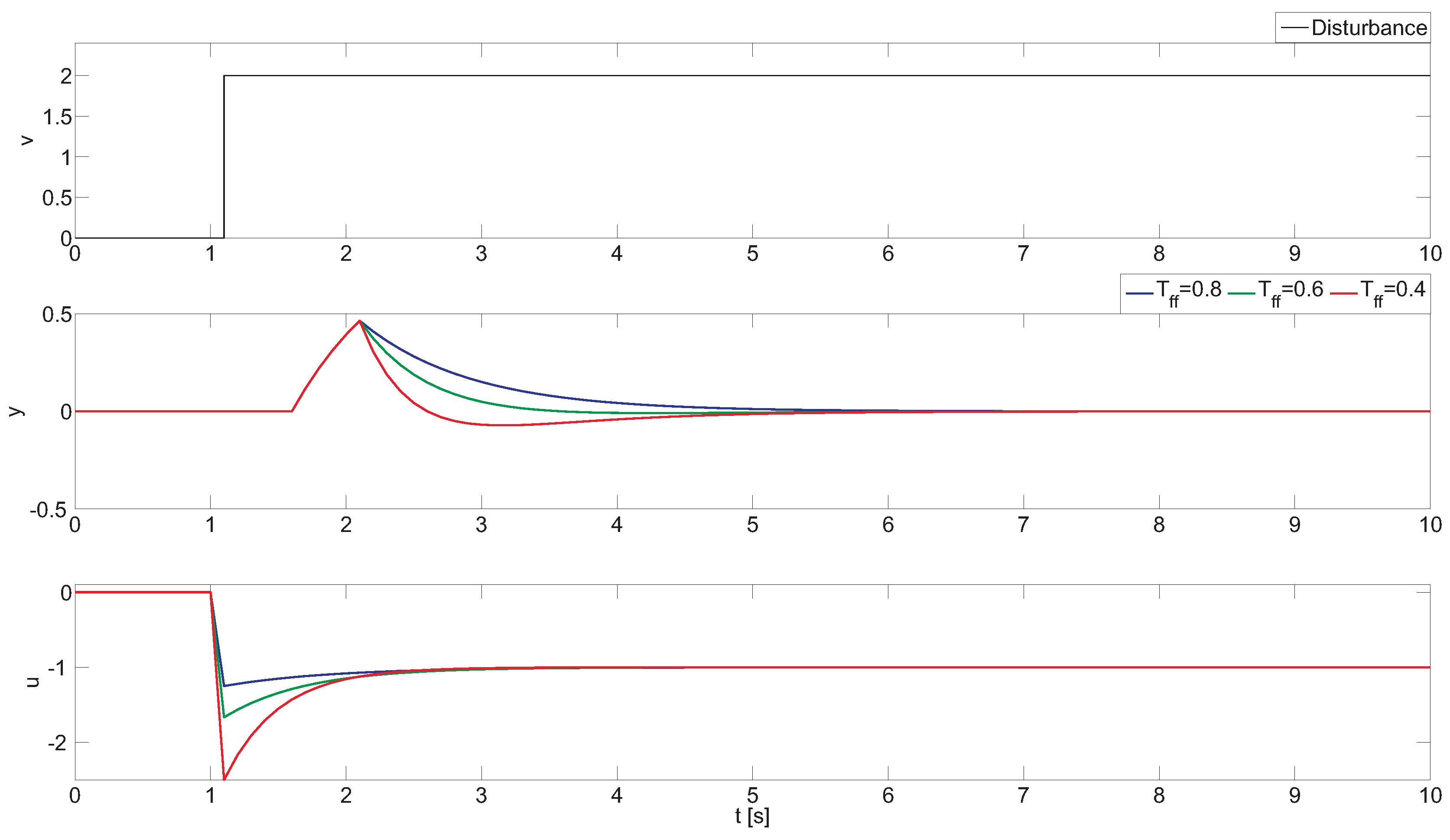

For the first example, the process transfer functions have been set up as follows:

In such a case, the resulting dead time difference

, and as a consequence, a classical feedforward compensator is realizable by dividing

and

with the reverse sign [

2]. Moreover, the GPC simulations for this example have been performed using two different values for

λ,

and

, respectively. The obtained results are shown in

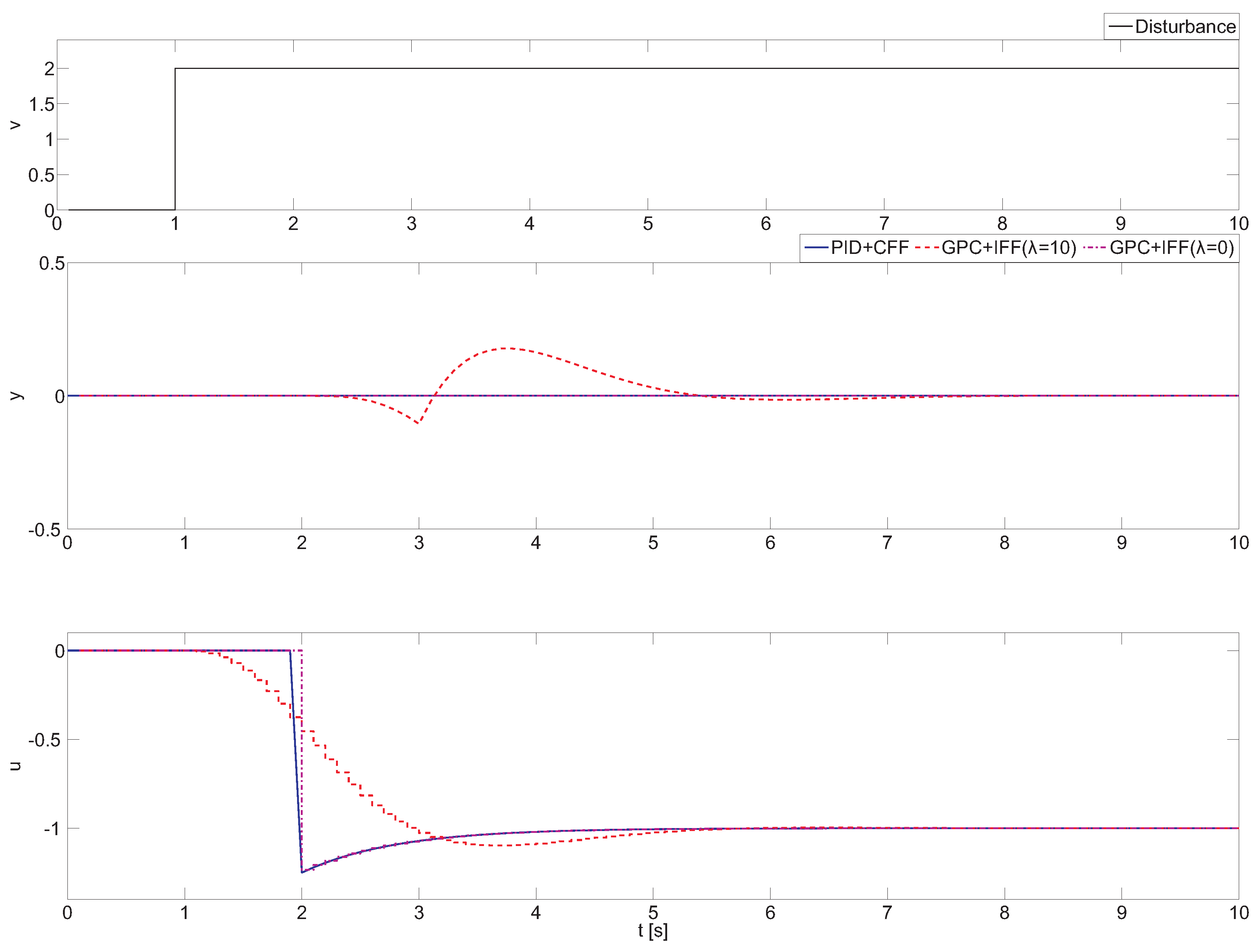

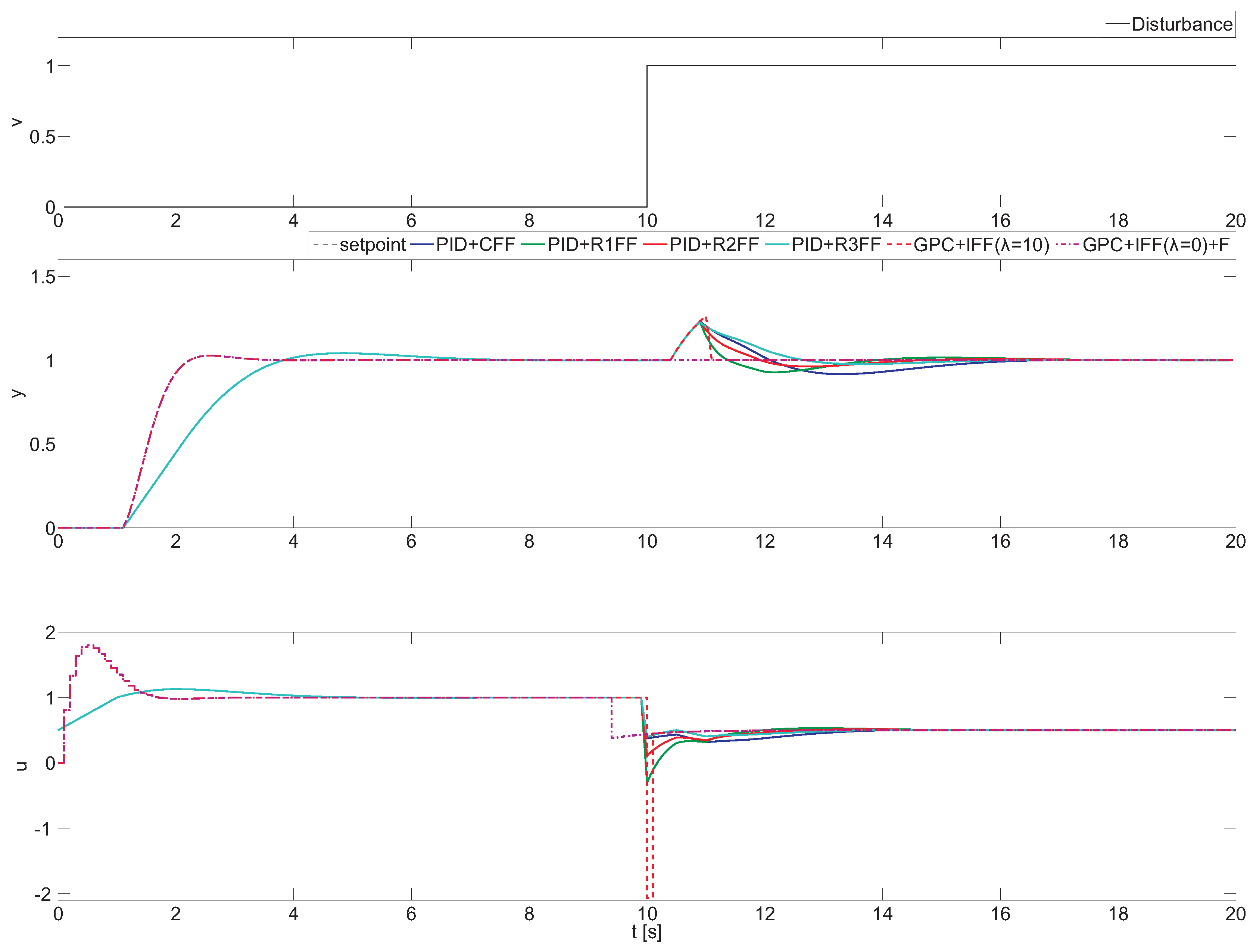

Figure 3, where it can be observed that when a classical feedforward compensator is used (PID + CFF), a perfect cancellation is obtained.

The situation changes for the next analyzed configuration, the GPC with implicit feedforward and control weighing factor

(GPC + IFF(

λ)). For this case, the implicit feedforward GPC controller starts to react in advance with respect to the classical feedforward controller thanks to the prediction capabilities of the GPC algorithm. However, the most important issue is that the GPC algorithm is not able to eliminate the disturbance effect. This result shows that the prediction capabilities of the GPC algorithm are not effective, and the GPC parameters must be properly tuned to reach a perfect disturbance effect cancellation (as was shown in

Section 2.2). Furthermore, this study allows one to observe the influence of the

λ design parameter in the disturbance rejection responses. However, this problem can be overcome by applying the previously introduced extended design for GPCs’ feedforward action and setting

. It can be observed that GPC + IFF (

) obtains perfect compensation, since the unweighted control signal is used. Based on this feature, significant improvements can be obtained also for non-realizable configurations, which are analyzed below.

The performance for the analyzed process configurations are summarized in

Table 1. In accordance with the previously described results, the PID + CFF and GPC + IFF (

) obtain perfect compensation (

= 0). In the GPC case, more control effort is required to achieve disturbance attenuation (

values). However, the PID + CFF scheme produces more aggressive changes in the control signal (

= 0.12).

To prove the effectiveness of the proposed design strategies, let us consider that the process is given by the transfer functions:

such that

. Thus, the ideal feedforward compensator cannot be formed due to a non-realizable delay inversion. Hereafter, PID plus feedforward and GPC with implicit feedforward controllers are designed according to the previously defined tuning rules. First, following the tuning guideline of

Section 3.1.3, PID plus feedforward controllers are explored, and the following lead-lag feedforward filters are obtained:

In the GPC approach, the implicit feedforward compensator has been implemented following the scheme shown in

Section 3.2. Furthermore,

for the robustness filter

was selected for all configurations. Additionally, two simulations have been performed to analyze the GPC compensator. The first one includes only past measured disturbances in control signal computations, and the second one considers additionally the future disturbance value in the prediction mechanism.

Figure 4 shows the control results for PID with invertible part (PID + CFF), aggressive tuning (PID + R1FF), moderate tuning (PID + R2FF) and conservative tuning (PID + R3FF). Moreover, two GPC configurations, GPC + IFF (

) and including future disturbance information, GPC + IFF(

) + F, are shown. In such an example, all of the analyzed configurations are tested against a step change in

v of a magnitude of two at

. Notice that for this example, the control system set point was set to one in

. It can bee seen that all provided configurations reach the reference, and the desired performance can be obtained by proper tuning of the feedback controller.

For this case, the resulting dynamics have a non-causal form, which means that future information is required in the resulting feedforward compensator structure. In the classic feedforward design (PID + CFF), only the causal part is implemented, and the non-causal part is omitted. This leads to obtaining a poor disturbance rejection response, as shown in

Figure 4. The same problem appears for the GPC with implicit disturbance compensator and without future information GPC + IFF (

), where the disturbance model is included within the predictive control structure, but only the past disturbance measures are used. In this case, the disturbance effect compensates much faster than in PID + CFF. This improvement is obtained at the expense of the aggressive change in the control signal (bottom plot in

Figure 4). This issue can be partially overcome using different tuning rules for the PID + feedforward scheme that improves the classical approach in compensation performance and simultaneously preserves the control resources. This behavior can be observed for the (PID + R1FF), (PID + R2FF), (PID + R2FF)configurations, where the compromise between compensation performance and control effort can be achieved. This property can be very useful in industrial practice where aggressive changes in control signal should be avoided.

Nevertheless, none of the previous cases completely eliminate the effect of the measurable disturbance, since the future information is not considered for the non-causal part. Complete disturbance compensation can be obtained when the future information is considered in the GPC + IFF (

) + F control scheme. It becomes possible to remove the influence of the disturbance thanks to the predictive capabilities of the control algorithm, as observed in

Figure 4. However, in contrast to the previous configurations, future disturbance information is required, not always being available. In this configuration, the control signal is less aggressive, but also, the velocity of the disturbance response can be managed by means of the robust filter design,

, and the

β tuning parameter [

3,

25].

The corresponding performance indexes are summarized in

Table 2. Notice that for this particular example, the indexes were computed between

and

; this is due to the different transient response of feedback controllers originated from the setpoint change. It can be observed that GPC + IFF (

) + F obtains

, providing perfect disturbance attenuation. Moreover, the

index shows that the required control effort can be adjusted in PID + FF schemes. From the

values, it can be observed that GPC-based compensators require more aggressive changes in the control signal, but also provide better disturbance attenuation.

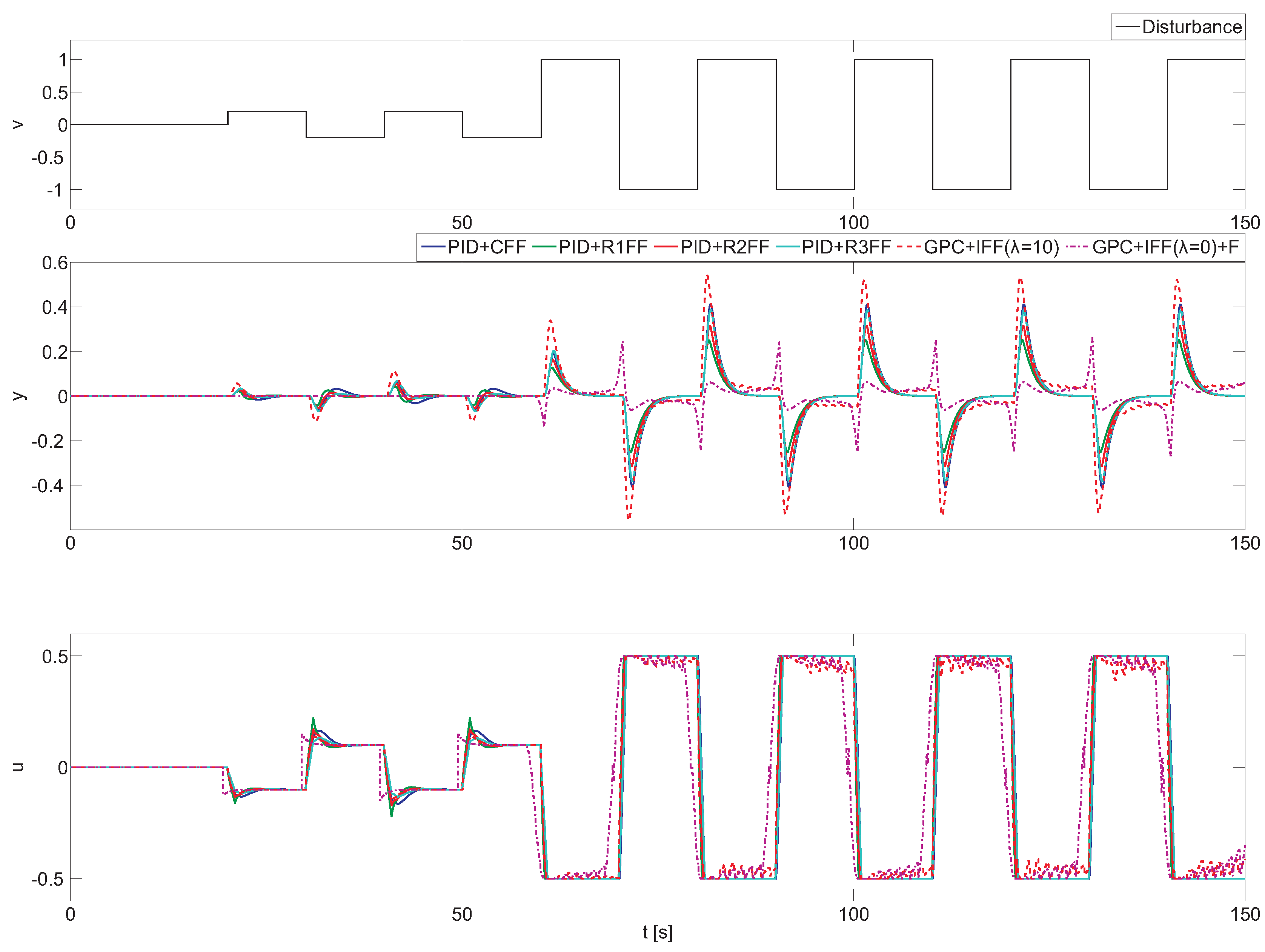

Furthermore, a last simulation is performed to demonstrate that the proposed tuning rules are also valid under the presence of input saturation. The tested configurations are the same as in the previous example and are evaluated against periodic squared disturbance. In the PID approaches, the process constraints are considered outside the controller structure; in the GPC-based schemes, the control signal limitations are taken into account using a constraint handling mechanism. The only difference is that now the robust filter is included in the control scheme, where

has been selected.

Figure 5 shows the simulation results for several consecutive steps in

v assuming that

.

In the first part of the simulation, the squared disturbance with an amplitude of is considered, and the disturbance effect is the same as in the previous example, since the required change in the control signal is possible. During this example, the GPC + IFF () configuration obtains the worst compensation performance. This is mainly due to the effect of control signal weighting factor λ. This configuration has been selected consciously to show that a badly-tuned implicit GPC compensator could produce weak disturbance compensation. In the second part of the simulation, the amplitude of the disturbance signal is increased to one at the time instant . Now, the control signals exceed the saturation limits, and differences are observed among the selected feedforward control configurations. The PID plus feedforward configurations keep all of the properties from the previous example and are able to reduce the disturbance effect taking into account the control effort. This can be observed in (PID + R1FF), (PID + R2FF) and (PID + R3FF), where the first one is more aggressive, and the last one requires a lower control effort. Notice how the GPC + IFF () + F manages much better the process input constraints, reducing the disturbance effect and only having steady-state error when the system is saturated (in nonlinear mode). The reason is because the feedforward compensator is implicit in the GPC algorithm, and thus, the combined control signal from the feedback plus feedforward actions is considered in the optimization problem. Additionally, it can be observed that this configuration starts to compensate even before the disturbance effect appears on the process output. Due to this feature, significant improvements are obtained, and the controlled variable stays closer to the control system reference.

Table 3 summarizes the obtained values for all analyzed approaches. Analyzing the

index, it can be observed that all new tuning rules (PID + R1FF, PID + R2FF, PID + R2FF) improve in performance the classical feedforward compensator that is formed only by the part of the dynamics that can be inverted. However, the GPC + IFF (

) + F configuration achieves the smallest

value, improving the best PID + FF configuration at about 20%. On the other hand, the GPC + IFF (

) scheme obtains a worse performance due to the tuning issues previously mentioned. With the

, it can observed that almost all structures need similar control effort; this is mainly due to process constraints, since all tested configurations saturate the system. Only the GPC + IFF (

) + F produces less variation in the control signal, reducing the average value around 7%. This is because of the future disturbance information that is considered in the prediction mechanism. Furthermore, due to the used FSP-GPC approach, the required control effort is also affected by the robustness filter setup, since there is an error between the nominal model and the process output due to saturation limits. The situation changes when the

index is evaluated, since it takes into account the control effort in terms of changes in control signal increments. For this particular measure, a higher value represents that the feedforward controller produced a control signal with more aggressive changes. According to this index, both GPC-based approaches are more aggressive in comparison to the PID + FF configurations. Particularly, the

index for the PID + R3FF scheme is about 40% lower when compared to the GPC + IFF(

) + F configuration. This outcome clearly indicates that the PID + R3FF compensator is more adequate for processes where abrupt changes in the control signal should be avoided. However, this measure is relative, and the overall balance of the benefits and drawbacks for each approach should be always considered for each particular process.